Patents

Literature

46results about How to "Uniform preload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

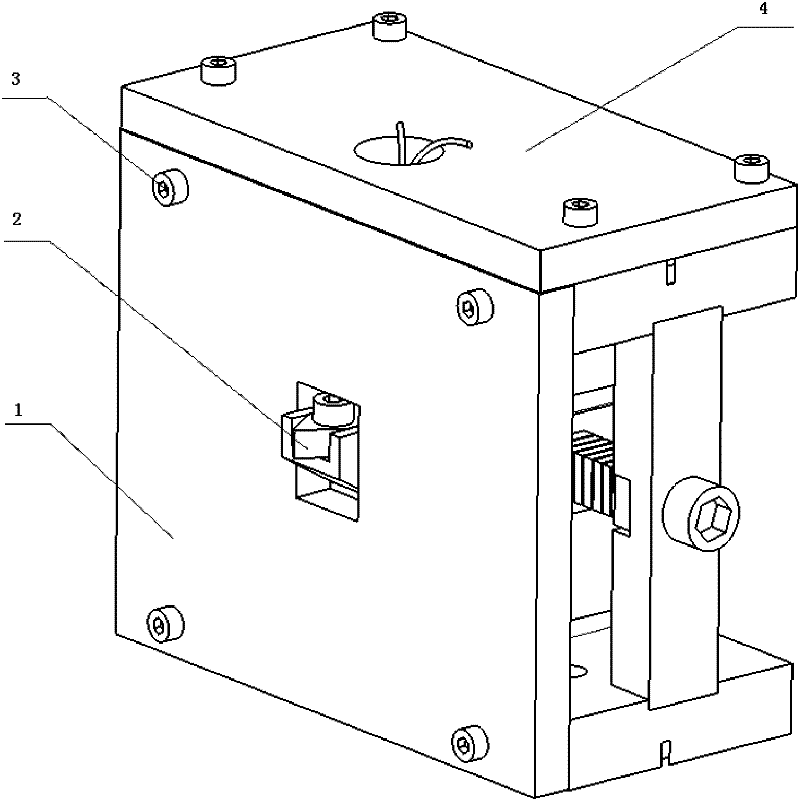

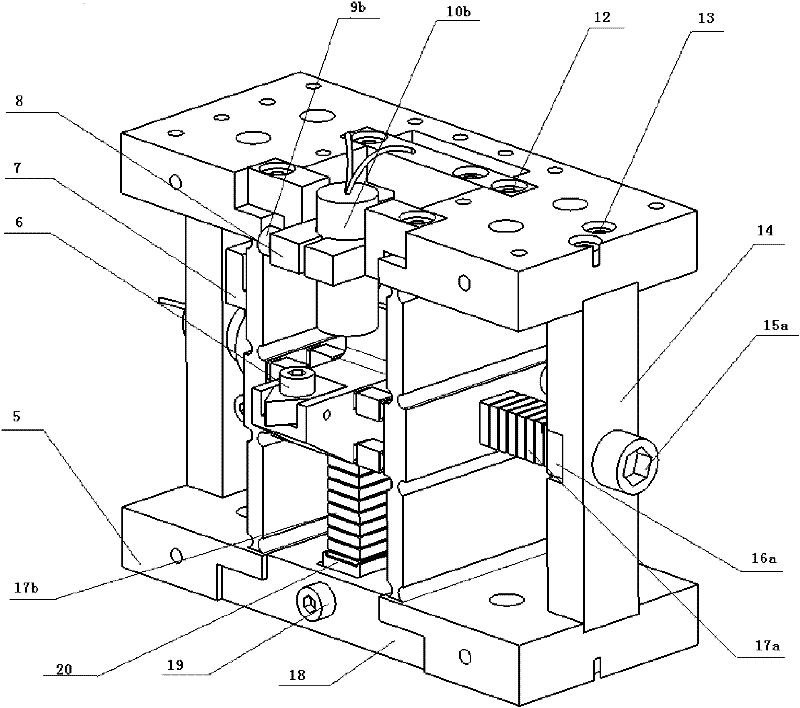

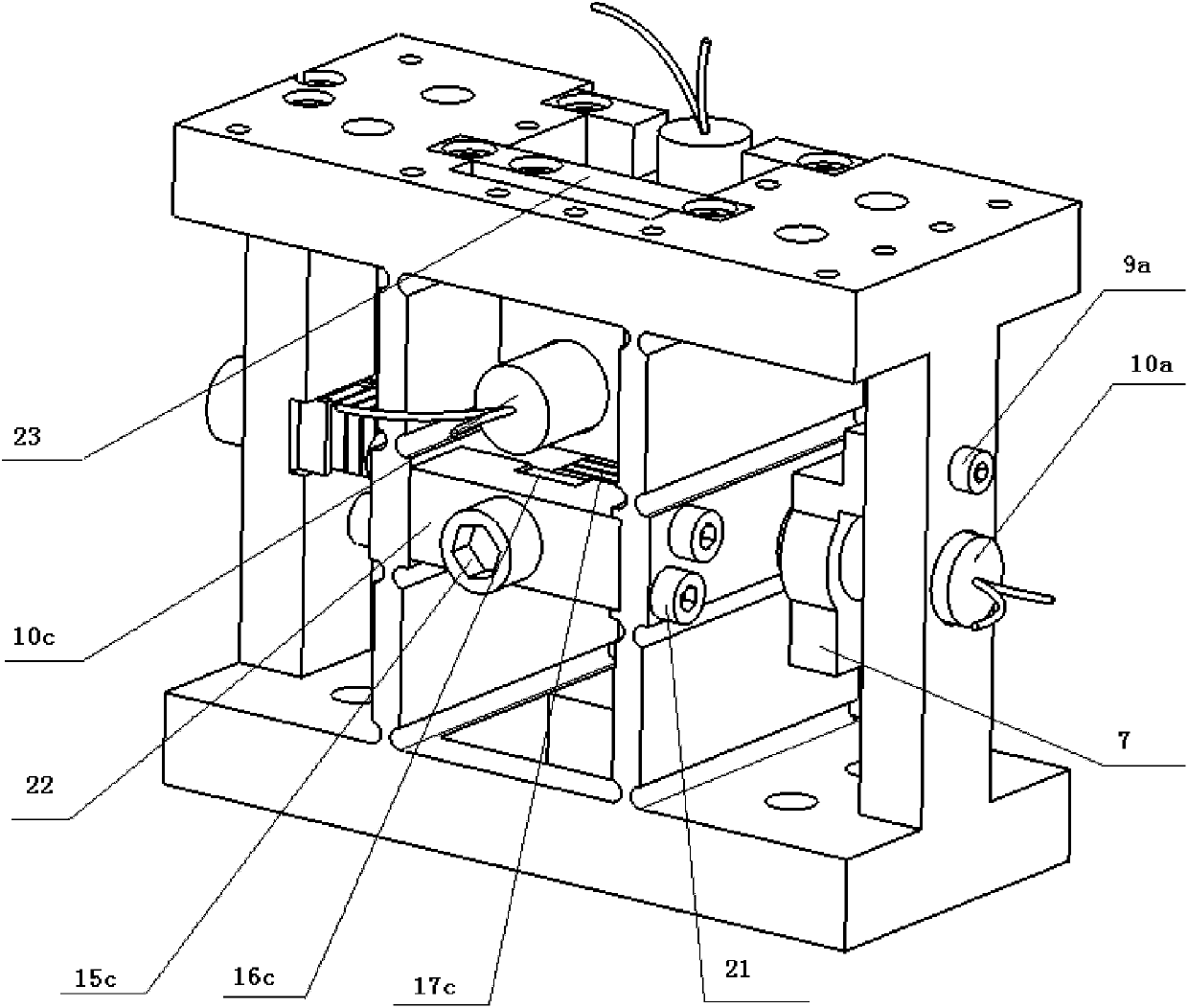

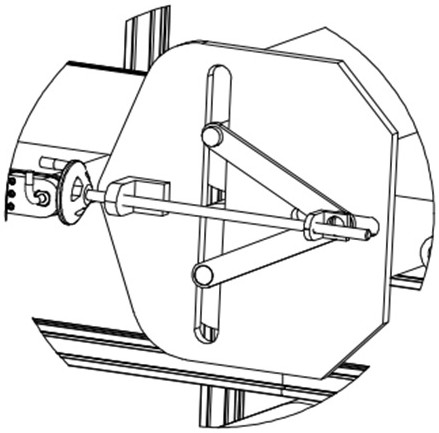

Three-dimensional elliptical vibration cutting device

ActiveCN102371359AImprove machinabilitySimplify the modeling processMeasurement/indication equipmentsTurning toolsLinear motionEllipse

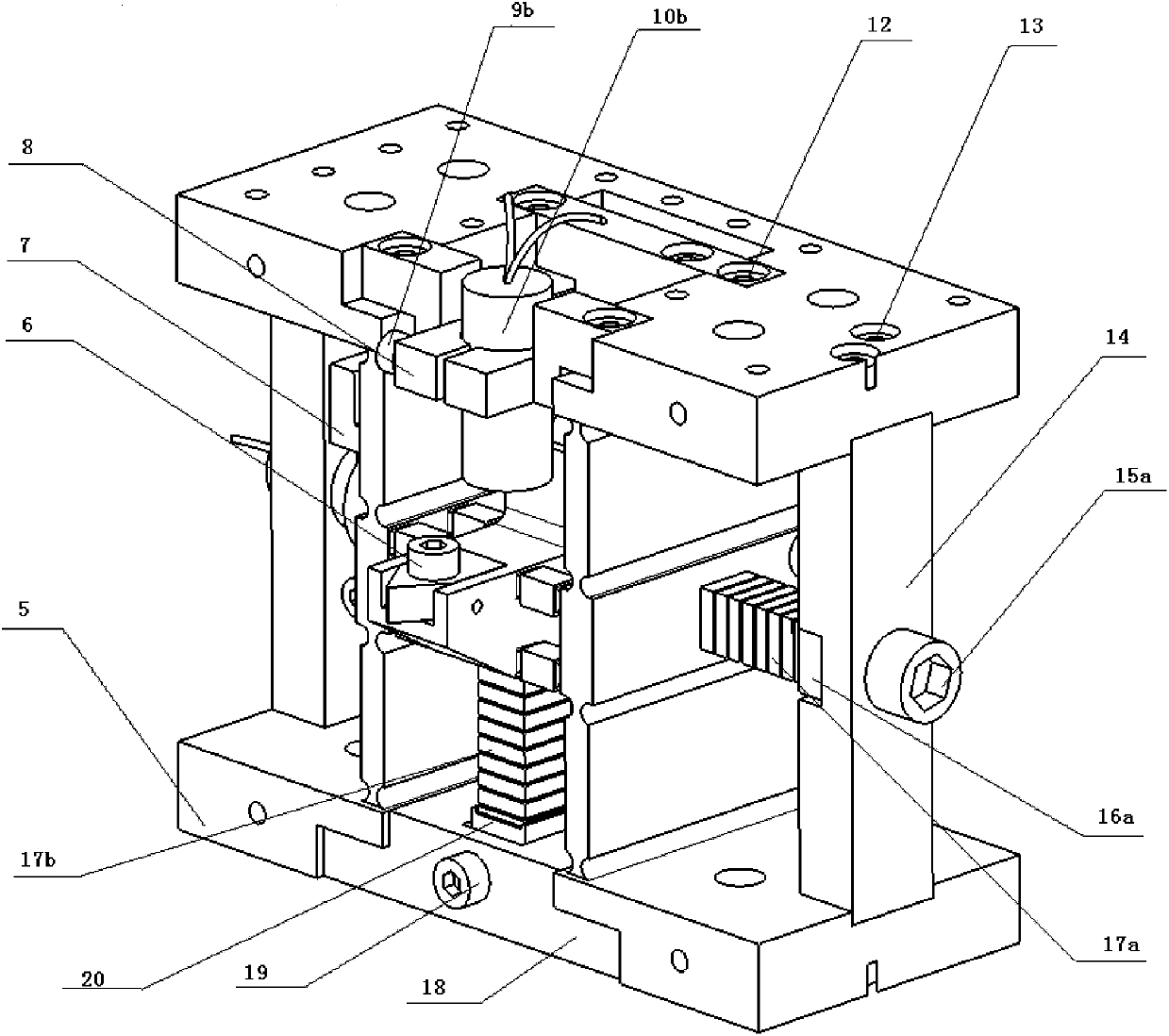

The invention relates to a three-dimensional elliptical vibration cutting device, belonging to the field of cutting and ultra-precision cutting machining of materials which are difficult to machine. A diamond cutter is guided through flexible hinge mechanisms respectively along an X direction, a Y direction and a Z direction, and further, is driven by three piezoelectric stacks respectively alongthe X direction, the Y direction and the Z direction; the piezoelectric stacks of the X direction and the Z direction are preloaded by preloading screw bolts along respective axial direction; the piezoelectric stack of the Y direction is preloaded through a screw bolt screwing wedge; the preloading processes of the three directions are mutually independent; through regulating and matching the initial phase position and the amplitude of a driving signal for each of the three piezoelectric stacks, the projections of the cutter location point movements of the diamond cutter in an X-Y plane and aY-Z plane are elliptical motions, and the projection of the cutter location point movements of the diamond cutter in an X-Z plane is reciprocating elliptical motion or linear motion. The three-dimensional elliptical vibration cutting device has a novel and simple structure, is easy to implement, and is beneficial to obtaining the best cutting machinability of the diamond cutter.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

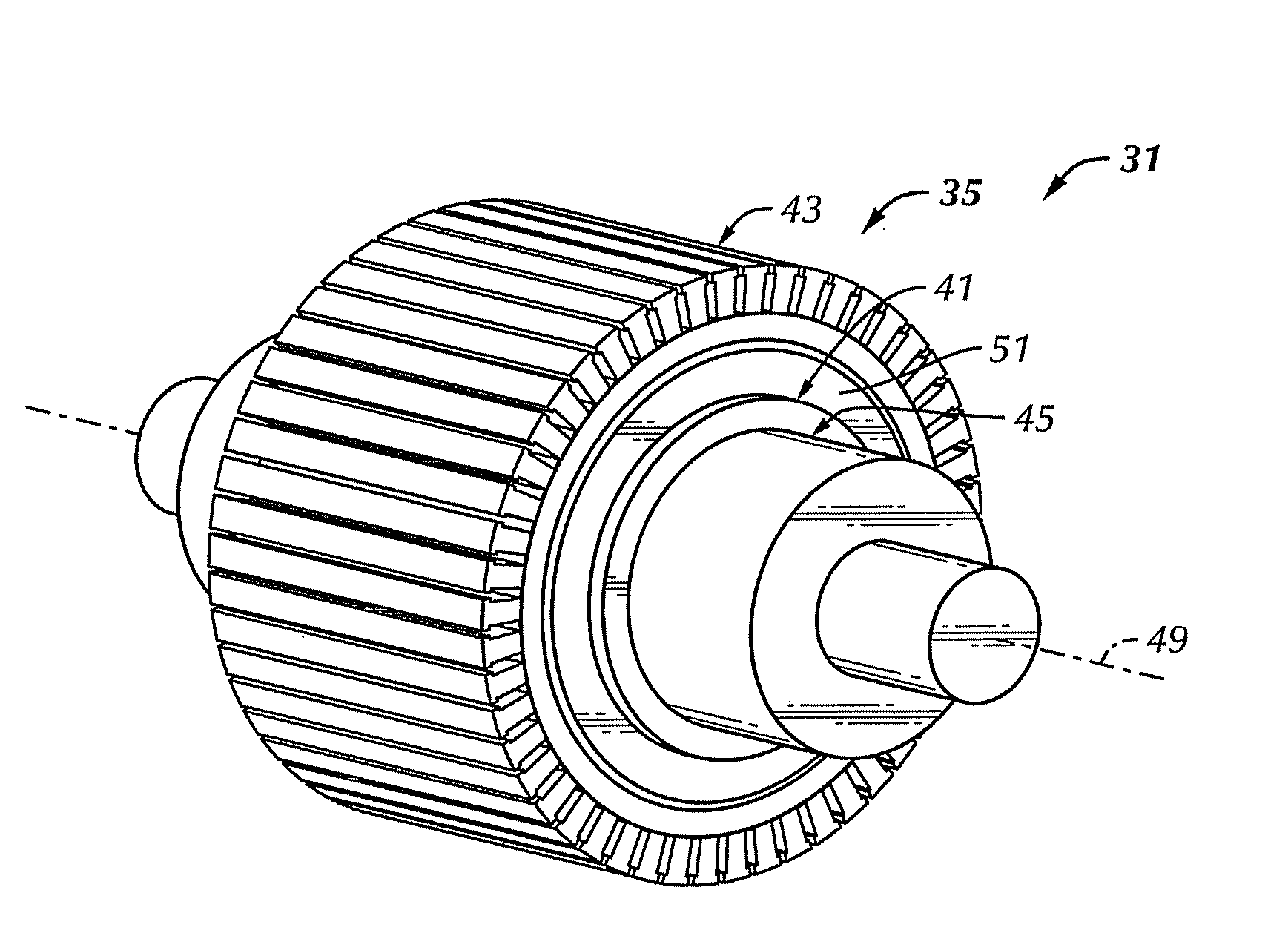

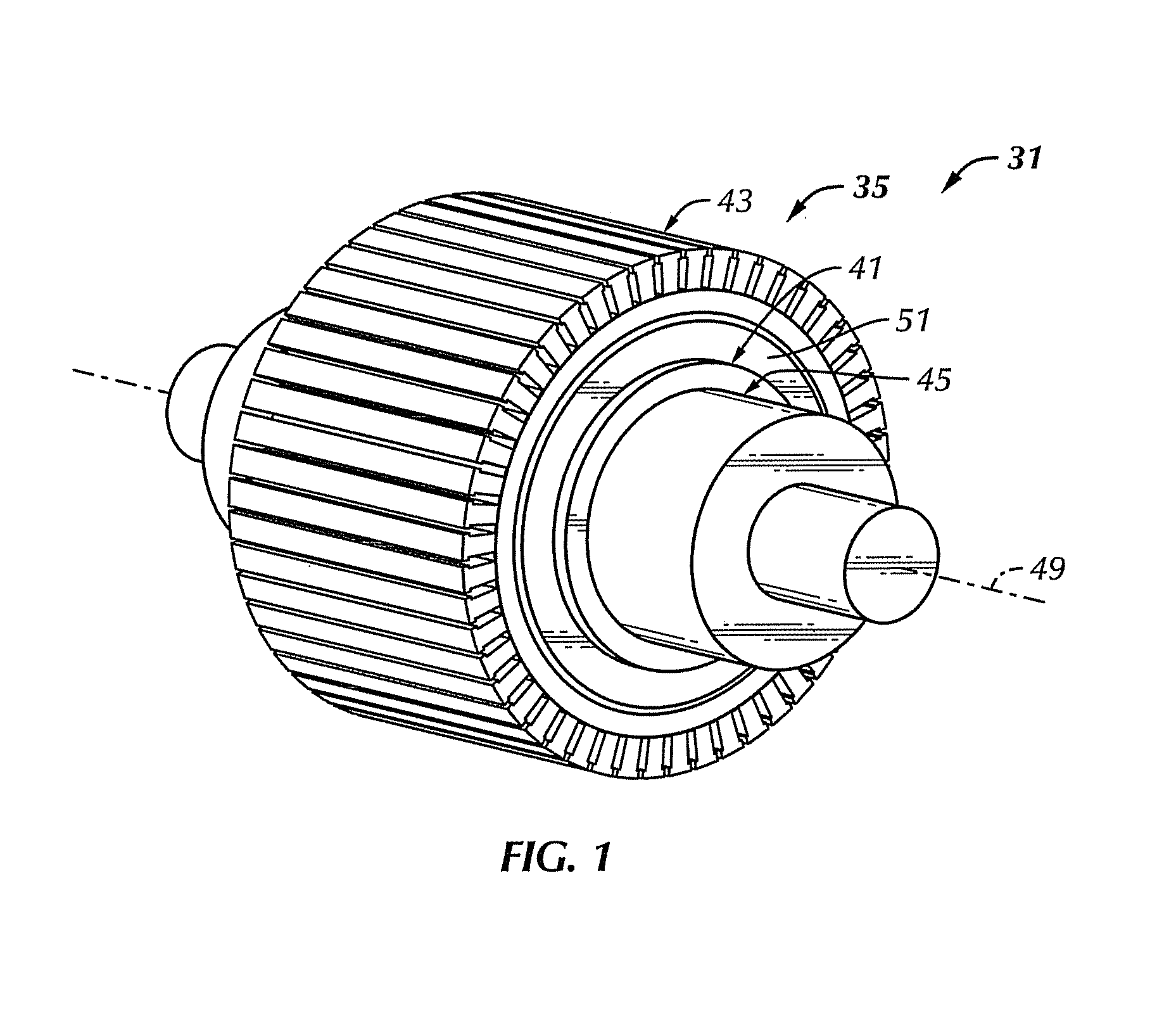

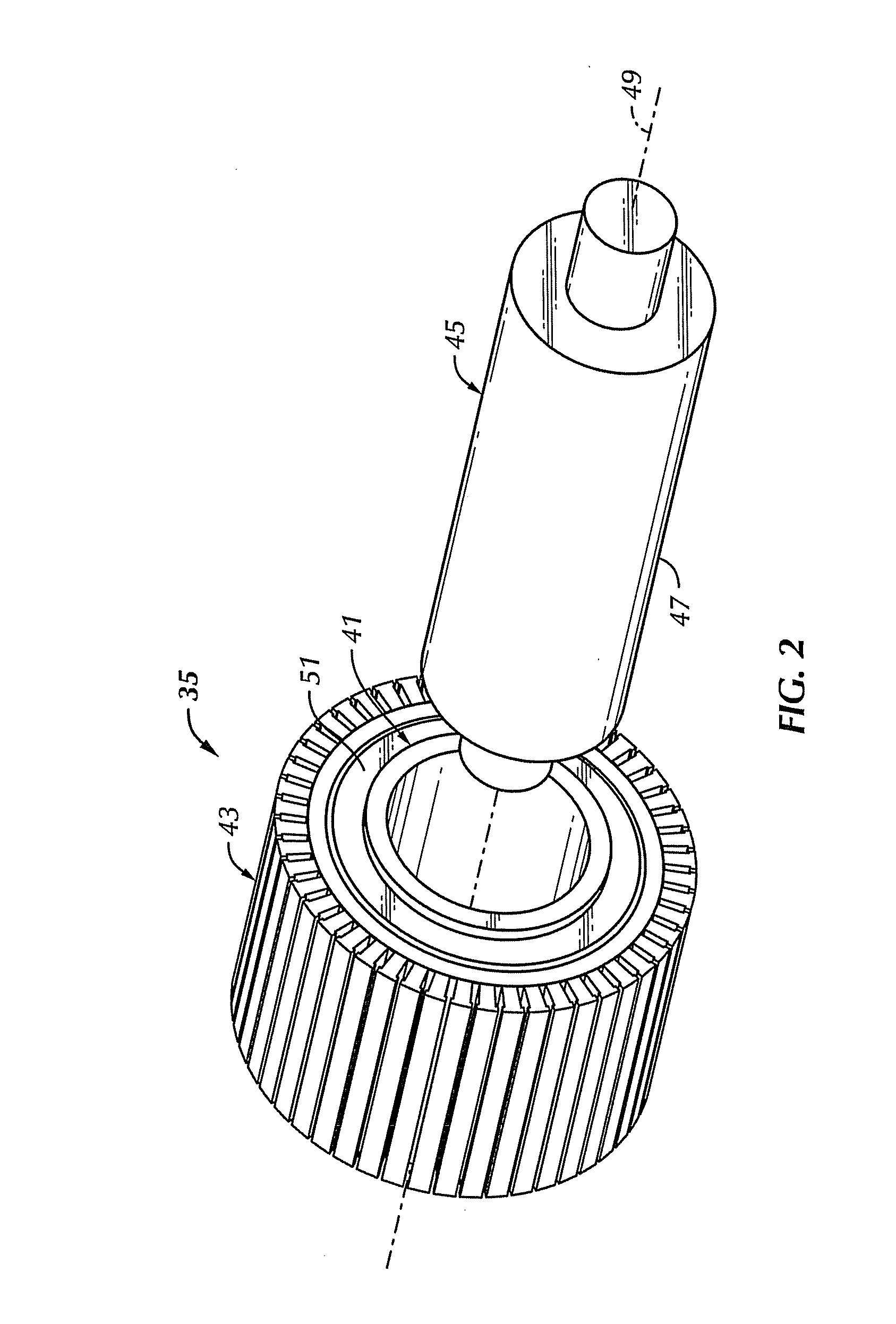

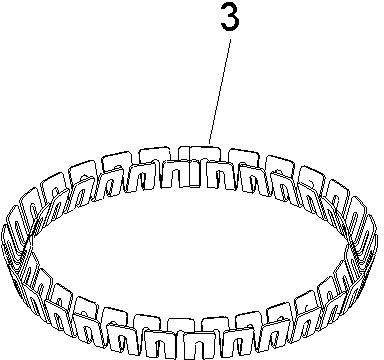

Rotor assembly and method of assembling a rotor of a high speed electric machine

InactiveUS20080122311A1Improve performanceImprove power densityMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringMechanical engineering

A rotor assembly for a high speed electric machine and associated methods are provided. The rotor assembly includes a shaft, a plurality of laminations positioned along an axial extent of the shaft forming a lamination stack, a pair of end plates each positioned on one of the respective ends of the lamination stack, and an internal clamping tube substantially surrounding major portions of the axial extent of the shaft, positioned between the shaft and inner portions of the lamination stack, and contacting the pair of endplates to provide clamping of the lamination stack.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

