Patents

Literature

142results about "Force measurement by permanent gauge deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

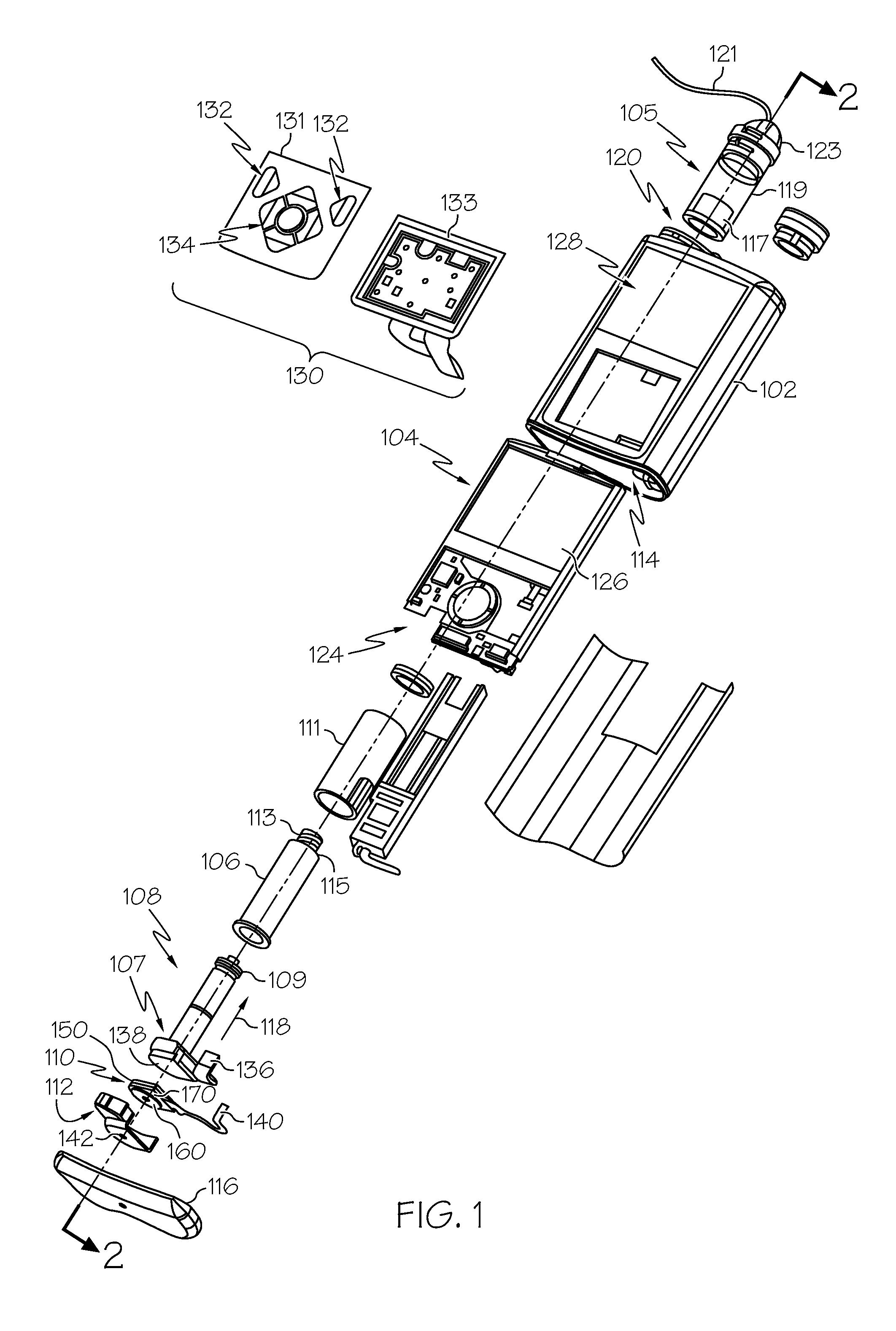

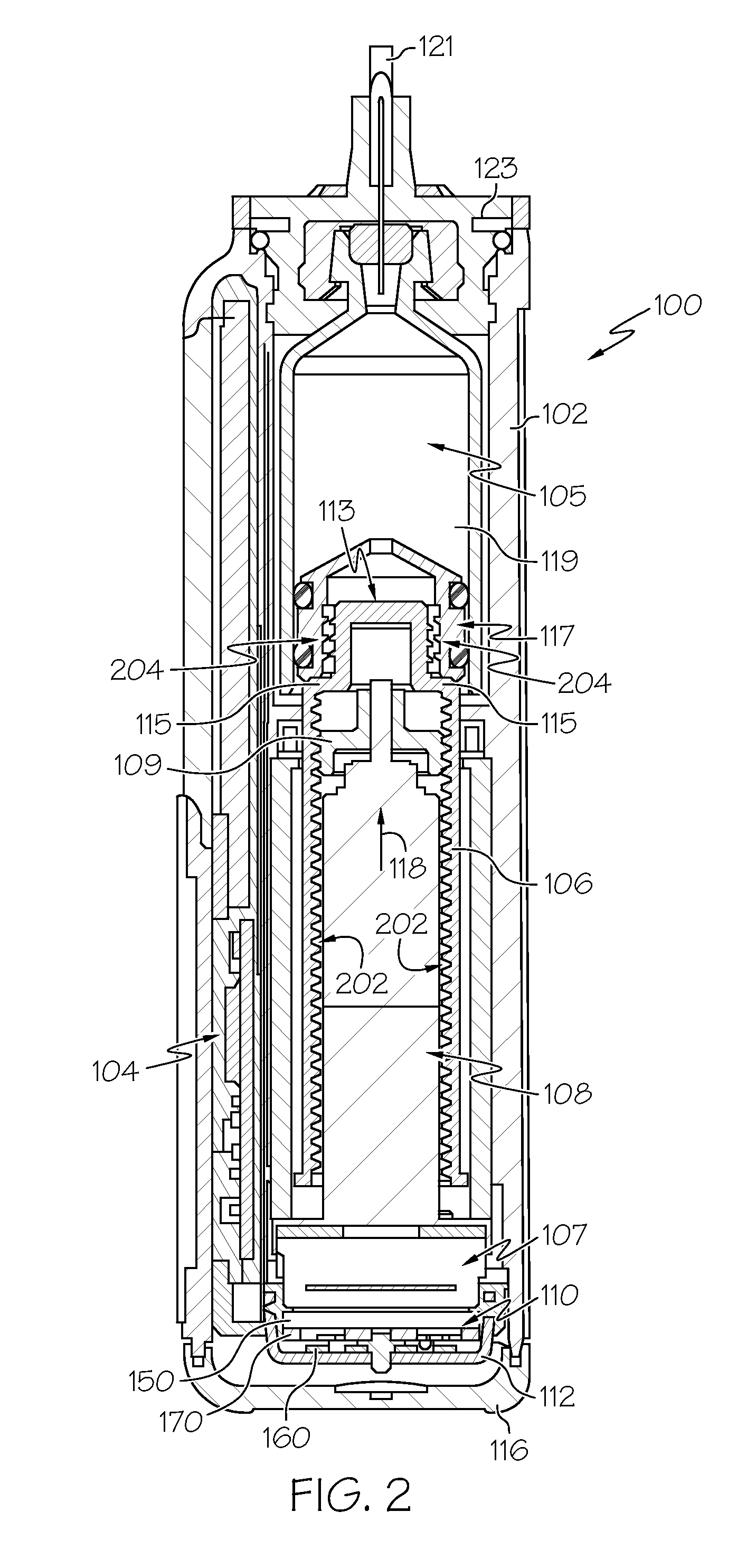

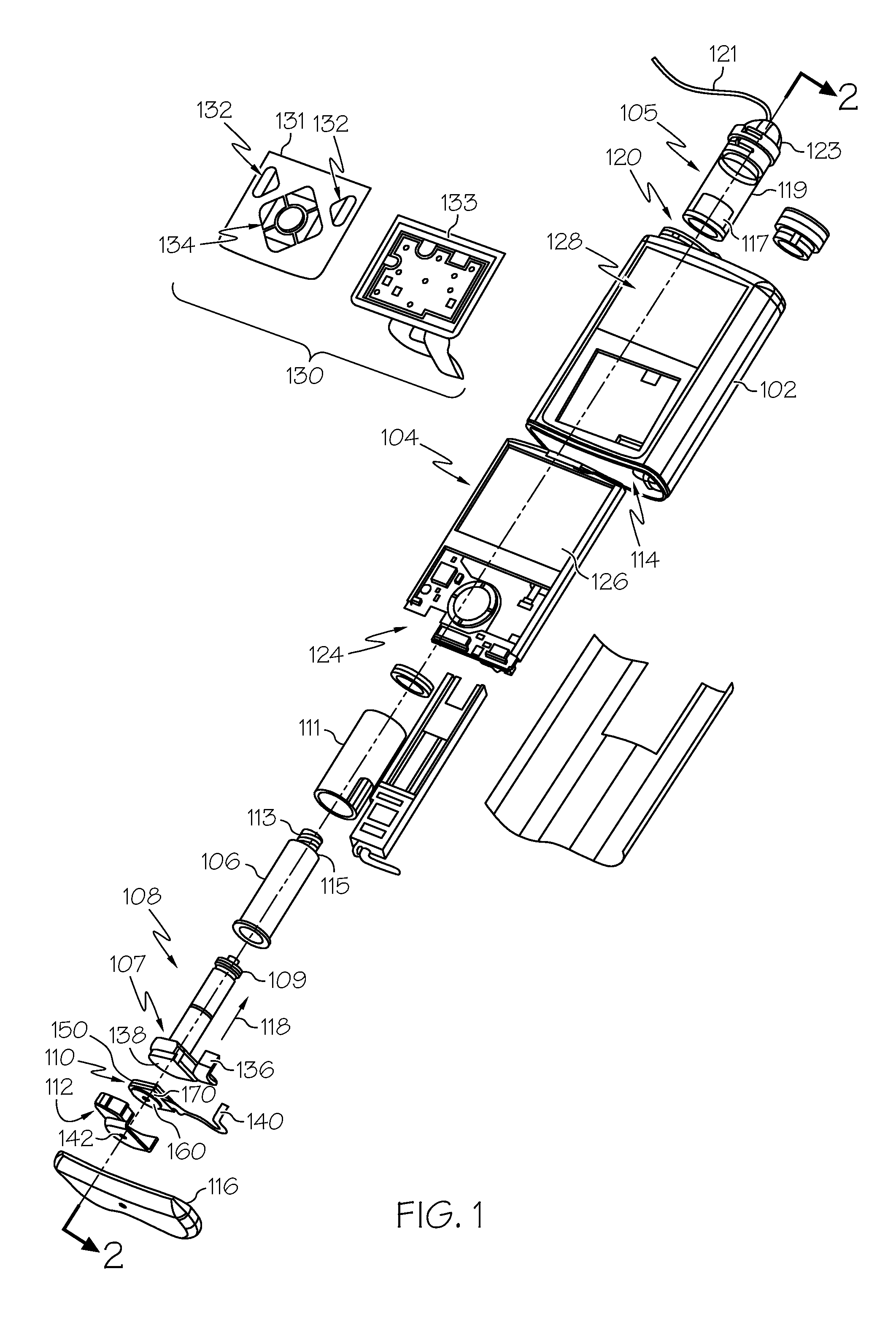

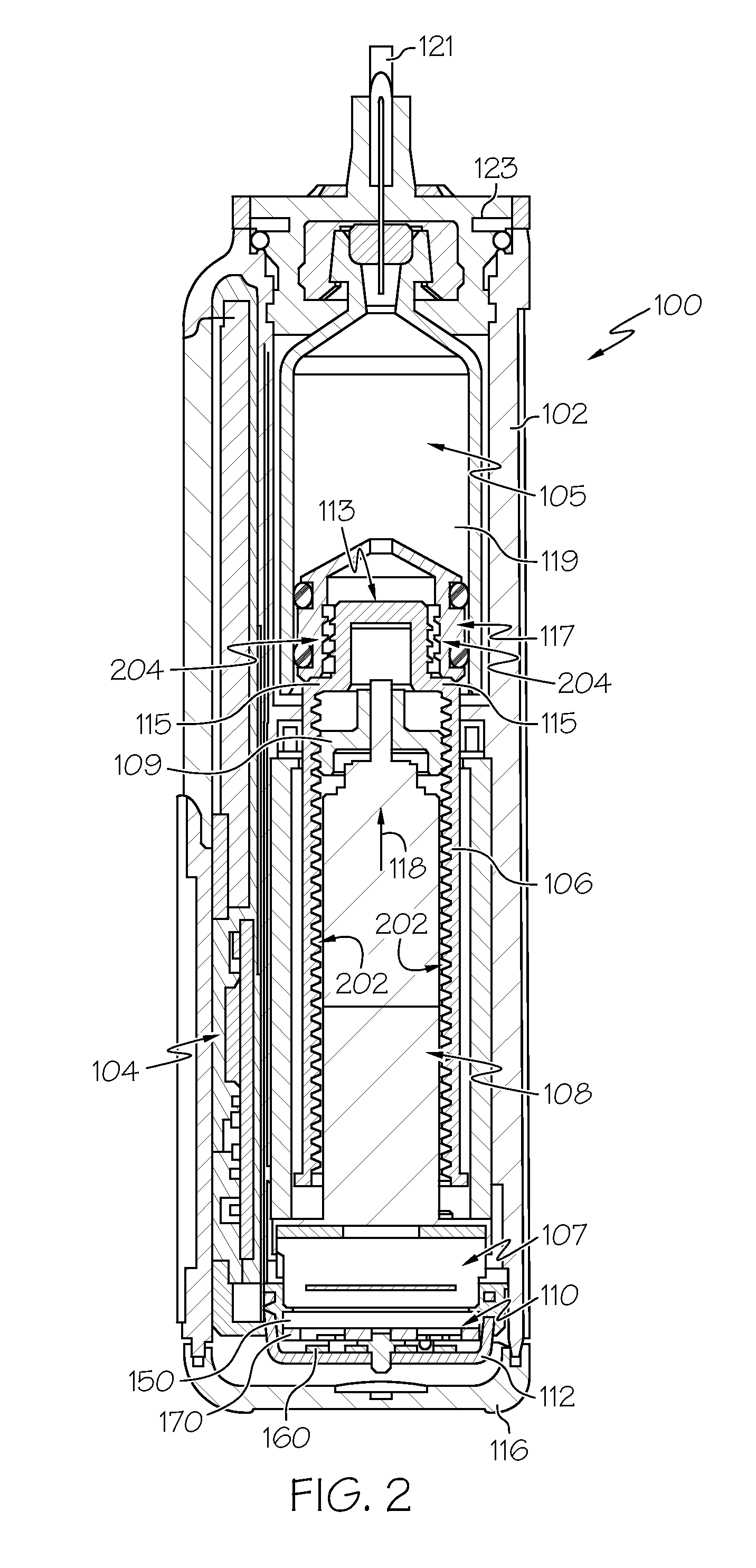

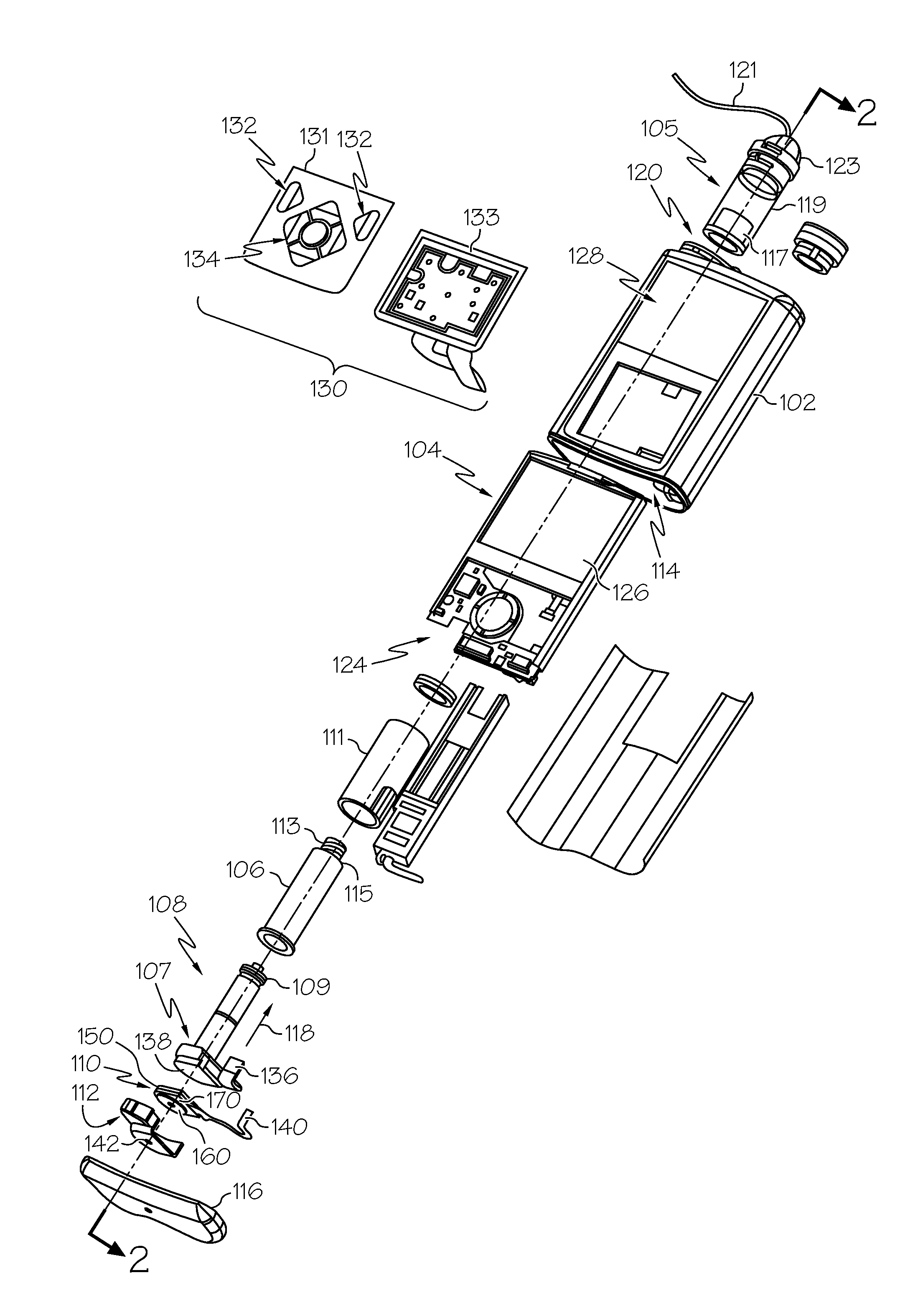

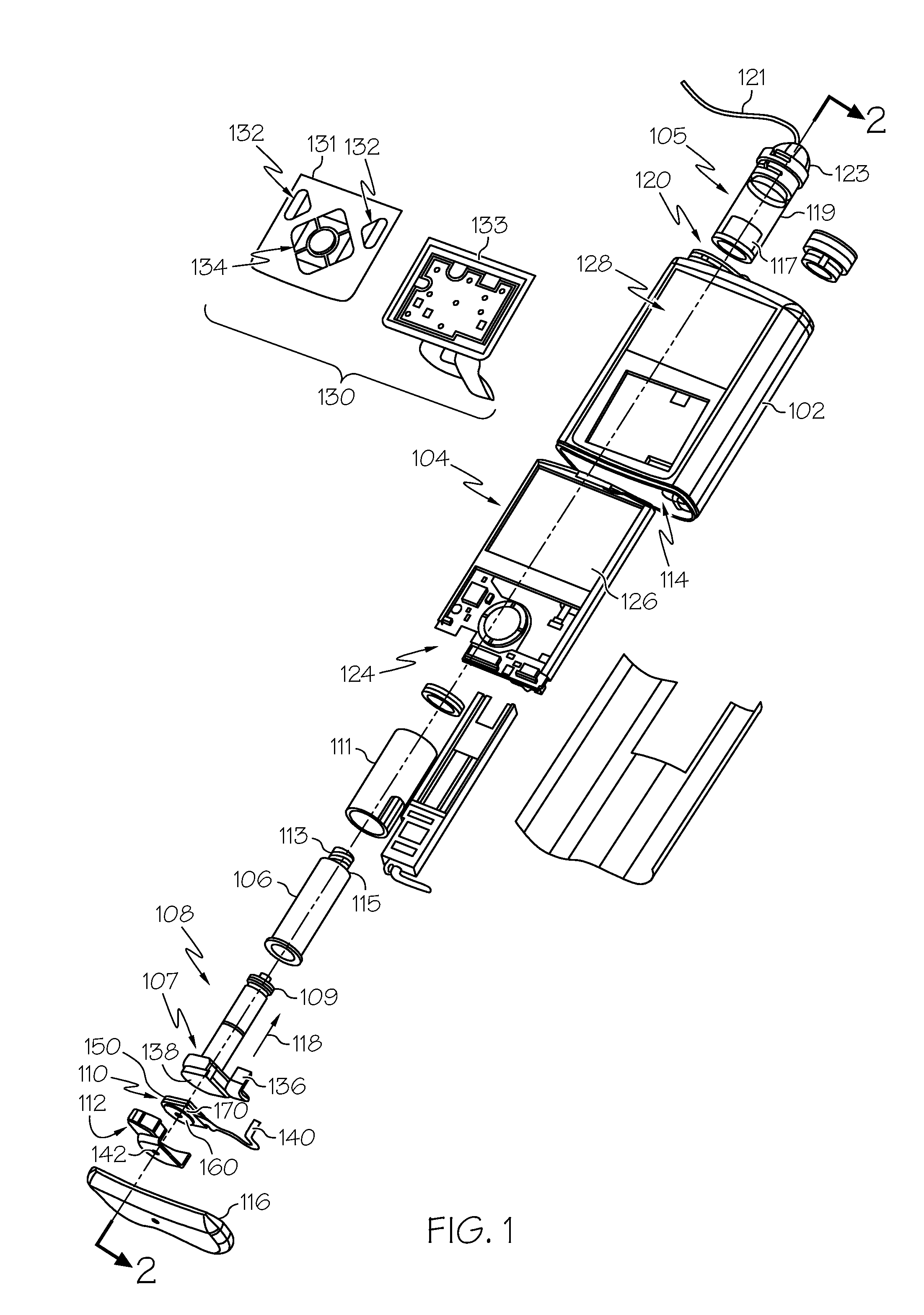

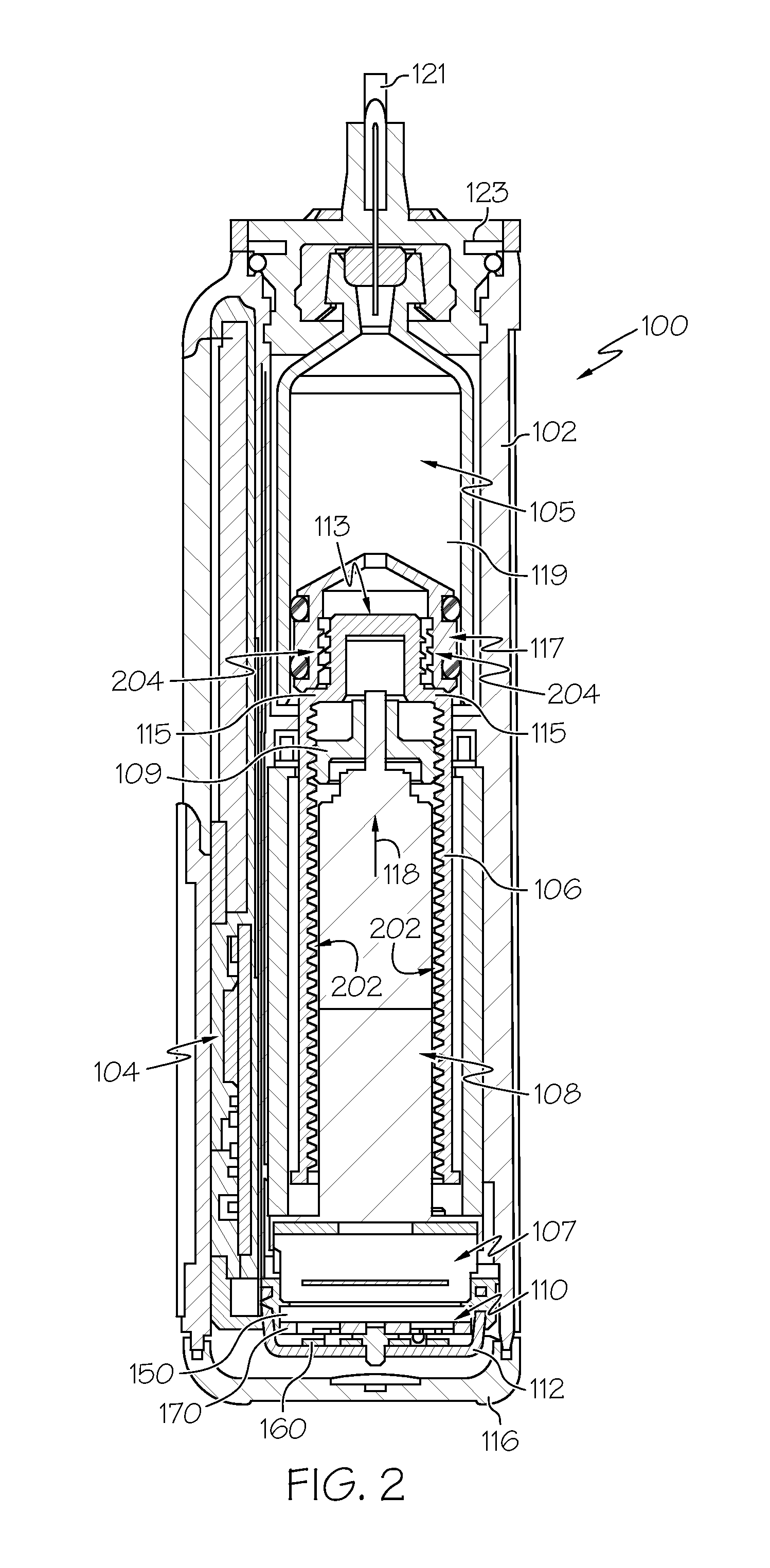

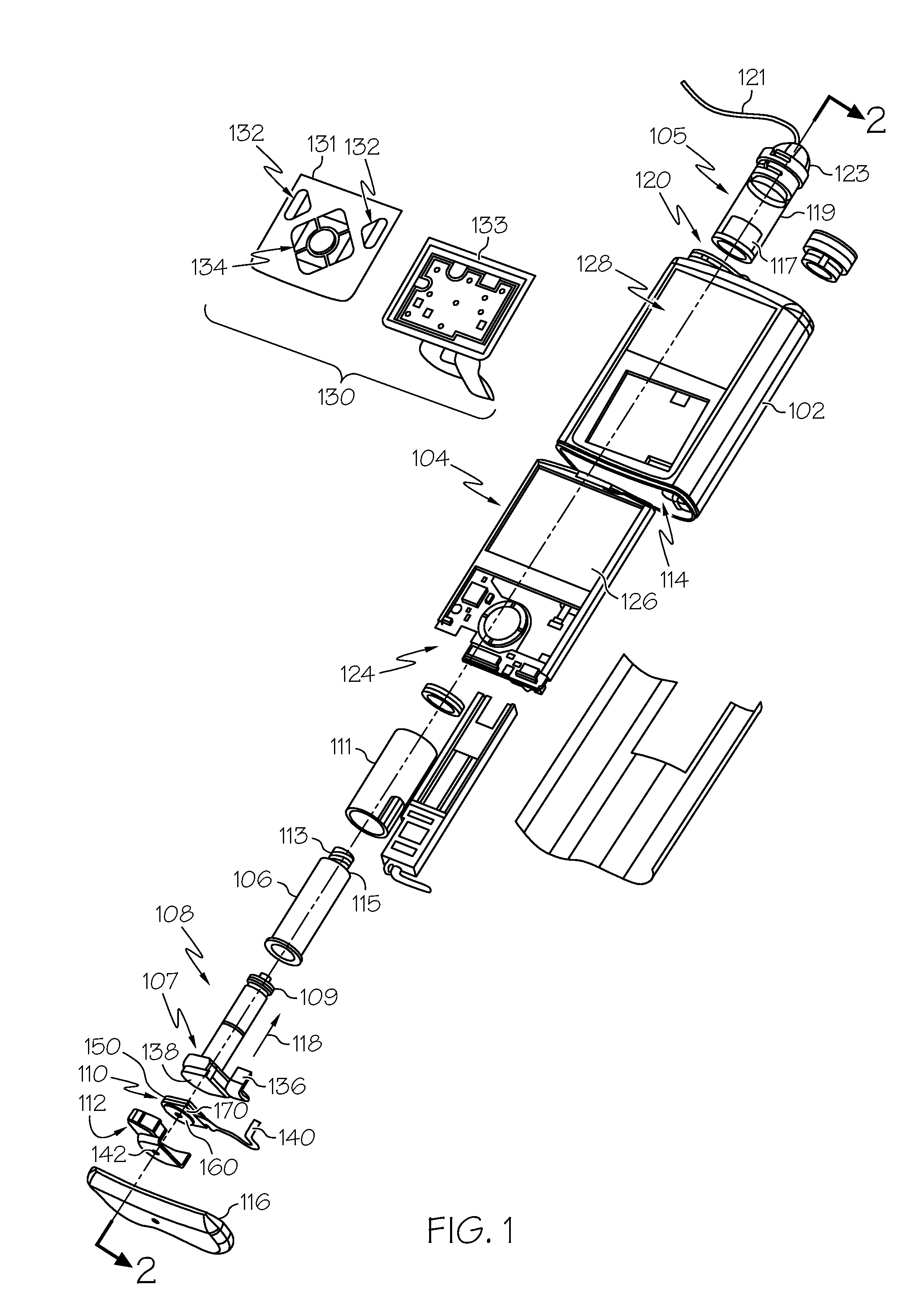

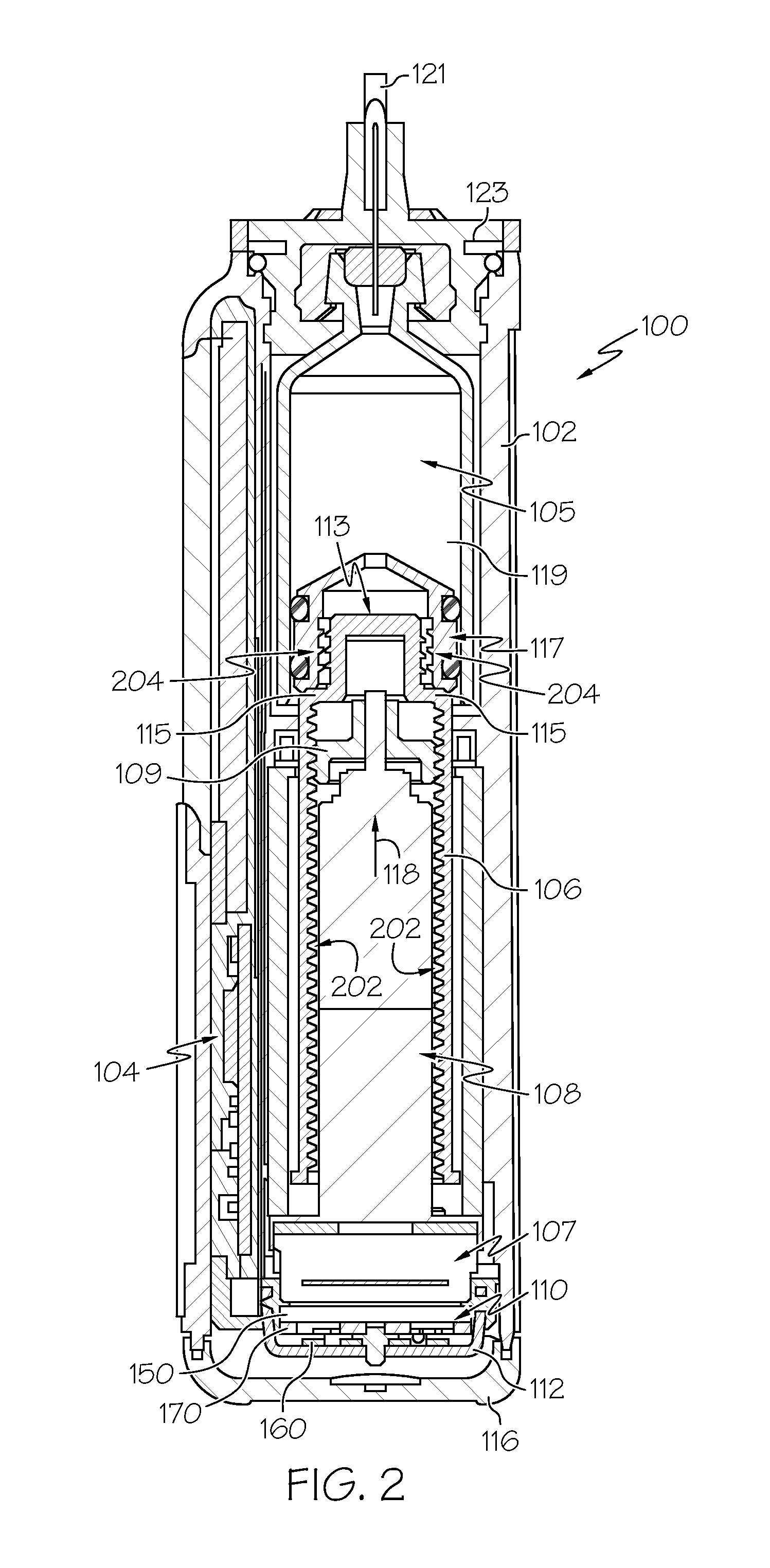

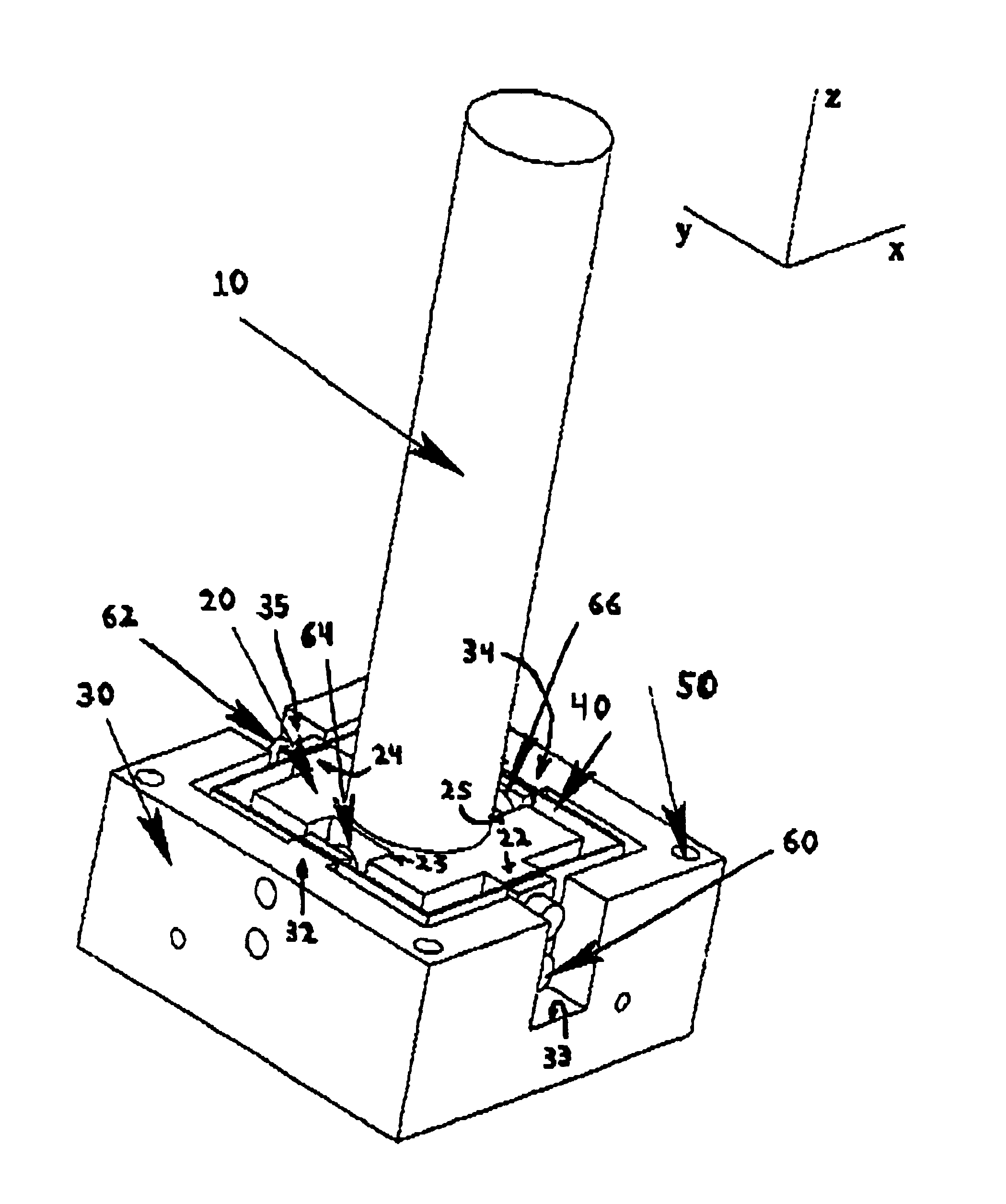

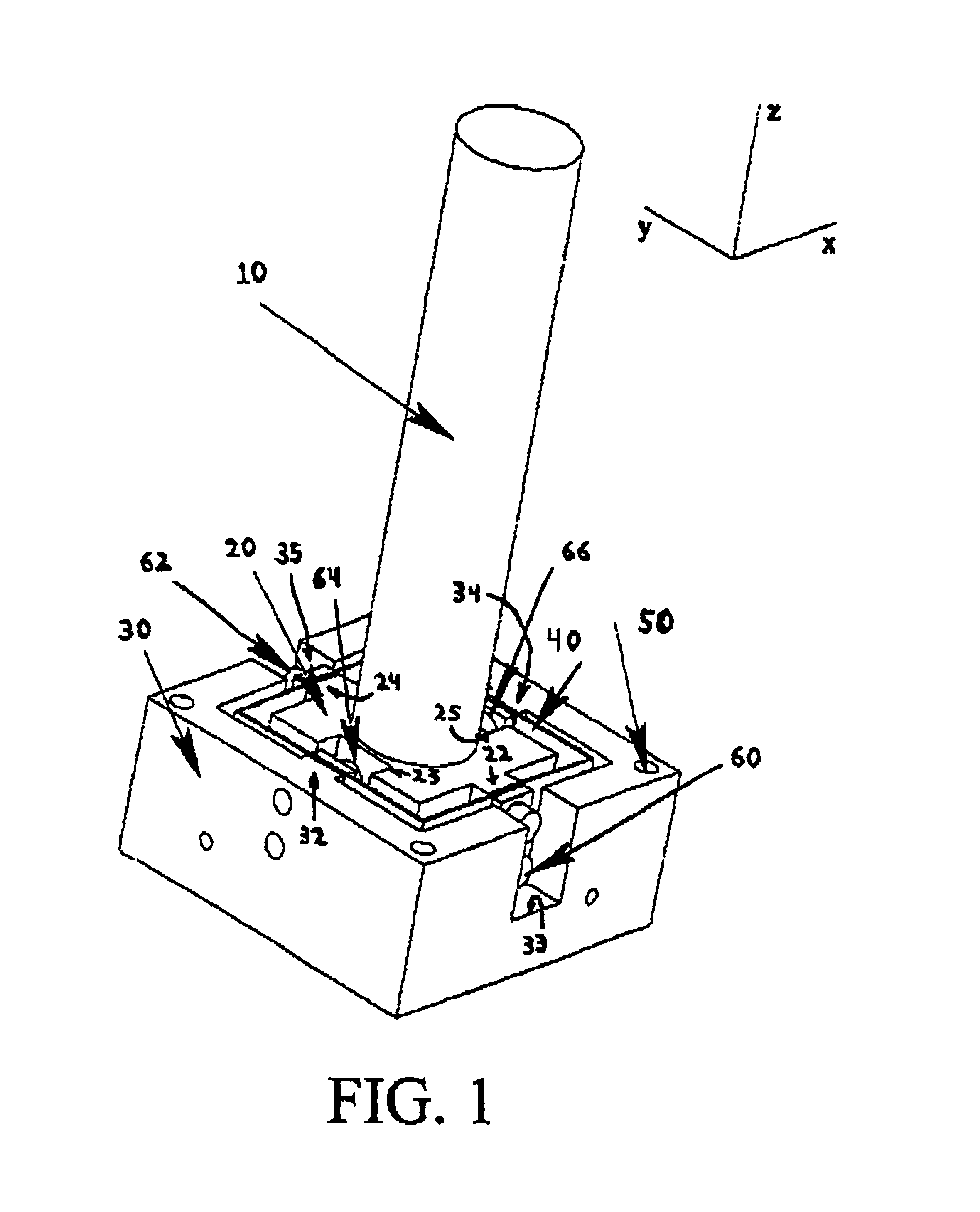

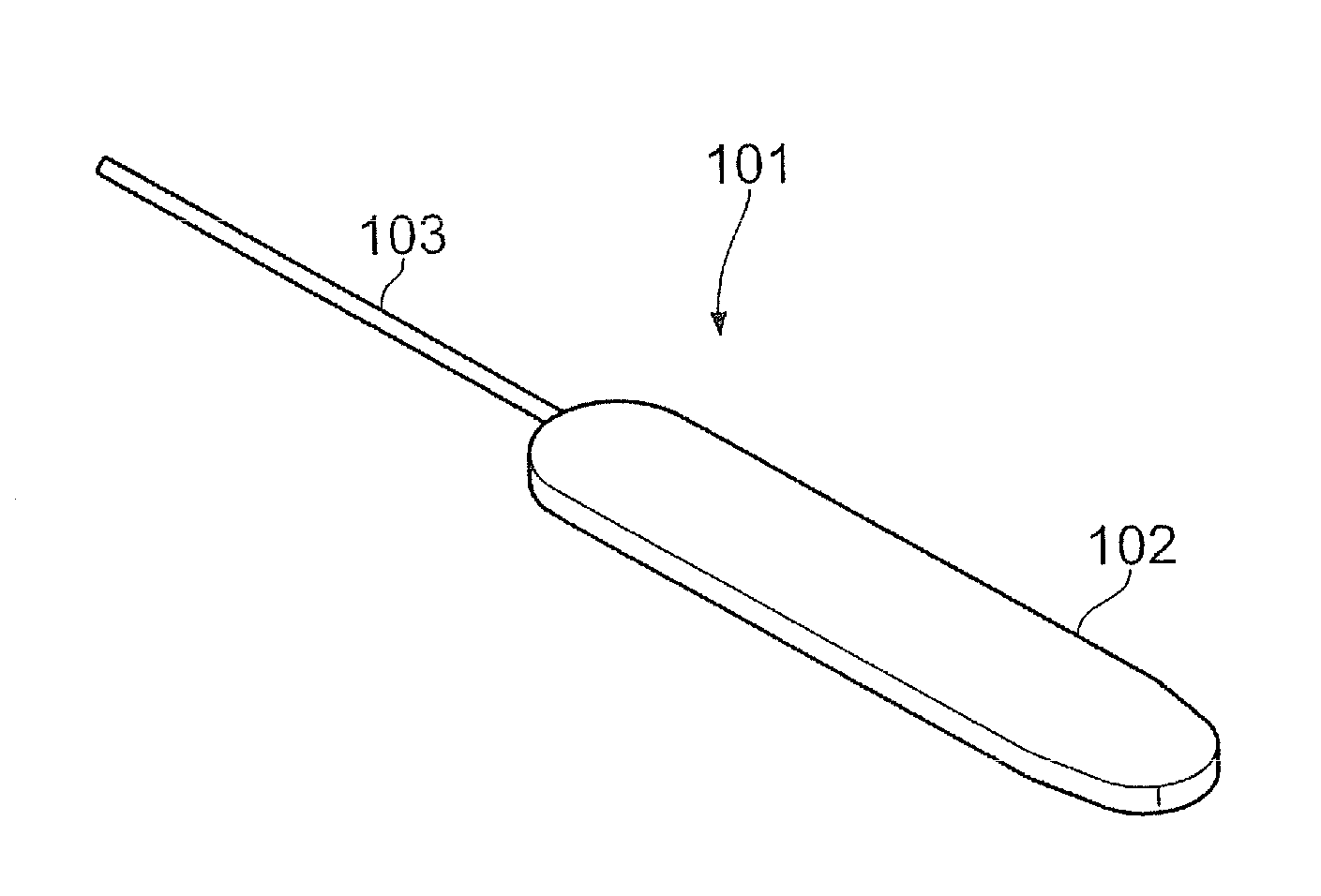

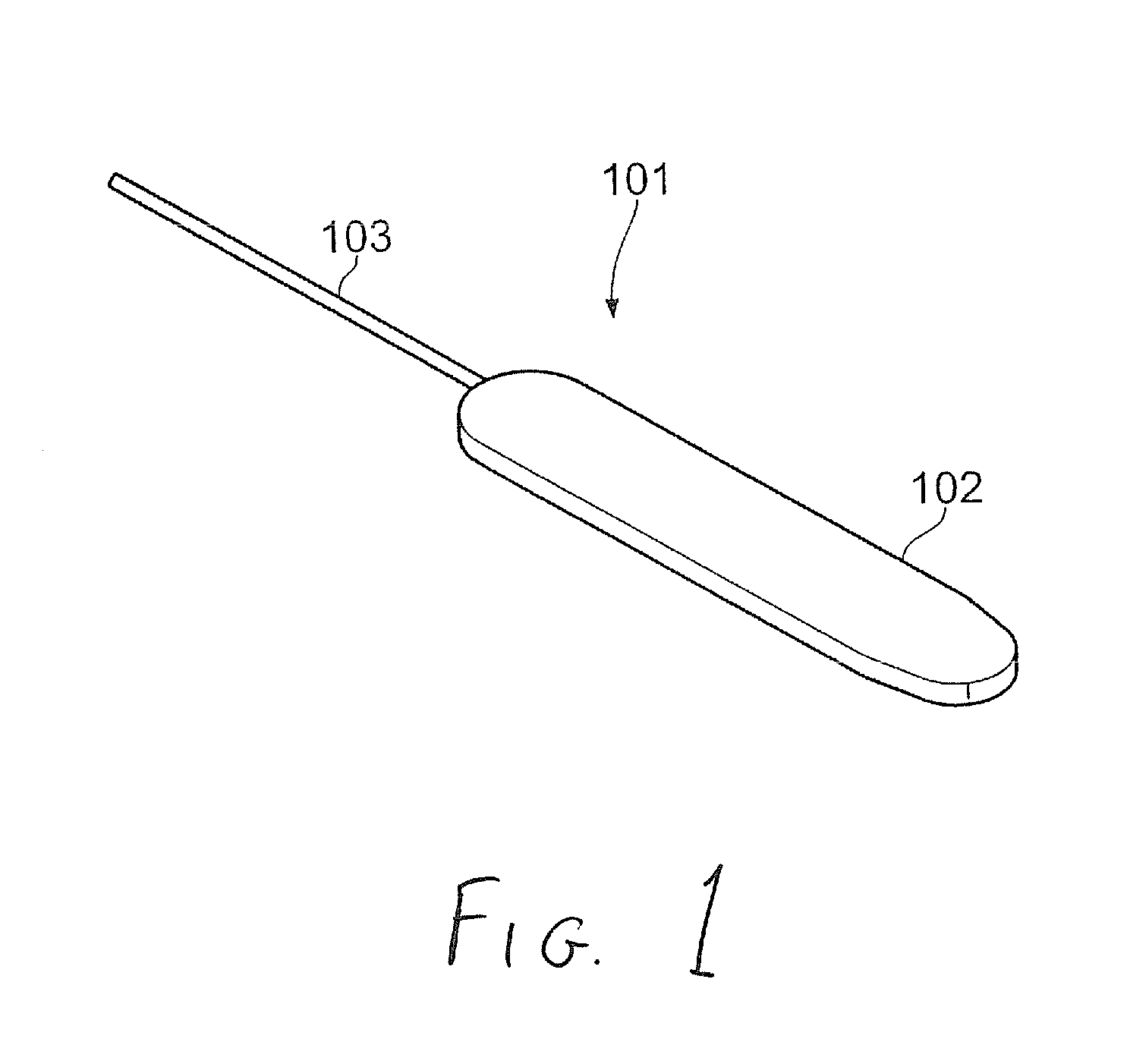

Sensor assembly and medical device incorporating same

ActiveUS8474332B2Force measurement by permanent gauge deformationMeasurement arrangements for variableMedical deviceMedical treatment

Apparatus are provided for sensor assemblies and related medical devices. An embodiment of a sensor assembly includes a beam and a sensing element disposed on the beam. The sensor assembly also includes a structure to prevent deflection of the beam when a force applied to the sensor assembly is greater than a threshold value.

Owner:MEDTRONIC MIMIMED INC

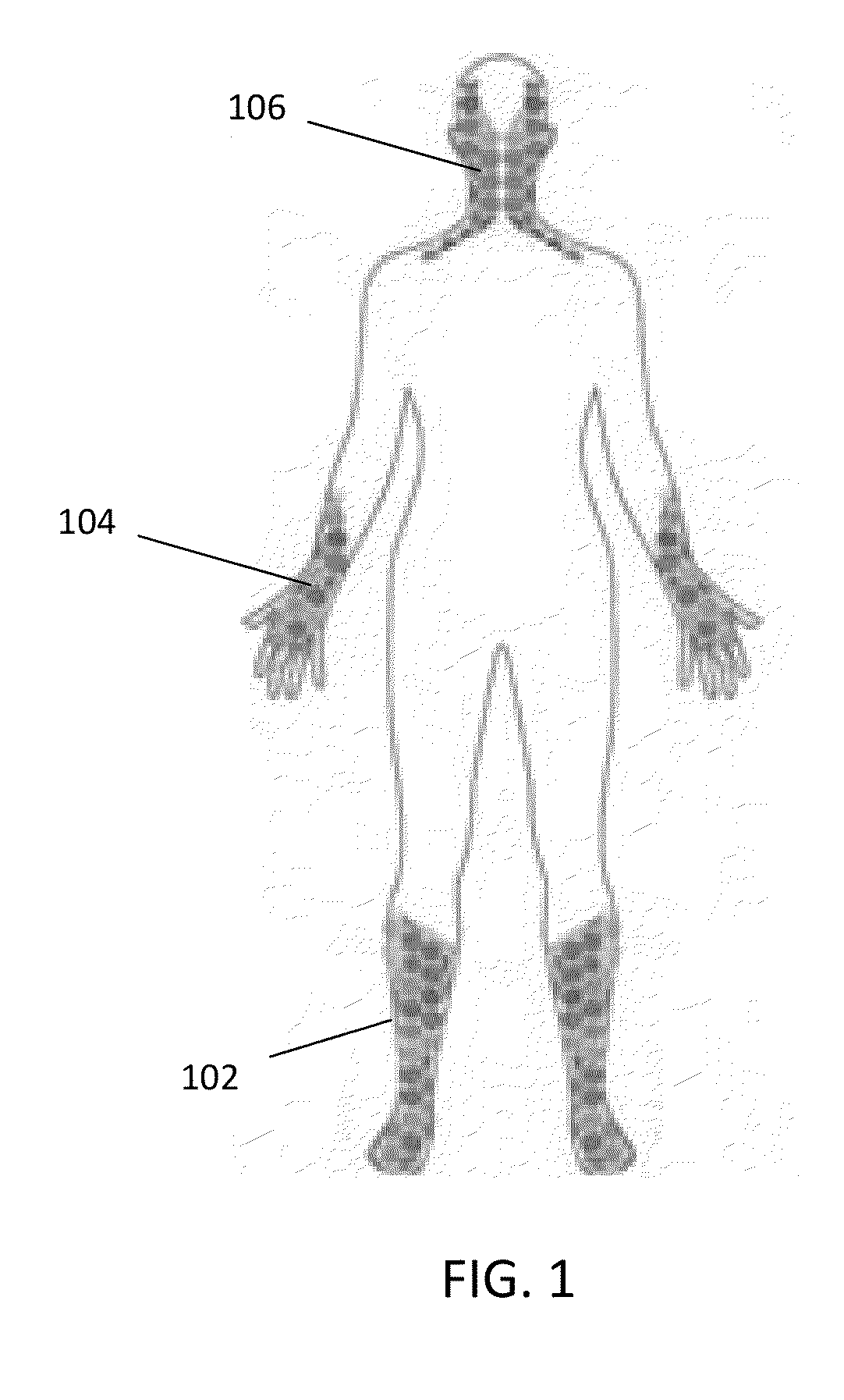

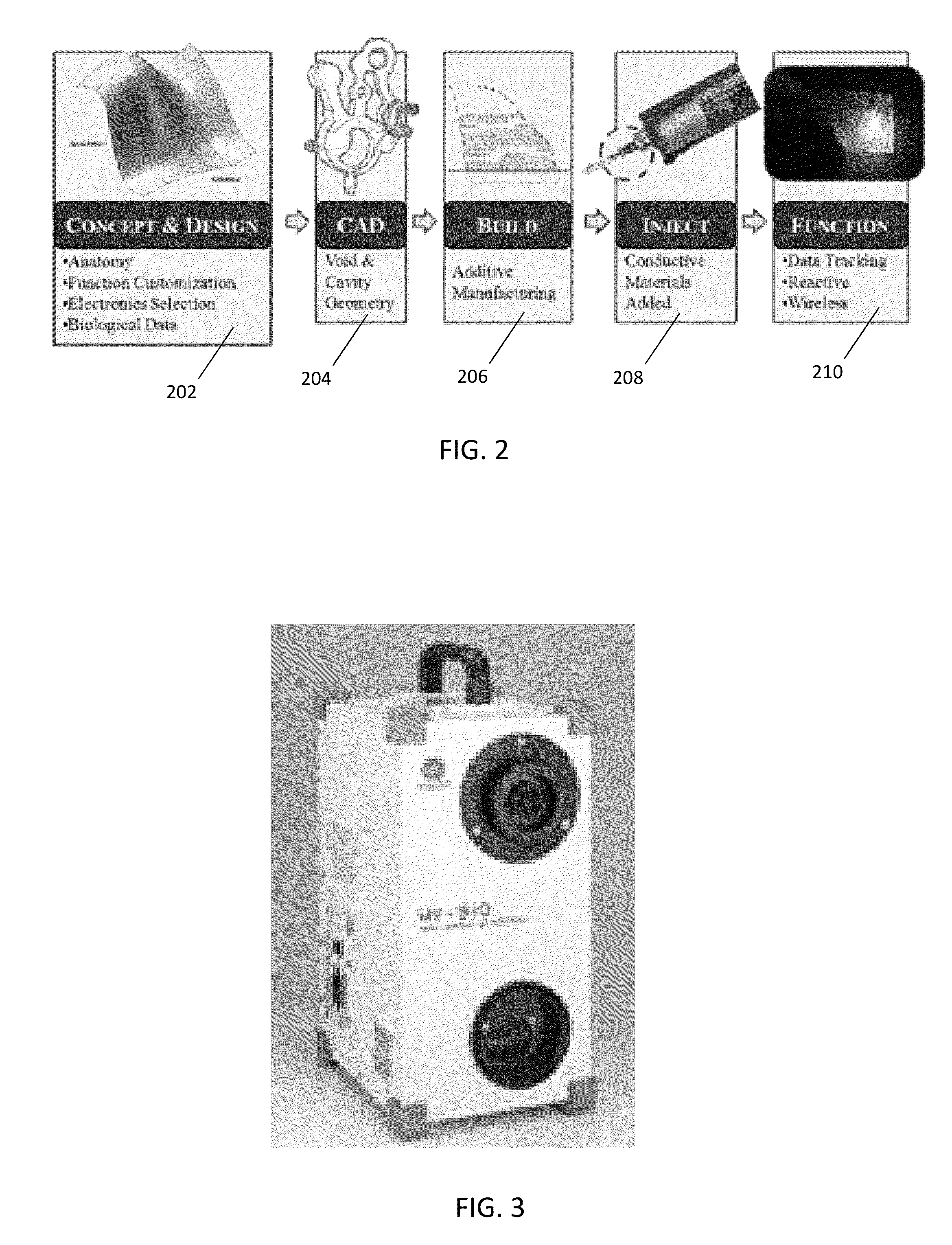

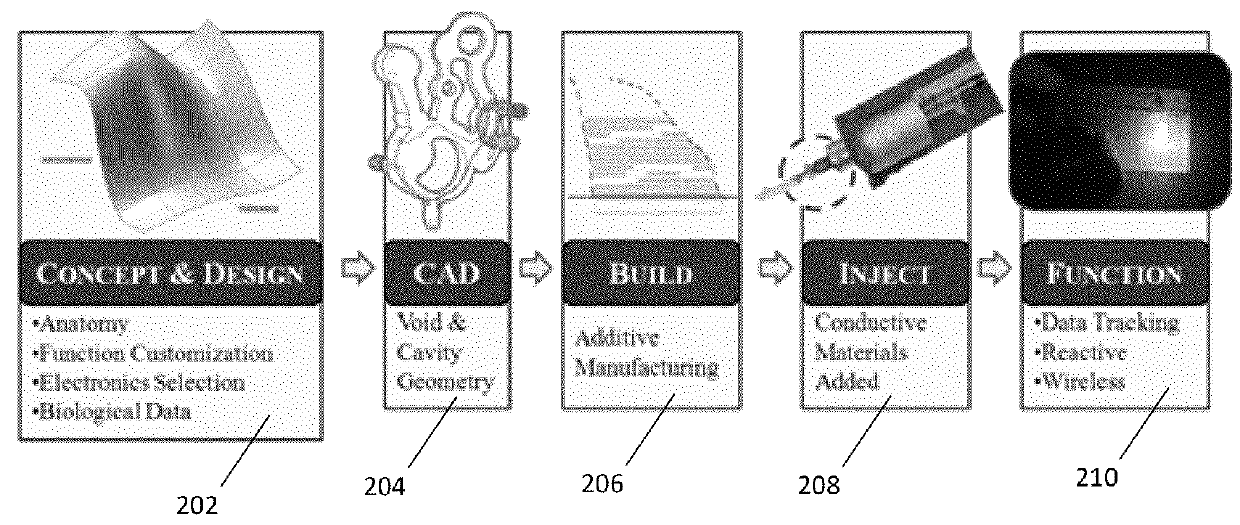

Customizable Embedded Sensors

InactiveUS20130079693A1Force measurement by permanent gauge deformationMeasurement apparatus componentsEngineeringEngineering physics

Owner:NORTHEASTERN UNIV

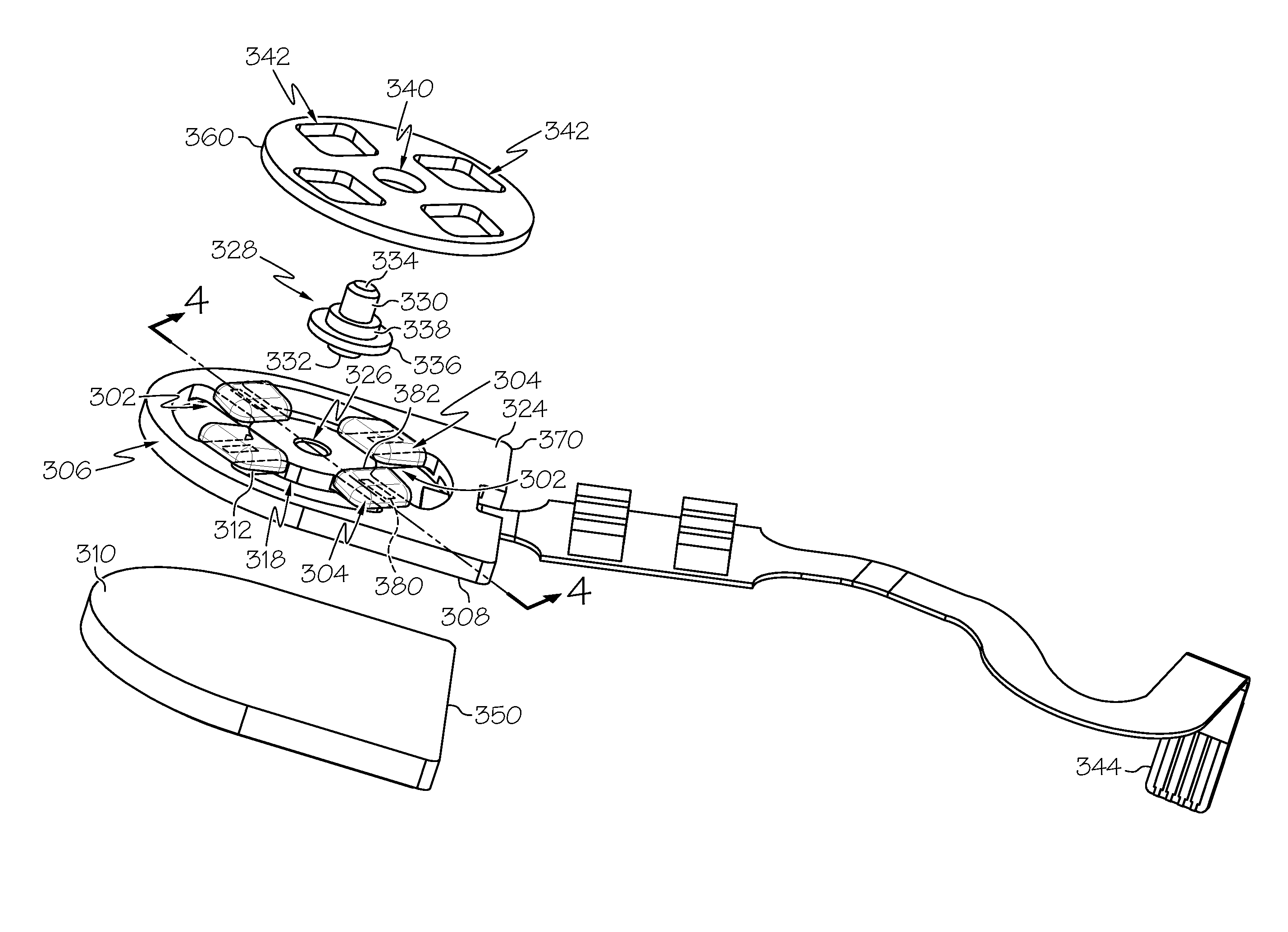

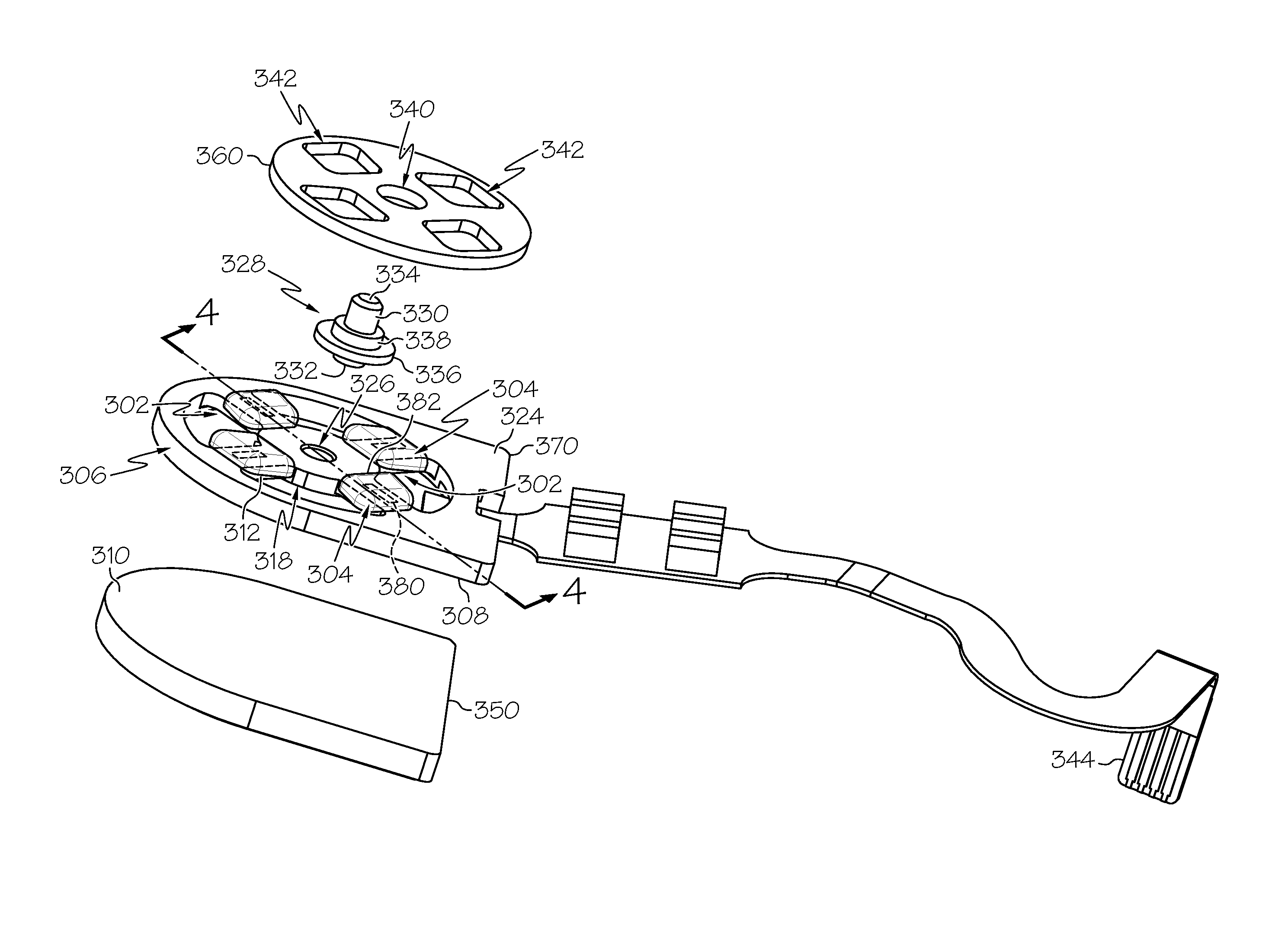

Sensor assembly and medical device incorporating same

ActiveUS20120096953A1Avoid skewWell formedForce measurement by permanent gauge deformationMedical devicesMedicineEngineering

