Patents

Literature

129results about How to "Large batch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

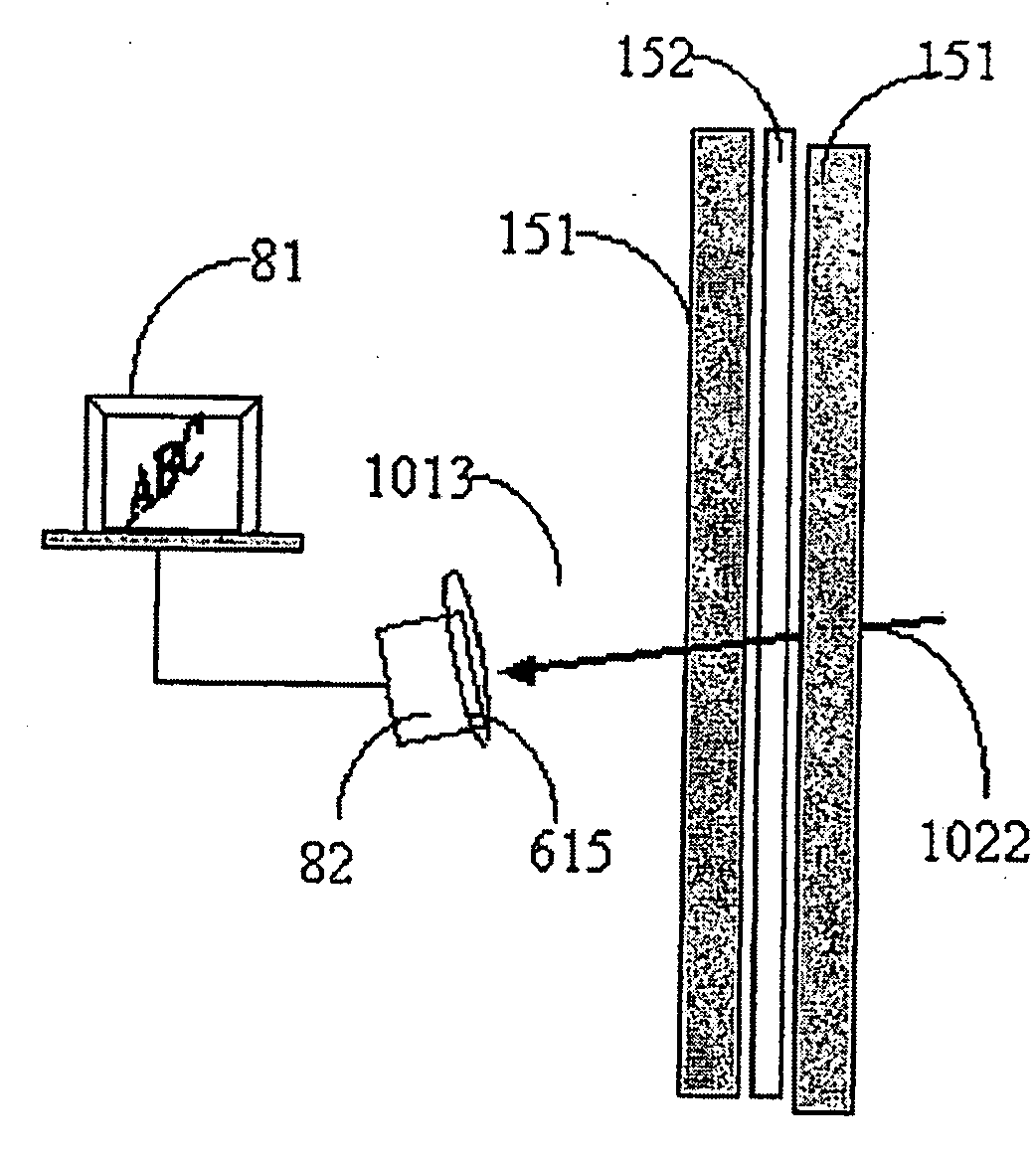

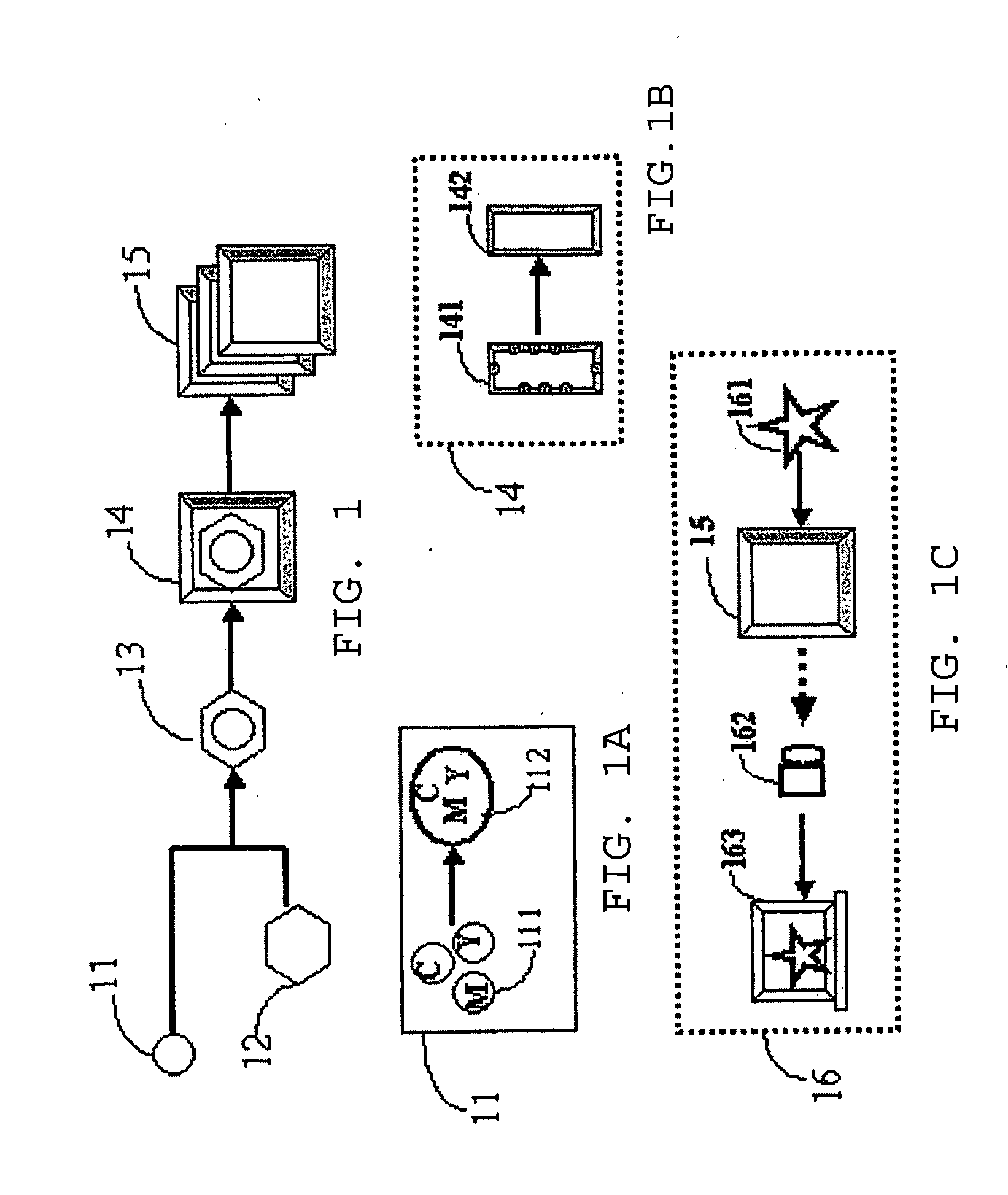

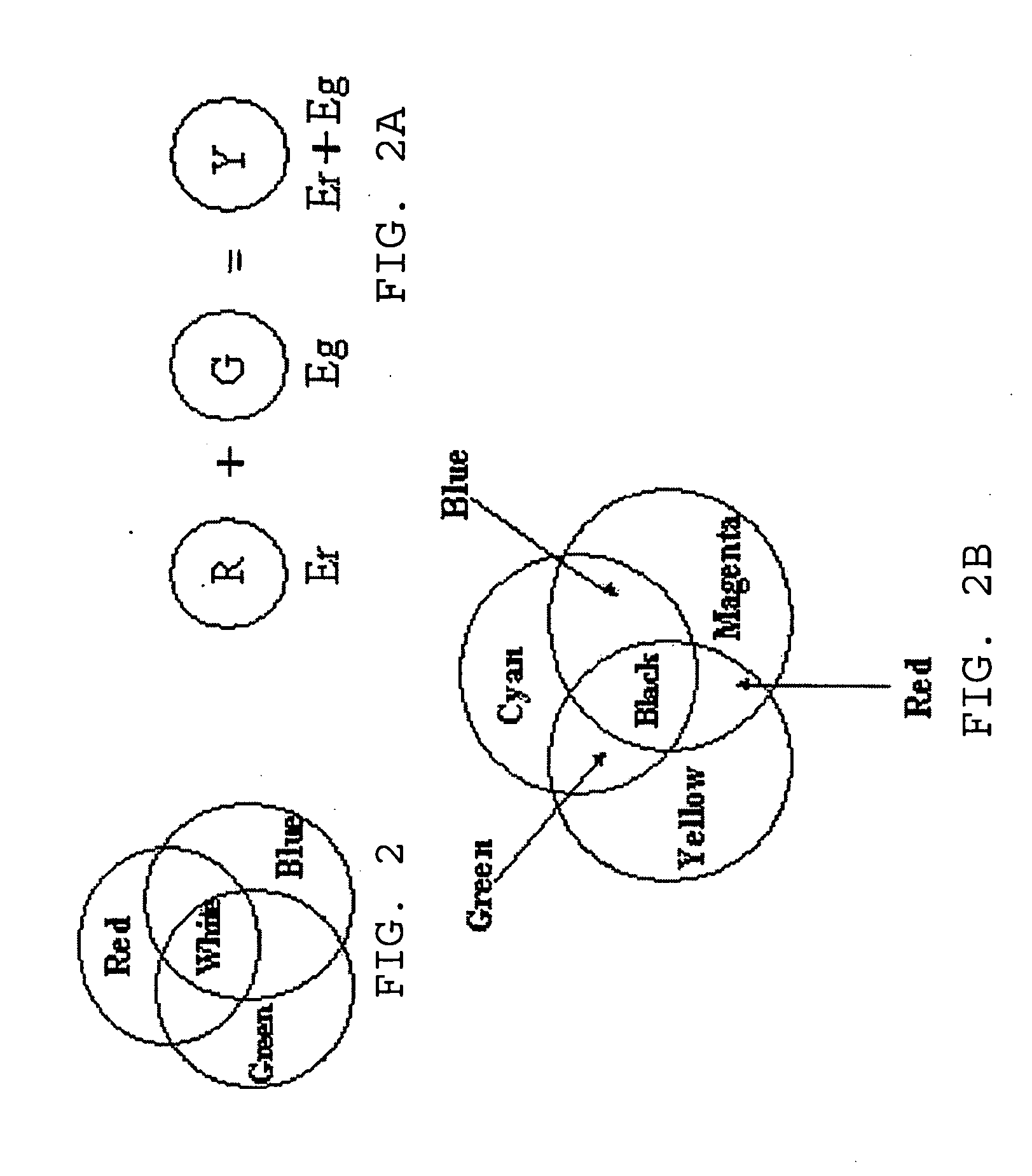

Method for manufacturing black plastic article capable of transmitting infrared ray

InactiveUS20090284603A1Large batchAvoid distractionTelevision system detailsOptical filtersInfraredEngineering

A method for manufacturing black plastic article capable of transmitting infrared ray, which includes mixing a black colorant, produced by mixing several transparent colorants of different color, into a transparent resin used as support, and processing the resulting mixture to manufacture a black plastic article. Said black plastic article is capable to absorbing visible light and transmitting infrared ray, and may be used in combination with an infrared region-sensitive CCD camera. The infrared region-sensitive CCD camera can take photos of the subject in a long distance through the black plastic article, if sufficient infrared ray from a subject may penetrate the black plastic article.

Owner:HSIEH CHI SHENG

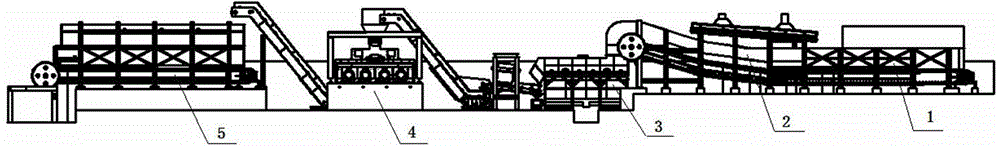

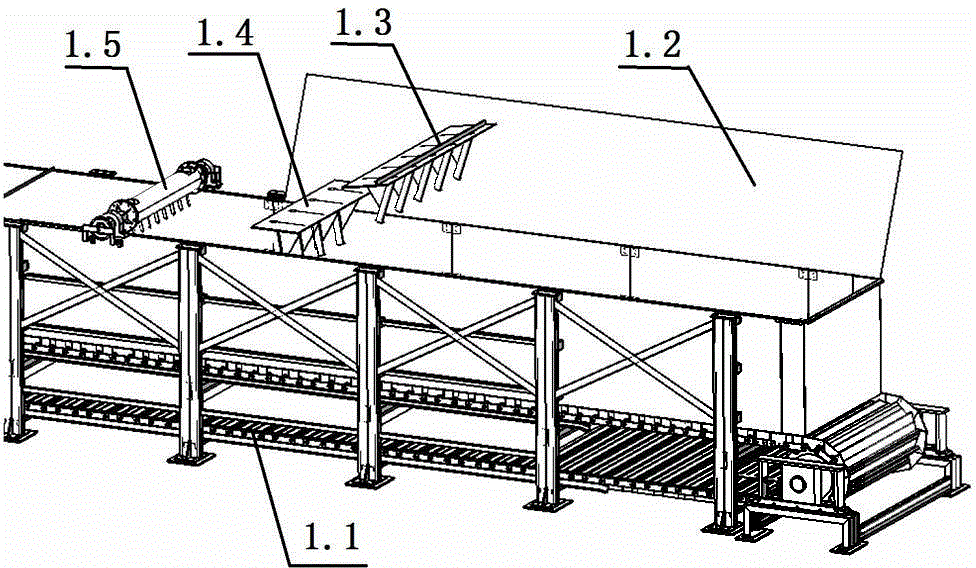

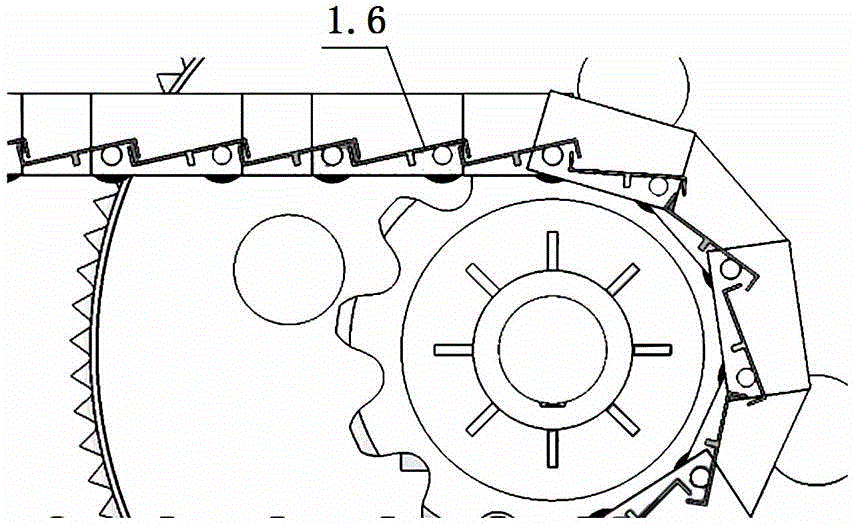

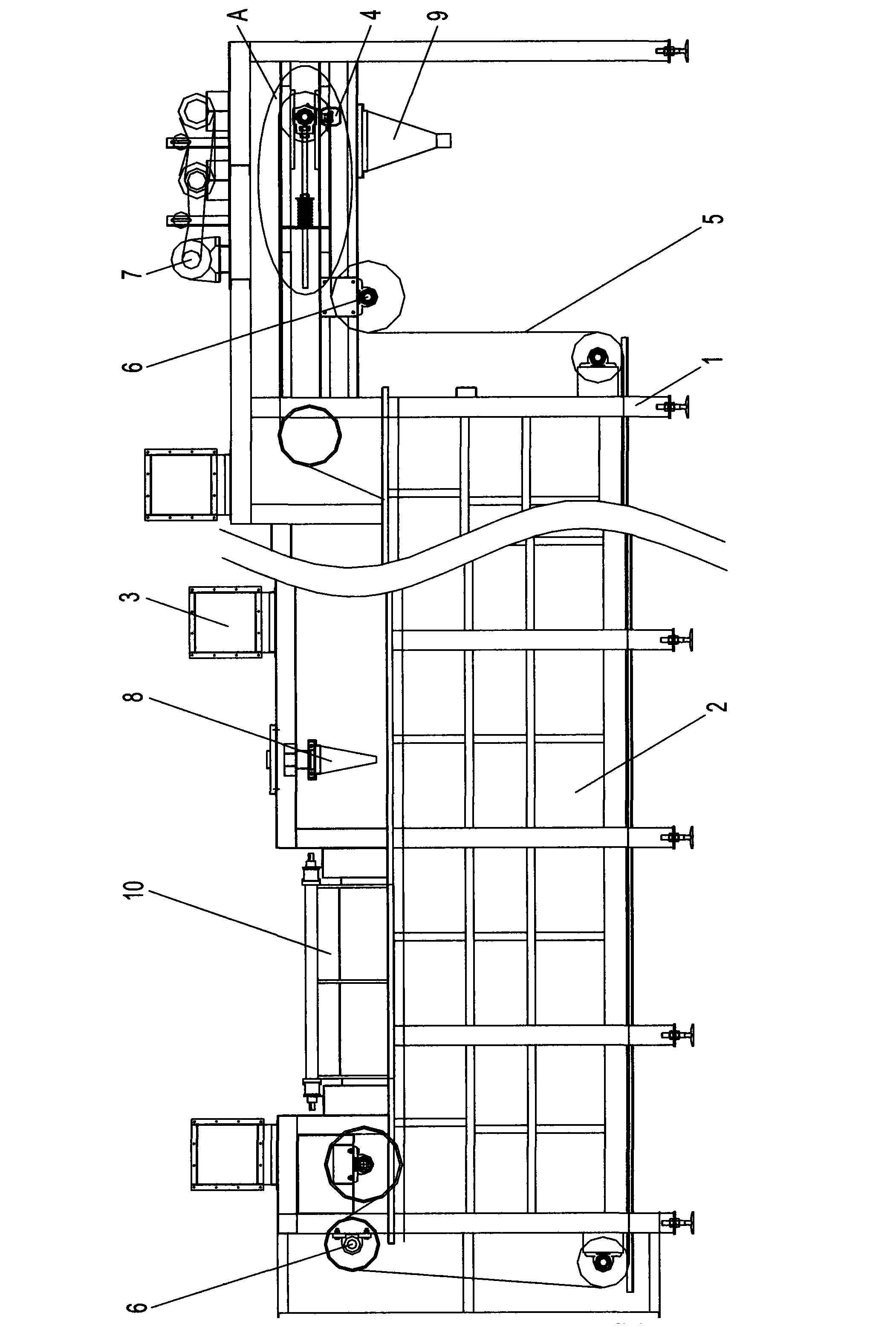

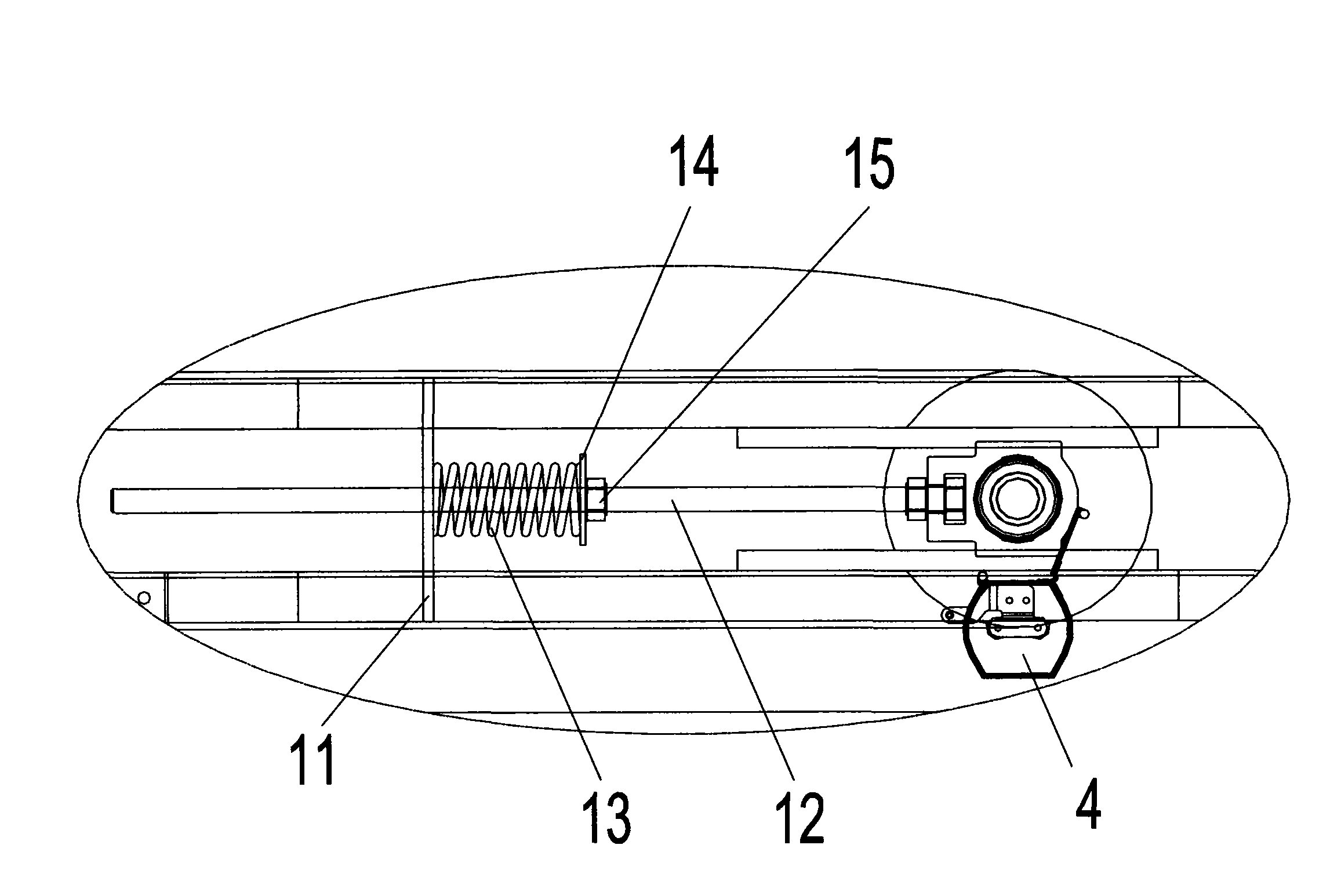

Continuous straw crushing system

The present invention discloses a continuous straw crushing system, which sequentially comprises a material feeding system, a pre-powder system, an impurity removing system, a fine powder system, and a material storage system along a material operation direction, wherein the impurity removing system is connected with the pre-powder system and the fine powder system, the material feeding system comprises a chain plate conveyor, a first-stage leveling grille, a second-stage leveling grille and a material turning roller, the pre-powder system is provided with a leveling device arranged at the foremost end, a first-stage coarse powder device and a second-stage coarse powder device, the cutter shaft of the leveling device is provided with a vibration detector, an impurity removing grille is arranged above the rear of the leveling device, the impurity removing system comprises a crushed stone removing device and an iron remover positioned on the rear portion, the fine power system is provided with two crushing bins, the material inlet position is provided with a quantification roller, and a row of material separation rollers are arranged on the lower portion of the quantification roller. With the continuous straw crushing system of the present invention, the continuous and efficient crushing operation can be performed on straws, the problems of high impurity content in straws and large material feeding operation strength are solved, the crushing efficiency is high, the operation is safe and stable, and the large-batch and continuous production requirement can be met.