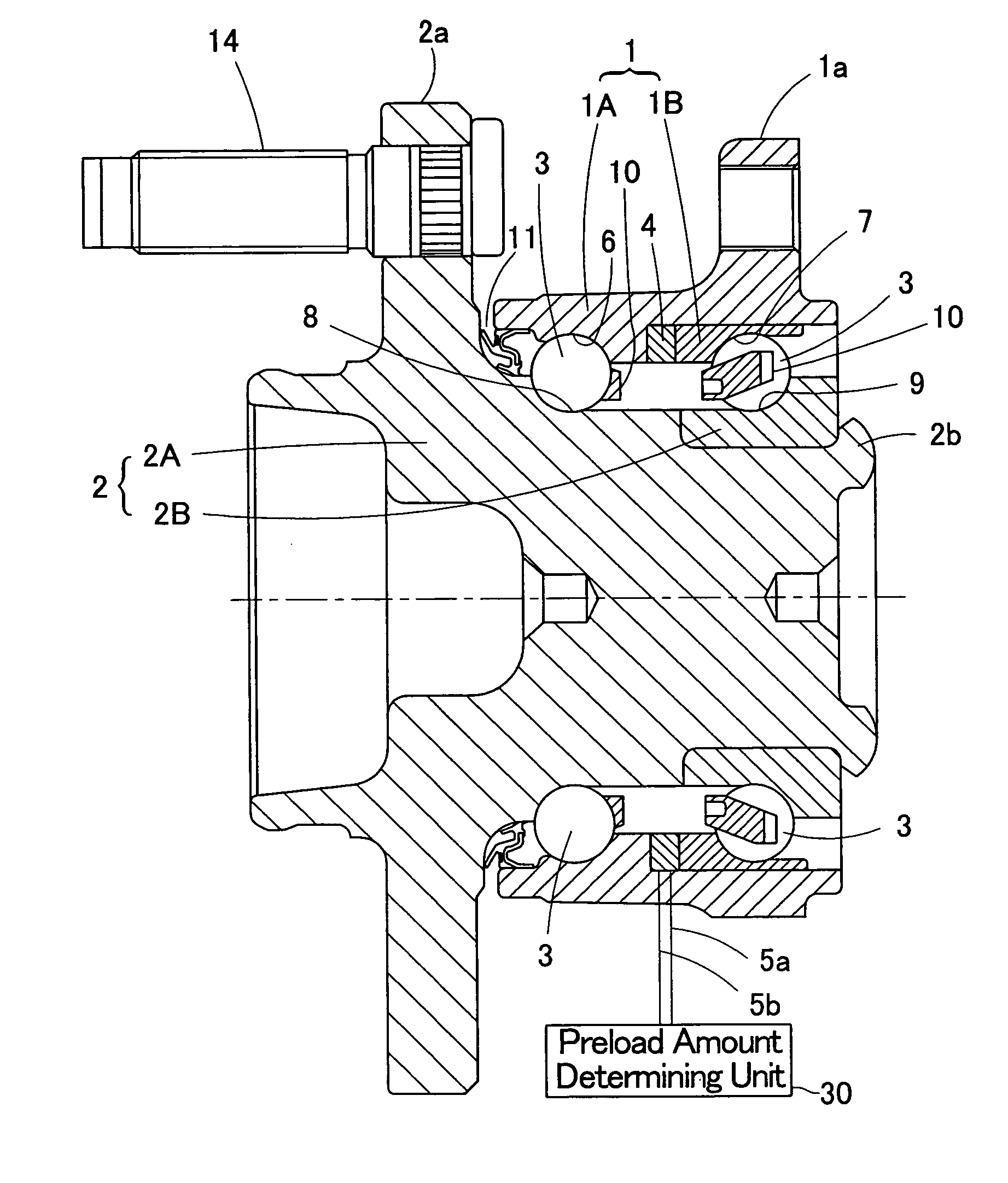

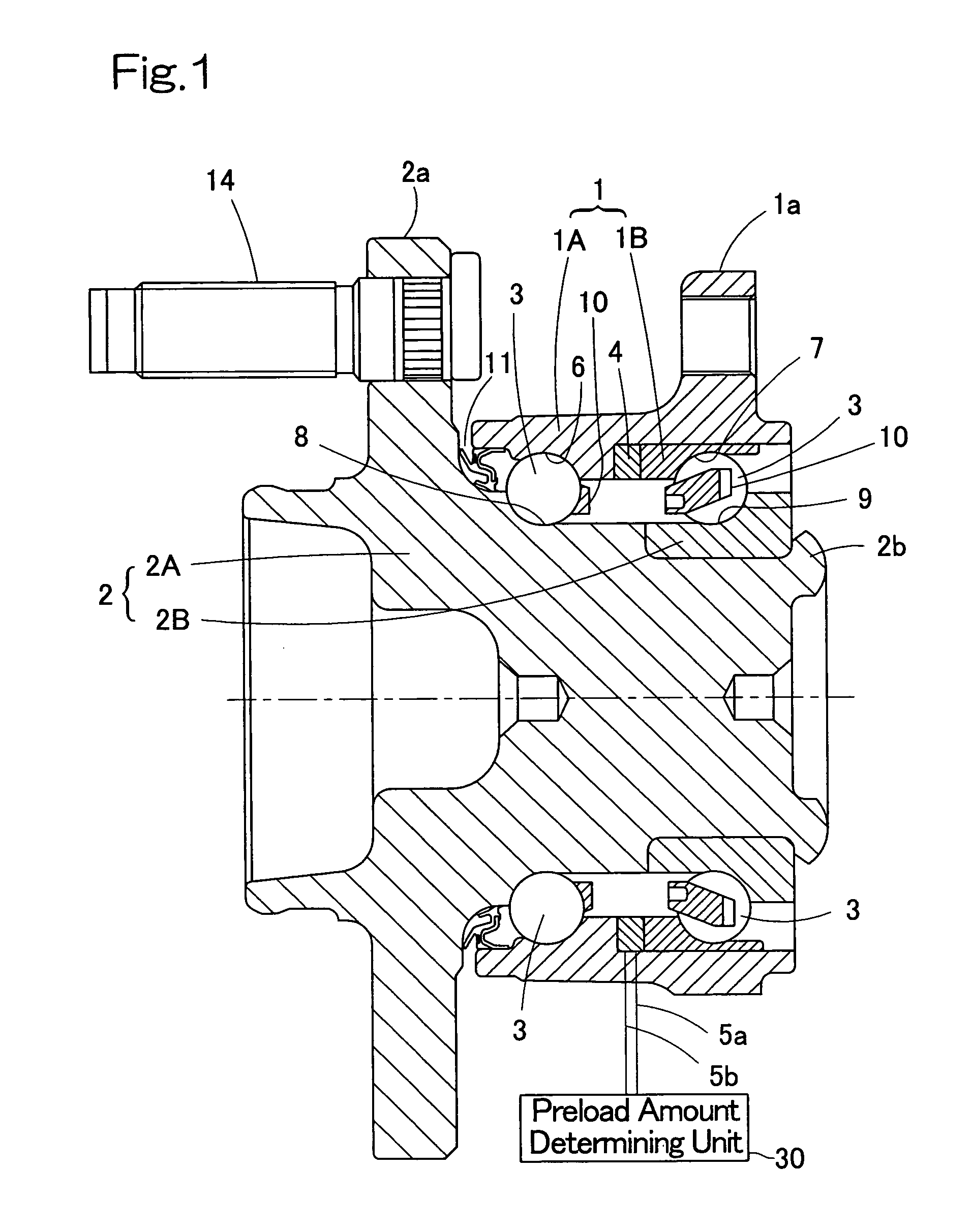

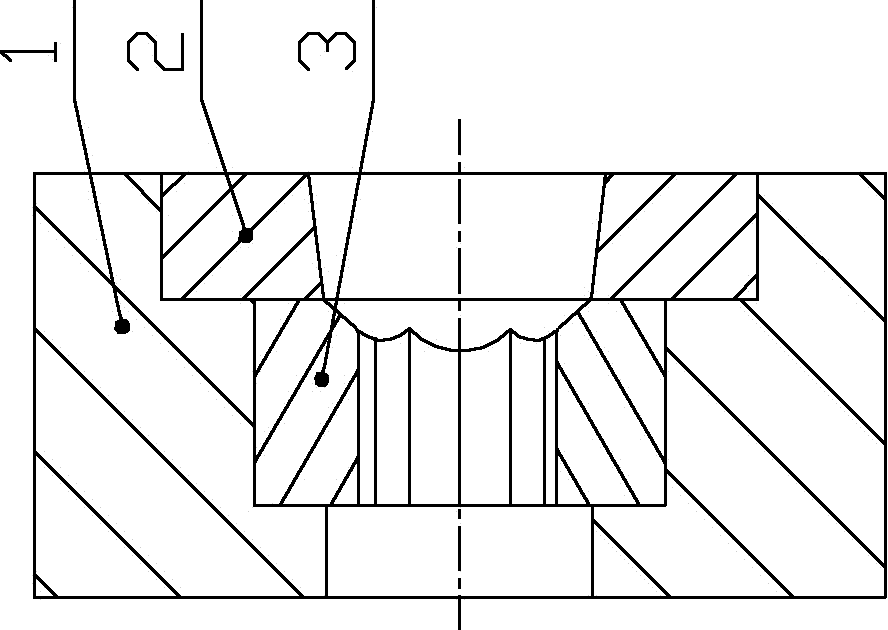

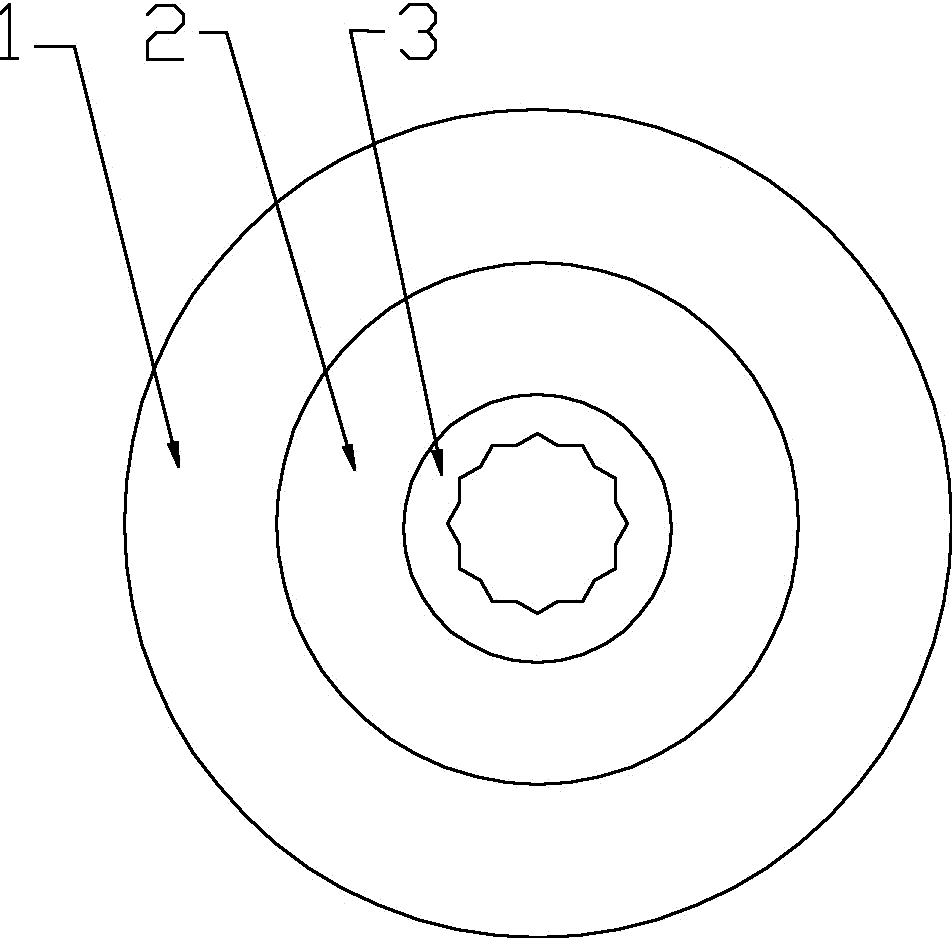

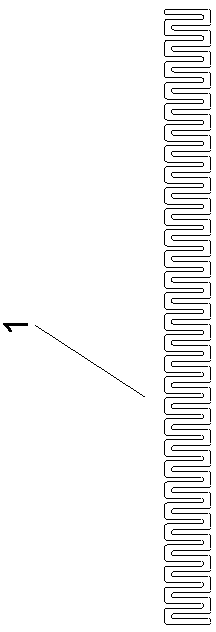

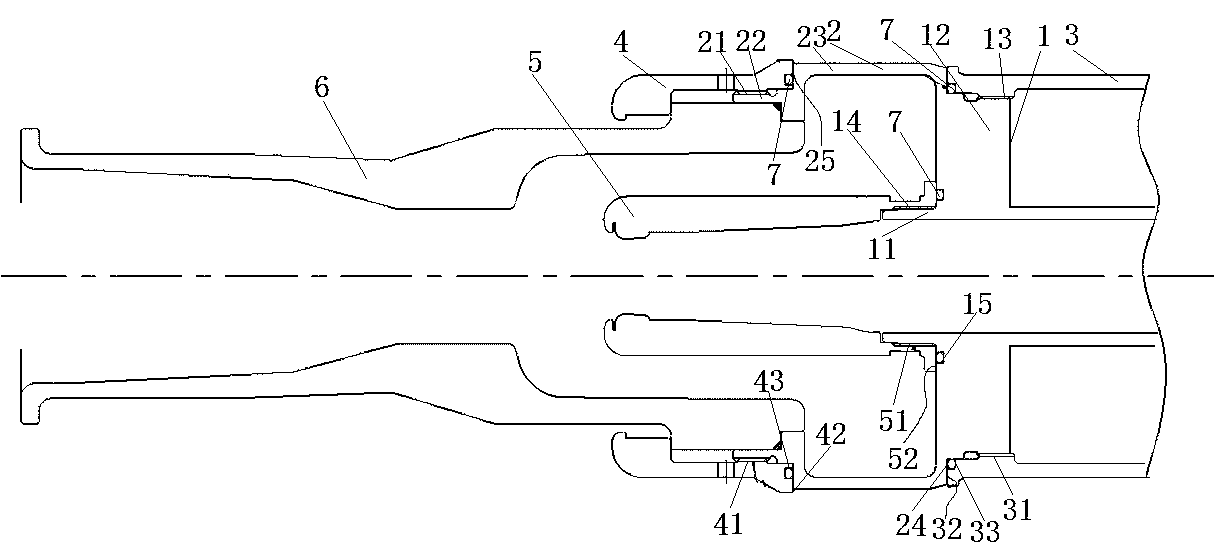

Bearing device for wheel

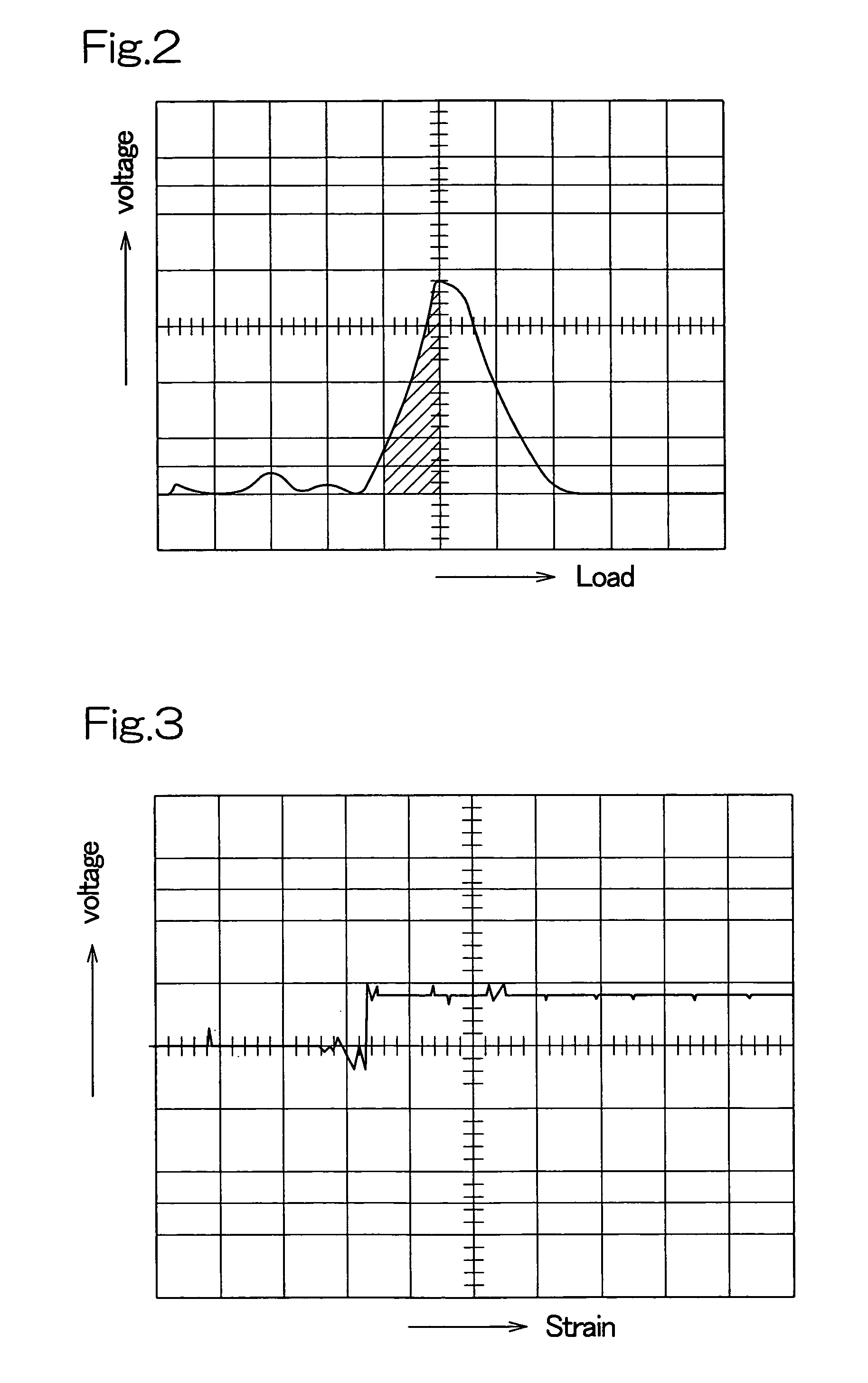

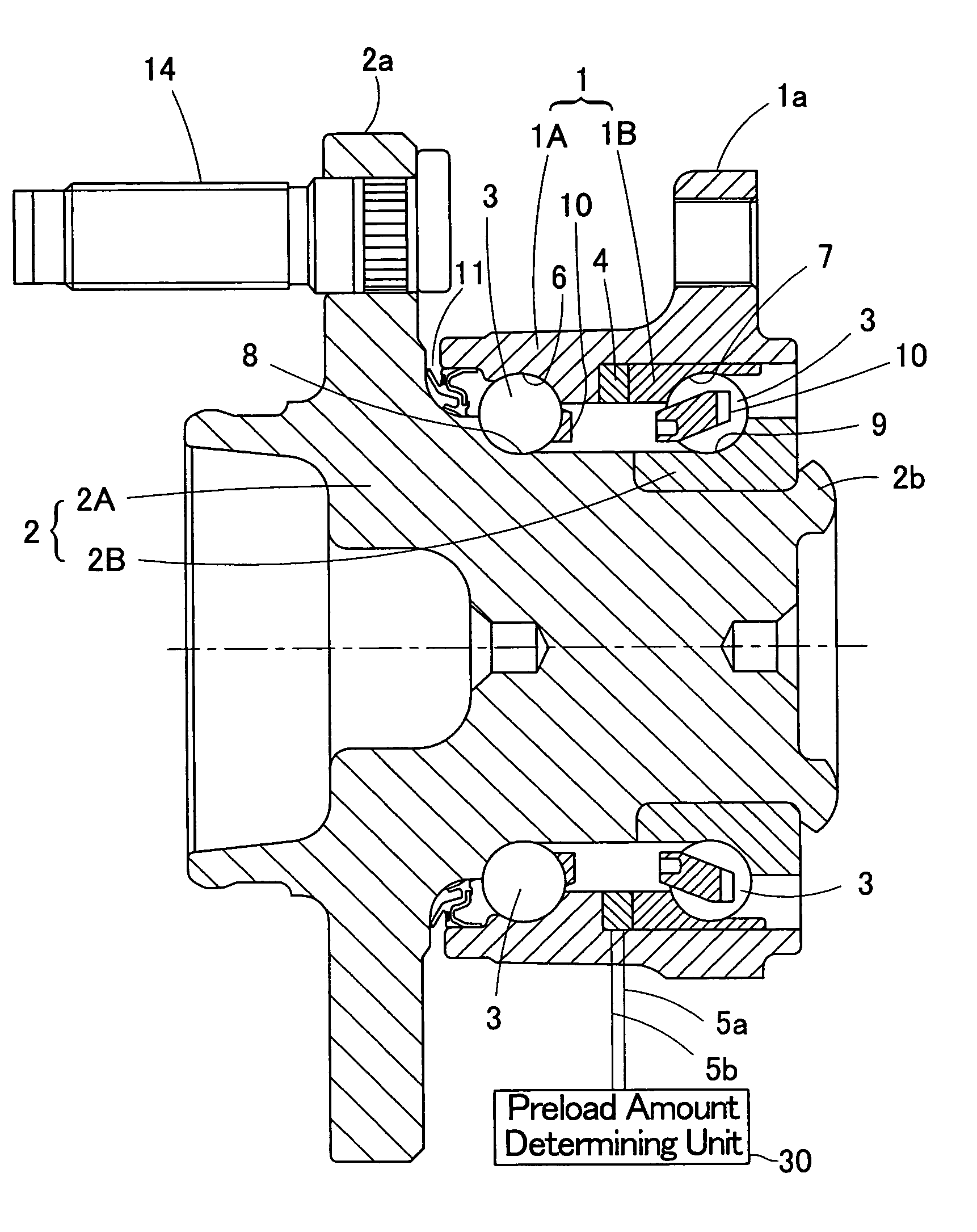

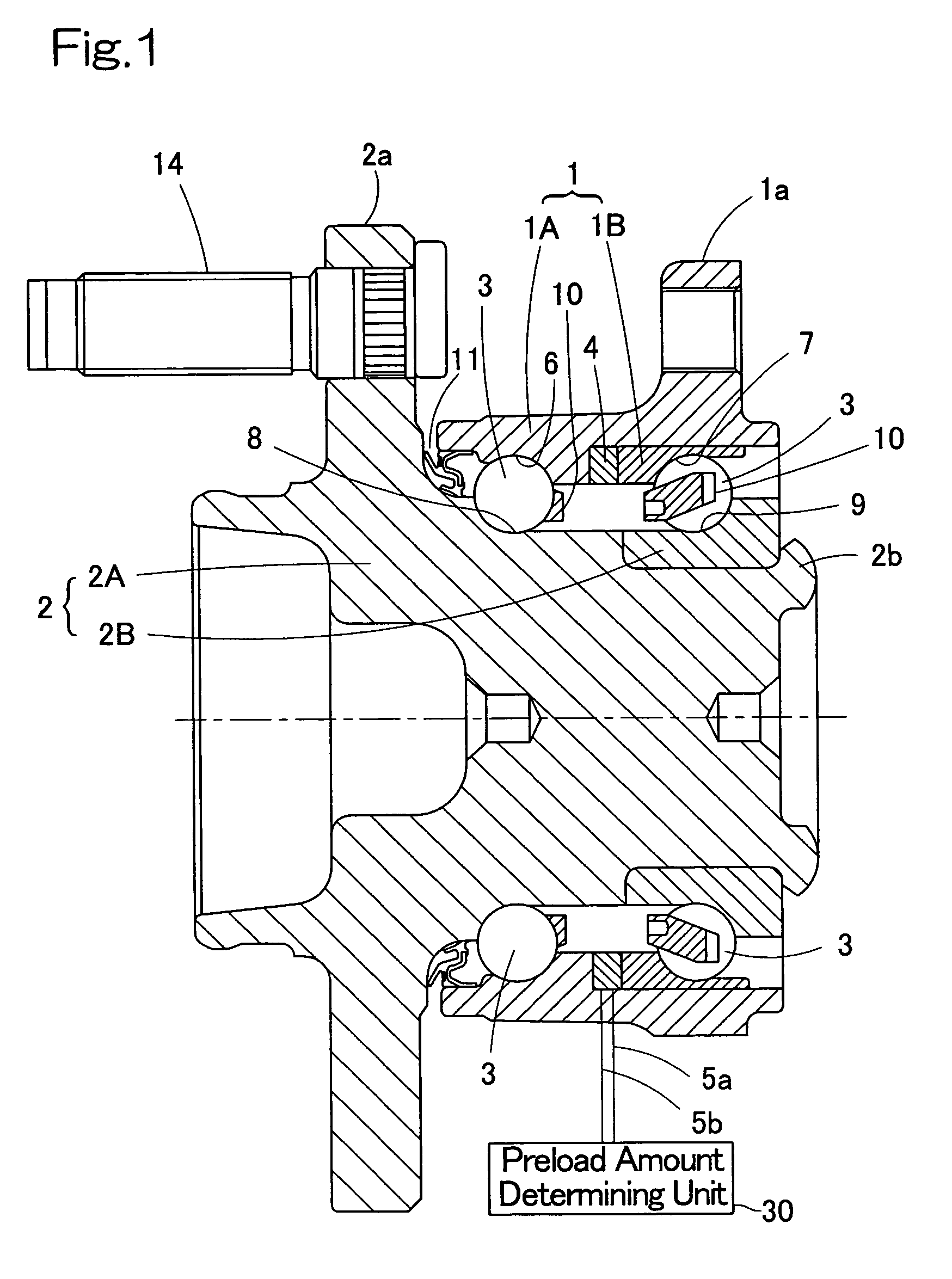

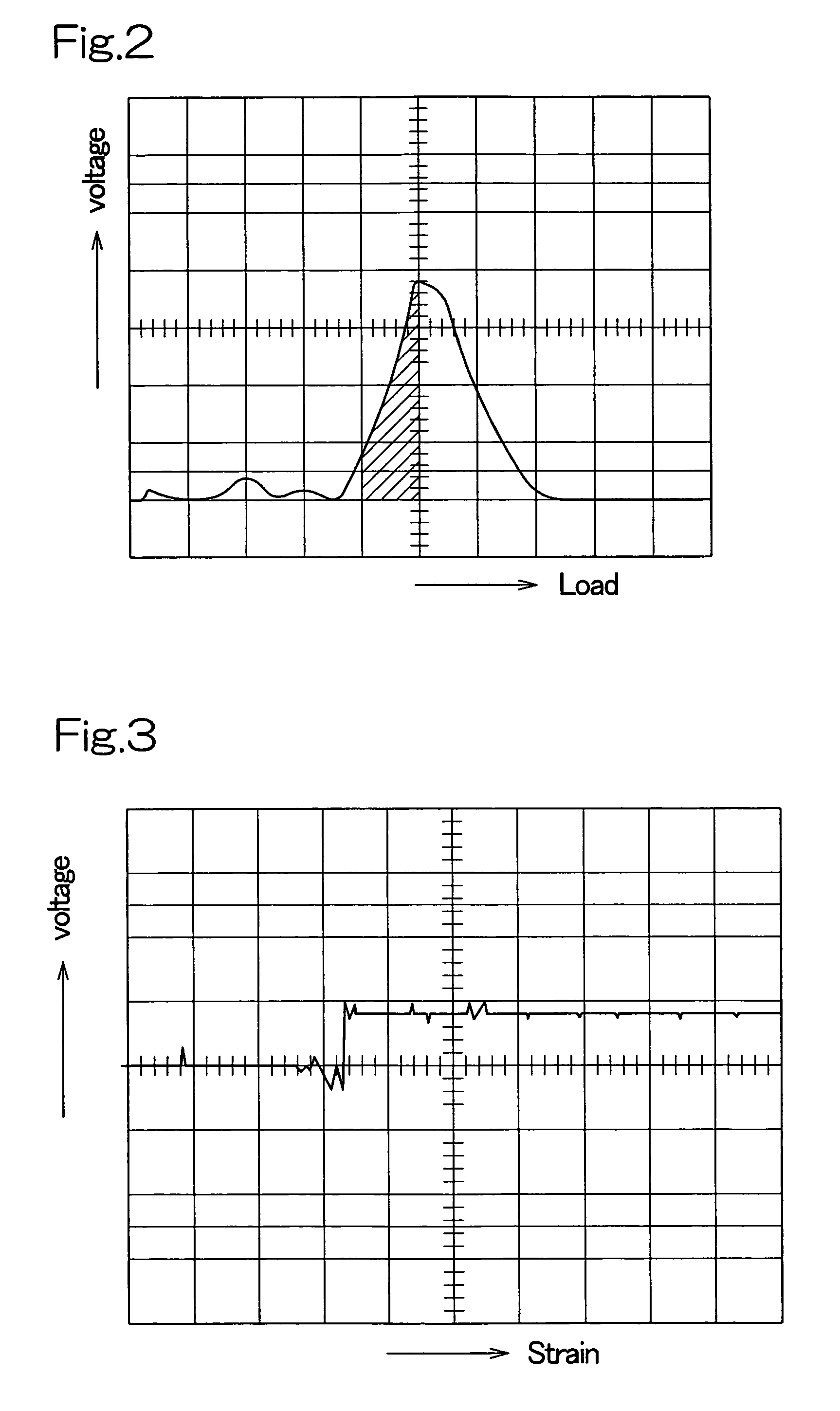

InactiveUS20070014500A1Suppress mutationSimple to executeRolling contact bearingsBearing assemblyEngineeringFlange

To provide a bearing device for a wheel, in which a preload control is easy and a uniform amount of preload can be applied with a bearing seal being mounted, the bearing device for the wheel includes an outer member, an inner member and double rows of rolling elements interposed between the outer member and the inner member. The outer member has a flange on an outer periphery thereof and also has an inner periphery formed with two rolling surfaces. The inner member is formed with rolling surfaces opposed to the rolling surfaces of the outer member. The double rows of the rolling elements are interposed between the rolling surfaces of the outer member and the inner member. A sensor for detecting the amount of preload of the bearing is provided in one of the outer and inner members.

Owner:NTN CORP

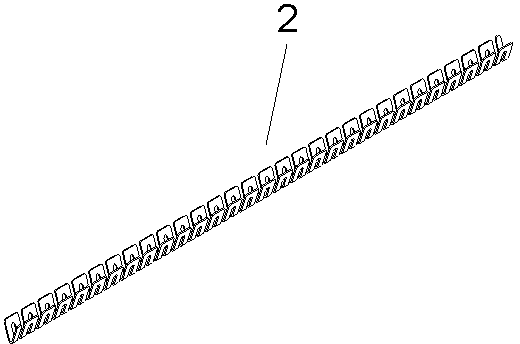

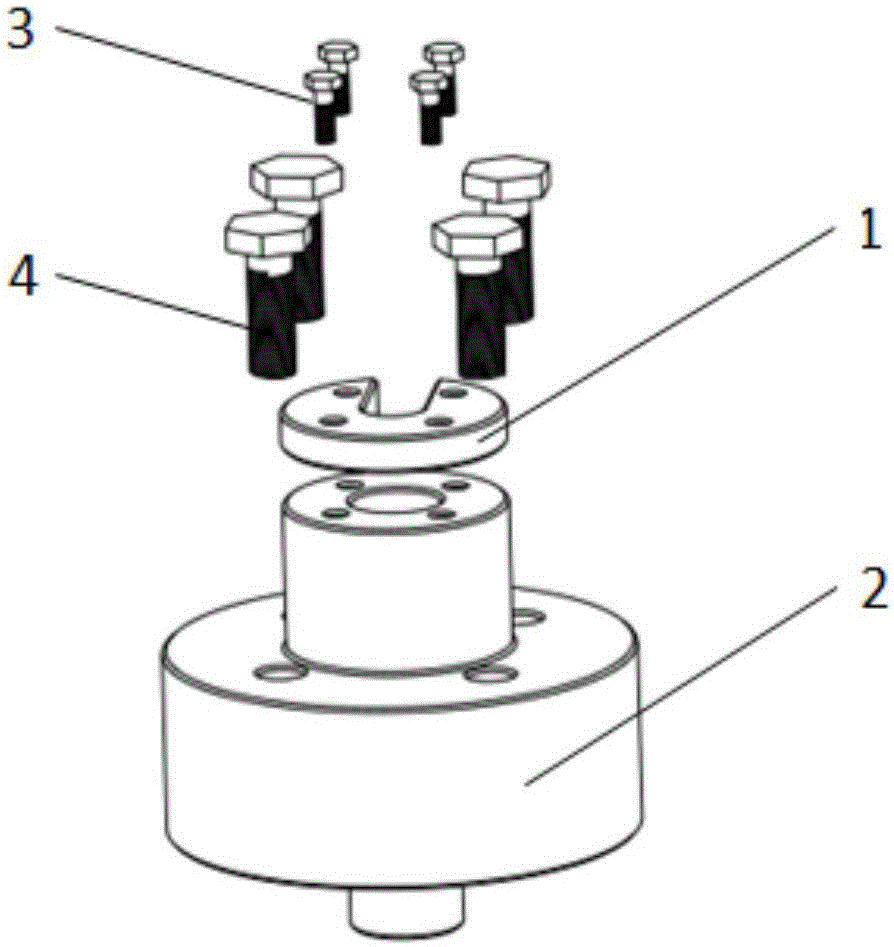

Bearing device for wheel

InactiveUS7628540B2Simple to executeUniform preloadRolling contact bearingsBearing assemblyEngineeringFlange

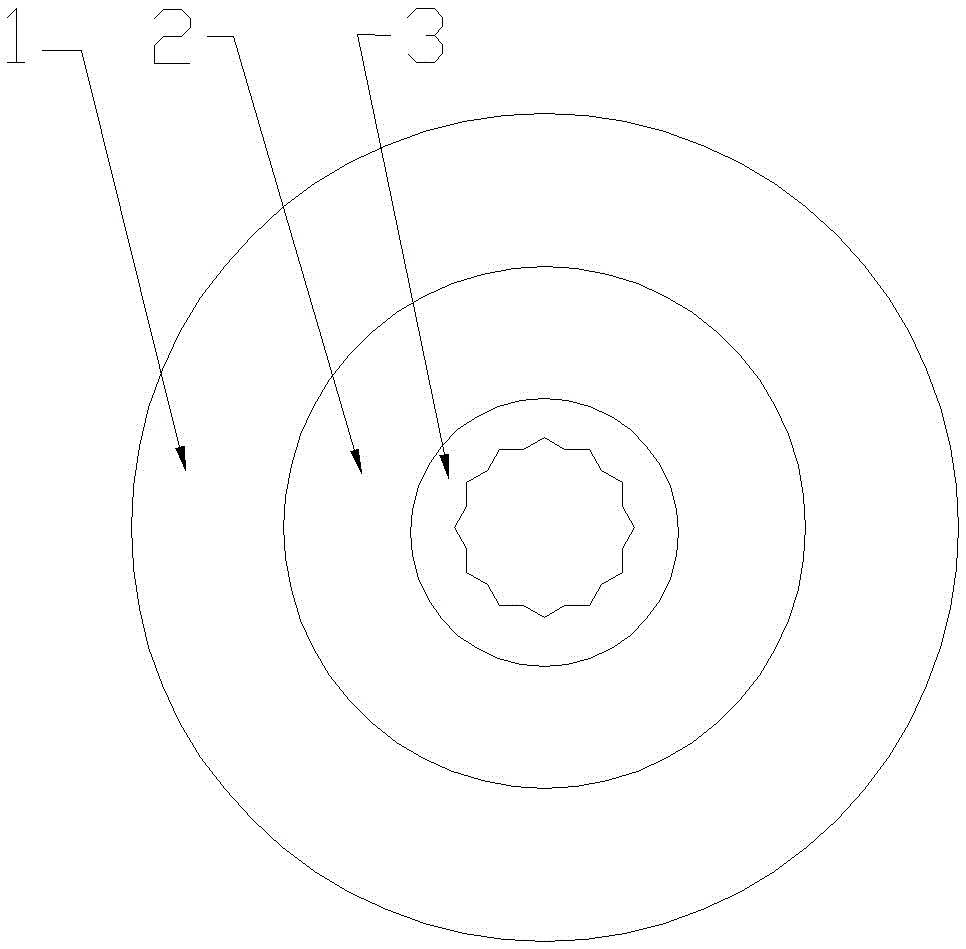

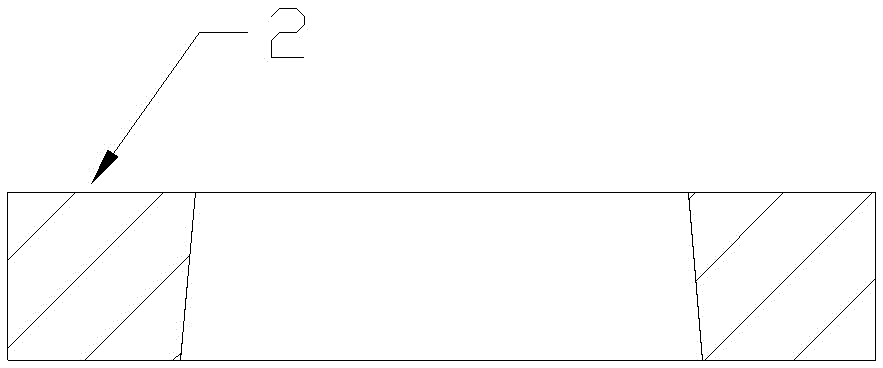

A bearing device for a wheel, where preload control is easy and a uniform amount of preload can be applied even if a bearing seal is installed in the bearing device. The bearing device rotatably supports a wheel and has an outer member 1, an inner member 2, and rolling elements 3 interposed between both members. The outer member 1 has on its outer periphery a vehicle body installation flange 1a, and double row rolling surfaces 6, 7 are formed on the inner peripheries of the outer member. Rolling surfaces 8, 9 facing the rolling surfaces 6, 7 of the outer member 1 are formed in the inner member 2. Between the rolling surfaces of both members 1, 2 are interposed the rolling elements 3. A sensor 4 for detecting the amount of preload of the bearing is provided on either the outer member 1 or the inner member 2.