Apparatus are provided for sensor assemblies and related medical devices. An embodiment of a sensor assembly includes a beam and a sensing element disposed on the beam. The sensor assembly also includes a structure to prevent deflection of the beam when a force applied to the sensor assembly is greater than a threshold value.

Owner:MEDTRONIC MIMIMED INC

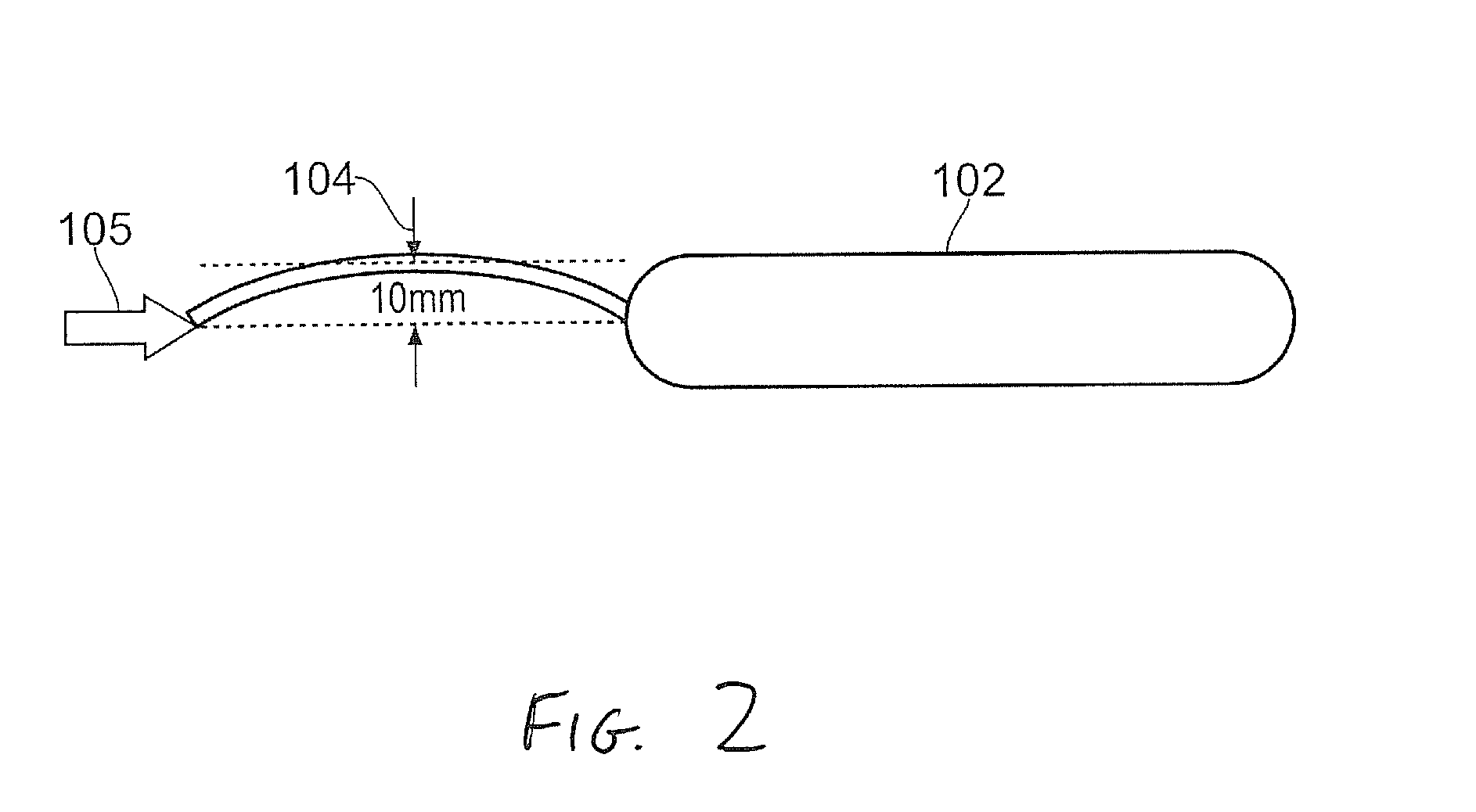

Sensor assembly and medical device incorporating same

ActiveUS20120096954A1Avoid skewForce measurement by permanent gauge deformationMeasurement arrangements for variableEngineeringMedical device

Apparatus are provided for sensor assemblies and related medical devices. An embodiment of a sensor assembly includes a beam and a sensing element disposed on the beam. The sensor assembly also includes a loading member to deflect the beam in response to a force applied to the sensor assembly. The loading member has a feature that prevents deflection of the beam when the force applied is greater than a threshold value.

Owner:MEDTRONIC MIMIMED INC

Sensor assembly and medical device incorporating same

ActiveUS8479595B2Avoid skewForce measurement by permanent gauge deformationMeasurement arrangements for variableEngineeringMedical device

Owner:MEDTRONIC MIMIMED INC

Sensor devices

ActiveUS20060230841A1Avoid noisy signalsForce measurement by permanent gauge deformationResistance/reactance/impedenceEngineeringActuator

A sensor device for measuring frequency and amplitude of a varying force signal is provided. The sensor device comprises a sensing element defined by a plurality of even numbered planar segments symmetrically disposed about a central axis, a protective housing for housing, an interface element comprising a pick up member, a planar mechanical actuator, a transfer member adapted to receive varying signals from the pick up, amplify the signals picked up and transfer the amplified signals to the said mechanical actuator; and leads for transmitting said output signals outside the sensing device for processing.