Owner:河南上源精工机械有限公司

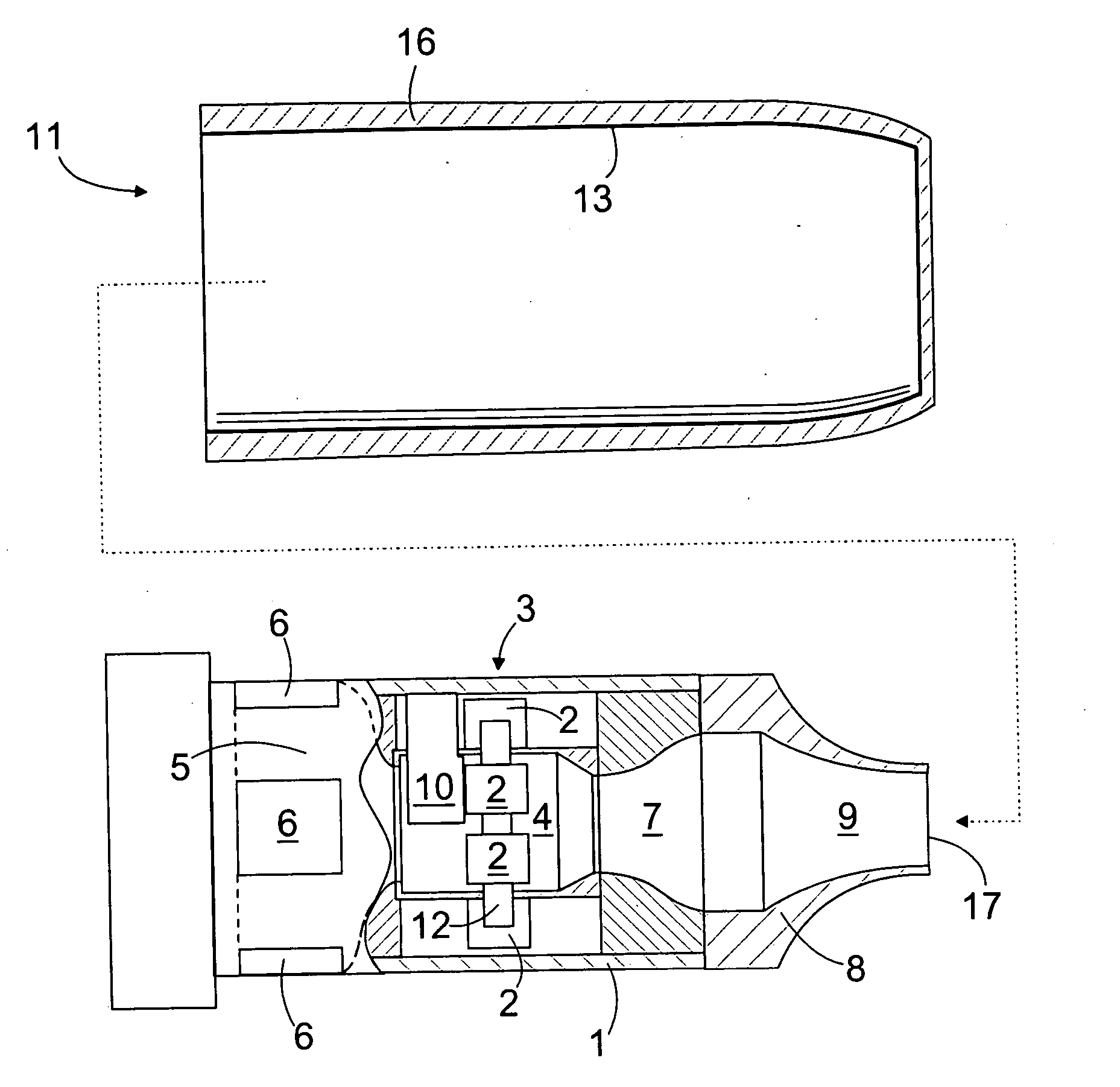

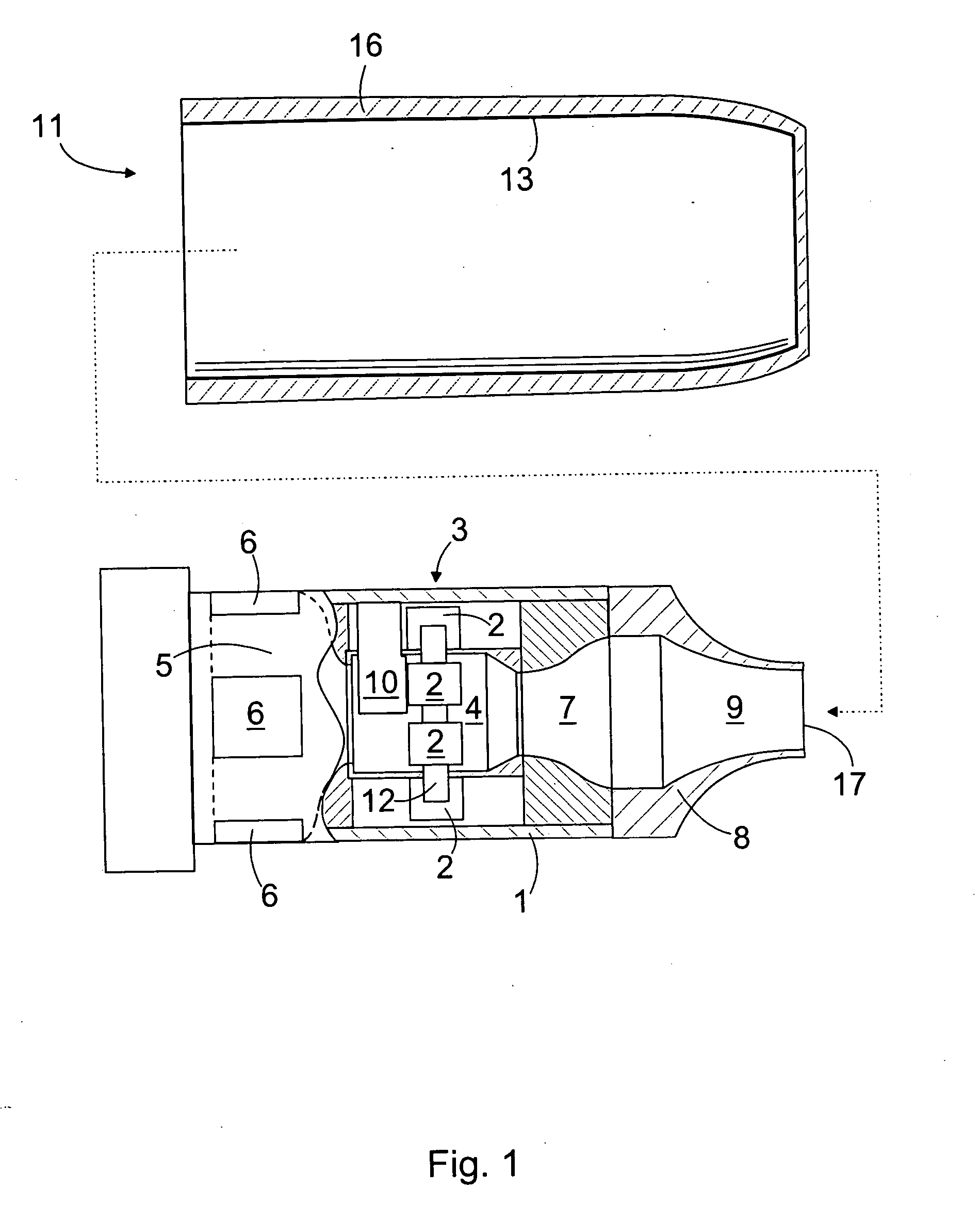

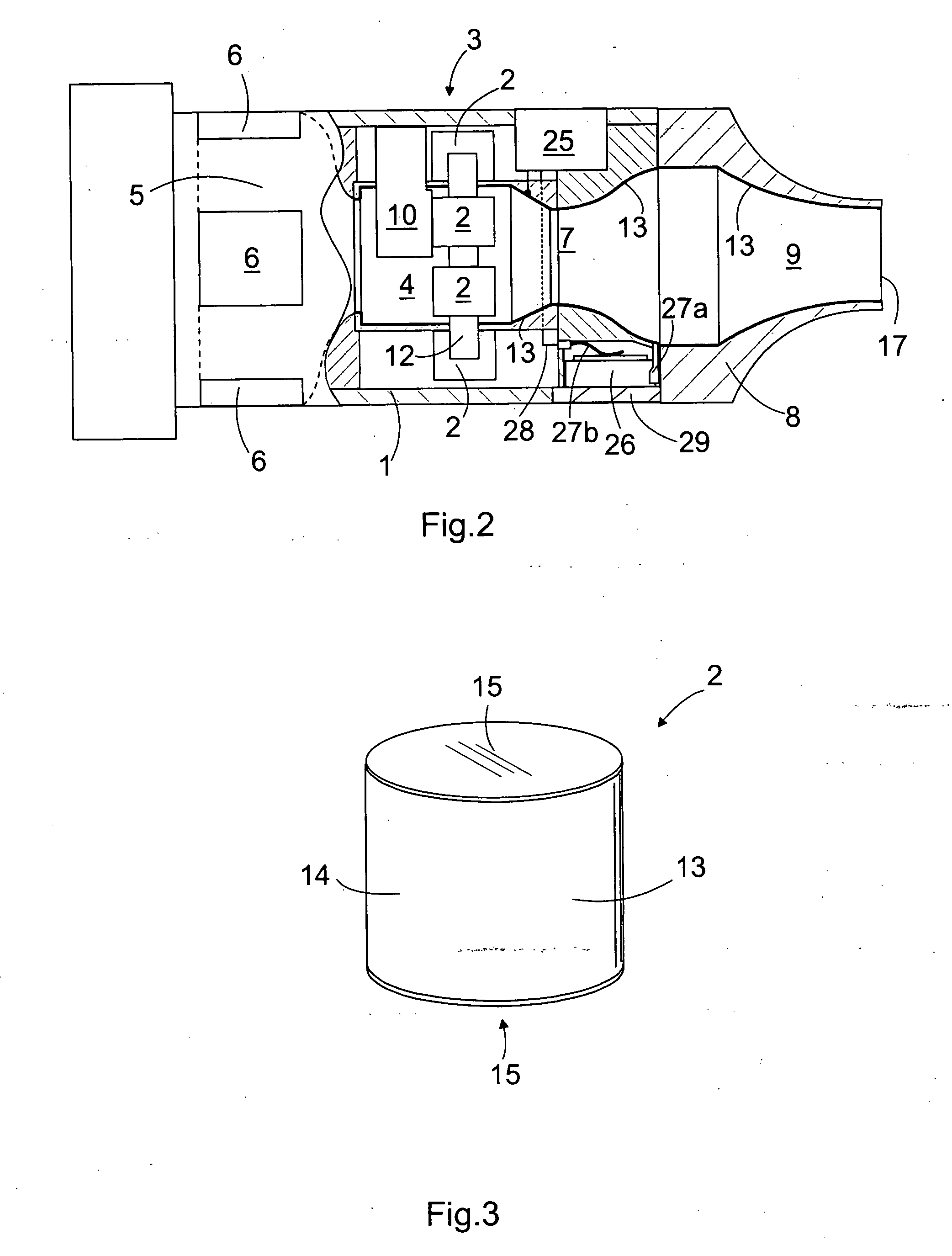

Inhalator and method of manufacturing same

InactiveUS20050133025A1Lower resistanceReduce moisture penetrationMedical devicesMedical atomisersMoisture penetrationPolymer

An inhalator, an inhalator component and a method for manufacturing an inhalator component. The inhalator and inhalator component have at least one surface made of polymer material that includes a coating layer. The coating layer substantially reduces moisture penetration through the surface and lowers the specific electric resistance of the surface.

Owner:LAIHO JUHA +2

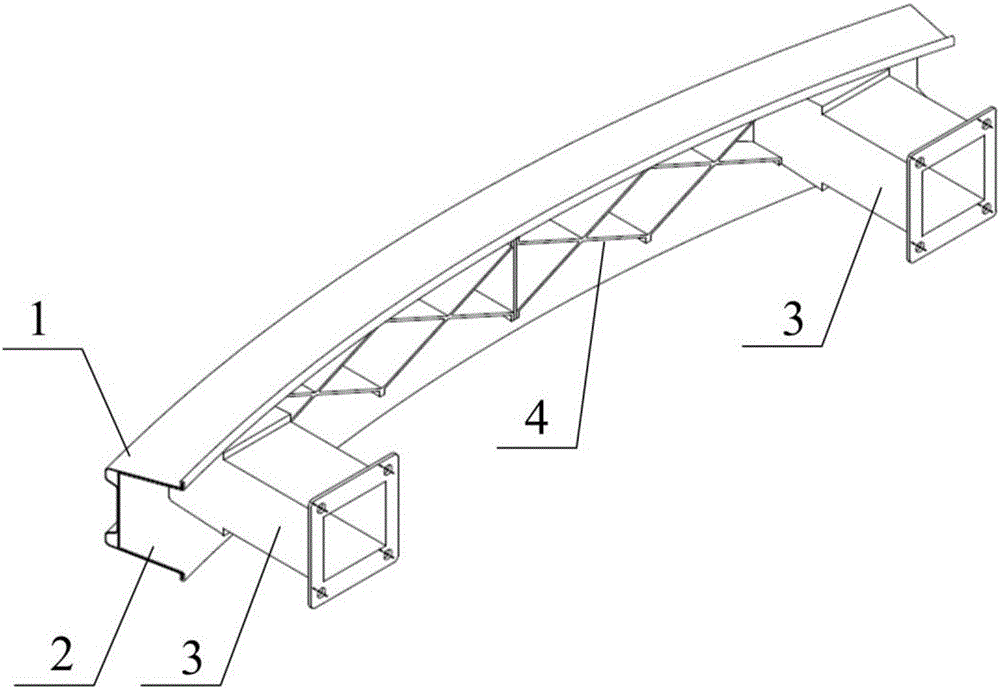

Bumper device integrally formed by metal/composite material

The invention discloses a metal / composite material integrated bumper device, which belongs to the technical field of automobile lightweight and collision safety. The bumper device comprises a bumper beam metal outer panel, a bumper beam composite material inner panel, an energy-absorbing box, a composite material inner panel reinforcing rib and a composite material lock buckle. Based on the design concept of lightweight and modularized automobiles, the invention comprehensively utilizes the characteristics of strong metal bearing capacity, high specific strength of composite materials, good impact energy absorption and complex geometry, and adopts advanced direct injection molding and adhesion integration Made by molding process. The integrally formed automobile bumper device has high integration, shortens the assembly process, has good economic benefits, and is easy to popularize. The use of composite materials reduces the weight of the bumper, realizes lightweight, reduces vehicle fuel consumption, reduces exhaust emissions, designs and manufactures a rib structure with good load-bearing capacity, and improves the collision safety of the vehicle bumper.

Owner:BEIHANG UNIV

Preparation method of indoor flatting powder paint

InactiveCN102850913AEasy material selectionSuperior performancePowdery paintsEpoxy resin coatingsChemistryOrganic acid

The invention relates to a preparation method of indoor flatting powder paint, which is characterized by comprising the following steps: adding polybasic acid or acid anhydride, polyalcohol, catalyst and antioxidant into a reaction kettle, mixing, introducing nitrogen, heating to carry out esterification reaction or ester exchange reaction until the reaction liquid is completely clear, carrying out vacuum polycondensation until the acid value is 40-200mg KOH / g and the viscosity is 10-50 poise, cooling, and discharging to obtain the light yellow transparent or semitransparent solid component A polyester resin; adding polybasic acid or acid anhydride, polyalcohol, catalyst and antioxidant into a reaction kettle, mixing, introducing nitrogen, heating to carry out esterification reaction or ester exchange reaction until the reaction liquid is completely clear, carrying out vacuum polycondensation until the acid value is 10-50mg KOH / g and the viscosity is 30-100 poise, cooling, and discharging to obtain the light yellow transparent or semitransparent solid component B polyester resin, wherein the molecular weight of the component A polyester resin and the component B polyester resin are respectively controlled at 1000-10000 dalton; evenly mixing the component A polyester resin, component B polyester resin and polybasic organic acid to obtain a component C polyester resin; and mixing the component C polyester resin, epoxy resin E-12, barium sulfate, titanium white, leveling agent, brightener, physical flatting agent and benzoin to obtain the indoor flatting powder paint. The synthesis method has the advantages of diversity and the like, and can easily implement industrialized mass production.