Owner:NTN CORP

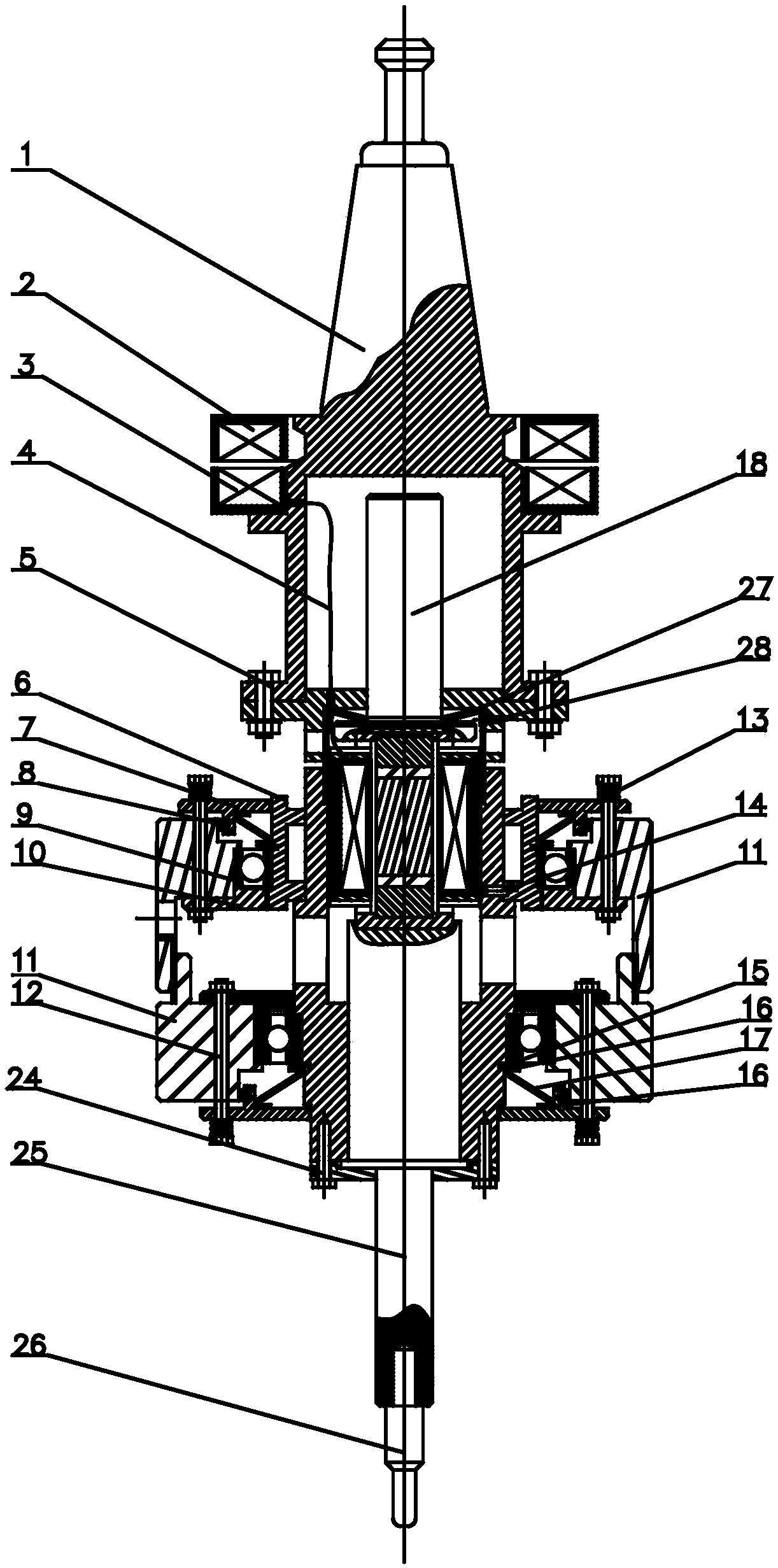

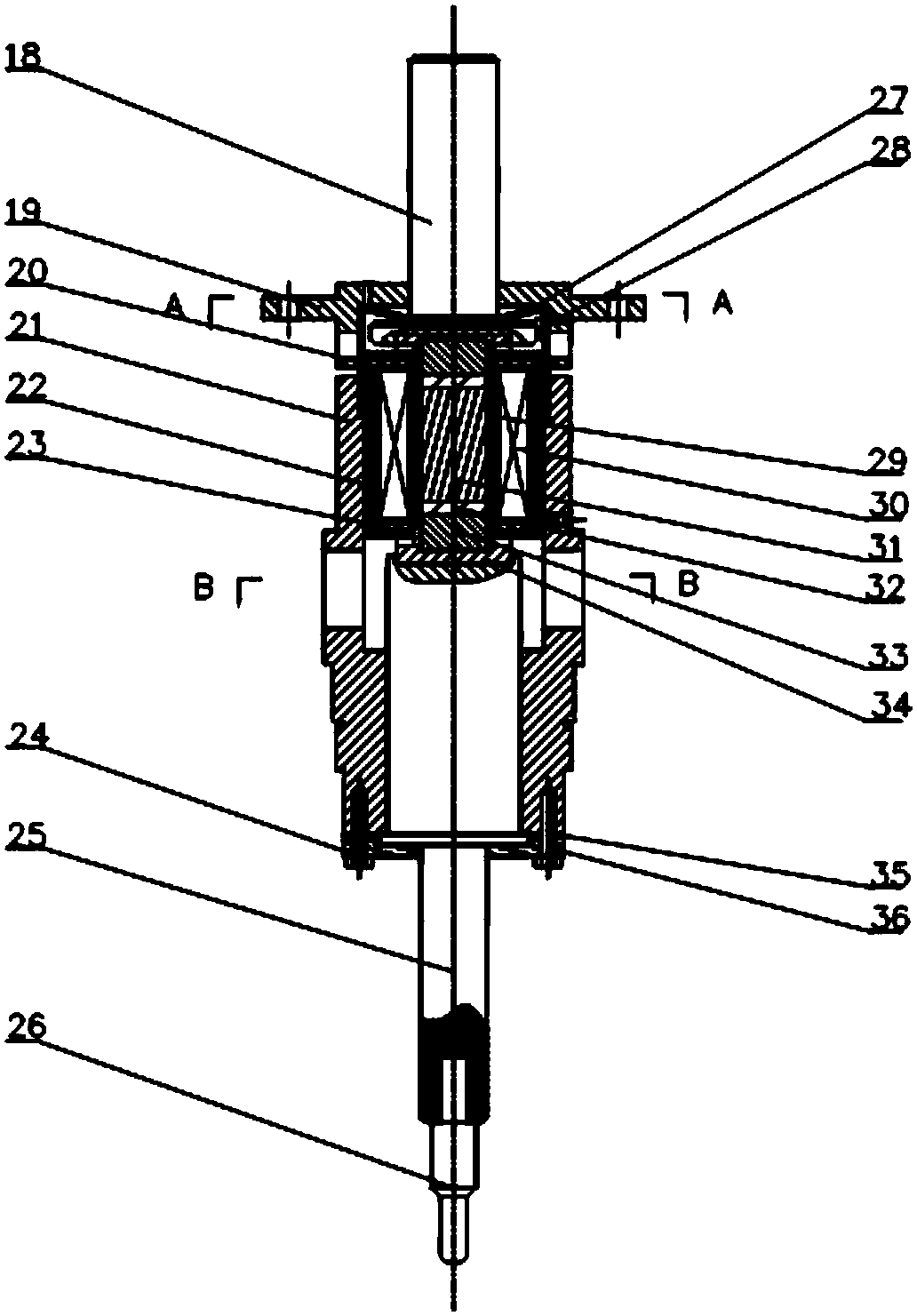

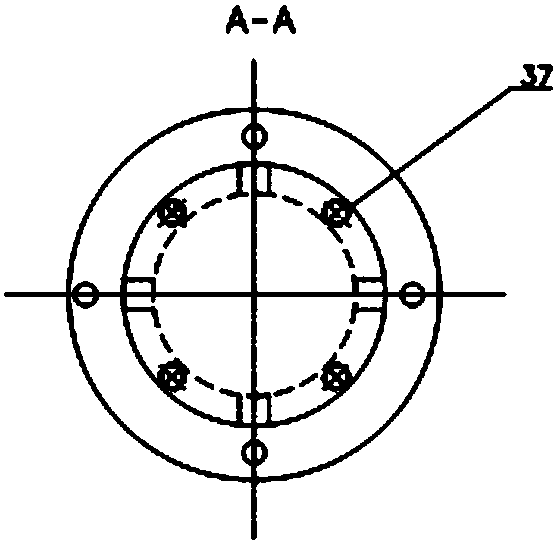

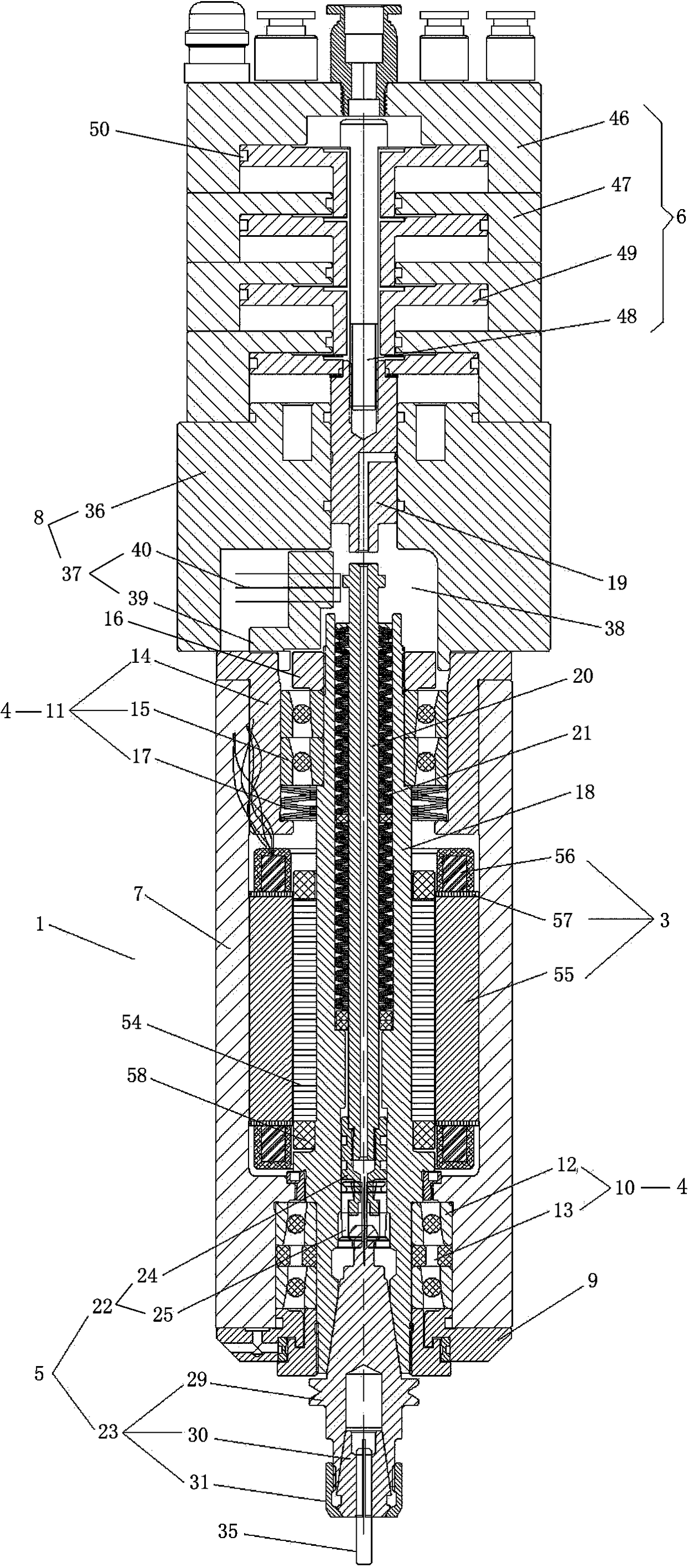

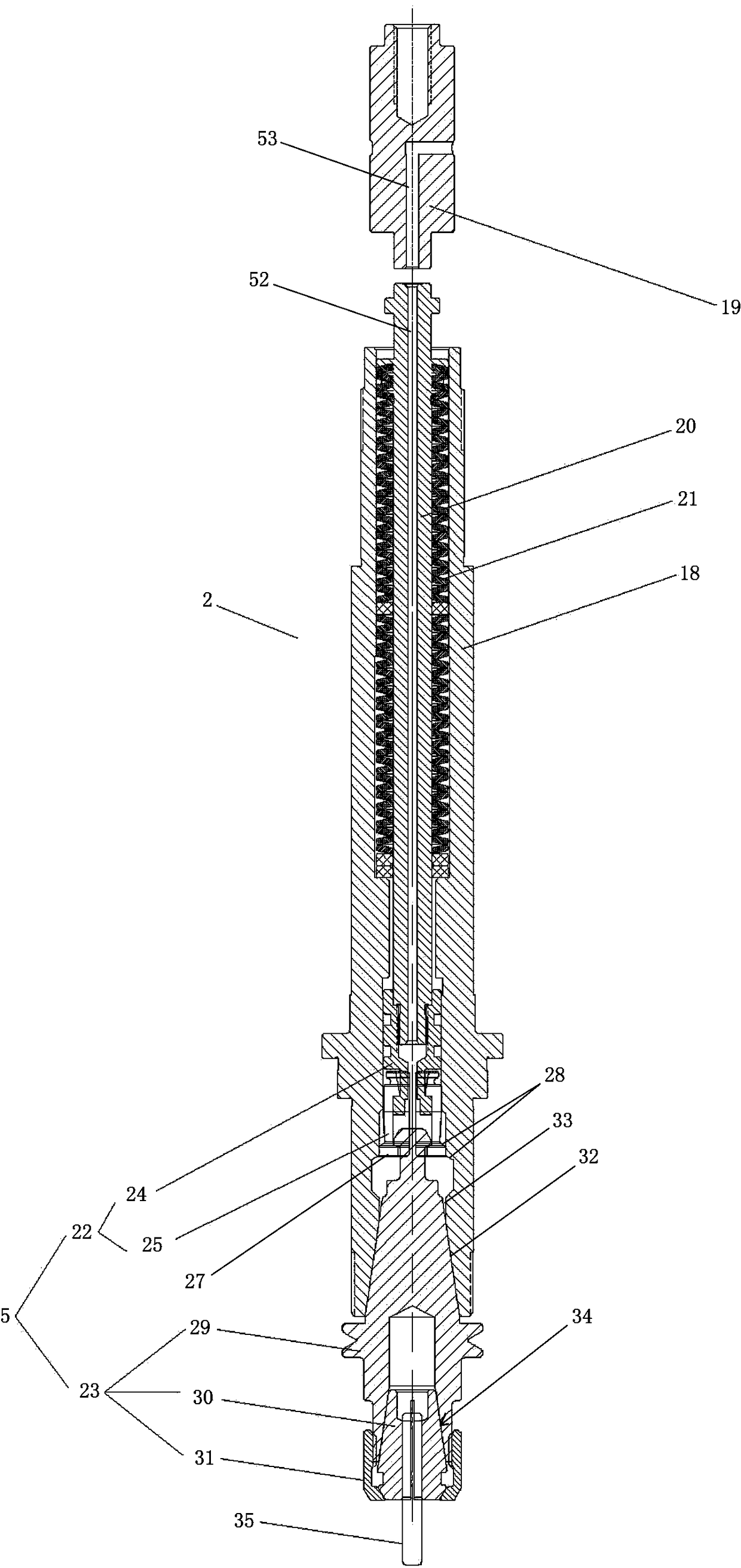

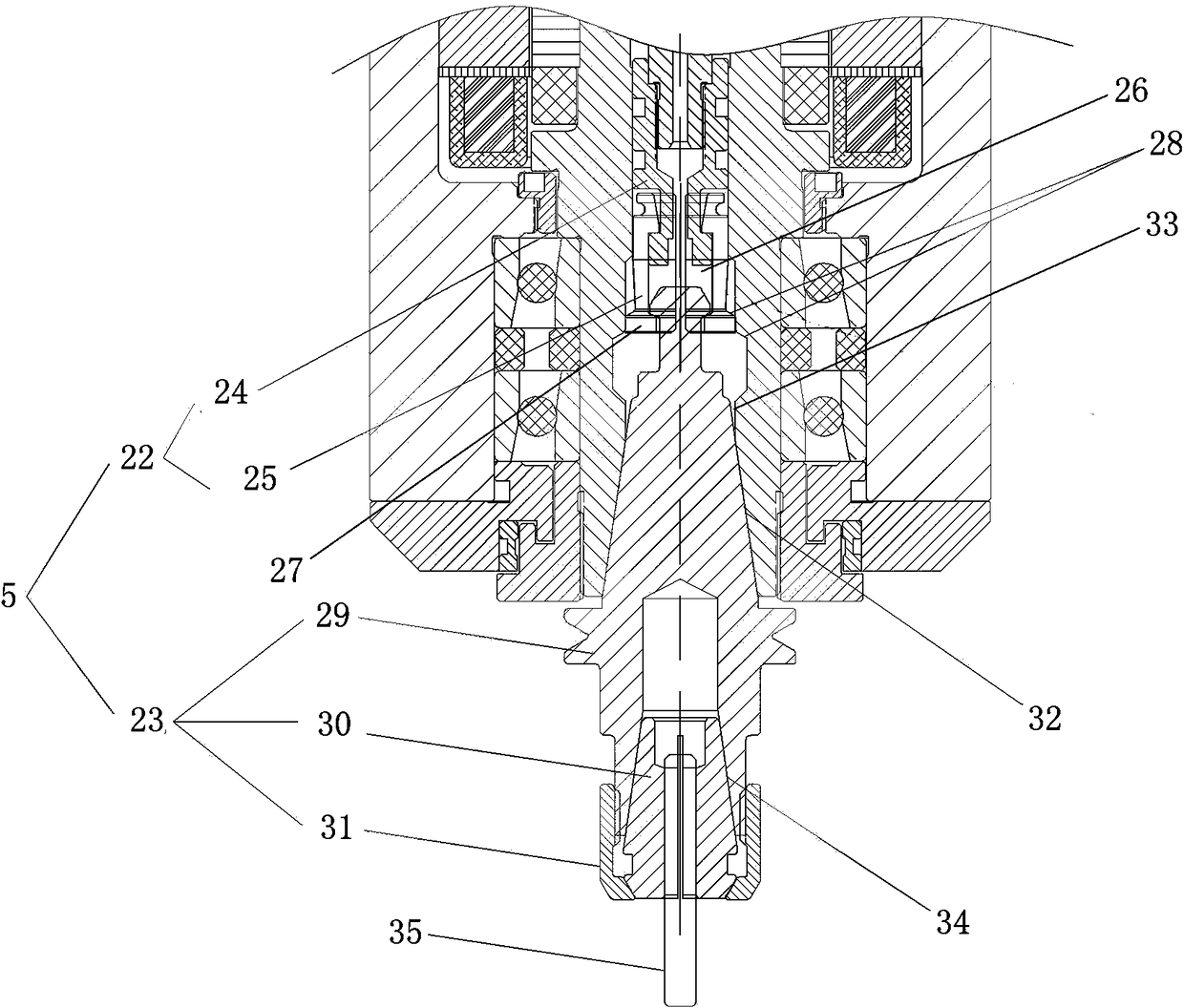

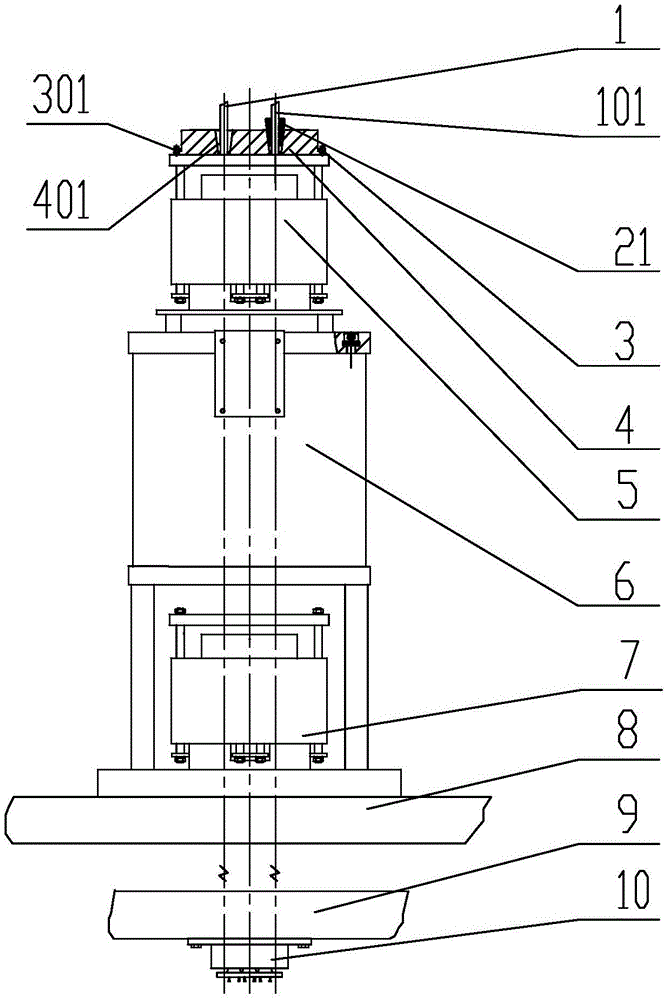

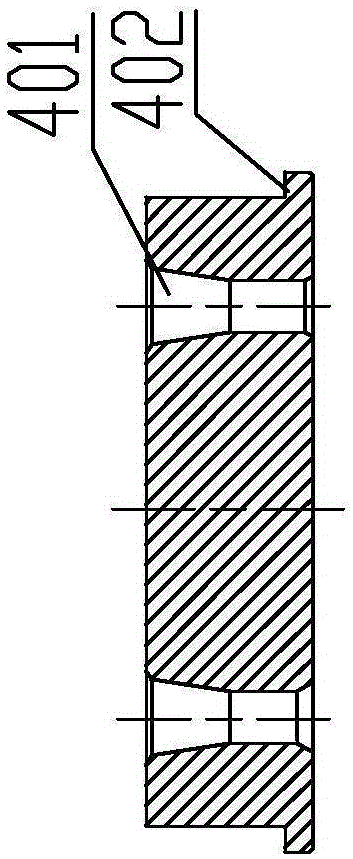

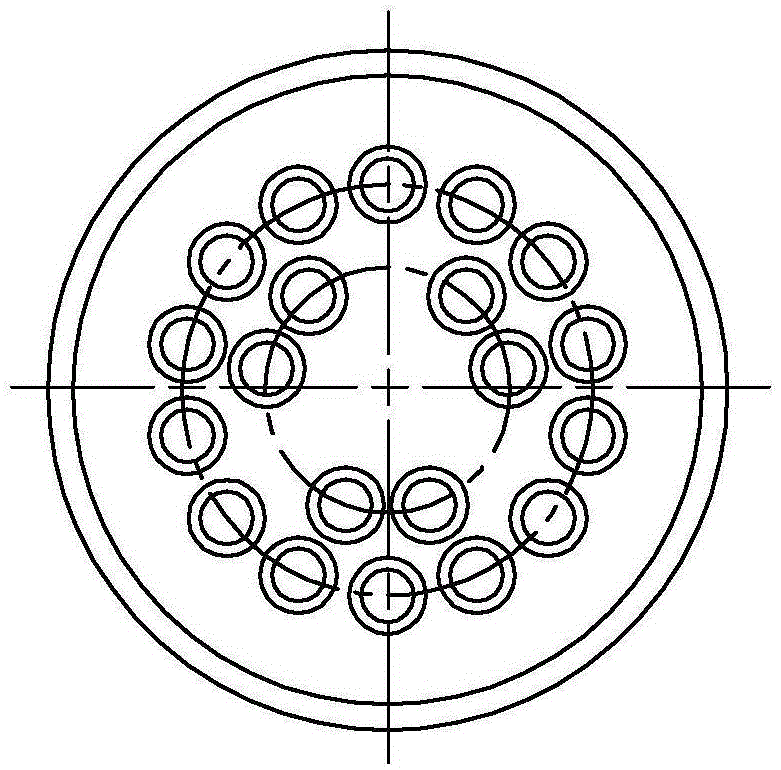

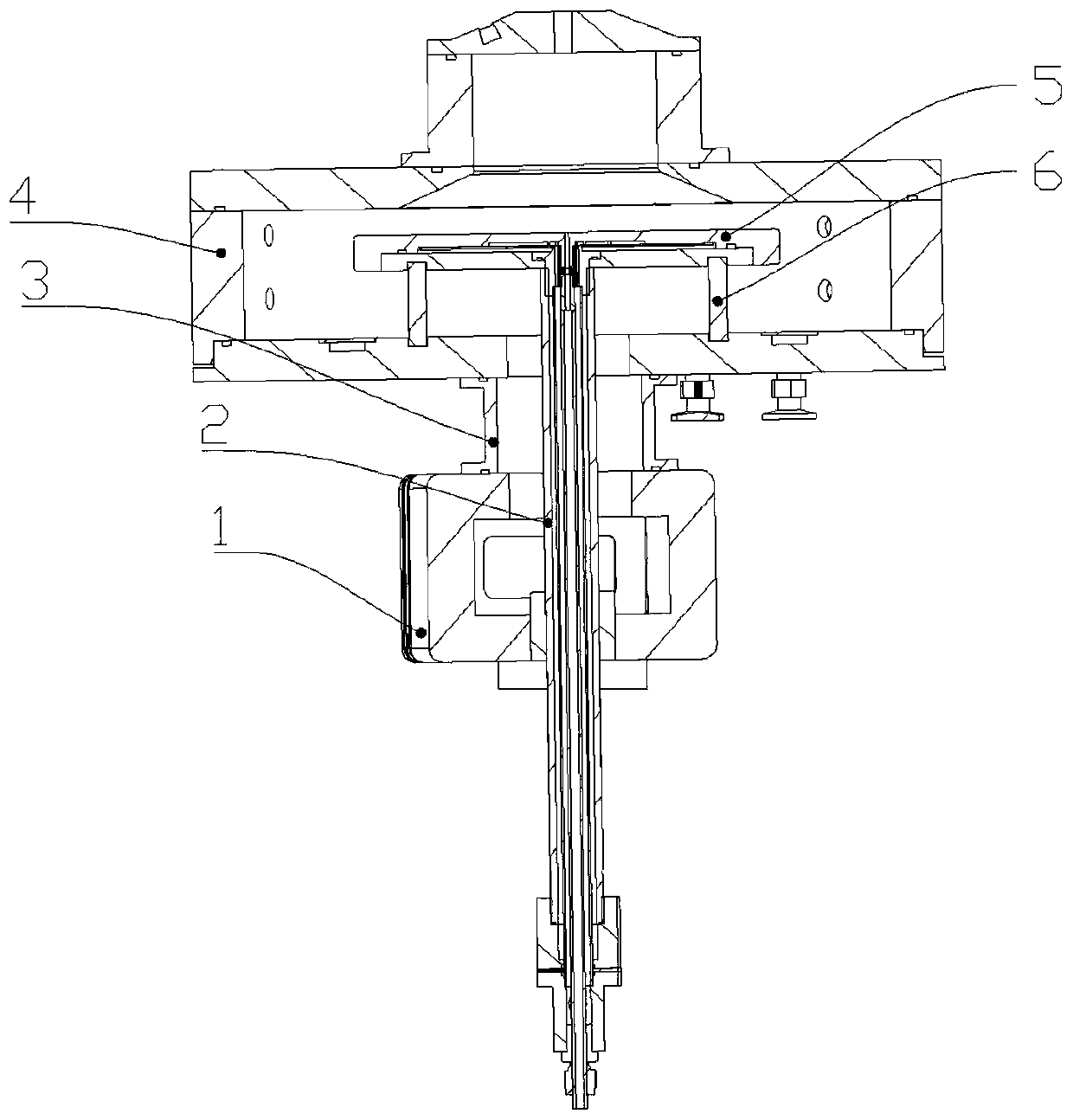

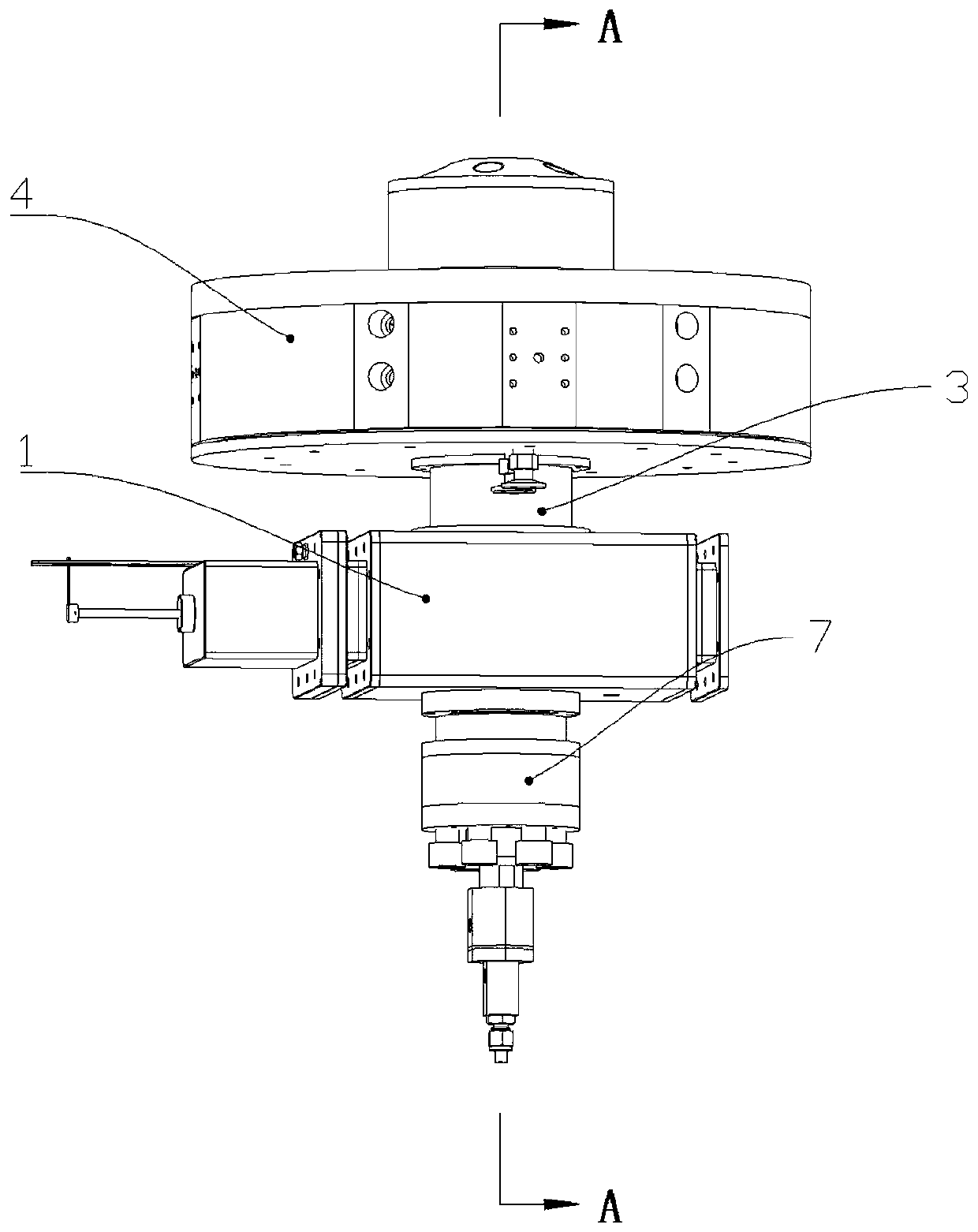

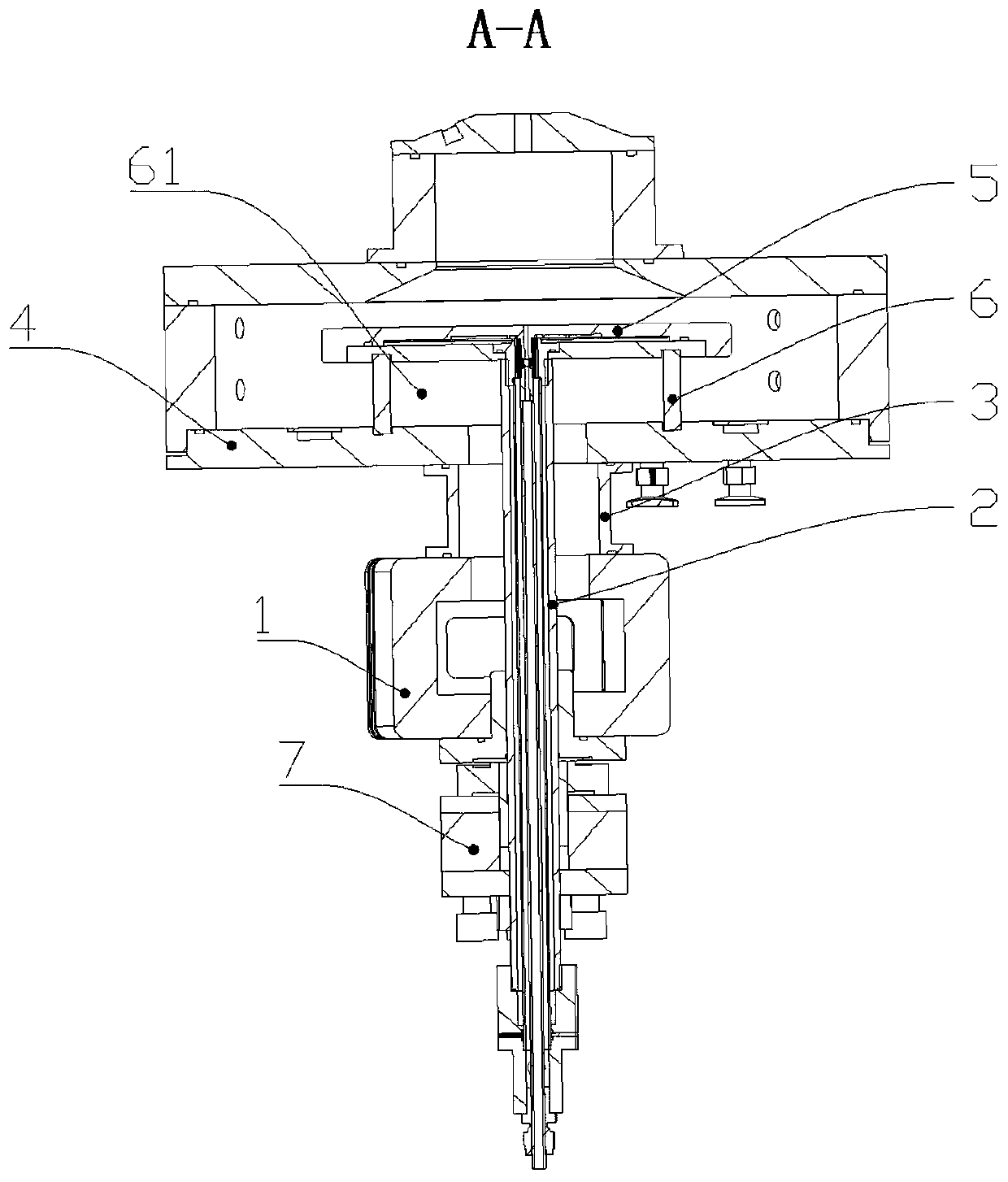

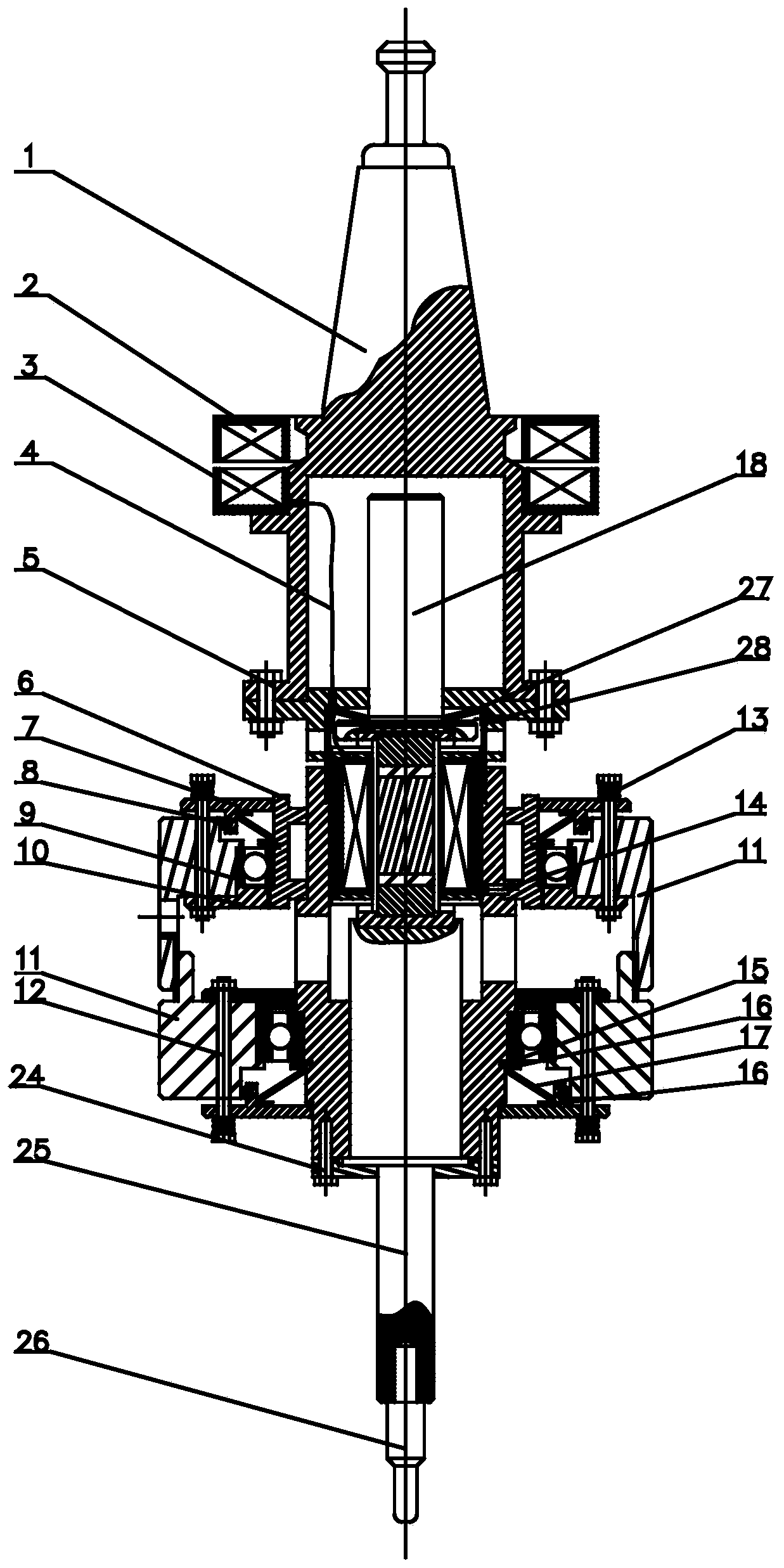

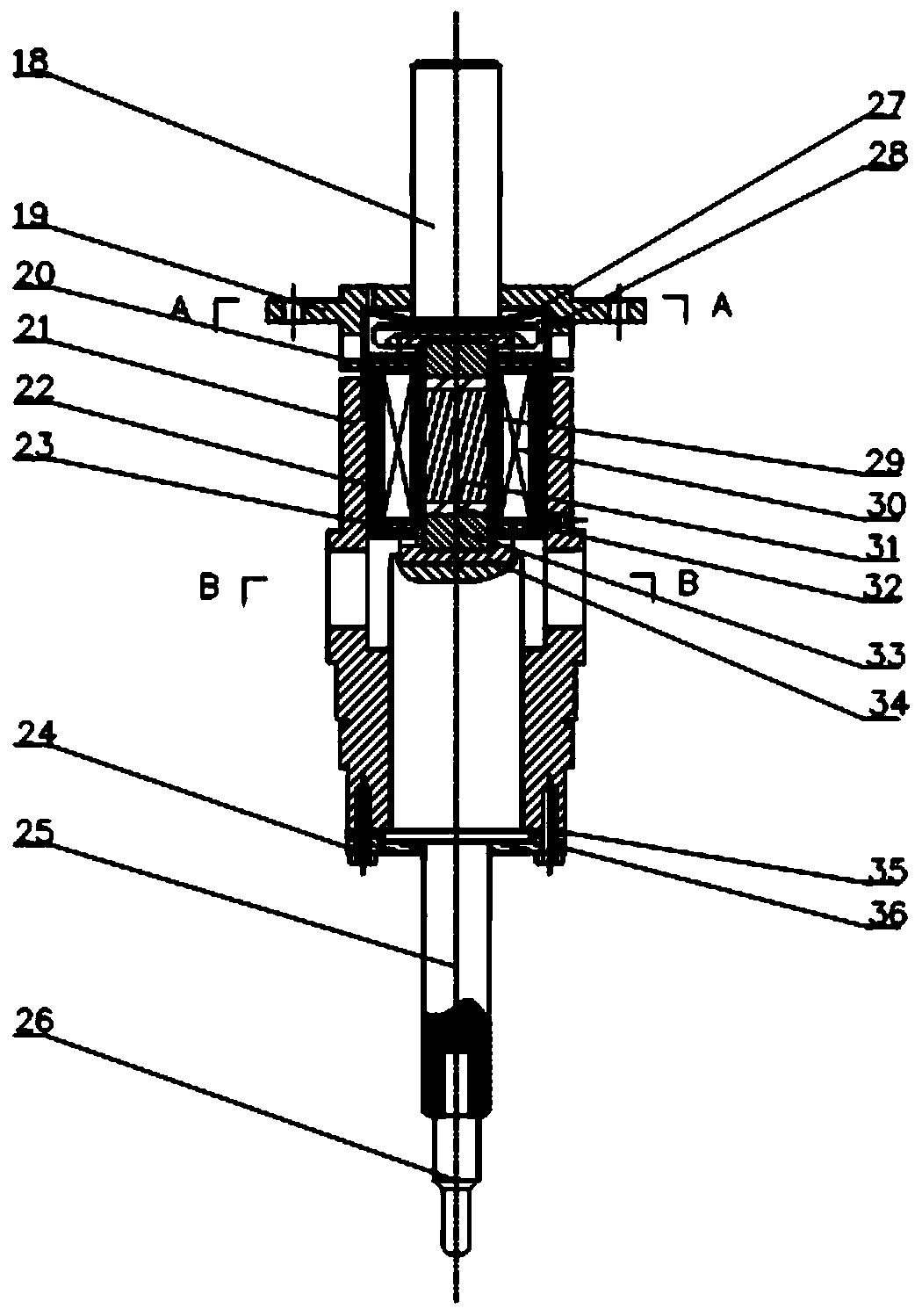

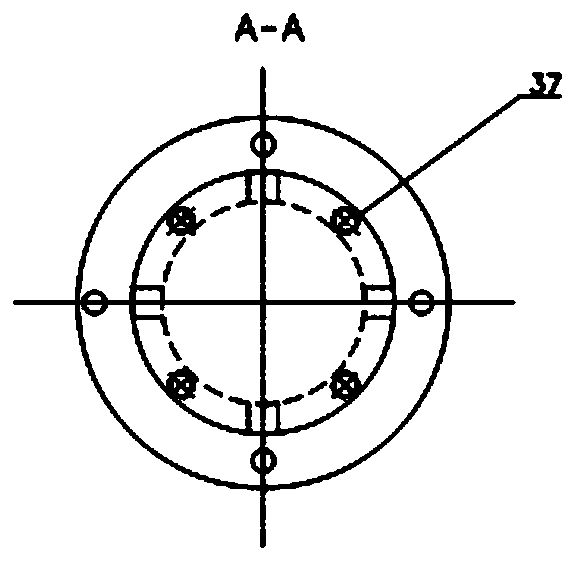

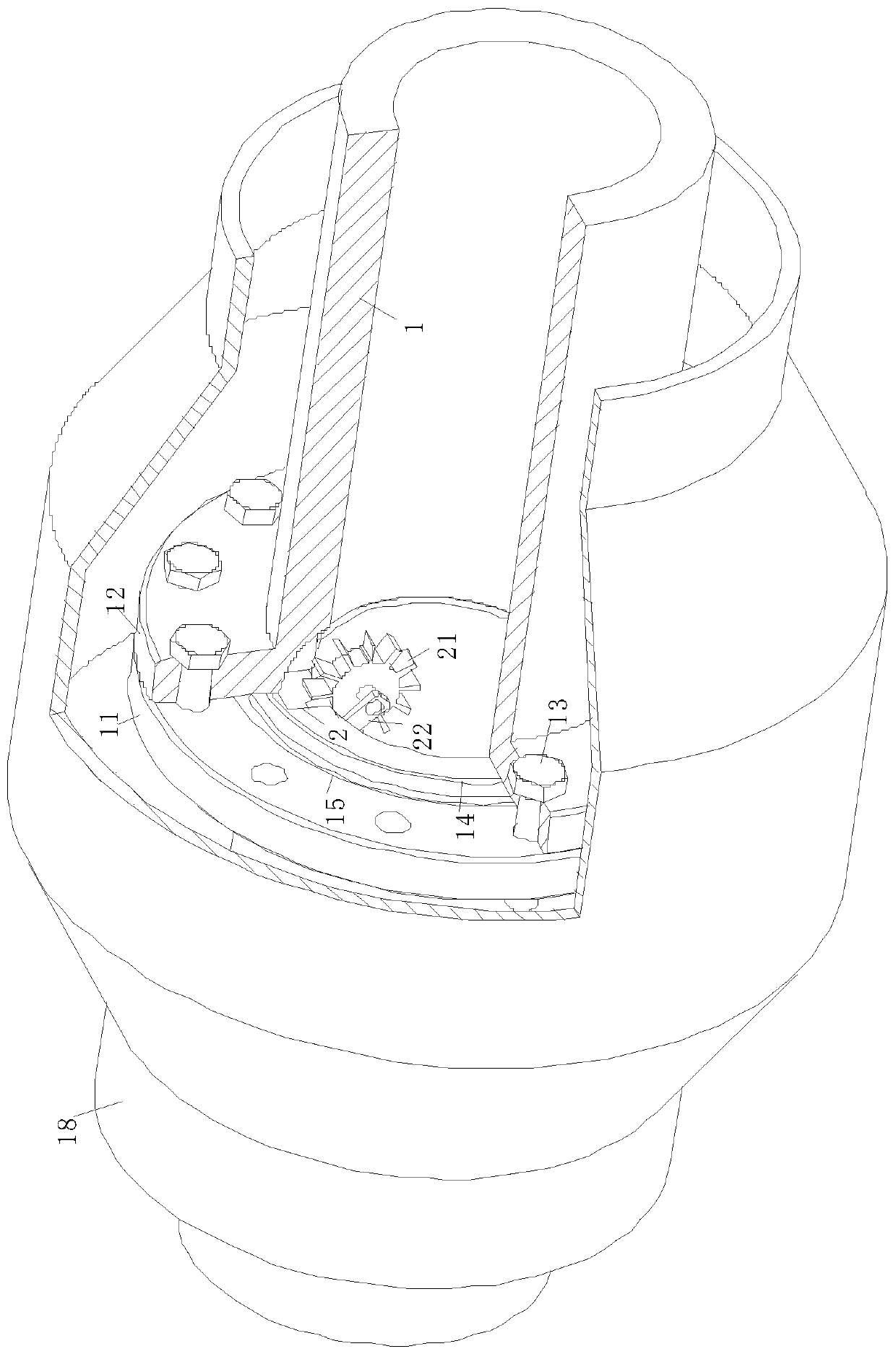

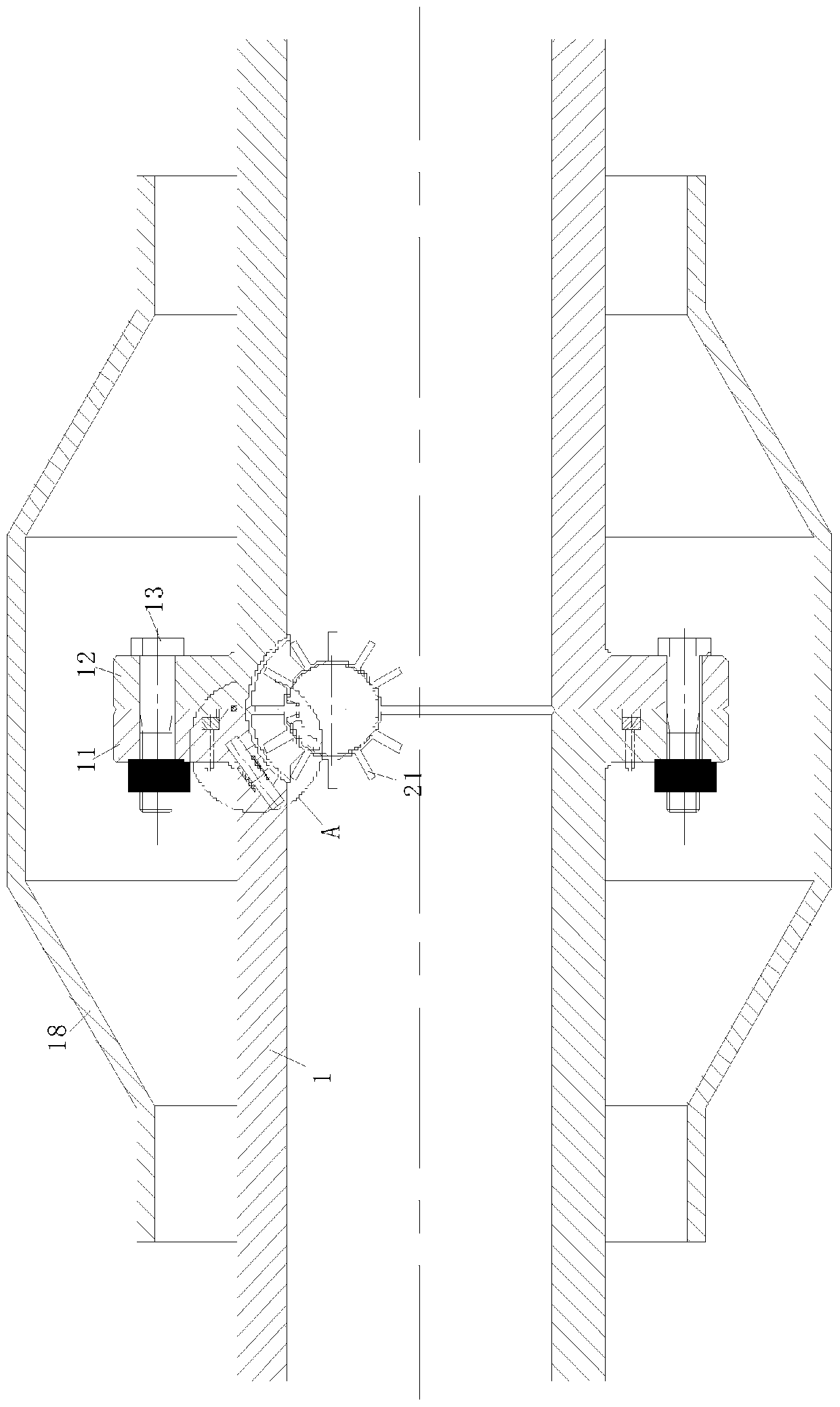

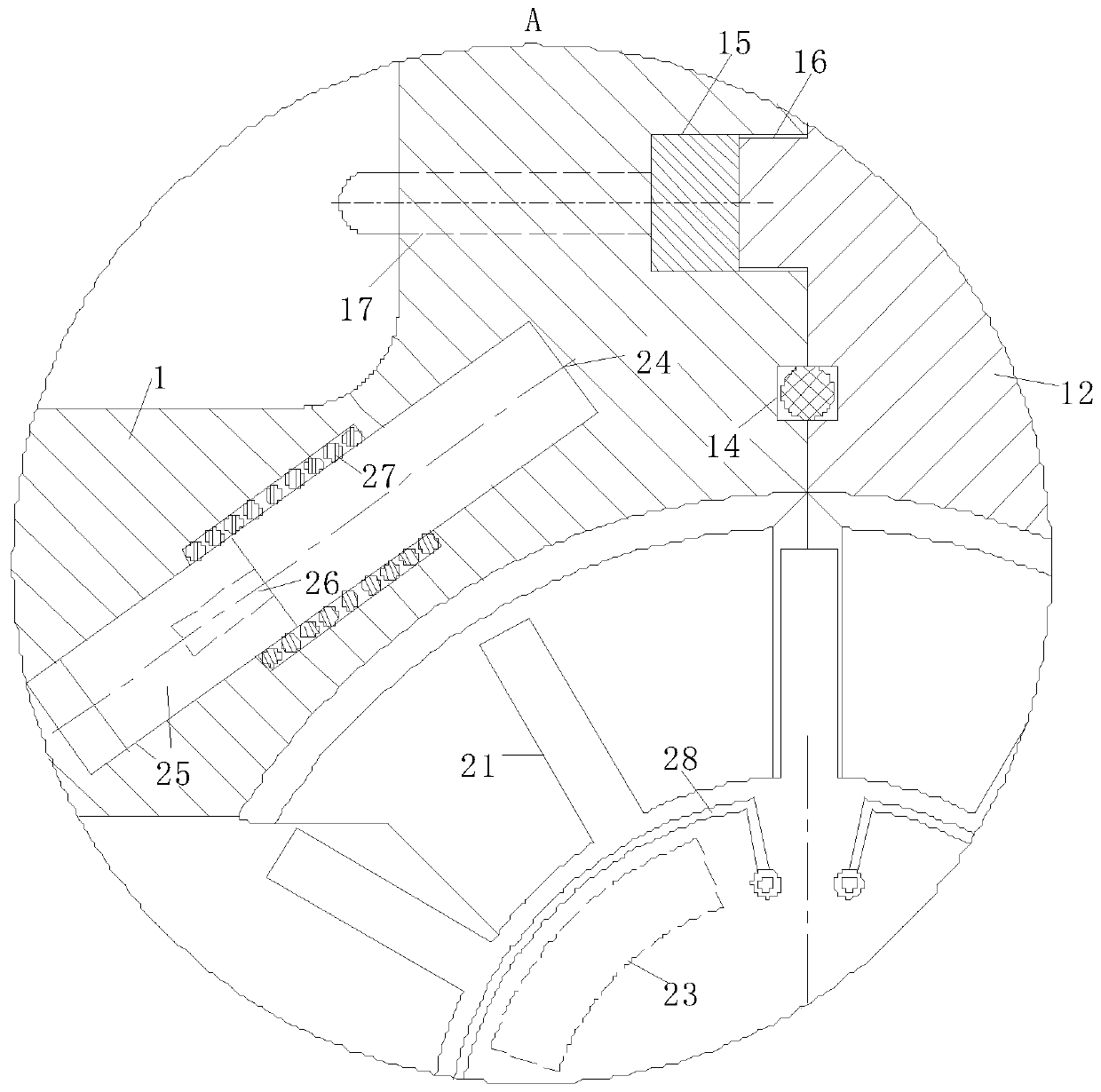

Giant magnetostriction rotary ultrasonic vibration device

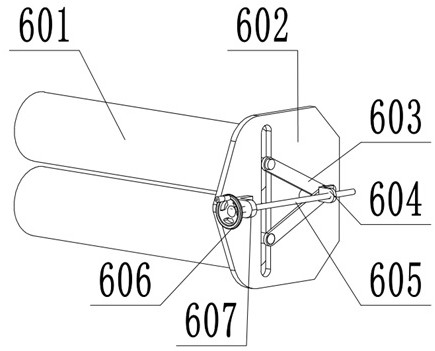

ActiveCN107931079ASolve fever problemLower operating temperatureMechanical vibrations separationCopper wireEngineering

The invention discloses a giant magnetostriction rotary ultrasonic vibration device comprising a knife handle, a primary winding, and two sets of bearing systems. A secondary winding is arranged on the knife handle, and the primary winding and the secondary winding are connected through inductive coupling; a giant magnetostriction transducer is installed at the lower part of the knife handle; thegiant magnetostriction transducer is sleeved with the two sets of bearing systems; and the bottoms of two sets of bearing systems are opposite and the two sets of bearing systems are connected by screw threads. An air cooling system is adopted to cool the giant magnetostriction transducer, and the problem of heat generation of the giant magnetostriction transducer in actual processing can be effectively solved; copper stranded wires are adopted by driving coils, compared with commonly used copper wires, the copper stranded wires are more conducive to heat dissipation, and the operating temperature of the coils is reduced; a thin-walled sleeve inside a transducer shell and a flange are arranged to ensure the coaxiality of the flange and the transducer shell, and the giant magnetostriction rod is subjected to uniform pre-tightening force; and the sleeve is arranged to facilitate the outward diffusion of heat generated by the giant magnetostriction rod and the coils.

Owner:XIAN UNIV OF TECH

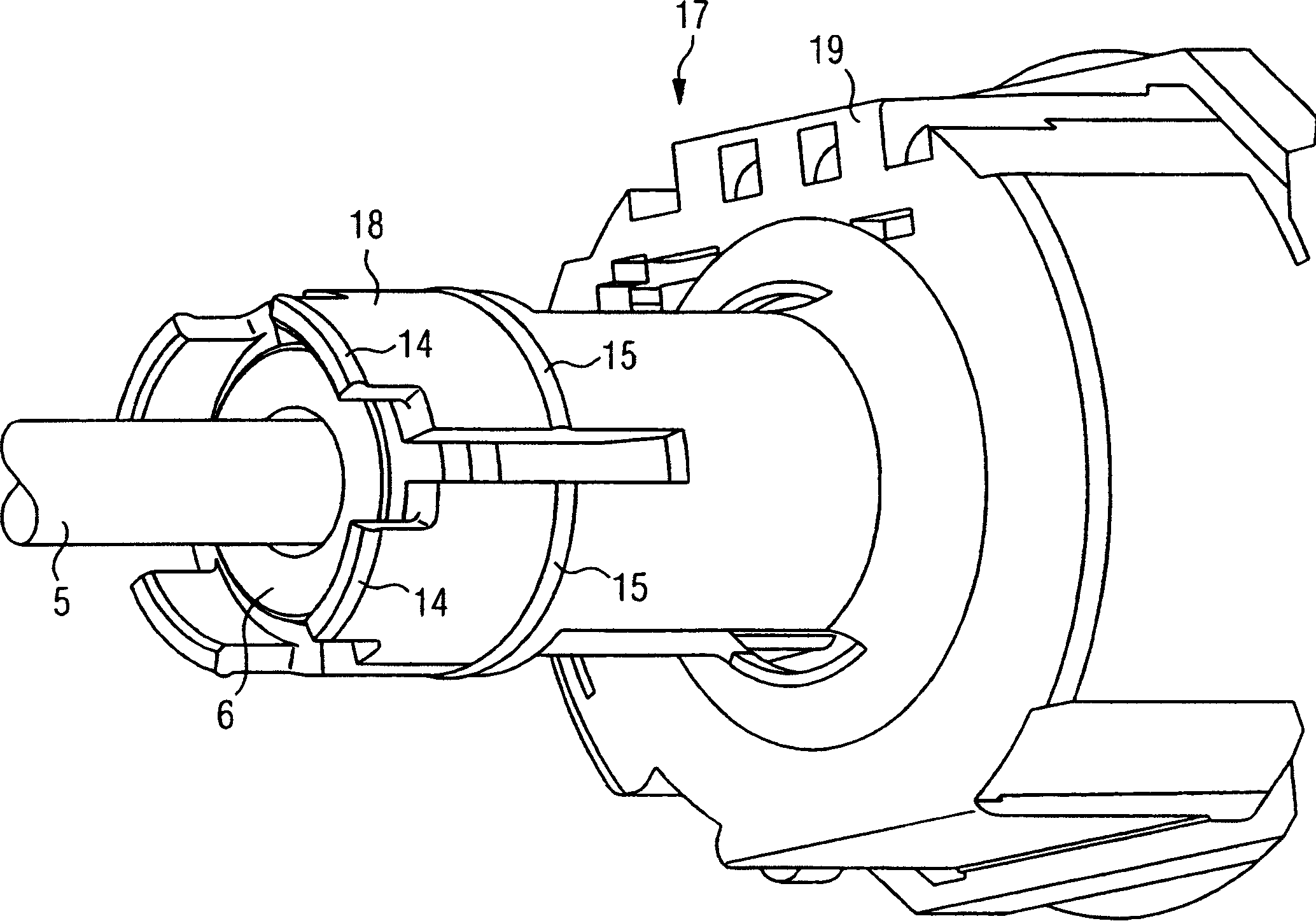

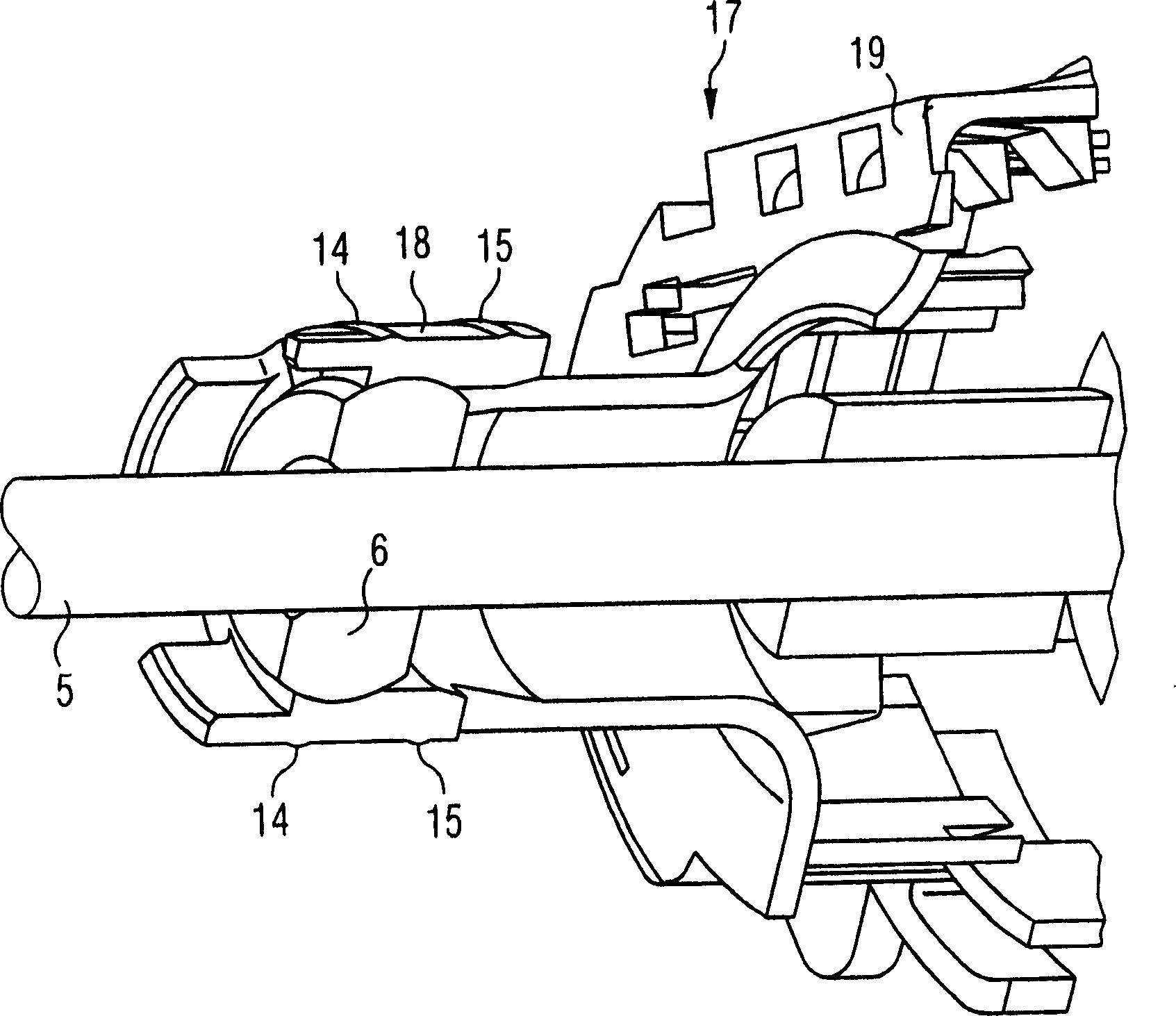

Actuator, in particular for a motor vehicle

InactiveCN1897416AAct as a preloadExtended service lifeGearboxesToothed gearingsDrive shaftEngineering

The actuator has a cylindrical bearing housing (18) protruding, along with a bearing and a drive shaft of a rotor, into an opening (7) in a gear housing (21) of a gear unit (2). An outer side of the bearing housing and an inner side of the opening are geometrically mutually harmonized such that clamping points (14, 15) and tension-free places (29) are formed between the bearing housing and the gear housing, when the actuator is assembled. The clamping points exert pre-tensioning force on the bearing through the bearing housing.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