Owner:SHRIKRISHNA VAIDYA AVINASH

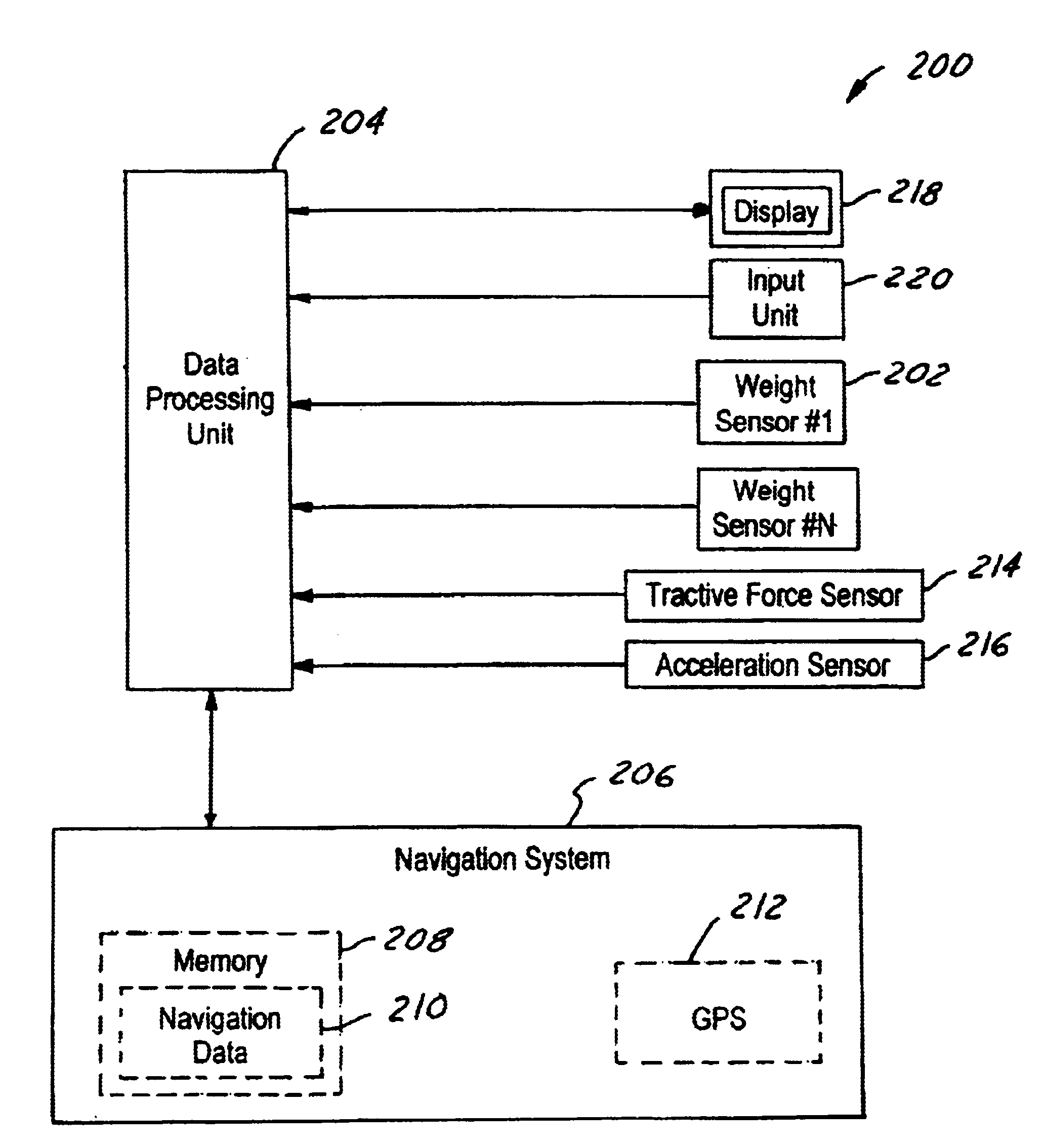

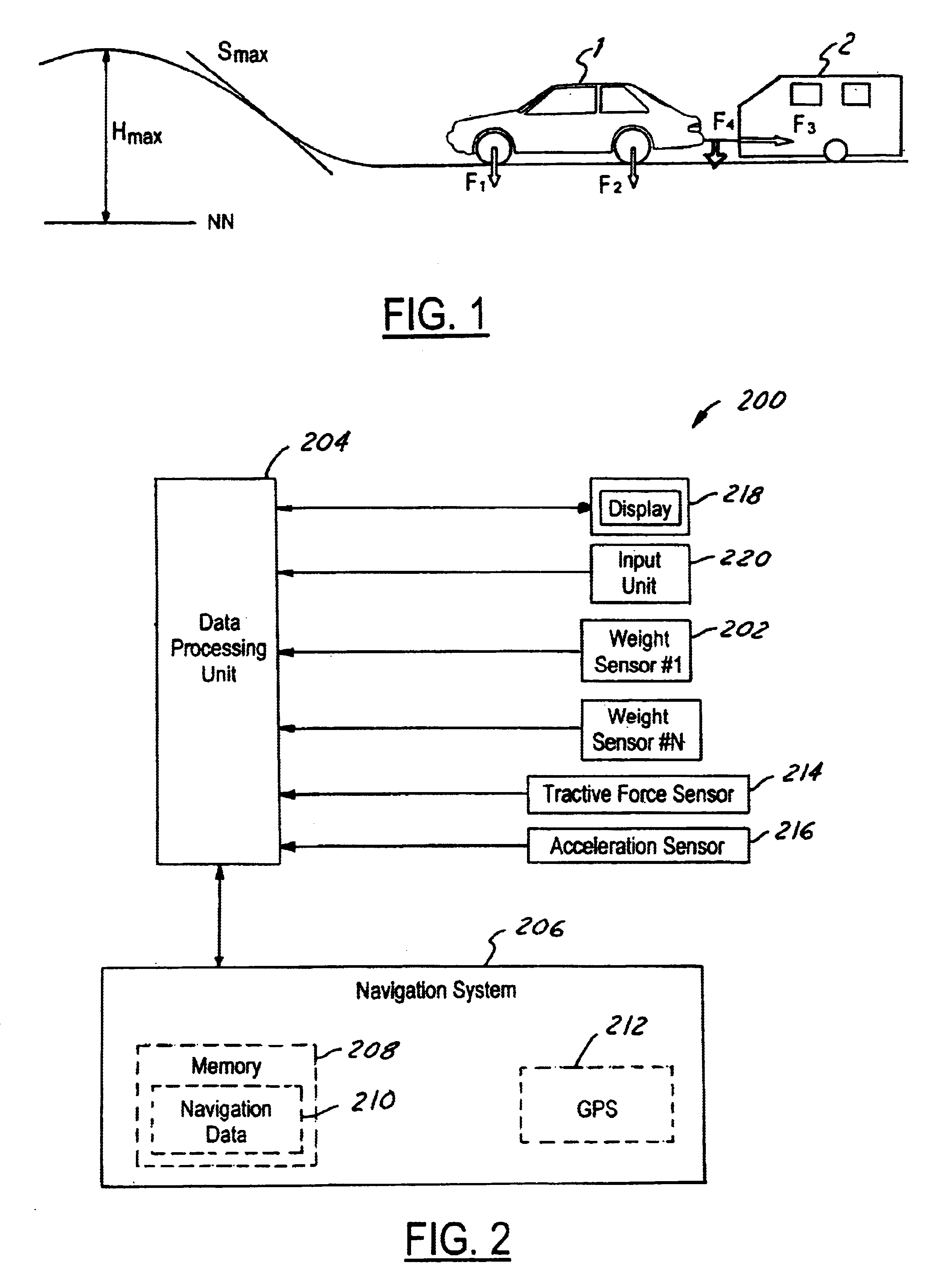

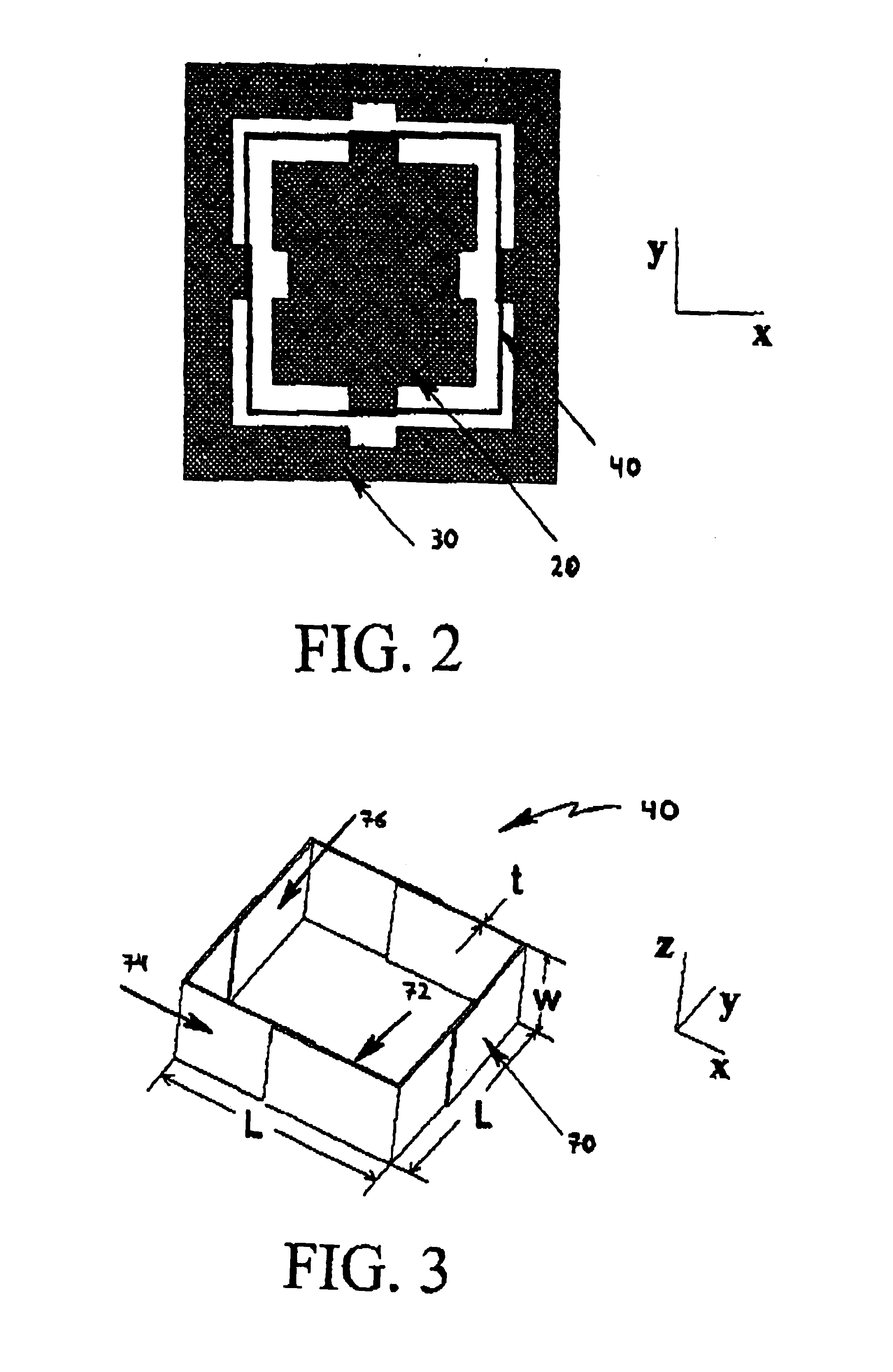

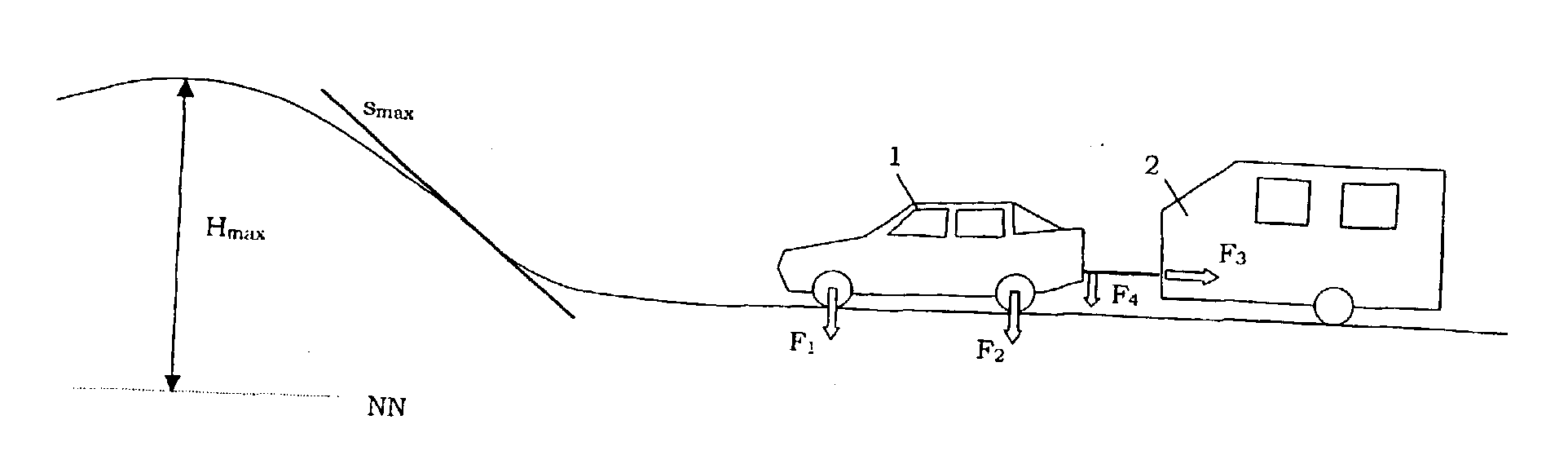

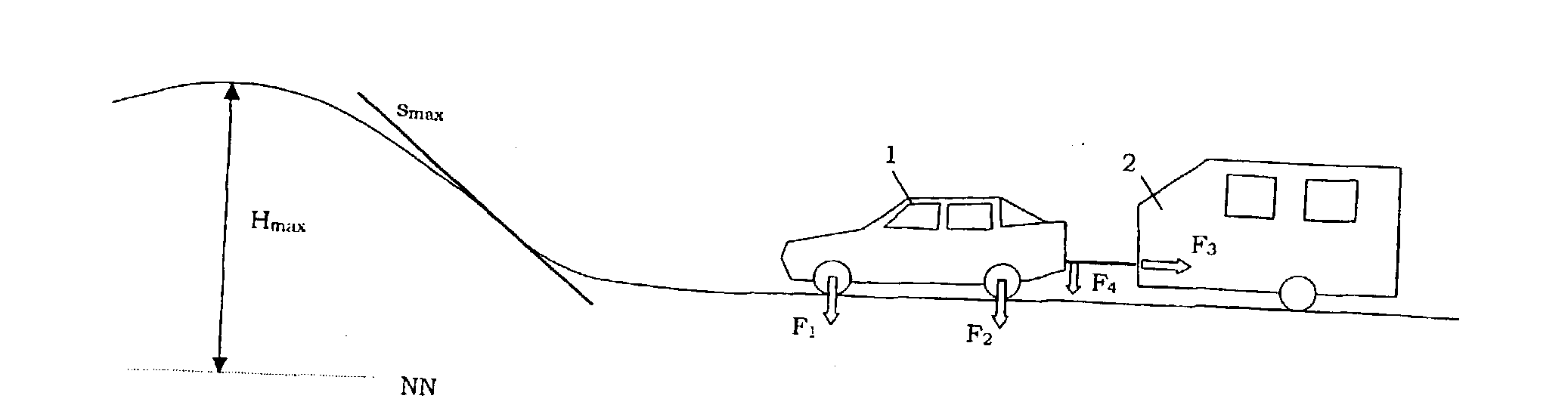

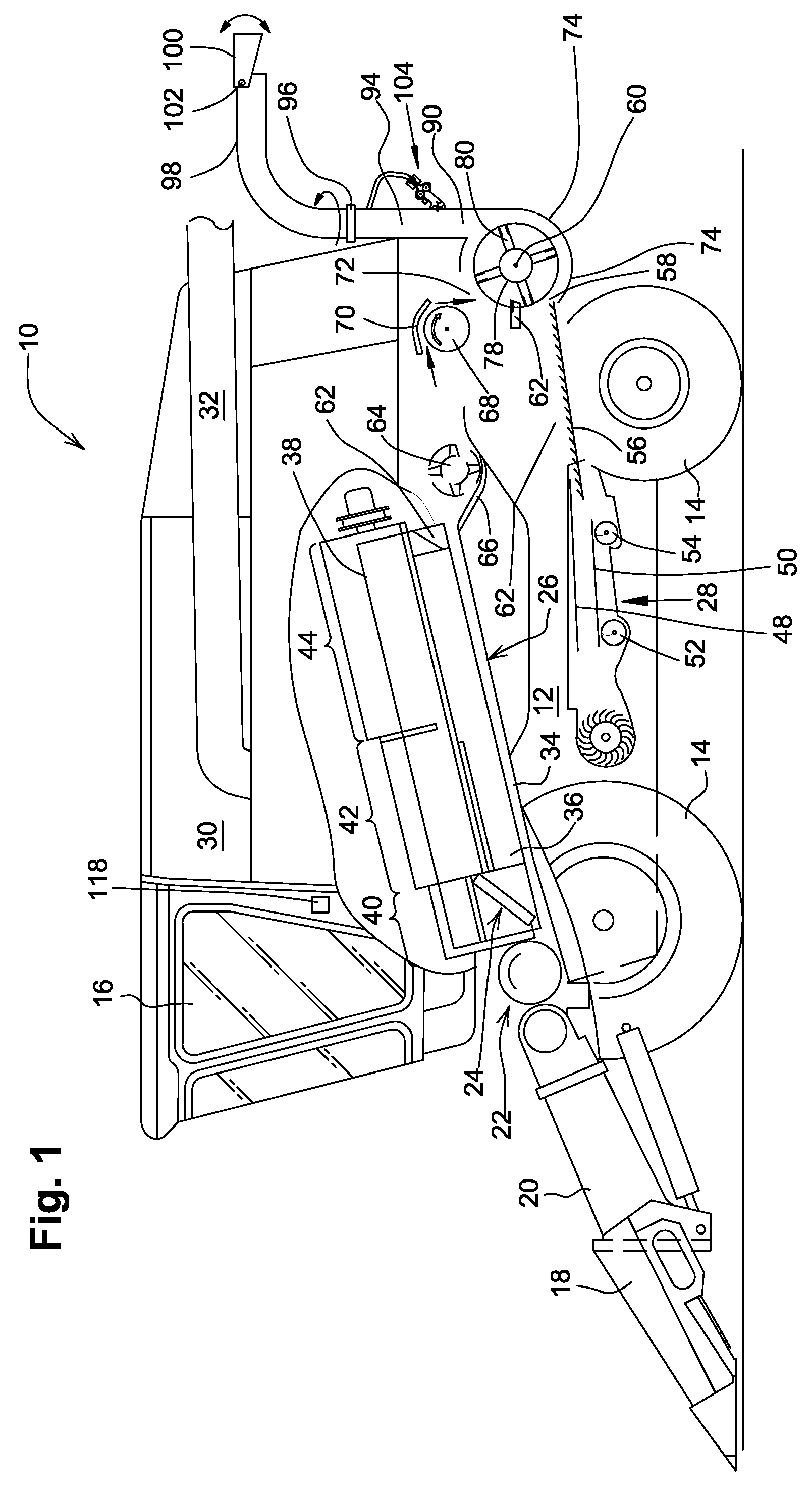

Vehicle weight observation system

InactiveUS6829943B2Improve protectionInstruments for road network navigationForce measurement by permanent gauge deformationDriver/operatorWeight monitoring

The invention relates to a weight monitoring system for a motor vehicle (1) which can, if appropriate, be connected to a trailer (2). The system uses weight sensors to determine the weights (F1, F2) acting on the axles of the motor vehicle, in order to calculate from them the overall weight of the vehicle, and the axle loads. In addition, a tractive force sensor may be provided in the trailer hitch so that the mass of the trailer (2) can be determined by means of the tractive force (F3) and the acceleration of the vehicle. The weight monitoring system calculates various weight variables from the measured values and monitors to determine whether they remain within defined limits. In this context, it is possible, in particular, to take into account a planned route in such a way that the limiting values of the charge are adapted with respect to the maximum altitude (Hmax) above sea level and / or the maximum gradient (smax) of the route. In addition, the system can be configured in such a way that it provides the driver with proposals for a different distribution of the payload which leads to a permissible axle load.

Owner:FORD GLOBAL TECH LLC

Fall detection system

ActiveUS8381603B2Improve reliabilityDesired level of detection accuracyForce measurement by permanent gauge deformationPerson identificationEngineeringFall detector

Owner:KONINK PHILIPS ELECTRONICS NV

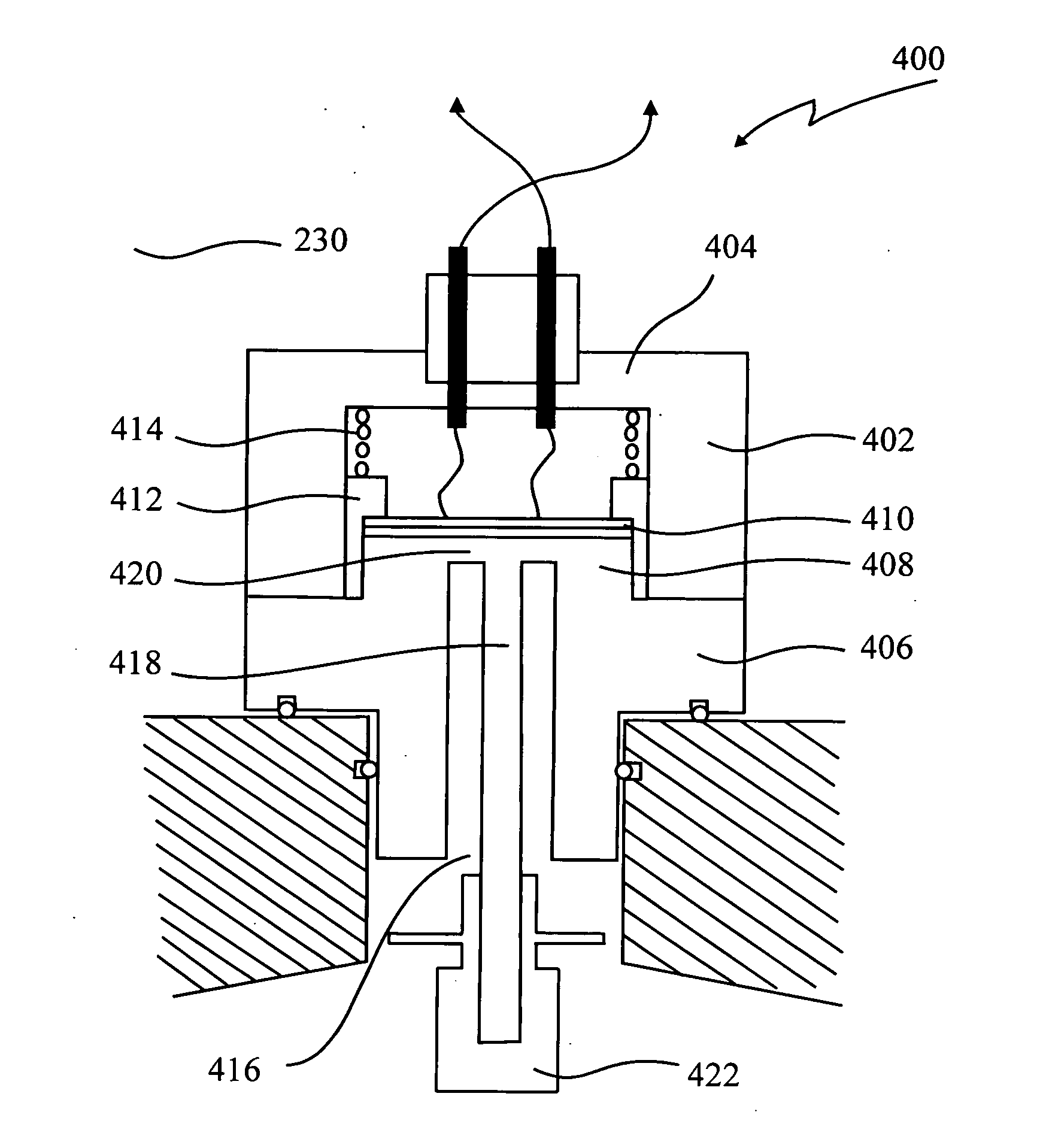

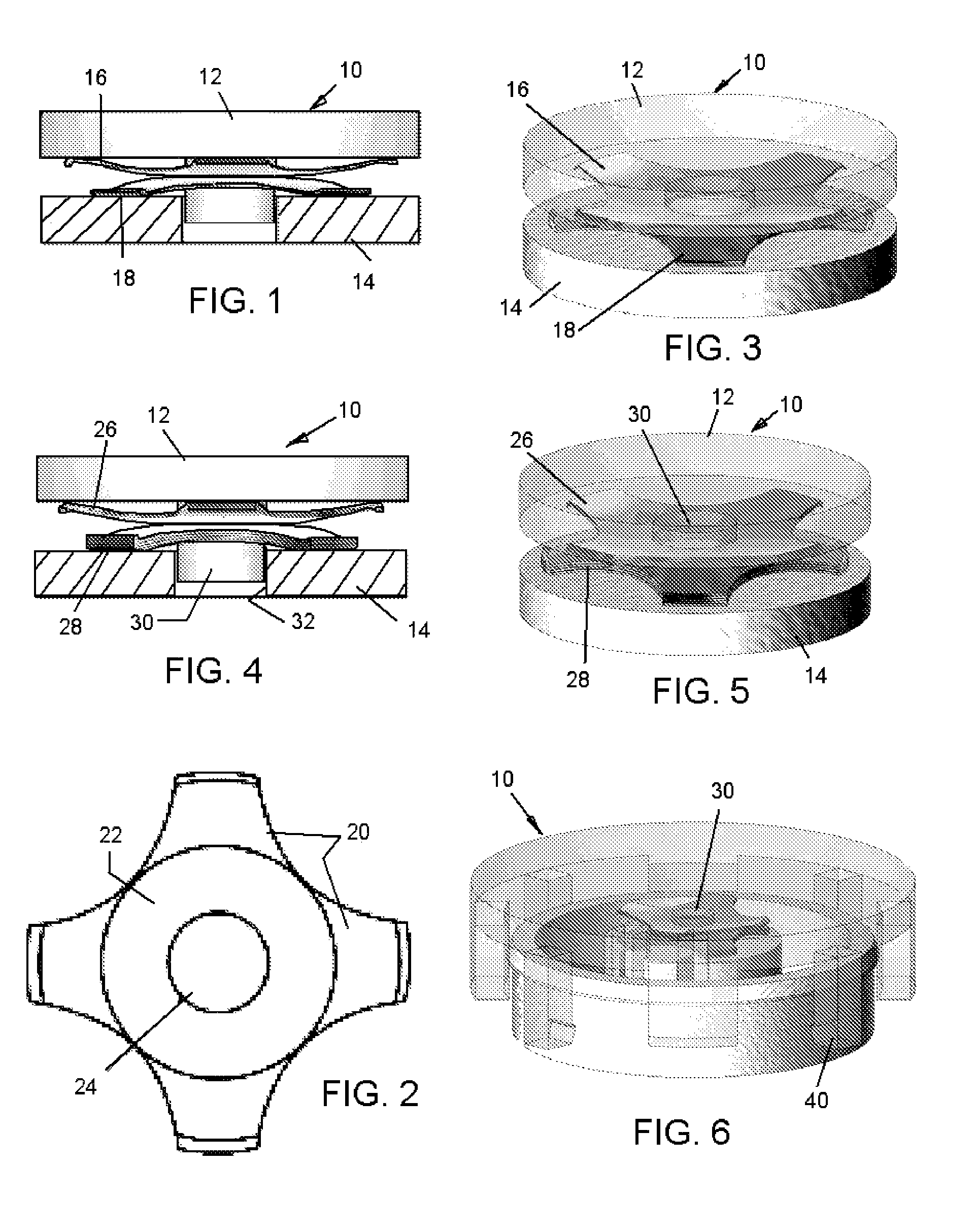

Force sensors

InactiveUS7047826B2Low stiffnessOvercome disadvantagesForce measurement by permanent gauge deformationMeasurement arrangements for variableElectricityElastomer

A force sensor for measuring force and / or torque about a single axis or multiple axes is rugged, inexpensive and can be fabricated over a wide range of sizes. The force sensor includes first and second members that are coupled to each other by an elastomeric flexure that allows at least one member to be movable with respect to the other member when a force is applied. The force sensor includes a transmitting coil or printed circuit trace and a receiving coil or printed circuit trace. In one embodiment, the transmitting and receiving coils are formed on different ones of the first and second members. In another embodiment, the transmitting and receiving coils are formed on the same member and the other member is formed as a shading plate. A signal applied to the transmitting coil induces a signal in the receiving coil that represents the force applied.

Owner:NORTHWESTERN UNIV

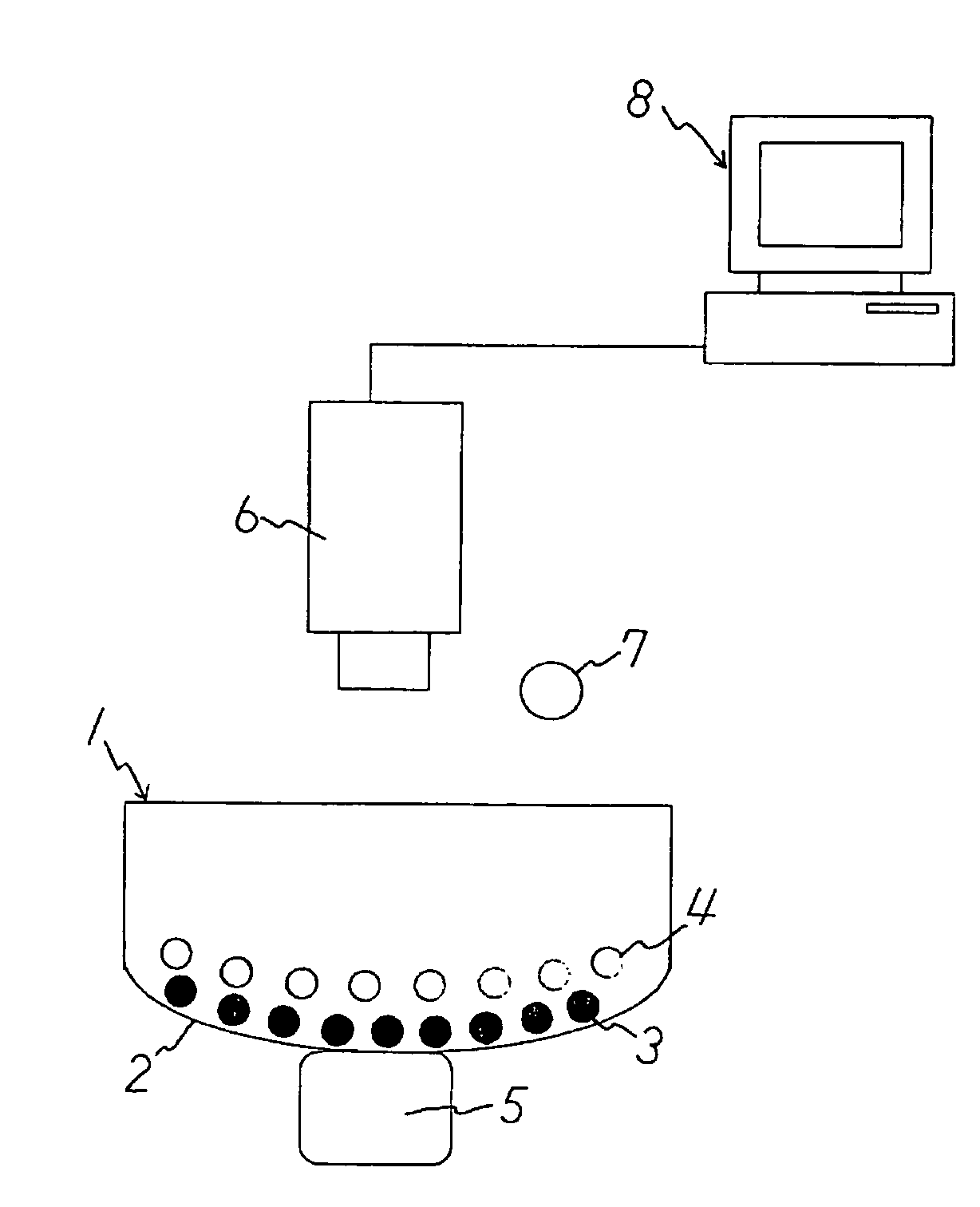

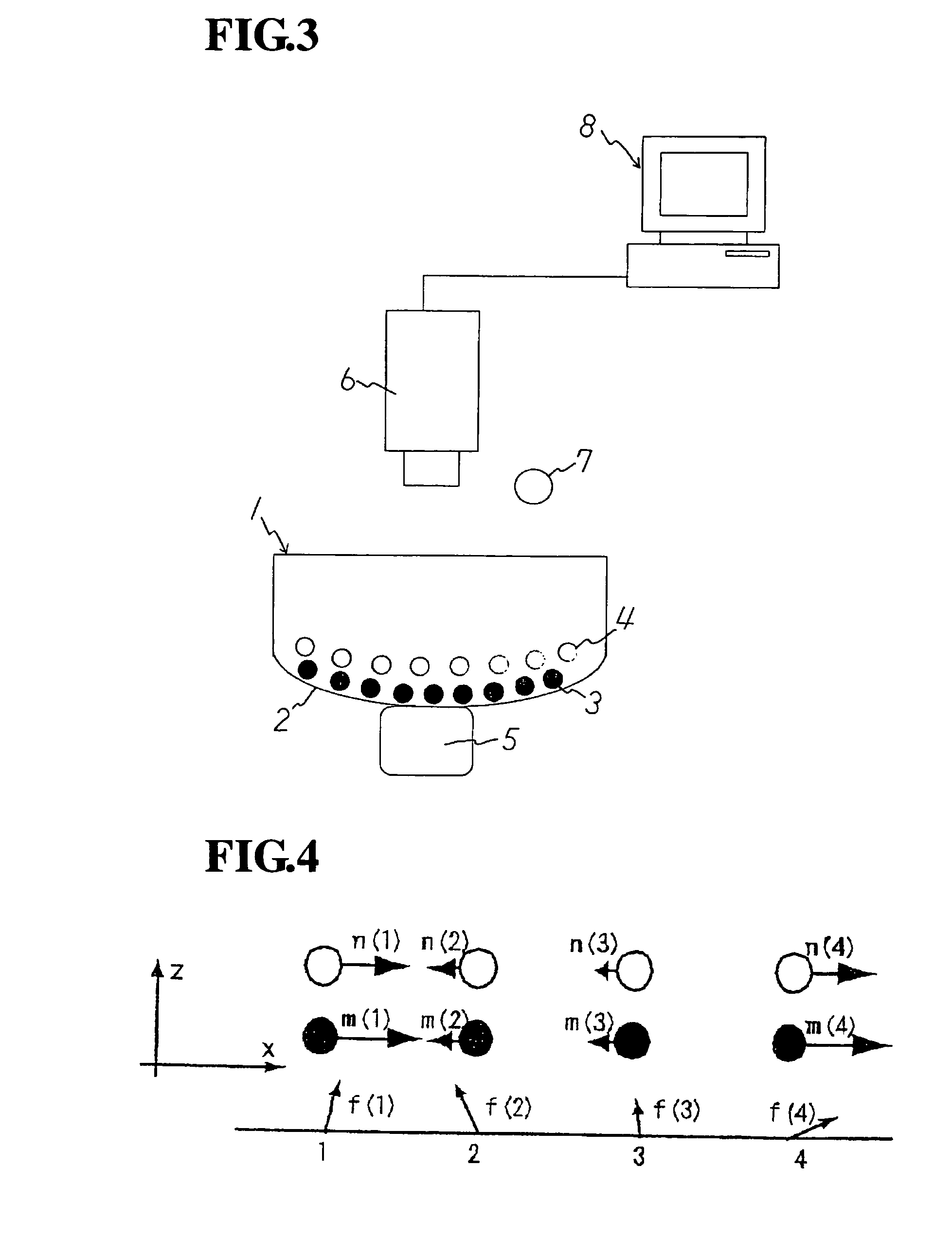

Force vector reconstruction method using optical tactile sensor

InactiveUS7460964B2Reduce the amount of calculationSmall sizeInflated body pressure measurementForce measurement by permanent gauge deformationReconstruction methodTactile sensor

The invention relates to a technique for reducing computation time for force vector calculation. A force vector reconstruction method that uses an optical tactile sensor, comprises a step for obtaining a marker image by taking an image of behavior of colored markers when an object contacts a contact surface of an elastic body, a step of obtaining information relating to the marker behavior from the marker image, the information being more than the number of force vectors to be obtained, and a step of obtaining force vectors as outputs by inputting information relating to the obtained marker behavior to a transfer function. The step of obtaining force vectors comprises calculating force vectors using only information relating to behavior of markers neighboring region A1 of a position A where it is desired to obtain force vectors.

Owner:TOUDAITLO LTD

Vehicle weight observation system

InactiveUS20030154798A1Improve protectionImprove securityInstruments for road network navigationForce measurement by permanent gauge deformationDriver/operatorWeight monitoring

The invention relates to a weight monitoring system for a motor vehicle (1) which can, if appropriate, be connected to a trailer (2). The system uses weight sensors to determine the weights (F1, F2) acting on the axles of the motor vehicle, in order to calculate from them the overall weight of the vehicle, and the axle loads. In addition, a tractive force sensor may be provided in the trailer hitch so that the mass of the trailer (2) can be determined by means of the tractive force (F3) and the acceleration of the vehicle. The weight monitoring system calculates various weight variables from the measured values and monitors to determine whether they remain within defined limits. In this context, it is possible, in particular, to take into account a planned route in such a way that the limiting values of the charge are adapted with respect to the maximum altitude (Hmax) above sea level and / or the maximum gradient (smax) of the route. In addition, the system can be configured in such a way that it provides the driver with proposals for a different distribution of the payload which leads to a permissible axle load.

