Bicycle handlebar assembly with integrated oleo-hydraulic controls

a technology of oleohydraulic control and handlebar, which is applied in the direction of cycle control system, steering device, cycle equipment, etc., can solve the problems of reducing braking performance, oleohydraulic group can be a hindrance to cyclists, appearance is less pleasing, etc., and achieves a large piston displacement, large bulk, and greater bulk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

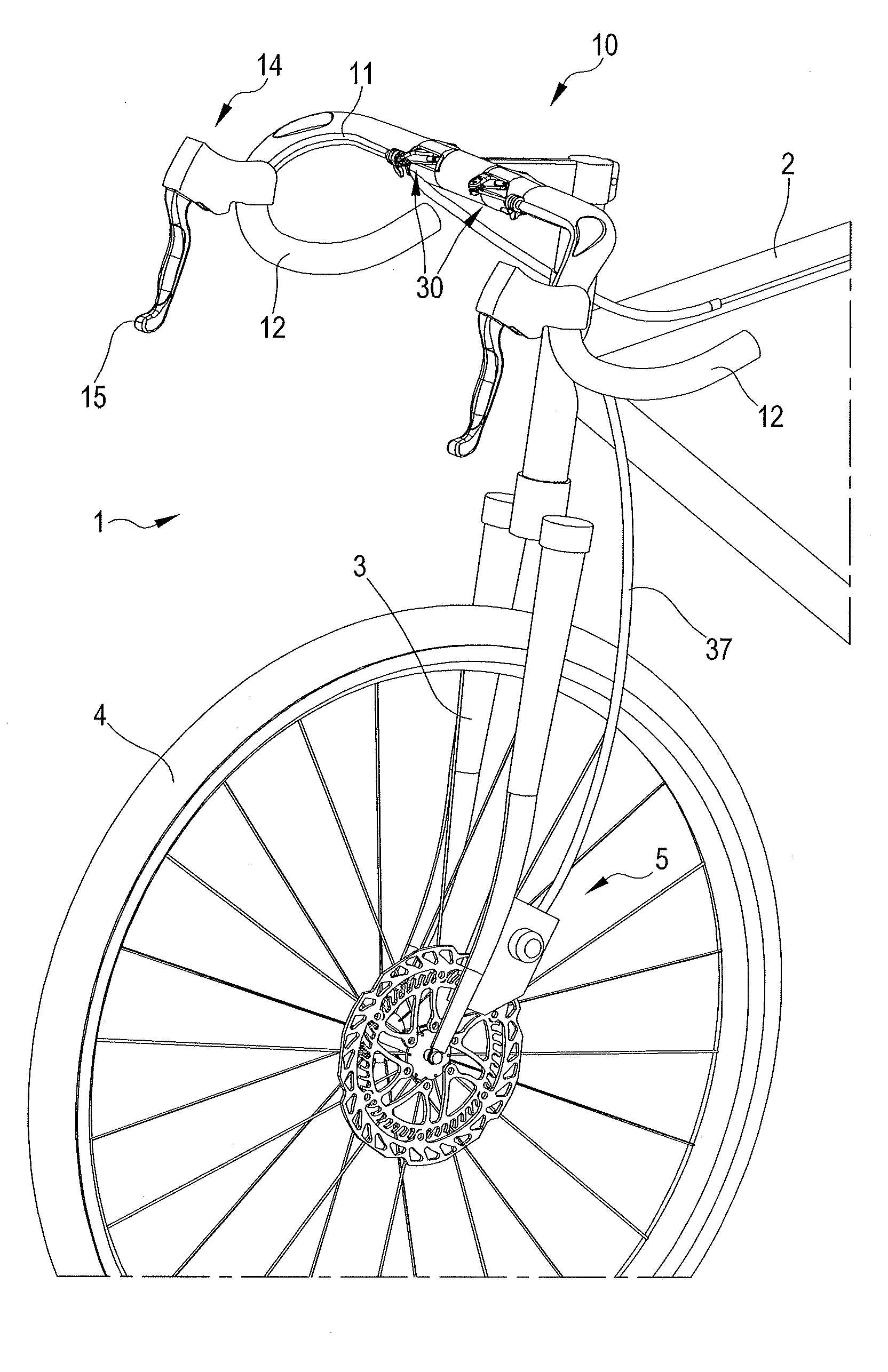

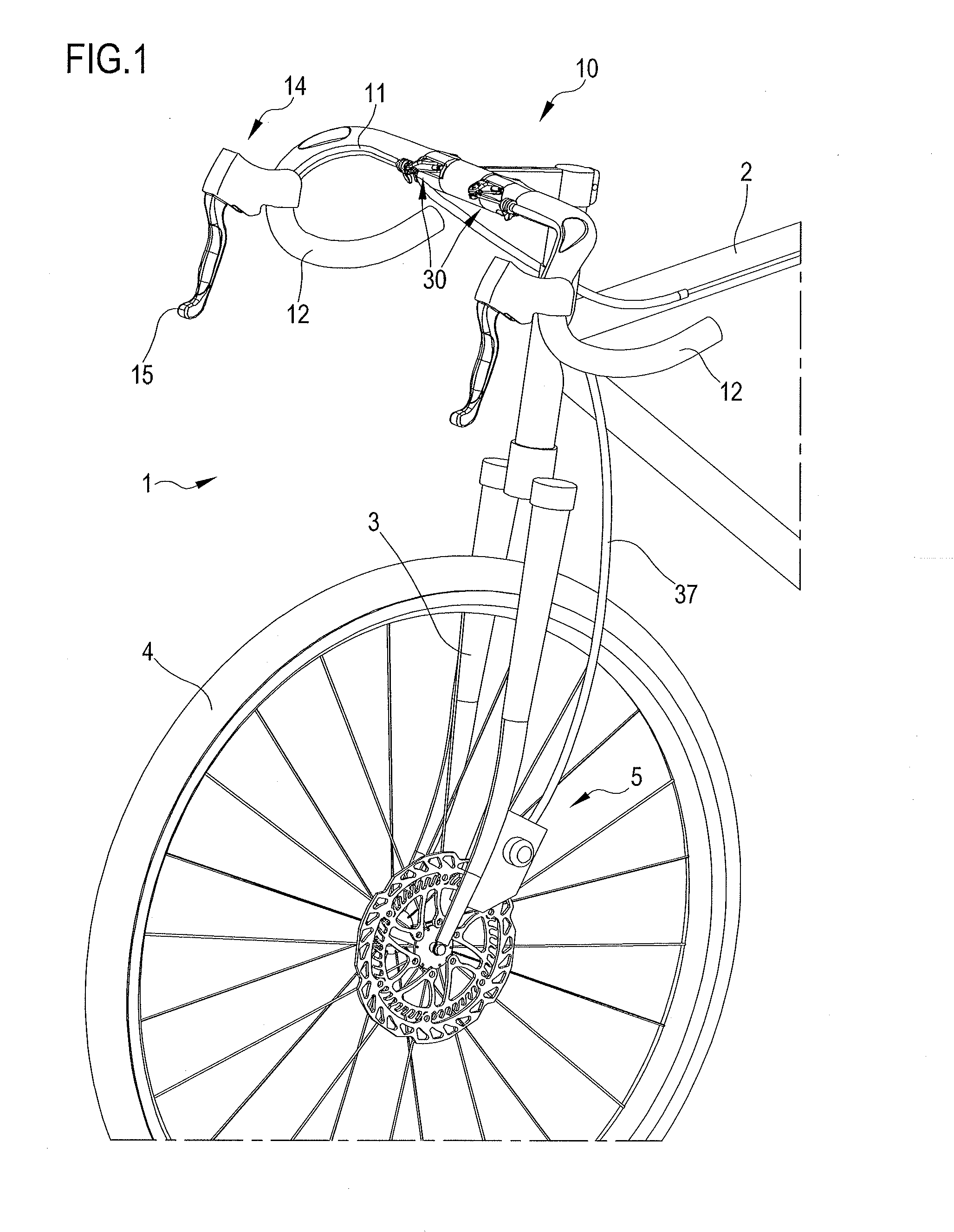

[0035]In the figures, reference numeral 1 wholly indicates a high-performance bicycle, of which in FIG. 1 it is possible to see at least partially a frame 2, a fork 3 and a front wheel 4. The bicycle 1 is provided with disc brakes 5, the front brake of which can be seen in the figures.