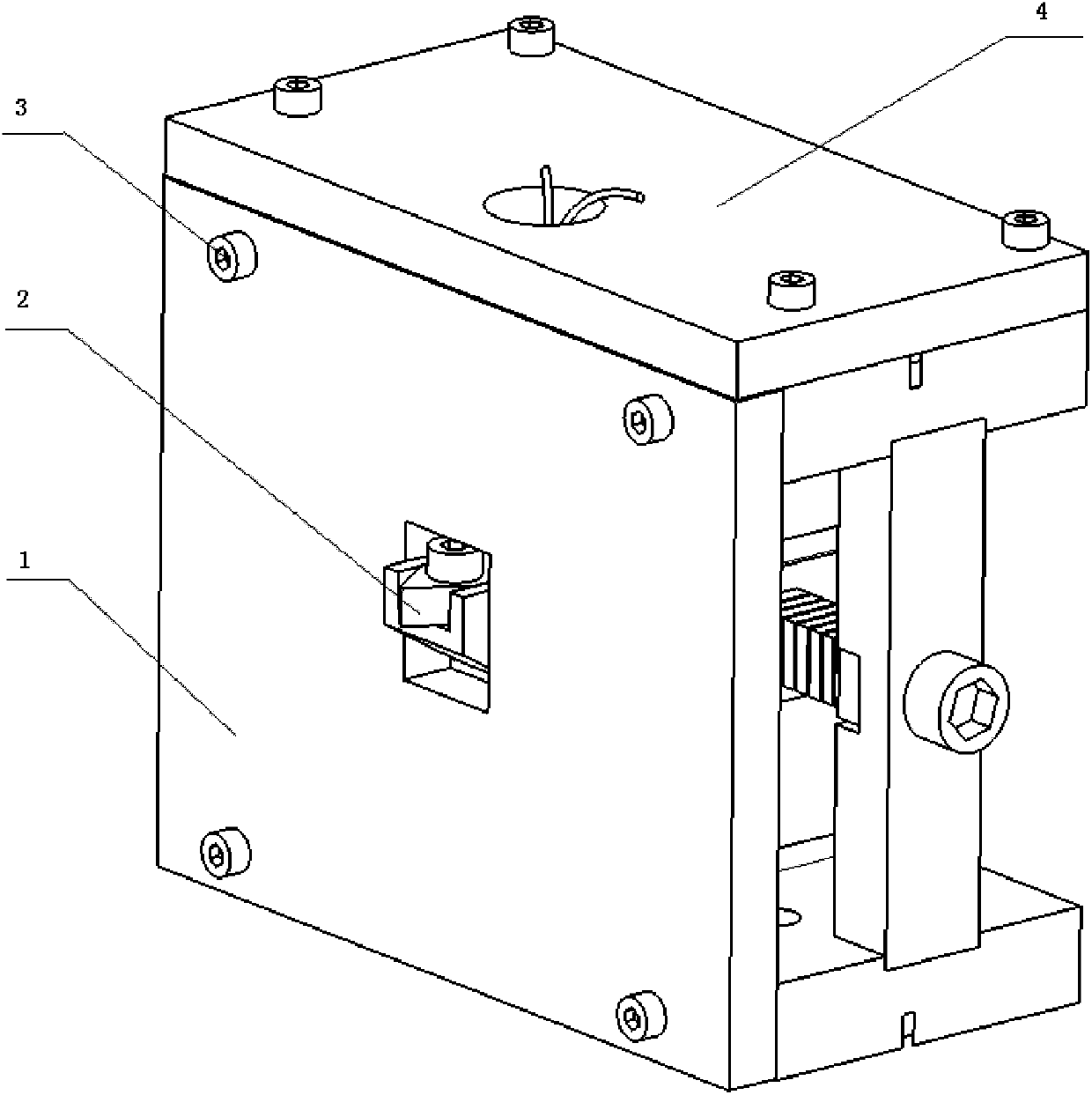

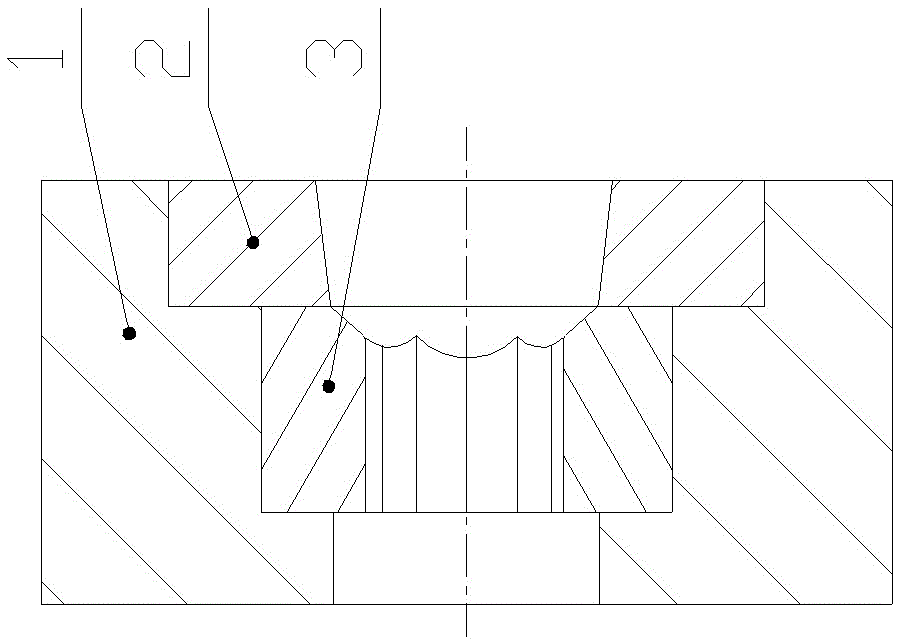

Extrusion forming mold

The invention relates to an extrusion forming mold. The extrusion forming mold comprises a mold sleeve; a ladder-shaped inner cavity penetrating a vertical direction is disposed in the mold sleeve; the inner cavity comprises a mold plate cavity, a mold core cavity and an open cavity successively along an axial direction; a mold core is arranged in the mold core cavity; a mold plate is arranged in the mold plate cavity; an outer peripheral surface of the mold plate is sleeved by an elastic ring that elastically contracts and expands in a radial direction; the elastic ring is provided with an inner peripheral surface matching the outer peripheral surface of the mold plate in a flexible support manner and an outer peripheral surface matching with the inner wall of the mold plate cavity in a flexible support manner. With the extrusion forming mold, cracking phenomenon of the mold plate can be prevented and a service life of the mold is prolonged.

Owner:河南航天精工制造有限公司

High-speed milling cutter handle type electric spindle

PendingCN109366205AConvenient preloadAxial force stabilityMilling cuttersLarge fixed membersMilling cutterEngineering

The invention relates to a high-speed milling cutter handle type electric spindle which comprises a main body mechanism, a rotor mechanism, a stator mechanism, a bearing mechanism, a broach mechanismand an air cylinder mechanism. The bearing mechanism comprises a front bearing assembly and a back bearing assembly arranged at two ends of the rotor mechanism; the front bearing assembly is providedwith an inner backing ring and an outer backing ring; a backing ring and an adjusting spring located in the same axis are arranged on the upper side and the lower side of the back bearing assembly; and the broach mechanism is detachably arranged on the rotor mechanism. The high-speed milling cutter handle type electric spindle provided by the invention has the beneficial effect that the electric spindle is provided with a position proximity switch connected with a programable logic controller (PLC) control center, so that a function on intelligently monitoring and automatically changing a cutter is realized. With an innovative self-designed cutter handle holding mechanism, the structural strength and the bearing surface are greatly increased, and the cutter holding force, the radial cutting rigidity and the loading force are further greatly improved, so that the high metal removal rate is achieved; and multi-process integrated processing of workpieces can be realized through a machinetool cutter rest, and a power assisting machine tool equipment manufacturer realizes high-intelligent automatic and integrated product functions.