Owner:FORD GLOBAL TECH LLC

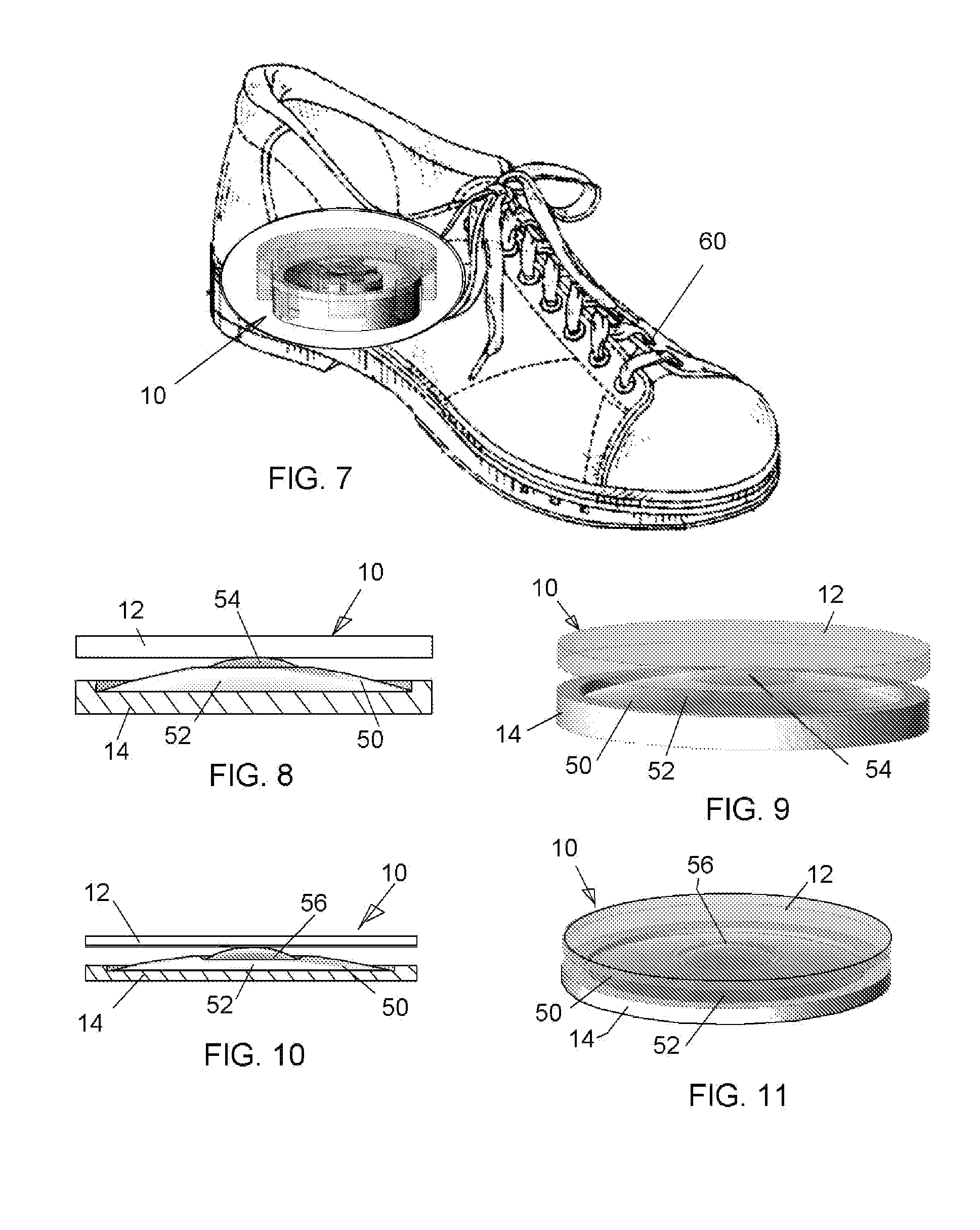

System and method for measuring plantar foot pressure

ActiveUS7337680B2Efficient and reliablePrevent ulcersForce measurement by permanent gauge deformationForce measurement by measuring optical property variationMeasurement deviceMedicine

Owner:KANTRO SCOTT

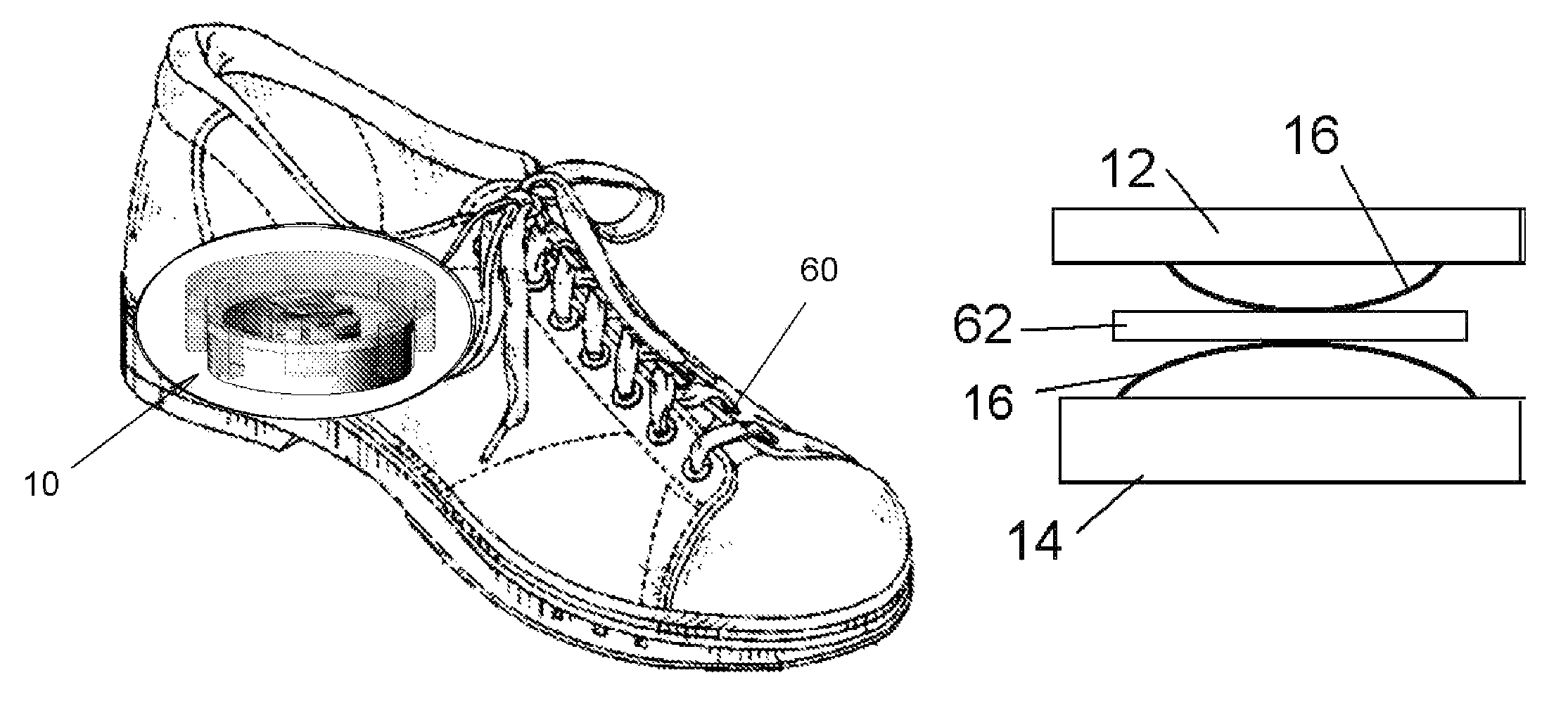

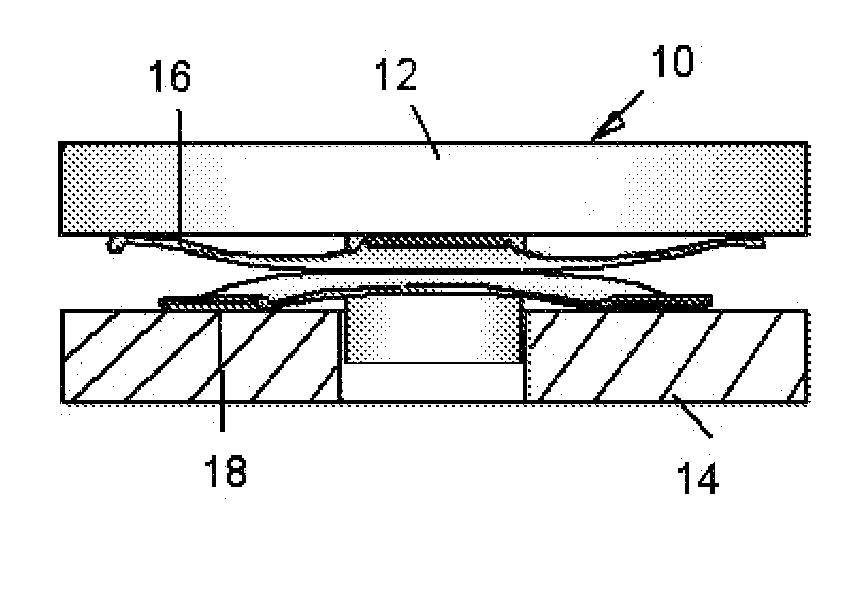

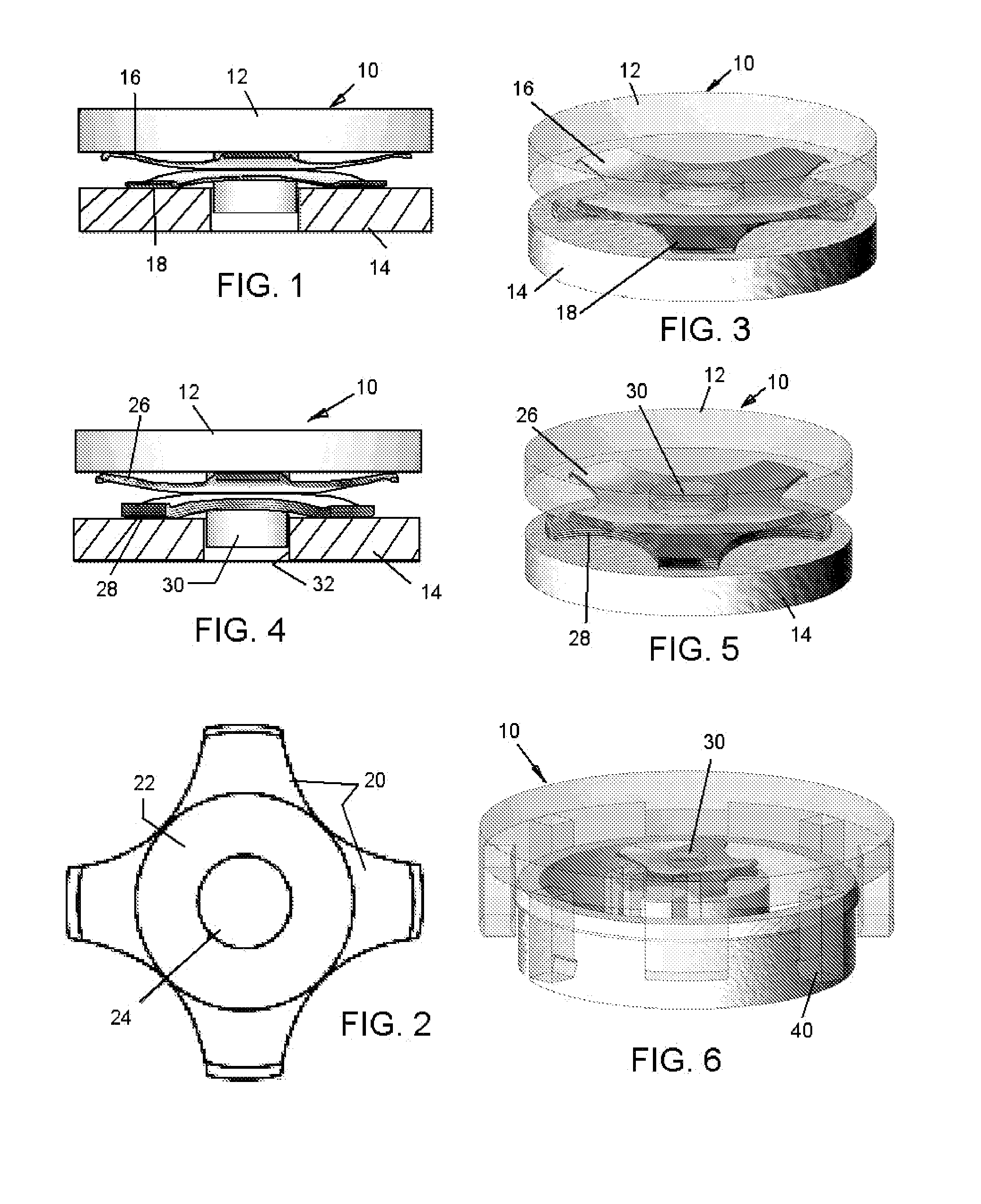

Device for mechanical weight bearing indication with load range capability

InactiveUS7493810B2Less attentionSimple designForce measurement by permanent gauge deformationMeasurement arrangements for variableEngineeringHigh load

A mechanical load bearing indicator producing signals to a user when the user applies more than selected amounts of load between an extremity of the use and a surface. The indicator has a base plate adapted to establish a frame of reference with the surface, a load plate mounted for movement toward and away from the base plate and adapted to receive loads from the user's extremity, and at least two snap domes mechanically engaged between the base plate and the load plate for generating two signals when more than two different respective loads are applied to the load plate by the extremity. The domes are either in series between the plates or are together in a dual dome containing both, or are one or more stacks of domes which individually collapse under incremental loads which are added together to form the selected lower and higher loads.

Owner:RENESSELAER POLYTECHNIC INST

Device for mechanical weight bearing indication with load range capability

InactiveUS20080041169A1Less attentionSimple designForce measurement by permanent gauge deformationMeasurement arrangements for variableEngineeringWeight-bearing

Owner:RENESSELAER POLYTECHNIC INST

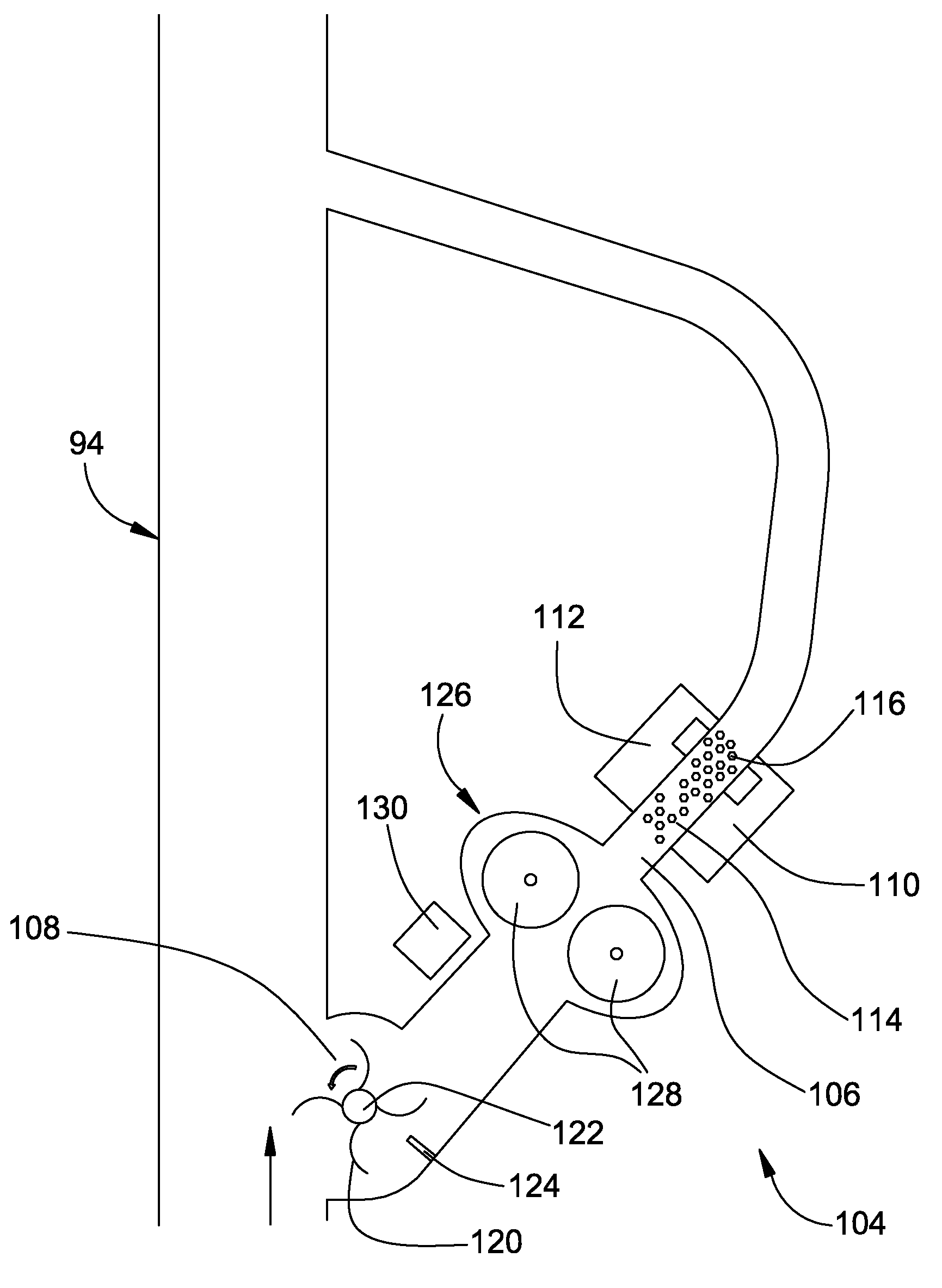

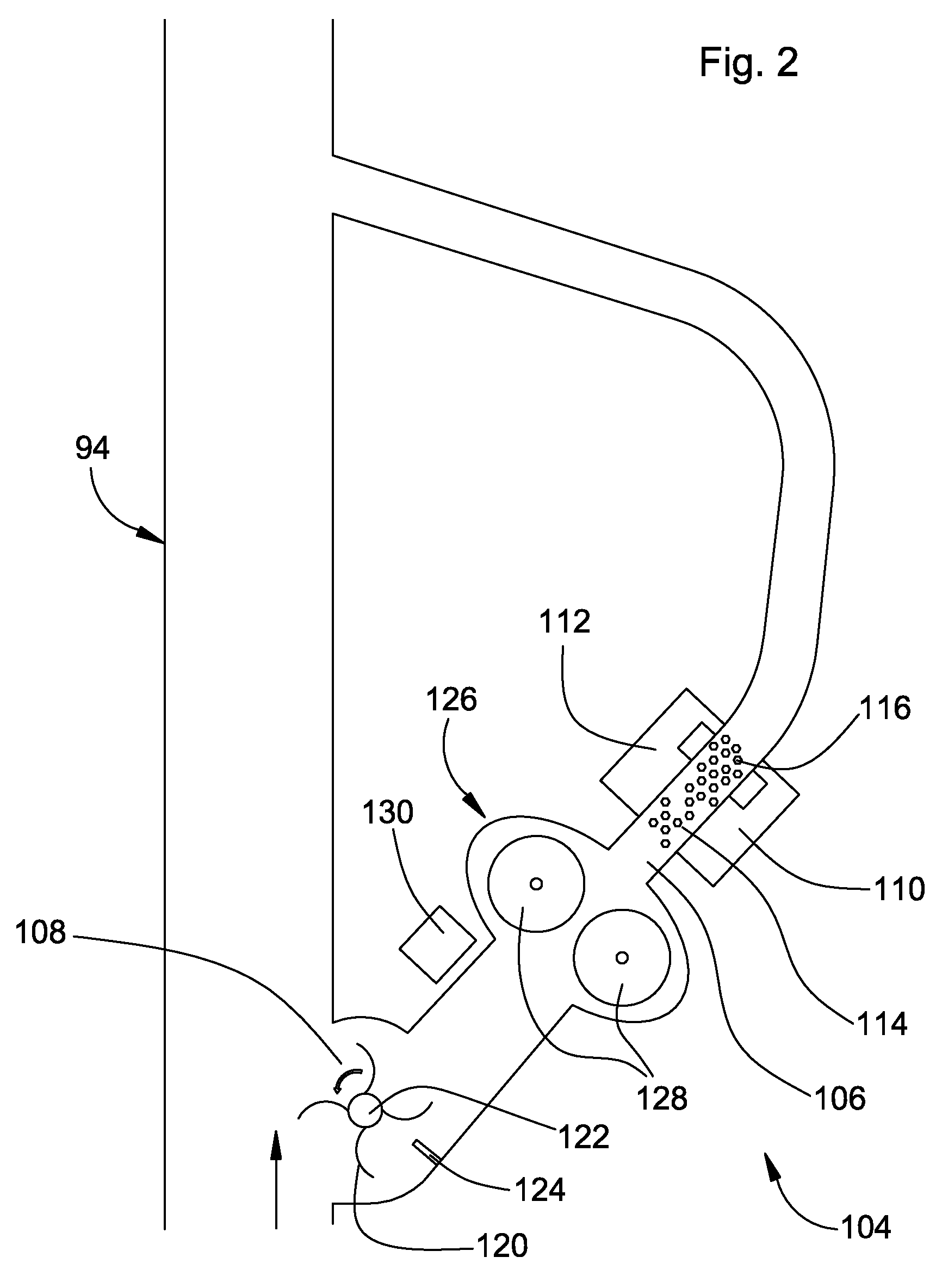

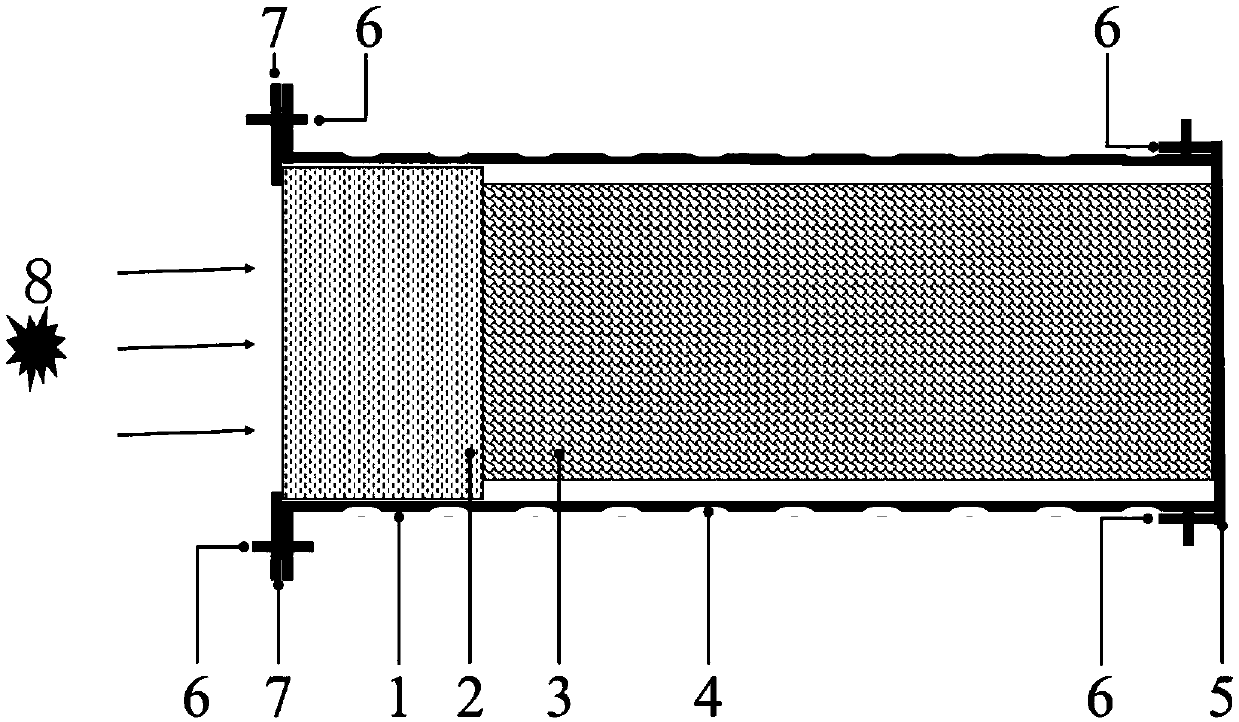

Measuring arrangement for determining the constituents of a sample taken from a crop stream

A measuring arrangement is associated with a branch channel of a channel through which crops flow. The measuring arrangement comprises a measuring device for detecting the constituents of a sample of a crop stream in the branch channel, where in the branch channel between an opening and the measuring device, a processing device is arranged for reducing in size or for squeezing the sample.

Owner:DEERE & CO

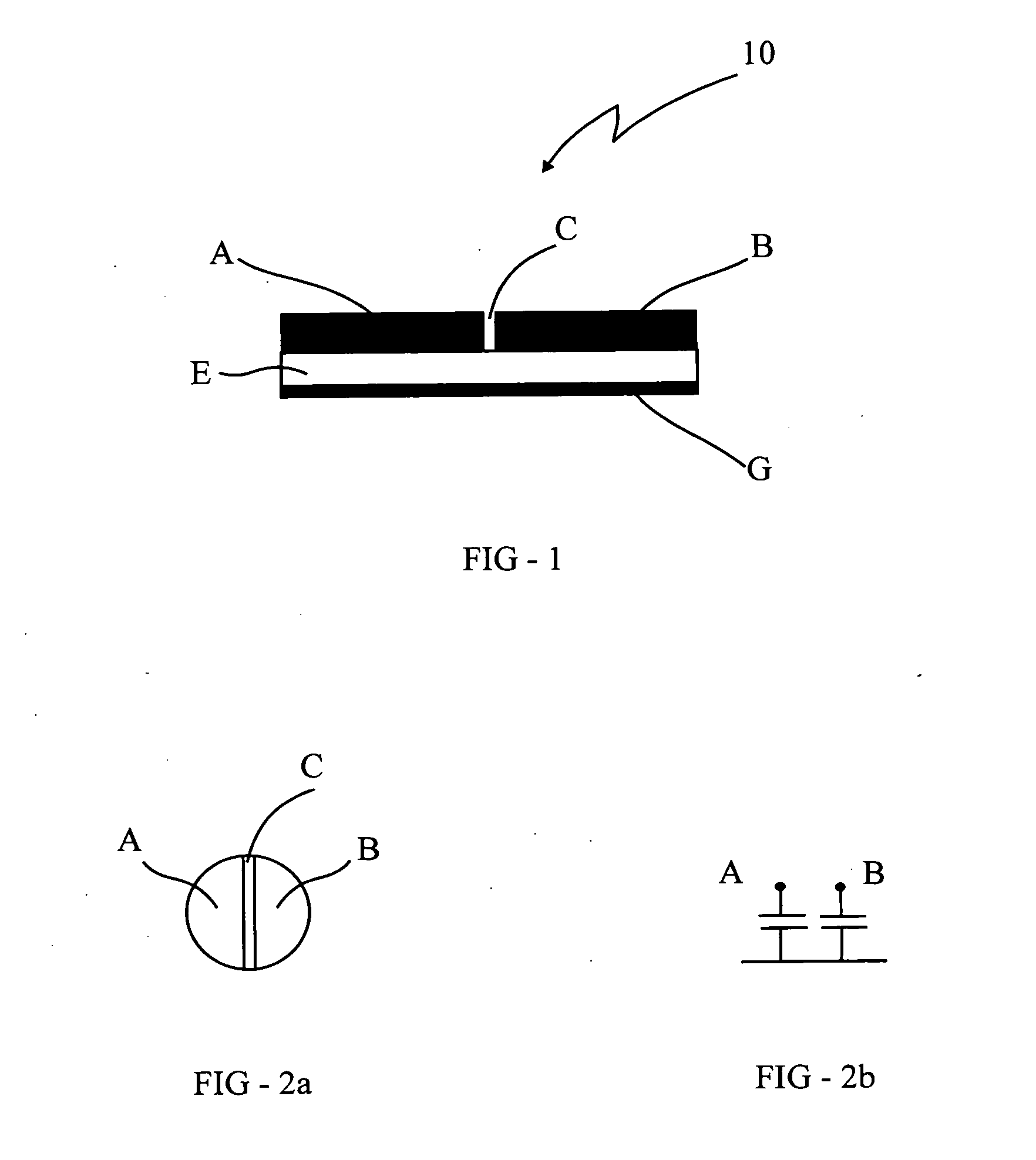

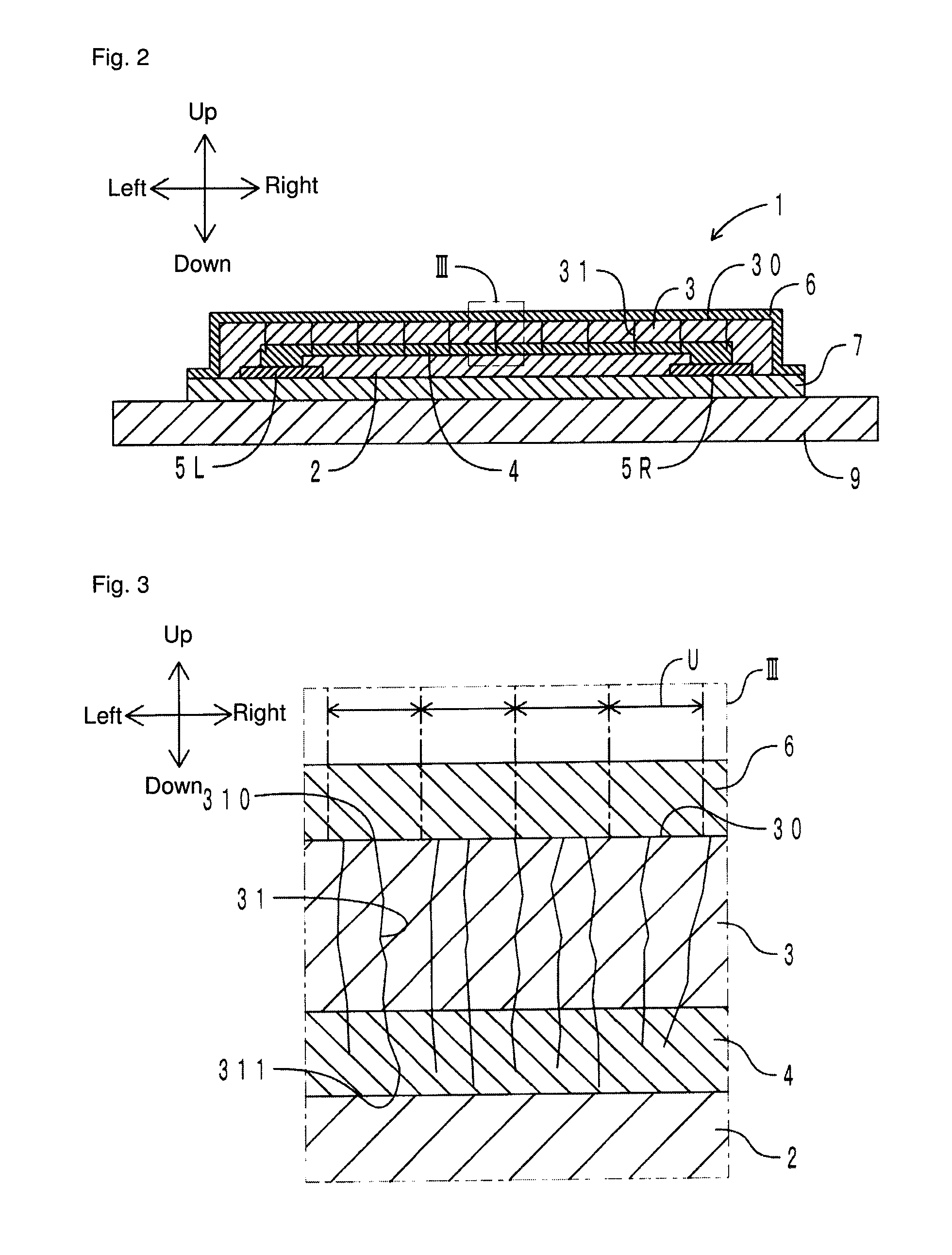

Bending sensor

ActiveUS20130133435A1High sensitivityLimited variation in sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesForce measurement by permanent gauge deformationElectrical resistance and conductanceHigh resistance

A bending sensor includes a high resistance layer; a low resistance layer having a crack and a lower electrical resistance than the high resistance layer in a state where the crack is closed; an insulating layer between the high and low resistance layers; and a plurality of electrode portions connecting electrically in parallel the high resistance and low resistance layers. In an OFF state where a bend amount is small, the crack is unlikely to open and a combined resistance of electrical resistances of the high resistance layer and the low resistance layer is output as OFF resistance from the plurality of electrode portions. In an ON state where the bend amount is large, the crack is likely to open and at least the electrical resistance of the high resistance layer is output as ON resistance higher than the OFF resistance from the plurality of electrode portions.

