Patents

Literature

110results about How to "Convenient preload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

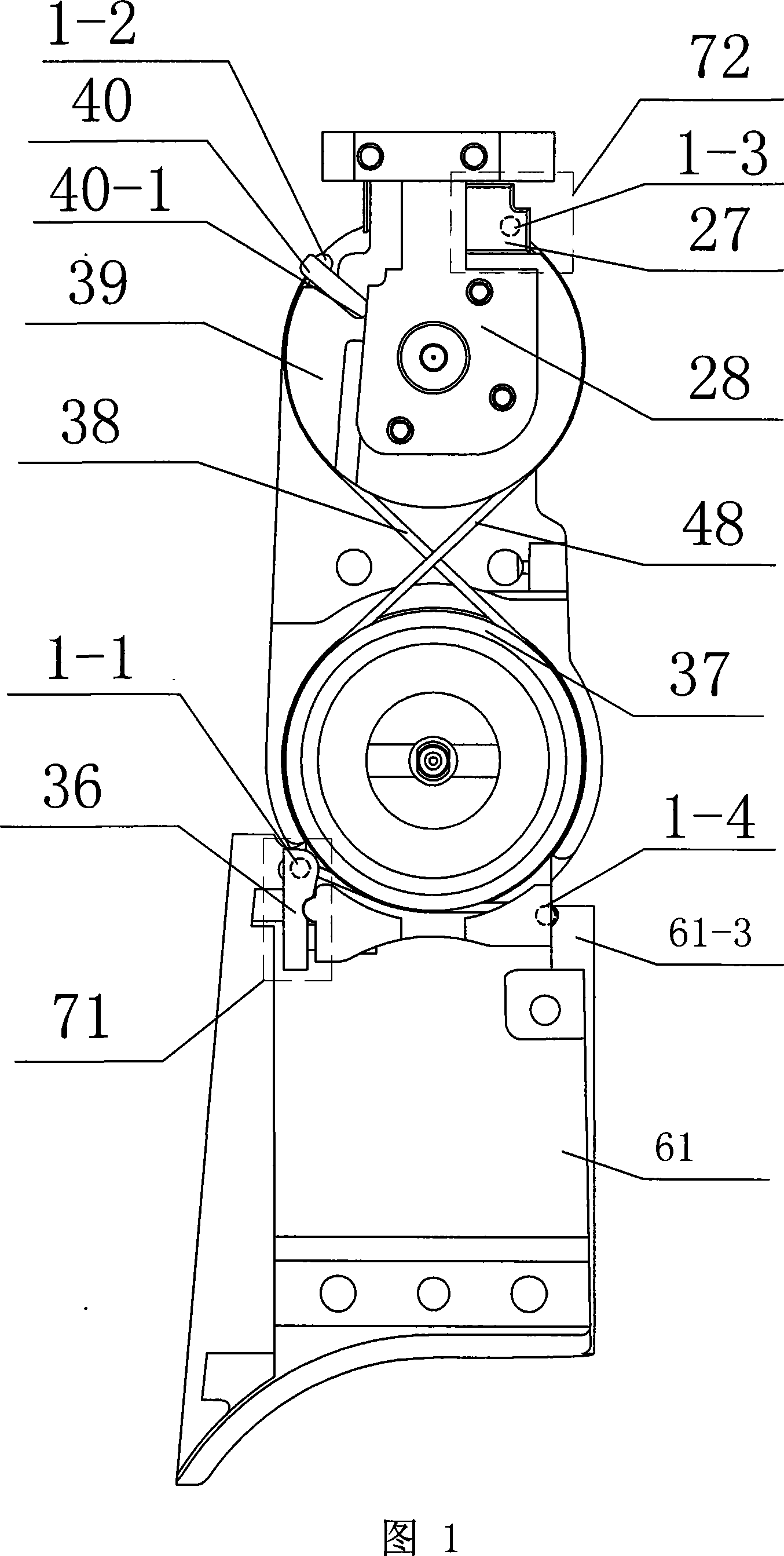

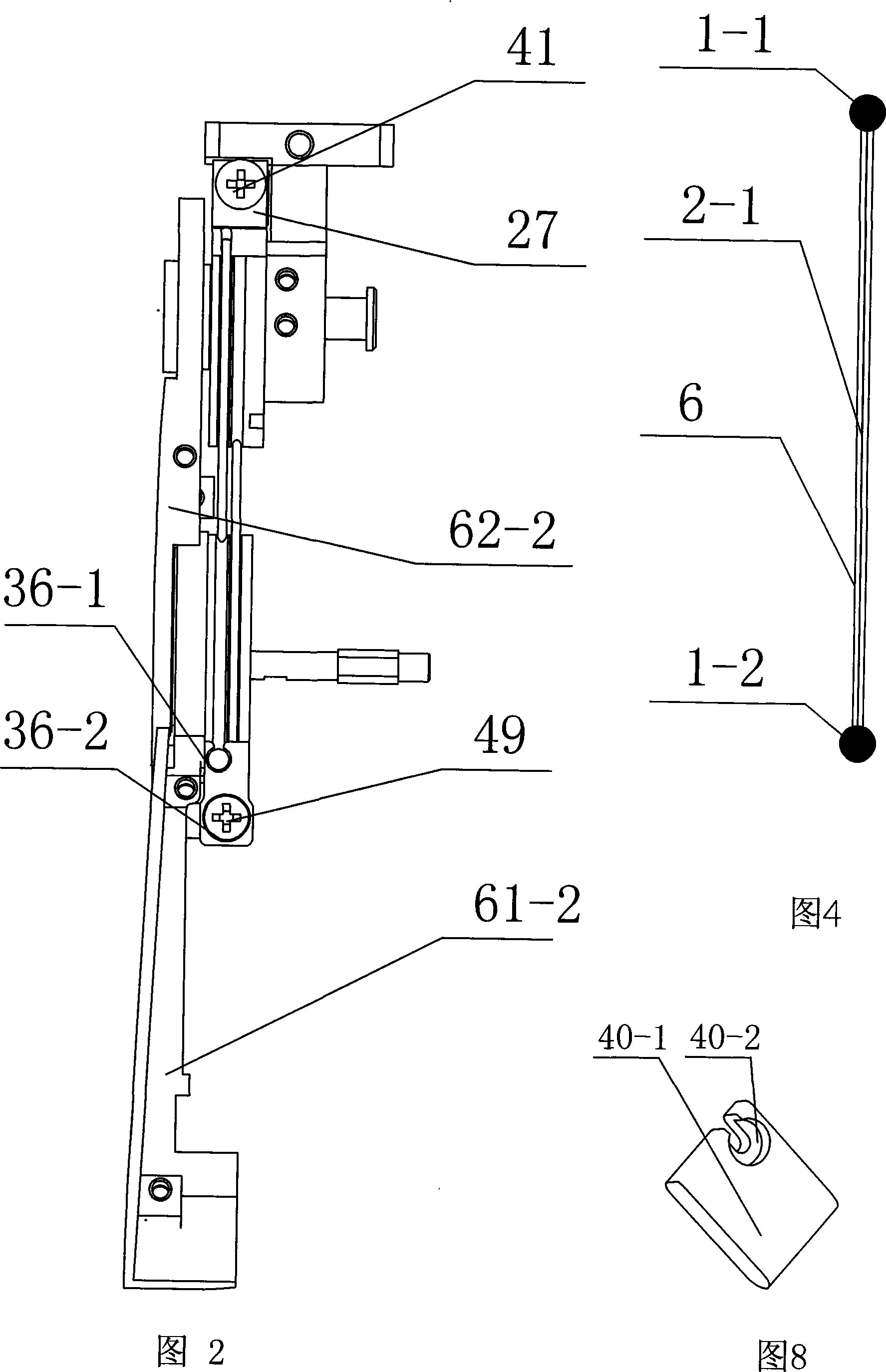

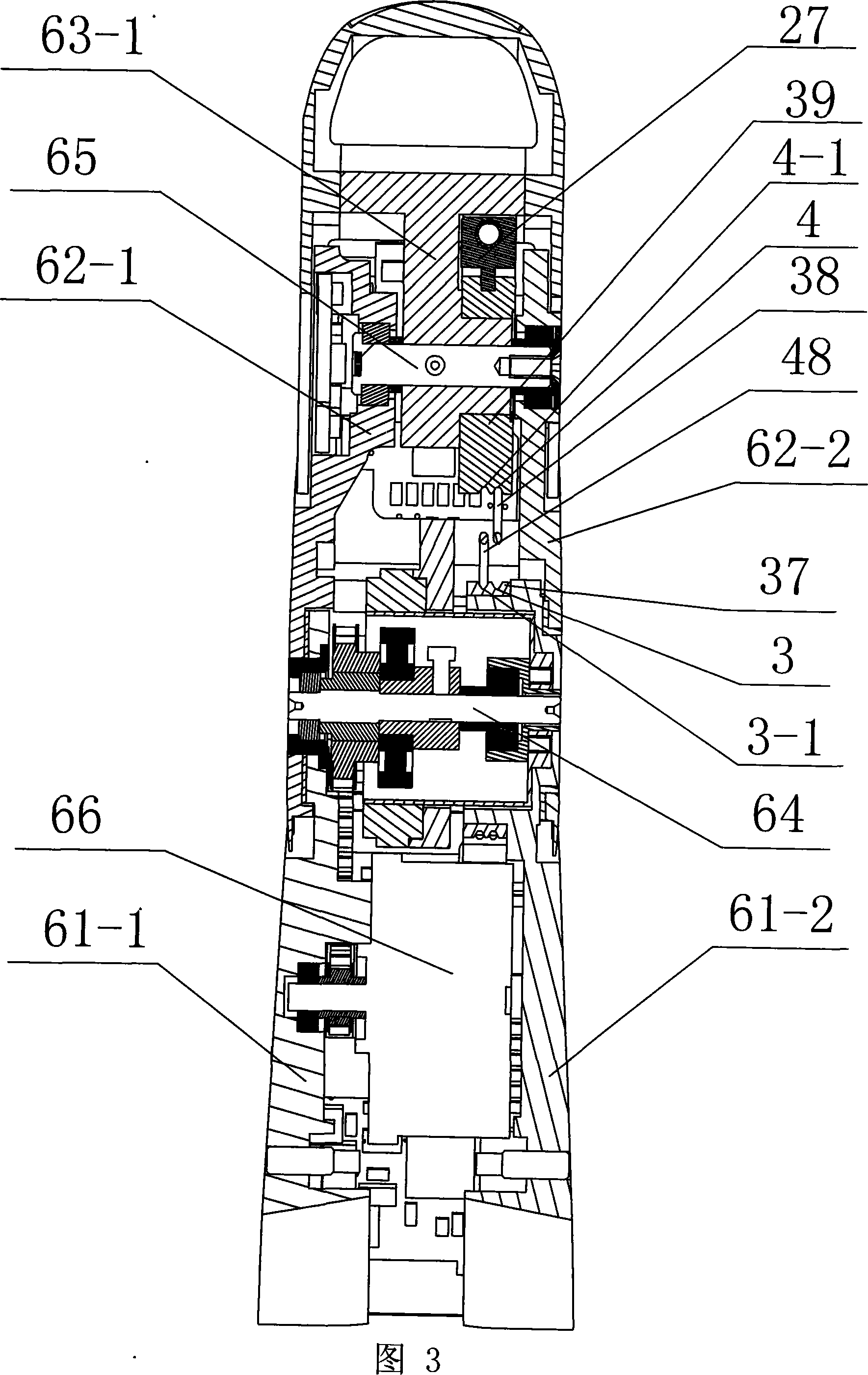

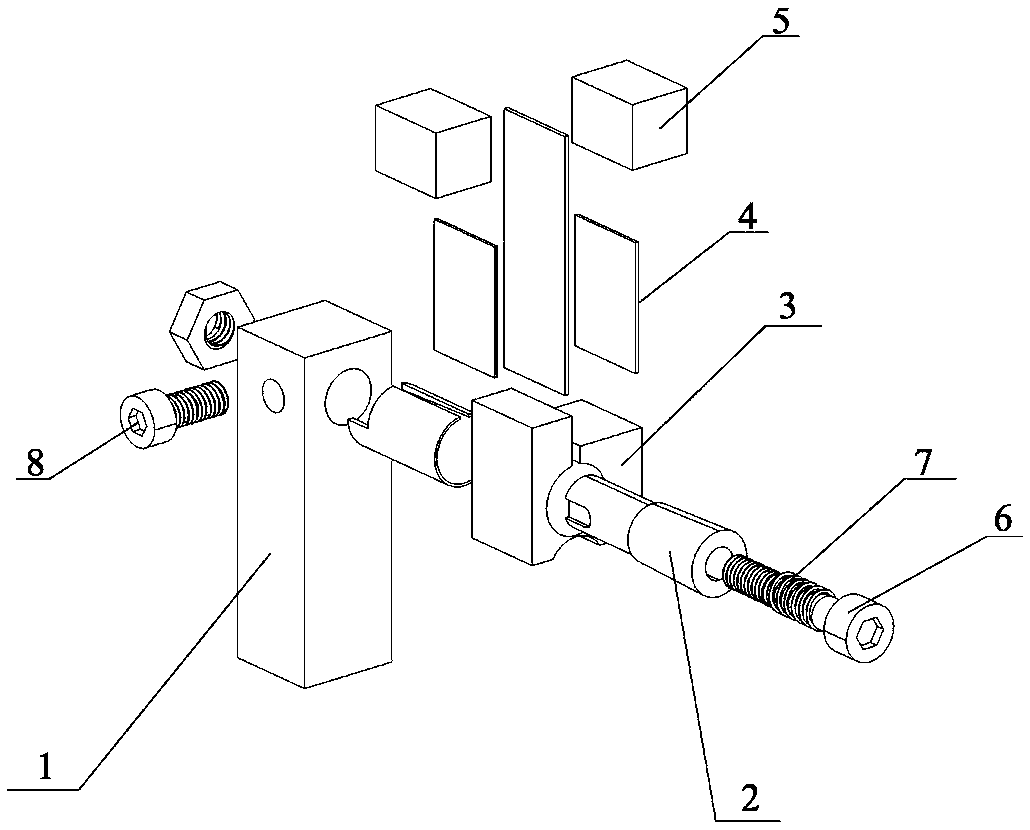

Finger joint steel wire coupled transmission mechanism for robot clever hand finger

InactiveCN101100064ASimple structureConvenient preloadJointsGripping headsSacroiliac jointEngineering

The present invention relates to finger driving mechanism of robot, and is especially wire coupled finger driving mechanism of skillful robot hand. The wire coupled finger driving mechanism has one first wire piece and one second wire piece twisted separately on the first joint wire wheel and the second joint wire wheel and crossed to form one 8 figure shape, one wire clamping board inserted in the first groove, one first steel ball mounted inside the first pretension device, one second steel ball mounted inside the wire clamping board, one third steel ball mounted inside the second pretension device, and one fourth steel ball mounted inside the wire clamping board. The present invention realizes the coupling motion of two finger joints in the same direction and the same angle, and has the advantages of high simple structure, convenient pretension, high reliability, etc.