Owner:广东大盈新材料科技有限公司 +1

Method for extracting high-purity solanesol from potato leaf, tobacco leaf and/or tobacco stem

ActiveCN101182284ASimple processEasy to industrializeHydroxy compound separation/purificationSaponificationMethanol

A method of extracting high-purified solanesol from potato leaves, tobacco leaves and / or tobacco stems is that the solanesol is extracted from the raw materials by extracting solvent, solanesol extract is obtained after solid-liquid separation; the solanesol extract is processed for the phase-transfer catalytic saponification reaction inside an organic-solvent-buck-phase-transfer catalyst system; the solanesol extract after saponification is completely dissolved in mixed alcohol-acetone solvent under 50 DEG C to 75 DEG C for stationary placing, cooling and filtering; filtrate is steamed to be dry to obtain the solanesol extract after wax removal, and the solanesol extract is dissolved in methanol or acetonitrile in reflux to be frozen and crystallized for obtaining white solid which is dried to obtain the solanesol. The present invention has the advantages of gentle reaction condition, simple technology, short production period, large batch, the high yield and purity of the solanesol and being convenient for industrialization.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

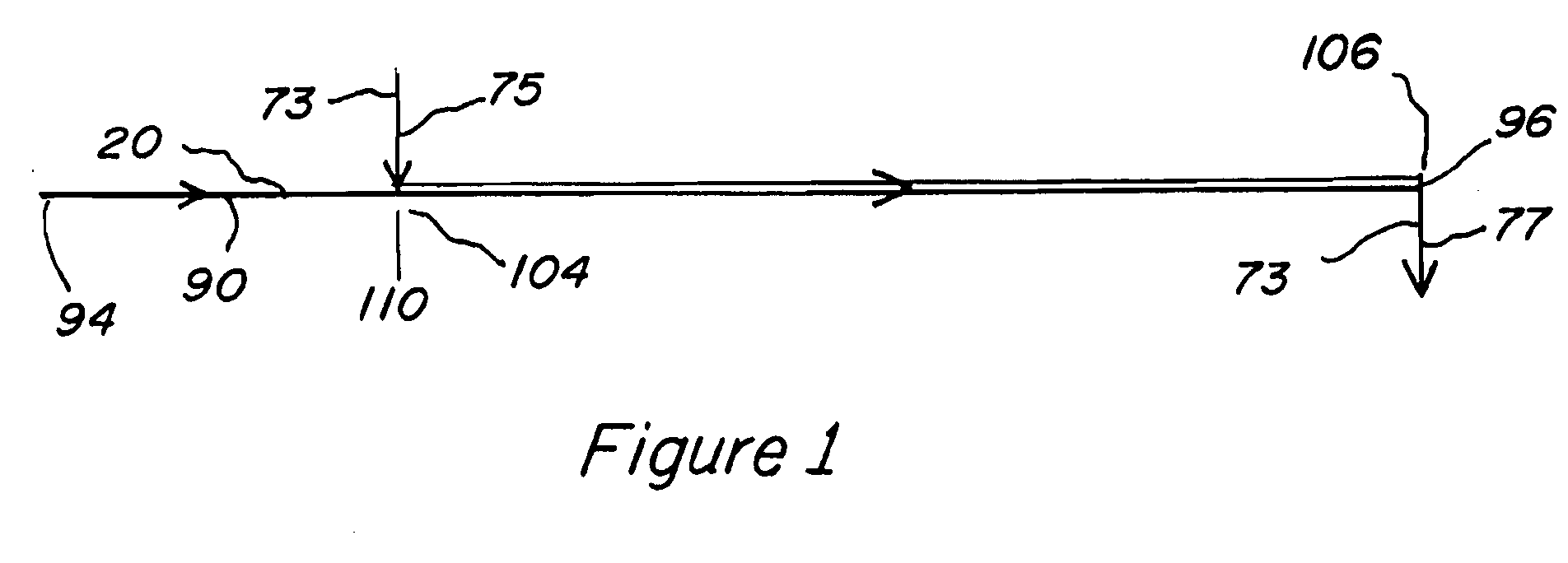

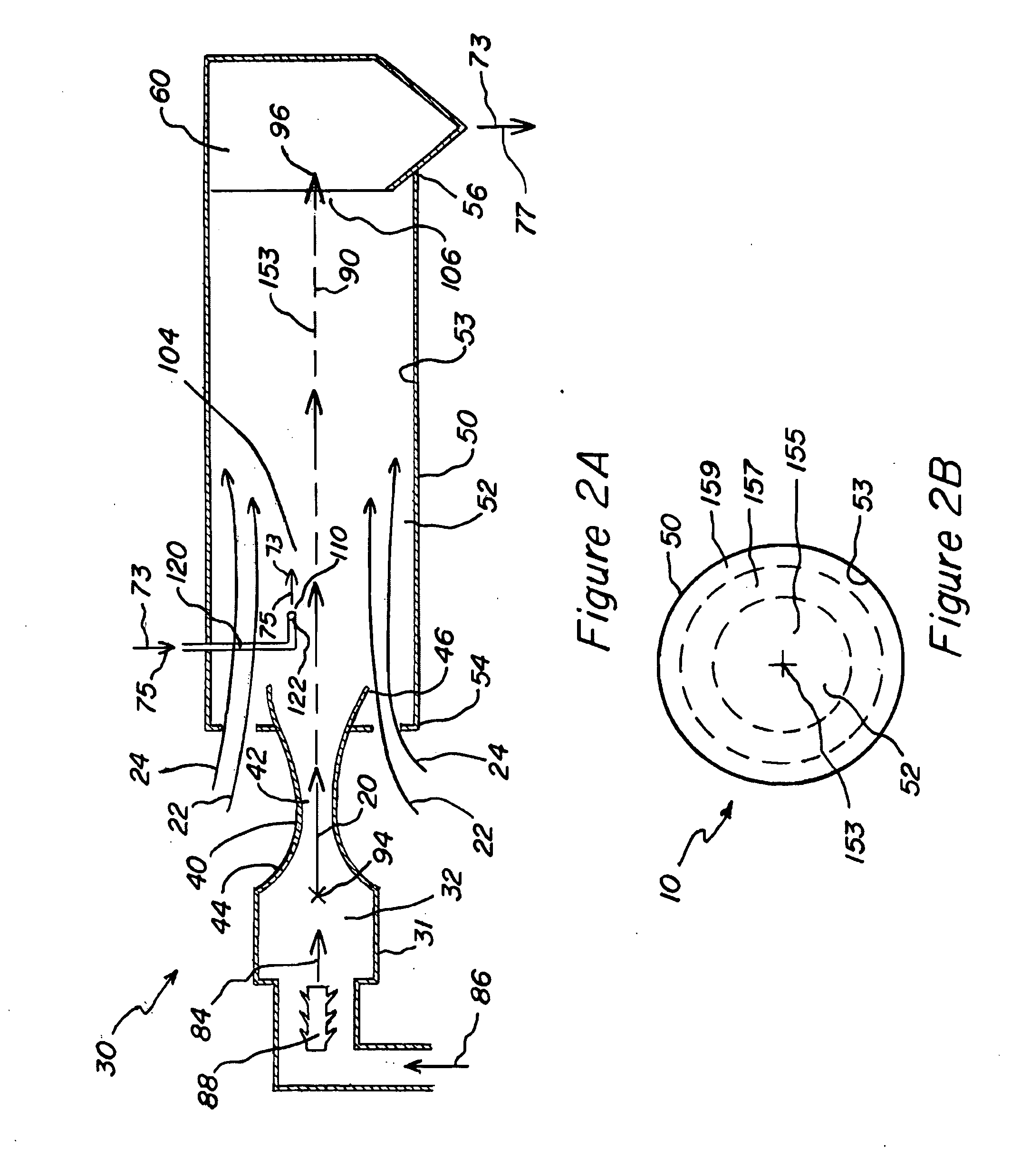

Methods and apparatus for the production of viral vaccines

ActiveUS20090087452A1Fast and efficient dryingLarge batchViral antigen ingredientsMicrobiological testing/measurementLiquid stateViral Vaccine

A viral vaccine in the dried state is described. Methods for drying viral vaccine in the liquid state into viral vaccine in the dried state are presented. The methods may include introducing the viral vaccine in the liquid state into a gas stream and recovering viral vaccine in the dried state from the gas stream.

Owner:PULSE HLDG

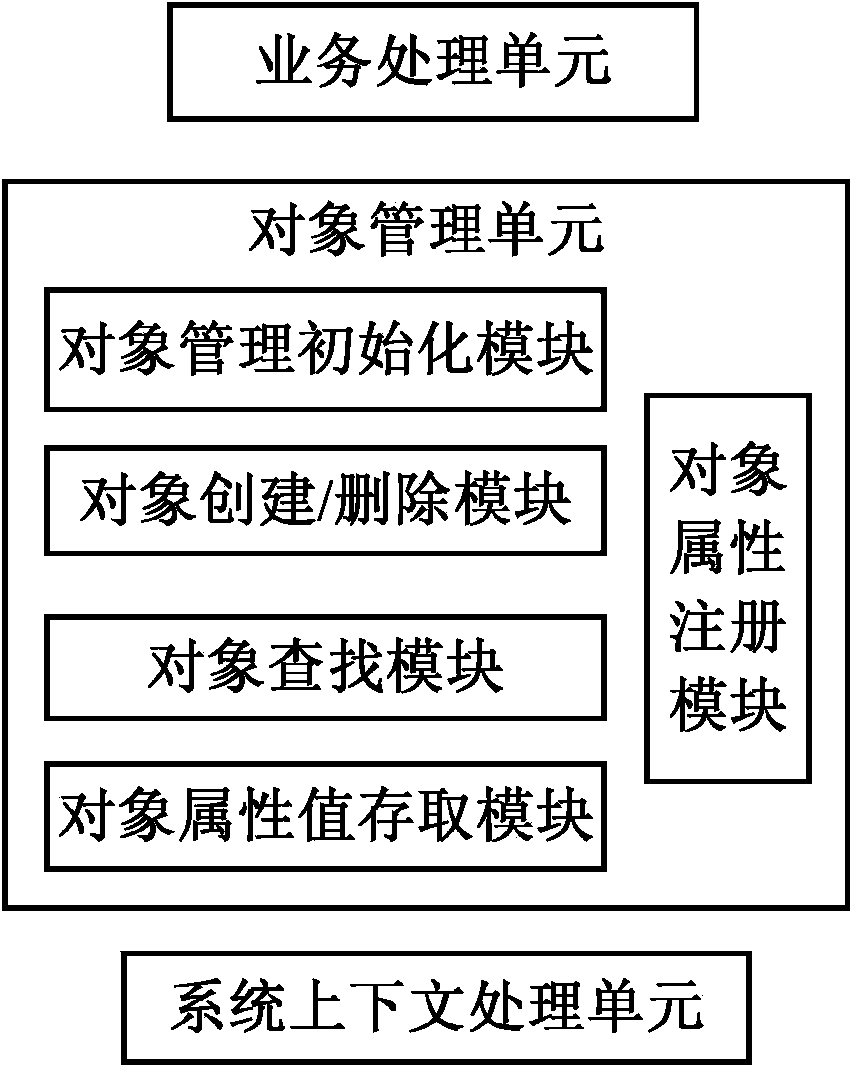

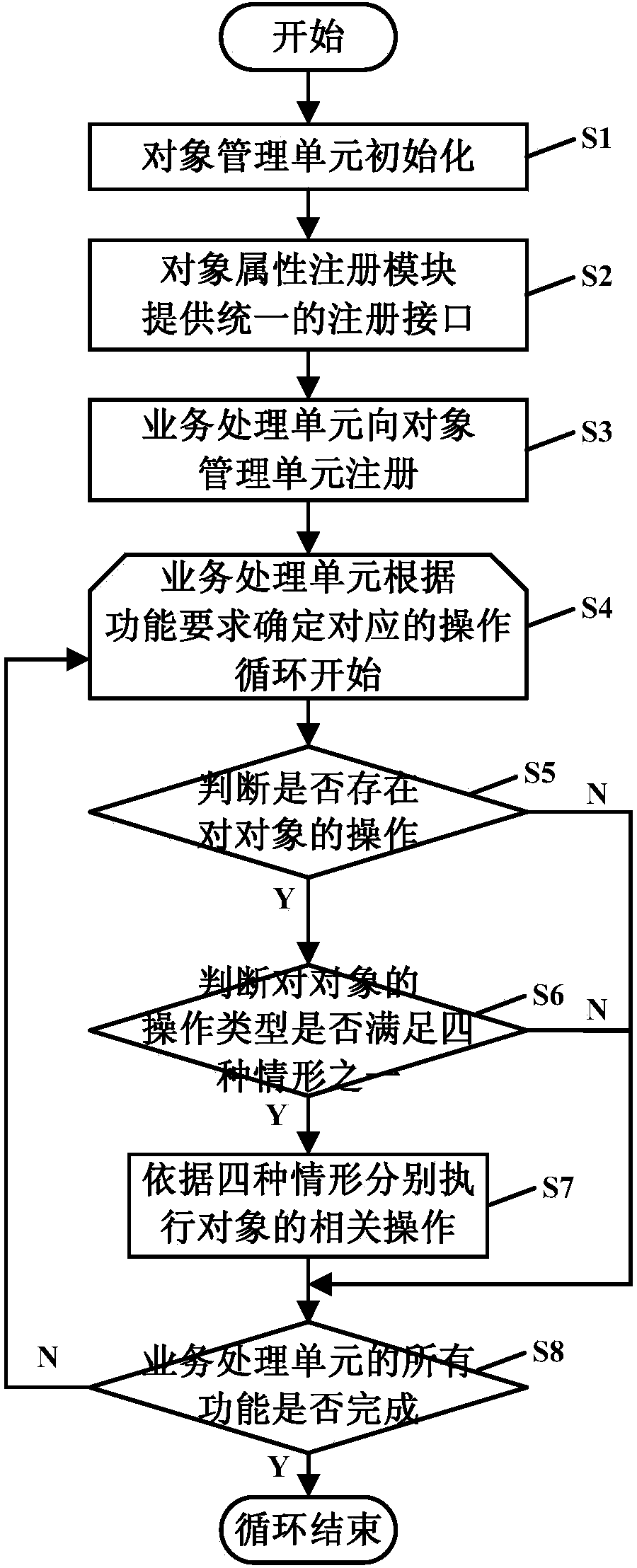

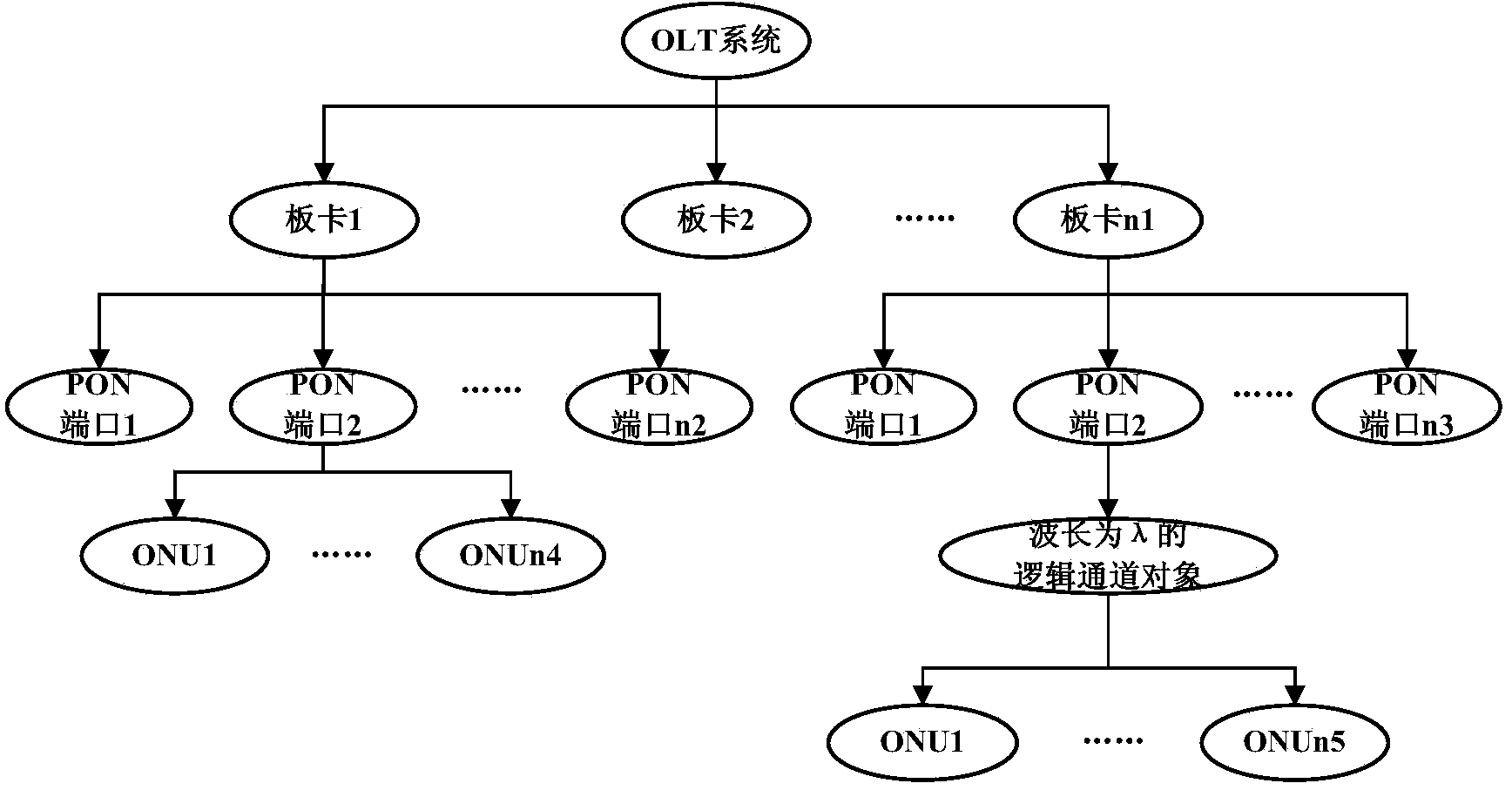

Device and method for managing objects of embedded system

ActiveCN103559032AImprove development efficiencyImprove securitySpecific program execution arrangementsExtensibilityManagement unit

The invention discloses a device and a method for managing objects of an embedded system and relates to the field of object management. The device comprises a business processing unit, an object managing unit and a system context processing unit, wherein the business processing unit is used for calling an interface of the object managing unit to finish a corresponding function, dynamically establishing and deleting an object to maintain an object tree, obtaining an index of the needed object and setting / obtaining an attribute value of the object by calling a corresponding object operation module according to the object index; and the object managing unit comprises an object management initializing module, an object attribute registering module, an object establishing and deleting module, an object finding module and an object attribute value access module. According to the device and the method for managing the objects of the embedded system, the reusability and the expandability between the different systems can be improved; the expansion of the object and the realization of an object function do not influence each other; and hardware storage resources are saved and the development efficiency of software is improved.