Owner:SUMITOMO RIKO CO LTD

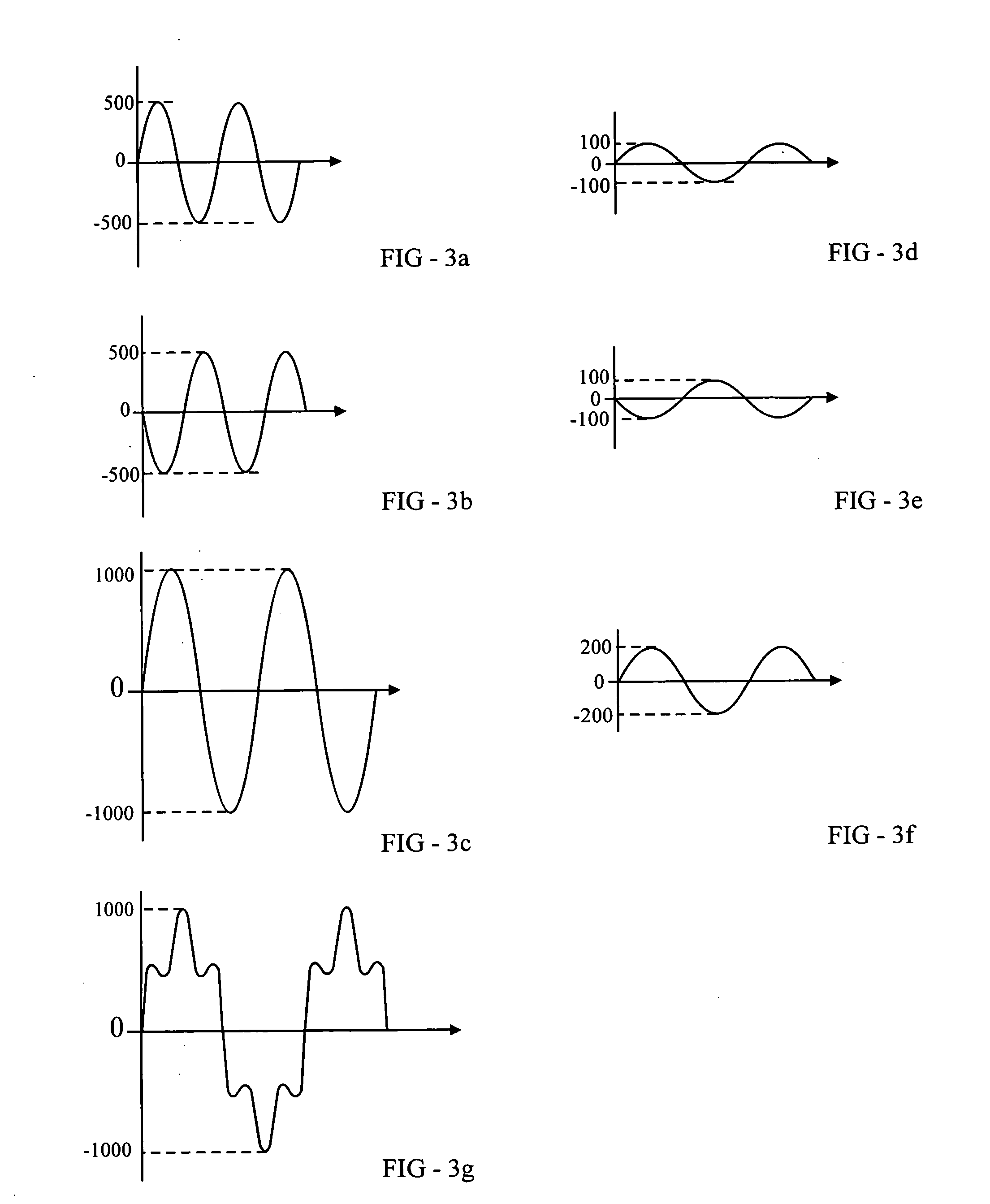

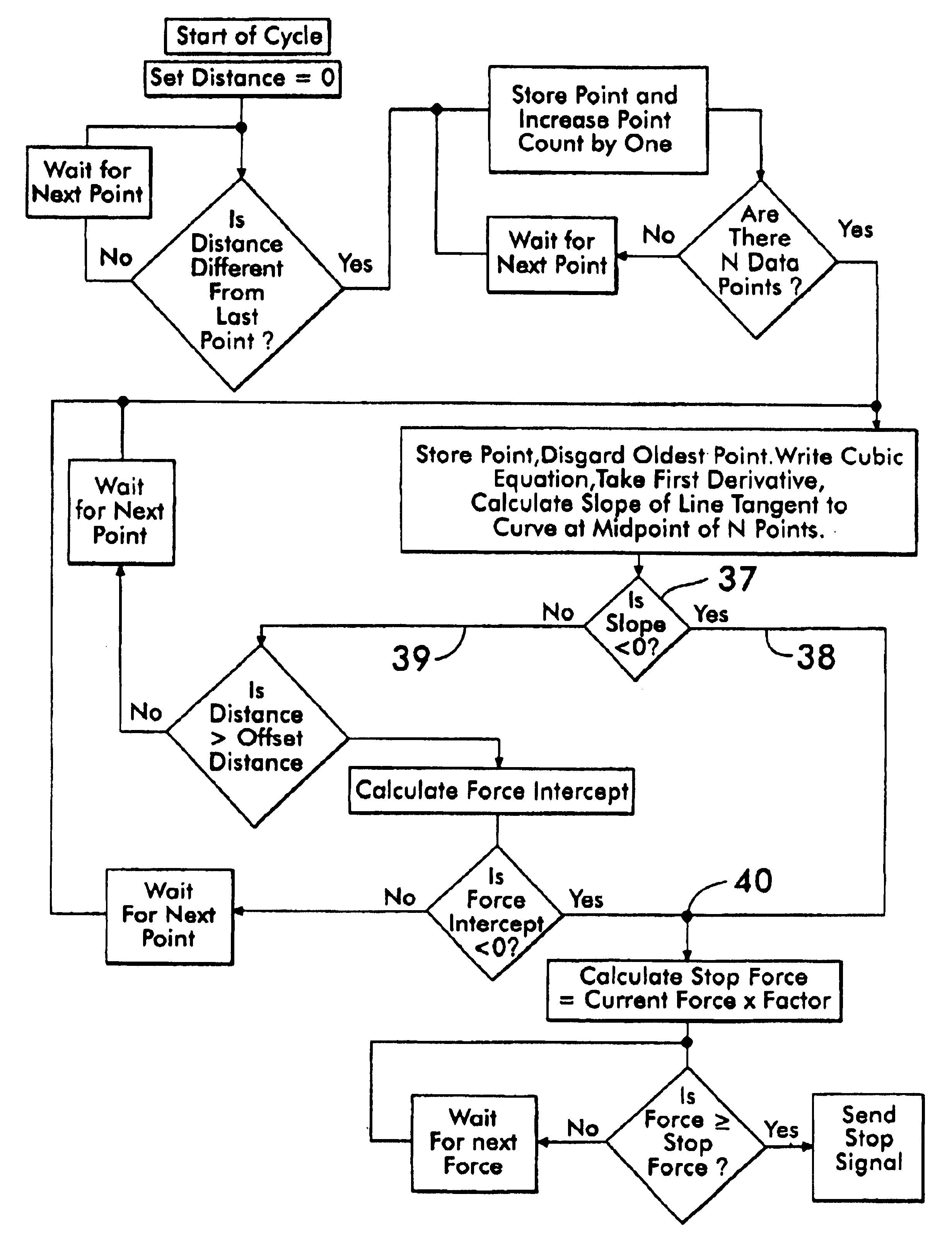

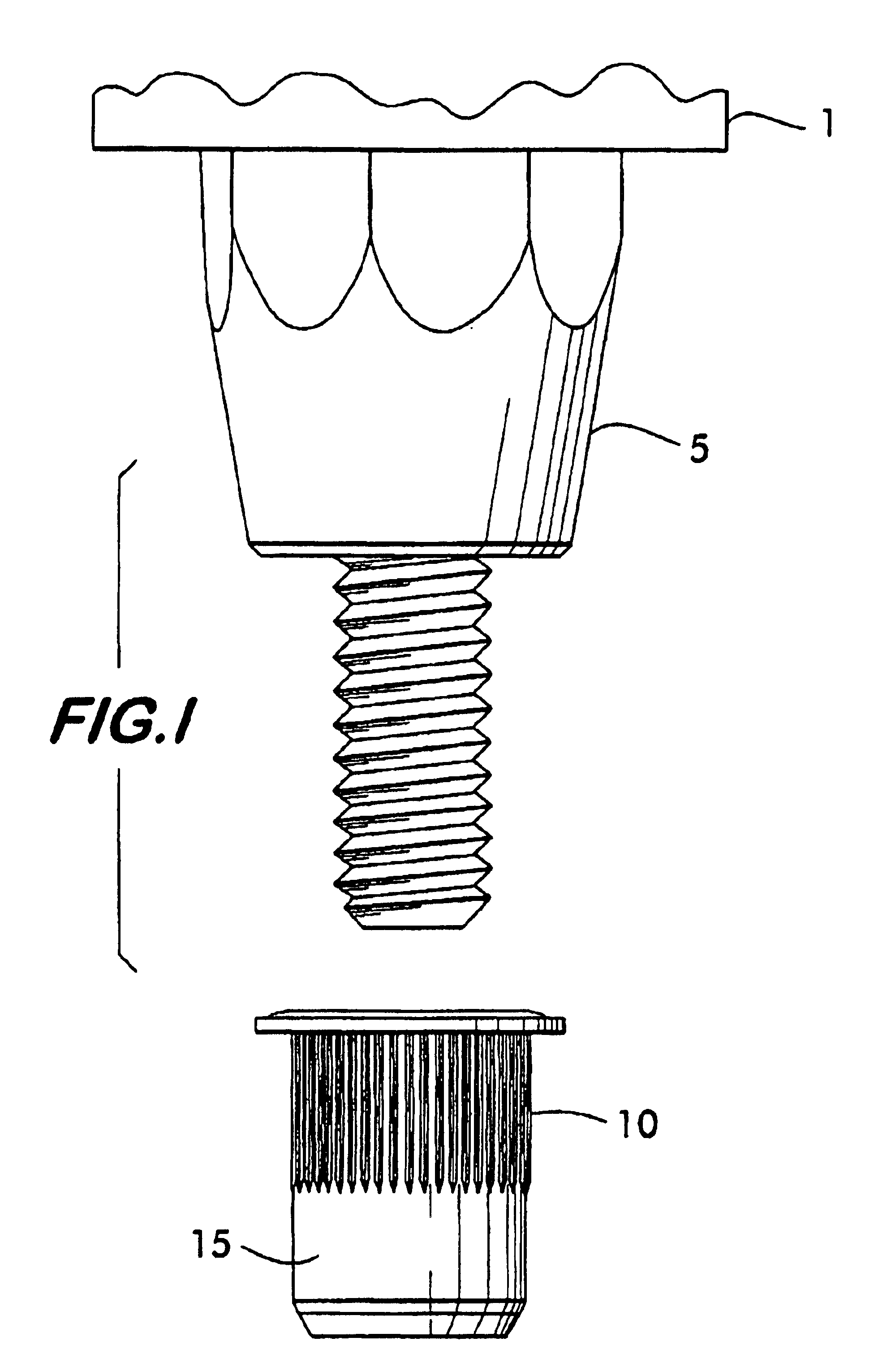

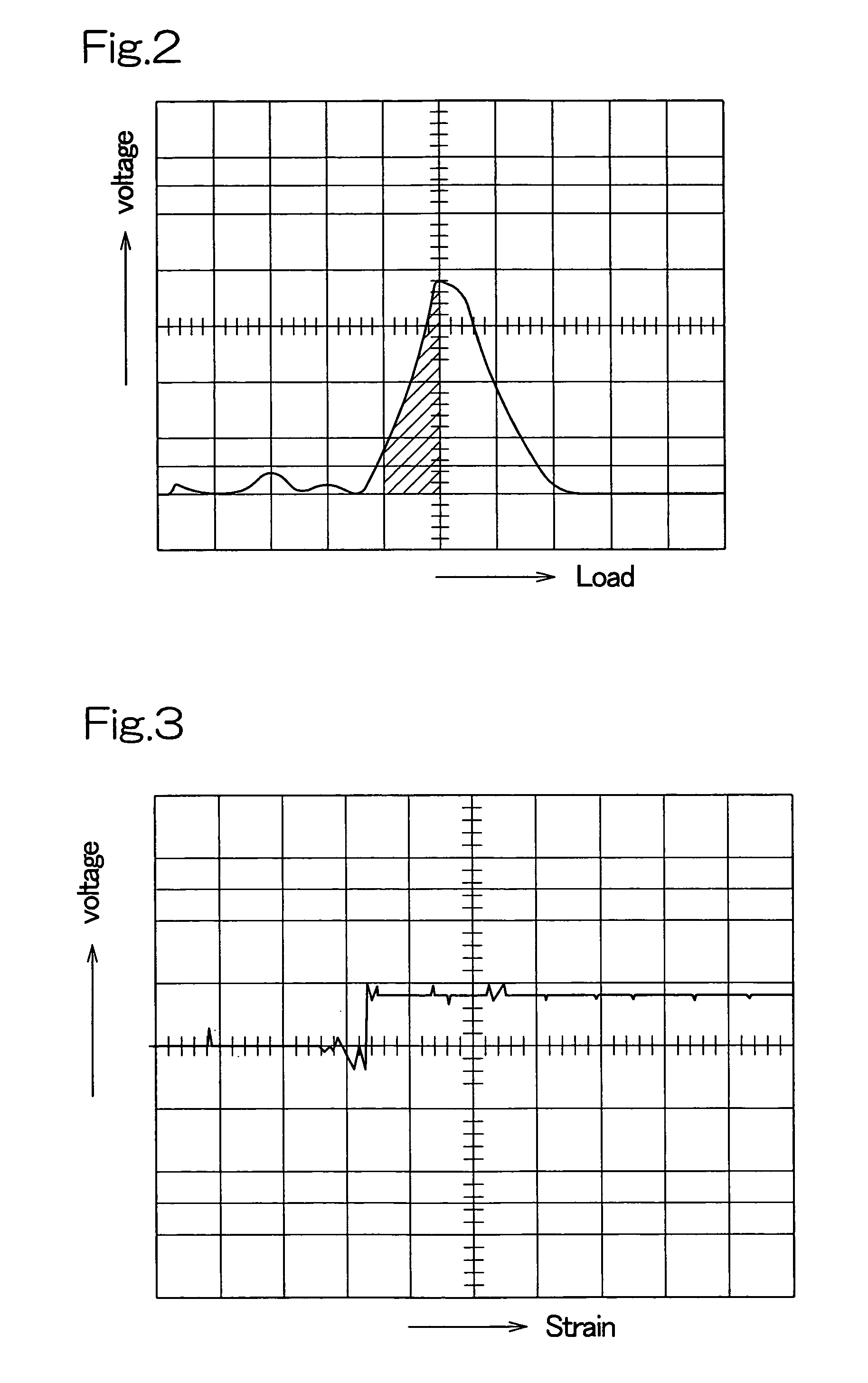

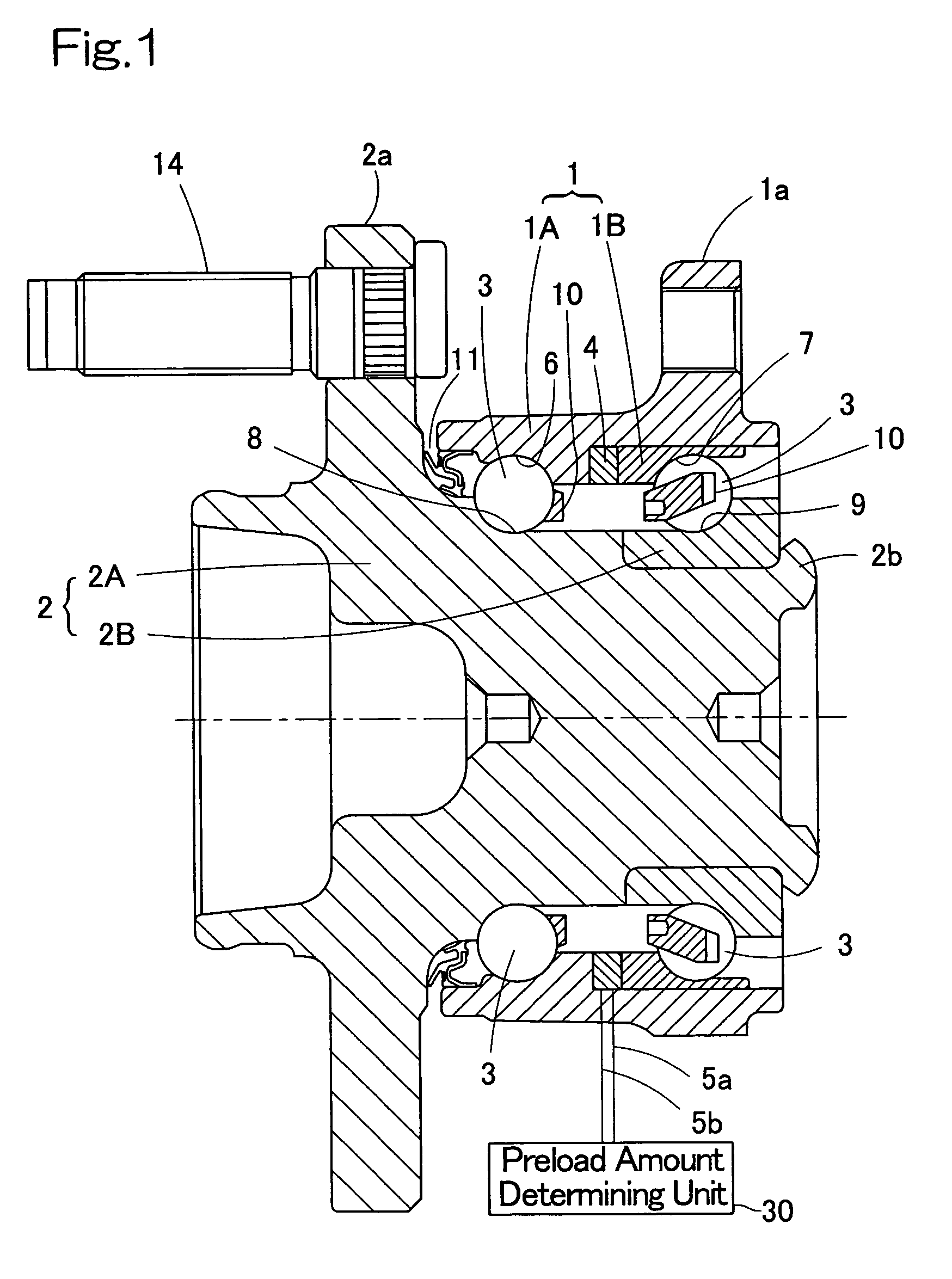

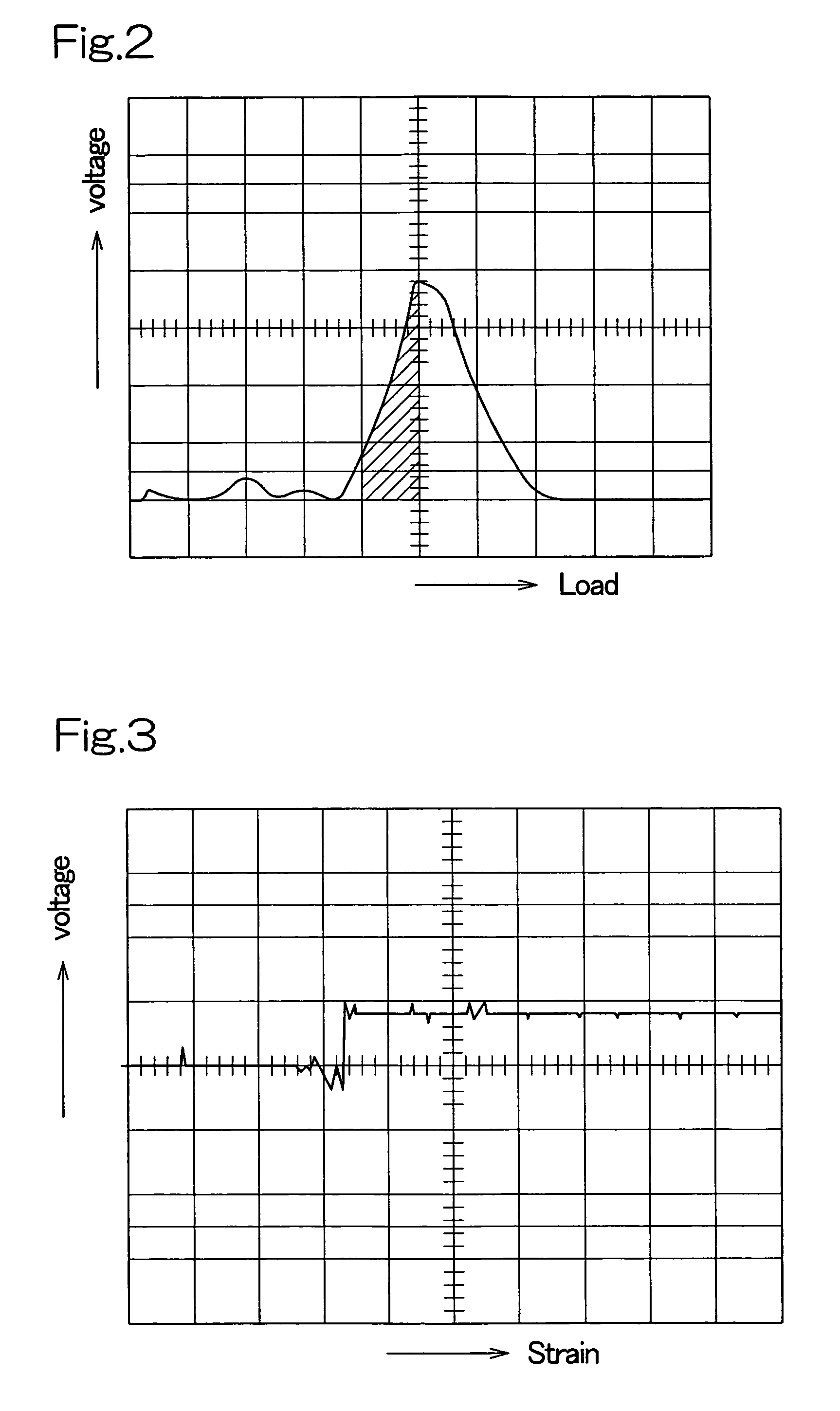

Method for installing blind threaded inserts

ActiveUS6851167B2Force measurement by permanent gauge deformationAssembly machinesControl systemEngineering

A spin-pull blind insert tool utilizes a control system that generates a stop signal based on the relationship between the force values and the motion values derived from the action of the tool mandrel. The improved control system utilizes the shape of the force-deformation curve and not just a given pre-set force value or pull distance. Hence, the control system of the present invention does not require any set-up for changes in panel thickness unless the mandrel is also changed to install a different thread size. This control system develops a force-deformation curve as the fastener is being installed. The stop signal is generated when a pre-set deformation point has been exceeded and the shape of the force curve can be characterized by either of two types. For either type, an algorithm is followed which establishes an optimum stopping point for the installation tool regardless of the panel thickness into which the blind rivet is being installed.

Owner:PEM MANAGEMENT INC

Bending sensor

ActiveUS8931351B2High sensitivityLimited variation in sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesForce measurement by permanent gauge deformationElectrical resistance and conductanceHigh resistance

A bending sensor includes a high resistance layer; a low resistance layer having a crack and a lower electrical resistance than the high resistance layer in a state where the crack is closed; an insulating layer between the high and low resistance layers; and a plurality of electrode portions connecting electrically in parallel the high resistance and low resistance layers. In an OFF state where a bend amount is small, the crack is unlikely to open and a combined resistance of electrical resistances of the high resistance layer and the low resistance layer is output as OFF resistance from the plurality of electrode portions. In an ON state where the bend amount is large, the crack is likely to open and at least the electrical resistance of the high resistance layer is output as ON resistance higher than the OFF resistance from the plurality of electrode portions.

Owner:SUMITOMO RIKO CO LTD

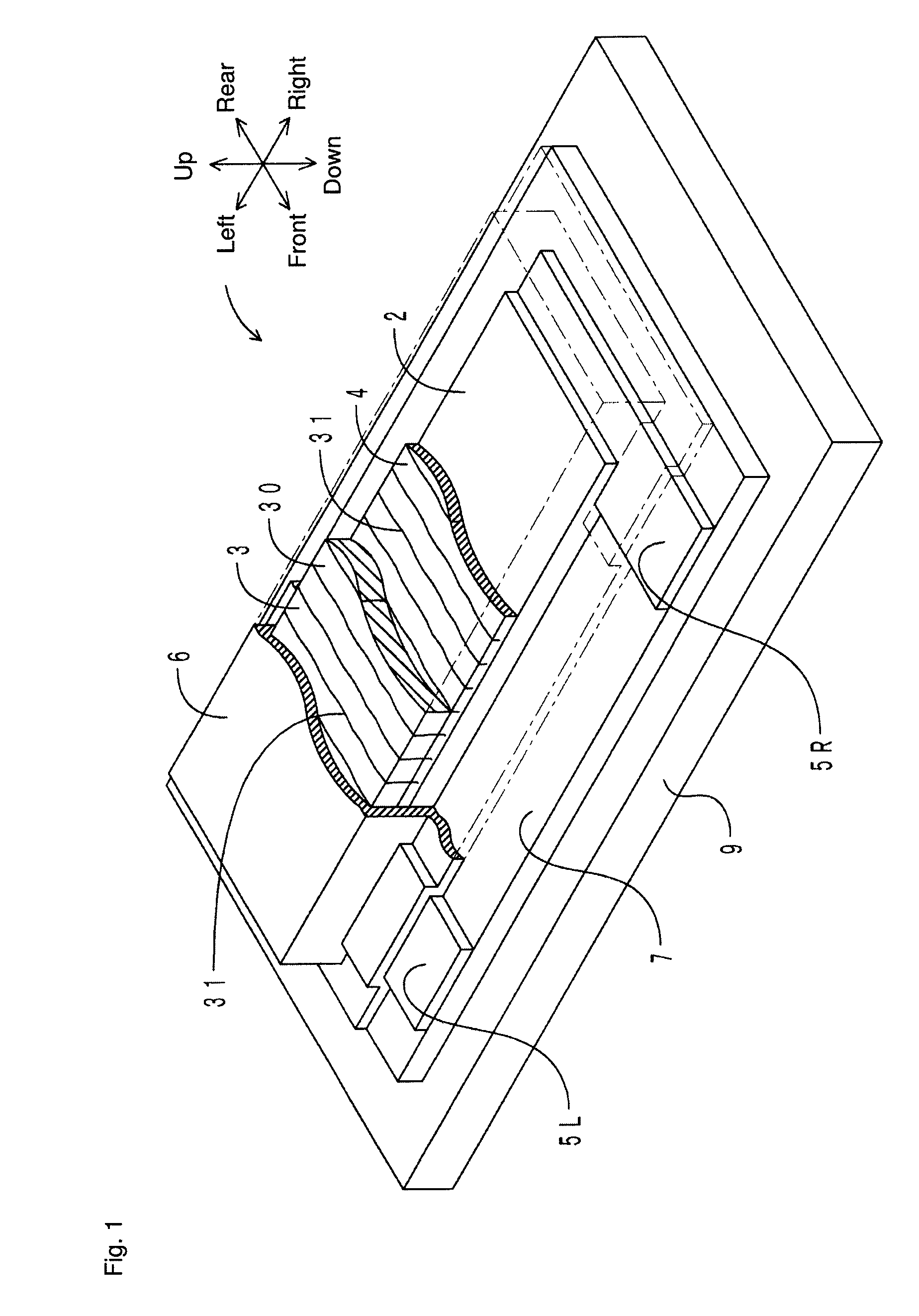

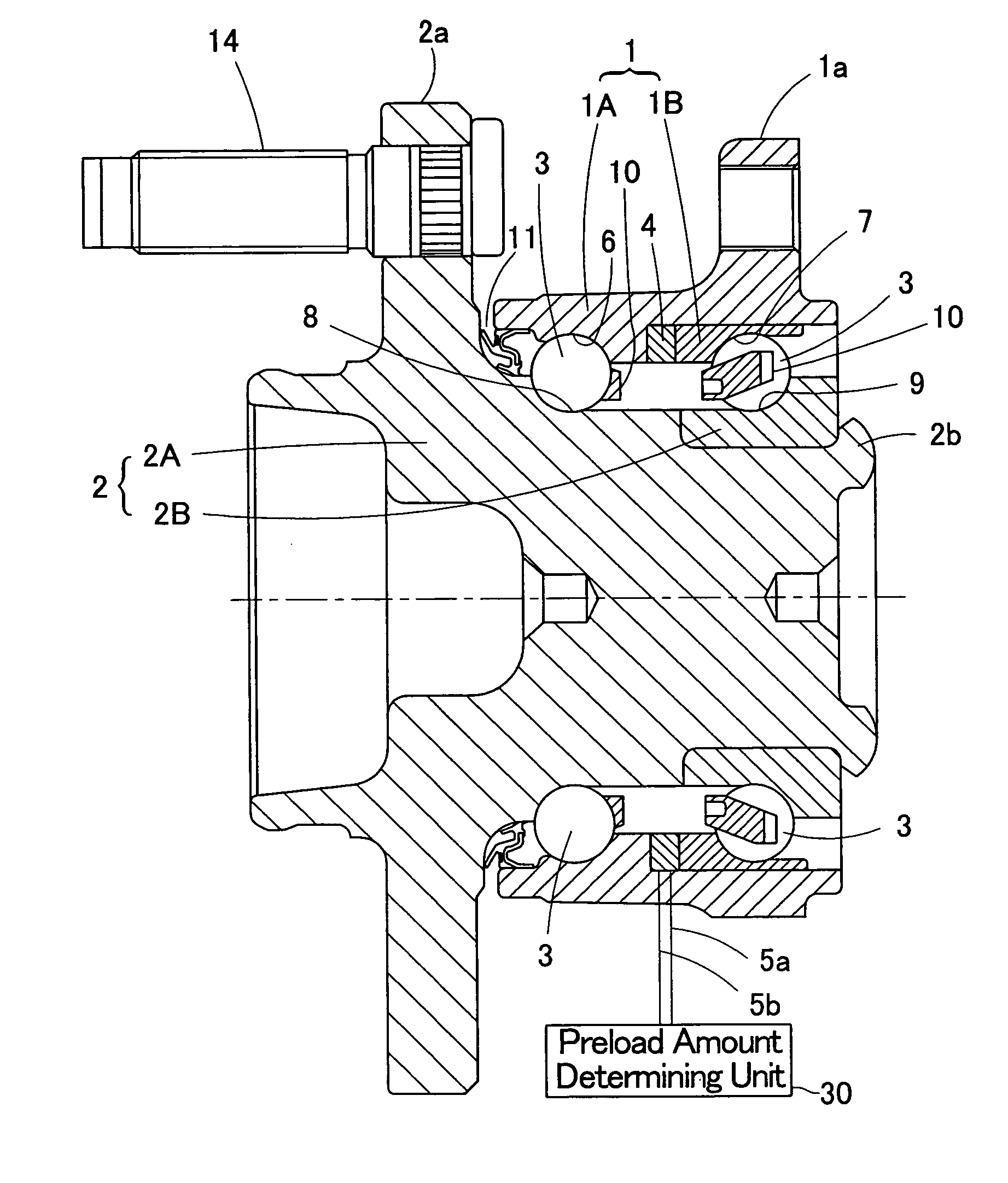

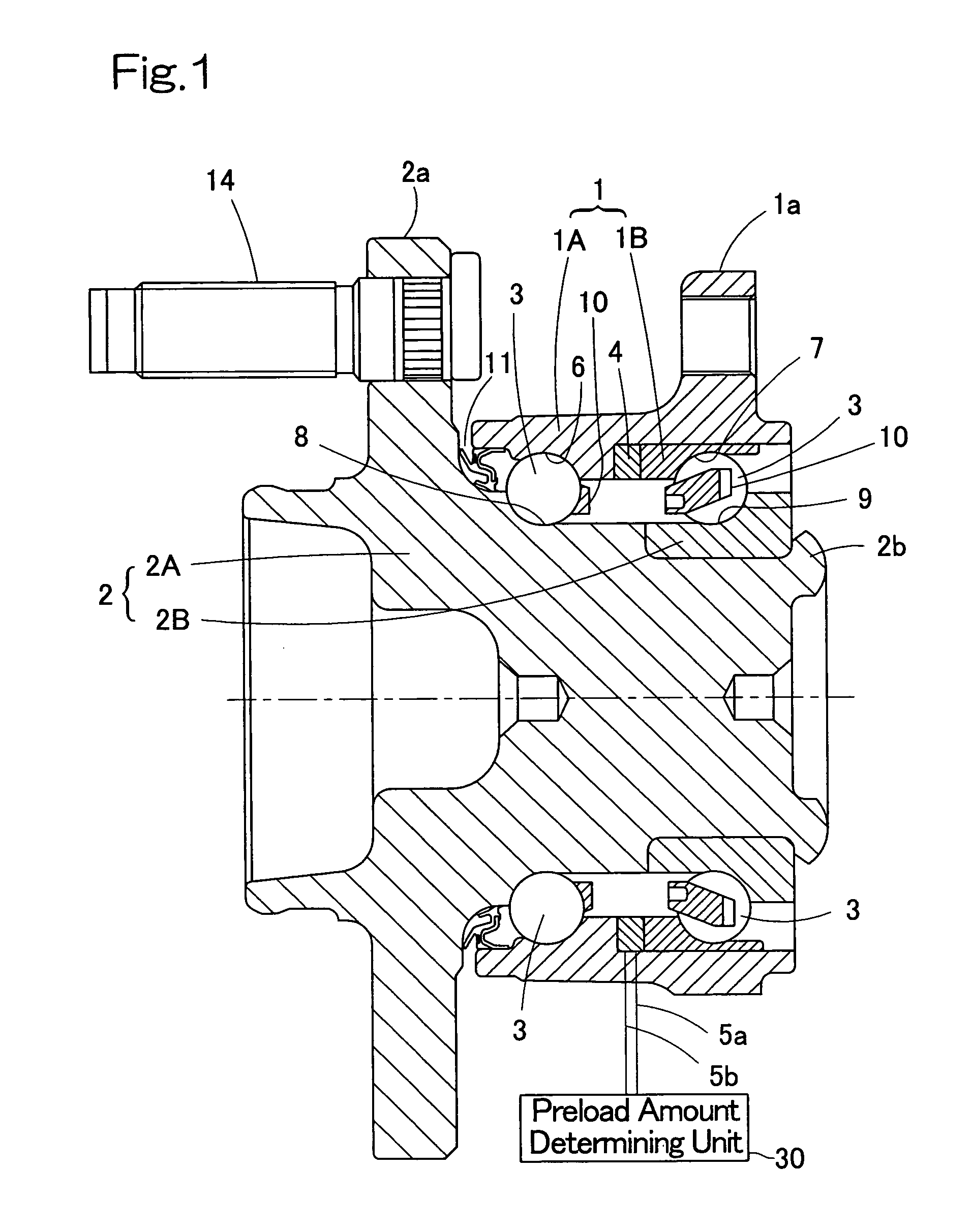

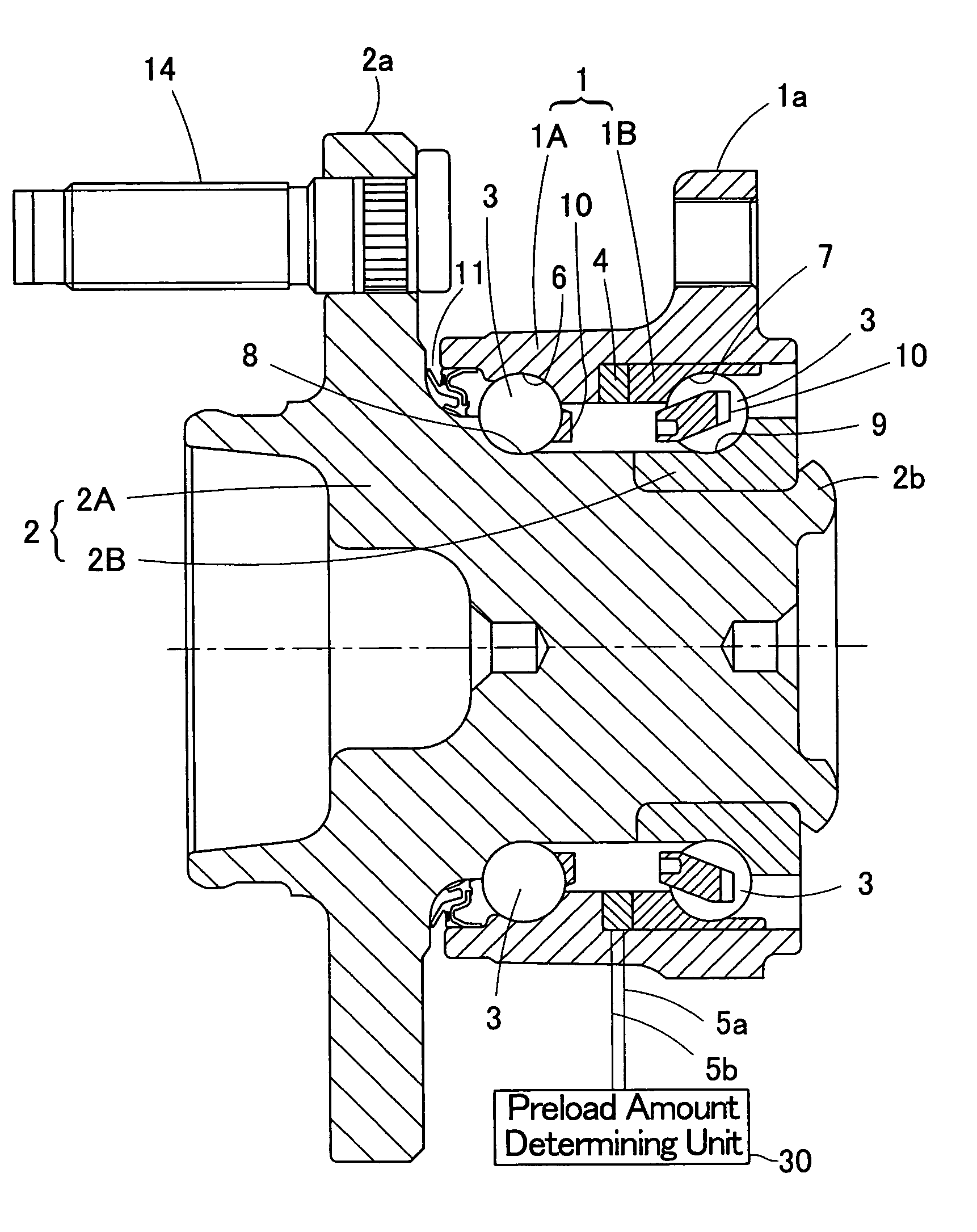

Bearing device for wheel

InactiveUS20070014500A1Suppress mutationSimple to executeRolling contact bearingsBearing assemblyEngineeringFlange

To provide a bearing device for a wheel, in which a preload control is easy and a uniform amount of preload can be applied with a bearing seal being mounted, the bearing device for the wheel includes an outer member, an inner member and double rows of rolling elements interposed between the outer member and the inner member. The outer member has a flange on an outer periphery thereof and also has an inner periphery formed with two rolling surfaces. The inner member is formed with rolling surfaces opposed to the rolling surfaces of the outer member. The double rows of the rolling elements are interposed between the rolling surfaces of the outer member and the inner member. A sensor for detecting the amount of preload of the bearing is provided in one of the outer and inner members.

Owner:NTN CORP

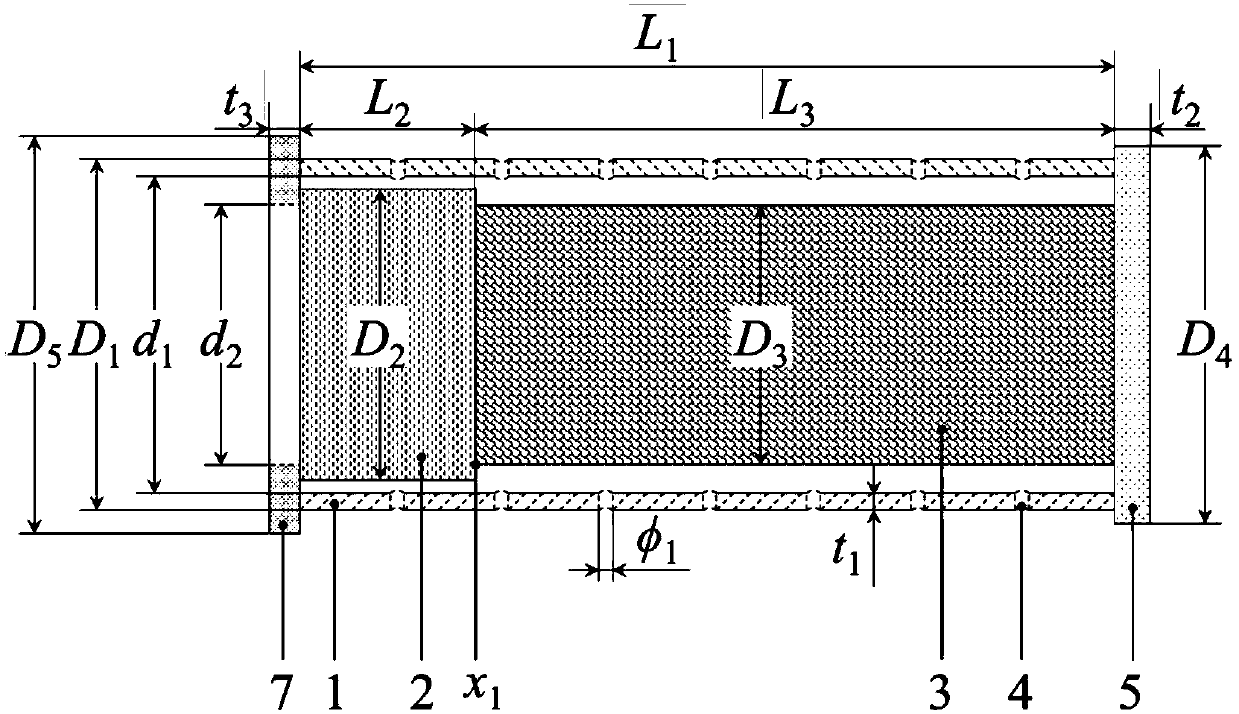

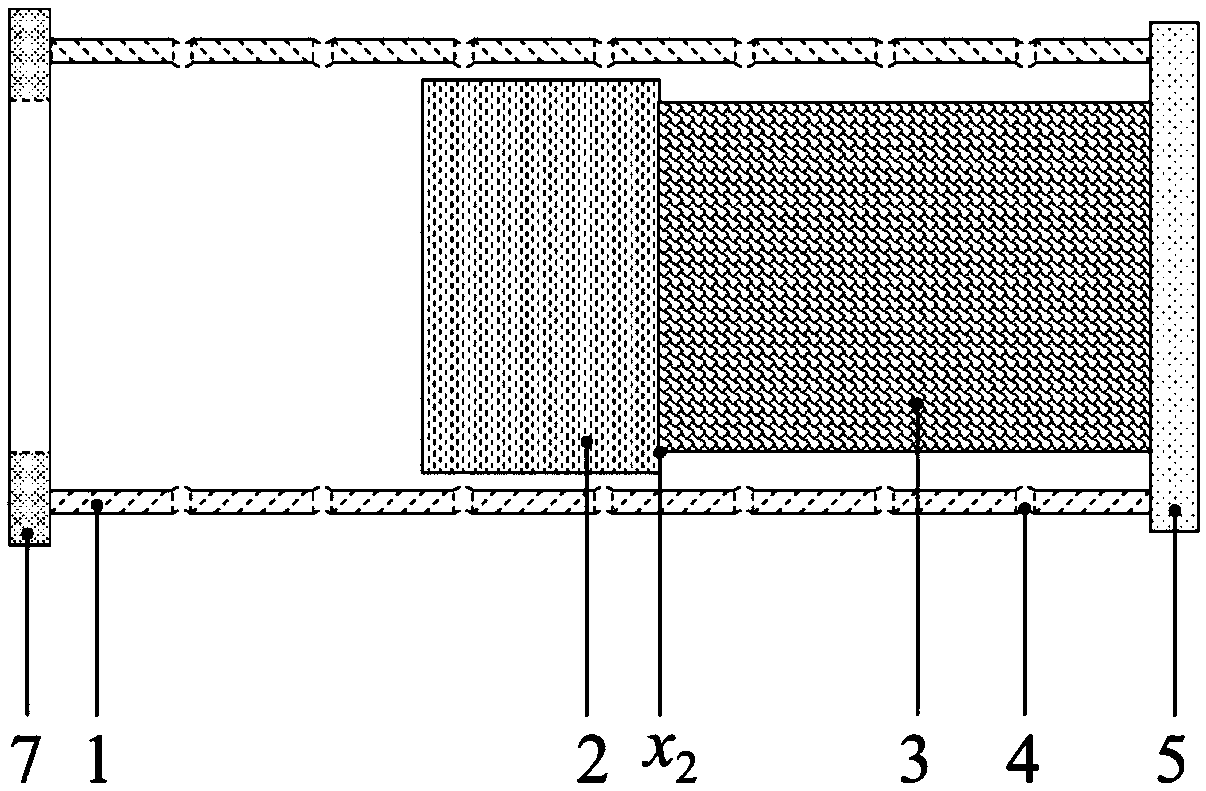

Passive sensor device for measuring shock wave energy based on combined aluminum honeycomb

ActiveCN109682525AHigh strengthImprove responsivenessForce measurement by permanent gauge deformationMeasurement of explosion forceResponse sensitivityShock wave

The invention discloses a passive sensor device for measuring shock wave energy based on a combined aluminum honeycomb, which consists of a packaging shell, a driving slide block, a combined aluminumhoneycomb energy absorbing element, a fixed wall stop plate, a moving bolt and a sealing baffle ring. And the driving slide block moves in the packaging shell under the action of the shock wave to compress the combined aluminum honeycomb energy absorbing element, and the combined aluminum honeycomb energy absorbing element generates plastic unrecoverable deformation. The shock wave energy acting on the driving slide block can be obtained by measuring the plastic deformation displacement on the combined aluminum honeycomb energy absorbing element caused by the driving slide block and utilizingthe relationship between the plastic deformation displacement and the absorbed energy. The combined aluminum honeycomb energy absorbing element has the advantages of simple structure, no need of powersupply, convenient arrangement and use, low cost and reusability, and the response sensitivity of the combined aluminum honeycomb energy absorbing element to lower shock waves is high, so that the technical problem that the shock wave energy is difficult to quantitatively test under partial severe environments can be solved.