Owner:HARBIN INST OF TECH

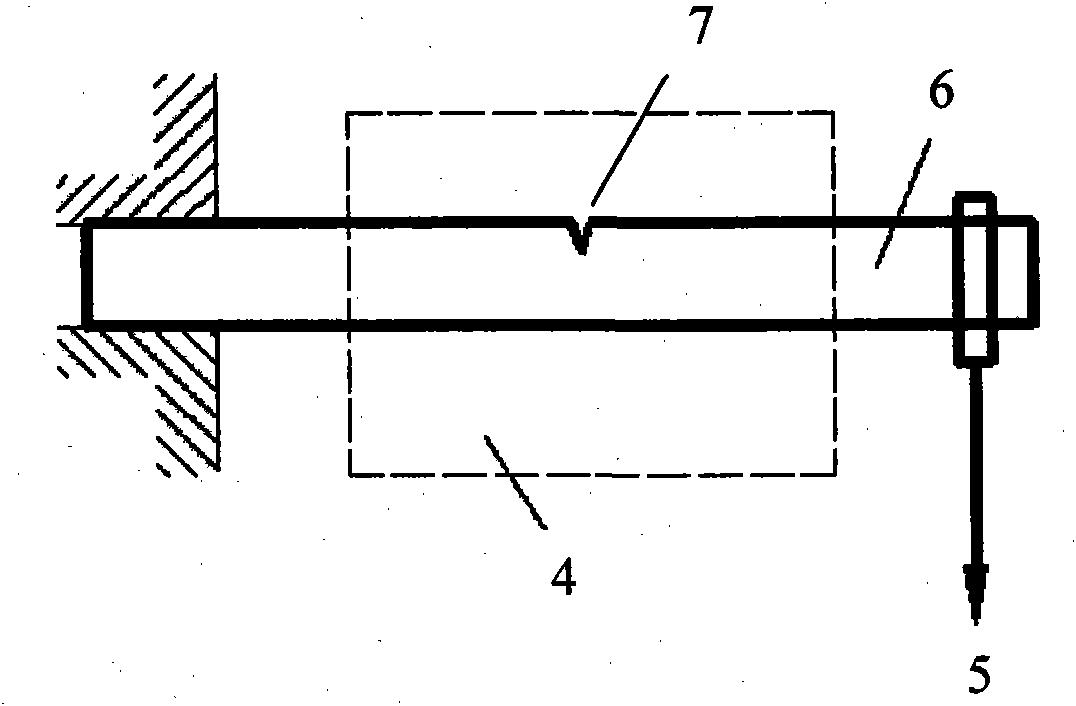

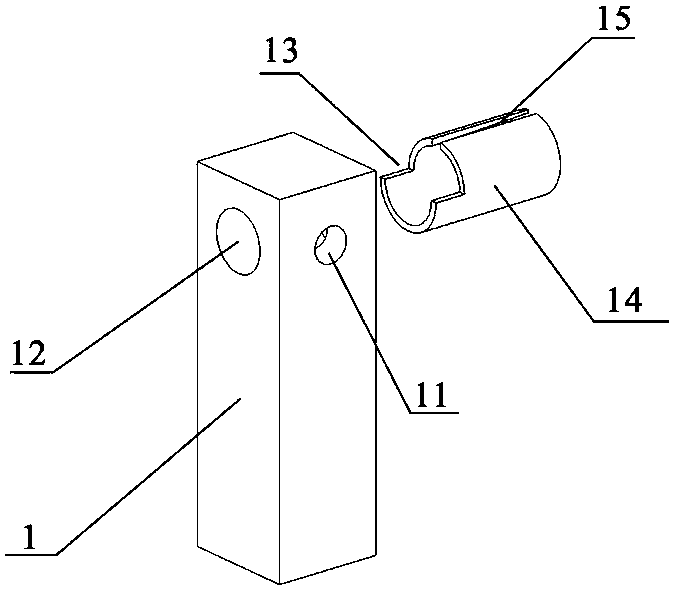

Novel stress corrosion test specimen and experiment method

InactiveCN101881709AEasy to processConvenient preloadWeather/light/corrosion resistancePreparing sample for investigationStatistical analysisStress corrosion cracking

The invention discloses a novel stress corrosion test specimen and an experiment method thereof. The test specimen is in a rectangular flat plate shape, and the plate-shaped test specimen is cut and formed in one step by a line cutting method. The method comprises the following steps: step 1. preparing the test specimen for getting ready to do the displacement deformation stretching stress corrosion experiment of the stress corrosion crack test; step 2. preparing 42 percent of MgCl2 solution and NaCl / NaOH mixed solution; step 3. building an experiment device, and placing the prepared test specimen into the experiment environment for carrying out stress corrosion experiment until the test specimen has corrosion cracks; and step 4. taking the test specimen for carrying out gold phase observation, finding the crack initialization position, and carrying out statistical analysis on the two-phase stainless steel stress corrosion mechanism. The processing of the test specimen of the invention is very convenient, and can be completed through one-step processing by line cutting in existence of plate-shaped test blocks.