Owner:FENGHUO COMM SCI & TECH CO LTD

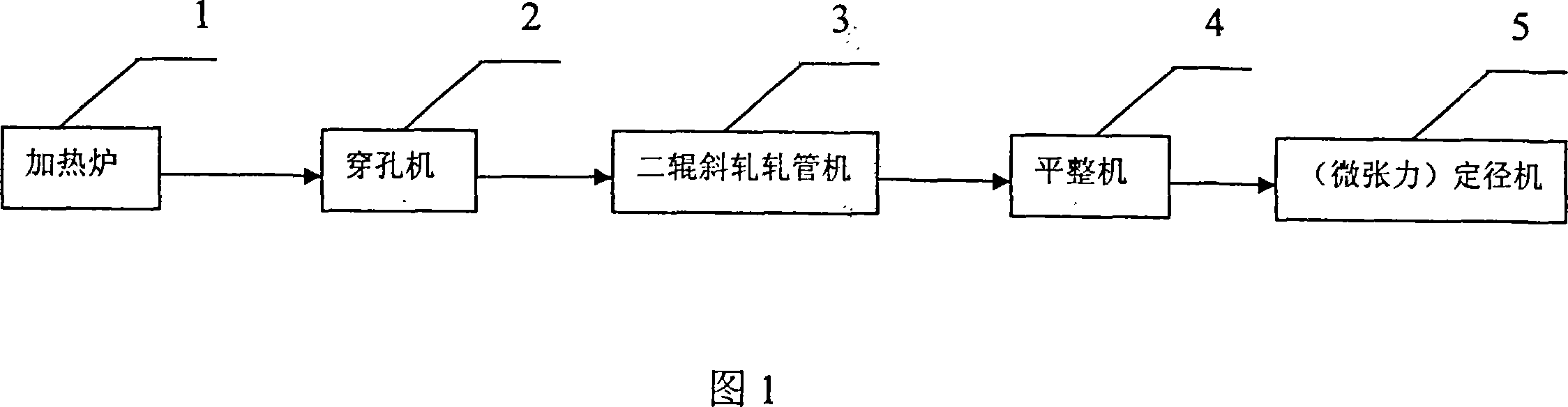

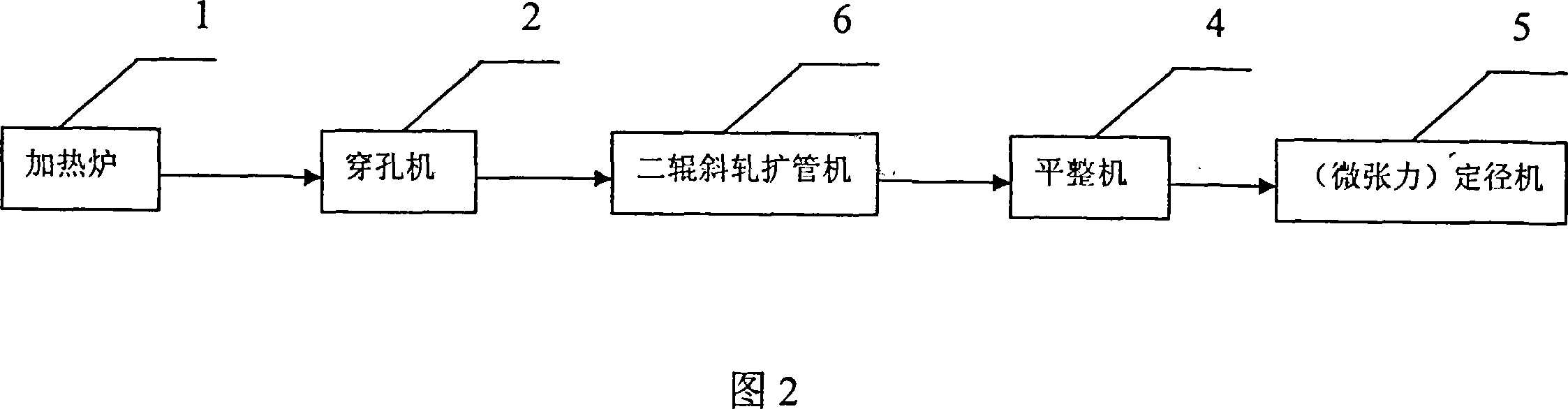

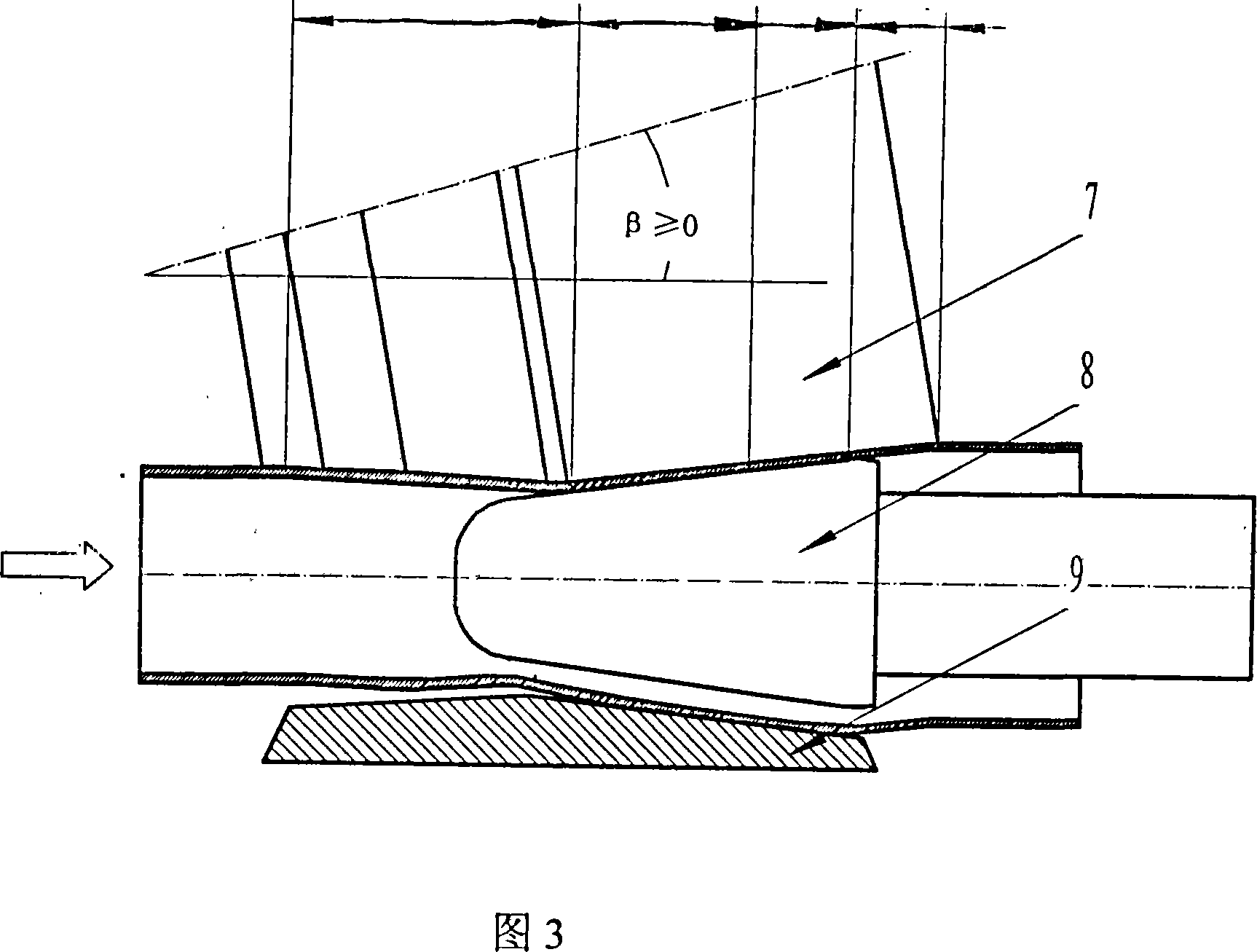

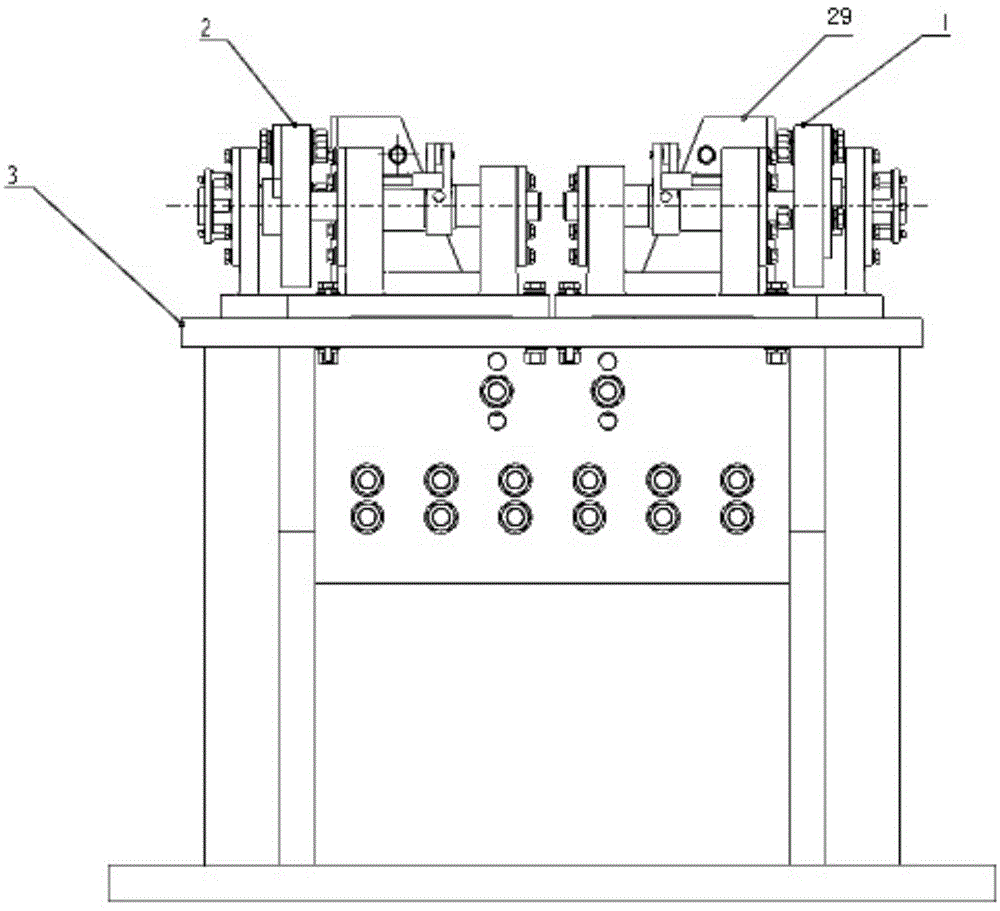

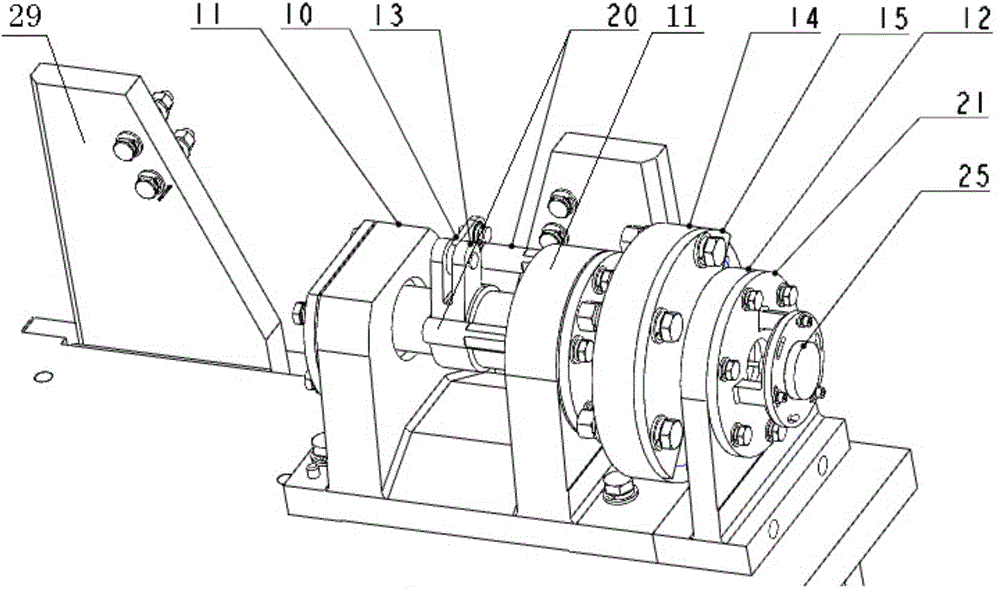

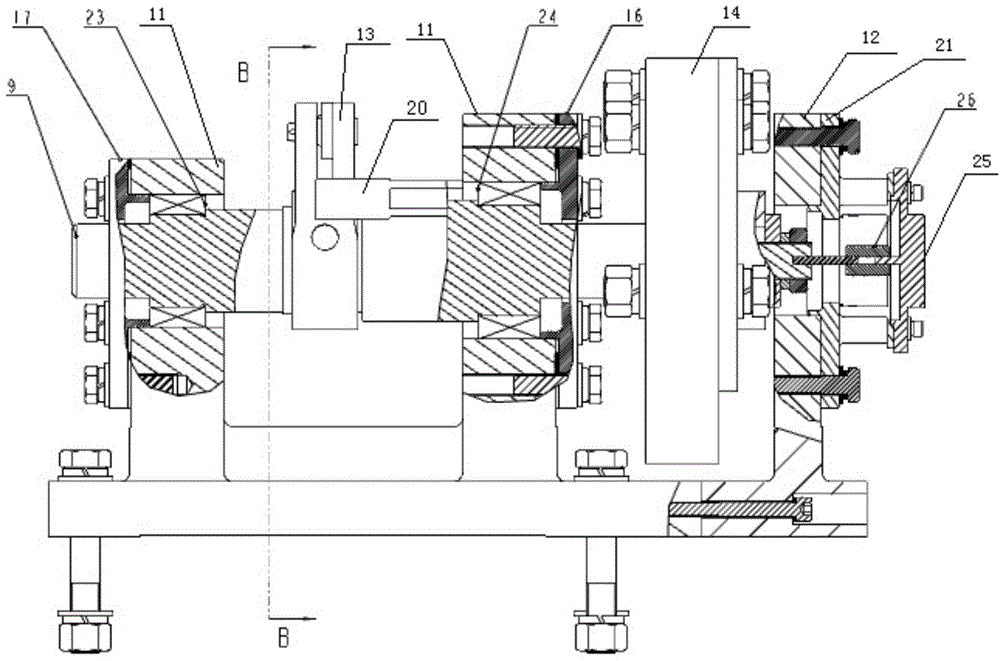

Technologic process and special apparatus for rolling seamless steel pipe

InactiveCN101066547AExpanded range of product specificationsMeet needsRoll mill control devicesMetal rolling arrangementsHeating furnaceMaterials science

The present invention discloses technological process and special apparatus for rolling seamless steel pipe. The technological process includes the steps of: heating in a heating furnace, perforating in a perforating machine, expanding in a two-roll skew rolling pipe expander, leveling in a leveling machine and sizing in a sizing mill. The two-roll skew rolling pipe expander therefor consists of two rolls, one forcer and two guide plates. The present invention has low apparatus investment, and can meet the requirement in rolling seamless steel pipe with wide size range and great batch.

Owner:烟台鲁宝钢管有限责任公司

Method for manufacturing steel-copper composite welded tube

The invention relates to a method for manufacturing a steel-copper composite welded tube, comprising the following steps: respectively washing the surfaces of a steel band and a copper band which are utilized as raw materials; matting the composite surfaces of the steel band and the copper band; heating the steel band to 750+ / -30 DEG C; heating the copper band to 550+ / -30 DEG C; then attaching the composite surface of the steel band to the composite surface of the copper band; and sending the steel band and the copper band to a cold mill, rolling and compounding; annealing, rolling, annealing, flattening and separating the steel and copper composite band in sequence to obtain a steel-copper composite band with a needed width; delivering the steel-copper composite band to a tube molder to mould the tube; then welding, replenishing copper, sizing, detecting flaw, decoiling, detecting leakage, annealing, pulling, annealing and decoiling in sequence; and then packing the product in storehouse. The method is suitable for tubes for the condensers and evaporators of domestic electric appliances such as air conditioner and refrigerator.

Owner:江苏其元集团有限公司

Method for separating and refining polyprenol in ginkgo biloba extract

ActiveCN101967083AMild operating conditionsHigh process yieldIon-exchange process apparatusIon-exchanger regenerationSolventGinkgo biloba plant

The invention relates to a method for separating and refining polyprenol in ginkgo biloba extract. The method comprises the following steps: placing polyprenol extract in alcoholic lye to fully stir, saponifying at 30-80 DEG C for 0.5-4h, neutralizing the reaction liquid with acid, concentrating to obtain the saponified polyprenol extract; dissolving urea in loading solvent, adding carrier to ensure that urea is loaded on the carrier, removing solvent, preparing stationary phase; performing the column-packing of the prepared stationary phase, then adding the saponified polyprenol extract in the column, injecting mobile phase in the chromatographic column at a constant speed to elute, collecting elution components during different periods; combining the elution components which are rich inpolyprenol, concentrating and evaporating; dissolving polyprenol which is processed by the urea column chromatography in the refluxed methanol, ethanol or acetonitrile to obtain saturated solution, freezing to crystallize, filtering, and drying to obtain polyprenol. The method of the invention has the advantages of mild operating conditions, high process recovery, high production purity, simple process and low operation cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Noodle stewing machine

The invention provides a noodle stewing machine. The problems in the prior art that fried and dried noodles are not good for the health, and the time and labor waste caused by that the noodles are eaten after being strewed with water can be solved. The noodle stewing machine comprises a rack, a pot body, an exhaust duct, a delivery system, a power motor, a noodle falling opening and a noodle outlet, wherein the pot body is arranged inside the rack; the exhaust duct is arranged at the top of the rack; the delivery system comprises a noodle basket for placing noodles, a delivery chain for mounting the noodle basket, and a chain wheel which is used for supporting the delivery chain, and changing the movement direction of the delivery chain and is arranged on the rack; the power motor is arranged at the top of the rack and is connected with the chain wheel; the noodle falling opening is used for enabling cut noodles to fall into the noodle basket, and is arranged on the rack; and the noodle outlet is used for discharging stewed noodles. The noodle stewing machine provided by the invention can be used for machining convenient wet noodles in a stewing manner, so that not only can the characteristics of the noodles be kept, but also the negative influence on the human health caused by the fried and dried noodles can be avoided. Furthermore, the large-scale production of factories can be satisfied. The noodle stewing machine can be used by being assorted with upstream and downstream equipment, so that the automatic control can be realized. The noodle stewing machine has the characteristics of security, high efficiency, convenience in use and the like.

Owner:北京金田麦国际食品有限公司

Method for cultivating large-size eel fries

InactiveCN103004650AIncreased survival rate of breedingQuality improvementClimate change adaptationPisciculture and aquariaFisheryPhacus

The invention relates to a method for cultivating large-size eel fries. The method is characterized in that cultivation net cages are arranged in rows in a pond, and the spacing between every two net cages in each row is 1-1.5m; the throwing density of the eel fries is 4000-5000 pcs / m<2>, and thrown feed is animal live baits, namely tubificidae; in the first one month of a cultivation stage, the feed quantity for every ten thousands of young eels is gradually increased from 500g to 2000g, and the eels are fed three times each day; after the eels are cultivated for one month, the daily feed quantity accounts for 8-10% of the weight of each ell fry, and the eels are fed once each day, and the feeding is stopped when water temperature is lower than 12 DEG C in the middle ten days of November each year; and during the cultivation period, attention is obliged to be paid to the complete condition of the net cages, grading feeding is performed timely according to the size of individual eels, and alternanthera philoxeroides is used to cover the inside of the cultivation net cages in a wintering period. According to the method disclosed by the invention, the cultivation survival rate of the eel fries can be increased to 80-90%; and after ten months of cultivation, the individual size of eels reaches 8-10g in average, and a large scale of high-quality large-size eel fries can be provided for scale cultivation of the eels.

Owner:YANGTZE UNIVERSITY

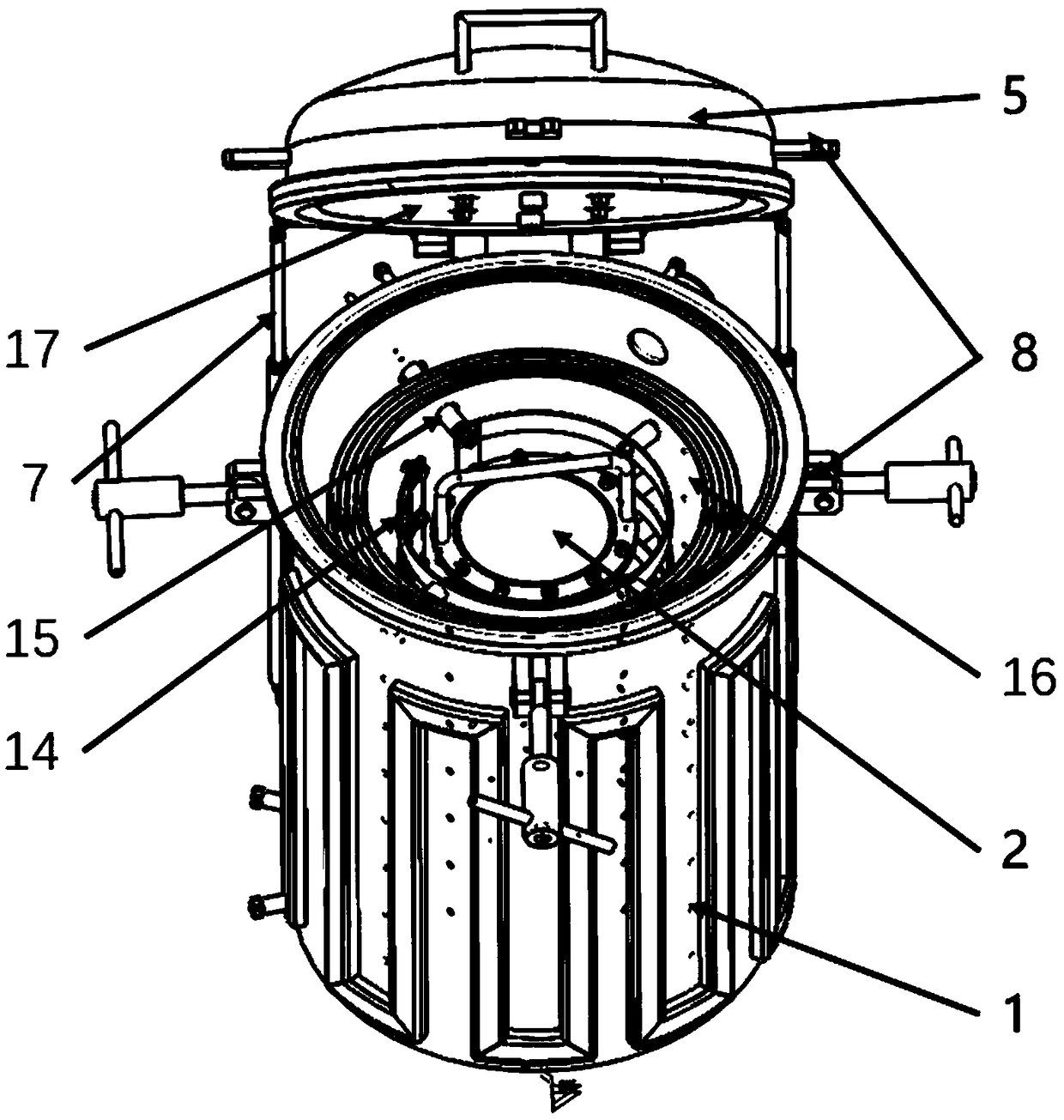

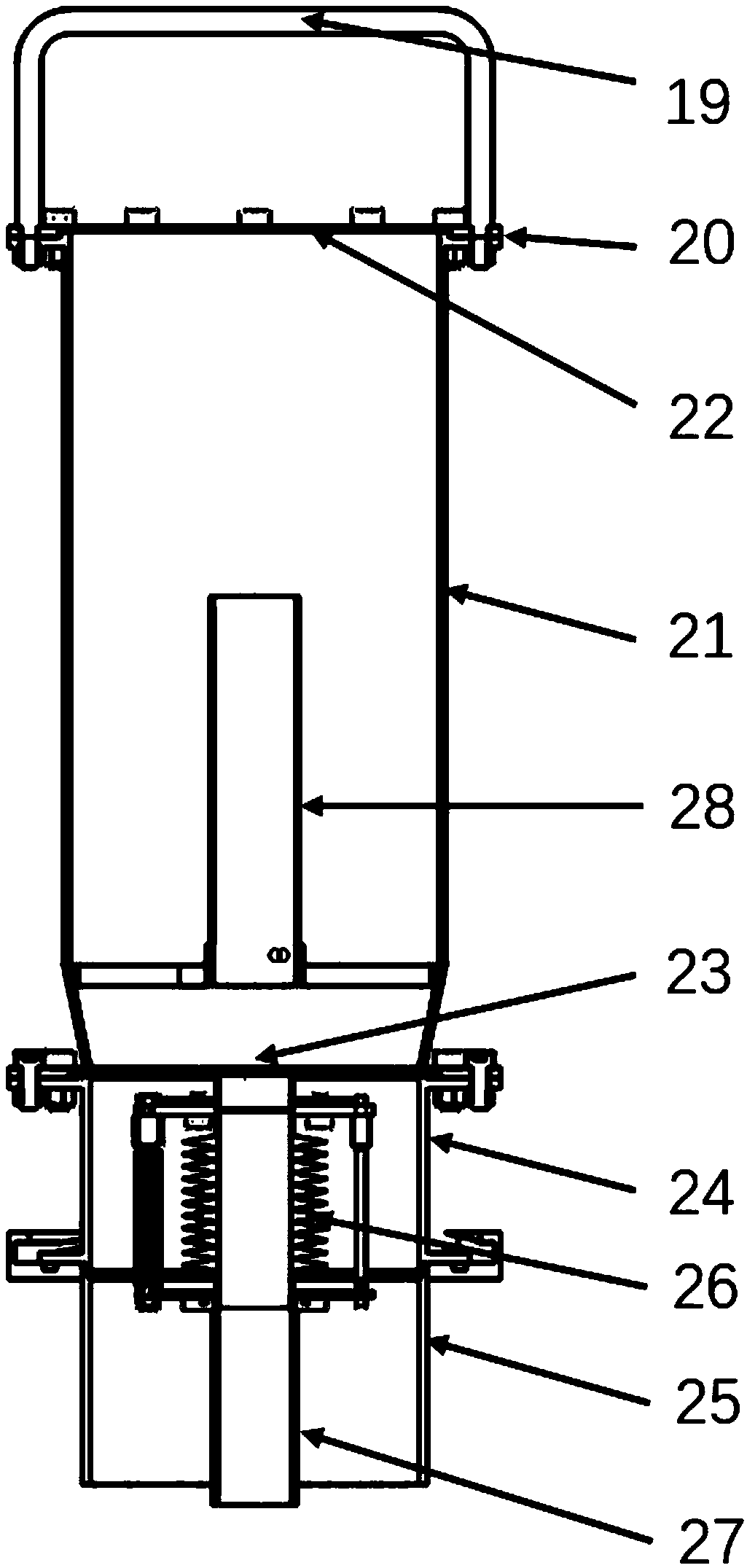

Atomic layer deposition device for coating large-scale micro-nano particles

ActiveCN108715998AIncrease profitHeating up fastChemical vapor deposition coatingMicro nanoReaction rate

