High-strength copper tin alloy contact line for high-speed electric railway and manufacturing method thereof

A technology of electrified railways and copper-tin alloys, applied in the direction of metal/alloy conductors, etc., can solve the problems of complex production process, small batch, high cost, etc., and achieve the effect of simple production process, low cost and large batch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

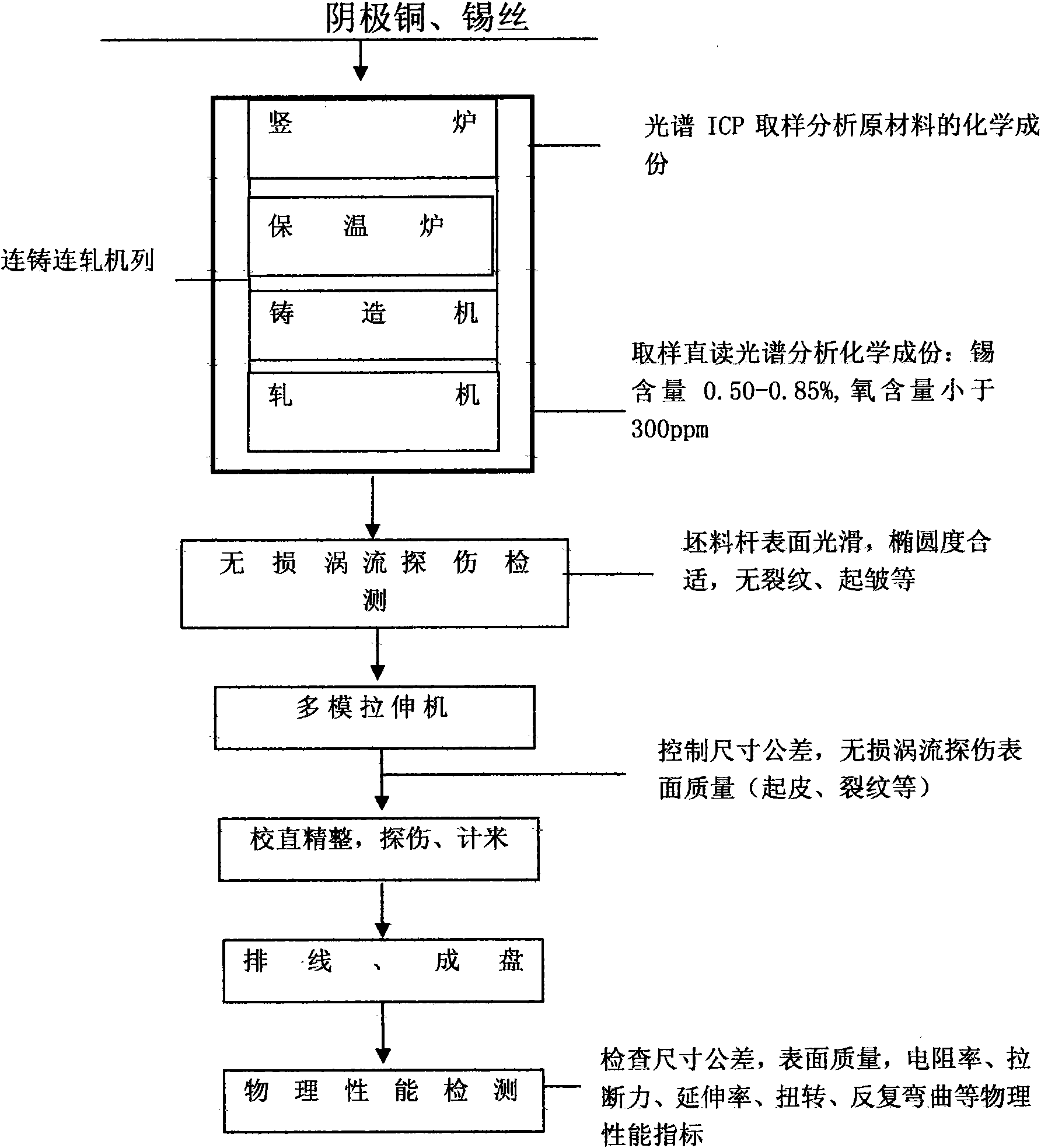

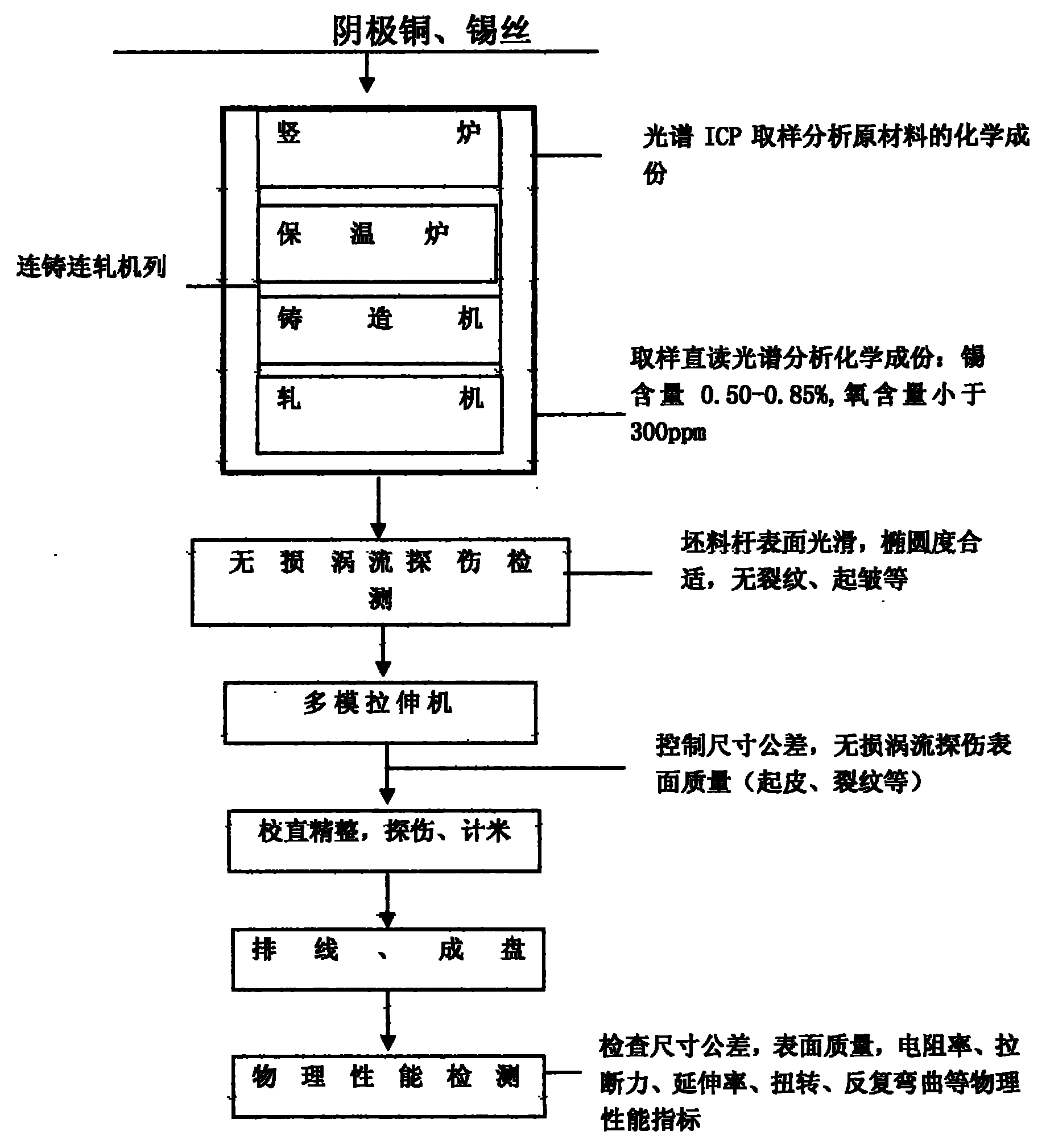

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: High-strength copper-tin alloy contact wire for high-speed electrified railway and its manufacturing method

[0027] Add 35 tons of high-purity cathode copper to the vertical melting furnace. When the temperature of the holding furnace rises to 1140°C-1150°C, the atmosphere in the furnace is guaranteed to be slightly reduced, and production begins. The molten liquid metal flows into the ladle continuously through the down launder, and metal tin wire is added in the down launder by wire feeding method controlled at 0.65% by weight, and the addition amount is synchronized with the casting speed. Sampling and analysis showed that casting and rolling started after the tin content was qualified. The temperature of the ladle was controlled at 1100-1120°C, the casting speed was 750rpm, and the cooling water pressure was 0.08-0.25Mpa. After cooling and solidification, the casting billet was formed. The casting cross-section was trapezoidal. Cross-sectional area 23...

Embodiment 2

[0033] Embodiment 2: High-strength copper-tin alloy contact wire for high-speed electrified railway and its manufacturing method