Owner:EAST CHINA UNIV OF SCI & TECH

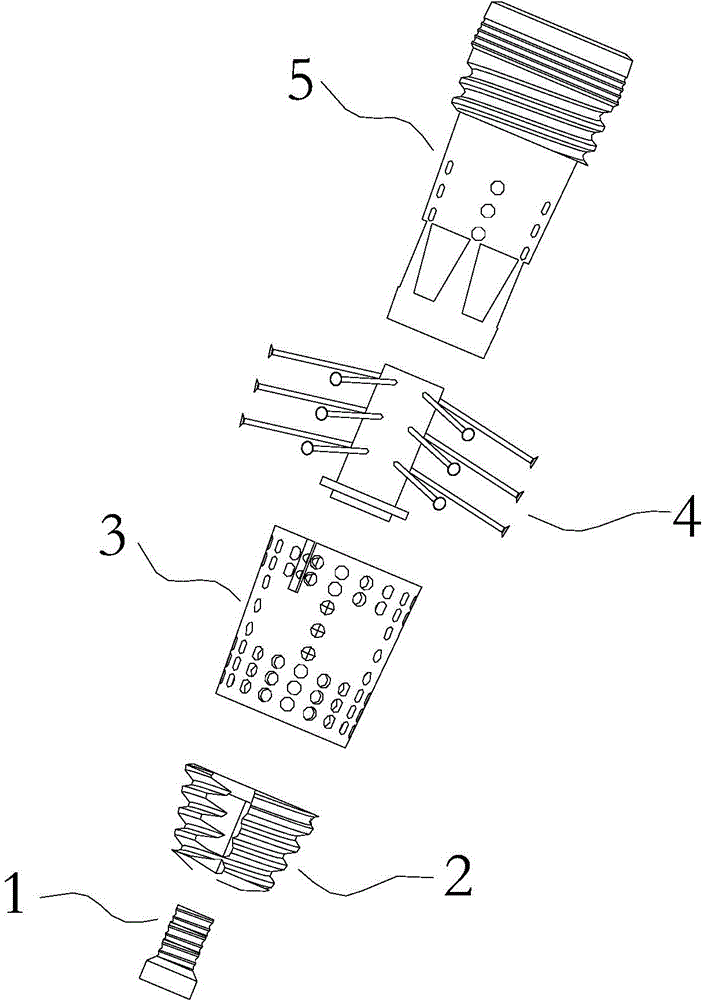

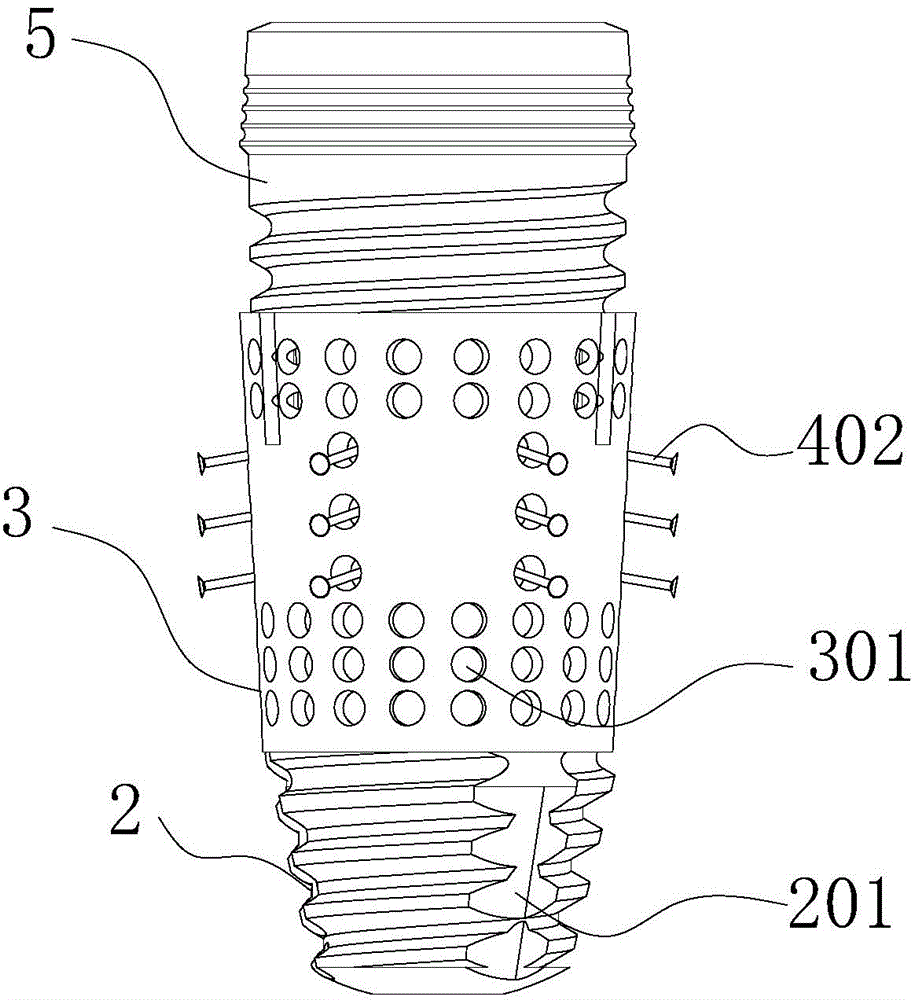

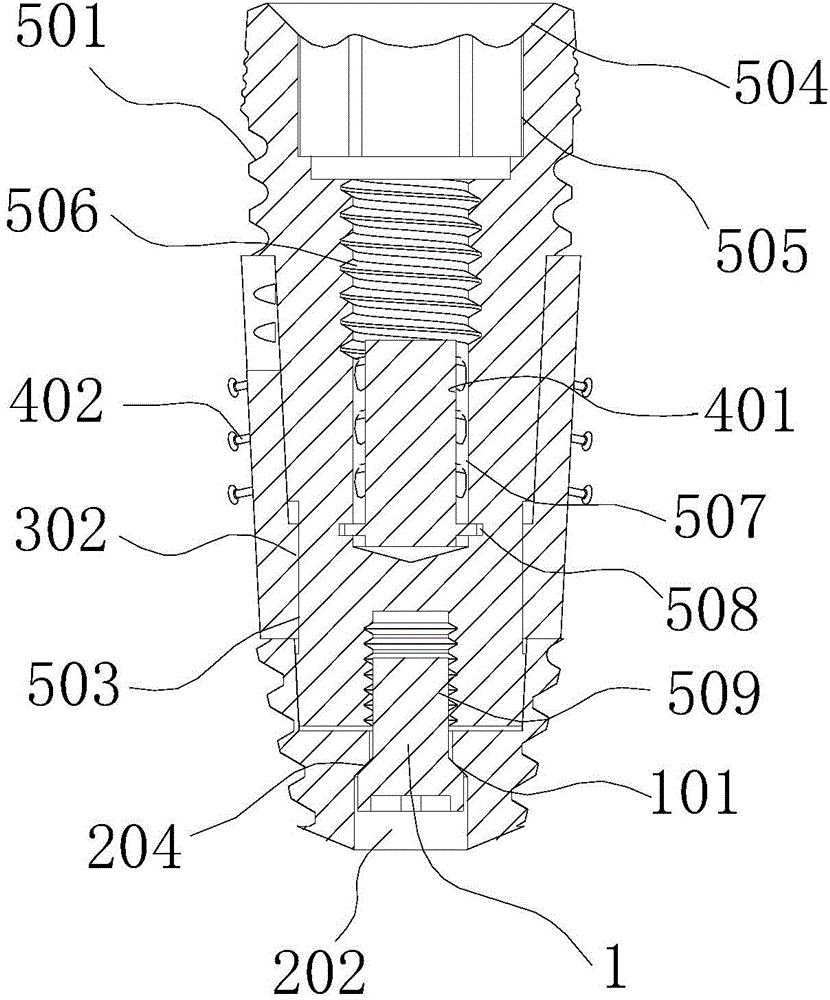

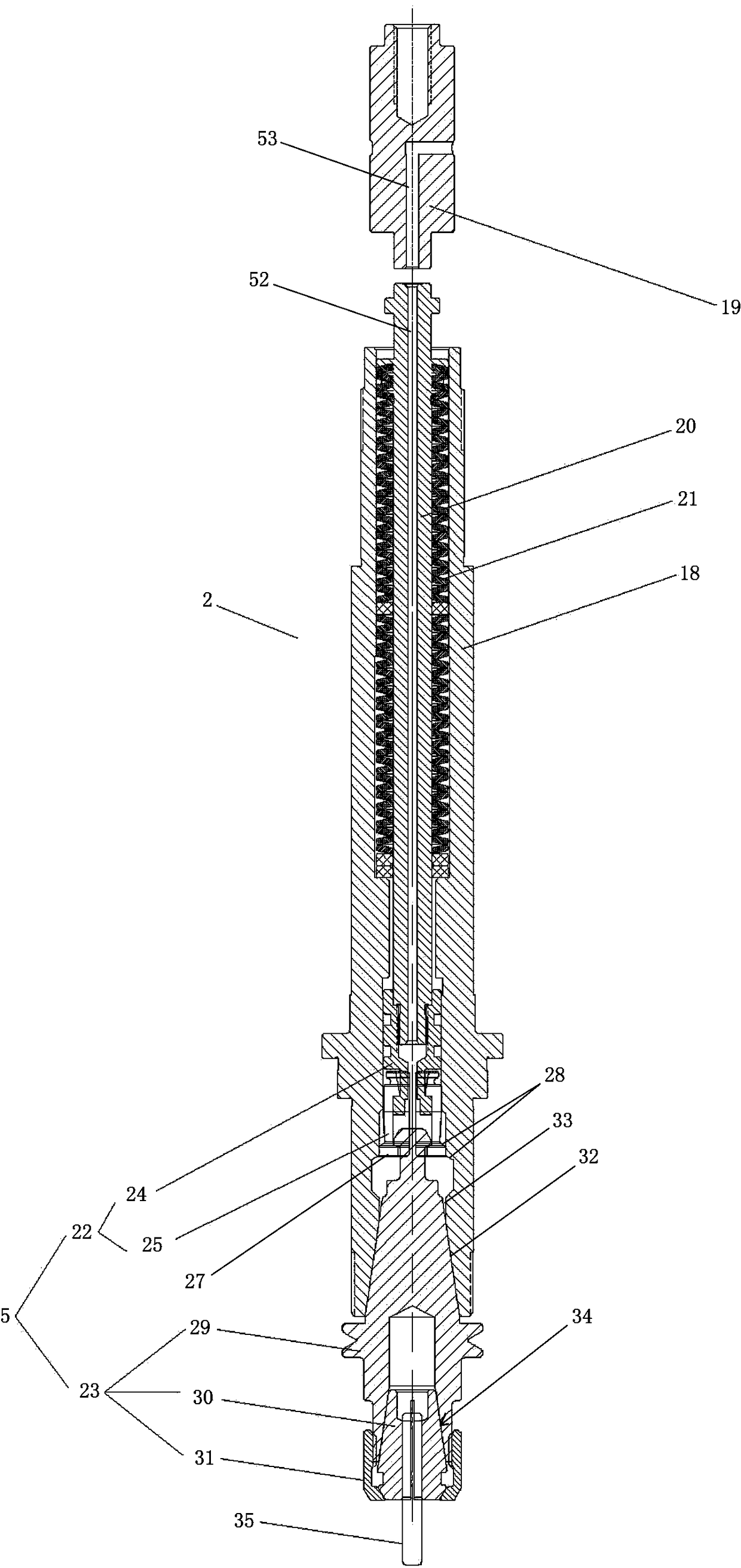

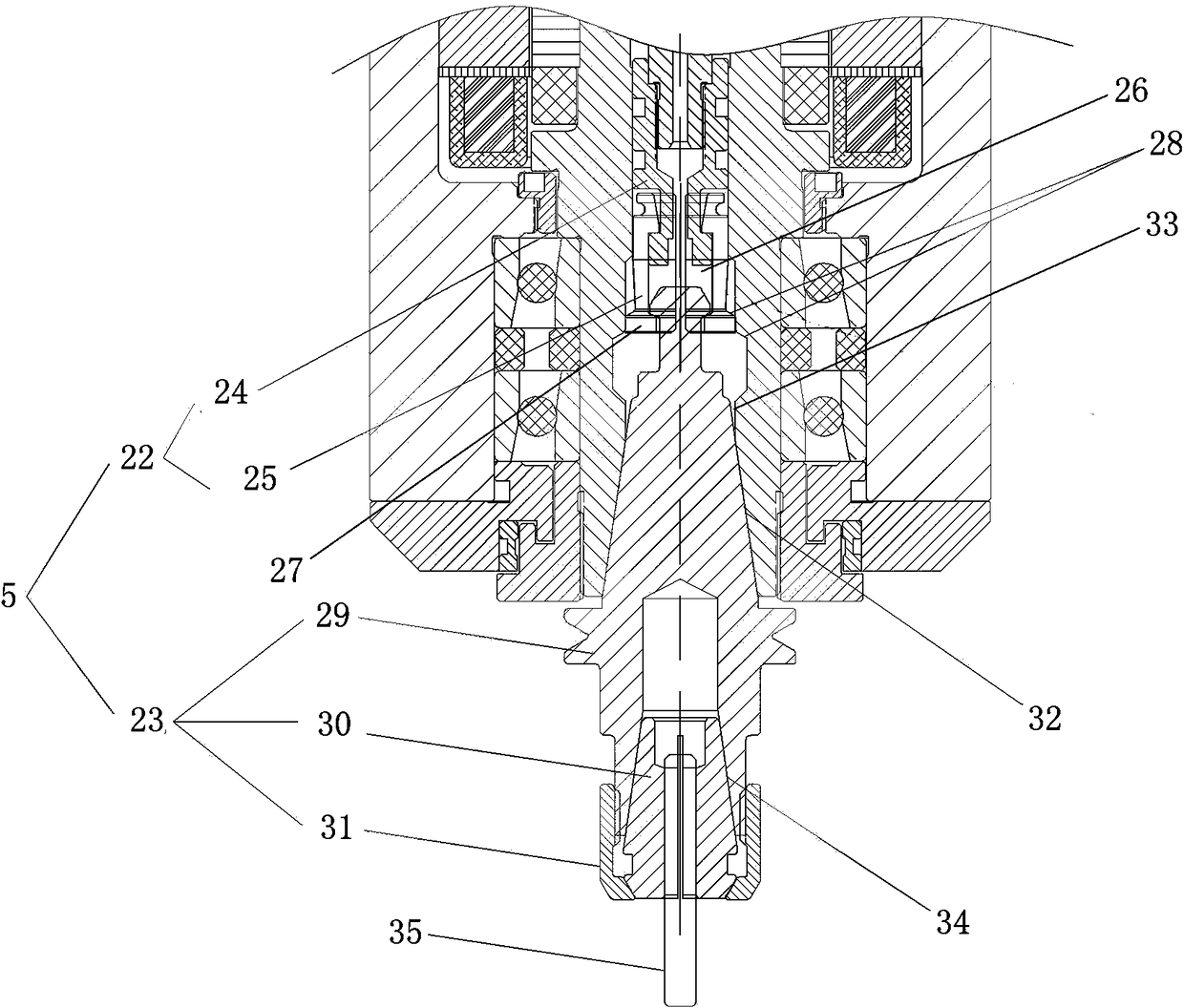

Dental implant of composite structure and manufacturing method of same

The invention provides a dental implant of a composite structure and a manufacturing method of the same. By adopting effective structural