Owner:NAT UNIV OF DEFENSE TECH

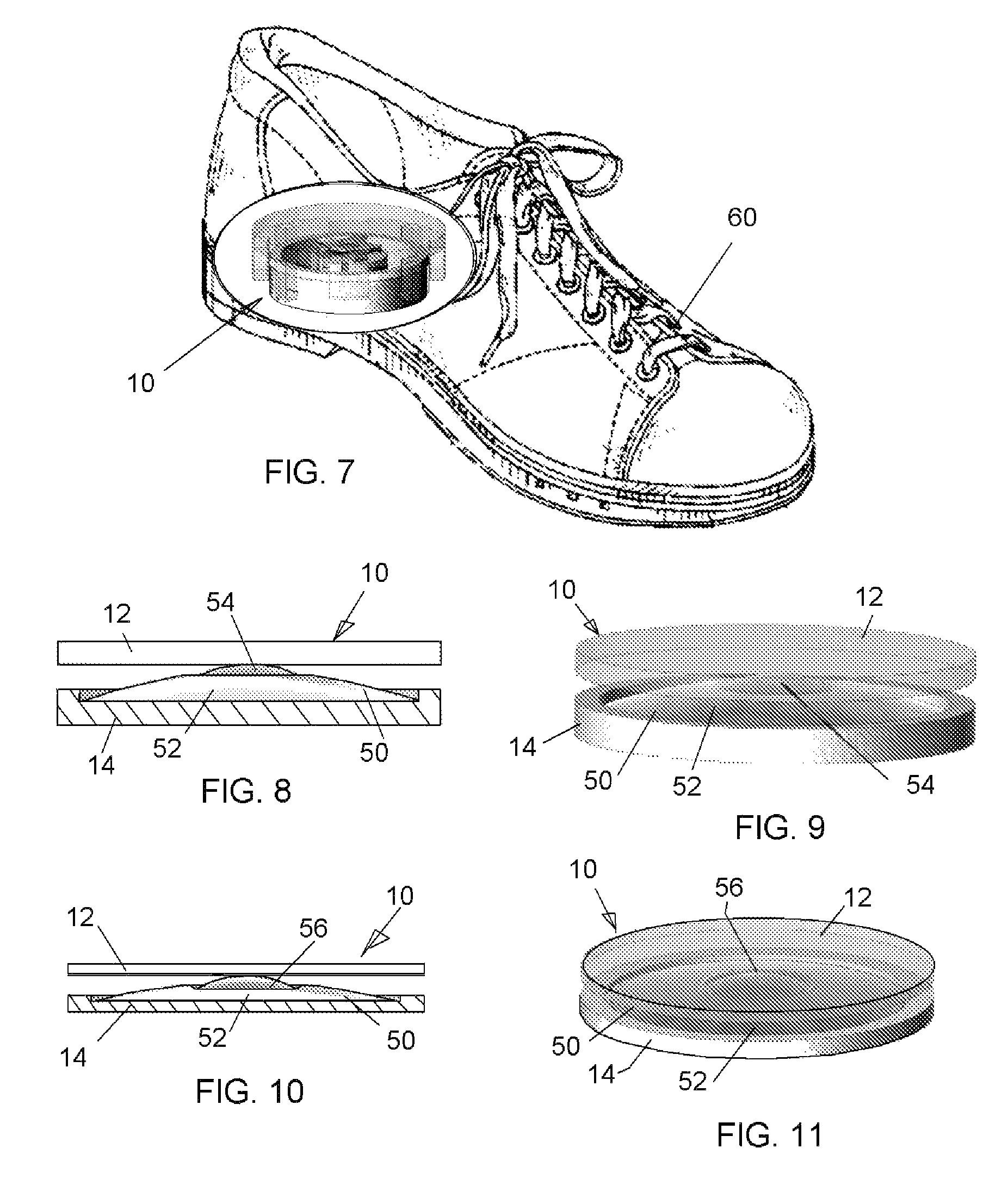

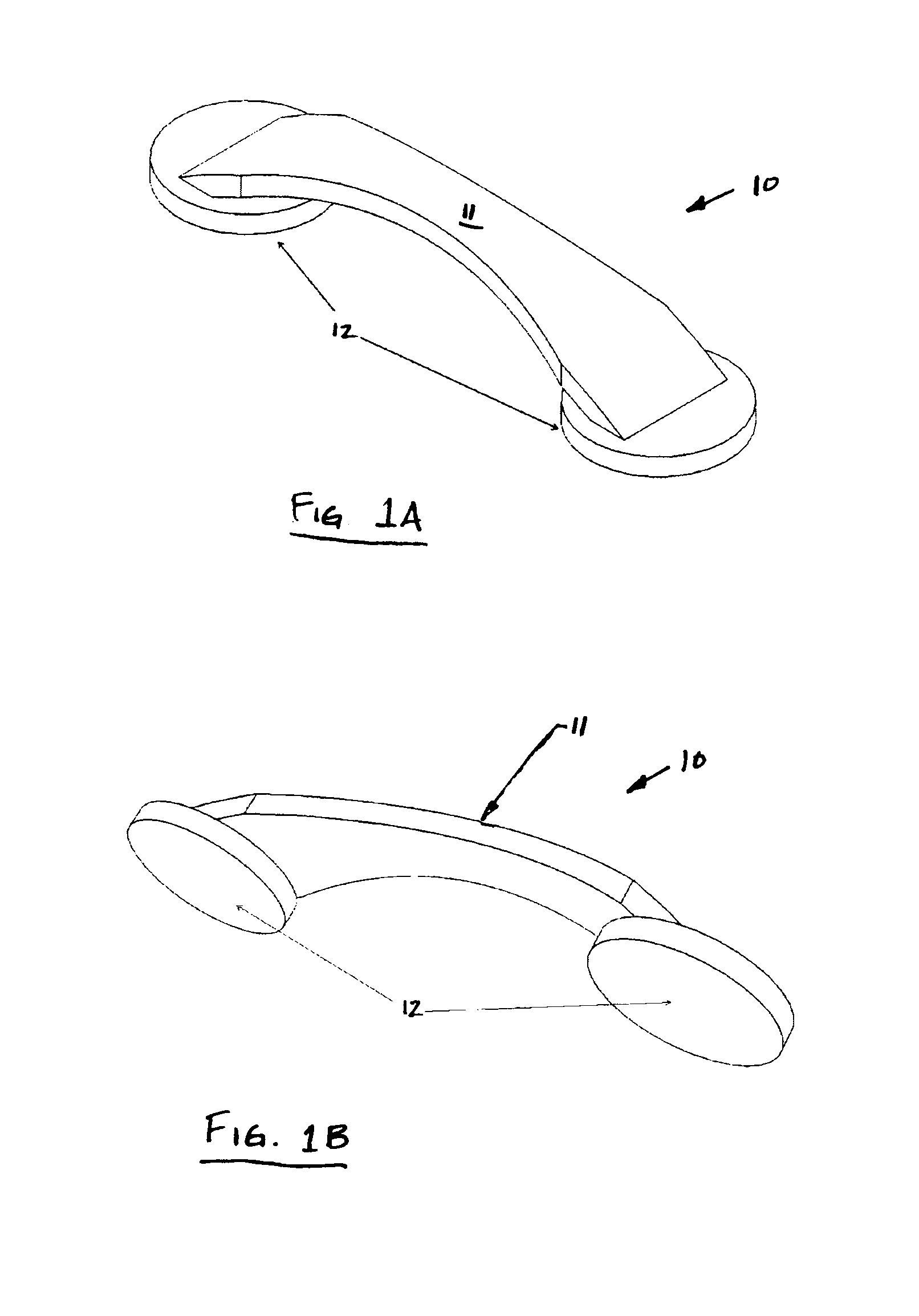

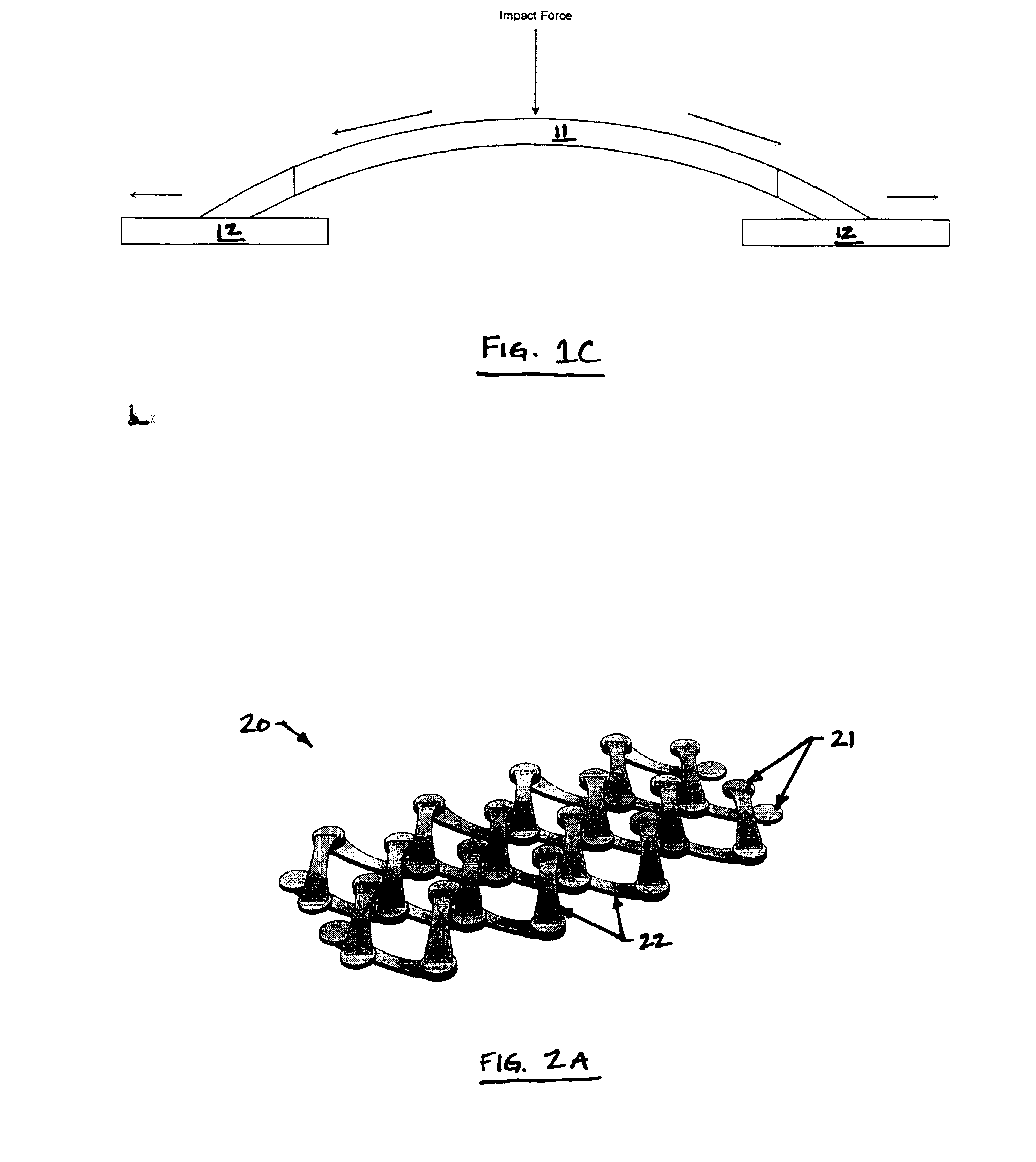

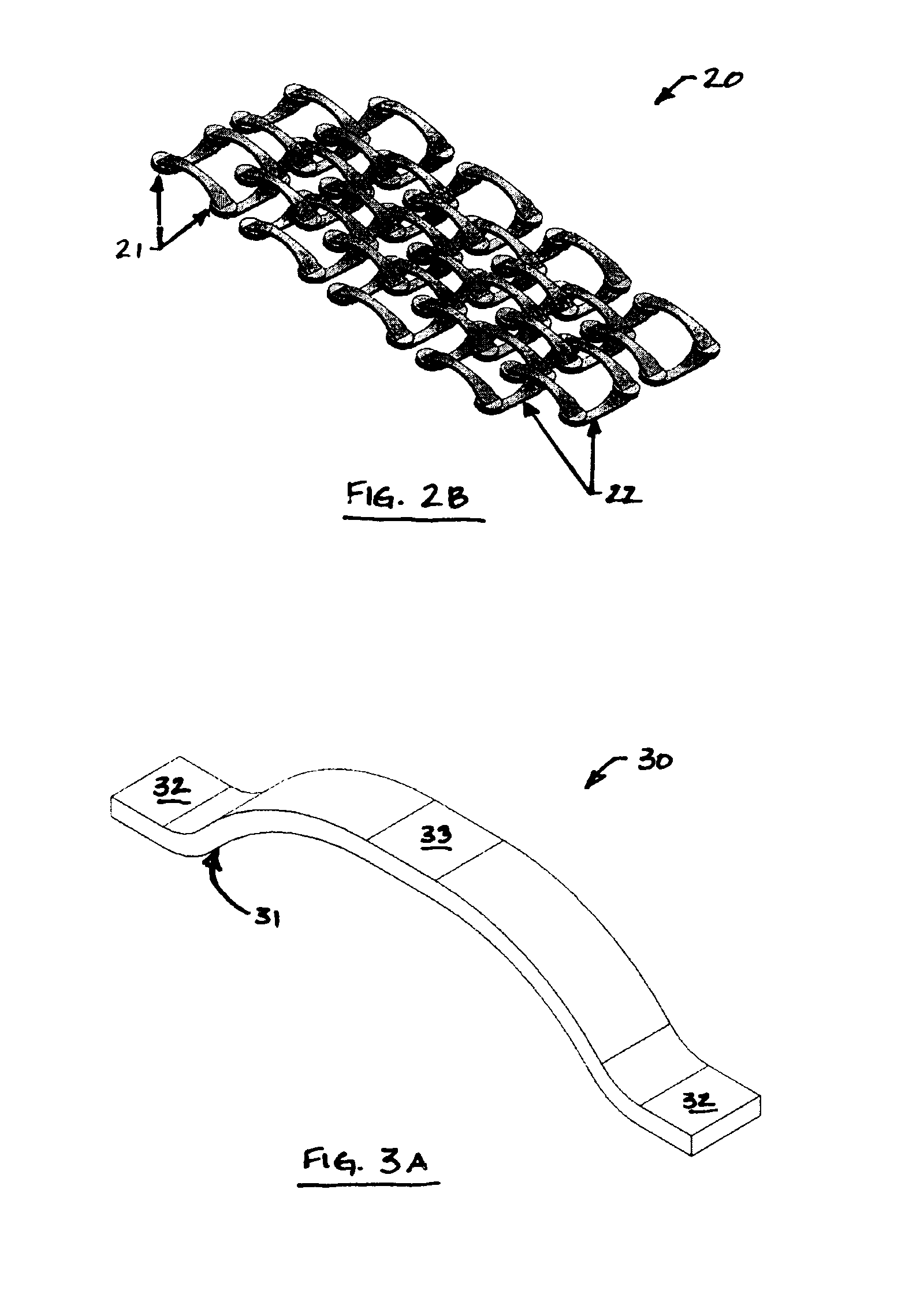

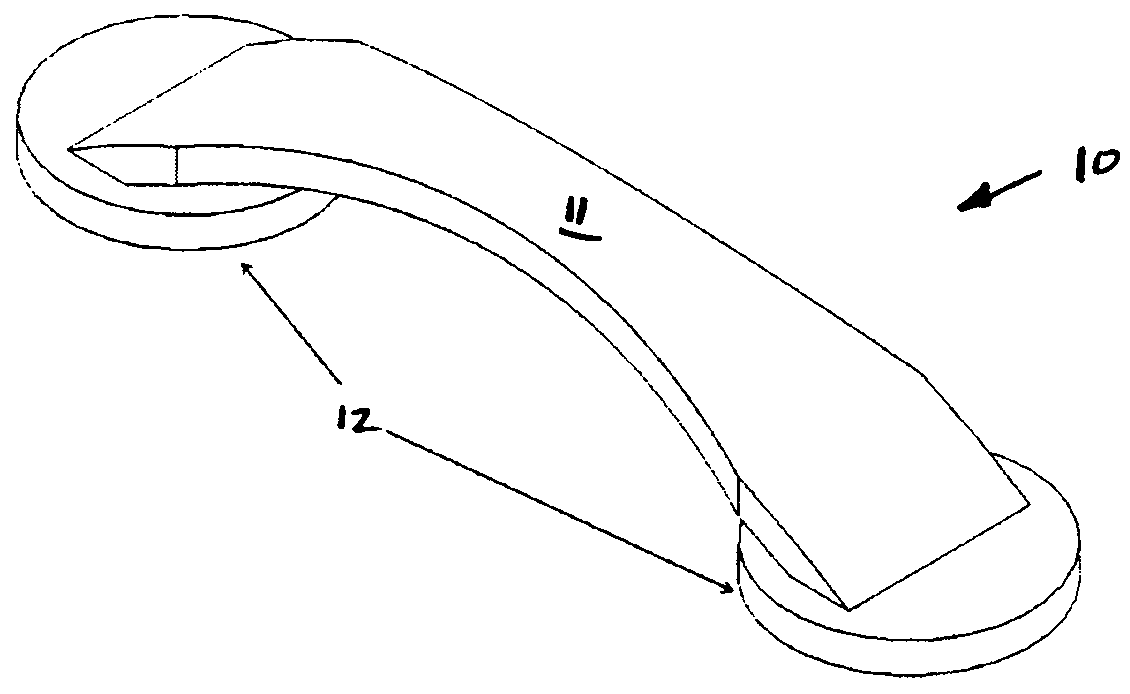

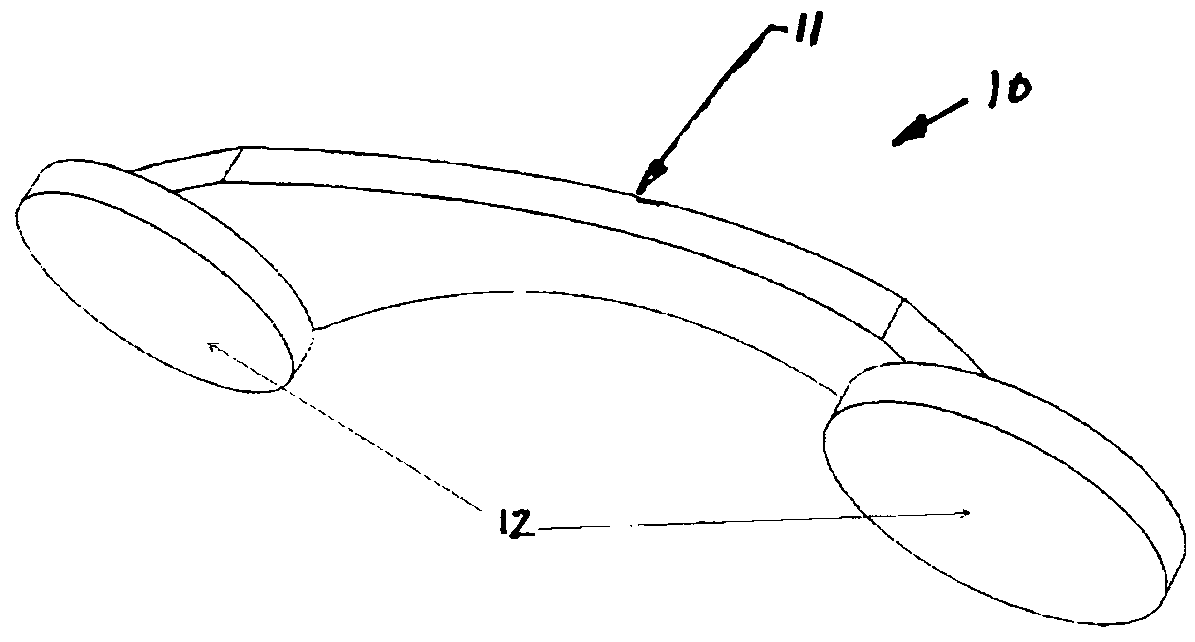

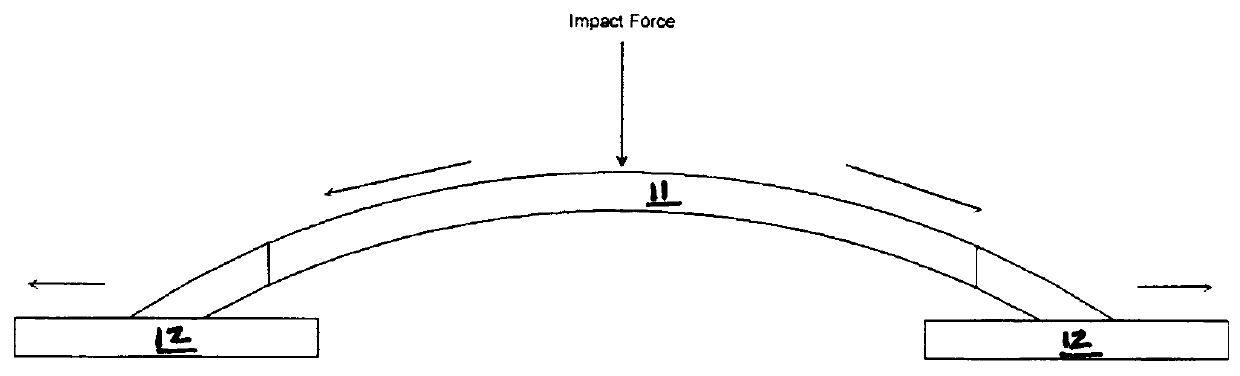

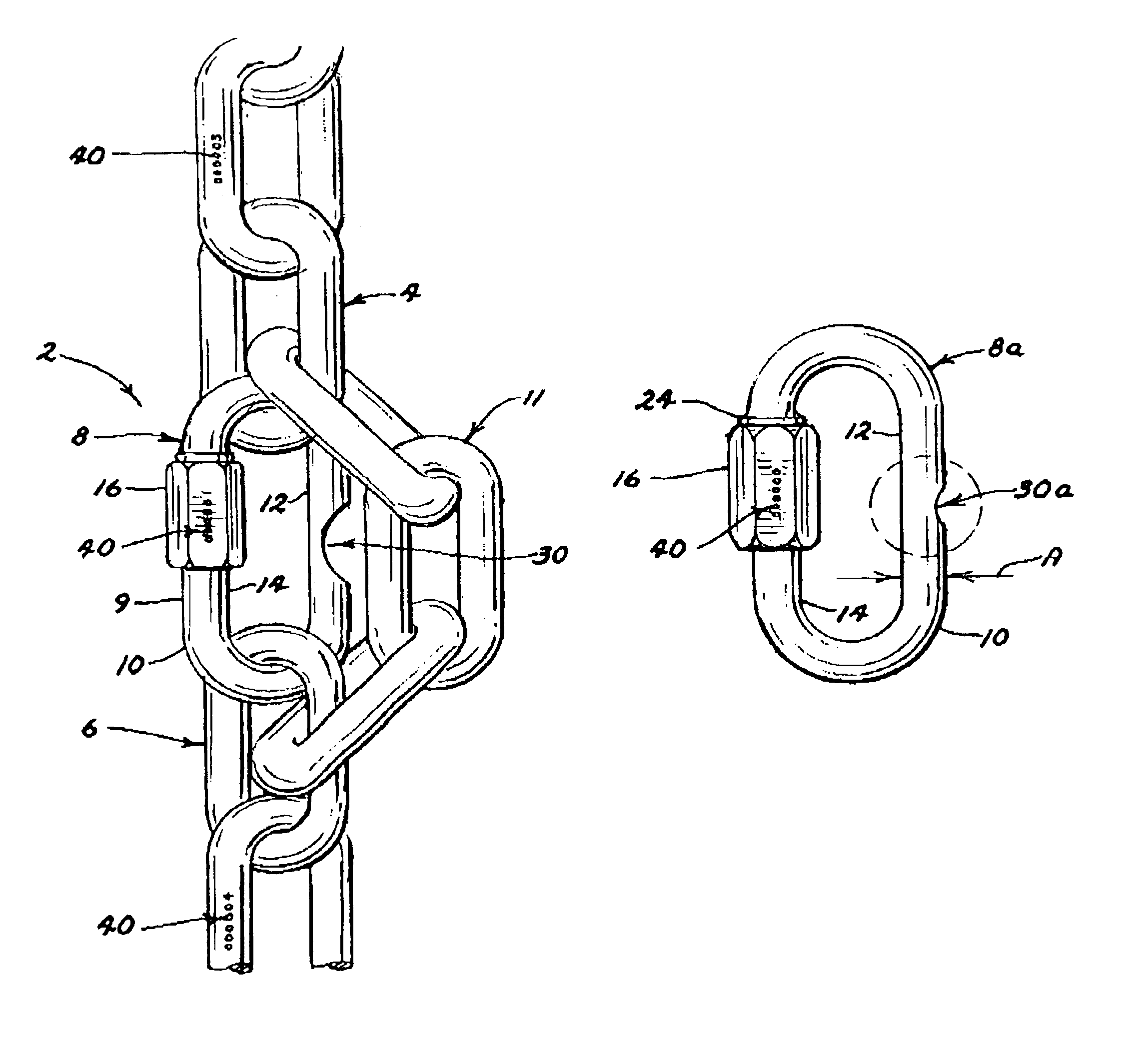

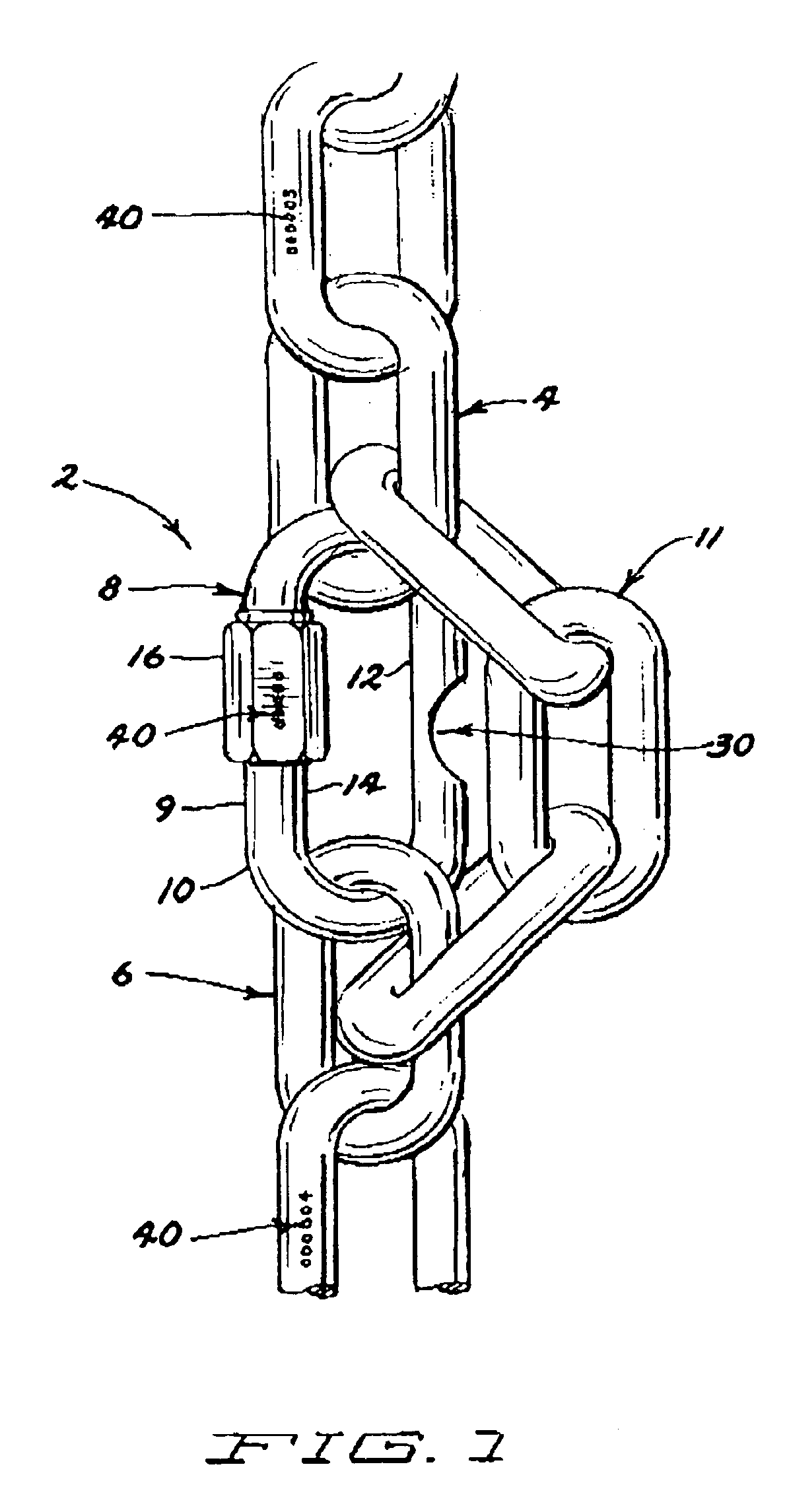

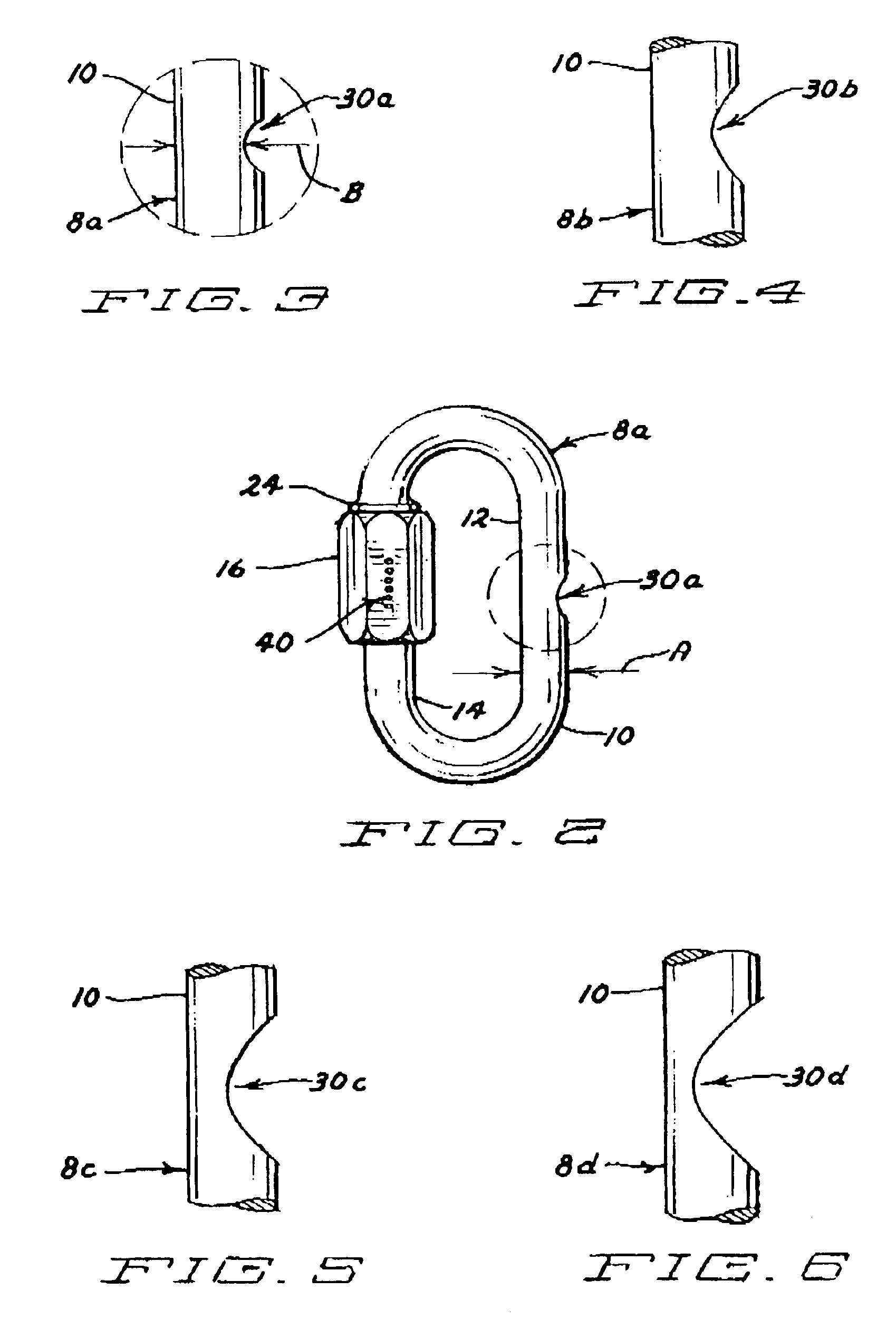

Impact Deflection, Absorption and Sensing Device and System

The present invention is directed to an impact absorption and detection system, including: one or more deflectable arch springs, having at least one leg with proximal and distal ends; and one or more bases, each of the proximal and distal ends attached to a base. Some embodiments may include: a plurality of arch spring assemblies, including: a deflectable arch spring having at least one leg with proximal and distal ends; one or more bases, each of the proximal and distal ends attached to a base; at least one sensor attached to the arch spring assembly; wherein the plurality of arch spring assemblies is configured in a chainmail arrangement and a base of one arch spring assembly is connected with a base of another arch spring assembly; a processor electrically connected to the sensors attached to the plurality of arch spring assemblies; and a data store in communication with the processor.

Owner:CHURCH HILL PUBLISHING

Impact deflection, absorption and sensing device and system

The present invention is directed to an impact absorption and detection system, including: one or more deflectable arch springs, having at least one leg with proximal and distal ends; and one or more bases, each of the proximal and distal ends attached to a base. Some embodiments may include: a plurality of arch spring assemblies, including: a deflectable arch spring having at least one leg with proximal and distal ends; one or more bases, each of the proximal and distal ends attached to a base; at least one sensor attached to the arch spring assembly; wherein the plurality of arch spring assemblies is configured in a chainmail arrangement and a base of one arch spring assembly is connected with a base of another arch spring assembly; a processor electrically connected to the sensors attached to the plurality of arch spring assemblies; and a data store in communication with the processor.