[0034] Put 35 tons of high-purity cathode copper into the vertical melting furnace. When the temperature of the holding furnace rises to 1140°C-1155°C, the atmosphere in the furnace is guaranteed to be slightly reduced, and production begins. The molten liquid metal flows into the ladle continuously through the down launder, and metal tin wire is added in the down launder by wire feeding method controlled at 0.70% by weight, and the addition amount is synchronized with the casting speed. Sampling and analysis showed that the casting and rolling started after the tin content was qualified. The temperature of the ladle was controlled at 1110-1125°C, the casting speed was 750rpm, and the cooling water pressure was 0.10-0.35Mpa. After cooling and solidification, the cast billet was formed. The casting cross-section was trapezoidal. Cross-sectional area...

Embodiment 3

[0041] Embodiment 3: High-strength copper-tin alloy contact wire for high-speed electrified railway and its manufacturing method

[0042] Put 35 tons of high-purity cathode copper into the vertical melting furnace. When the temperature of the holding furnace rises to 1145°C-1160°C, the atmosphere in the furnace is guaranteed to be slightly reduced, and production begins. The molten liquid metal flows into the ladle continuously through the down launder, and metal tin wire is added in the down launder by wire feeding method controlled at 0.75% by weight, and the addition amount is synchronized with the casting speed. Sampling and analysis showed that casting and rolling started after the tin content was qualified. The temperature of the ladle was controlled at 1115-1130°C, the casting speed was 800rpm, and the cooling water pressure was 0.15-0.40Mpa. After cooling and solidification, the billet was formed. The casting cross-section was trapezoidal. Cross-sectional area 2300mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com