The invention belongs to the field related to atomic layer deposition preparation instruments, and discloses an atomic layer deposition device for coating large-scale micro-nano particles. The devicecomprises a particle container and a reaction cavity, wherein a source inlet is formed in the lower end of the reaction cavity, an air inlet pipe used for inputting a precursor and a carrier gas is arranged in the source inlet in a sealed mode, the upper end of the reaction cavity is provided with a cavity door, the particle container can be freely placed in the reaction cavity, or is taken out ofthe reaction cavity, an air inlet hole is formed in the lower end of the particle container, and the air inlet pipe enters an inner cavity of the particle container through the air inlet hole. According to the atomic layer deposition device, the airflow internal circulation method and the airflow external circulation method can be effectively combined, so that the collision between the particlesand the contact probability between the particles and gas molecules are remarkably increased, the reaction rate and the precursor utilization rate are improved, and high-quality and high-efficiency coating of the large-scale micro-nano particles is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for separating and purifying solanesol by urea column chromatography

ActiveCN101973848AMild operating conditionsHigh process yieldHydroxy compound separation/purificationRefluxStationary phase

The invention relates to a method for separating and purifying solanesol by urea column chromatography. The method comprises the following steps of: fully stirring solanesol concrete in alcoholic-alkaline solution; saponifying the mixture at the temperature of between 30 and 80 DEG C for 0.5 to 4 hours; neutralizing the reaction solution by using acid; concentrating to obtain saponified solanesolconcrete; dissolving urea into a loaded solvent; adding carriers to ensure that the urea is loaded on the carriers; removing the solvent to prepare a stationary phase; loading the prepared stationaryphase to a column; loading the saponified solanesol concrete to the column; eluting by injecting a mobile phase into a chromatography column at a uniform speed; collecting elution partitions at different stages; merging the elution partitions rich in the solanesol; concentrating and evaporating to dryness; dissolving solanesol solution after the urea column chromatography into methanol, ethanol or acetonitrile in reflux; saturating the solution; freezing and crystallizing; filtering; and drying to obtain the solanesol. The method has the advantages of mild operation condition, high process yield, high product purity, simple process and low operation cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

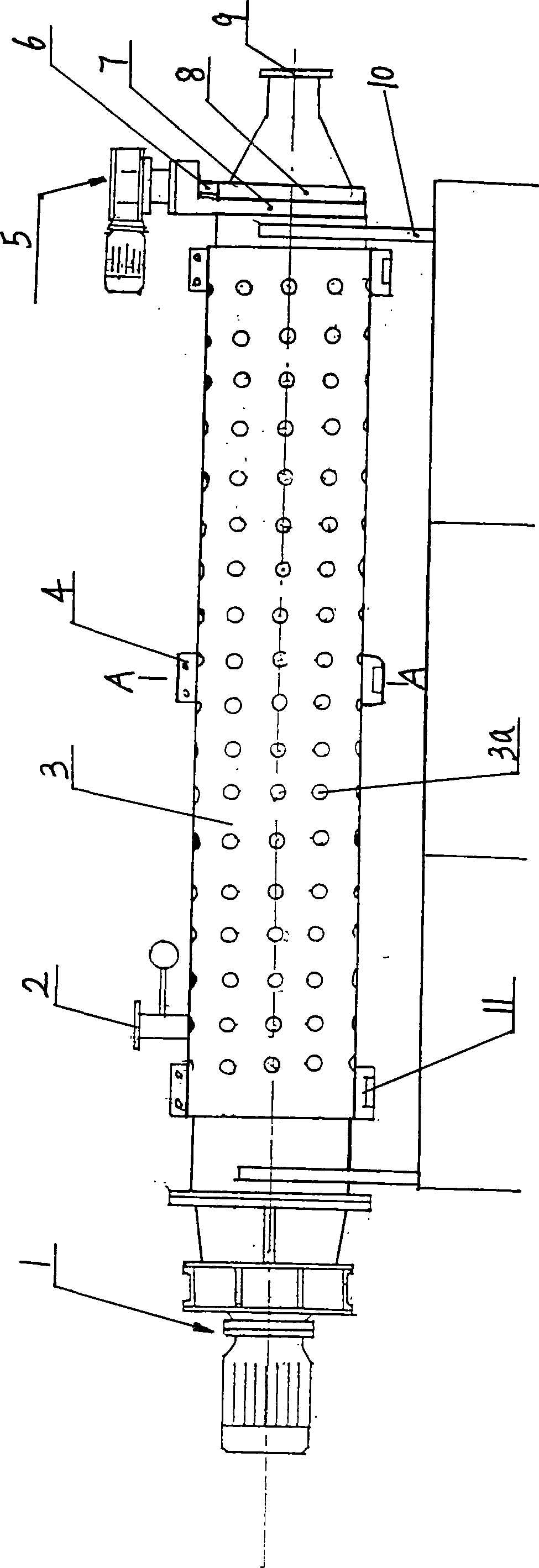

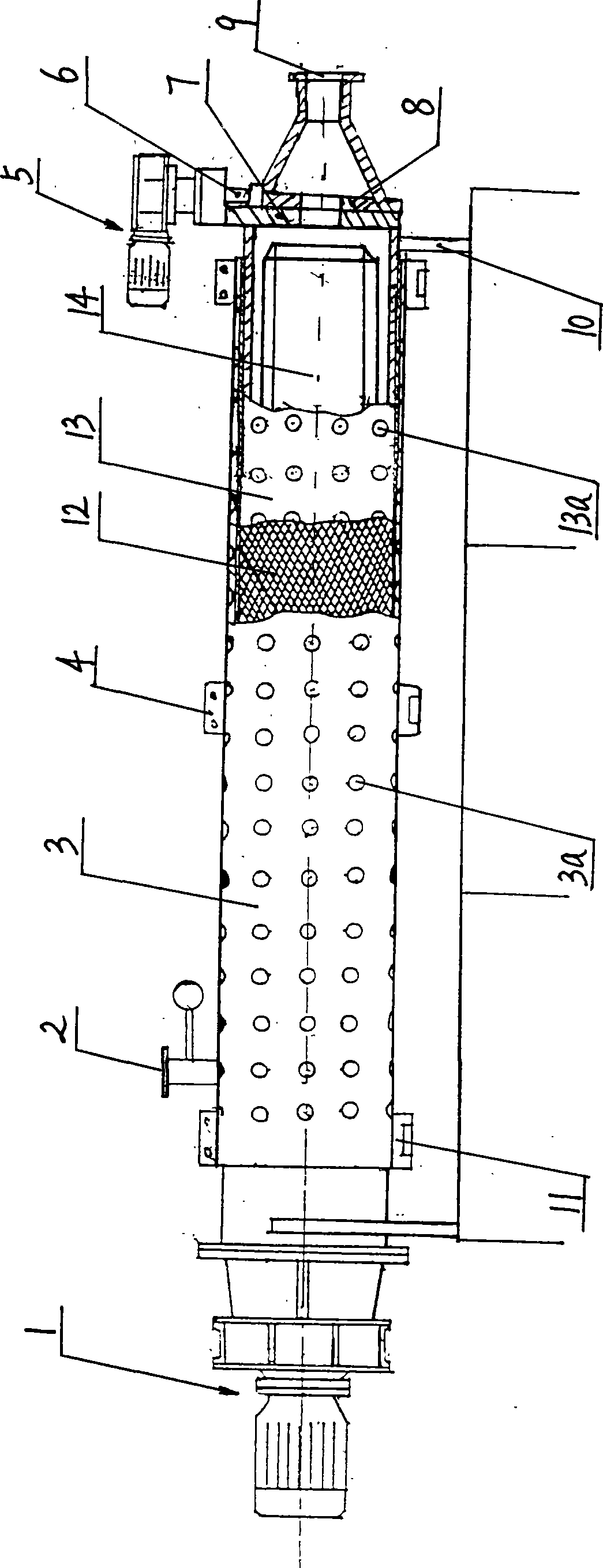

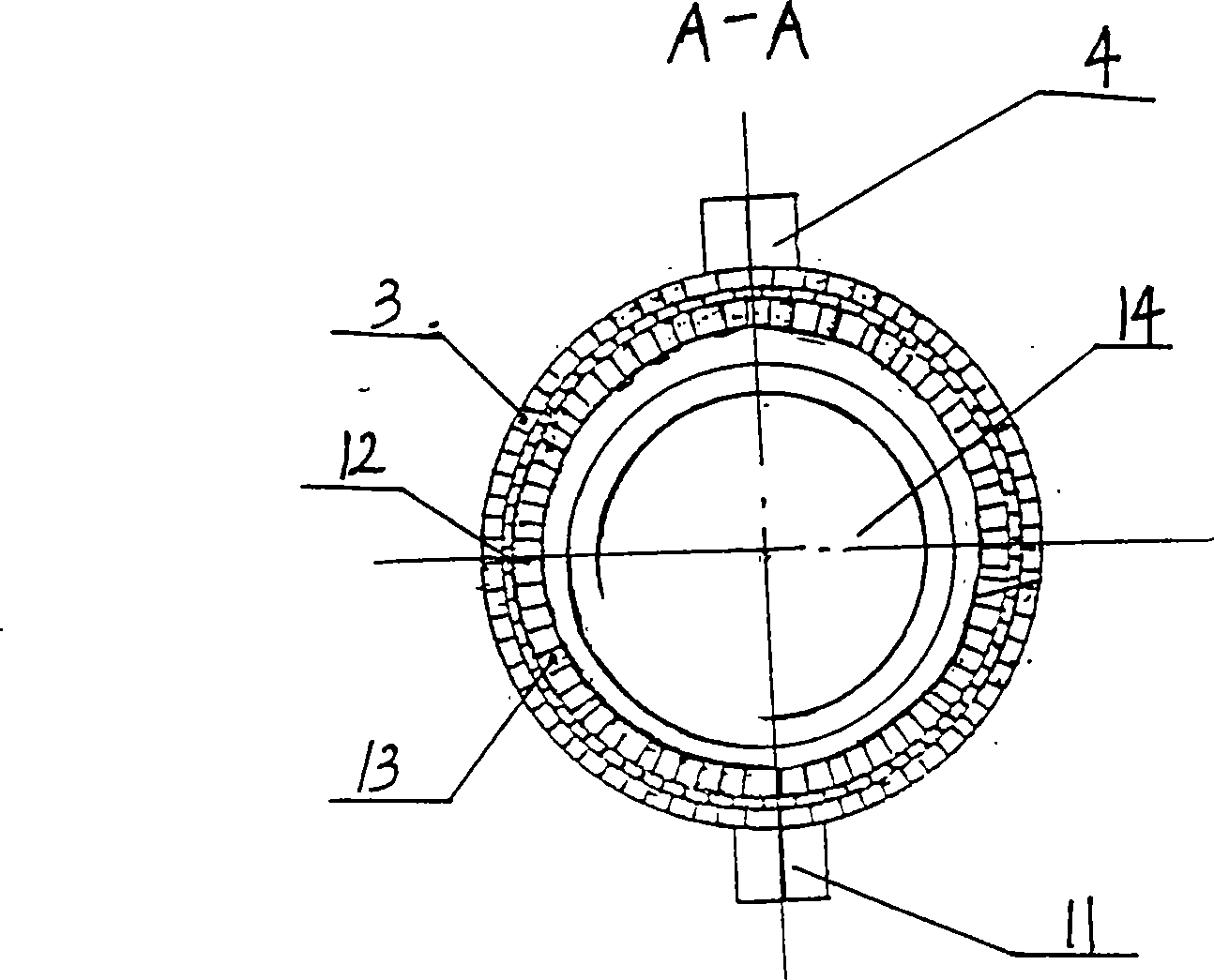

Screw rod drum-type filter press for continuous operation

InactiveCN101503004AImprove filtration efficiencyLarge batchPressesPulp and paper industryFilter press

The invention discloses a screw cylinder type pressure filter capable of continuously working, comprising a body, a support saddle for supporting the body, and a driving device. The body is provided with a feeding hole and a discharge hole. The invention is characterized in that the body is a horizontal cylinder body, wherein a screw rod is installed at the shaft line, the screw rod penetrates through the whole cylinder body, the outer diameter of the screw rod is matched with the inner diameter of the cylinder body, the feeding hole and the discharge hole are respectively positioned at both ends of the cylinder body, and simultaneously a drainage mechanism is further provided on the cylinder body; the screw rod is connected with the driving device, the rotation of the screw rod is driven by the driving device, materials in the cylinder body are transported and dehydrated, and the squeezed water is discharged out of the cylinder body by the drainage mechanism. The pressure filter in the invention not only can realize continuous work of pressure filter for materials, but also can greatly improve the dewatering efficiency of the materials by using higher pressure to press the materials, thereby achieving the purposes of adapting to increasingly-developed industrial production development requirements for large mass and high strength.

Owner:冼自根

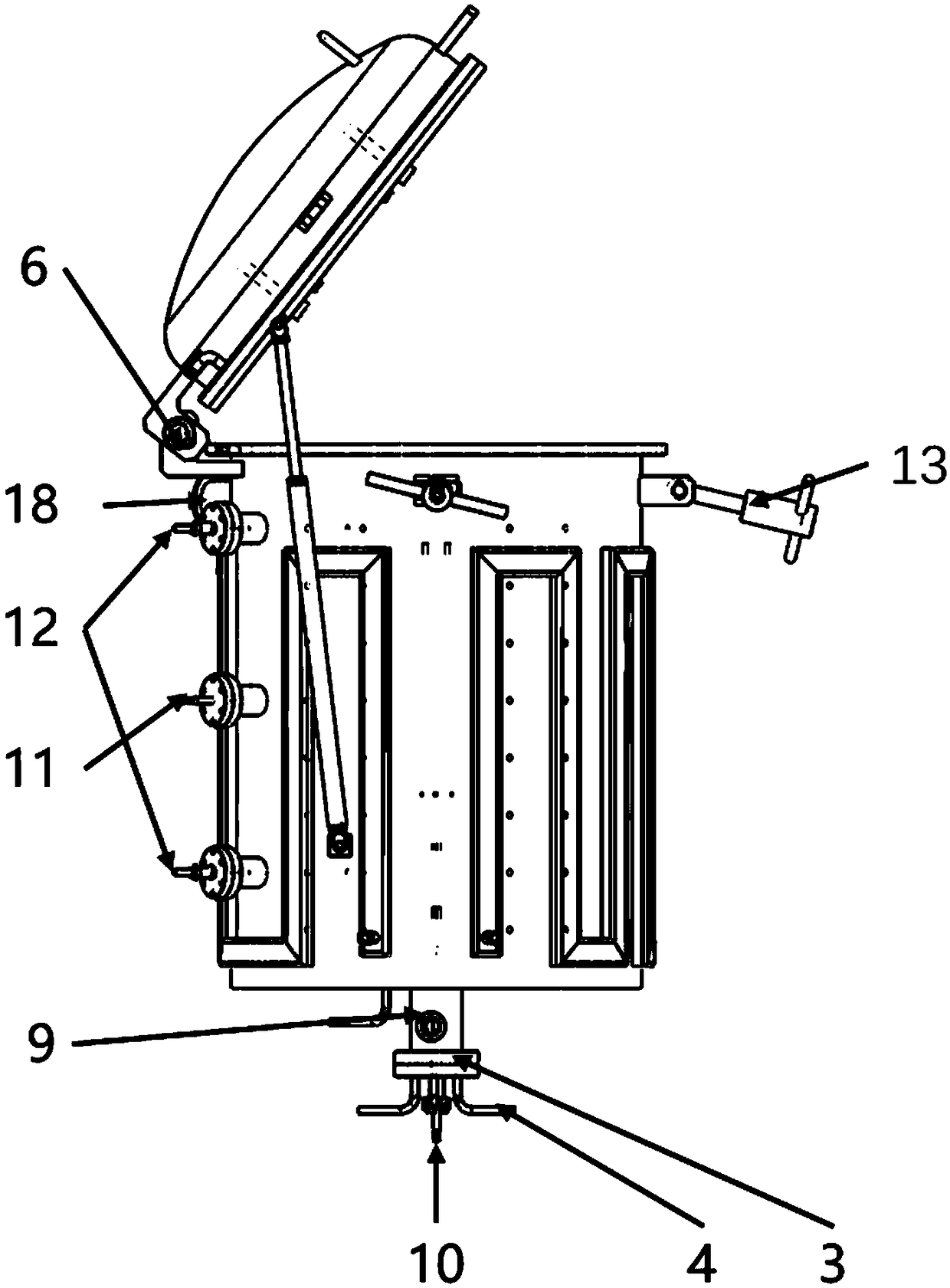

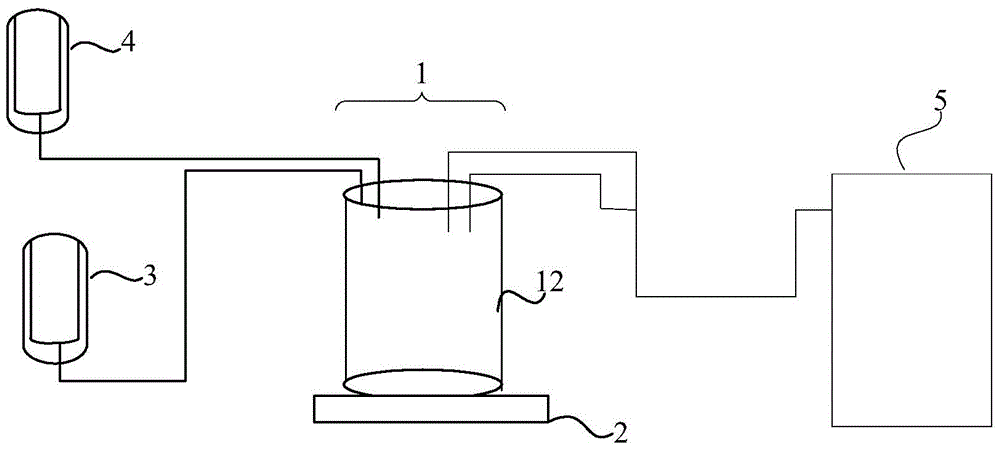

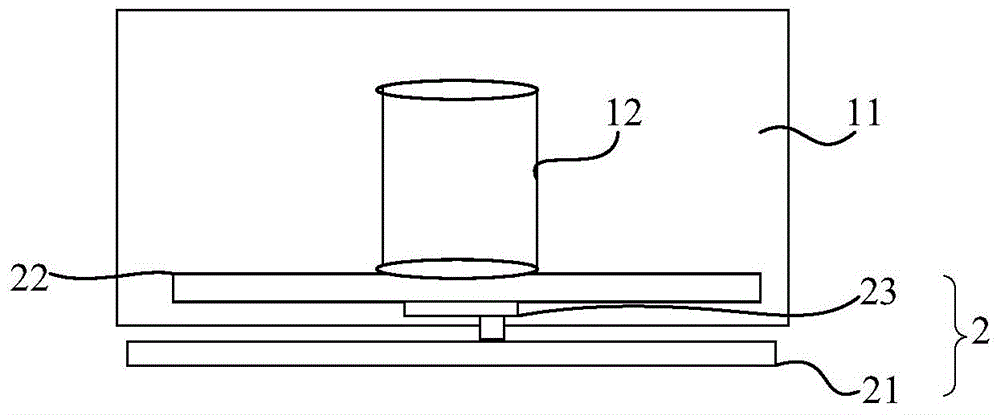

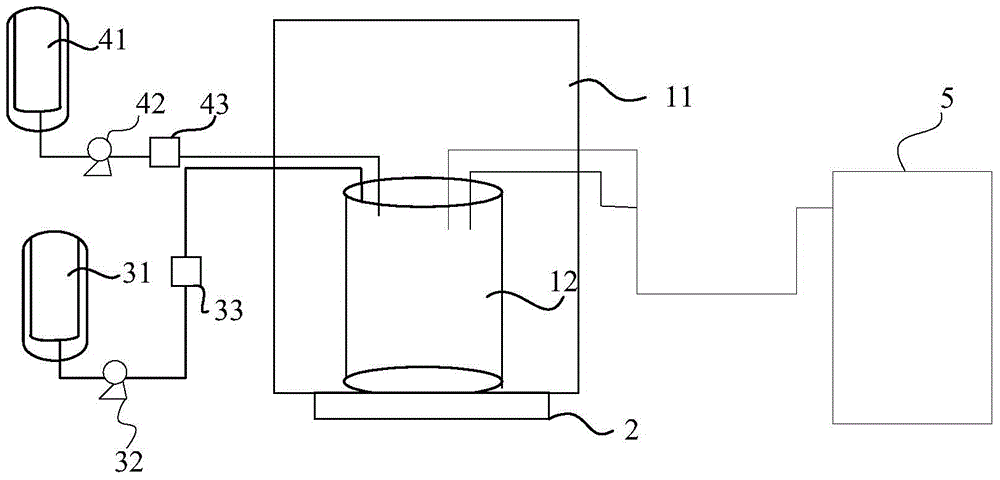

Cornea decellularization system and decellularization method

ActiveCN106267343AReduce manual interventionConditions are metEye implantsAutomatic controlDecellularization

The invention relates to the technical field of cornea decellularization, and especially relates to a cornea decellularization system and decellularization method. Automatic control is carried out to reduce artificial intervention in the cornea decellularization process, realize large batch throughput and create conditions for large-scale production and application of corneas. The defects of small batch throughput and restriction of the large-scale production and application of corneas are overcome in the prior art. The cornea decellularization system provided in the embodiment of the invention comprises a decellularization device comprising a reaction tank, and also comprises an oscillation device, a decellularization reagent supply device, an injection water supply device, a waste liquid discharging device and a control device; and the control device is used for controlling the on and off of the oscillation device, controlling the decellularization reagent supply device to supply a decellularization reagent to the reaction tank from, controlling the injection water supply device to supply injection water to the reaction tank and controlling the waste liquid discharging device to discharge a liquid in the reaction tank.