Owner:CHURCH HILL PUBLISHING

Fall detection system

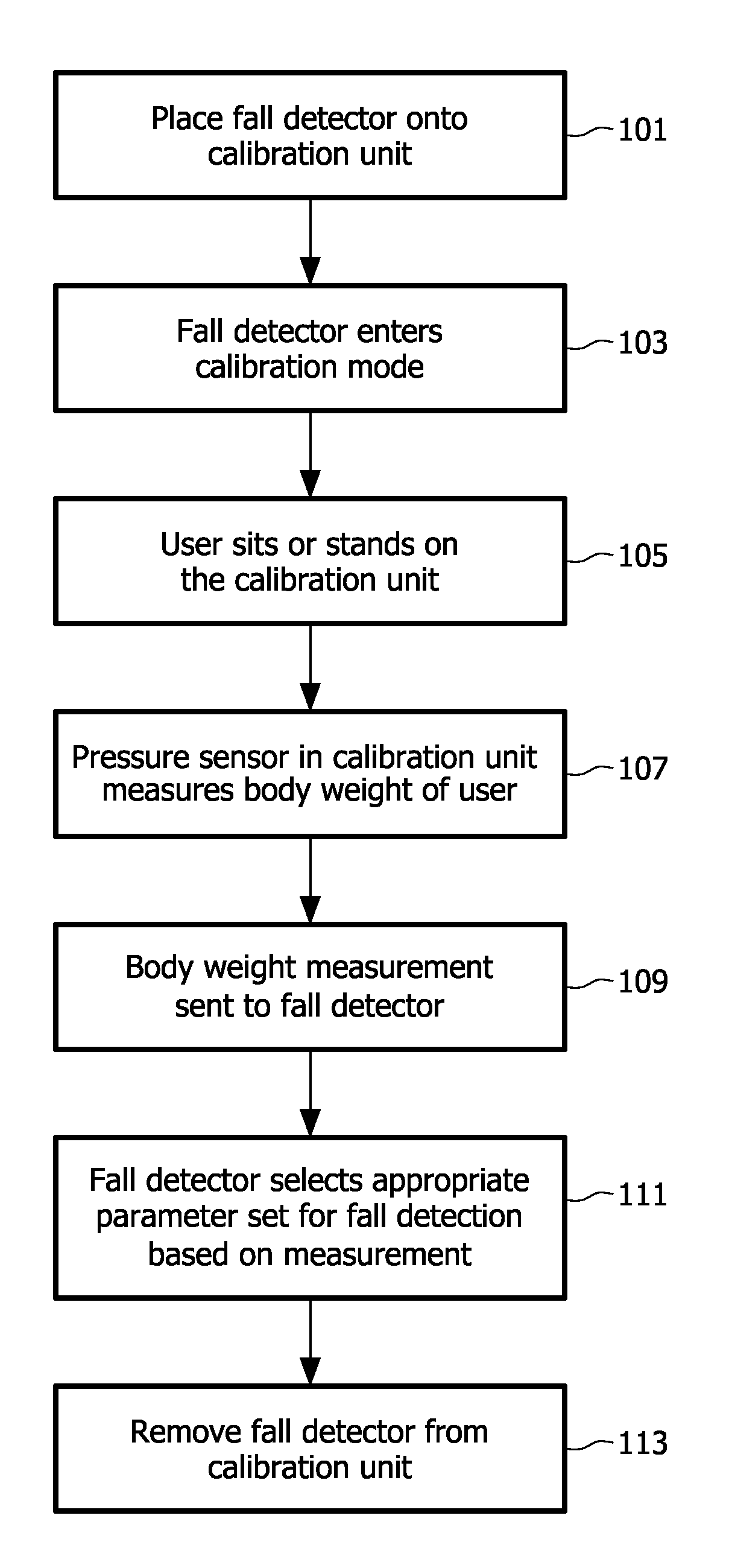

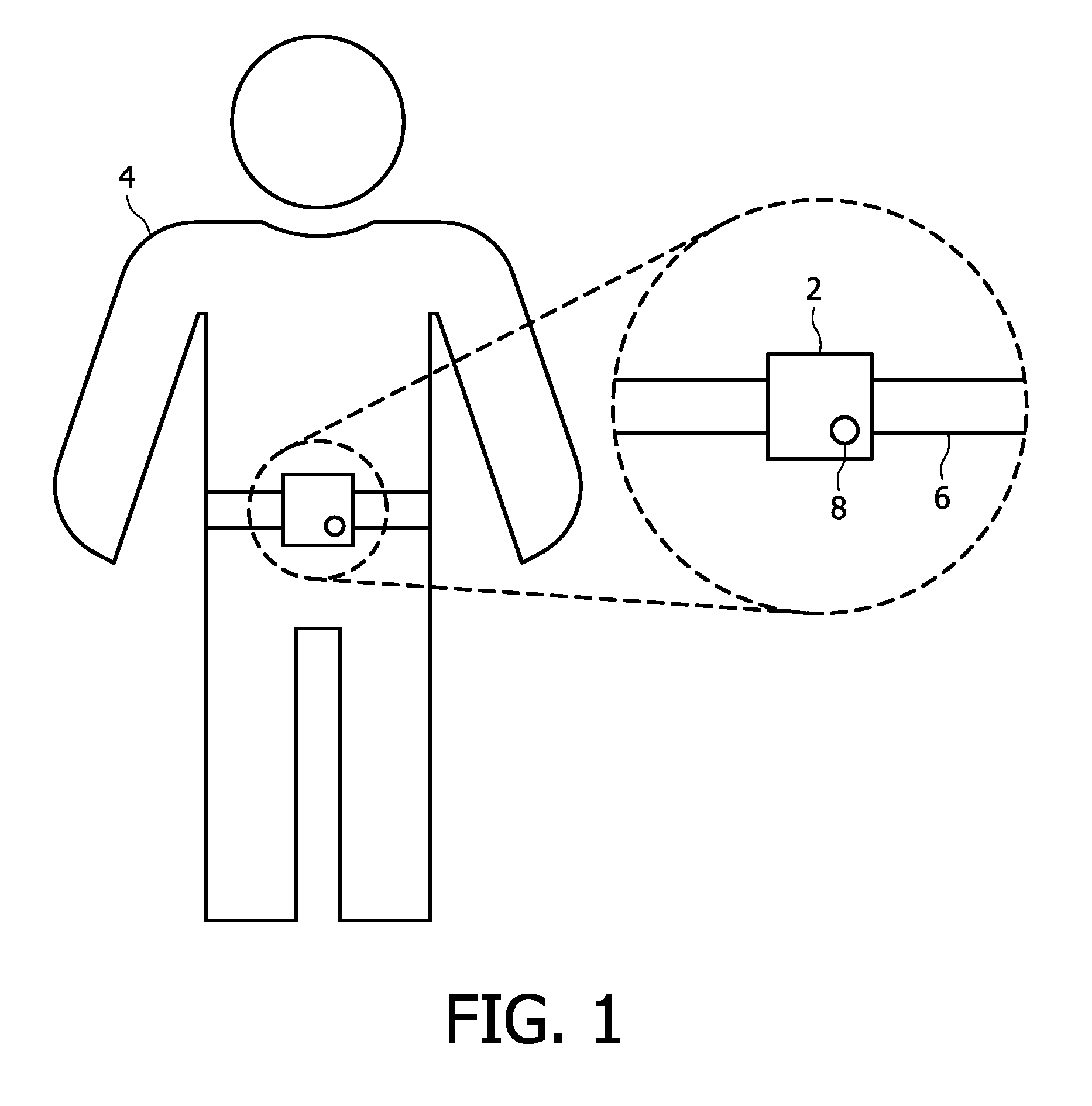

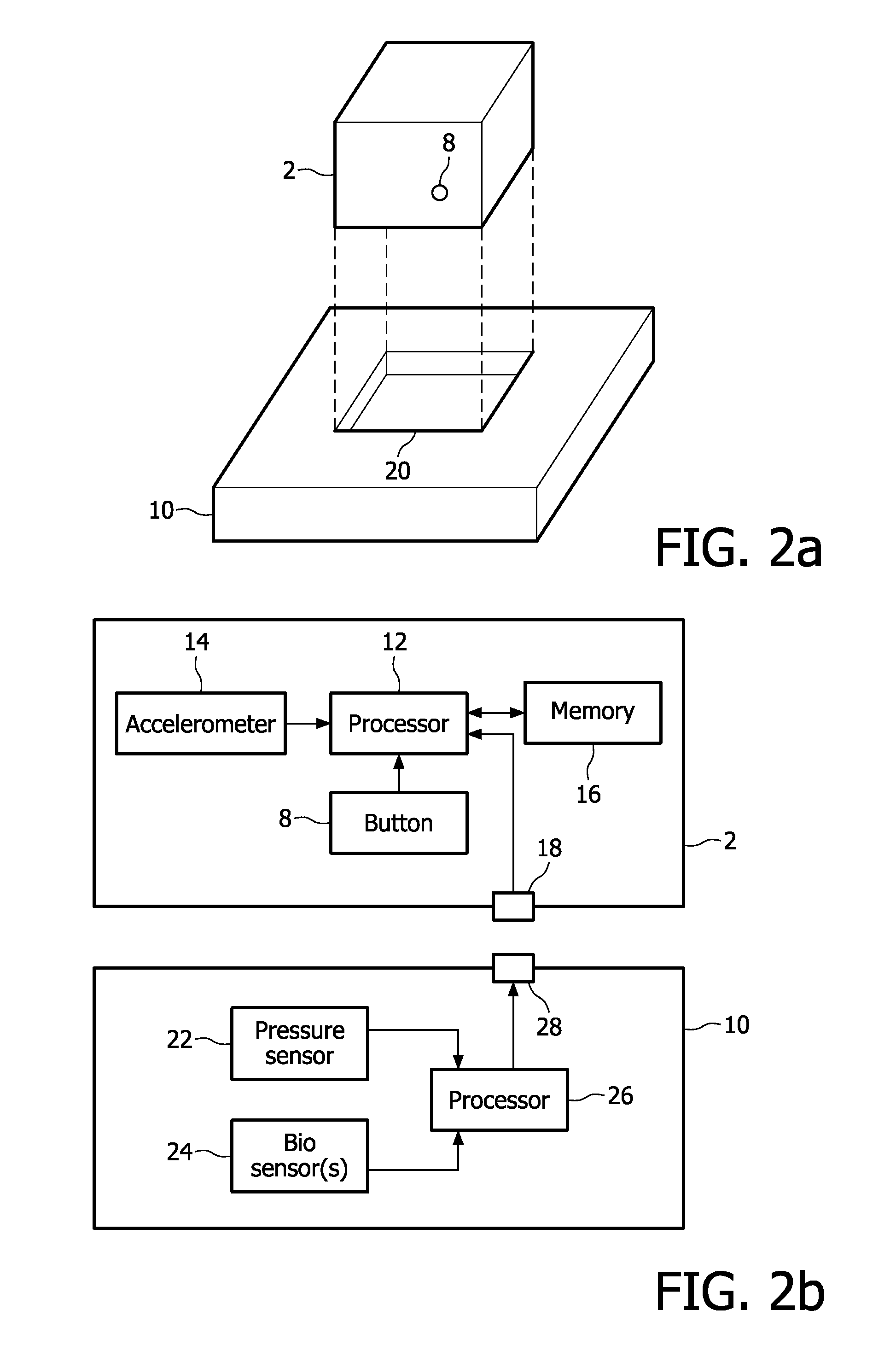

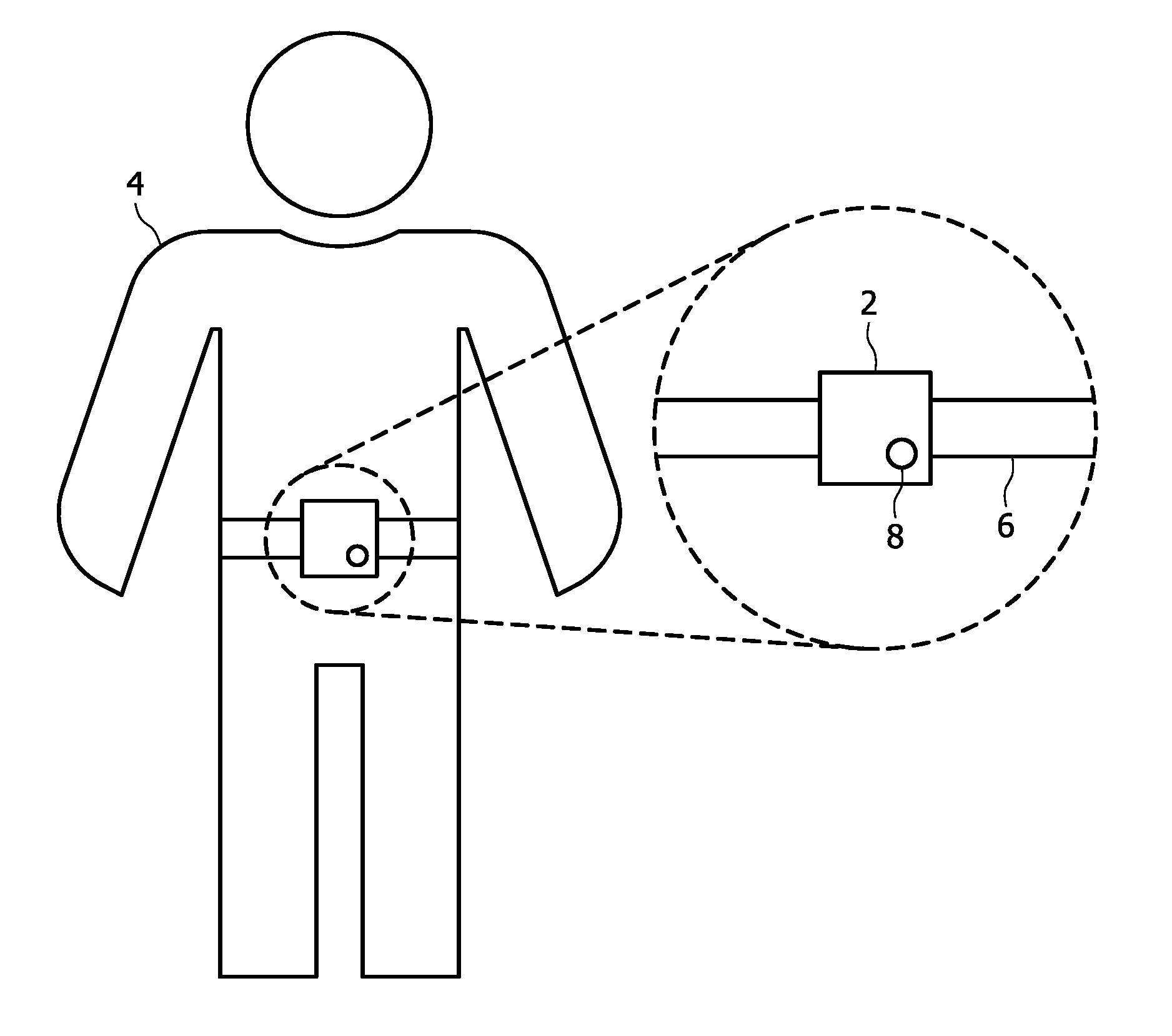

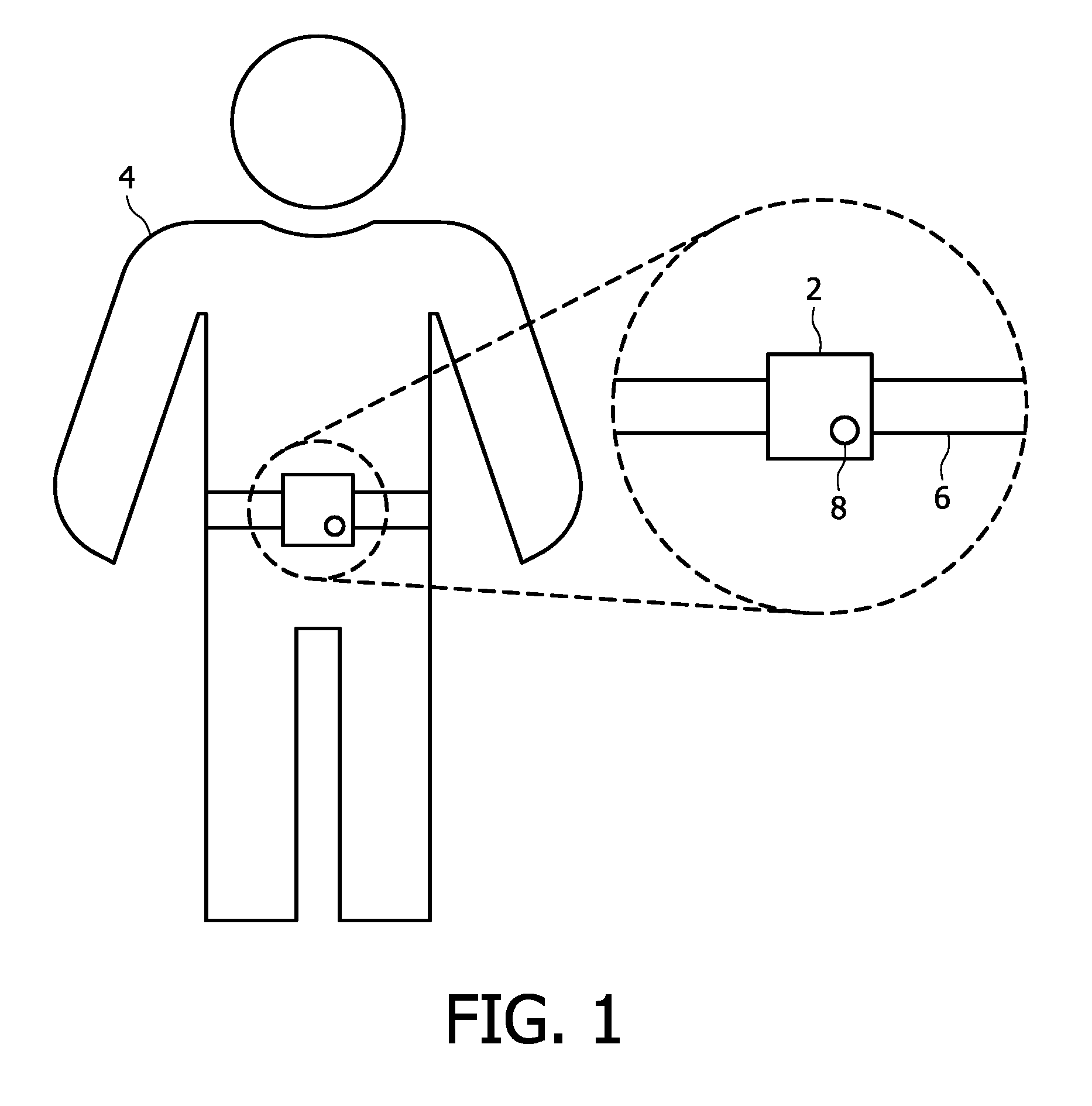

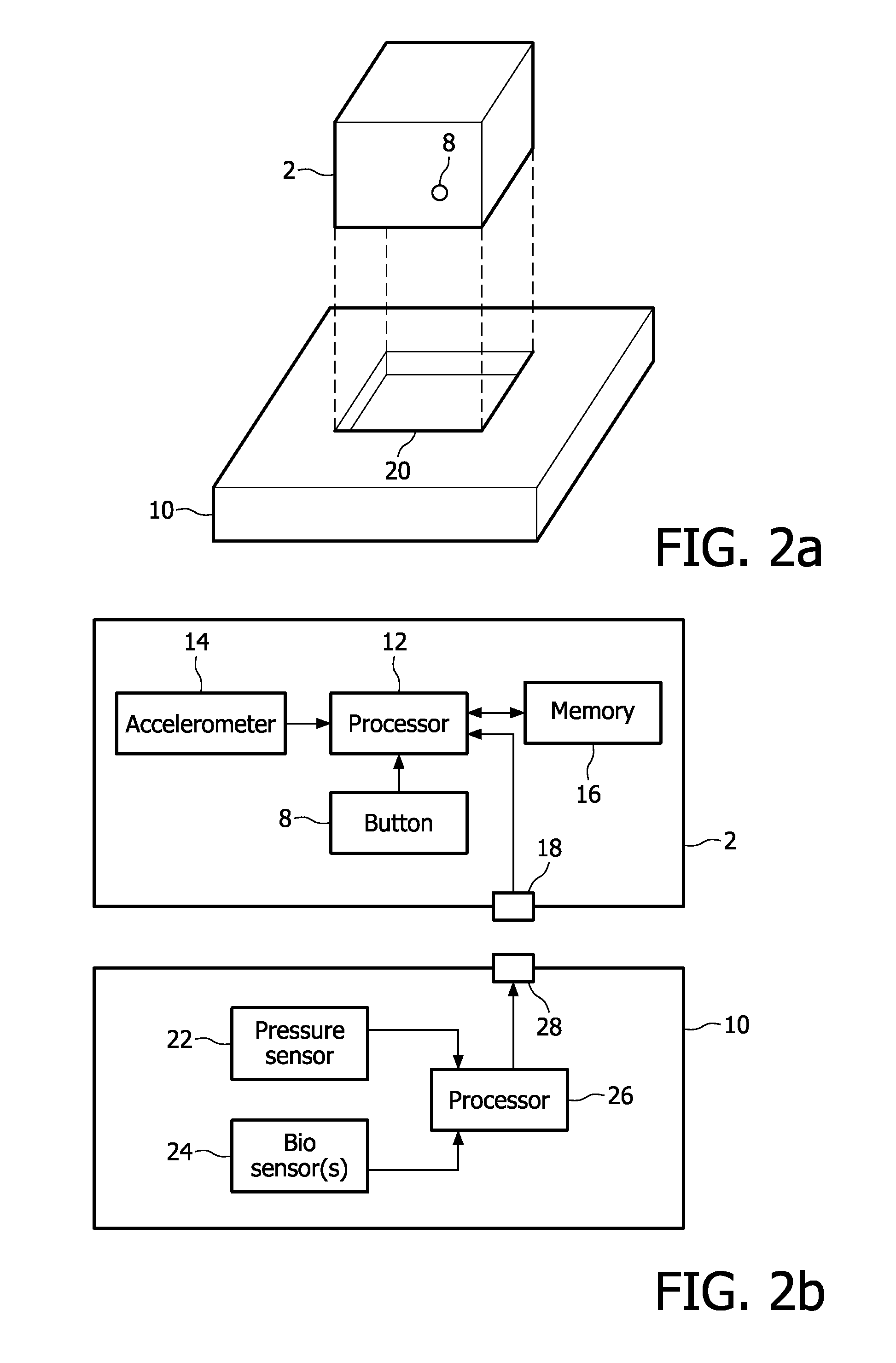

ActiveUS20110162433A1Improve reliabilityDesired level of detection accuracyForce measurement by permanent gauge deformationPerson identificationEngineeringFall detector

There is provided a fall detection system comprising a fall detector for monitoring the movement of a user and detecting if the user has fallen or is about to fall, one or more sensors for collecting measurements of one or more physical characteristics of the user, wherein the fall detector uses the measurements to adapt the fall detection to the physical characteristics of the user.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

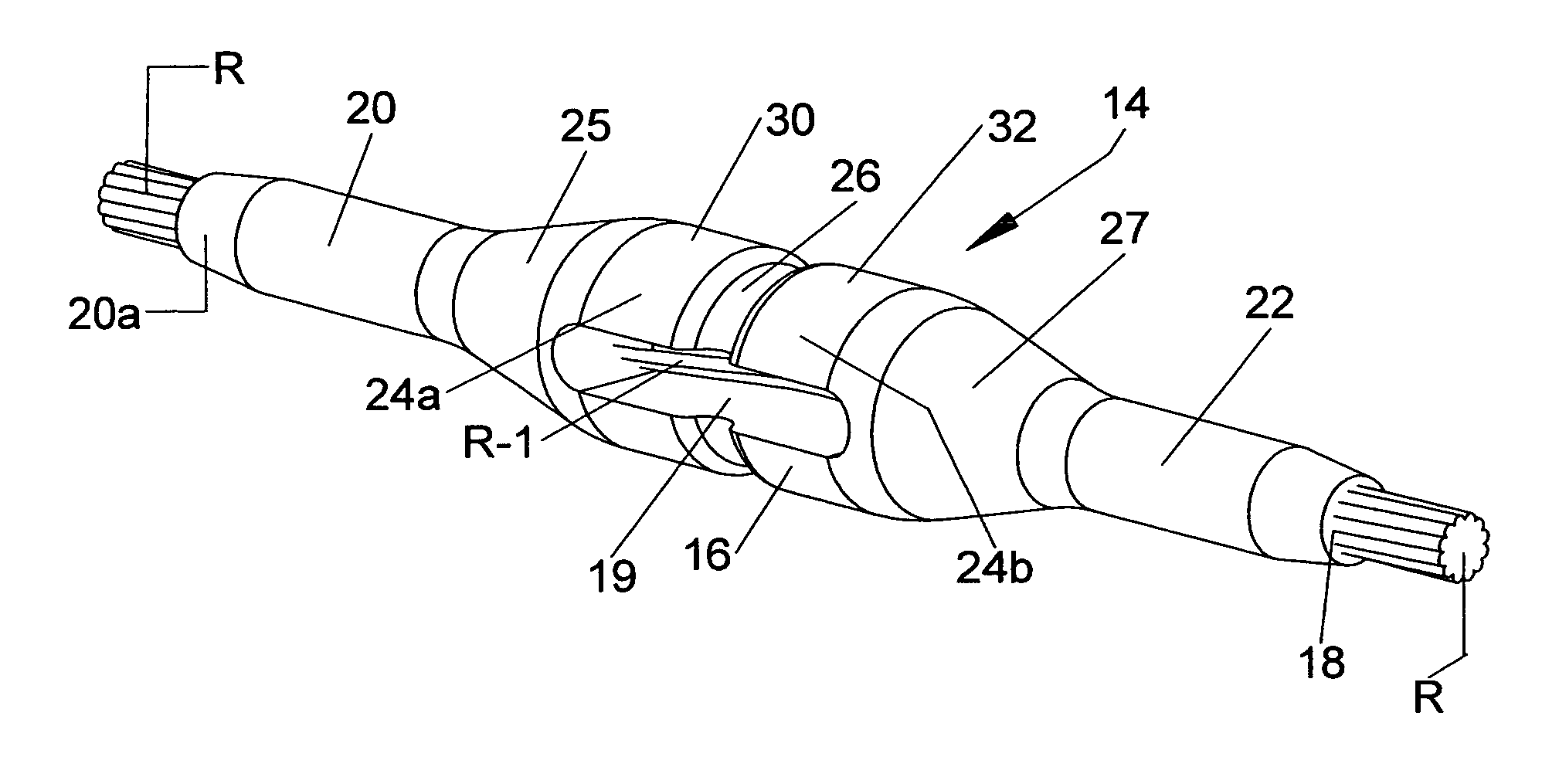

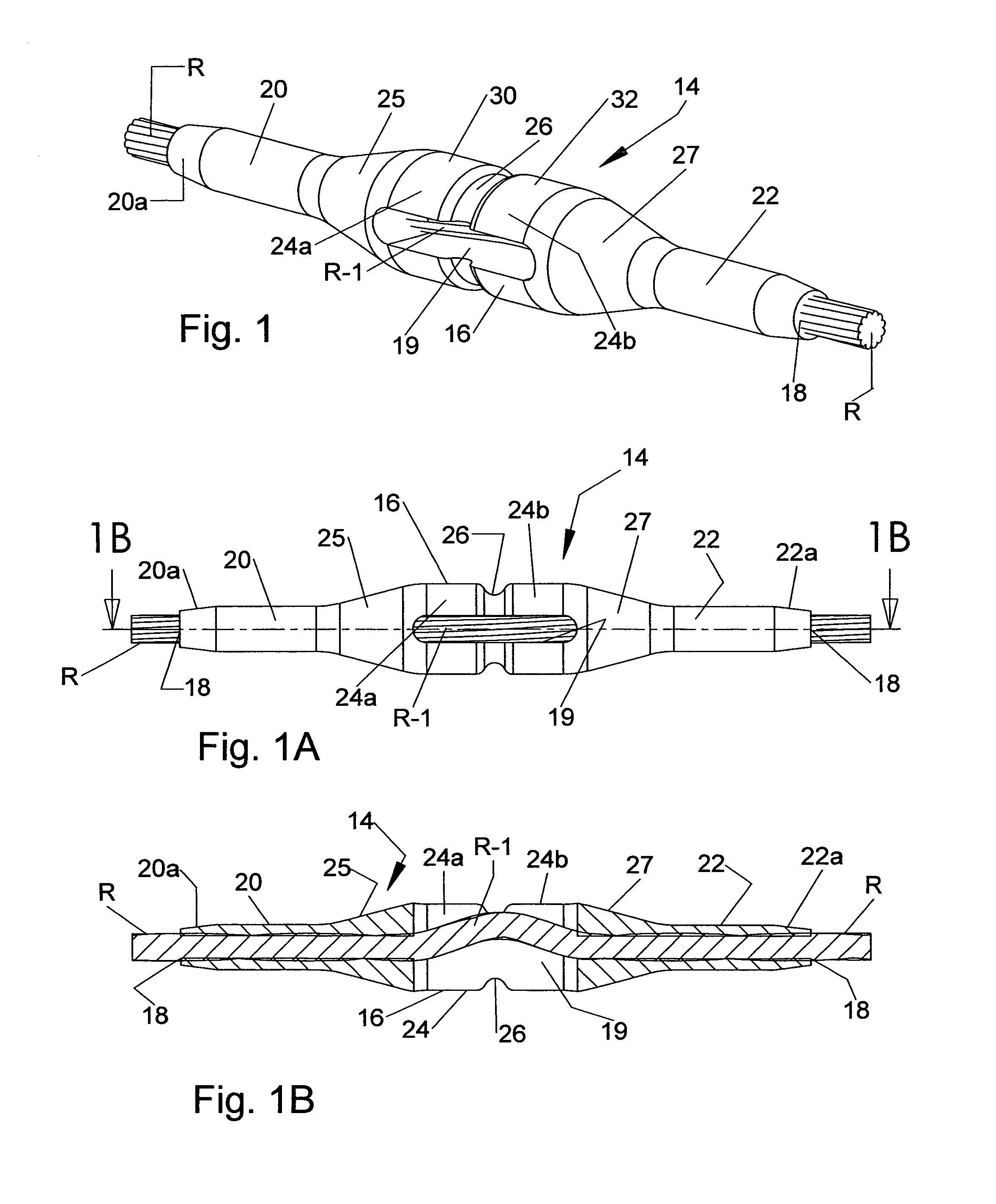

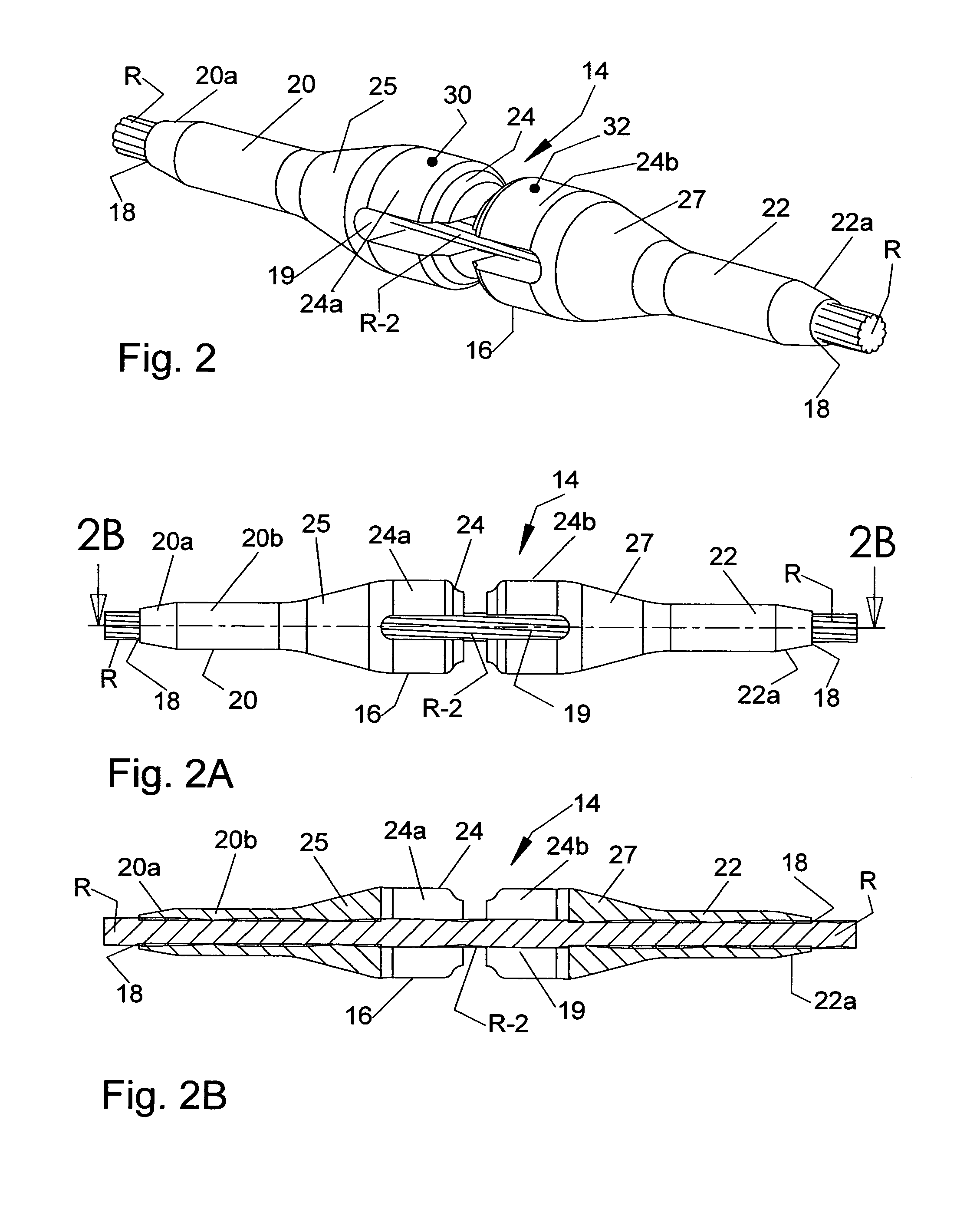

Wire rope pre-failure indicator and method of using same

InactiveUS7424996B2Conveniently and frequently checkedEasy to seeForce measurement by permanent gauge deformationMeasurement arrangements for variableWire rope

A wire rope pre-failure indicating device that can be installed at any location along a length of conventional wire rope of the character used in many industrial applications. The indicating device reliably functions to provide a pre-failure warning that the wire rope has been loaded beyond a specified magnitude. The indicating device also provides a pre-failure warning that the swaged fittings, which interconnect the indicator to the wire rope, have undesirably slipped.