Owner:岳阳市显隆电机有限公司

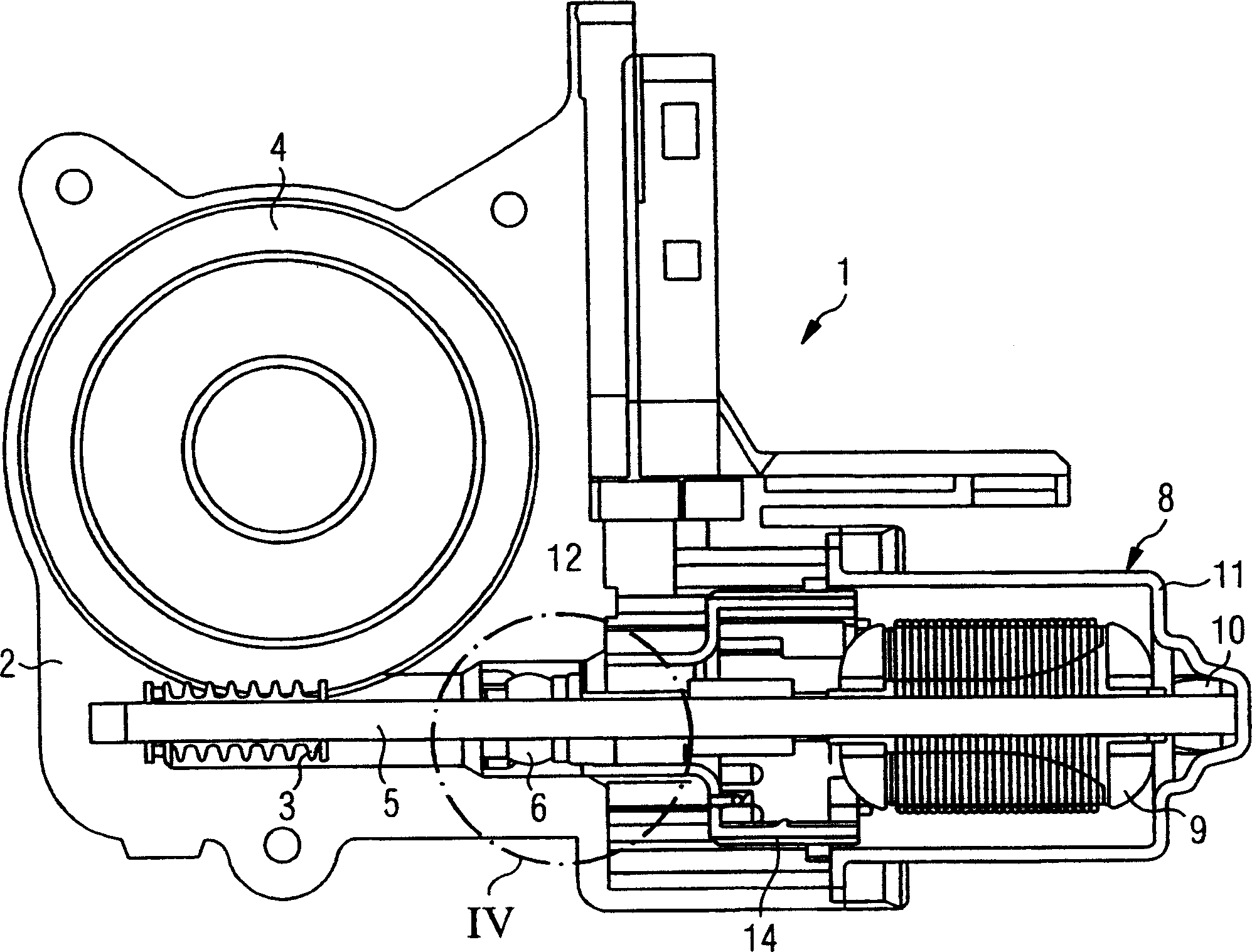

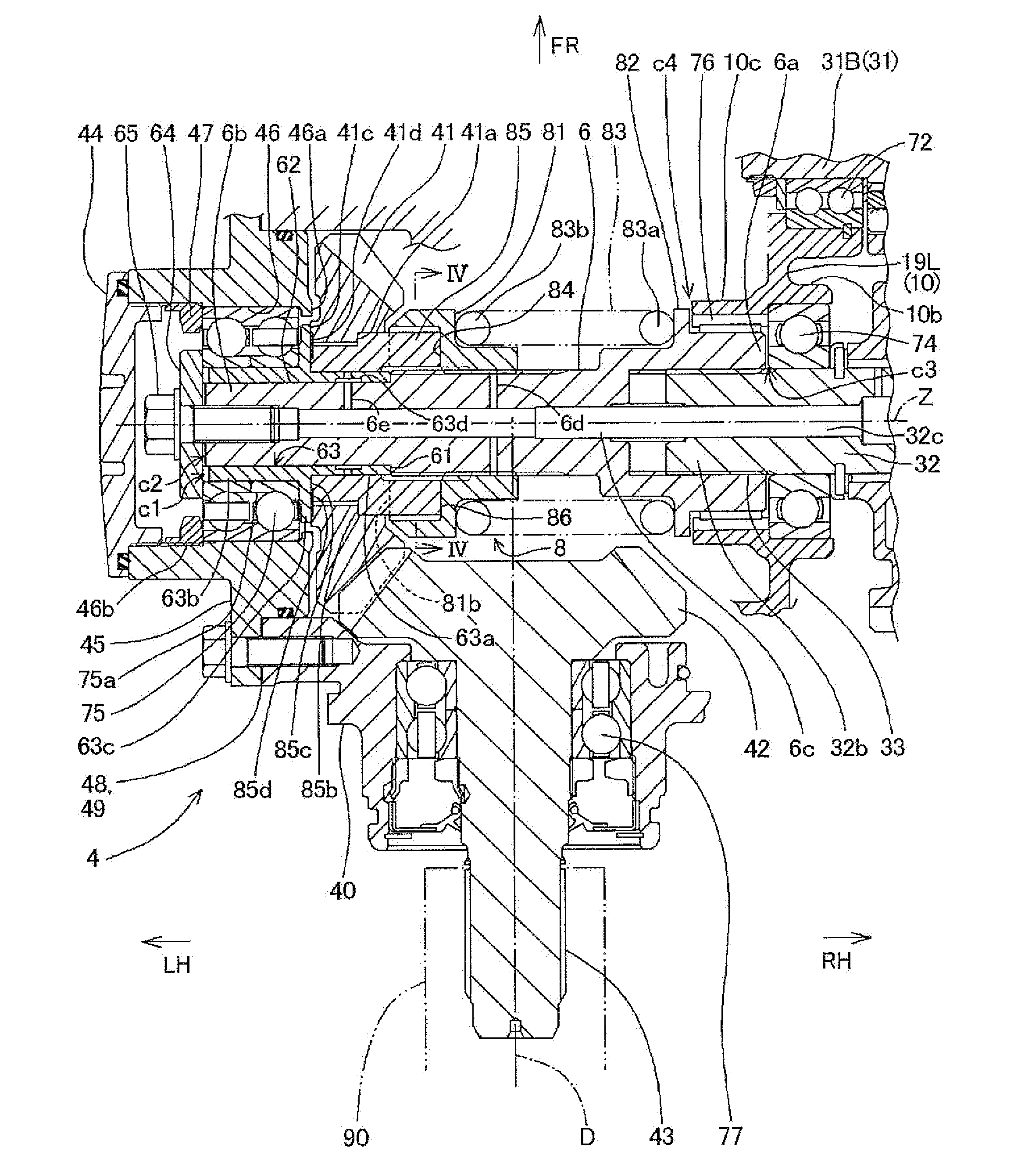

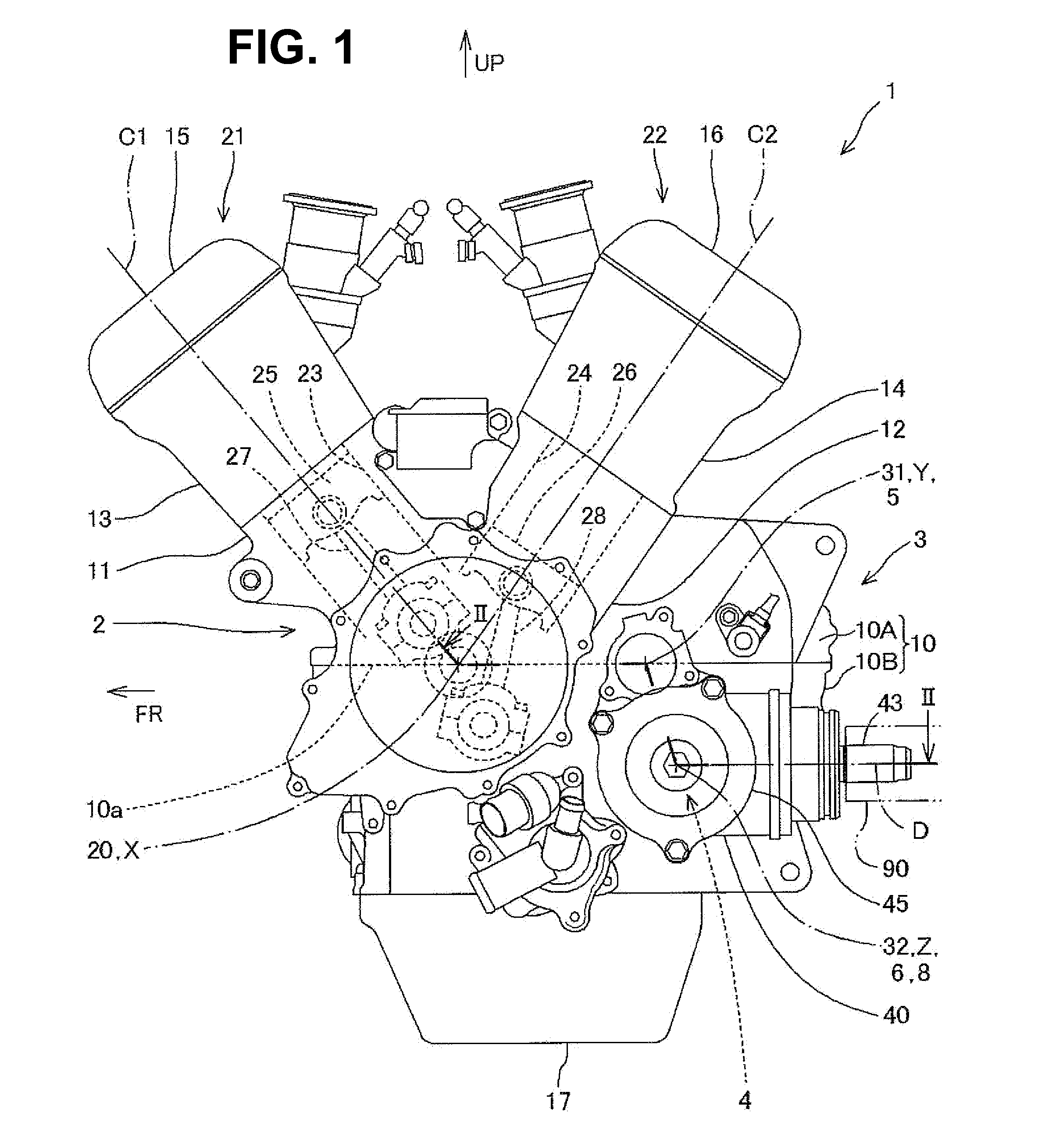

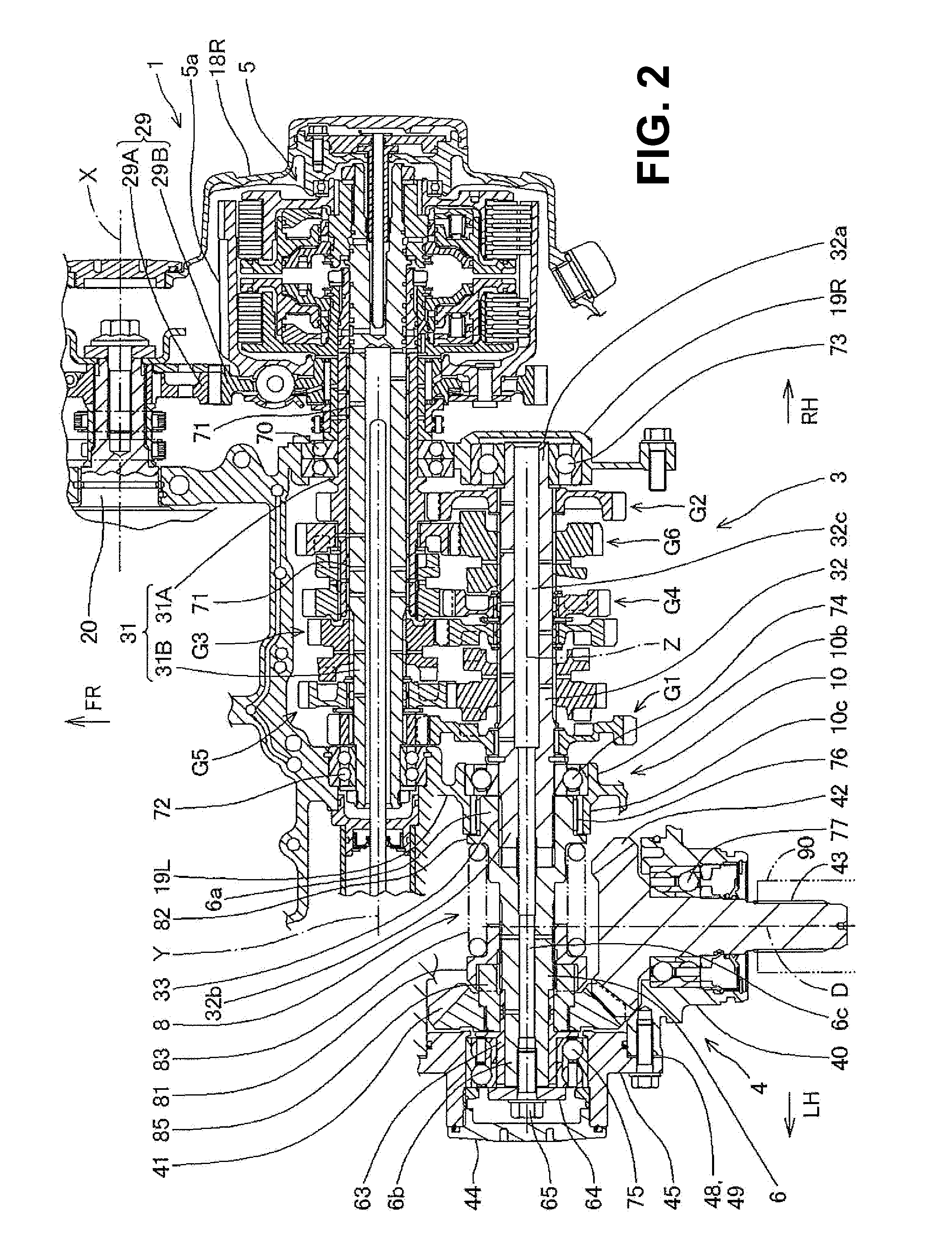

Power unit of shaft drive type vehicle

ActiveUS20130255417A1Uniform preloadFacilitate adjustment of mesh amountRotary transmissionsToothed gearingsCamBevel gear

A power unit includes a cam damper mechanism having a cam member reciprocally and unrotatably provided on one of a pair of bevel gears, and rotatably provided on an extended shaft; a lifter member slidably and unrotatably provided on the extended shaft in an axial direction; a damper spring configured such that one end portion thereof is supported on a first flange portion of the extended shaft, and the other end portion thereof biases the lifter member toward the cam member in an axial direction by abutting on the lifter member, and the biasing force is supported by the one bevel gear. The extended shaft has the one of the bevel gears and the cam damper mechanism between the first flange portion and a first bearing, and is accommodated in the bevel gear case so as to be fixed to a bevel gear holder along with the first bearing.

Owner:HONDA MOTOR CO LTD

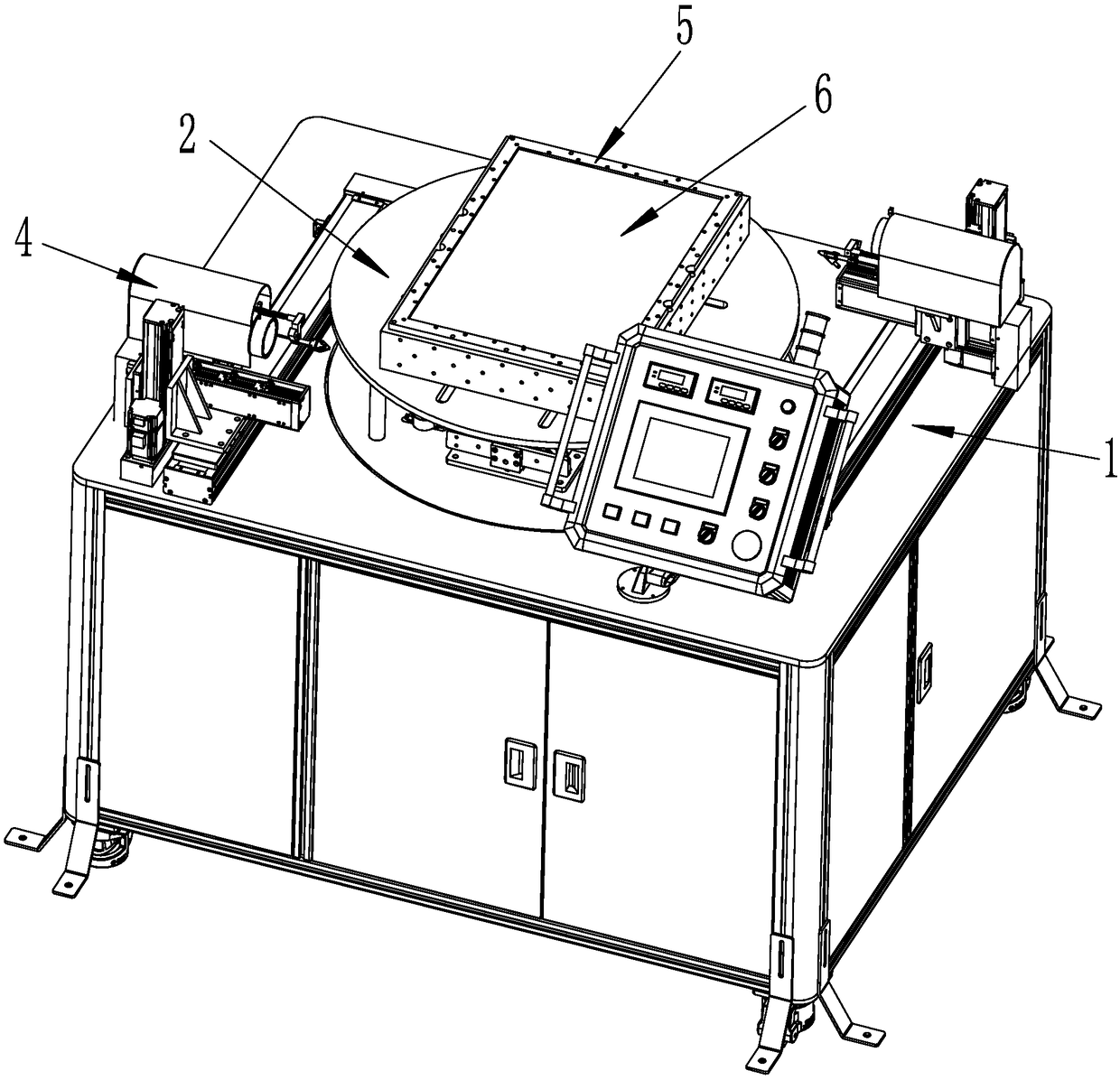

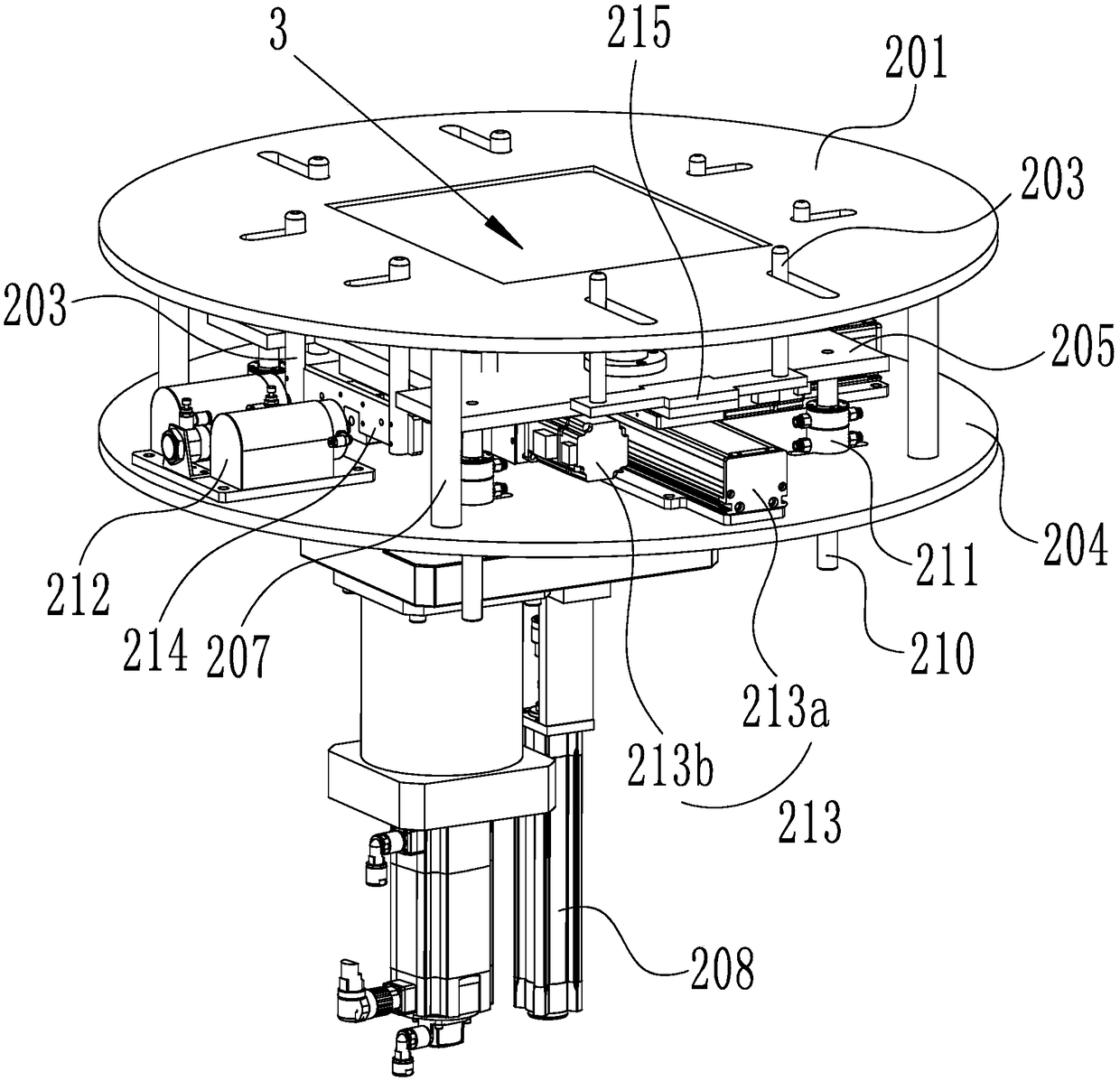

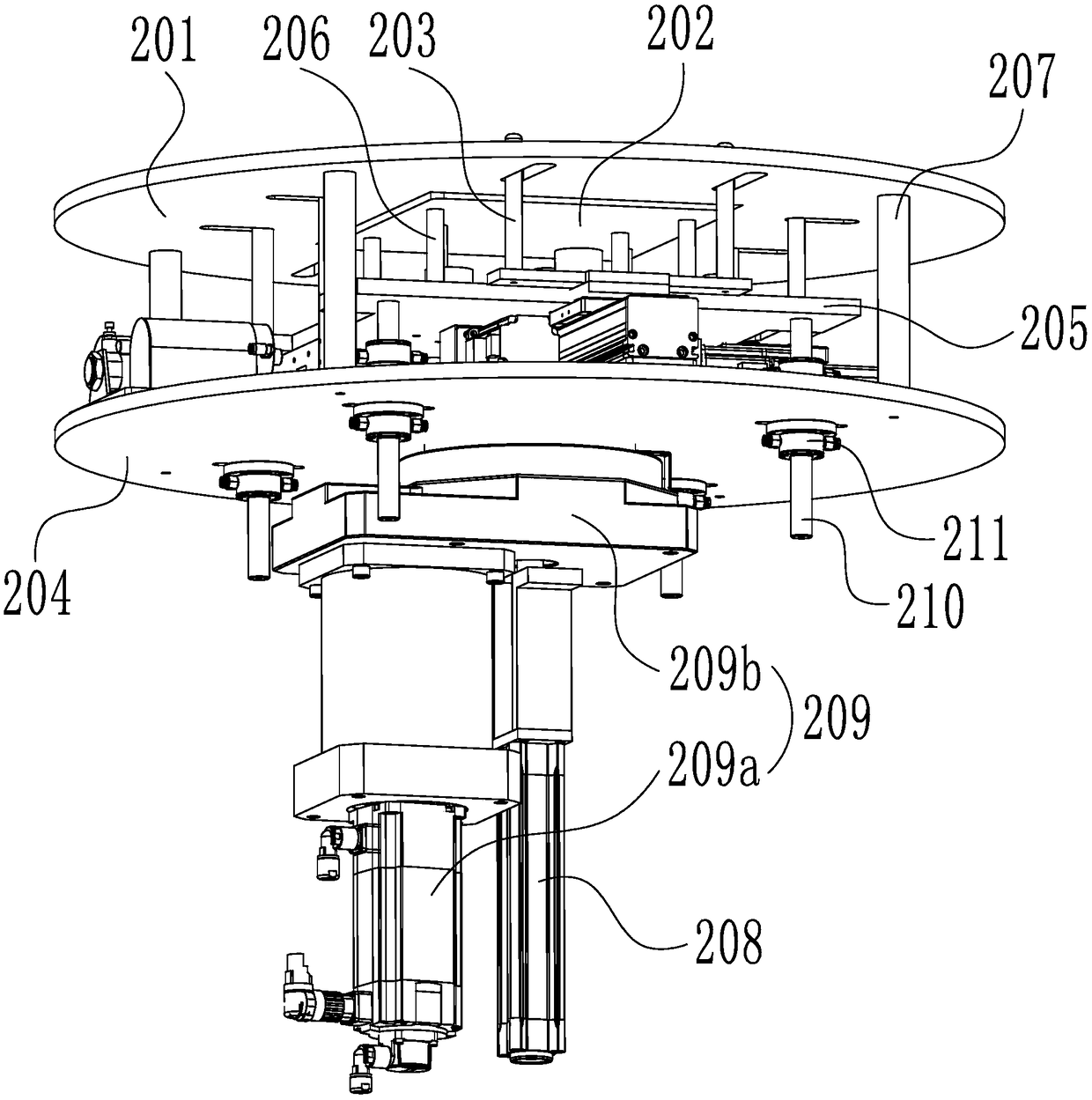

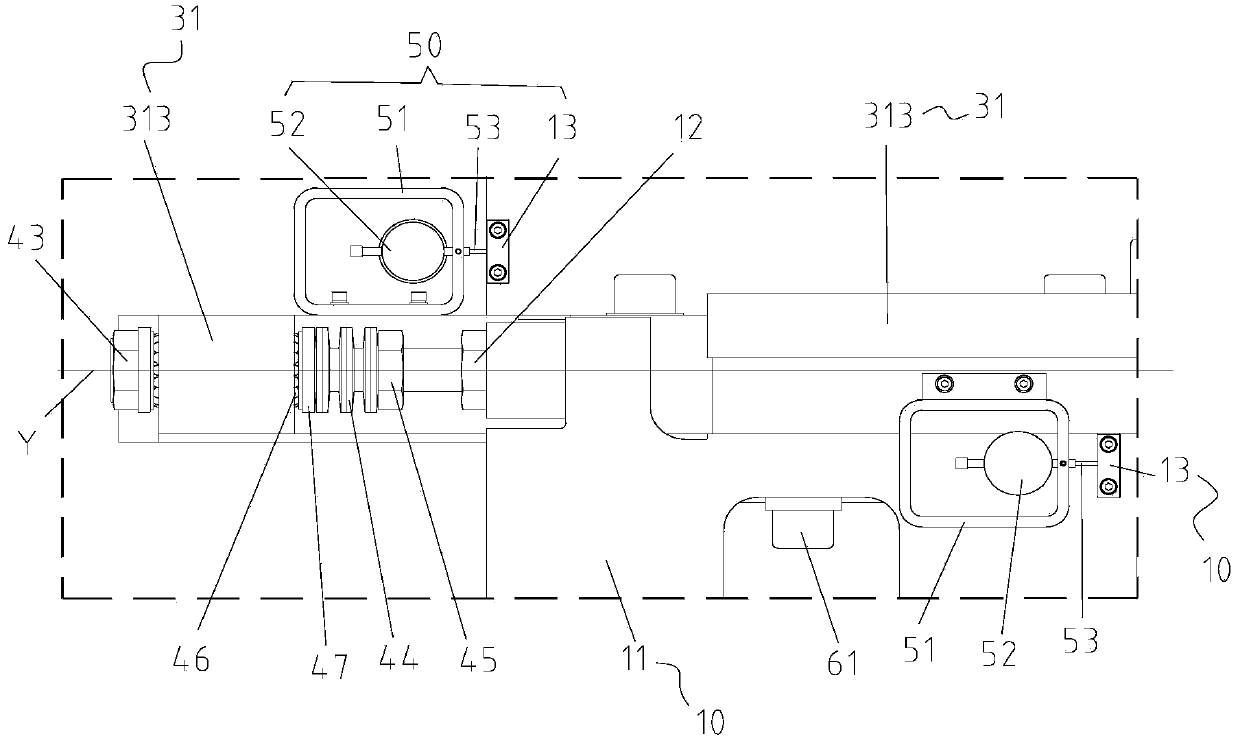

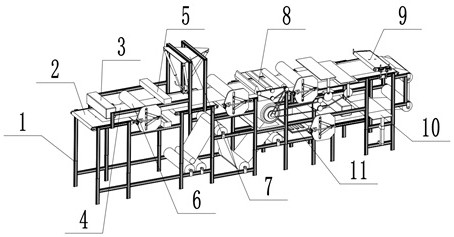

Automatic flexible assembling and calibration platform and method for meter-scale reflector

ActiveCN109164554ASolve the problem of automatic flexible batch assemblyUniform preloadMountingsEngineeringSurface plate

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS +1

Three-dimensional elliptical vibration cutting device

ActiveCN102371359BImprove machinabilitySimplify the modeling processMeasurement/indication equipmentsTurning toolsLinear motionEllipse

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Integrated side pressure V-shaped spring and sealing ring with same

InactiveCN105202089AImprove stabilityEven by forceEngine sealsLow internal friction springsMechanical engineeringEngineering

Owner:上海大亚密封技术有限公司

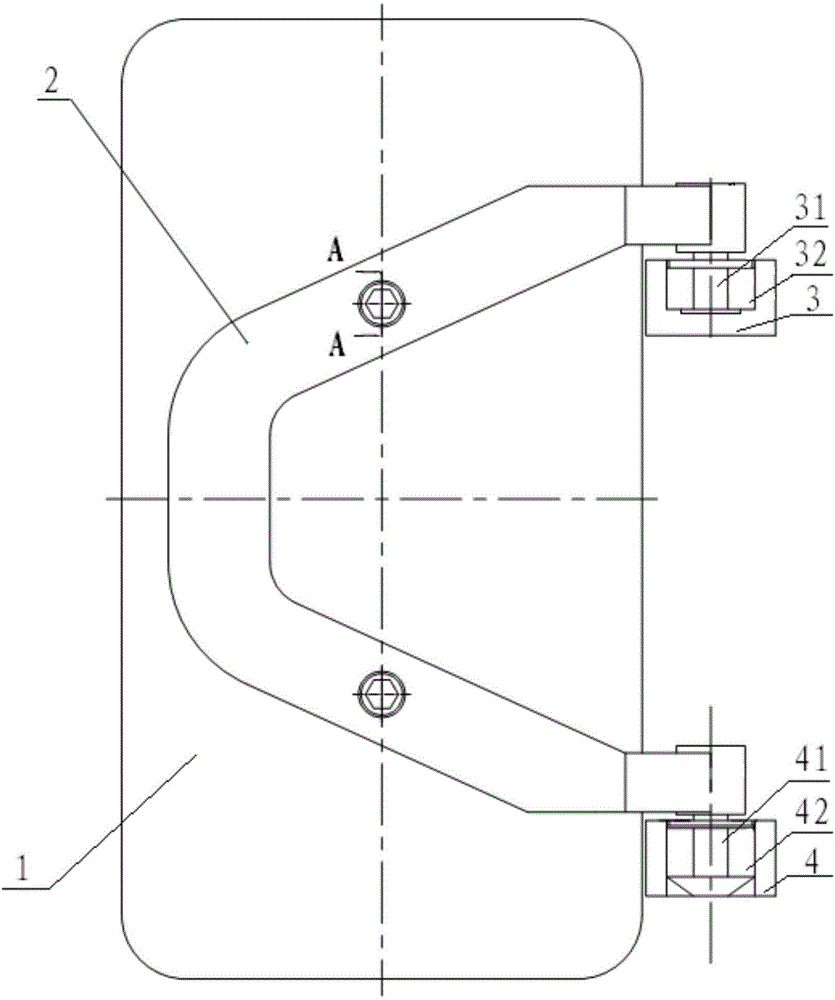

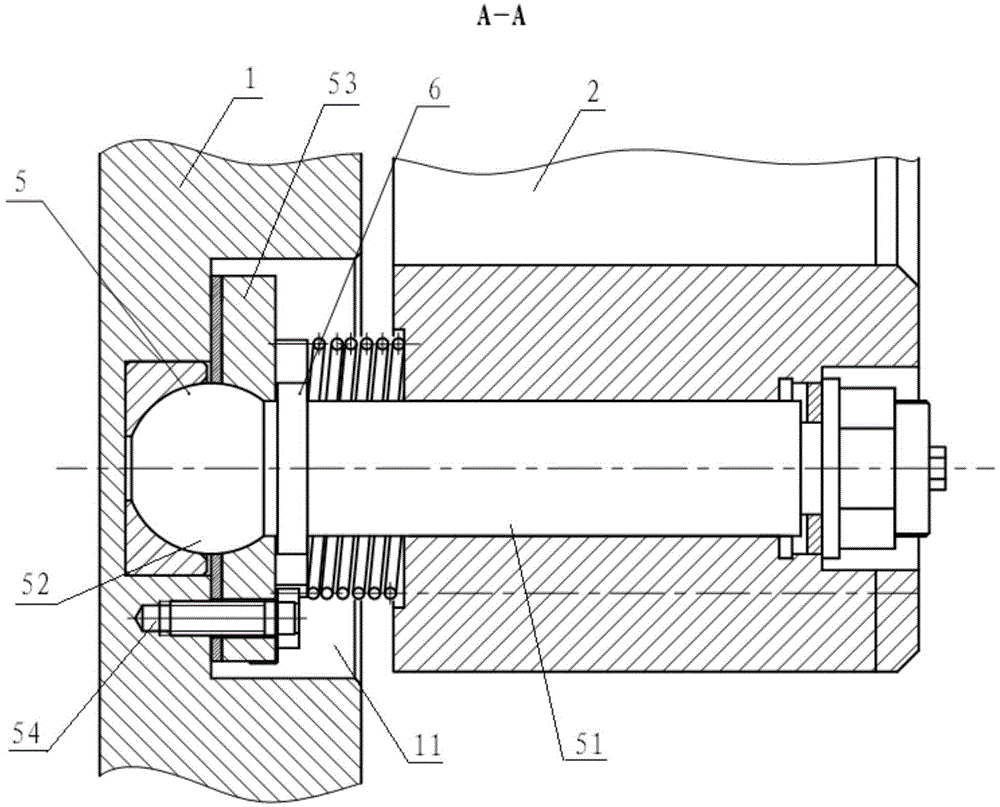

Door panel supporting and power buffering device

ActiveCN104314399APlay a supporting roleAct as a power bufferBuilding braking devicesPin hingesSpherical bearingSpherical form

The invention provides a door panel supporting and power buffering device. The device comprises a support frame (2), wherein a body of the support frame (2) is connected with a door panel through a spherical support structural member (5), both ends of the support frame (2) are respectively connected with an external structure of the door panel through an upper bearing hinge body (3) and a lower bearing hinge body (4); the spherical support structural member (5) comprises a connecting shaft (51) and a spherical bearing (52), and the spherical bearing (52) is arranged in a groove (11) in the door panel; the connecting shaft (51) penetrates through the body of the support frame (2) to be connected with the spherical bearing(52). According to the supporting and power buffering device disclosed by the invention, for each operation of opening a door, and in a certain state, the load of the door panel can be supported and the door panel can be driven to move, at the same time, the door is opened and closed, the device has the function of buffering, so that resilient displacement is reduced, and the safety and the stability of the door panel during operating can be ensured.