Owner:SHENZHEN AINEAR CORNEA ENG

Continuous-phase-change soy sauce residue oil extraction method

ActiveCN103173280ALower retention rateHigh retention rateFatty-oils/fats productionSulfur hexafluorideGas phase

The invention provides a continuous-phase-change sauce residue oil extraction method. According to the invention, a dried and crushed sauce residue raw material is placed into an extraction kettle; under a condition with a pressure constantly lower than an extracting agent critical pressure and a temperature constantly lower than an extracting agent critical temperature, the extracting agent is compressed into a liquid; the extracting agent flows through the extraction kettle with a certain flow rate, such that castor oil is extracted; the material is delivered into a resolution kettle; heating and pressure reducing are carried out, such that the extracting agent is changed into a gas phase; instant compression is carried out, the extracting agent is changed into liquid, and flows through the extraction kettle, such that the material is extracted again. The steps are repeated several times. The extracting agent is one of ethanol, propane, butane, high-purity isobutane, R134a, dimethyl ether, liquefied petroleum gas, and sulfur hexafluoride. The method provided by the invention has the advantaged of high efficiency, no solvent residue in product, and high aroma component retention rate of a supercritical extraction method. Extraction pressure and resolution pressure of the method are lower than those of supercritical extraction. The method also has the advantages of large extraction volume, large-amount batch production, low production cost, and the like of a conventional solvent extraction method.

Owner:广东惠尔泰生物科技有限公司

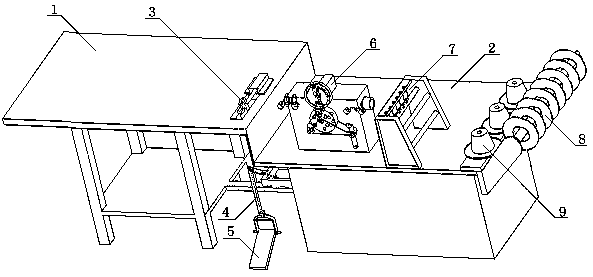

Workbench special for cutting wires

The invention relates to a workbench special for cutting wires. The workbench special for cutting wires is characterized in that an operation table and an equipment table which is connected with one end of the operation table are included, the part, close to the equipment table, on the surface of the operation table is provided with a guide wire cutter, and a guide wire length measuring device, a guide wire guiding device and a guide wire fixing device are sequentially arranged on the equipment table from the end, close to the operating table, of the equipment table to the other end of the equipment table. The workbench is the special equipment for cutting secondary guide wires needed when high and low voltage switch equipment is machined, and under the conditions that the cut guide wires are in large batch, and specifications are various, the advantages of being high in working efficiency and accurate in cut length specification are achieved. Meanwhile, the structure is simple, and operation is convenient.

Owner:DALIAN POWER SUPPLY COMPANY STATE GRID LIAONING ELECTRIC POWER +2

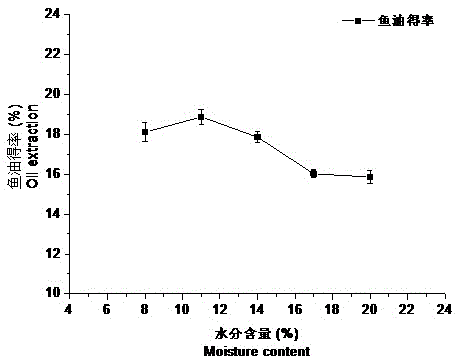

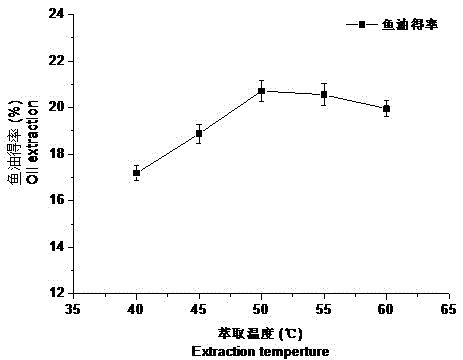

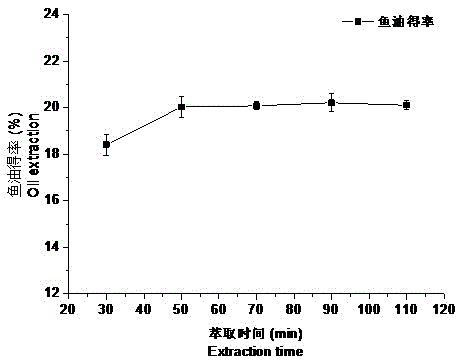

Method of extracting decapterus maruadsi oil through low-temperature continuous phase transition

ActiveCN105670781AHigh yieldReduce churnFatty-oils/fats productionPhysical chemistryDecapterus maruadsi

The invention discloses a method of extracting decapterus maruadsi oil through low-temperature continuous phase transition and decapterus maruadsi oil.The method includes: placing decapterus maruadsi powdery raw materials in an extraction kettle; under conditions of extraction temperature of 40-60 DEG C and extraction pressure 0.3-1.0 Mpa, compressing an extraction agent into liquid, enabling the liquid to flow through the extraction kettle at a flow rate of 100-150 L / h for continuous extraction of 30-110 min, and after decapterus maruadsi oil is extracted, enabling the liquid to enter an analysis kettle with analysis temperature of 50-80 DEG C and analysis pressure of 0.1-0.4 Mpa; performing phase transition on the extraction agent to form gas, immediately compressing the gas into liquid, enabling the liquid to flow through the extraction kettle, extracting materials again, enabling the materials to carry oil to enter an analysis tank through a solvent of an extraction tank, and obtaining a decapterus maruadsi oil product after analysis.Compared with conventional extraction methods, the method is accurate and stable in process, the decapterus maruadsi oil is high in quality, extraction rate is increased remarkably, and efficient extraction of ocean low-value decapterus maruadsi oil is realized, so that cost can be saved, product yield can be increased, and economic benefit of production enterprises can be improved.

Owner:SOUTH CHINA AGRI UNIV

Method for quickly slicing fish tissues

InactiveCN102062709AResolve blurShorten the timePreparing sample for investigationStainingDistilled water

The invention belongs to the field of microscopic tissue slice, particularly relates to a method for quickly slicing and dyeing fish tissues. The method comprises the following steps: 1) solidifying the fish tissues for 4-6 hours by using stationary liquid, cutting the solidified fish tissues into slice tissue blocks being 2mm long, 2mm wide and 1-2mm high, soaking the slice tissue blocks for 10-20 seconds in egg white which is diluted by using distilled water at the volume ratio of 1:1, freezing the slices, and pasting slices, and 2) placing for 3-5 minutes at room temperature after being pasted, dyeing, airing, and sealing by using neutral gum and cover glass for observing with microscope. Through the method, the time is shortened and the problems of freezing slice tissues, cell dissolution and blurry image under microscope are solved.

Owner:SUZHOU UNIV

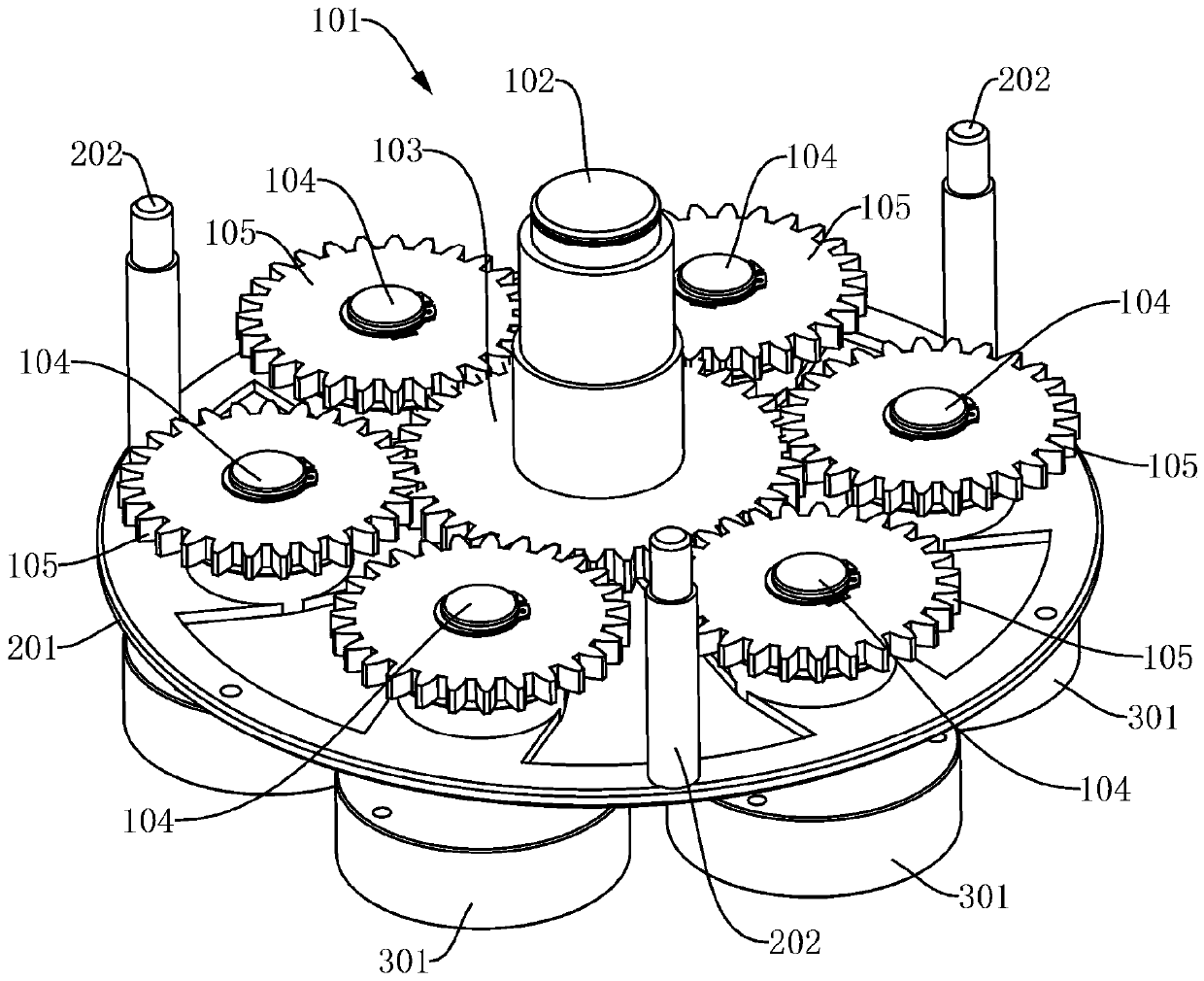

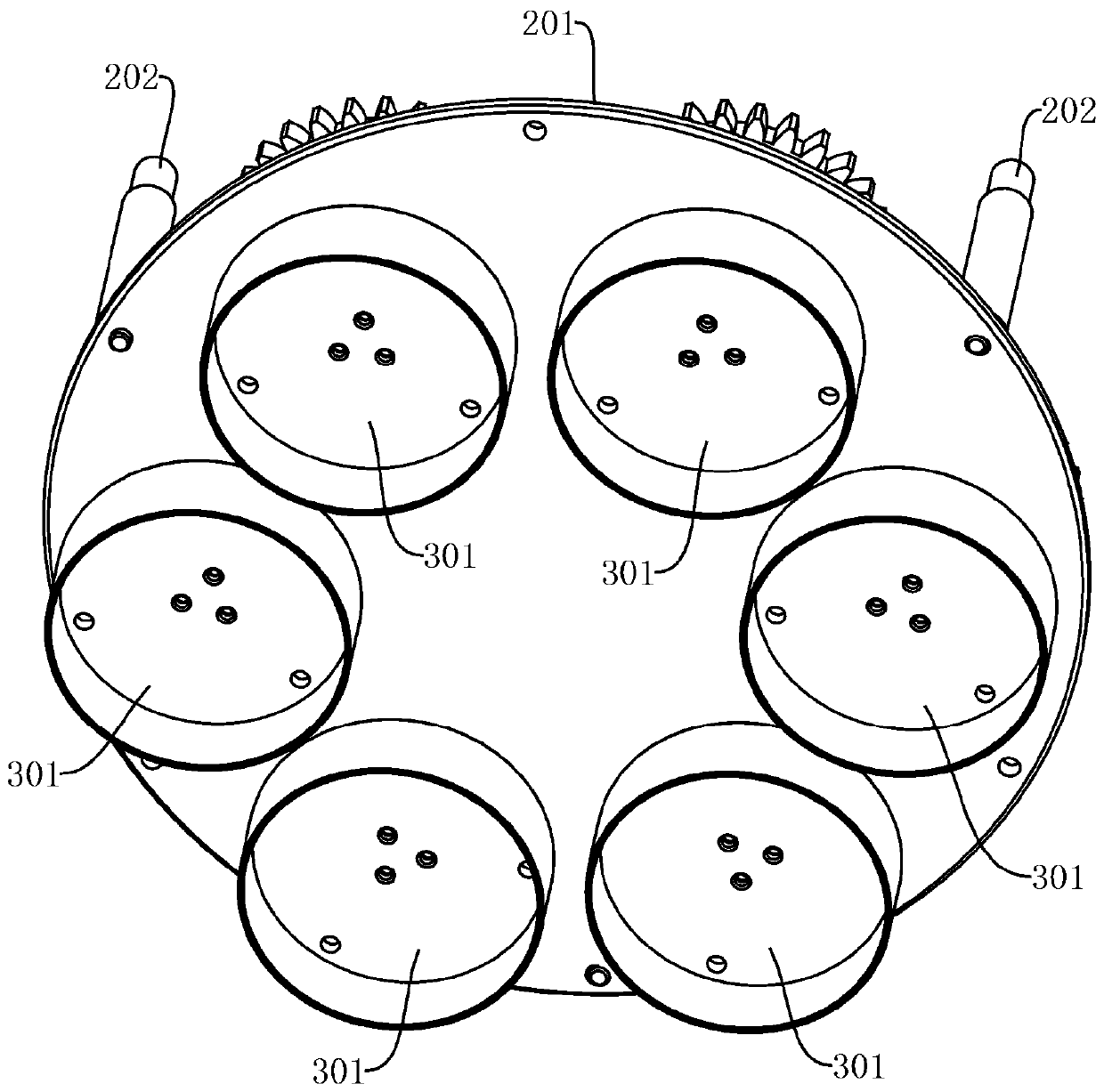

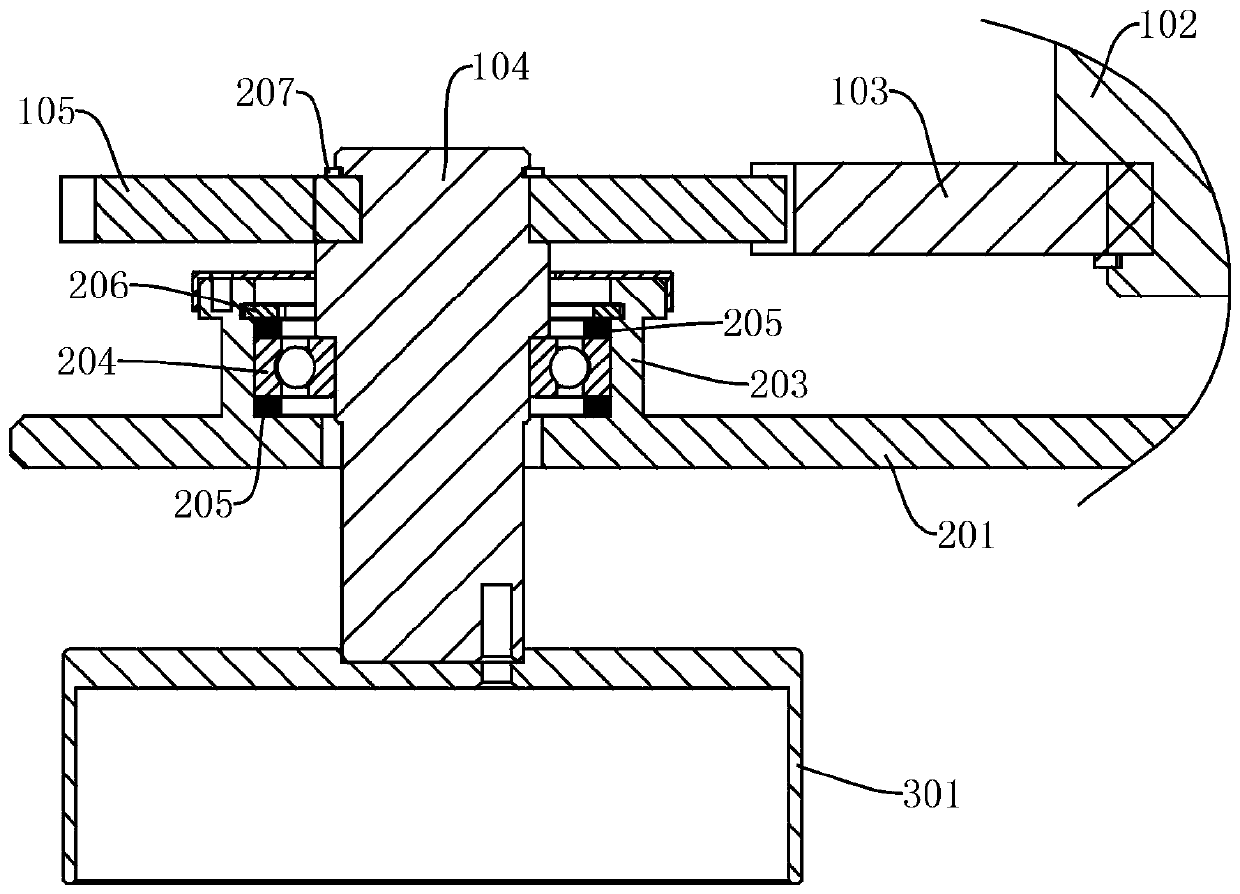

Planet rotating device and coating equipment capable of achieving large-batch production

ActiveCN110846634AEnhanced Thickness Uniformity FeatureRealize mass productionVacuum evaporation coatingSputtering coatingHigh volume manufacturingEngineering

The invention relates to a planet rotating device and coating equipment capable of achieving large-batch production. The planet rotating device comprises multiple workpiece hanging scaffolds and a first transmission mechanism. The workpiece hanging scaffolds is connected with the first transmission mechanism. The first transmission mechanism is used for driving the workpiece hanging scaffolds to achieve synchronous autorotation. According to the planet rotating device, the structure is compact, the workpiece hanging scaffolds achieve synchronous autorotation and revolution, and therefore uniformity of film layers on the surface of a spherical optic element is effectively optimized, and films on the surface of the coated spherical optic element are distributed in central symmetry; and the multiple workpiece hanging scaffolds can coat multiple spherical optic element mirror billets at the same time, and coating efficiency can be effectively improved. The planet rotating device and the coating equipment are especially suitable for the coating field for large batches of small-caliber spherical elements and distribution of high film thickness uniformity.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Capsule containing granular pharmaceutical compositions

A capsule for oral administration to a human subject. The capsule comprises at least two different pharmaceutical compositions in granular form. This Abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:SOVEREIGN PHARMA