Owner:LARSEN STUART +1

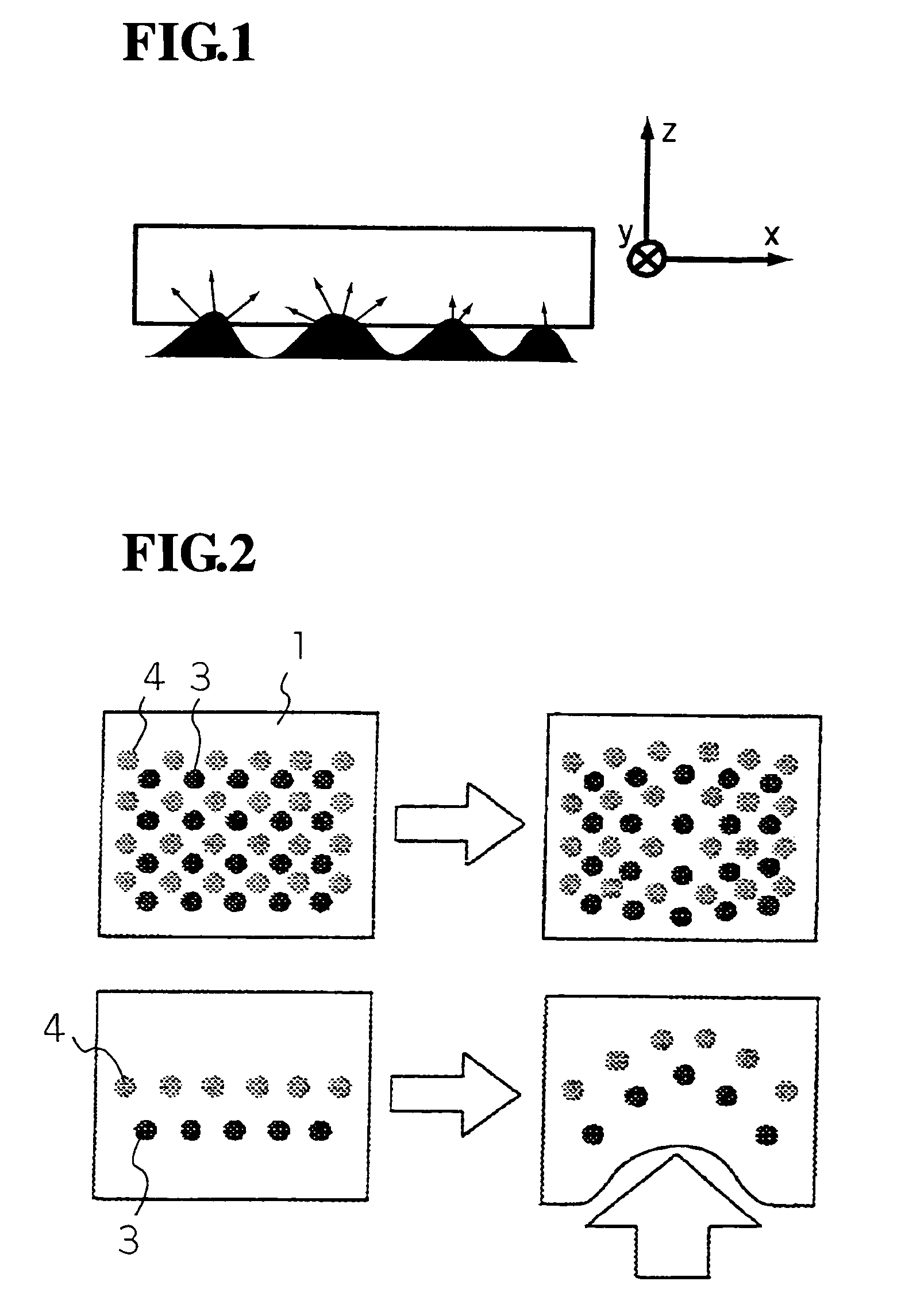

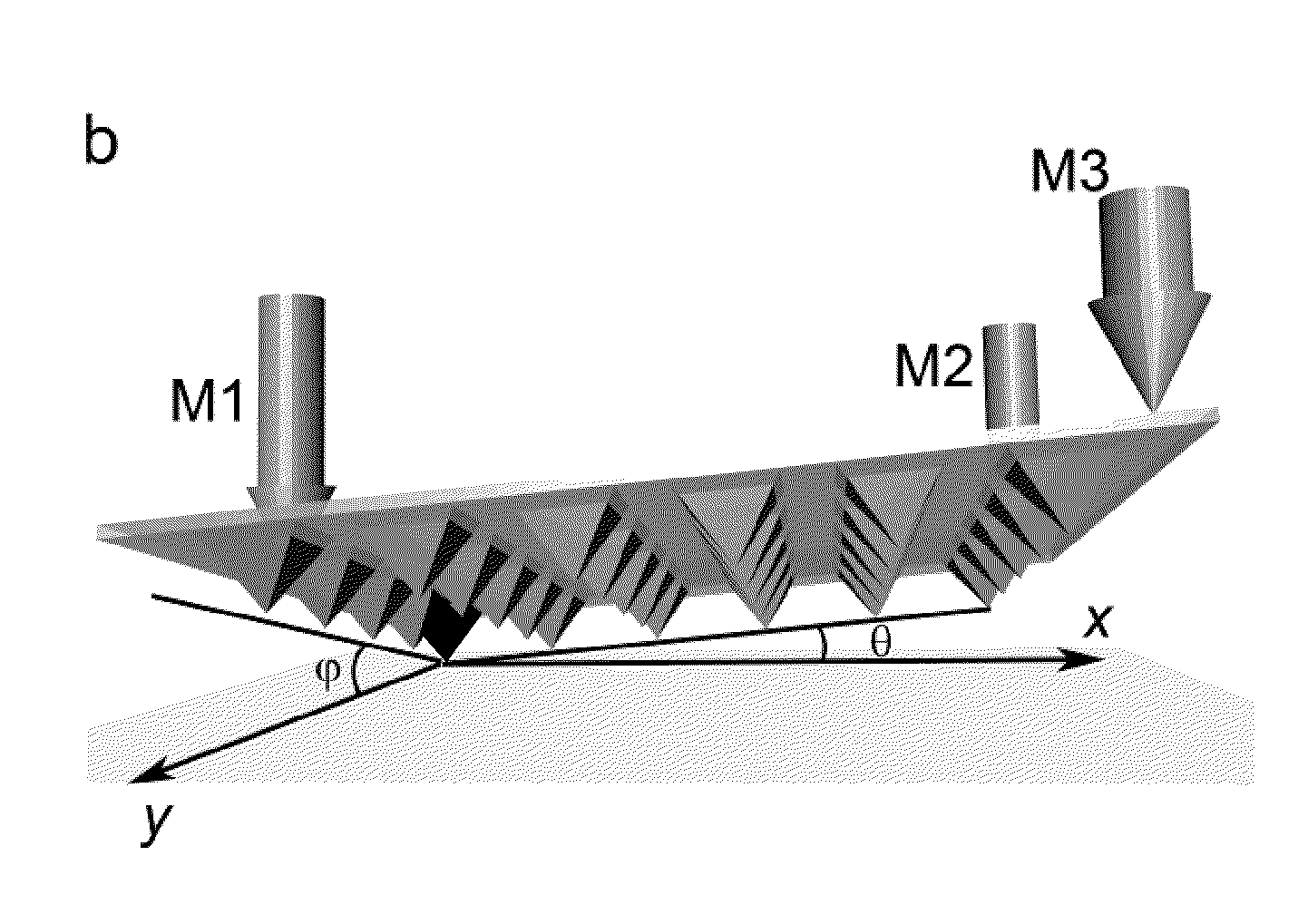

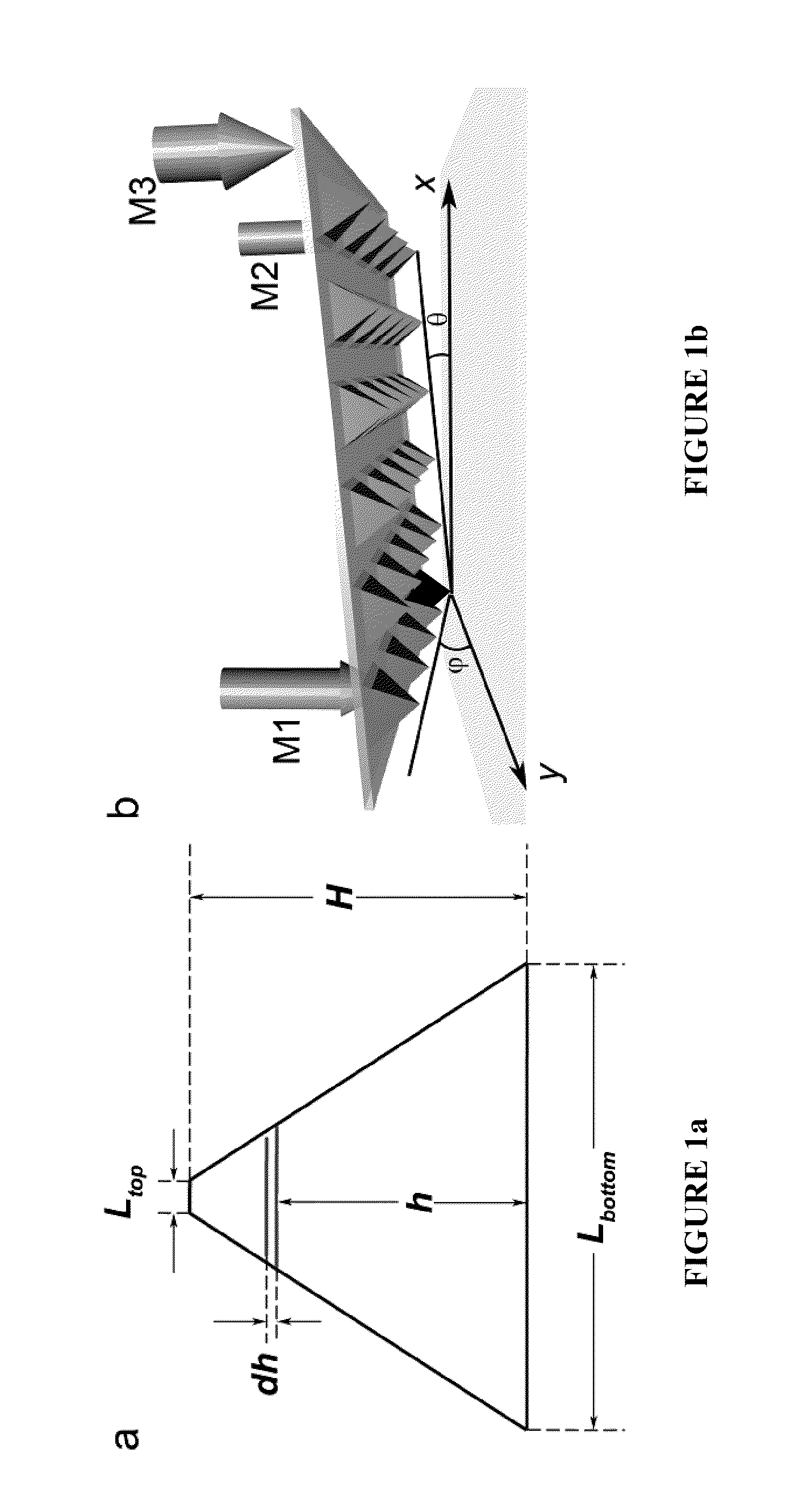

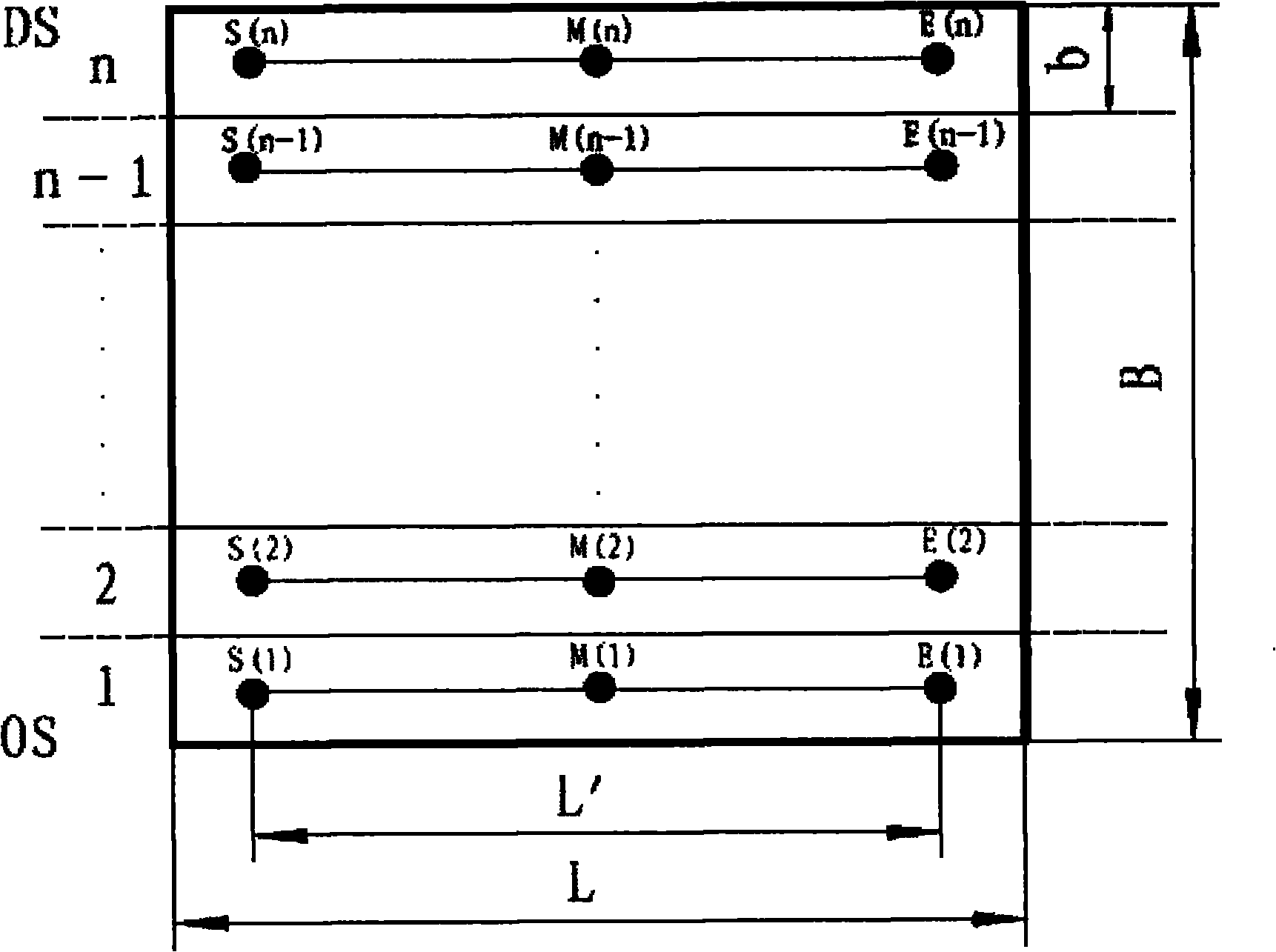

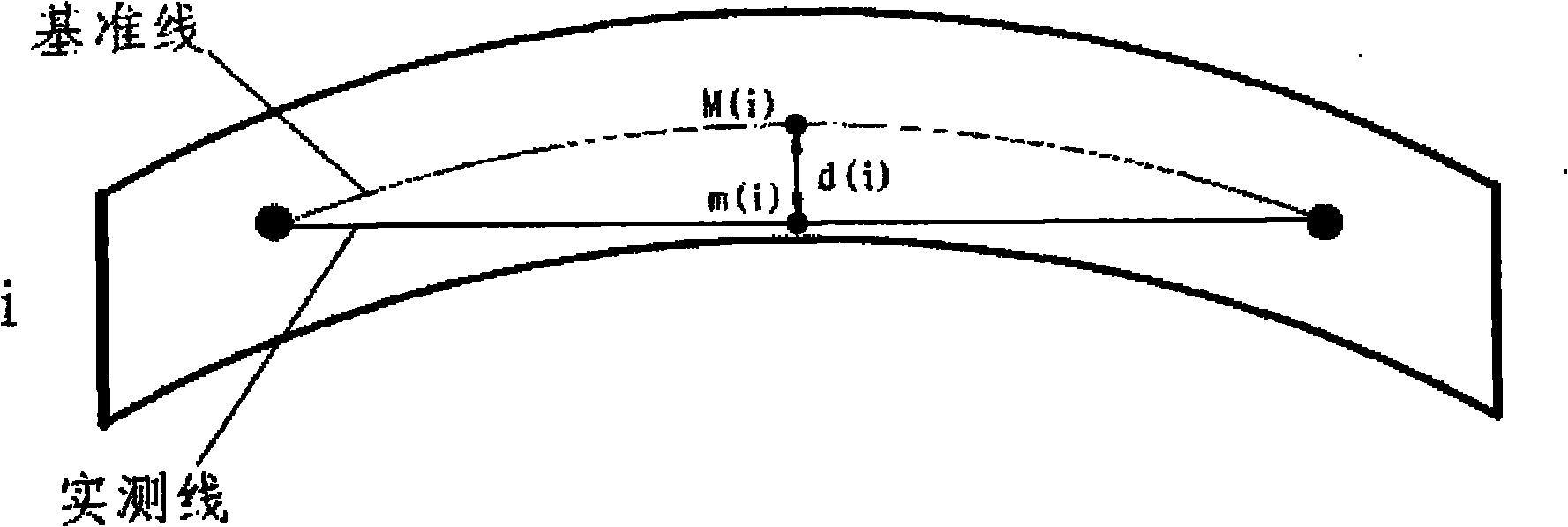

Force Feedback Leveling of Tip Arrays for Nanolithography

ActiveUS20110165329A1Force measurement by permanent gauge deformationPhotomechanical apparatusNanolithographyClassical mechanics

A method of leveling a polymer pen array includes contacting a pen array with a surface and measuring a total force exerted on the surface by the pen array, the pen array being disposed at a first angle with respect to a first axis of the surface and a second angle with respect to a second axis of the surface; tilting one or both of the pen array and the surface to vary the first and second angles of the pen array with respect to the surface; measuring the total force exerted by the tilted pen array on the surface; and repeating the tilting and measuring steps until a global maximum of the total force exerted on the surface by the pen array is measured, thereby determining first and second angles which correspond to a leveled position of the pen array with respect to the surface.

Owner:NORTHWESTERN UNIV

Force transducer, medical instrument, and machine implemented method

ActiveUS20100113966A1Improve test accuracyGood reproducibilityForce measurement by permanent gauge deformationSurgeryEngineeringActuator

A force transducer comprises a handle operably connected to a probe having an elongate tip. The force transducer includes a biasing element arranged with respect to the handle, in force transmitting communication with the probe, and a detector operable to detect a degree of force applied between the probe and the handle. The force transducer further includes an actuator operable to exert a force on the biasing element in dependence upon the degree of force detected by the detector so as to cause a predetermined force to be transmitted from the handle to the probe.

Owner:SPRUCE MICHELLE C

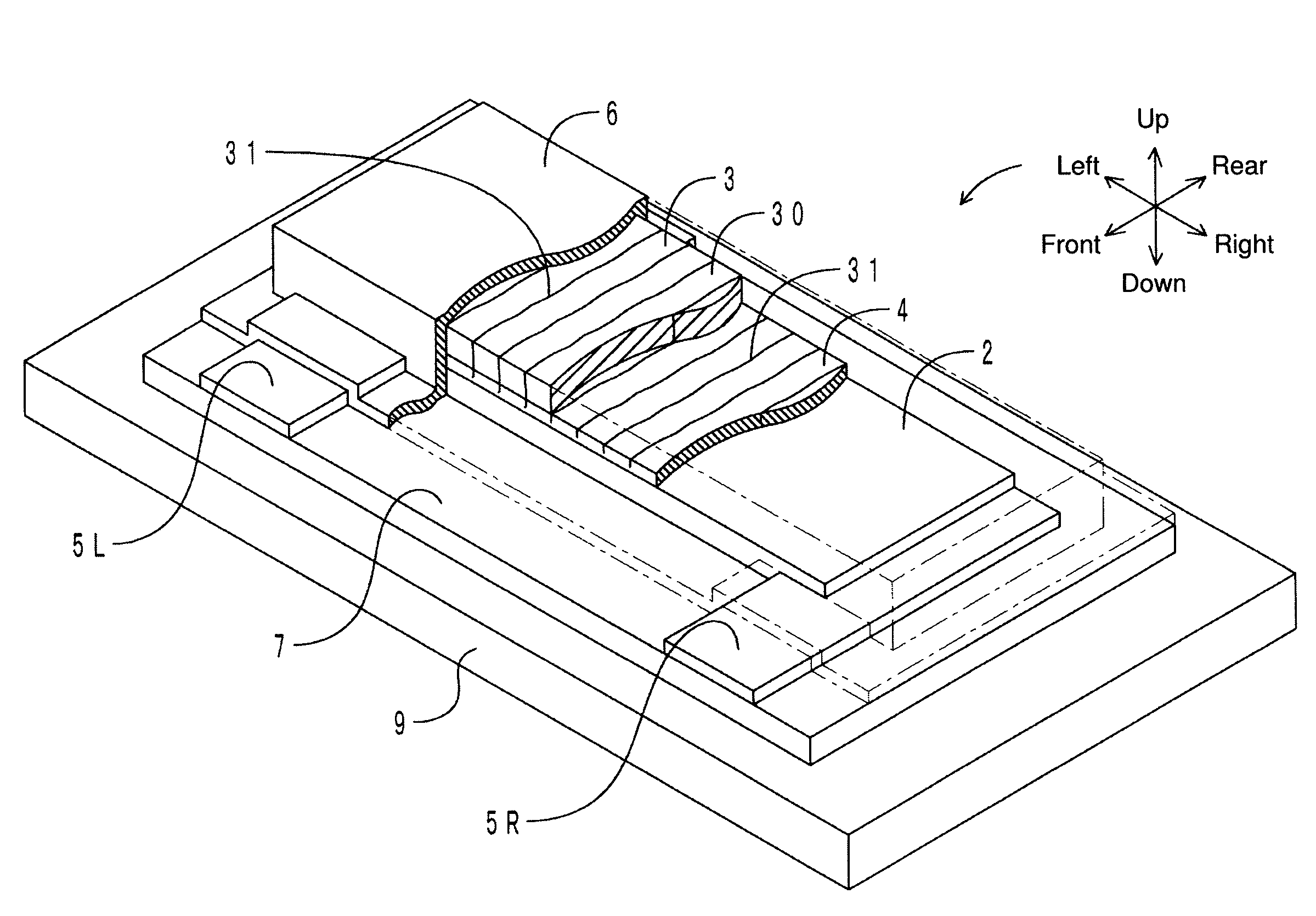

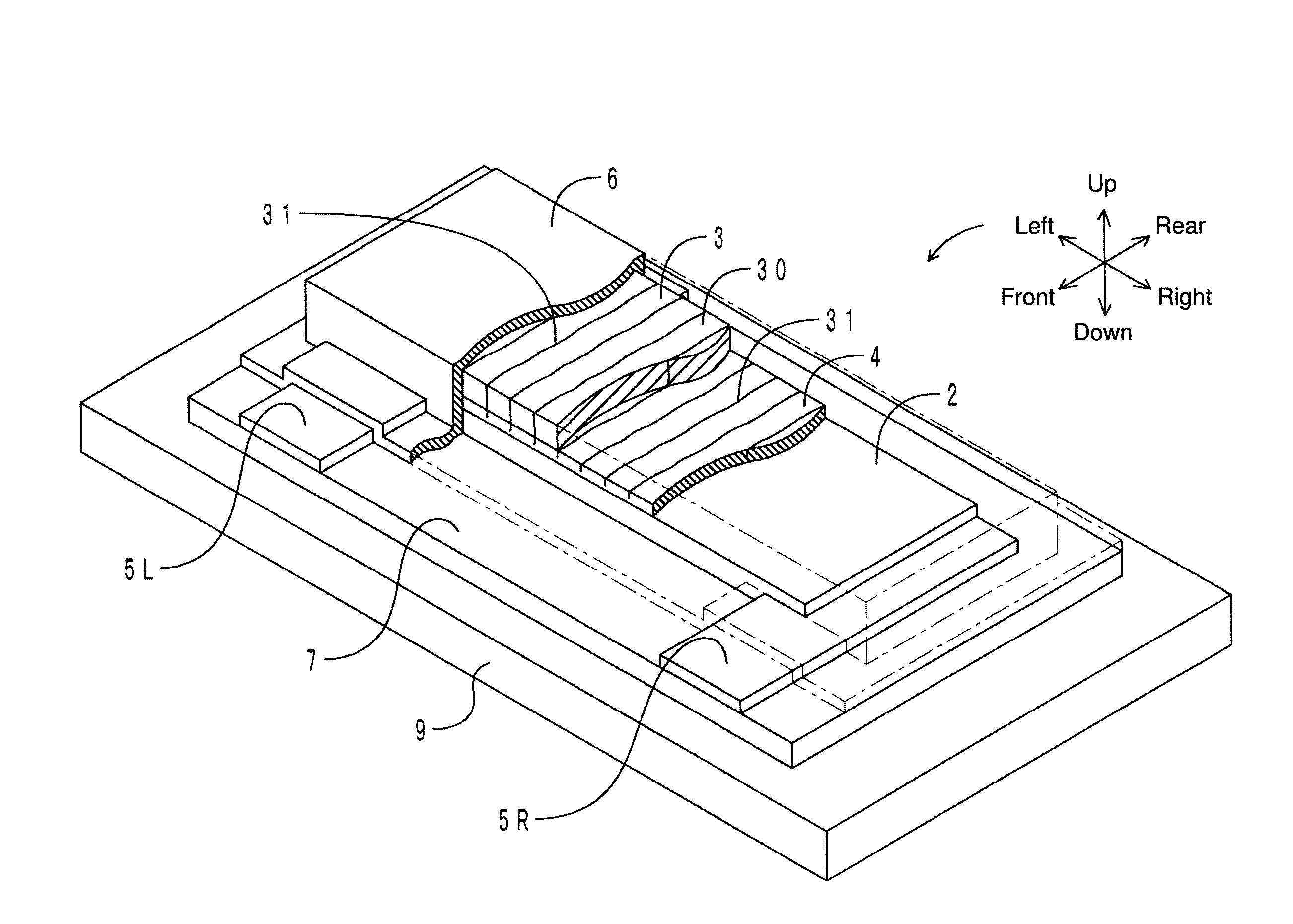

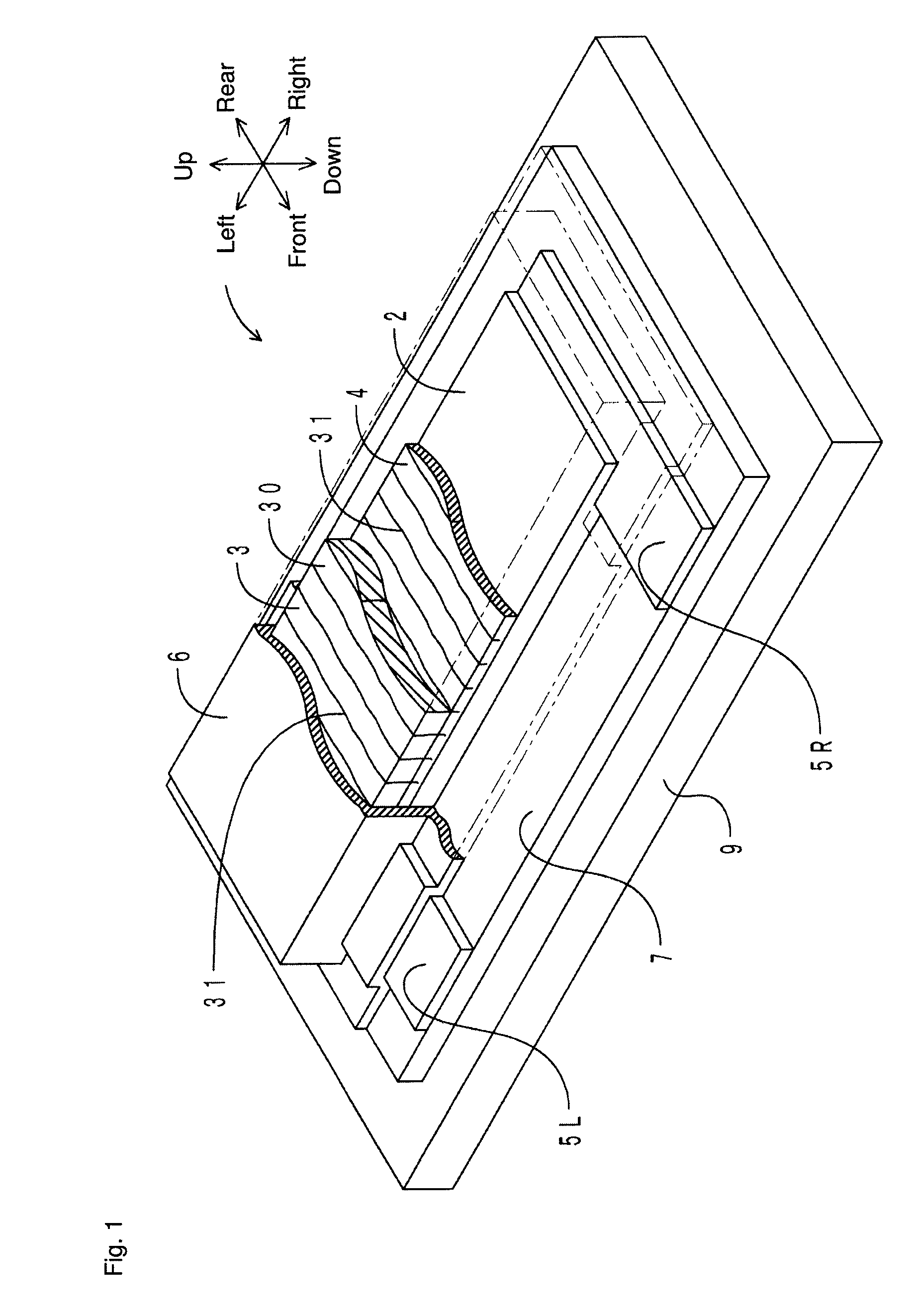

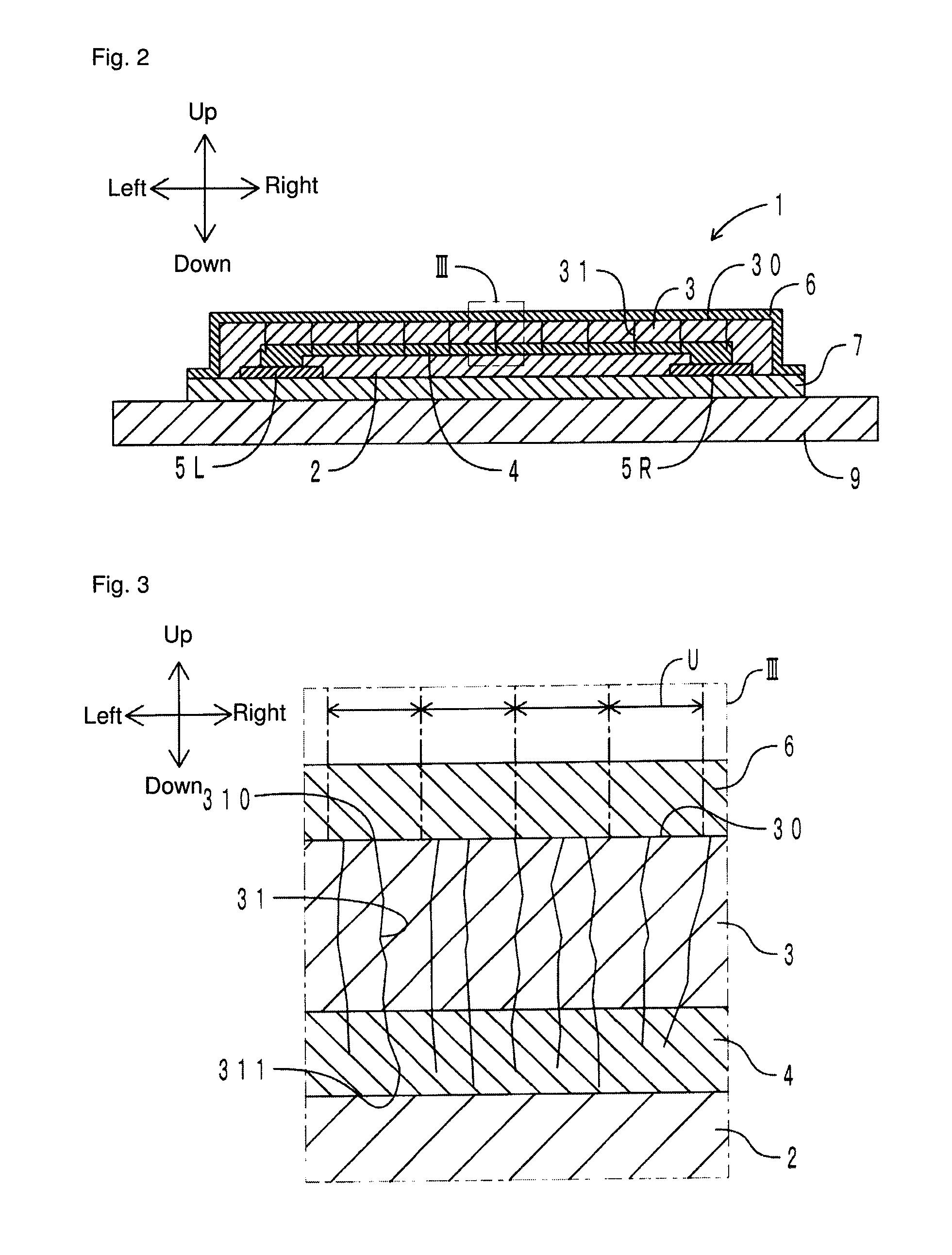

Bearing device for wheel

InactiveUS7628540B2Simple to executeUniform preloadRolling contact bearingsBearing assemblyEngineeringFlange

A bearing device for a wheel, where preload control is easy and a uniform amount of preload can be applied even if a bearing seal is installed in the bearing device. The bearing device rotatably supports a wheel and has an outer member 1, an inner member 2, and rolling elements 3 interposed between both members. The outer member 1 has on its outer periphery a vehicle body installation flange 1a, and double row rolling surfaces 6, 7 are formed on the inner peripheries of the outer member. Rolling surfaces 8, 9 facing the rolling surfaces 6, 7 of the outer member 1 are formed in the inner member 2. Between the rolling surfaces of both members 1, 2 are interposed the rolling elements 3. A sensor 4 for detecting the amount of preload of the bearing is provided on either the outer member 1 or the inner member 2.

Owner:NTN CORP

Load bearing device including overboard indicator

InactiveUS7032466B2Force measurement by permanent gauge deformationMeasurement arrangements for variableEngineeringInterconnection

A load-bearing device including an overload indicator and a wire form overload indicator are provided for interconnection of load bearing connectors, preferably elongated load bearing connectors, for bearing a load. In preferred embodiments, the load bearing connectors are chains, ropes, wire ropes, cables, straps and the like, preferably chain. The wire form overload indicator preferably includes a wire form quick-link having a first thickness, and first and second elongated sides. The first elongated side preferably includes an interconnectable gap through which connection loops of the load bearing connectors can pass when the interconnectable gap is unconnected. The interconnectable gap includes a connection end and a connectable end, the connecting end having a connector capable of connecting the connecting end to the connectable end to close the gap. The second elongated side preferably has a portion having a diminished thickness as compared to the first thickness. The diminished thickness preferably has a predetermined load bearing capability and is calibrated to reduce the load bearing capability of the methods of making an overload indicator and a load bearing device including an overload indicator are also provided.

Owner:CIT GRP BUSINESS CREDIT

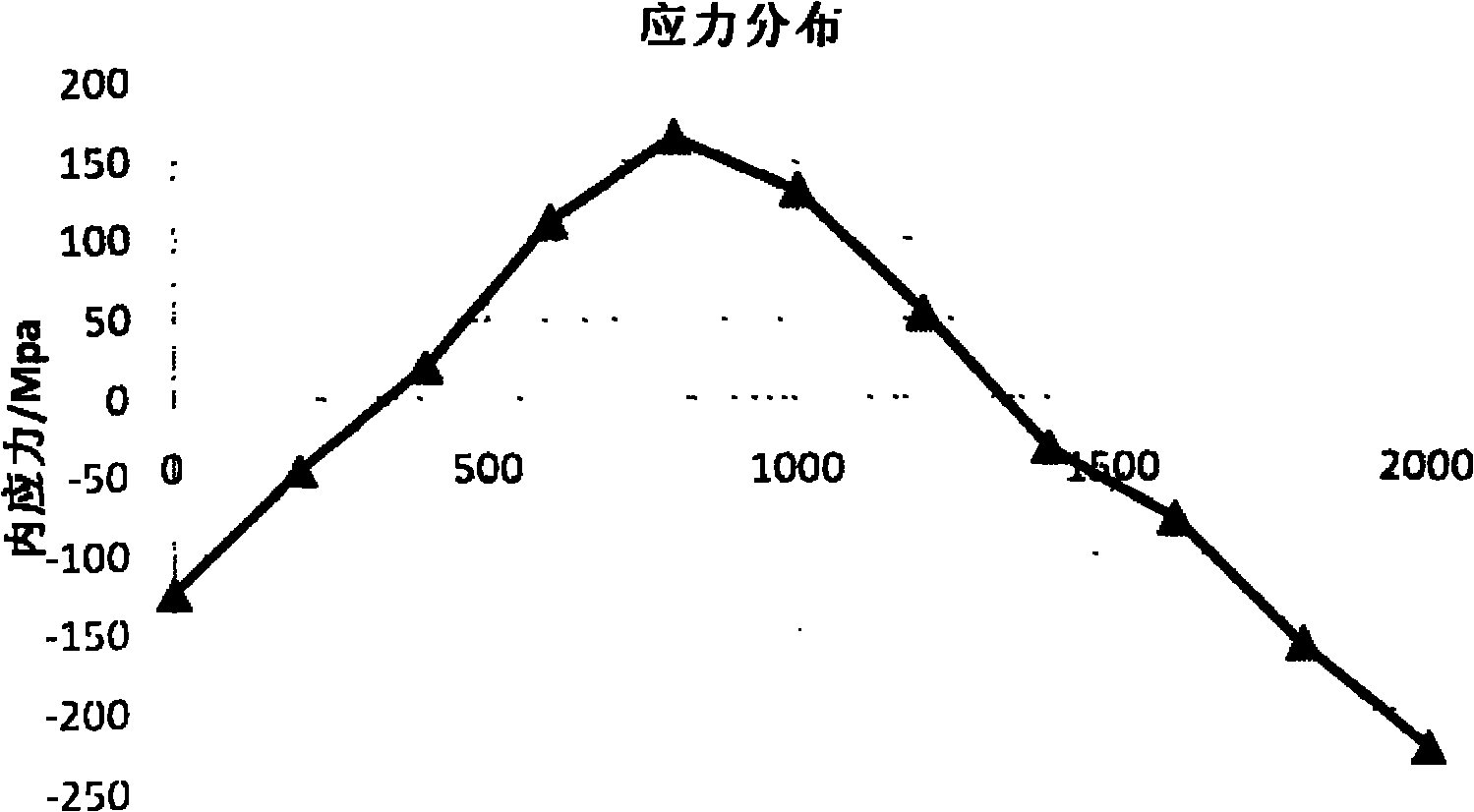

Internal stress measuring method of opening plate

ActiveCN102156010AFast stress measurementStress quickly derivedForce measurement by permanent gauge deformationStress distributionProcess optimization

The invention provides an internal stress measuring method of an opening plate, belonging to the technical field of measurement. An opening plate is evenly cut into strips via marking benchmark straight lines on the opening plate for releasing the internal stress; the bending deformation of the benchmark straight line, corresponding to each measuring strip, is measured; the internal stress before releasing the stress is calculated according to the bending deformation of each measuring strip, so that the internal stress distribution of the whole opening plate is obtained. Advantageously, under the precondition of satisfying the internal stress measurement precision of the opening plate, sample preparation and measurement can be performed by common workers with conventional cutting tools, ordinary rulers and tapered rulers; and the internal stress of the opening plate is obtained fast by a mathematical model built by the invention. The method of the invention is used in the works of the process optimization of hot-rolling ship plates and opening process optimization of chip plates, and respectively used for measuring the internal stresses of D36 and D32 levels of ship plate opening plates which are 2000 mm in length and 2000 mm in width, so that the internal stress distribution of the ship plate opening plate is obtained accurately, and reliable reference data is provided for the optimization of production process.

Owner:SHOUGANG CORPORATION

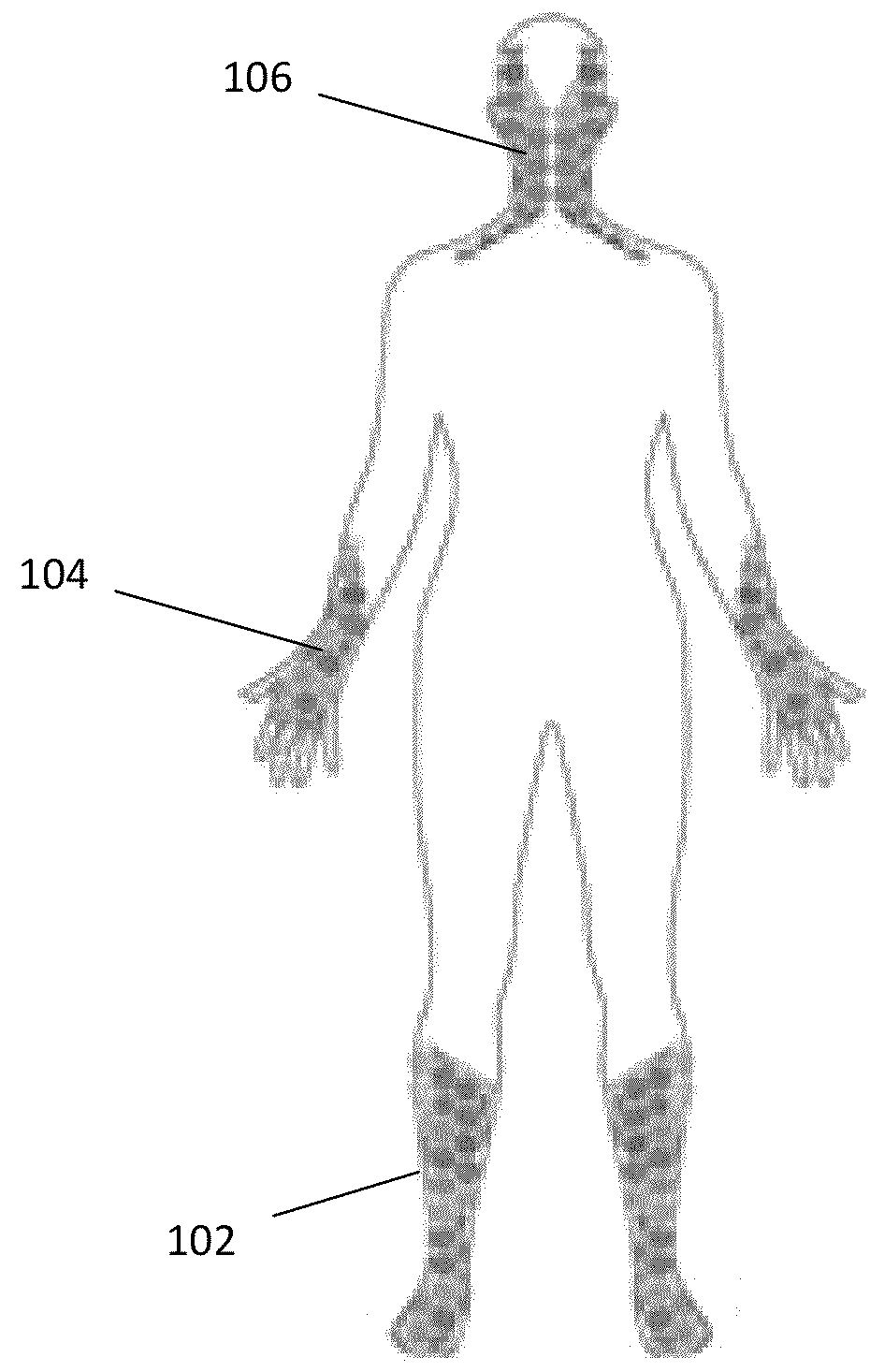

Customizable embedded sensors

InactiveUS9228859B2Force measurement by measuring magnetic property varationMeasurement apparatus componentsEngineering

Owner:NORTHEASTERN UNIV

Popular searches

Intravenous devices Apparatus for force/torque/work measurement Fluid pressure measurement using ohmic-resistance variation Acceleration measurement Force measurement using piezo-resistive materials Electrical/magnetic solid deformation measurement Torque measurement Coatings Material analysis by using resonance Piezoelectric/electrostrictive device manufacture/assembly

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com