Owner:CHINA NUCLEAR POWER ENG CO LTD

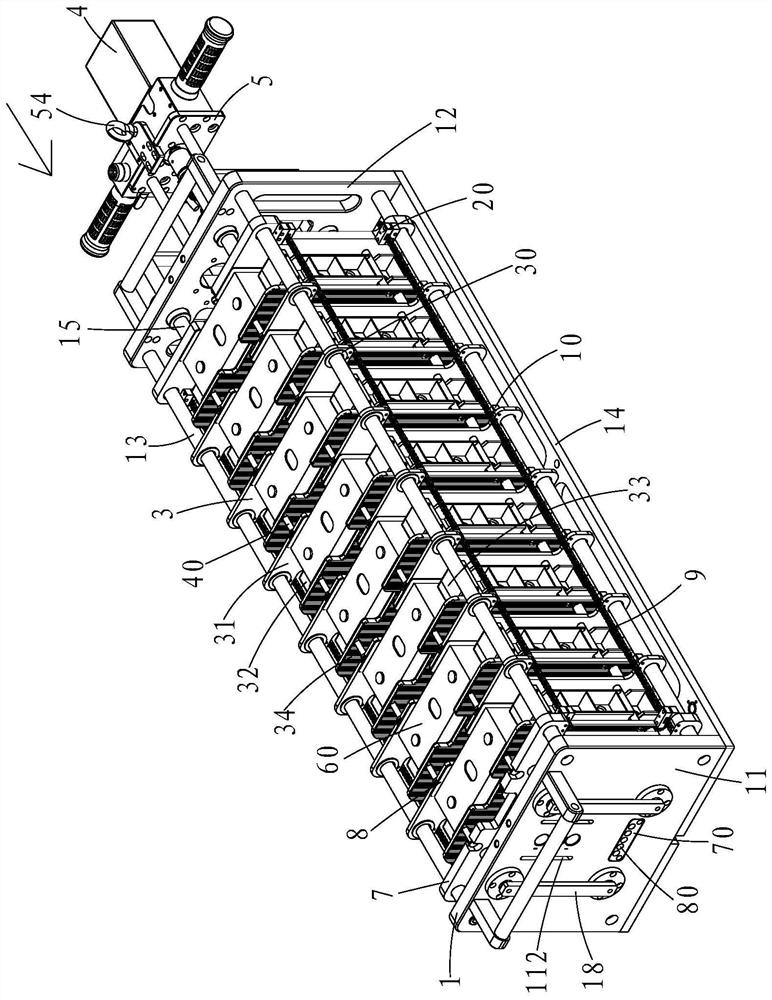

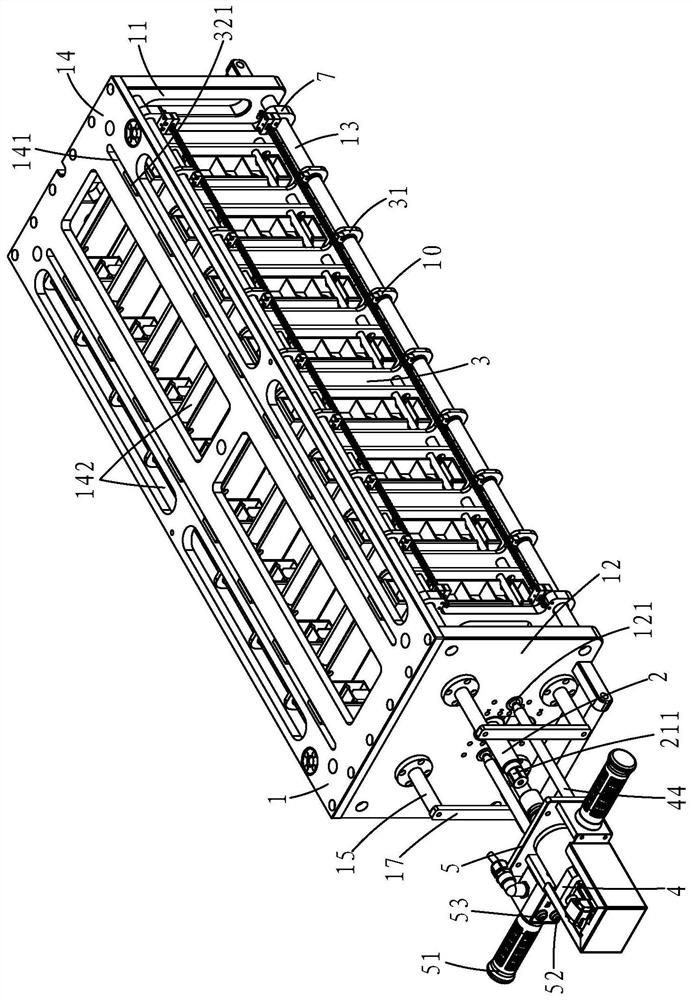

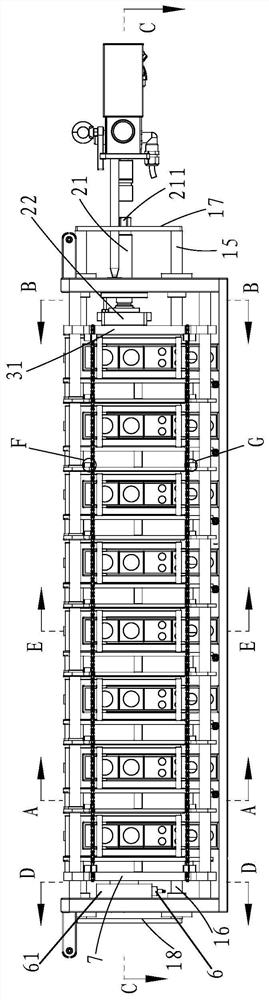

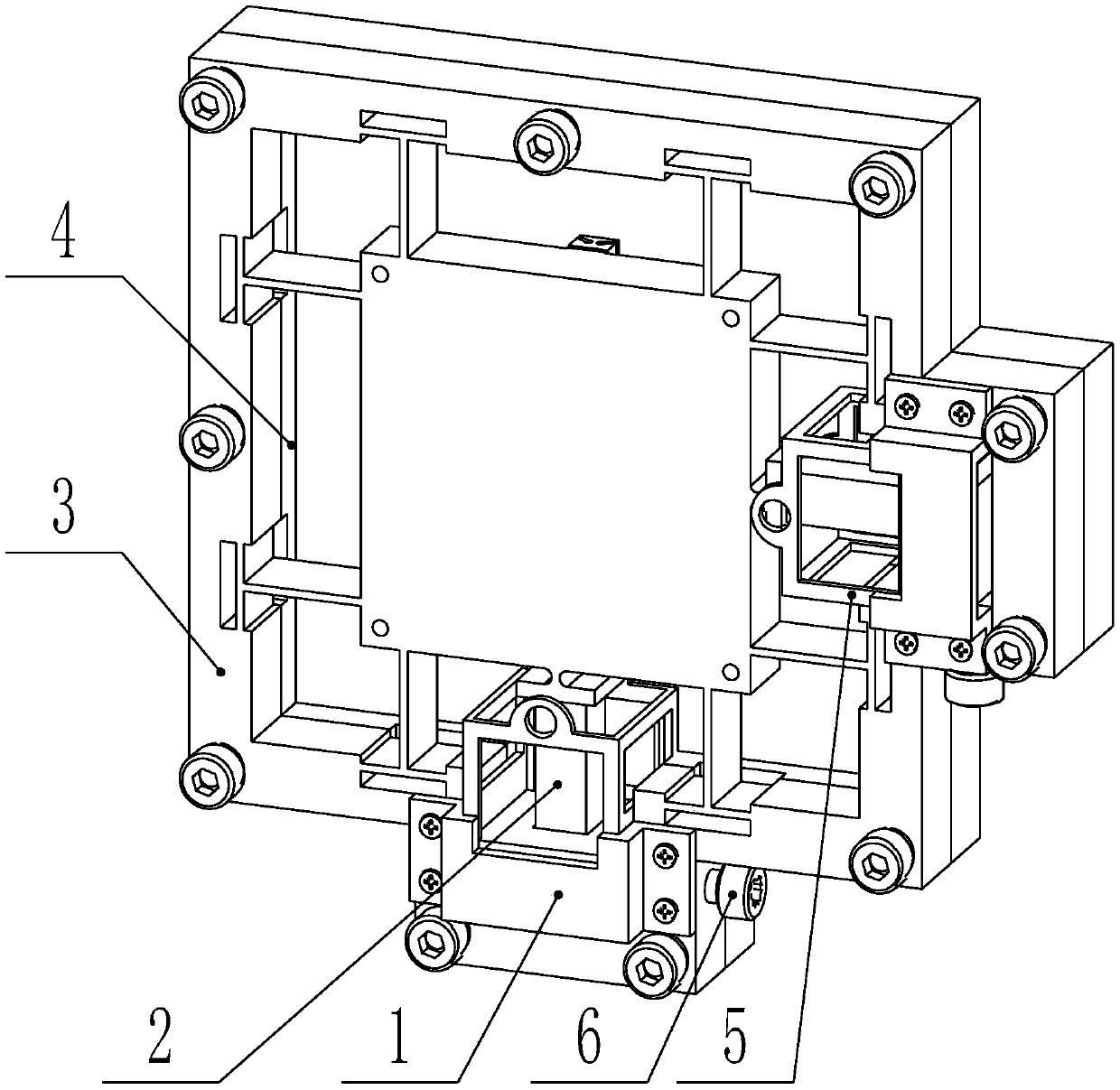

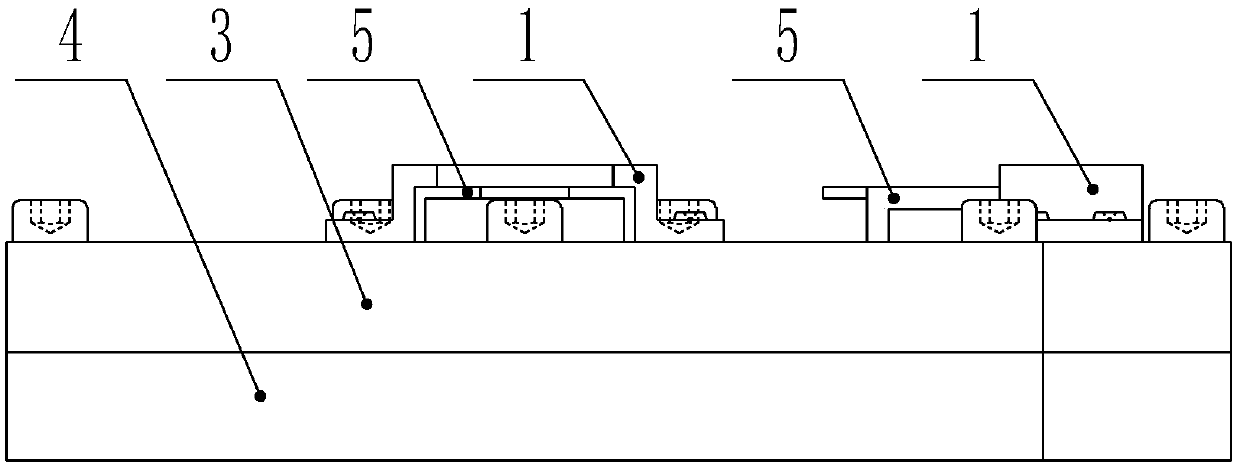

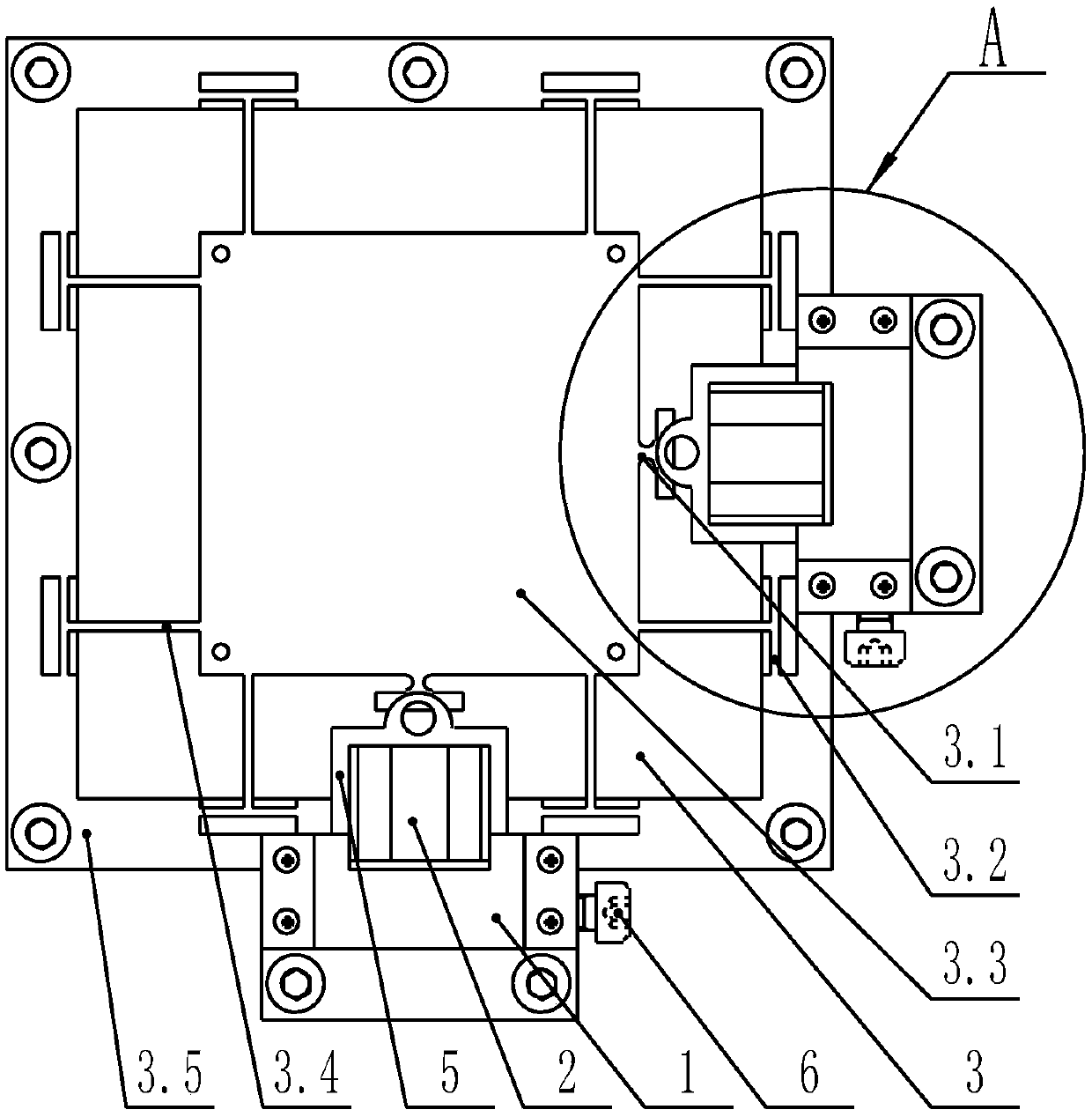

Clamp type pressurizing device for formation and capacity grading ofsquare battery cell

PendingCN112993424AAdjust the pressure in timeA pressure detection device for detecting the pressure on the tray and adjusting it in timeElectrical testingSecondary cells charging/dischargingEngineeringBattery cell

The invention provides a clamp type pressurizing device for formation and capacity grading of a square battery cell. The clamp type pressurizing device comprises a clamp type tray, a support frame, a pressurizing connecting mechanism and a plurality of trays, the plurality of trays are movably connected to the support frame, and the plurality of trays are connected together to realize linkage; the pressurizing connecting mechanism is connected to one of the trays; the pressurizing device comprises a driving device and a fixed seat; the driving device is fixedly connected to the fixed seat; the output end of the driving device is detachably connected to the pressurizing connecting mechanism; and the pressure detection device is used for detecting the pressure borne by the tray. The tray is pressurized through the pressurizing device, the pressure on the tray is detected through the pressure detection device, and the pressure applied by the pressurizing device can be adjusted in time, so that the applied pre-tightening force is more uniform, more stable and optimal.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

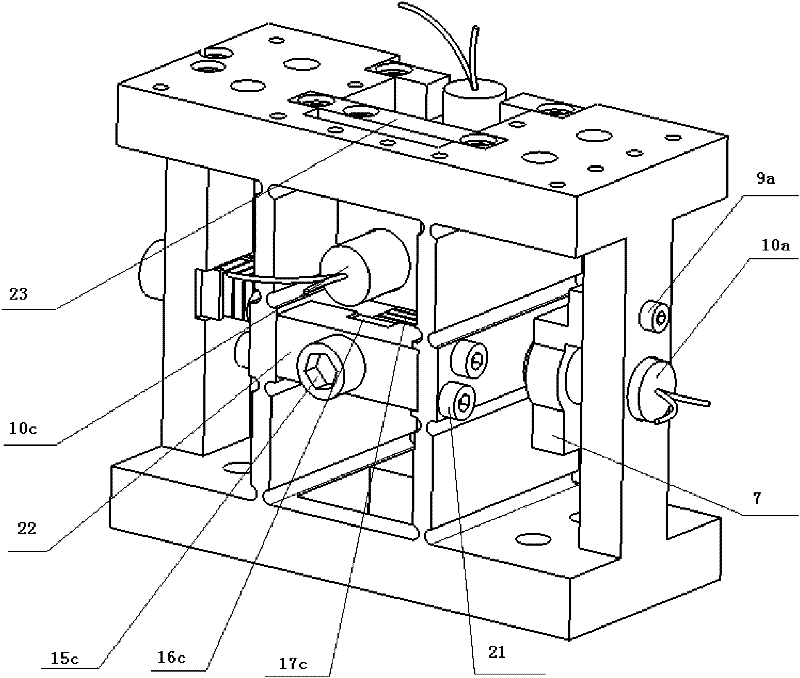

Two-dimensional compliant vibration platform with wedge pre-tightening

PendingCN109530198AIncreased operating frequency rangeAmplitude controllableMechanical vibrations separationEngineeringWedge prism

The invention discloses a two-dimensional compliant vibration platform with wedge pre-tightening. The platform includes driving sources, a compliant vibration platform, a base and wedge pre-tighteningdevices. The compliant vibration platform includes arc type flexible hinges, outer straight beam type flexible hinges, a work table, inner straight beam type flexible hinges and a compliant vibrationplatform outer frame. When the driving sources in two directions move at the same time, the work table generates mechanical vibration in two directions so as to realize two-dimensional vibration assisted processing. The driving sources provide micron-level vibration for the work table through the arc type flexible hinges. The outer straight beam type flexible hinges and the inner straight beam type flexible hinges are arranged symmetrically about the work table so as to realize the decoupling motion of the work table and provide guarantee for the high precision motion of the vibration platform. The vibration platform uses the wedge pre-tightening devices, and so the adjustment is more intuitive and the pre-tightening force is even. The driving sources of different types and sizes are pre-tightened by adjusting the position of pre-tightening screws, and so the adaptability is strong.

Owner:HEBEI UNIV OF TECH

Lifting jack with lifting pre-tightening device and method for lifting jack for pre-tightening lifting steel strands

InactiveCN105152069ASimple structureEasy to disassembleLifting devicesJackscrewIndustrial engineering

Owner:LIUZHOU OVM MASCH CO LTD

Tensioning device for MPCVD

PendingCN110684961AAdjustable tensionTimely measurementPolycrystalline material growthChemical vapor deposition coatingClassical mechanicsDisplay device

The invention relates to the technical field of MPCVD equipment, in particular to a tensioning device for an MPCVD, and solves the problems of incapacity of timely measuring and adjusting of tensioning force of a connecting rod in MPCVD equipment in the prior art. The tensioning device comprises a reaction cavity, a waveguide cavity and a connecting rod, a tensioning device body located below thewaveguide cavity is further mounted on the connecting rod, the tensioning device body comprises a tensioning assembly, an elastic element, a pallet, a pre-tightened piece, a tensioning piece and a weighing sensor, and the weighing sensor is electrically connected to a display. According to the tensioning device for the MPCVD, as the change of the tensioning force of the elastic element is caused by the change of the tensioning force of the connecting rod, the expected force of the elastic element can be measured at any time through the weighing sensor in the tensioning device body and displayed on the display, the change of the tensioning force of the connecting rod can be viewed at any time through the display, and the change of the tensioning force of the connecting rod can be measured timely, so that the tensioning force of the connecting rod can be adjusted timely.

Owner:四川三三零半导体有限公司

A giant magnetostrictive rotating ultrasonic vibration device

ActiveCN107931079BSolve fever problemLower operating temperatureMechanical vibrations separationCopper wireConductor Coil

The invention discloses a giant magnetostriction rotary ultrasonic vibration device comprising a knife handle, a primary winding, and two sets of bearing systems. A secondary winding is arranged on the knife handle, and the primary winding and the secondary winding are connected through inductive coupling; a giant magnetostriction transducer is installed at the lower part of the knife handle; thegiant magnetostriction transducer is sleeved with the two sets of bearing systems; and the bottoms of two sets of bearing systems are opposite and the two sets of bearing systems are connected by screw threads. An air cooling system is adopted to cool the giant magnetostriction transducer, and the problem of heat generation of the giant magnetostriction transducer in actual processing can be effectively solved; copper stranded wires are adopted by driving coils, compared with commonly used copper wires, the copper stranded wires are more conducive to heat dissipation, and the operating temperature of the coils is reduced; a thin-walled sleeve inside a transducer shell and a flange are arranged to ensure the coaxiality of the flange and the transducer shell, and the giant magnetostriction rod is subjected to uniform pre-tightening force; and the sleeve is arranged to facilitate the outward diffusion of heat generated by the giant magnetostriction rod and the coils.

Owner:XIAN UNIV OF TECH

Petrochemical conveying pipeline

InactiveCN110657295AGuaranteed tightnessAvoid safety hazardsFlanged jointsThermal insulationEngineeringStructural engineering

The invention belongs to the technical field of pipelines, and particularly relates to a petrochemical conveying pipeline. The petrochemical conveying pipeline comprises pipeline bodies, the two pipeline bodies are connected through a left flange and a right flange, the left flange and the right flange are fixedly connected through a set of bolts, first sealing ring grooves are formed in the sides, in contact with each other, of the left flange and the right flange, O-shaped sealing rings are arranged in the first sealing ring grooves, a second sealing ring groove is formed in the end face, atthe outer ring of the corresponding first sealing ring groove, of the left flange, metal with lower hardness is inlaid in the second sealing ring groove, and a convex ring matched with the second sealing ring groove is arranged at the position, corresponding to the second sealing ring groove, of the end face of the right flange. According to the petrochemical conveying pipeline, the metal in thesecond sealing ring groove is extruded through the convex ring, so that the metal with lower hardness in the second sealing ring groove fills a gap between the convex ring and the second sealing ringgroove after being extruded, secondary sealing is carried out at the joint between the pipeline bodies, the sealing performance of the pipeline bodies is further guaranteed, and the potential safety hazard caused by leakage of petrochemical liquid in the pipeline bodies is prevented.

Owner:王为迪

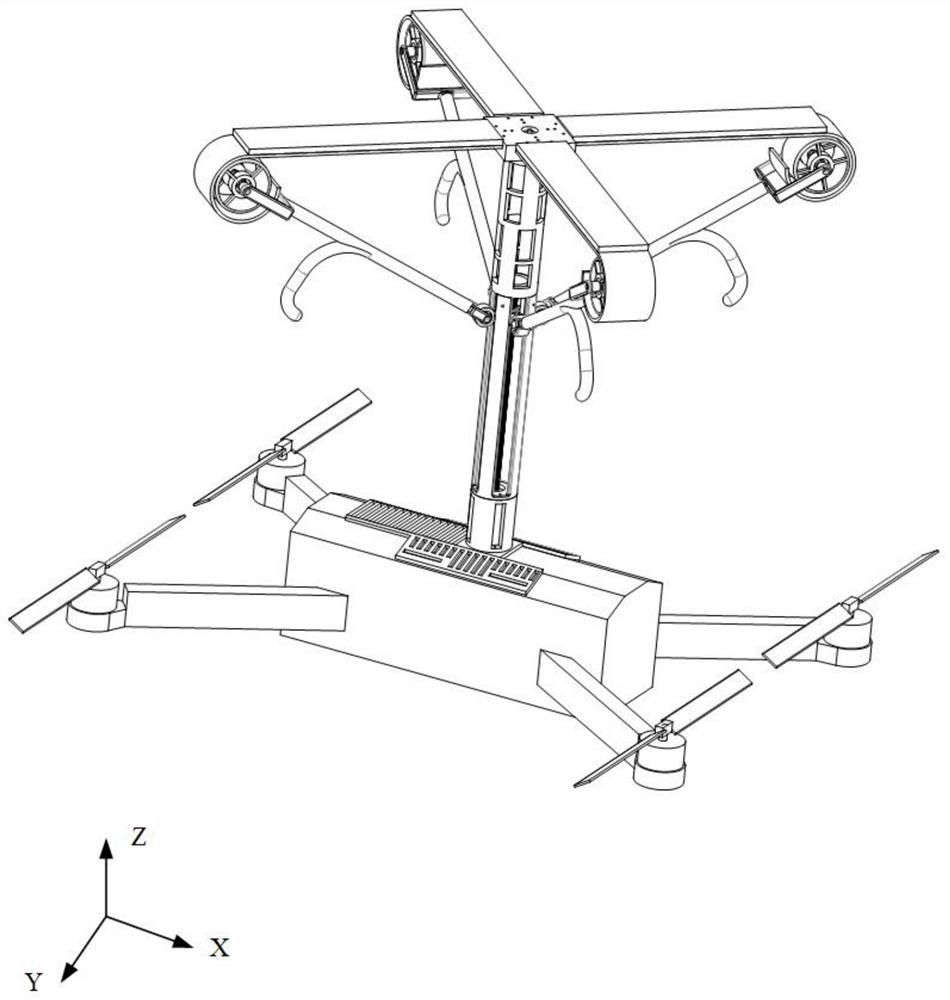

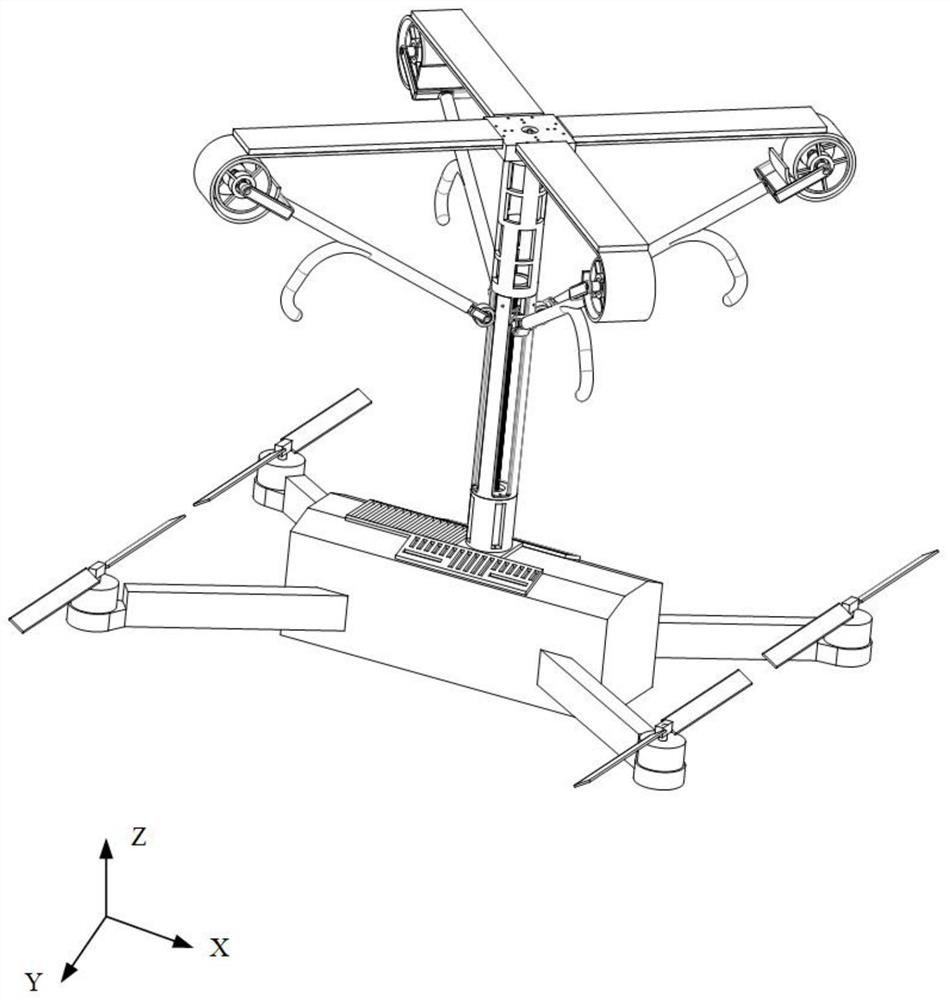

Multi-rotor bionic roosting UAV and attached motion method

ActiveCN112937840BEnable multi-habitat workExtended working hoursRotocraftUndercarriagesElectric machineryUncrewed vehicle

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

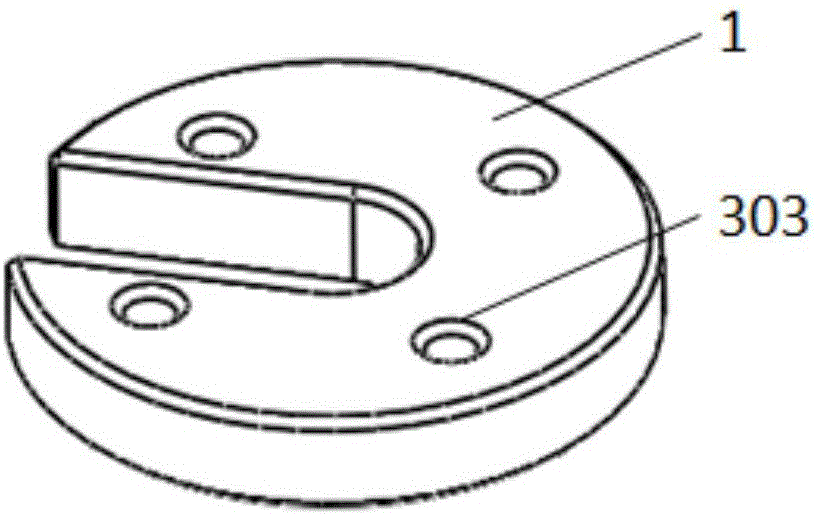

Sealing pressure-resistant device mounted with constant-volume-bomb oil atomizer

ActiveCN106353099AFully fixed positionFully fixedEngine testingHigh frequency vibrationPetroleum engineering

The invention provides a sealing pressure-resistant device mounted with a constant-volume-bomb oil atomizer. The sealing pressure-resistant device comprises an oil atomizer base and an oil atomizer gland, the oil atomizer base is divided into upper, middle and lower portions and is through from top to bottom, the inside of the oil atomizer base is hollowed for mounting the oil atomizer, an inner cavity is matched with the oil atomizer to well limit radial movement of the same, the oil atomizer gland is a cover with a U-shaped opening, connected with the oil atomizer base through a bolt and embedded with the oil atomizer through the U-shaped opening to limit rotation of the oil atomizer, and the oil atomizer is fixed through two fixing measures of the oil atomizer base and the oil atomizer gland. The oil atomizer base is provided with a sealing device, so that sealing between the oil atomizer and a constant volume bomb body can be guaranteed. The sealing pressure-resistant device is simple in structure, convenient to mount, adaptable to all types of mounting devices, good in fixing effect, capable of guaranteeing position of the oil atomizer to be unchanged under high-frequency vibration and guaranteeing sealability and suitable for specific requirements of constant volume bomb atomization burning experiments.