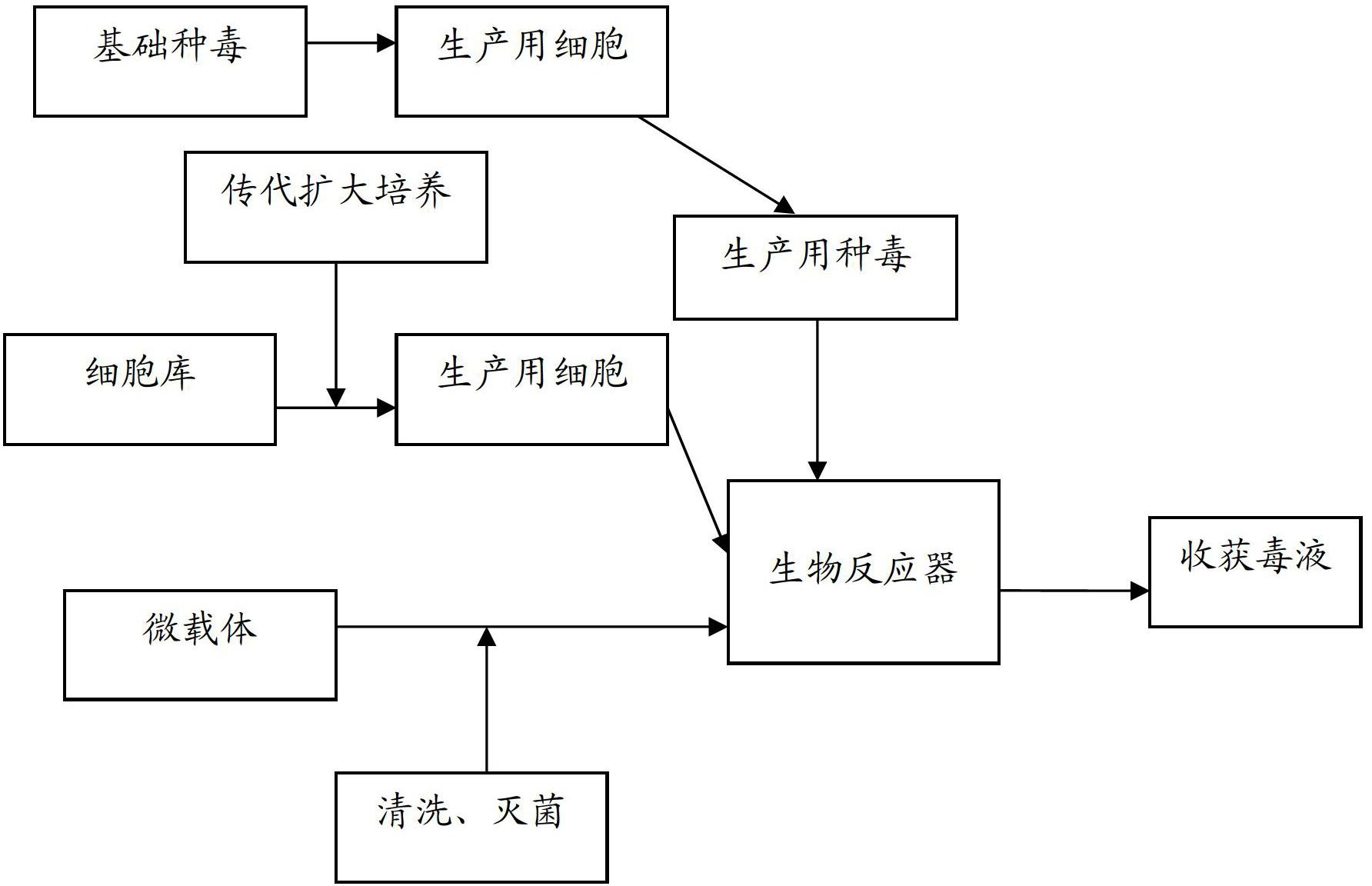

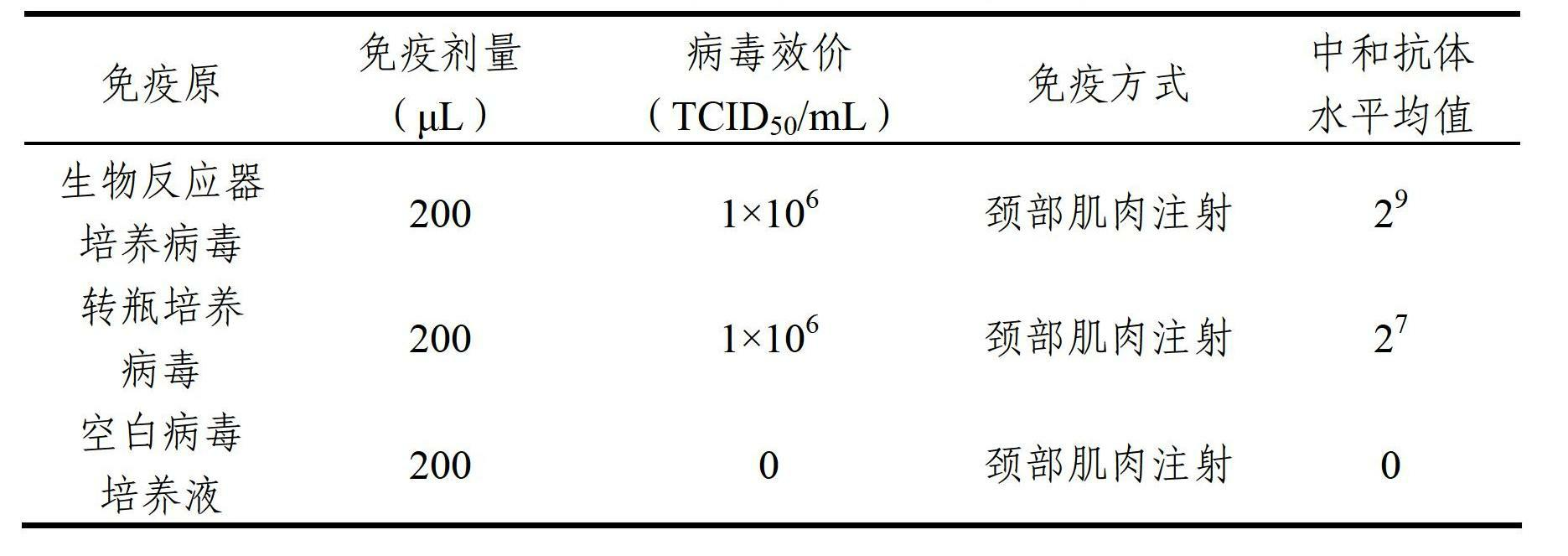

Production method of porcine transmissible gastroenteritis virus by utilizing bioreactor

ActiveCN102660510AQuality improvementIncrease productionMicroorganism based processesViruses/bacteriophagesVultureTiter

The invention provides a production method of porcine transmissible gastroenteritis virus by utilizing a bioreactor. The method comprises the following steps: 1) preparing monolayer subculture cells; 2) preparing virus seed for porcine transmissible gastroenteritis virus production; 3) preparing a cell suspension from the monolayer subculture cells prepared in the step 1), and inoculating into a bioreactor to carry out adsorption culture on the subculture cells in a microcarrier in the bioreactor; 4) inoculating the virus seed prepared in the step 2) at the inoculation amount of 2 to 5 percent when the subculture cells grow to 80-90 percent of the microcarrier, the empty bead rate is lower than 5 percent, the full bead rate is more than 80 percent and the cell count is over 3-5*10<6> per mL, and performing virus adsorption culture; and 5) harvesting virus fluid when over 80 percent of the subculture cells on the microcarrier have pathological changes. The method can be used for solving the problems of low production efficiency, unstable product quality and low virus titer, so that the unit vulture titer of the virus can be improved by 5 to 10 times, the quality and yield of vaccine can be comprehensively improved, and the safety of vaccine is improved.

Owner:兆丰华生物科技(南京)有限公司 +1

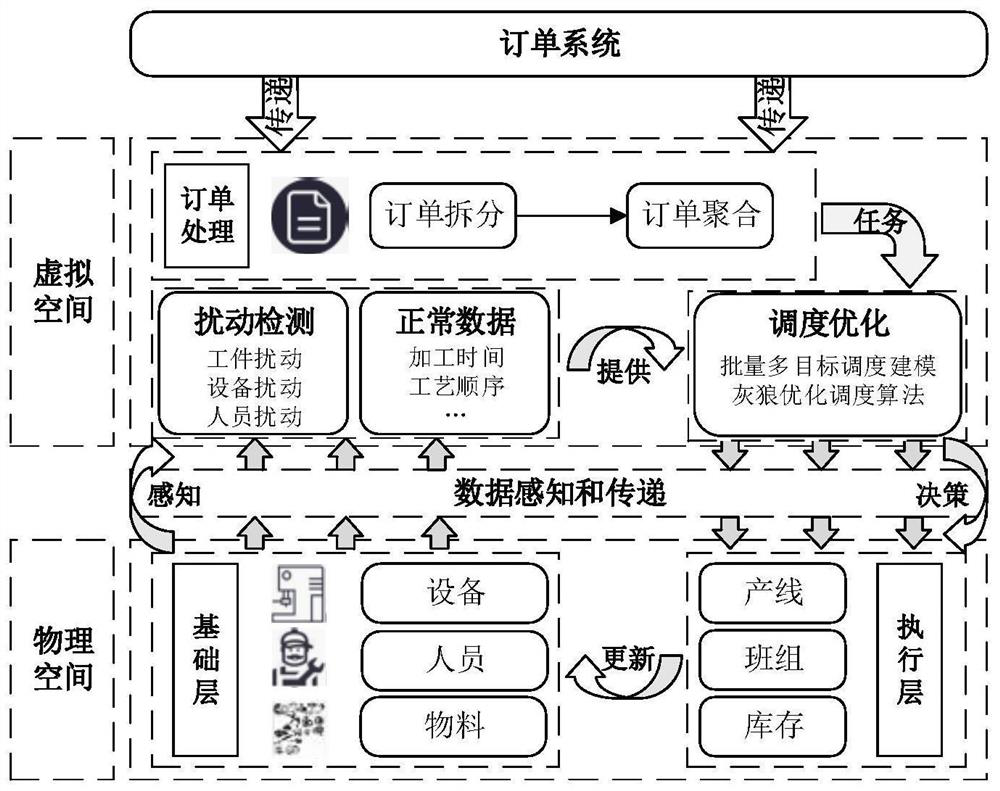

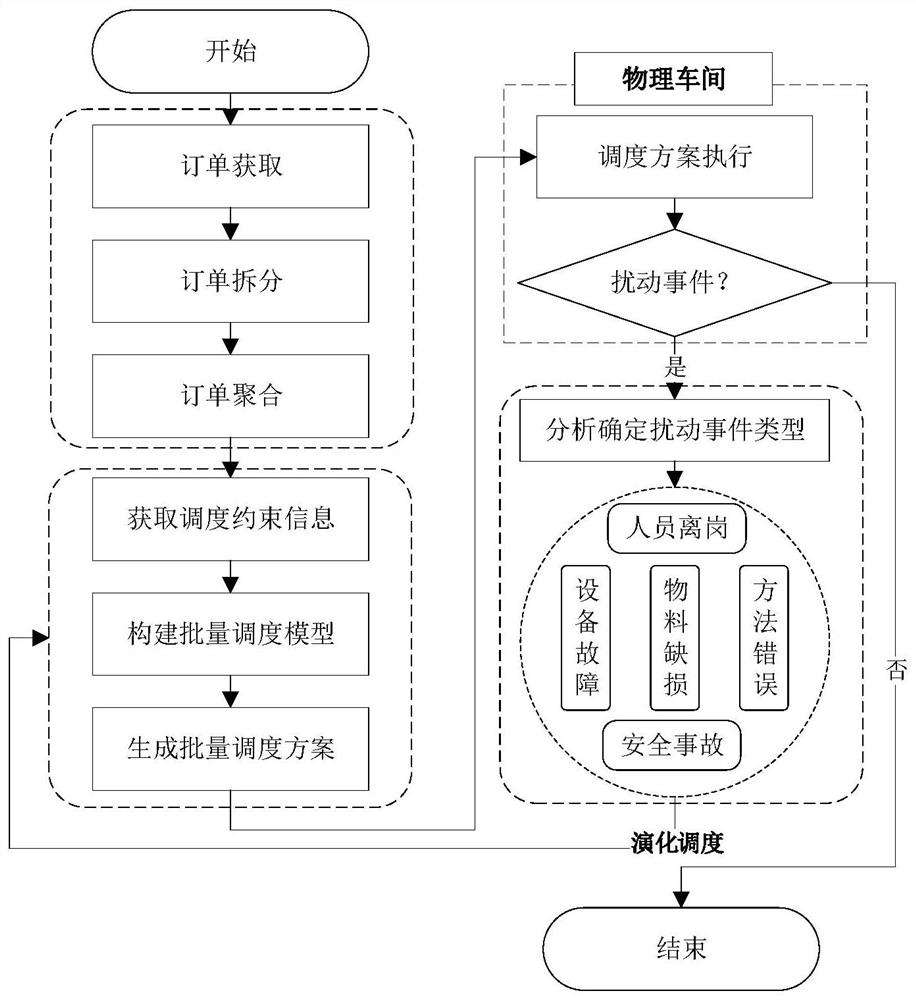

Multi-variety and small-batch multi-resource scheduling system and method based on digital twinning

PendingCN113850488AIncrease flexibilityImprove robustnessCharacter and pattern recognitionDesign optimisation/simulationInformation transmissionMulti resource

The invention discloses a multi-variety and small-batch multi-resource scheduling system and method based on digital twinning. The order optimization module splits an order and performs similar batch combination according to process similarity, and transmits the order as a basic task of production to the scheduling optimization module; a workshop data perception and disturbance event detection module is used for realizing real-time acquisition of 'man-machine-object-method-ring' state information of a workshop based on a perception data fusion workshop disturbance detection method, transmitting the acquired information to the disturbance event processing module for disturbance factor judgment, and transmitting the disturbance event to a scheduling optimization module to realize dynamic evolution of production; and a scheduling optimization module is used for receiving and processing information data transmitted by other modules and calculating to obtain a target scheduling scheme. According to the method, the problems of multiple product varieties and small batch in the order are solved, meanwhile, the problem of workshop multi-target multi-resource scheduling distribution is solved, and the flexibility and robustness of the workshop for sudden accidents and the effectiveness of a scheduling plan are improved.

Owner:WUHAN UNIV OF TECH

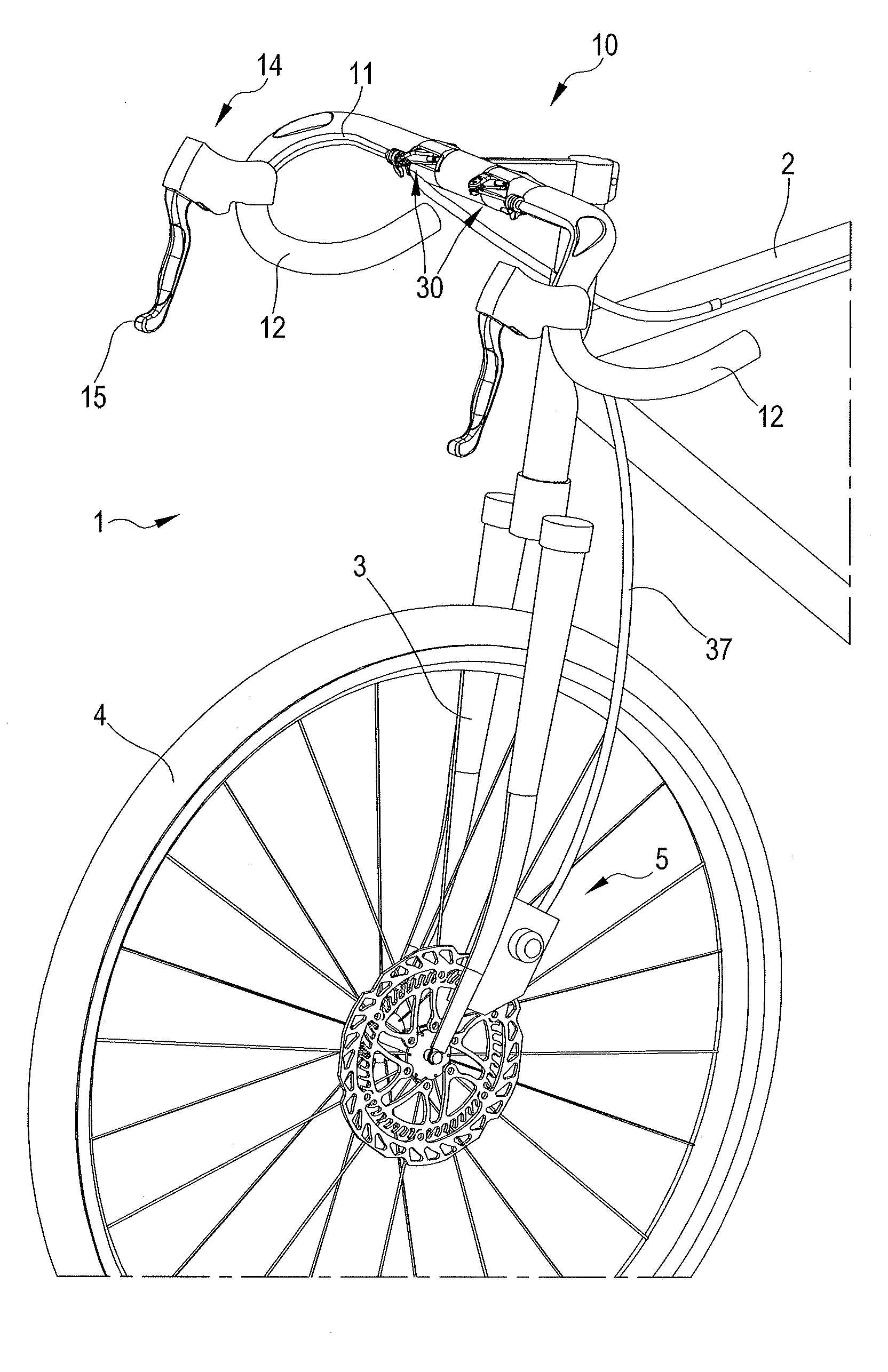

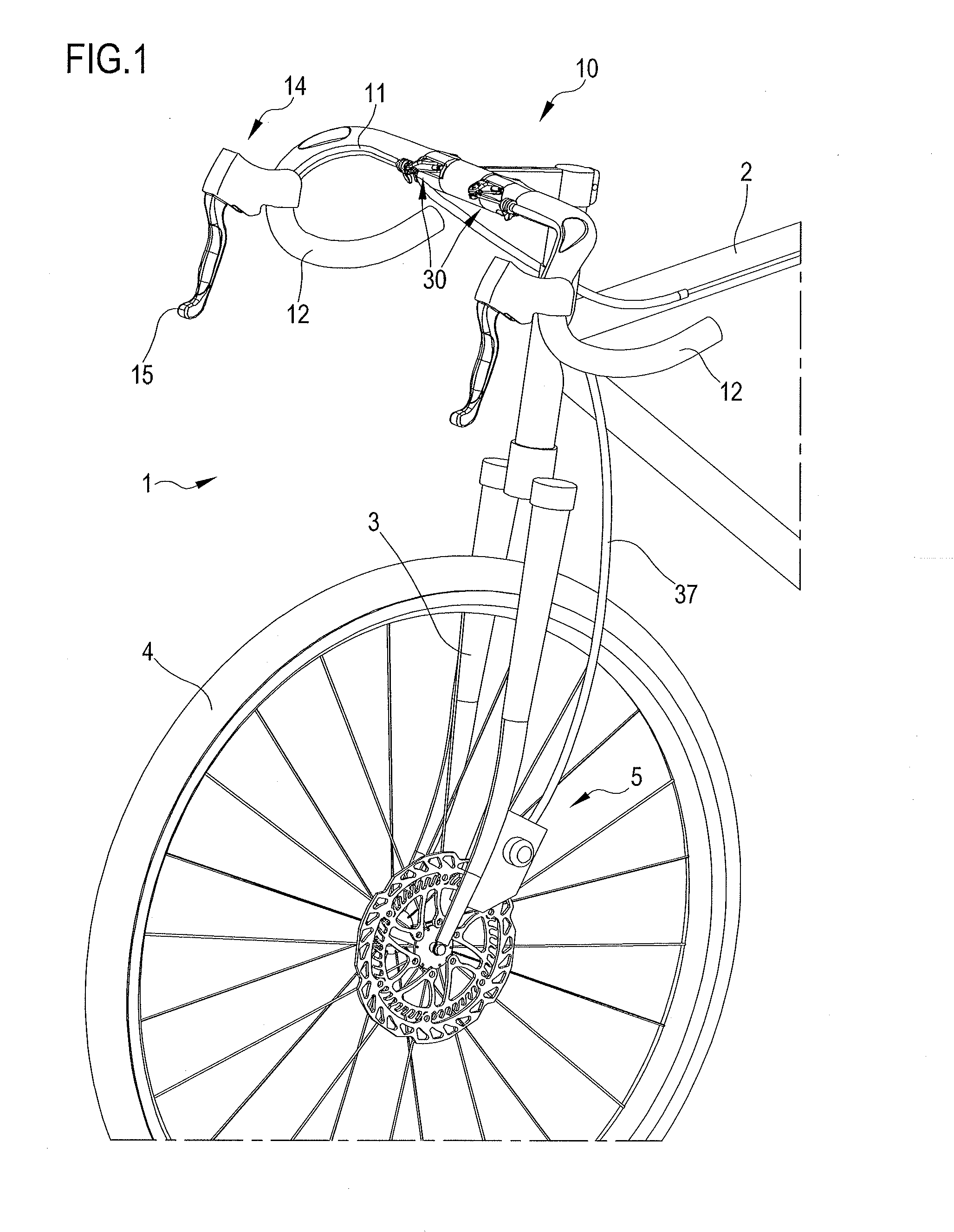

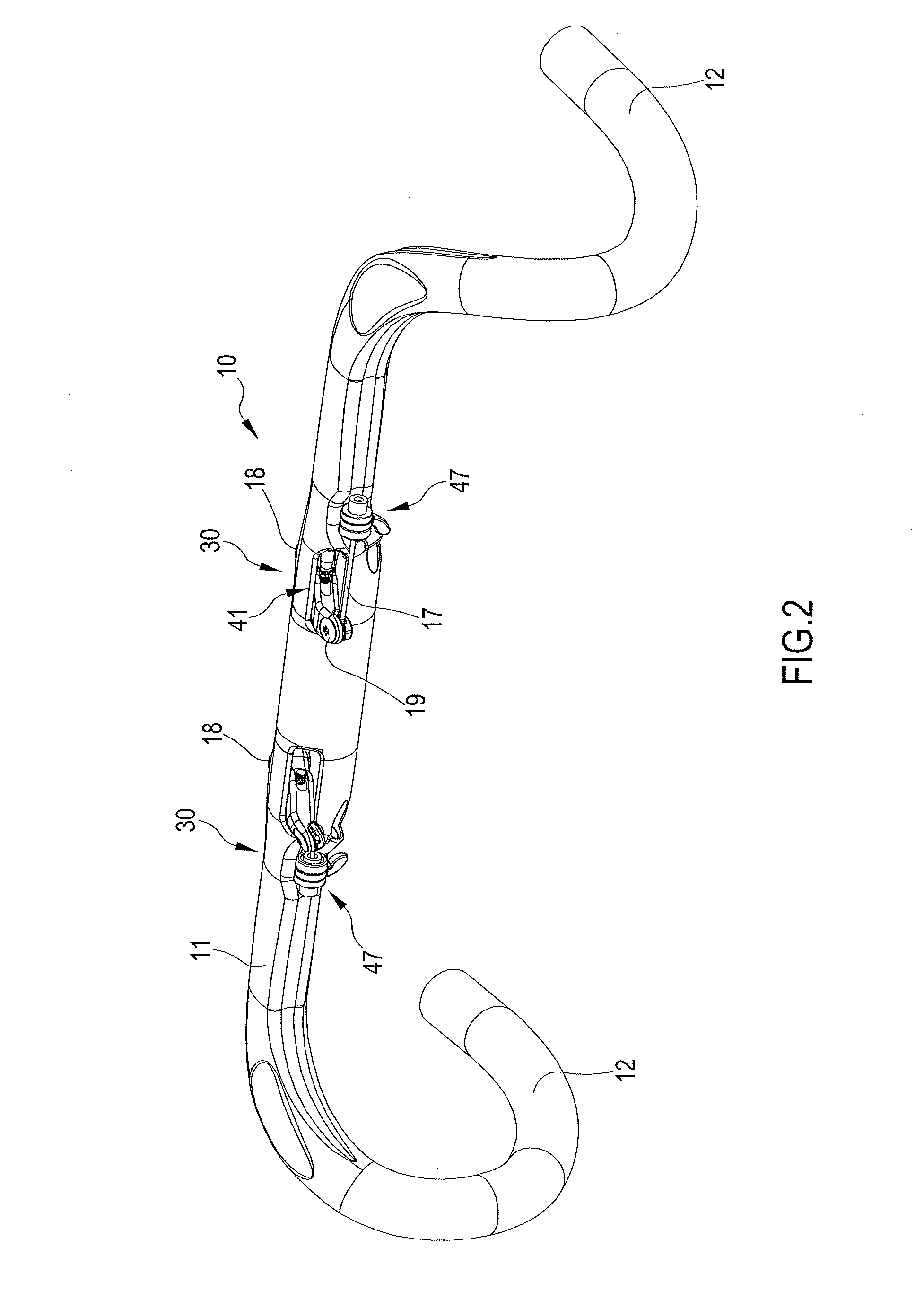

Bicycle handlebar assembly with integrated oleo-hydraulic controls

ActiveUS20140360303A1Large displacementEasy to moveMechanical apparatusCycle control systemsOn boardHydraulic pump

