Clamp type pressurizing device for formation and capacity grading ofsquare battery cell

A pressurizing device and square cell technology, applied in the direction of measuring devices, measuring device shells, electrochemical generators, etc., can solve the problems of cell pressurization, unable to limit cell swelling, and affect battery system life and safety. Achieve uniform preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

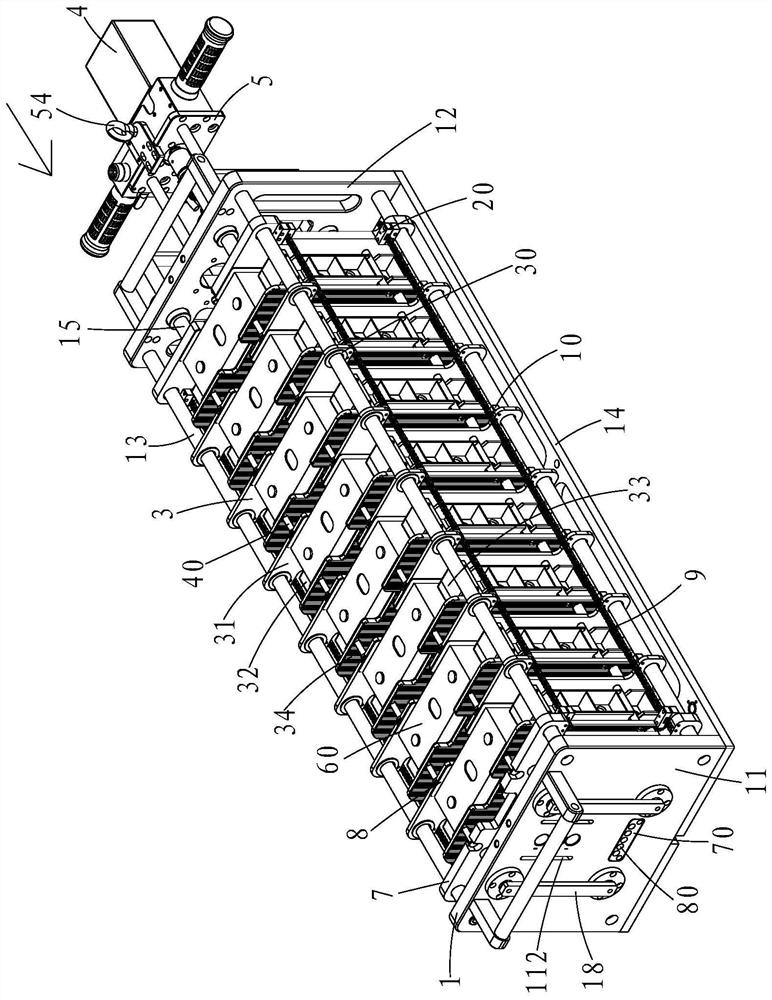

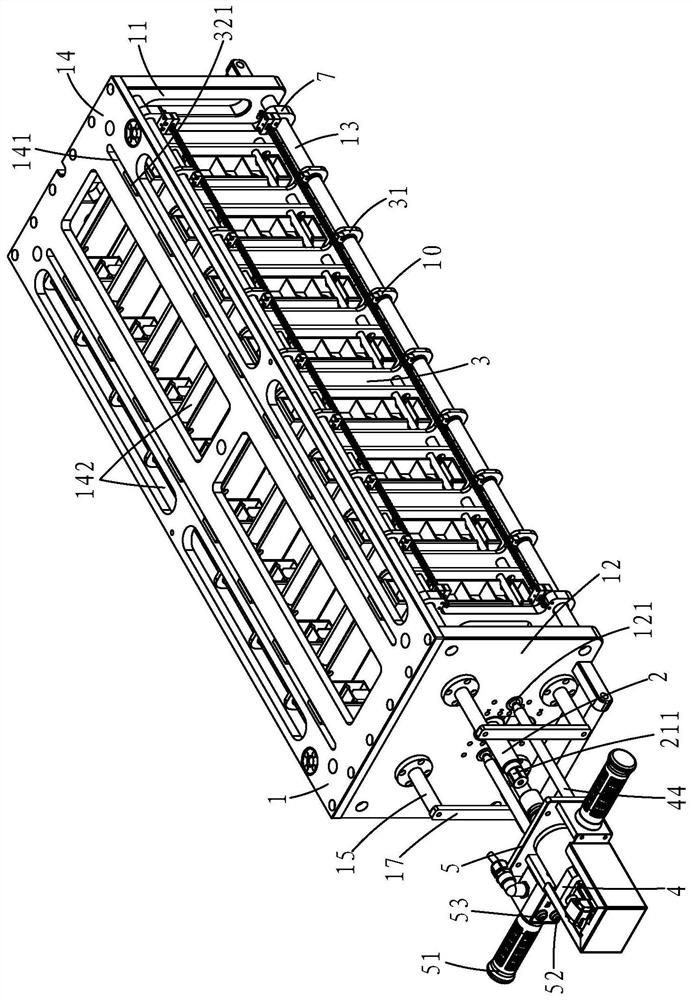

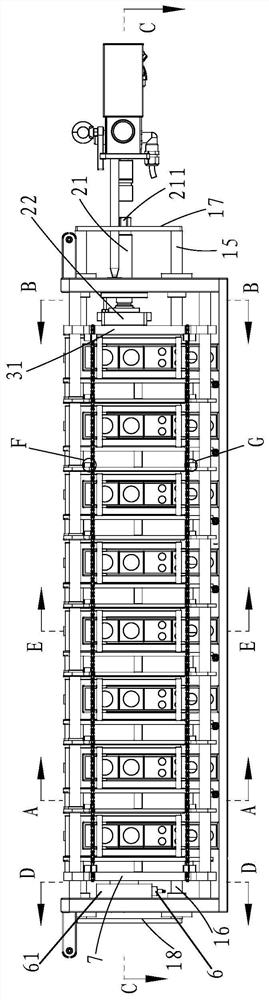

[0104] A clamp-type pressurizing device for forming a square cell into a capacity according to the present invention, comprising

[0105] The clamp-type tray includes a support frame 1, a pressurized connection mechanism 2 and several trays 3, and several of the trays 3 are movably connected to the support frame 1, and several of the trays 3 are connected together to realize linkage; The pressure connection mechanism 2 is connected to one of the trays 3;

[0106] The pressurizing device includes a driving device 4 and a fixing seat 5; the driving device 4 is fixedly connected to the fixing seat 5; the output end of the driving device 4 is detachably connected to the pressurizing connection mechanism 2;

[0107] The pressure detection device 6 is used to detect the pressure on the tray 3 . In a specific embodiment, the pressure detection device 6 may use a load cell.

[0108] The support frame 1 includes

[0109] rear side panel 11;

[0110] The front side plate 12 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com