Integrated side pressure V-shaped spring and sealing ring with same

A side pressure, integrated technology, applied in the field of springs, can solve the problem of small preload force of ring coil springs, etc., and achieve the effects of uniform force, improved stability and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

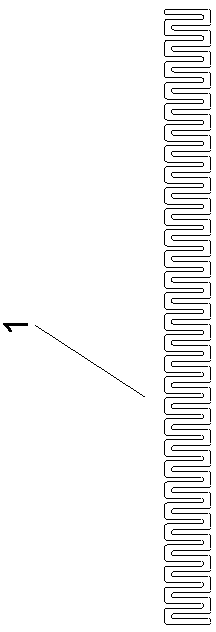

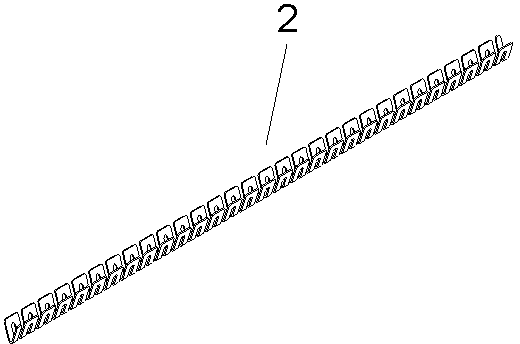

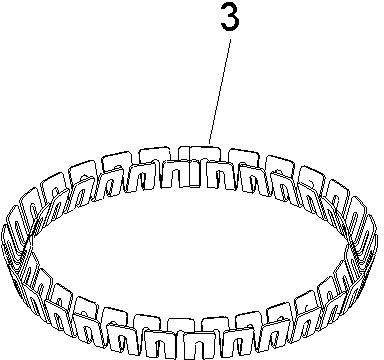

[0025] Such as Figure 5 or Image 6 As shown, this embodiment is a preferred embodiment of the present invention. First, we make the raw materials into Figure 4 The illustrated ring-shaped planar structure 4 with a rectangular opening (as long as it is a ring-shaped planar structure, it does not have to be the ring-shaped planar pattern of this embodiment; other ring-shaped planar patterns are also protected by the present invention Range), and then use a circular cylinder (not shown in the figure) to bend it into Figure 5 The cross section shown is a V-shaped ring structure 5, which is as follows Figure 5 An integral side pressure V-shaped spring 5 with a ring structure connected end to end is shown. The center line of the final V-shaped spring is determined according to the axis of the aforementioned annular cylinder. Because the integral side pressure V-shaped spring 5 of the present invention is made into an integral ring shape, it can bear the external force from the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com