Owner:HARBIN ENG UNIV

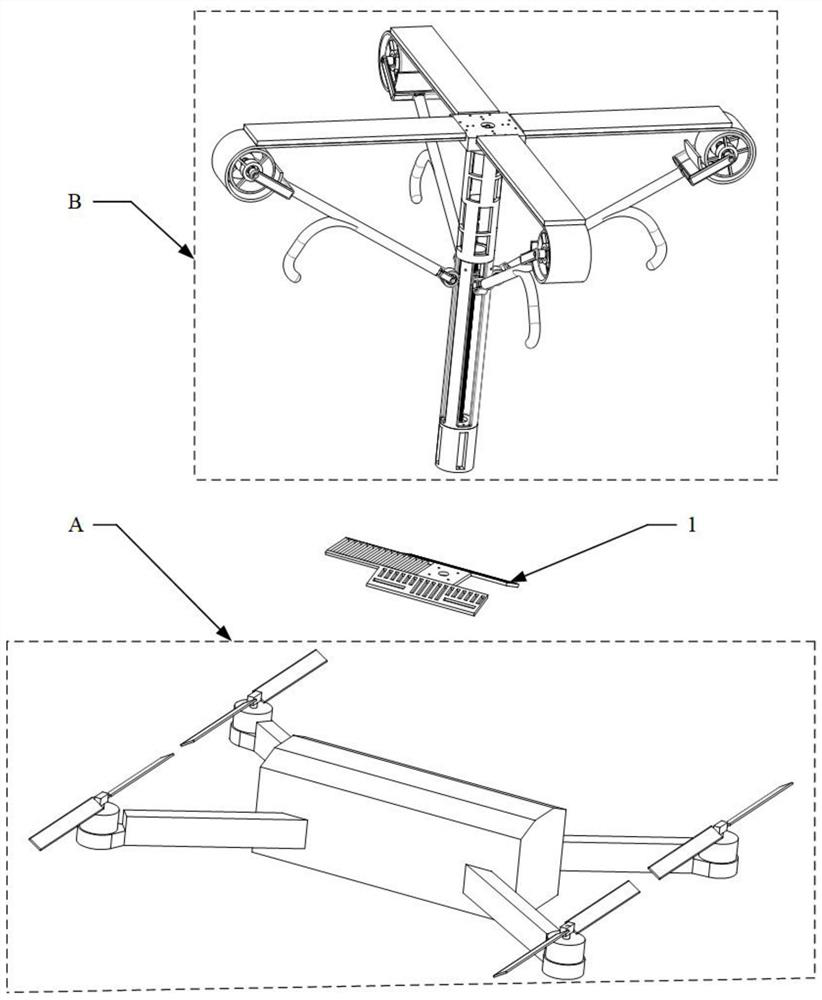

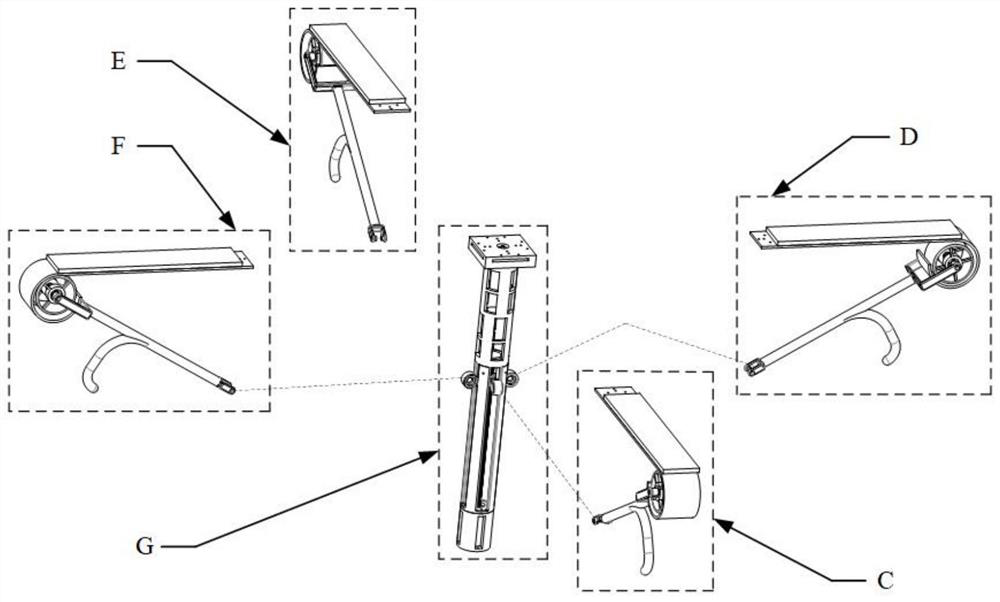

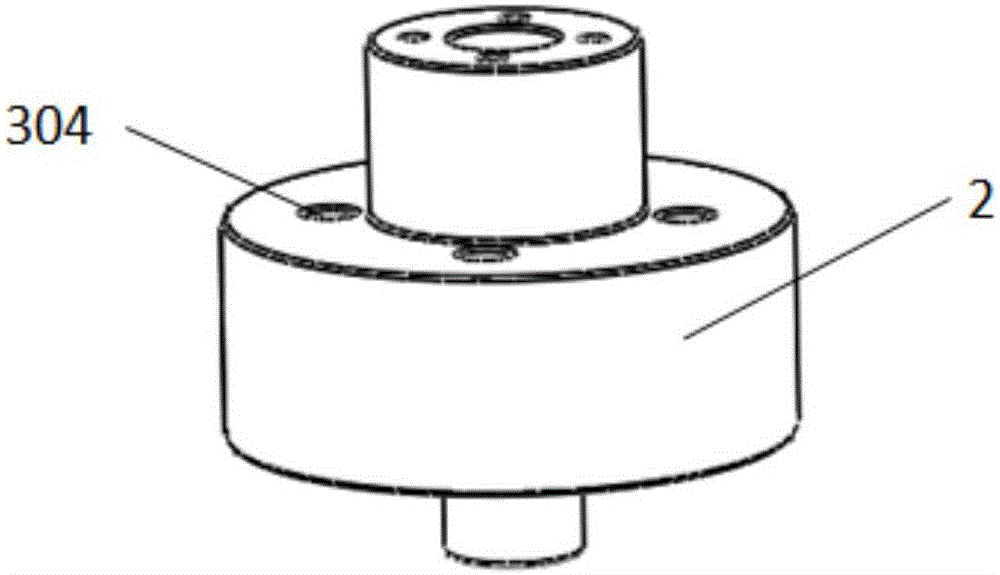

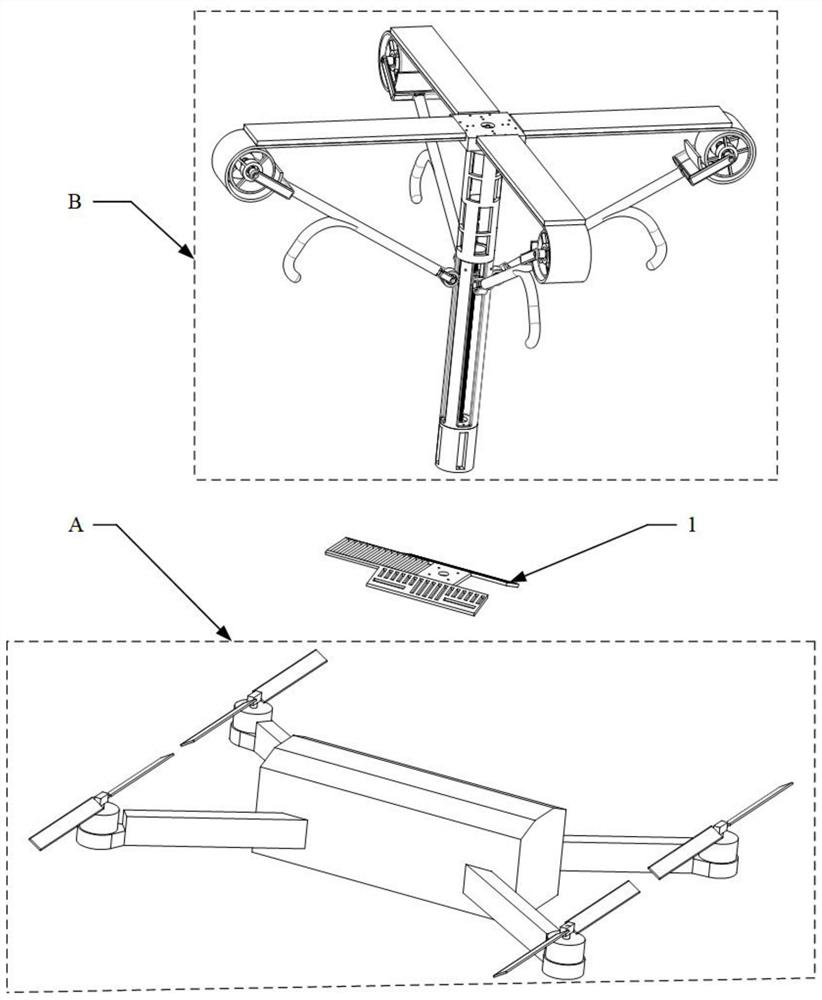

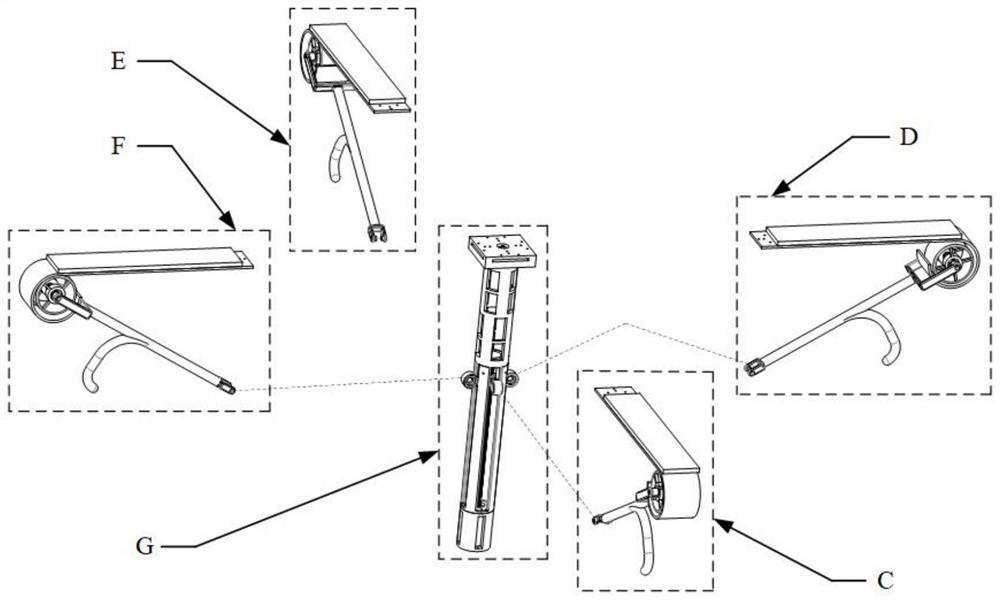

Inhabiting device, multi-rotor bionic inhabiting unmanned aerial vehicle and attachment movement method

ActiveCN112937840AEnable multi-habitat workExtended working hoursRotocraftUndercarriagesUncrewed vehicleElectric machinery

The invention relates to an inhabiting device, a multi-rotor bionic inhabiting unmanned aerial vehicle and an attachment movement method, and belongs to the technical field of robot application. The inhabiting device (B) is fixed right above the multi-rotor unmanned aerial vehicle (A) through a connecting plate (1) and comprises N symmetrically mounted toe mechanisms (C-F) and a power system (G); a threaded push rod motor (2) rotates forwards or reversely to drive the inhabiting device (B) to contract or expand; each toe mechanism (C-F) comprises a curled sole (10), an adhesive material (9), a guide roller (8) and a claw push rod (11); and the first end of the claw push rod (11) is hinged to a threaded flange support (4), and the guide roller (8) is installed at the second end of the claw push rod (11) and is always tangent to the lower surface of the second end of the curled sole (10). The inhabiting device can be charged in the air and is suitable for a horizontal top surface, a horizontal cylindrical surface and a horizontal round hole top surface, and the all-weather multi-inhabiting function of the multi-rotor unmanned aerial vehicle is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

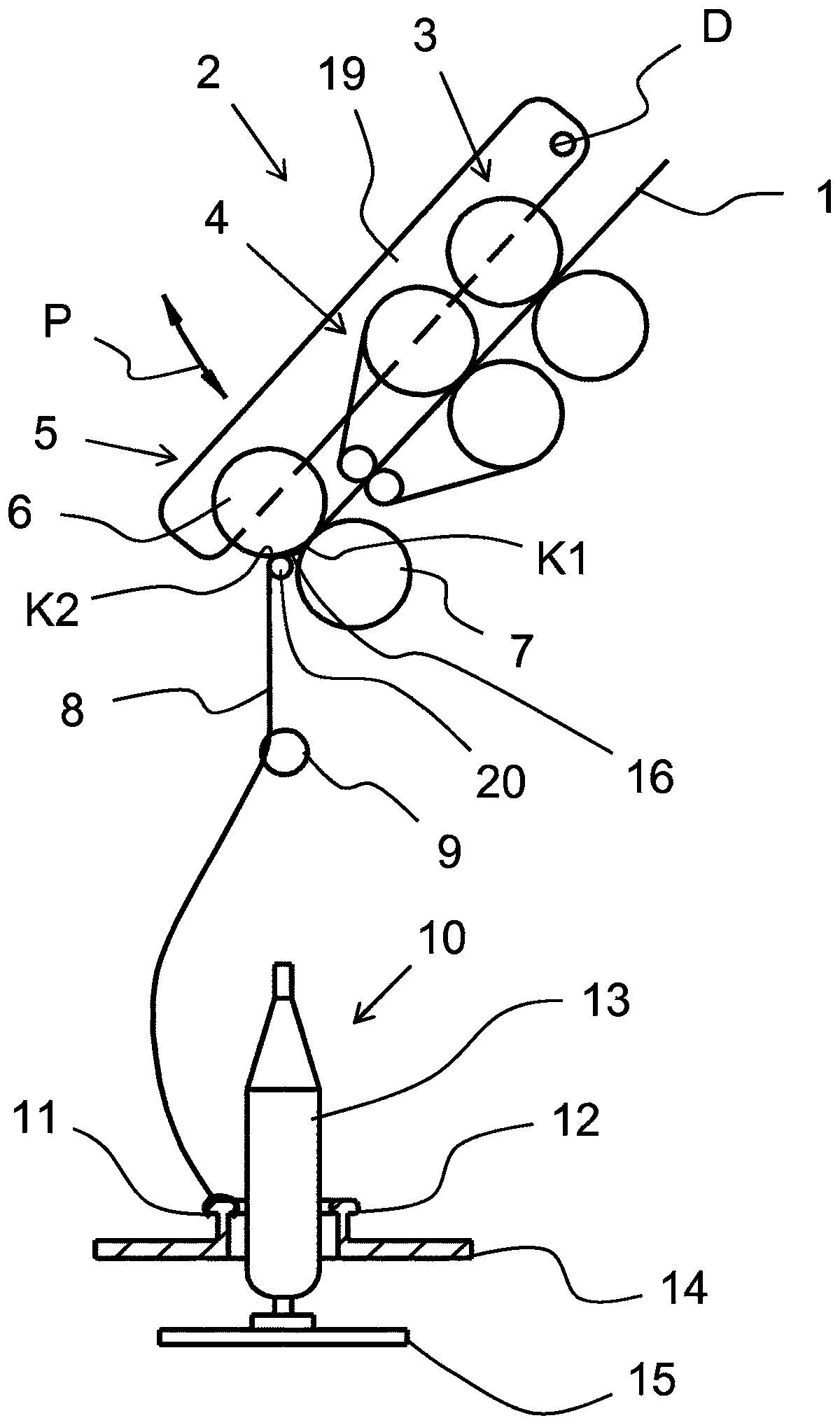

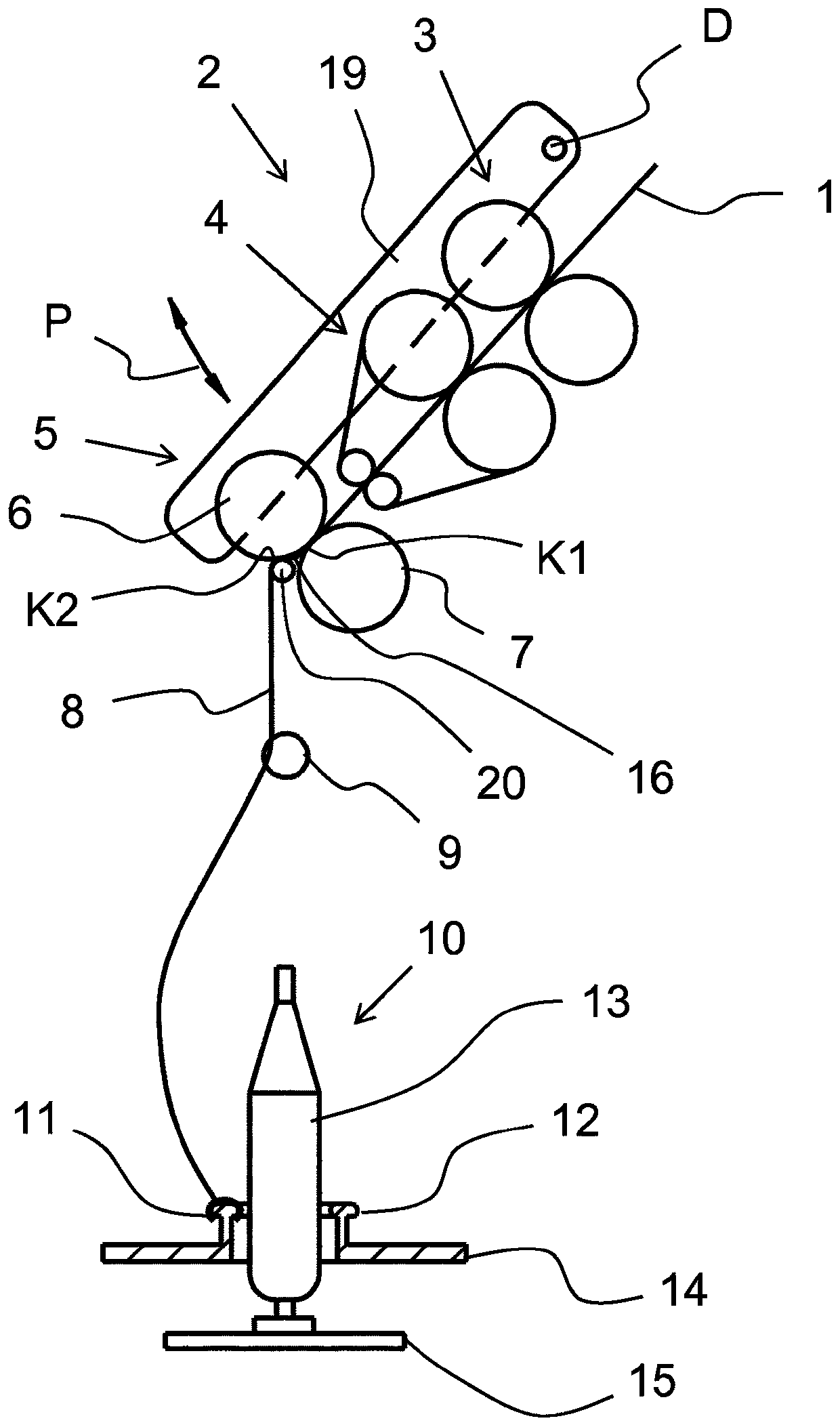

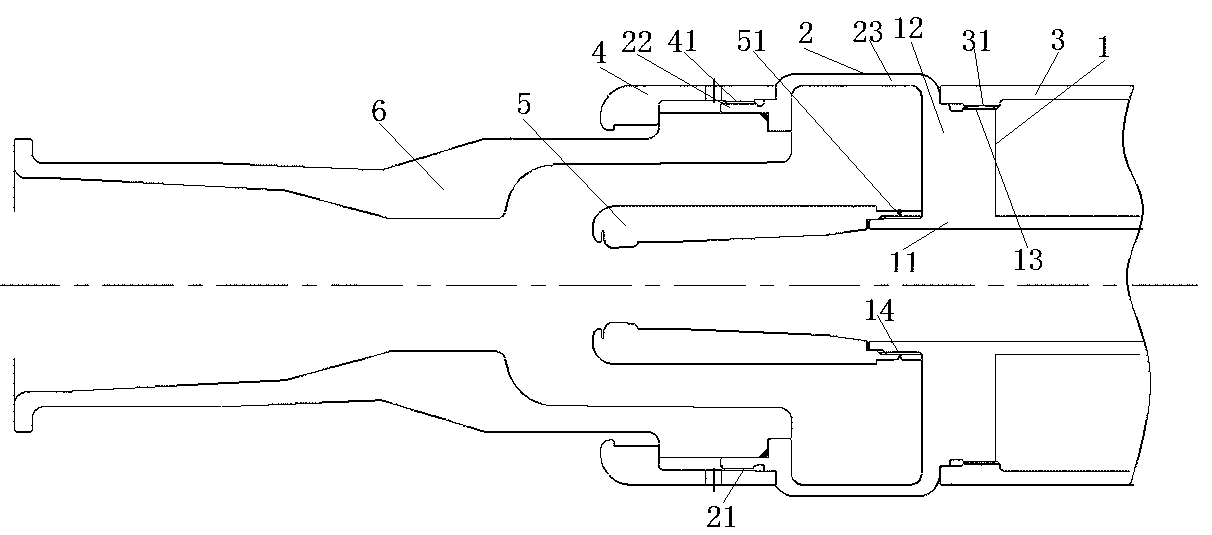

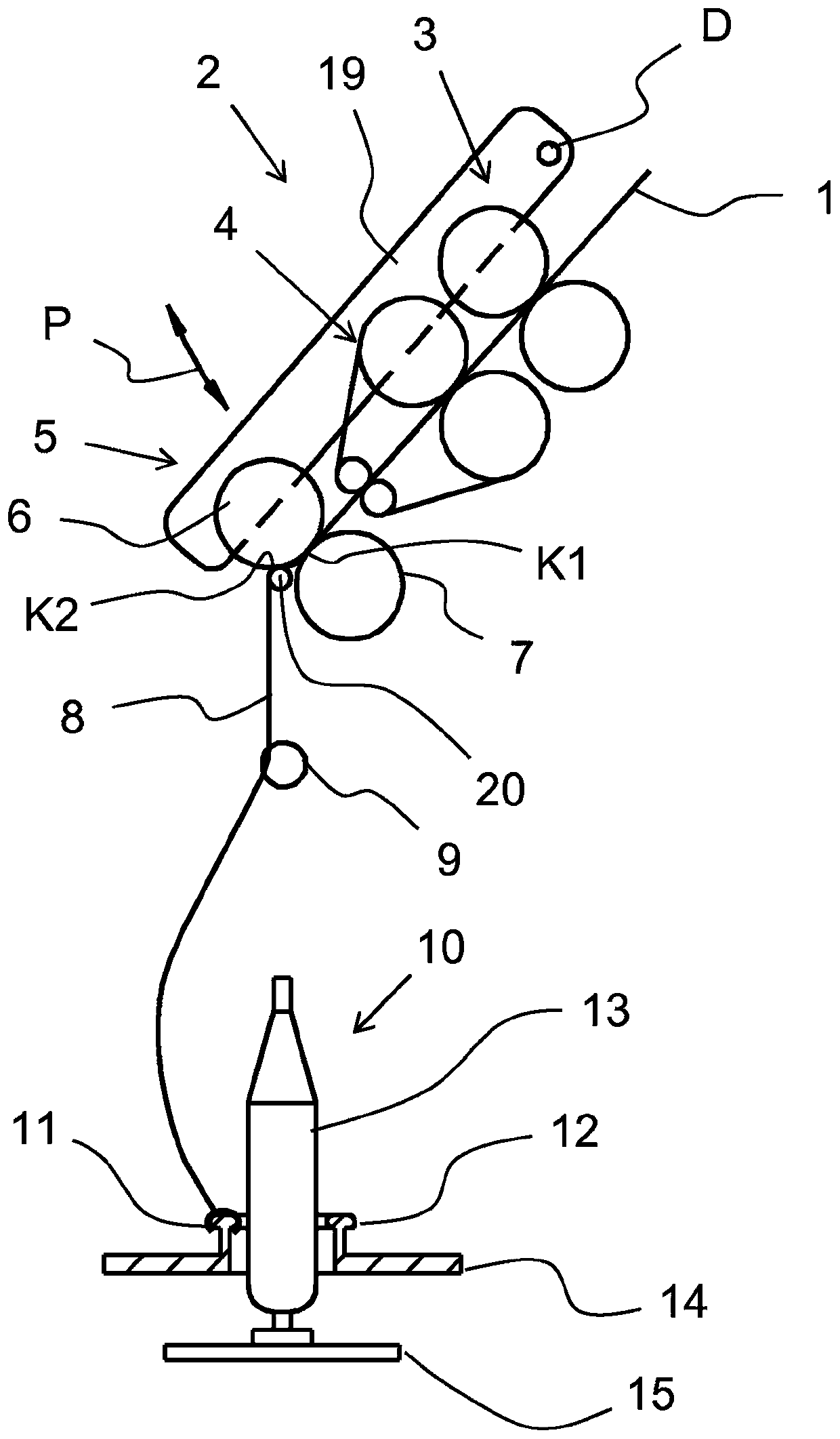

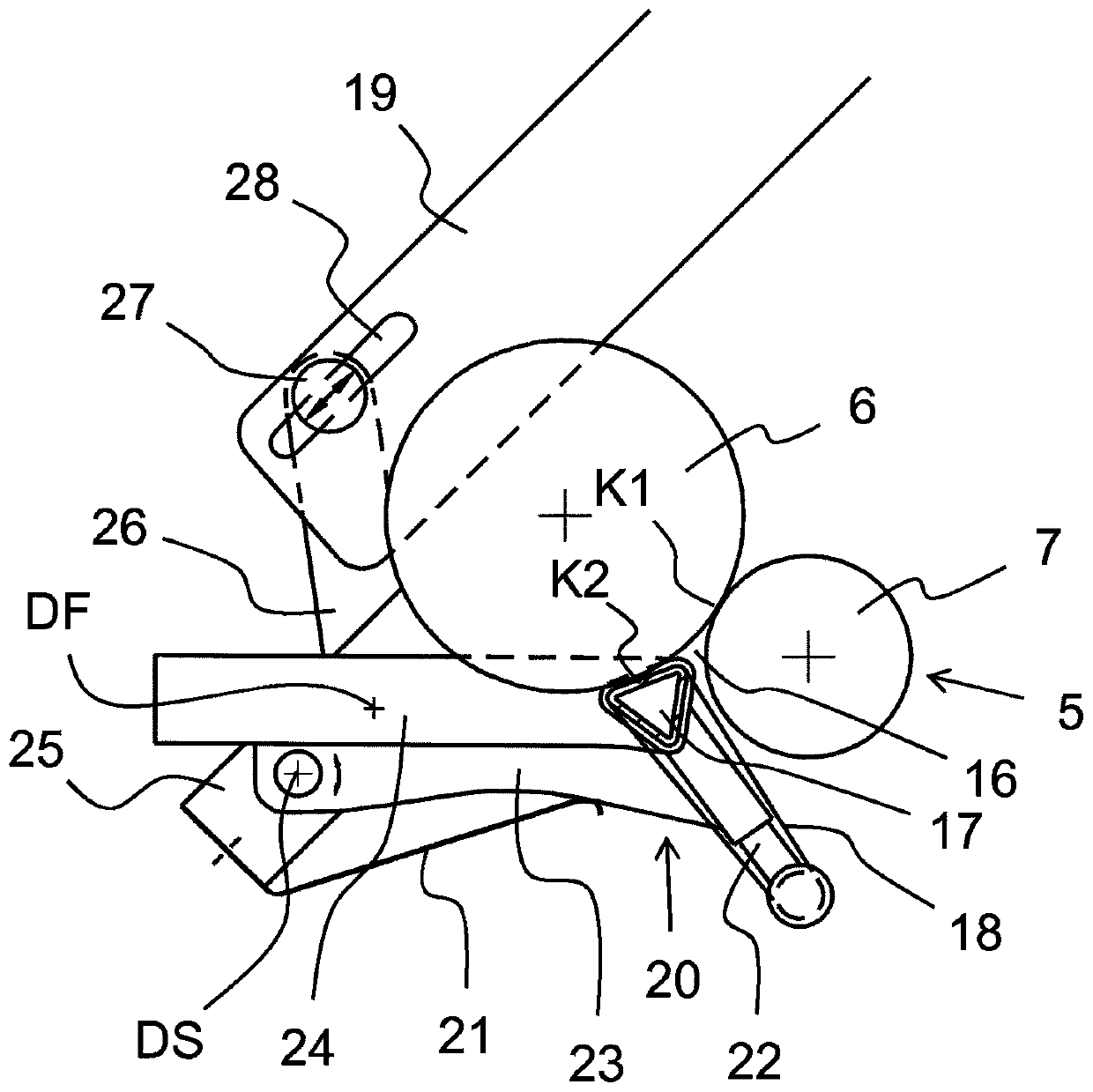

Drawing frame for spinning machine, and compaction device

ActiveCN111527248AReliable and uniform compressionUniform compressionDrafting machinesContinuous wound-up machinesFiberClassical mechanics

The invention relates to a drawing frame for a spinning machine for drawing a fiber composite (8), comprising top and bottom rollers and a loading arm (19) on which the top rollers of the drawing frame (2) are mounted, an output roller pair (5) which is formed by an output top roller (6) and an output cylinder (8) arranged thereunder, and a pneumatic compaction device (20) arranged downstream of the output roller pair (5) of the drawing frame (2) for compacting the drawn fiber composite (8) having a suction tube (17) which can be subjected to suction. The suction tube (17) is mounted on a bearing shell (25) and the bearing shell (25) is mounted on the output cylinder (7). In a compaction device for a drawing frame having a suction tube (17) which can be subjected to suction, the suction tube (17) is mounted on a bearing shell (25) and the bearing shell (25) is provided to be mounted on the output cylinder (7).