The bicycle handlebar assembly comprises a handlebar rod and at least one oleo-hydraulic group for controlling on-board bicycle equipment; the oleo-hydraulic group is housed inside the handlebar rod.The internal housing in the handlebar rod overcomes any problems of bulk of the oleo-hydraulic group. Moreover, thanks to the relatively large size of the handlebar rod, the dimensional constraints imposed on the designer are much less stringent with respect to controls associated directly to the brake lever; it is thus relatively easy to make controls capable of exerting very large forces.

Owner:CAMPAGNOLO SRL

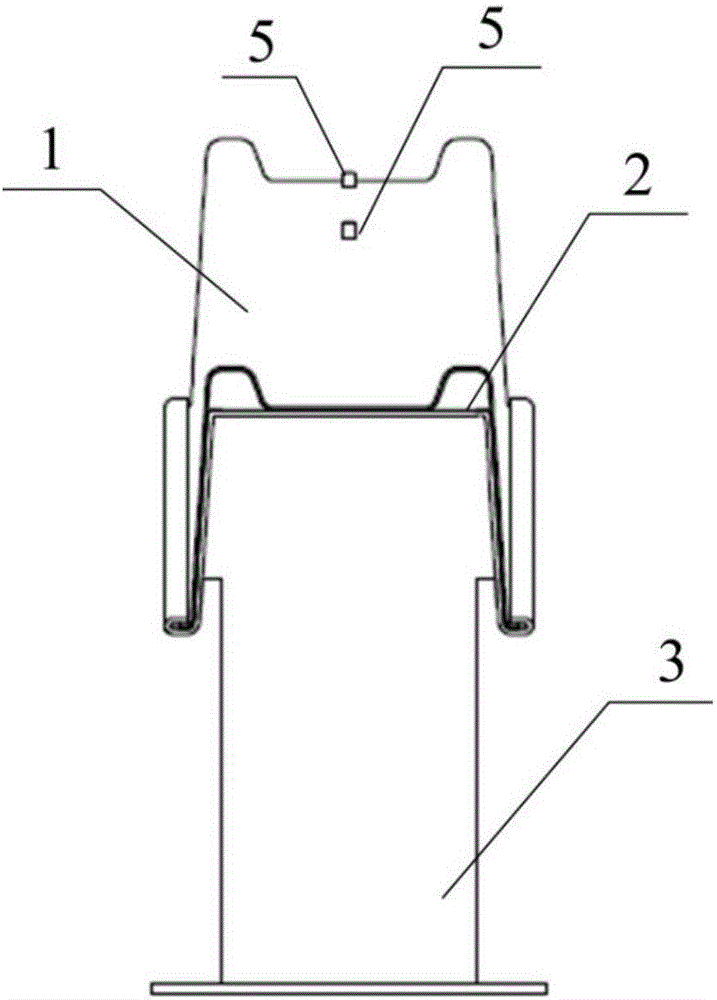

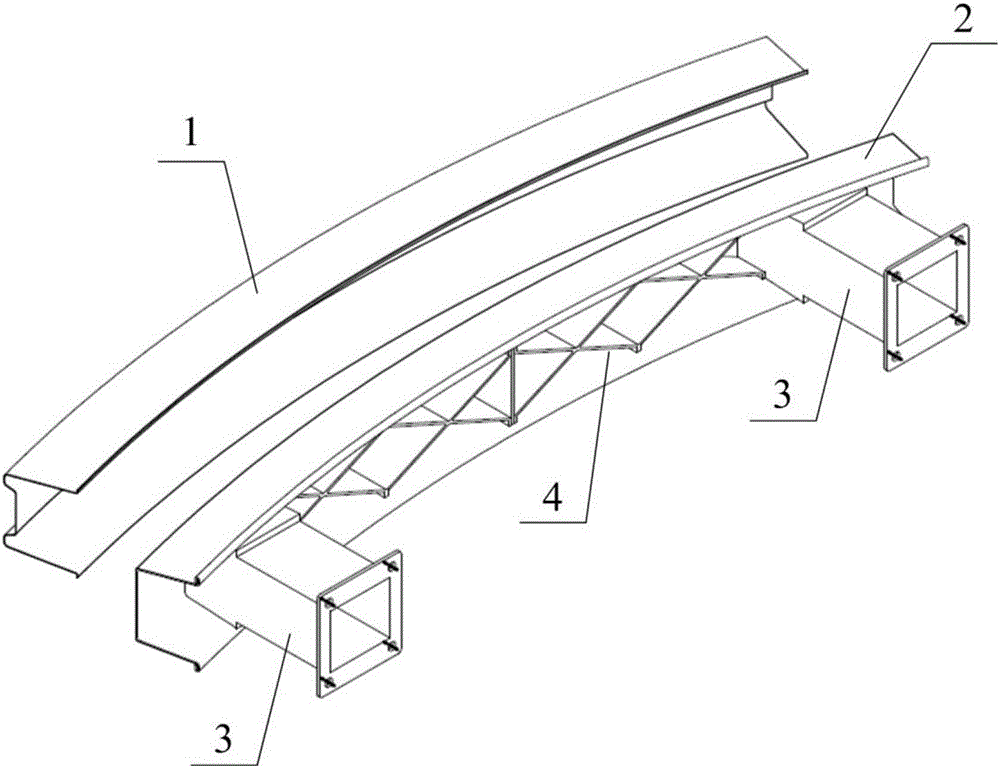

Adjustable-rigidity double-air-rudder equivalent load simulation device

ActiveCN105628349AEasy to assemble and disassembleMeet the densityMachine part testingVacuum pumpingSpatial structure

The invention belongs to the field of a servo mechanism, relates to an adjustable-rigidity double-air-rudder equivalent load simulation device, and specifically relates to an adjustable-rigidity double-air-rudder equivalent load simulation device for acceptance inspection of electro-hydraulic servo mechanism. The device comprises a right-end inertia assembly, a left-end inertia assembly, a base and an elastic support ear assembly; and the right-end inertia assembly and the left-end inertia assembly are symmetrically fixed on the base, and the elastic support ear assembly is fixed to a side face of the base. The device has the advantages of two-position integration and the small space structure, a load characteristic is guaranteed to be stable and reliable in a long term, and assembly and disassembly of a to-be-detected product, filling of a servo mechanism, vacuum pumping and other operation are convenient to perform; the rotational inertia, the inertia moment and the load rigidity parameter are adjustable; and, when the device does not work, a swinging scope of a rocker arm can be limited through a limited rod, and then the object of protection of n angle displacement sensor is achieved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

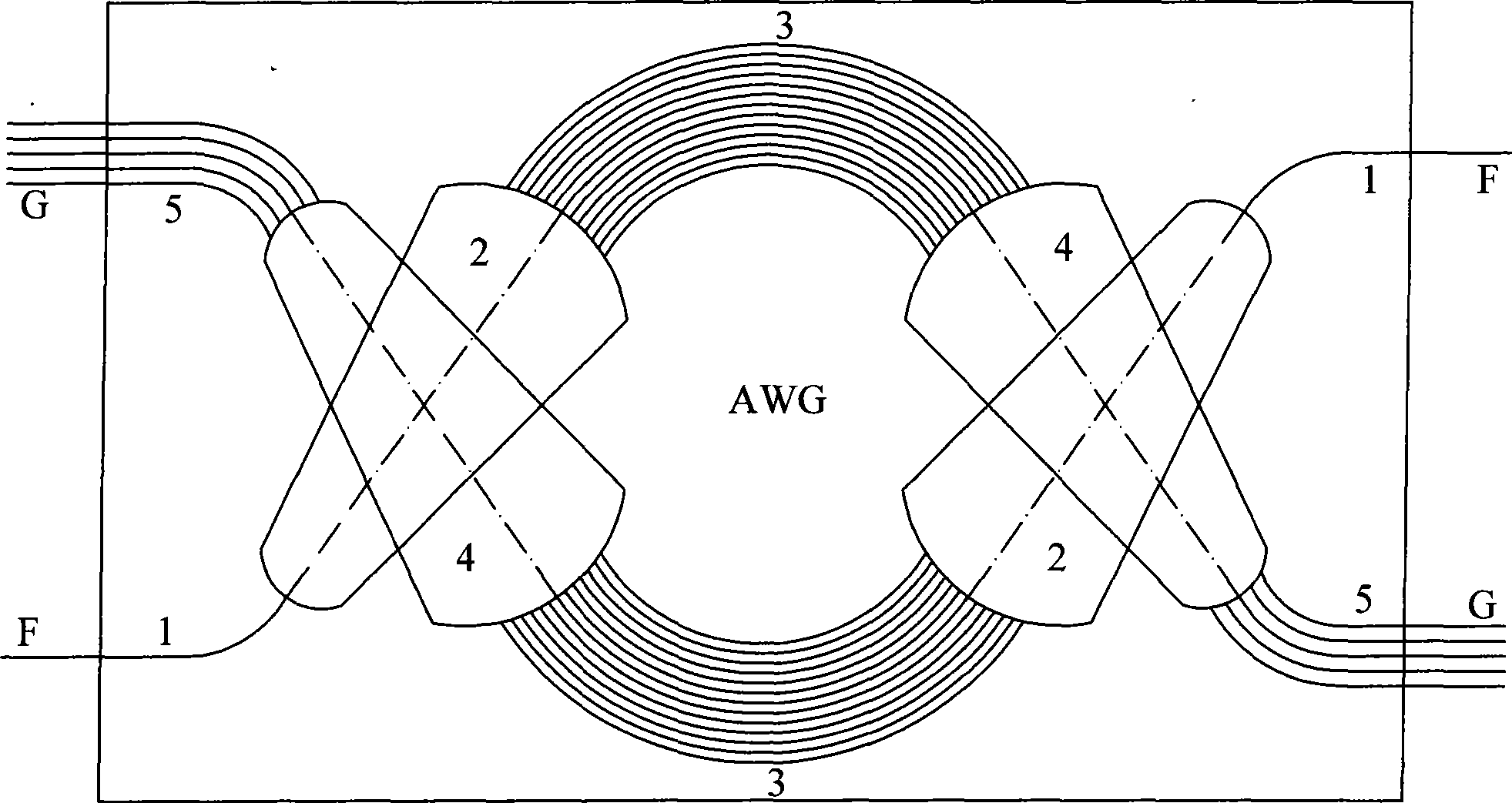

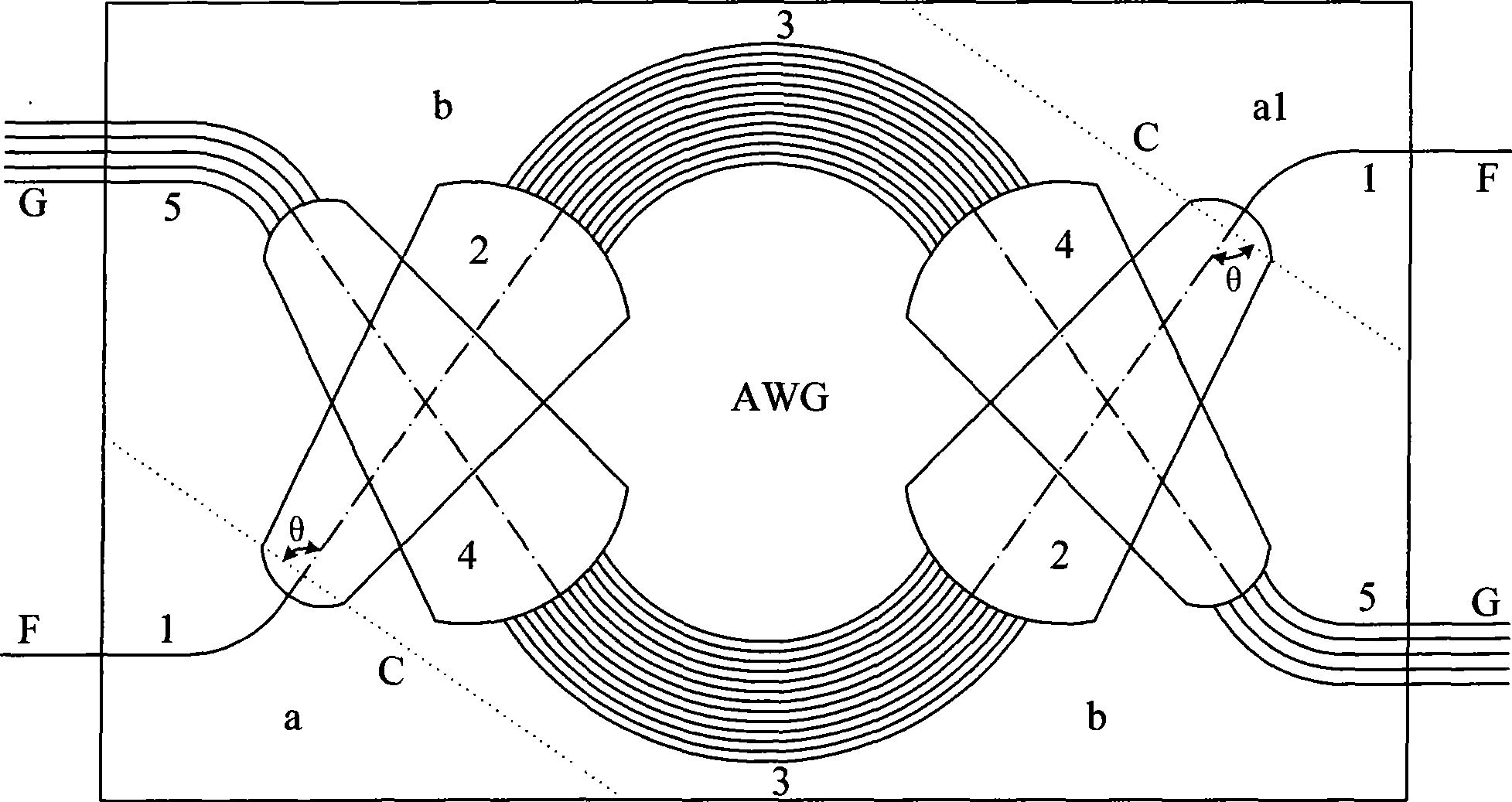

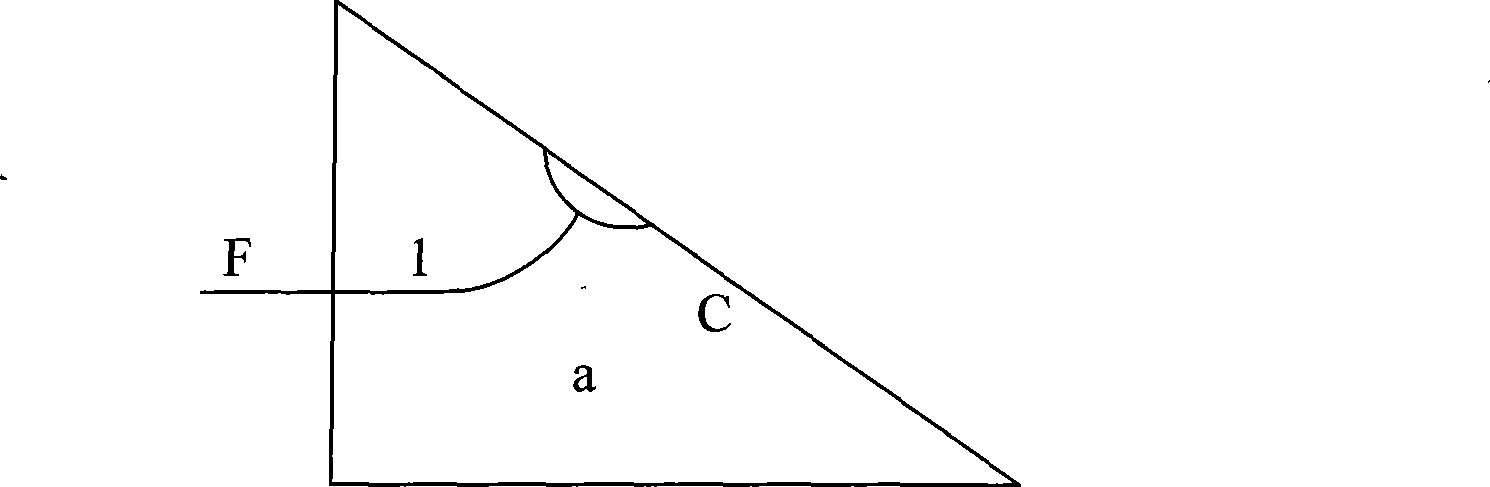

Temperature compensation rod and method for manufacturing multiplexing and de-multiplexing non-heat array wave guide grating

ActiveCN101414030AWith multiplexing functionWith demultiplexing functionWavelength-division multiplex systemsCoupling light guidesMultiplexingGrating

The invention discloses a temperature compensation rod and a method for making an athermal array waveguide grating (AWG) for multiplexing and demultiplexing. The temperature compensation rod consists of a rod body and two I-shaped structures respectively formed on two ends of the rod body, clearance is formed between the upper end structure of the I-shaped structure at one side of the rod body and the rod body while the lower end structure of the I-shaped structure is integrated with the rod body into a whole; the upper end structure of the I-shaped structure at the other side of the rod body is integrated with the rod body into a whole while clearance is formed between the lower end structure of the I-shaped structure and the rod body. The method comprises the following steps: coupling two AWGs on a chip; cutting the chip into three parts along cut lines; fixing a third part and respectively arranging a first part and a second part on a 6D precision fine turning frame so as to realize coupling alignment and restore the parts to the original shapes for online testing; carrying out the online testing after arranging the temperature compensation rod; and curing two temperature compensation rods on positions at which the two rods are arranged on the three parts of the chip if the three parts are tested qualified. The temperature compensation rod has the advantages of lower cost, large batch, good repeatability, smaller size, good stability and extremely simple process.

Owner:GUANGXUN SCI & TECH WUHAN

Slow running water circulation type method for cultivating finless eel fries by the aid of grids

InactiveCN104335930AGood application prospectImprove survival rateClimate change adaptationPisciculture and aquariaWater circulationFinless eel

The invention relates to a slow running water circulation type method for cultivating finless eel fries by the aid of grids, and belongs to the technical field of fishery science application. The slow running water cyclic type method is characterized in that a plurality of cultivation buckets with water circulation systems and a plurality of cylindrical finless eel cultivation grids placed in the cultivation buckets are provided, young finless eels hatched at the same time or in the same size are transported to the cylindrical grids in good time and are cultivated with live feed, and thus, eel fry cannibalism caused by nonuniform individual sizes is effectively prevented. By means of design and installation of slow running water circulation type cultivation equipment, design, manufacture and installation of the finless eel cultivation grids, throwing and cultivating of the young eels and management on the water circulation systems and the grids during cultivation, the survival rate of the finless eel fries can be increased to 90-95% and each fry can reach 8-10g in average after 4-5 months of cultivation of the finless eel fries. The method has the advantages that large high-quality finless eel fries can be provided massively for large-scale finless eel cultivation, and the method has a quite good application prospect.

Owner:YANGTZE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com