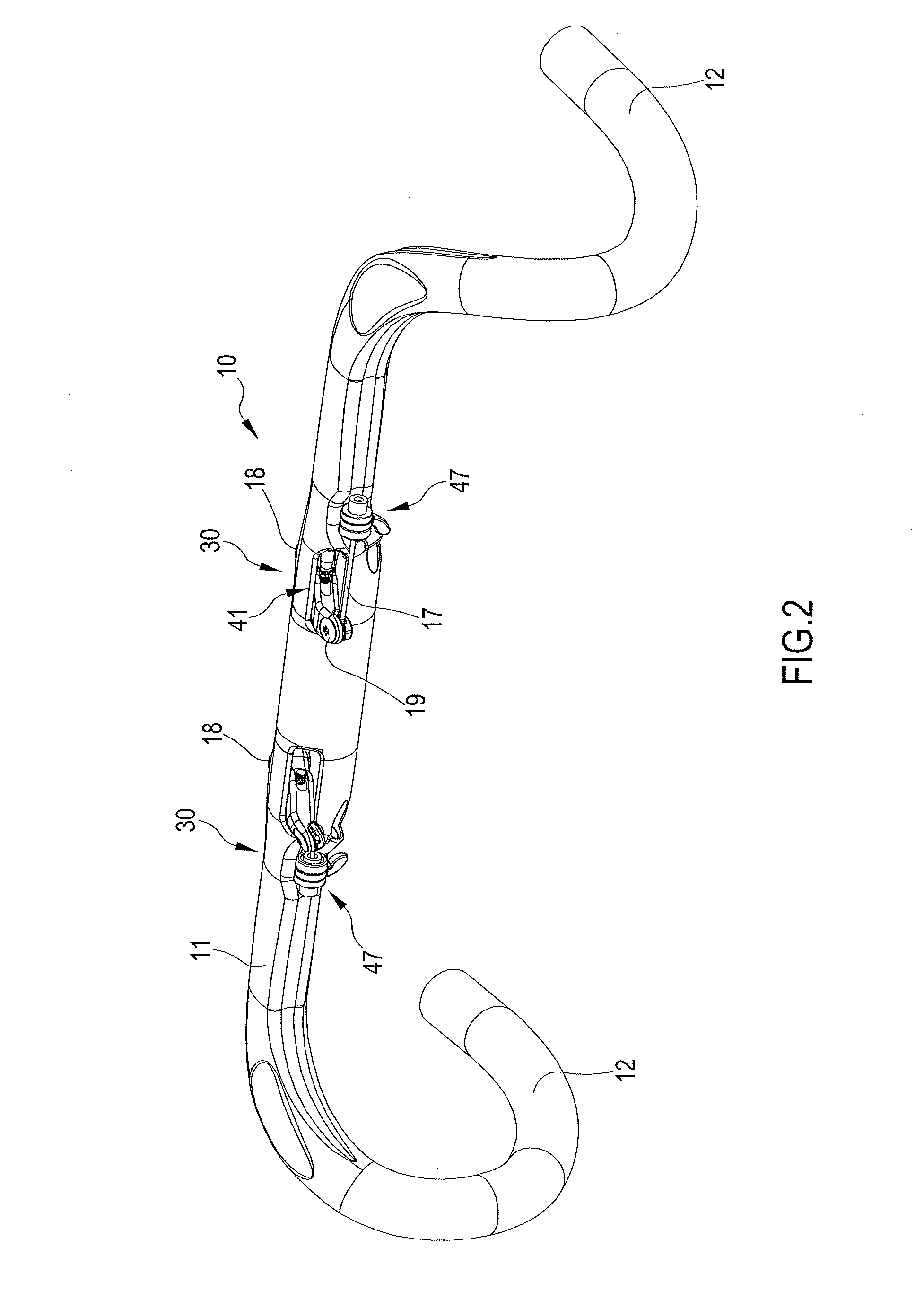

[0036]The fork 3 has a handlebar assembly 10 mounted on it, in accordance with the invention. The handlebar assembly 10 comprises a handlebar rod 11 provided at its two ends with respective handgrips 12, for example of the curved type as shown in the figures.

[0037]The handlebar rod 11 is preferably made hollow from composite material, obtained by moulding from a matrix of polymeric material in which structural fibres (for example carbon fibres or similar) are included.

[0038]In the handlebar rod 11, in a central area thereof, two oleo-hydraulic groups are housed, both indicated with 30, each for controlling one of the two brakes of the bicycle 1. The oleo-hydraulic groups 30 are housed inside the handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com