Owner:MASCHINENFABRIK RIETER AG

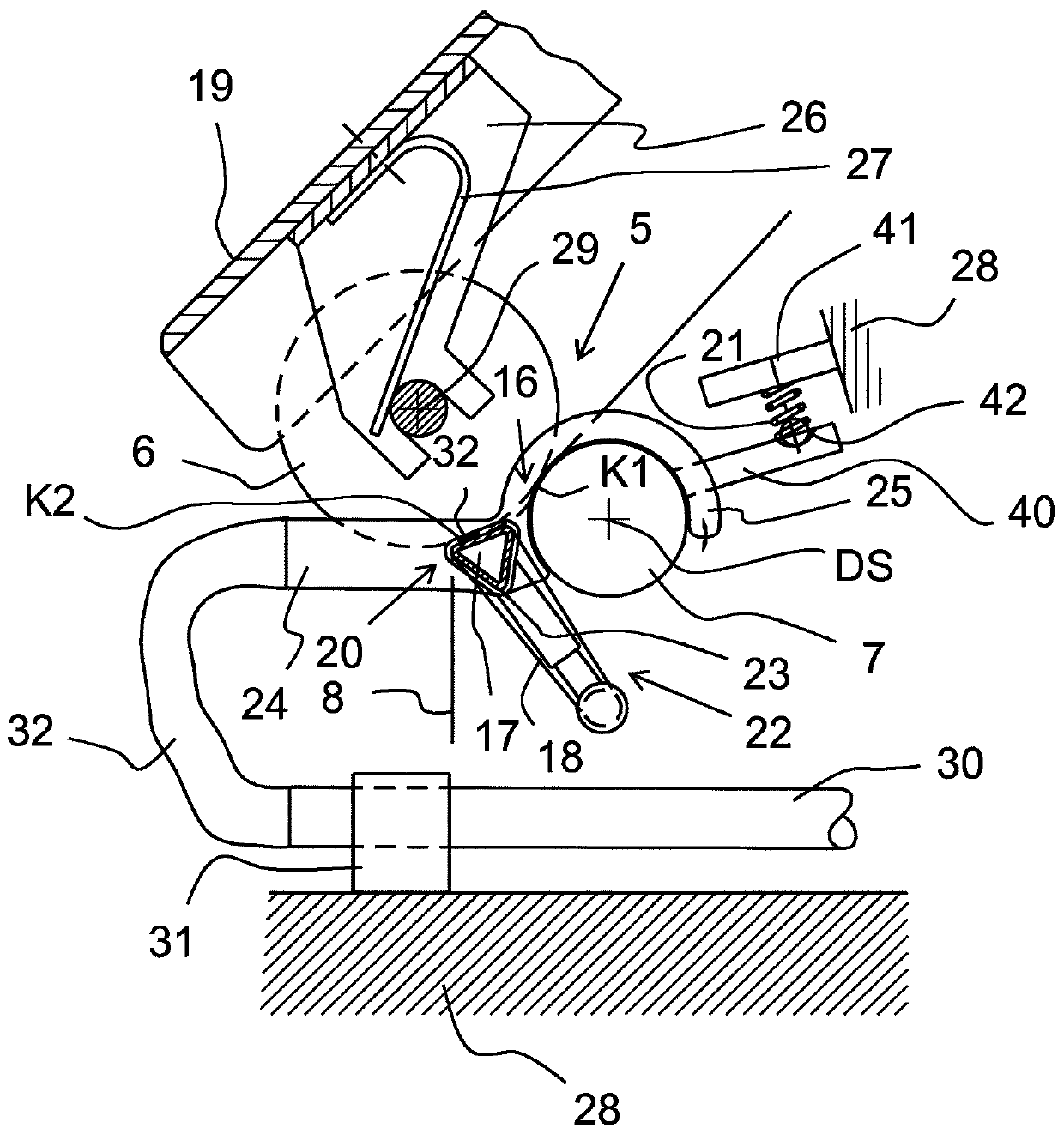

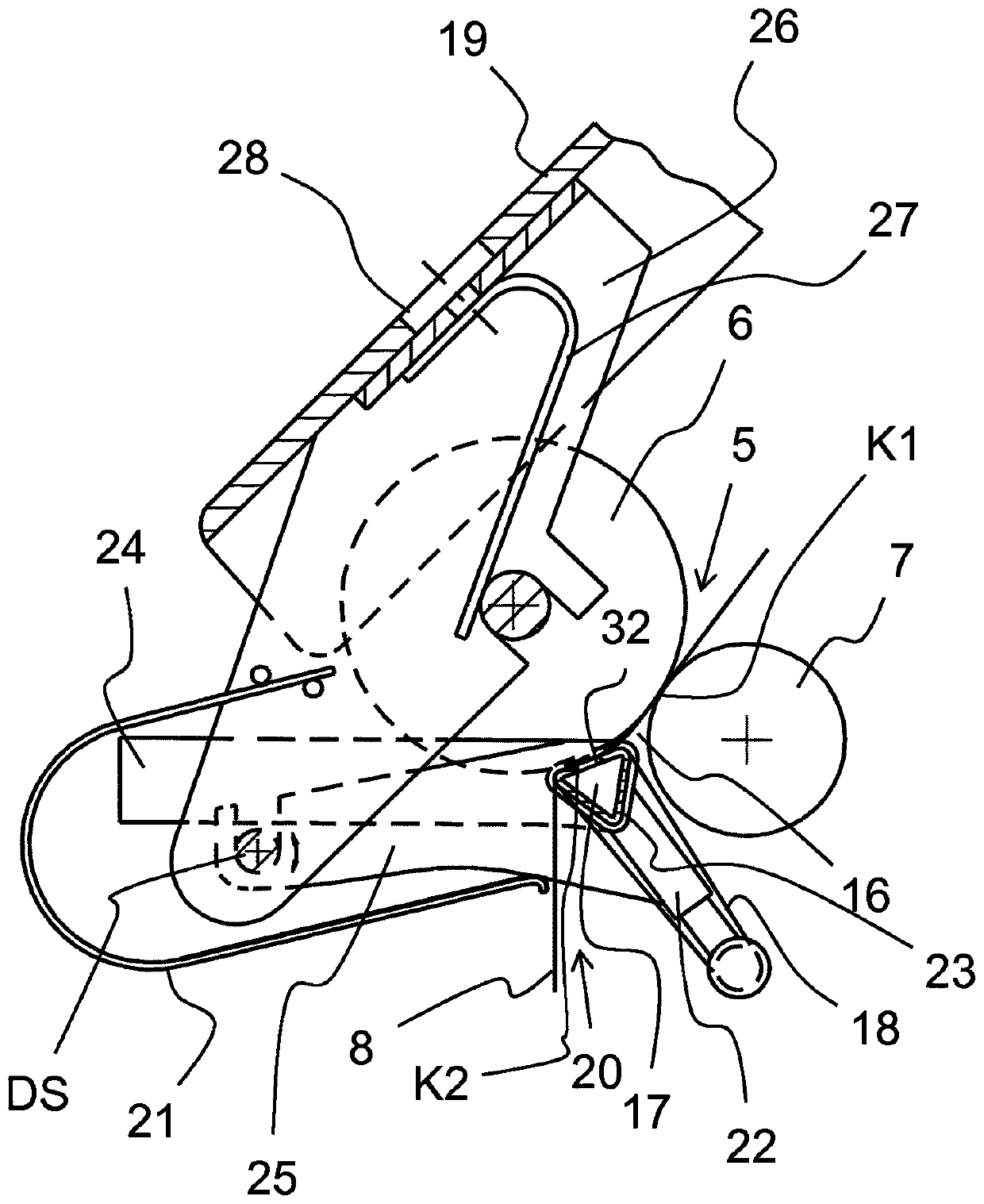

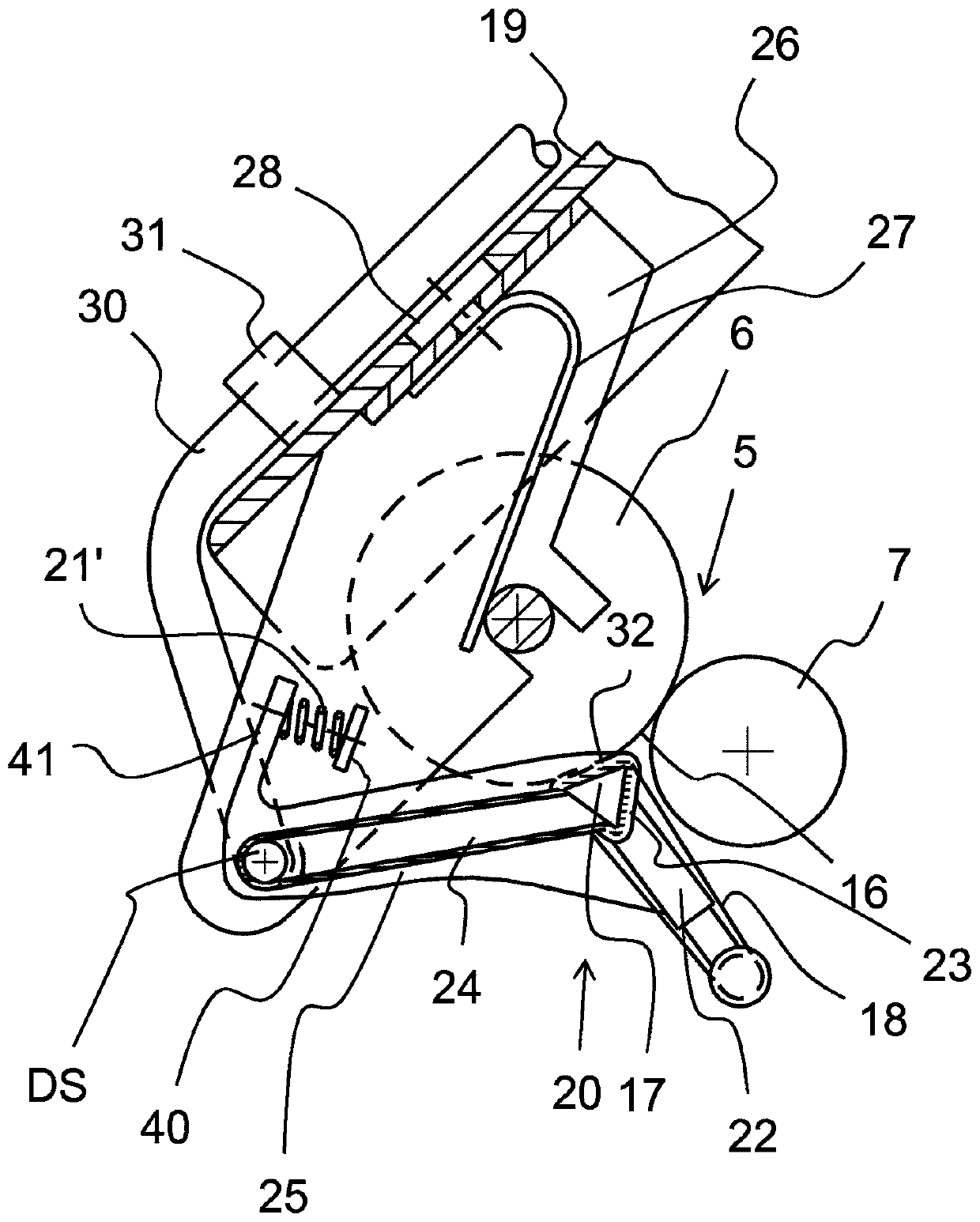

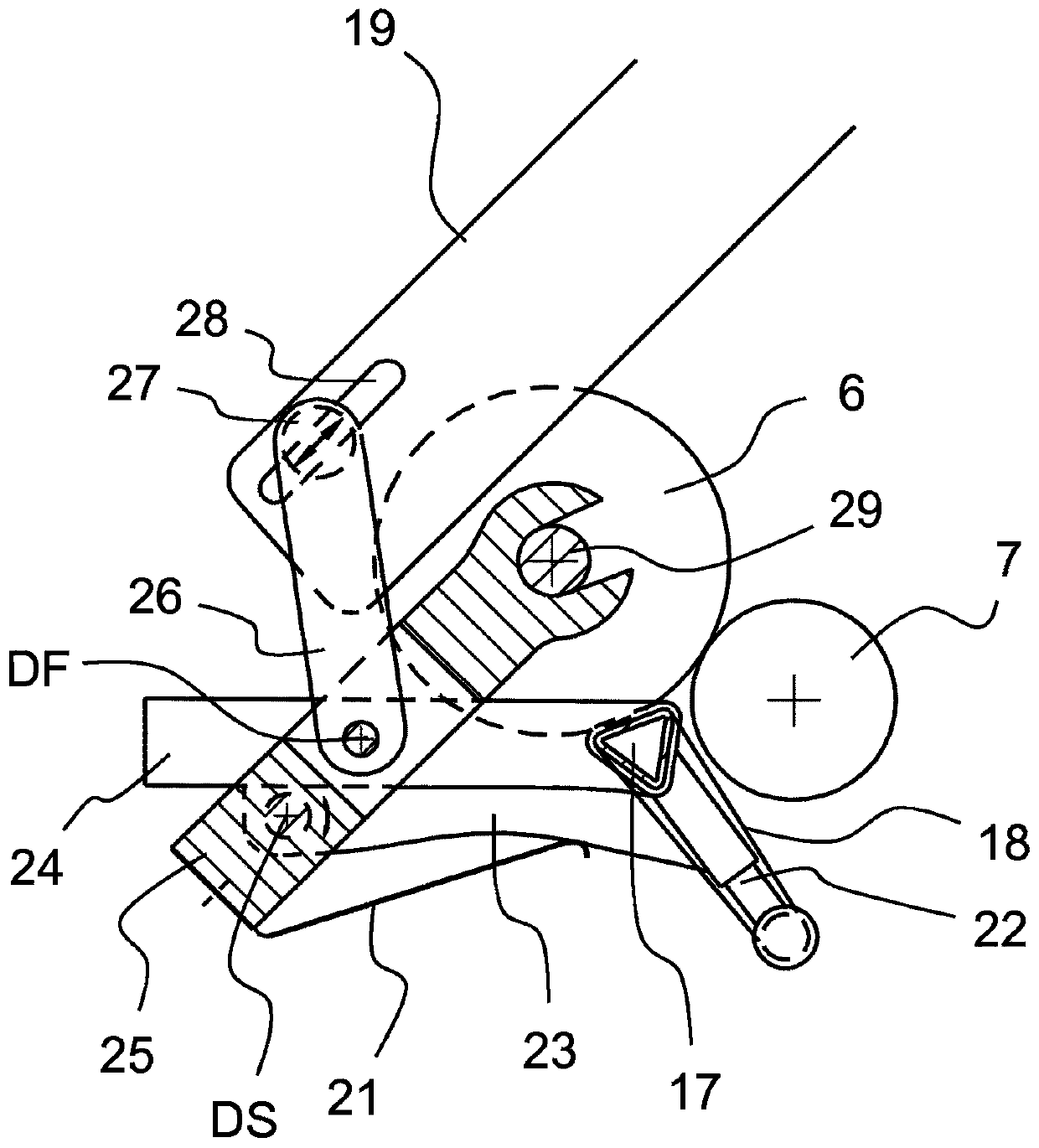

Drawing frame and compaction device for spinning machine

ActiveCN111465727AReliable and uniform compressionSimple structureDrafting machinesFiberClassical mechanics

The invention relates to a drawing frame for a spinning machine, comprising top and bottom rollers, a loading arm (19) on which the top rollers of the drawing frame (2) are mounted, an output roller pair (5) which is formed by an output top roller (6) and an output bottom roller (7), and, mounted on the loading arm (19), a loading unit (26) on which the output top roller (6) is mounted. A pneumatic compaction device for compacting a drawn fiber composite (8) is arranged downstream of the output roller pair (5) of the drawing frame (2), said compaction device having a suction tube (17) which can be subjected to suction. The suction tube (17) is mounted on a lever (25), the lever (25) is rotatably and / or displaceably mounted on the loading unit (26), and a spring device (21; 21', 40, 41) isprovided which acts on the suction tube (17) and / or the lever (25) in order to elastically press the suction tube (17) against the output top roller (6) or the output bottom roller (7). A corresponding compaction device comprises a suction tube (17) which can be subjected to suction and a loading unit (26), wherein the suction tube (17) is mounted on a lever (25), the lever (25) is rotatably and / or displaceably mounted on the loading unit (26), and a spring device (21; 21', 40, 41) is provided which acts on the suction tube (17) and / or the lever (25) in order to be able to elastically press the suction tube (17) against the output top roller (6) or the output bottom roller (7).

Owner:MASCHINENFABRIK RIETER AG

Anti-loosening structure and contact assembly and circuit breaker using the structure

ActiveCN106098458BEven by forceUniform deformationHigh-tension/heavy-dress switchesAir-break switchesClassical mechanicsCoil spring

The invention relates to a loosening prevention structure and a contact assembly and circuit breaker using the same, which are used for solving the problem that a threaded connection structure in the prior art is easy to loosen during switch-on and switch-off of the circuit breaker. In the loosening prevention structure disclosed by the invention, a canted-coil spring is arranged between a first connection element and a second connection element, thus, the canted-coil spring can be pressed by a first push surface or a second push surface to make the canted-coil spring compressed and deformed along a plug-in direction (namely, an axial direction of the first connection element) of the two connection elements and then apply a pre-tightening force, far away from the second connection element along an axial line, to the first connection element during the process that the first connection element is screwed into the second connection element, thread teeth, adapted to each other, of the first connection element and the second connection element can be contact and are engaged by means of the pre-tightening force, and an effect of preventing a thread joint surface from loosening is achieved; and meanwhile, the canted-coil spring is beneficial for enabling relatively uniform force applying and deformation of all positions where the canted-coil spring between the first push surface and the second push surface is arranged, a more uniform pre-tightening force can be provided for the first connection element, and a loosening prevention effect is better.

Owner:HENAN PINGZHI HIGH VOLTAGE SWITCHGEAR +2

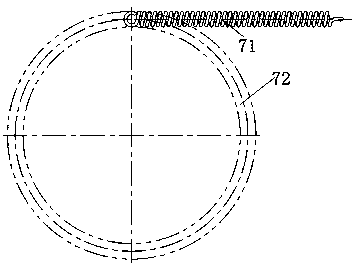

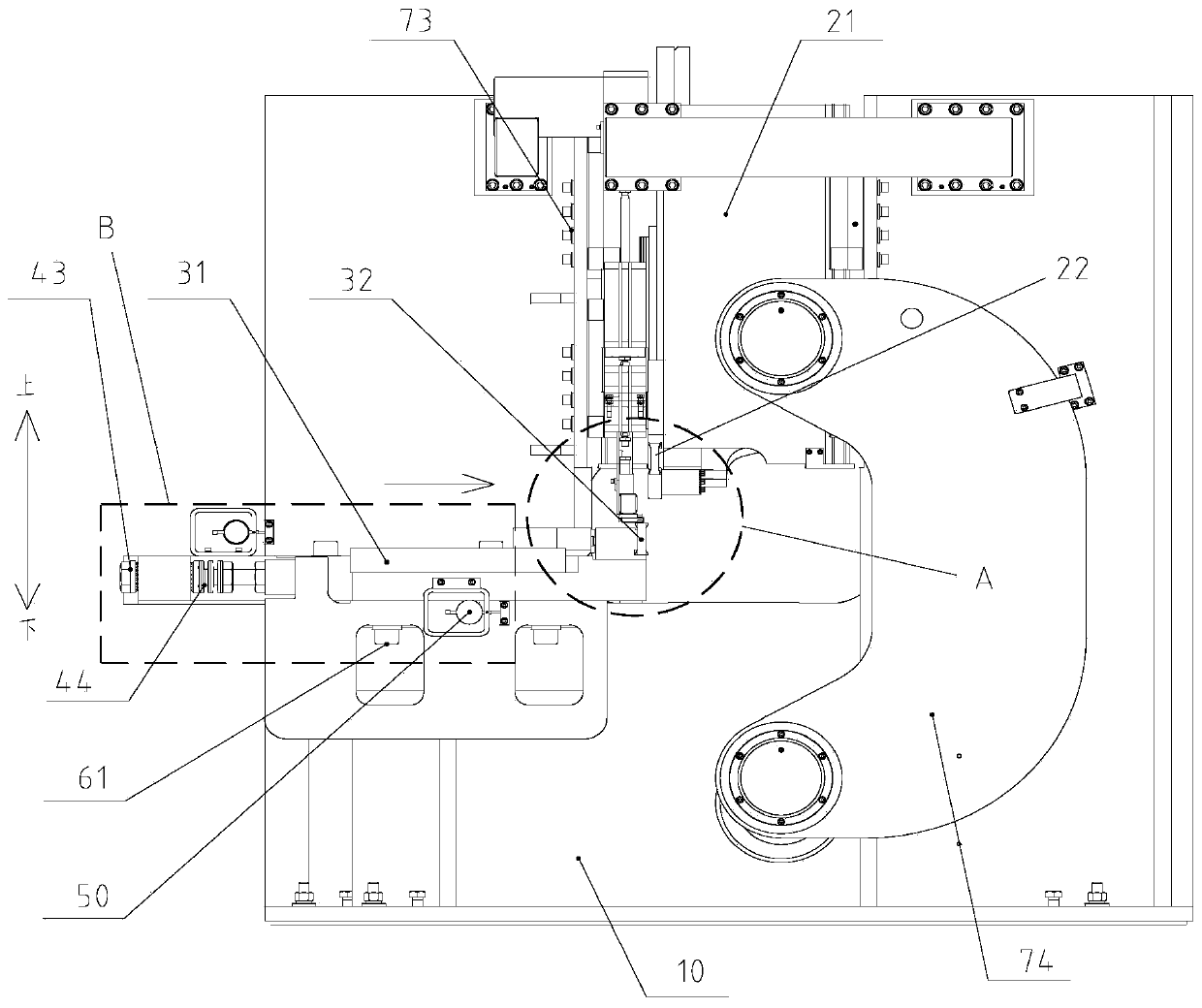

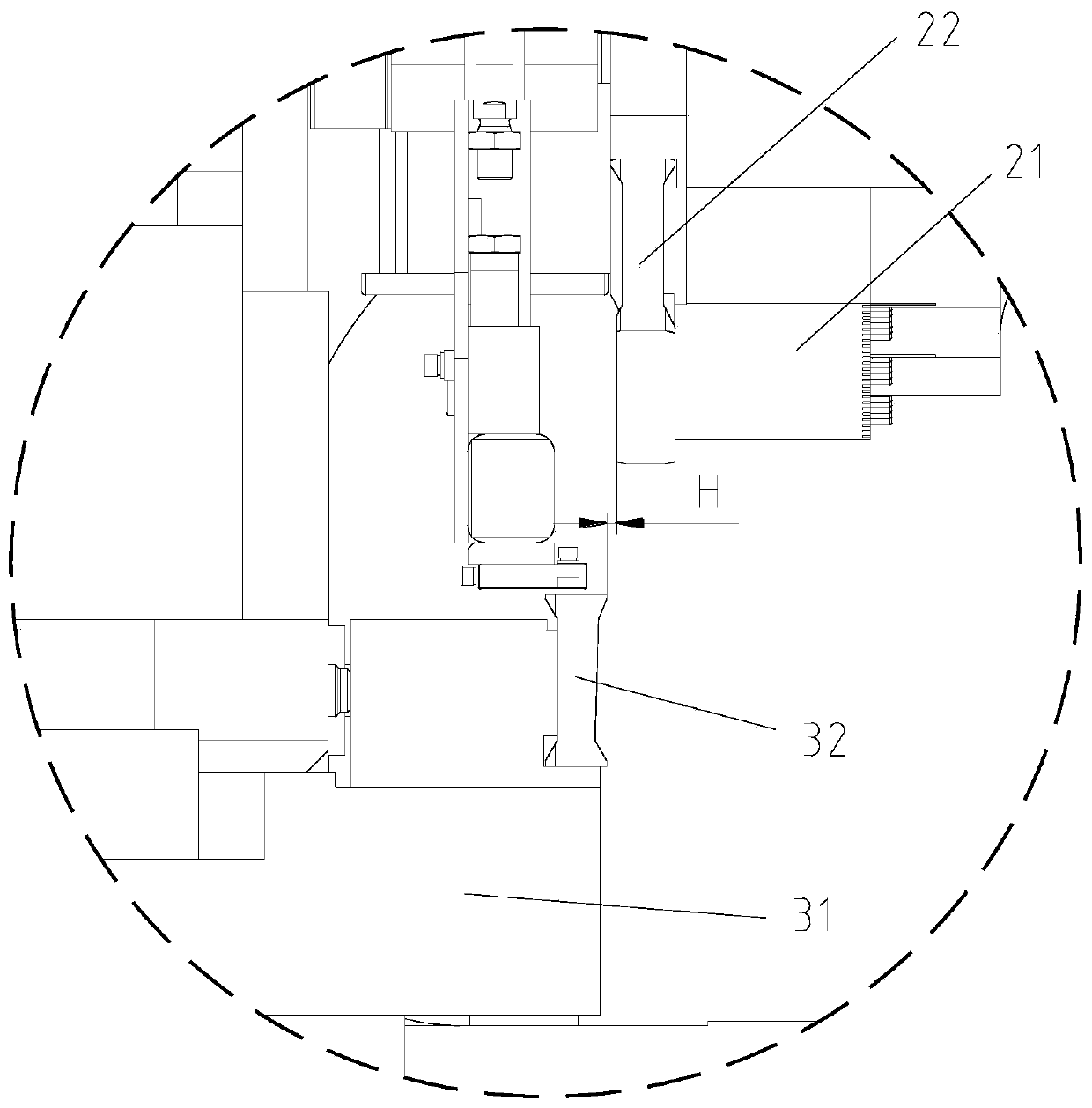

Cutting device for wire cord fabric

PendingCN111251637AUniform preloadEasy to placeTyresMetal working apparatusBlade plateStructural engineering

The invention provides a cutting device for wire cord fabric. The device comprises a rack, an upper cutter mechanism, a lower cutter mechanism, adjusting mechanisms and display instrument assemblies;the lower cutter mechanism is arranged in the moving direction of a cutter board, and a cutter gap H is formed between an upper cutter and a lower cutter; the adjusting mechanisms are arranged on thecutter board and connected with the rack, and the adjusting mechanisms comprises first mounting holes, screw holes, screw rods, elastic pieces and first nuts, wherein the first mounting holes, the screw holes, the screw rods, the elastic pieces and the first nuts are coaxially arranged, the first mounting holes are formed in the cutter board, the screw holes are formed in the rack, an adjusting gap is formed between the cutter board and the rack, the screw rods penetrate through the first mounting holes and the screw holes, the first nuts extrude the elastic pieces so as to enable the elasticpieces to apply elastic force to the cutter board, and the screw rods are screwed to drive the cutter board to move to adjust the size of the adjusting gap so as to adjust the size of the cutter gap H; and the display instrument assemblies are arranged on the cutter board and abut against the rack. According to the technical scheme, the problem that in the related art, the gap amount displayed bya dial indicator is inaccurate, so that the screw rods are blindly adjusted is effectively solved.

Owner:MESNAC +1

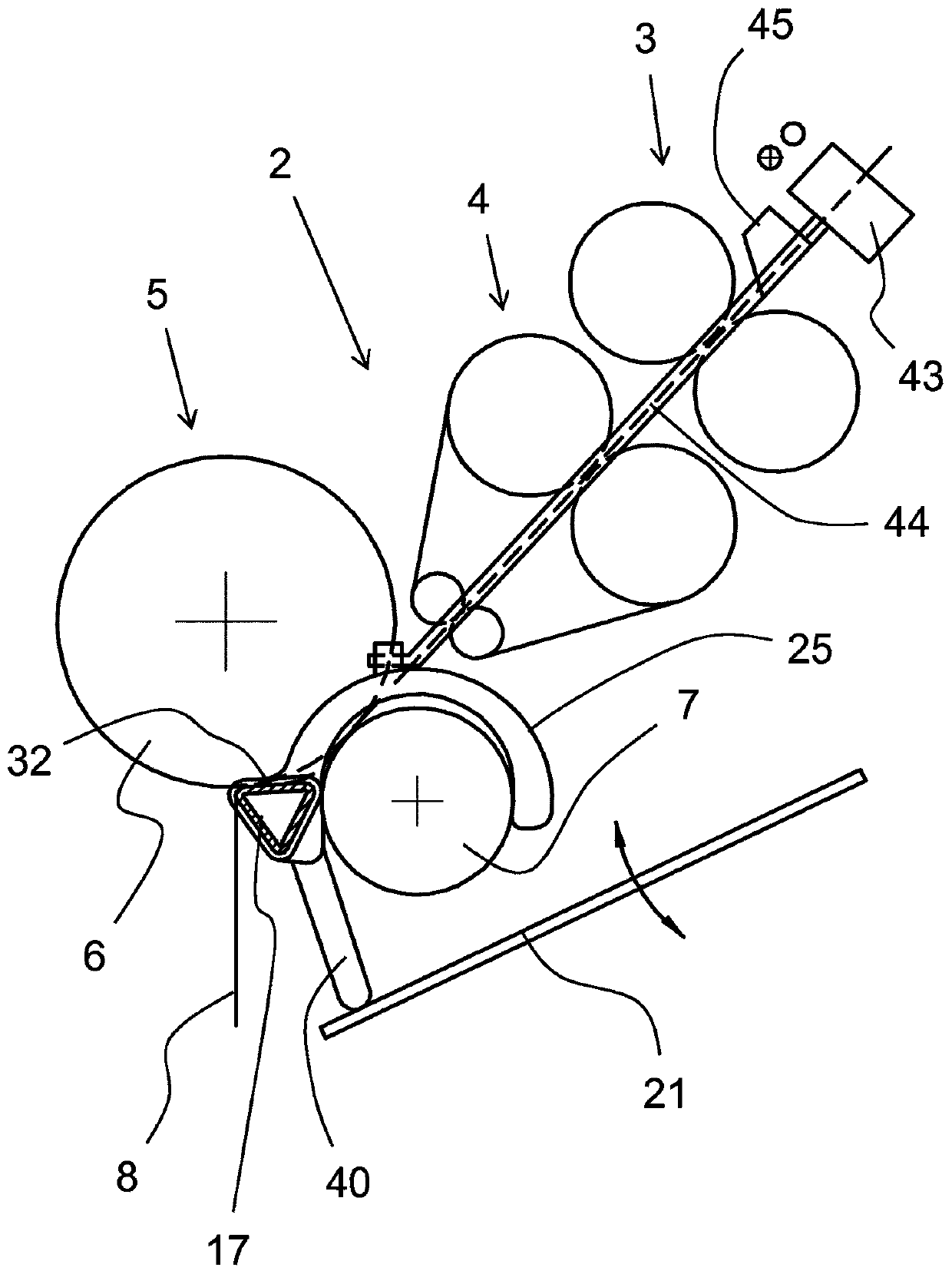

Drafting arrangement for spinning machine

PendingCN111479960AReliable and uniform compressionNo angular deviationDrafting machinesContinuous wound-up machinesFiberEngineering

The invention relates to a drafting arrangement for a spinning machine. The drafting arrangement has top and bottom rollers and having a load arm (19) on which the top rollers of the drafting arrangement are arranged, and also has a starting roller pair (5) which is formed by a starting top roller (6) and a starting bottom roller (7), and has a pneumatic compression device (20) downstream of the starting roller pair (5) of the drafting arrangement (2) for sealing a drafted fiber strand (8). The pneumatic compression device has a suction tube (17) to which suction can be applied, wherein the suction tube (17) is entwined by a screen element (18), the pneumatic compression device (20) has a fiber bundling zone (16), and the fiber bundling zone (16) is delimited by two clamping locations (K1,K2), wherein a first clamping location (K1) is defined by the two rollers of the starting roller pair (5), and a second clamping location (K2) is formed by one (6) of the two rollers of the startingroller pair (5) and the screen element (18), wherein the suction tube (17) is arranged on a base holder (25), and the base holder is arranged on the starting top roller (6) and the load arm (19). In the compression device for the drafting arrangement, the suction tube (17) is arranged on the base holder (25) and the base holder has receptacles for fixing to a starting top roller (6) and a load arm(19) of the drafting arrangement.

Owner:MASCHINENFABRIK RIETER AG

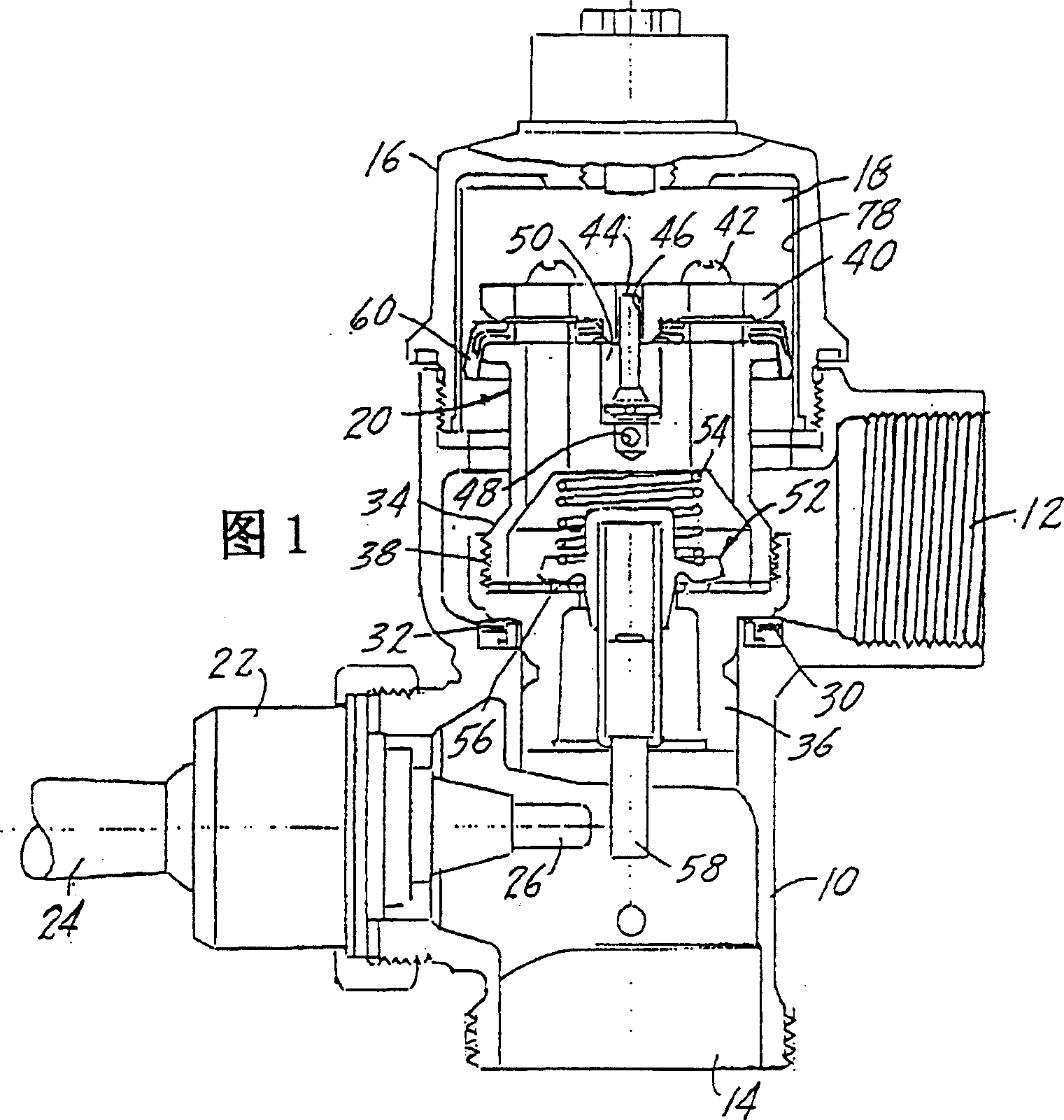

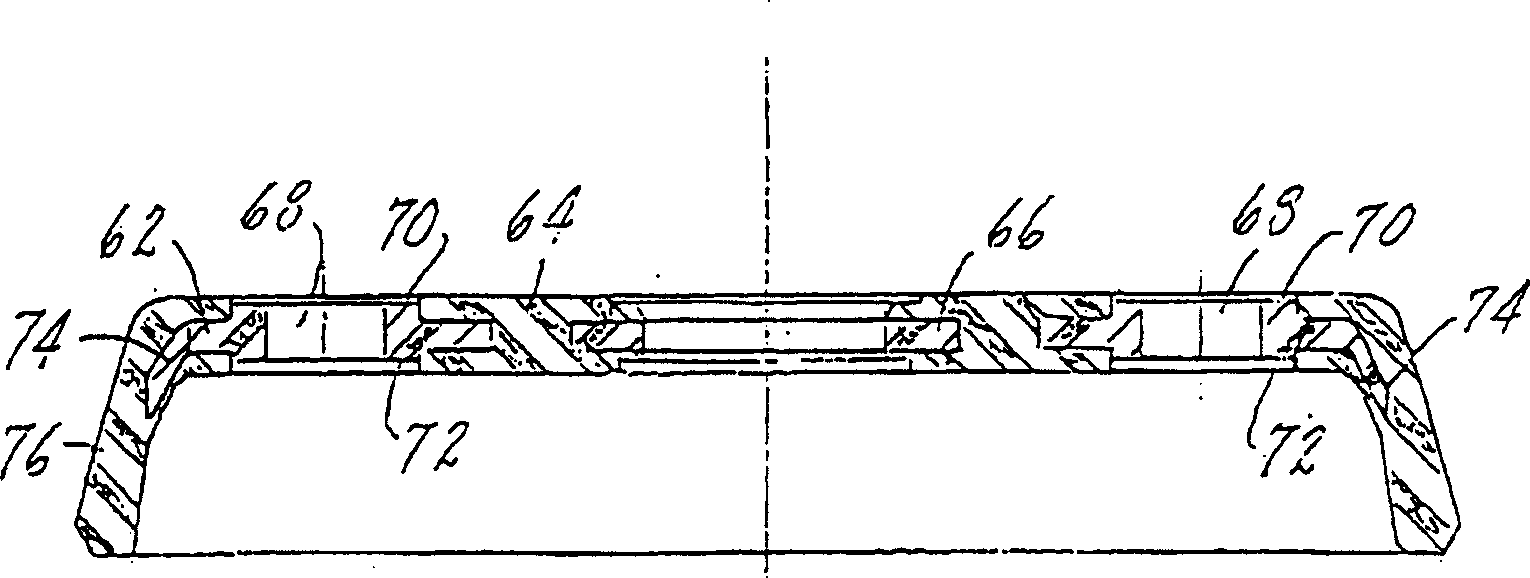

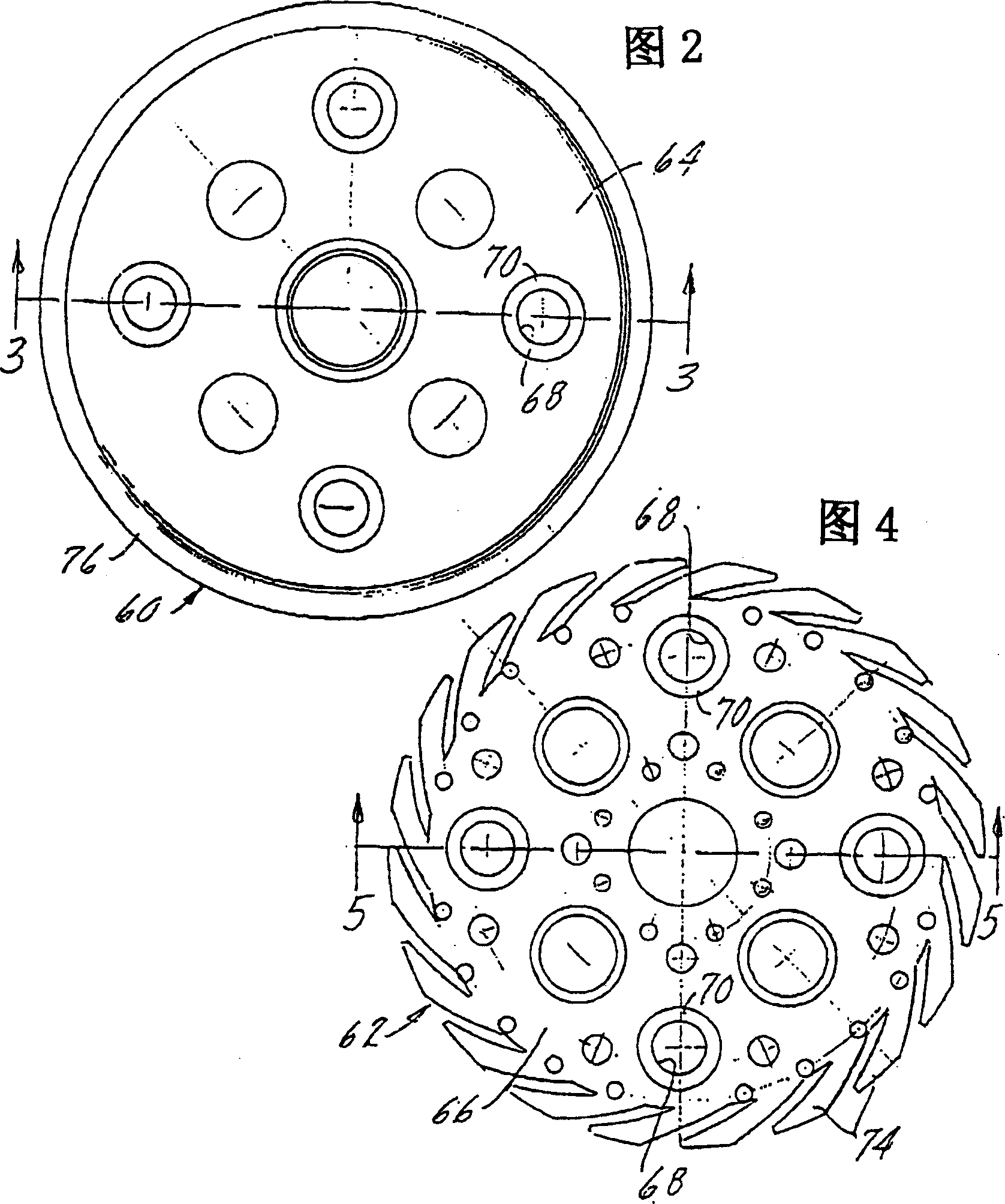

Lip sealing device for piston flushing valve

InactiveCN1285807CExtend your lifeImprove consistencyEngine sealsOperating means/releasing devices for valvesElastomerBody shape

The present invention relates to a piston member for a flush valve for lavatories and urinals, the flush valve having a valve body with an inlet and an outlet, and a valve seat at the outlet. The piston member is movable within the valve body towards and away from the valve seat to control flow from the inlet to the outlet. In the piston part there is a safety valve for communicating the pressure chamber of the flushing valve with the outlet of the flushing valve. The piston member has an outwardly directed lip seal which bears against the inner wall of the valve body and the lip seal is retained between facing elements of the piston member. The lip seal includes an insert, and an elastomer covering and substantially enveloping the insert. Both the elastomer and the insert have a portion extending towards the flush valve body, and the insert has a support element which contacts a facing element of the piston member, transferring load from such element from the lip Remove from the elastomeric body of the shaped seal.

Owner:SLOAN VALVE COMPANY

an extrusion mold

Owner:河南航天精工制造有限公司

A pre-pressing device for non-woven fabric processing

The invention discloses a pre-pressing device for non-woven fabric processing, which mainly relates to the technical field of non-woven fabrics, including a seat frame, a transmission belt, a nozzle, a non-woven fabric, a grating, a first flattening mechanism, a respraying mechanism, a second pressure Flattening mechanism, conveyor belt flattening mechanism, weighing mechanism, ironing mechanism; the transmission belt set on the seat frame is used to transmit the processed non-woven fabric, and the grating set on the seat frame is used to detect whether the nozzle sprays evenly on the surface of the non-woven fabric; The first flattening mechanism is provided with several groups, which are used to roll and flatten the non-woven fabric; the second flattening mechanism can perform rolling operation on the non-woven fabric again; the weighing mechanism is responsible for the quality of the non-woven fabric. Inspection; the ironing mechanism is responsible for drying and flattening the non-woven fabric.

Owner:南通梦思霖纺织品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com