design, different materials and different manufacturing modes, the dental implant is divided into a fastening screw, a screw thread implanting section, a multi-hole implanting section, a tentacle supporting structure and an implant main body which are integrated to form a composite structure, and the dental implant has good strength, good bone combining capability and good initial stability. The thread implanting section, the fastening screw and the implant main body form a main frame of a composite implant, thus strength of the whole implant is guaranteed; meanwhile, the composite structure can be used for overcoming the defects caused by a single manufacturing mode, and the respective advantages of structural design, the manufacturing modes and materials are fully realized; a tentacle supporting structure made from a degradable material has the effects of well inducing osteogenesis and enhancing initial stability of the implant whole and can be applied to immediate implantation; elasticity modulus of the implant overall material is optimized by virtue of a porous structure of the outer layer, combination of bone growth and guiding in initial stage can be facilitated, and initial stability with osseointegration is also improved by the combined expanded-type structure.

Owner:广东健齿生物科技有限公司 +2

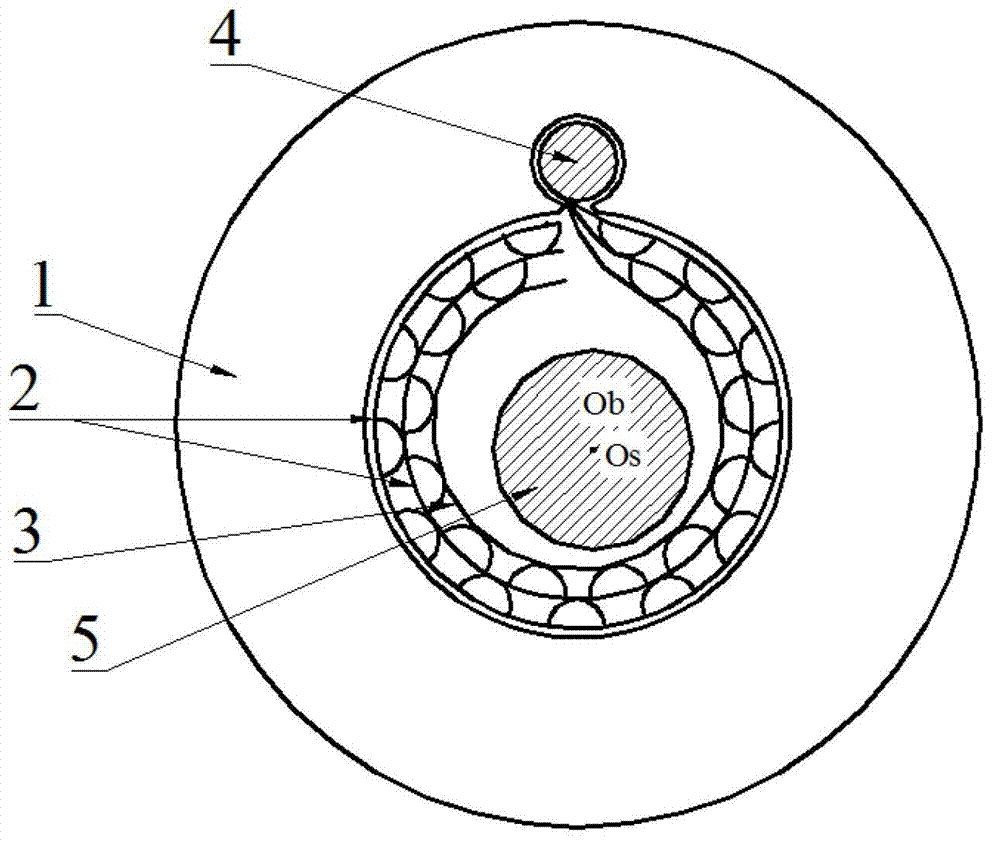

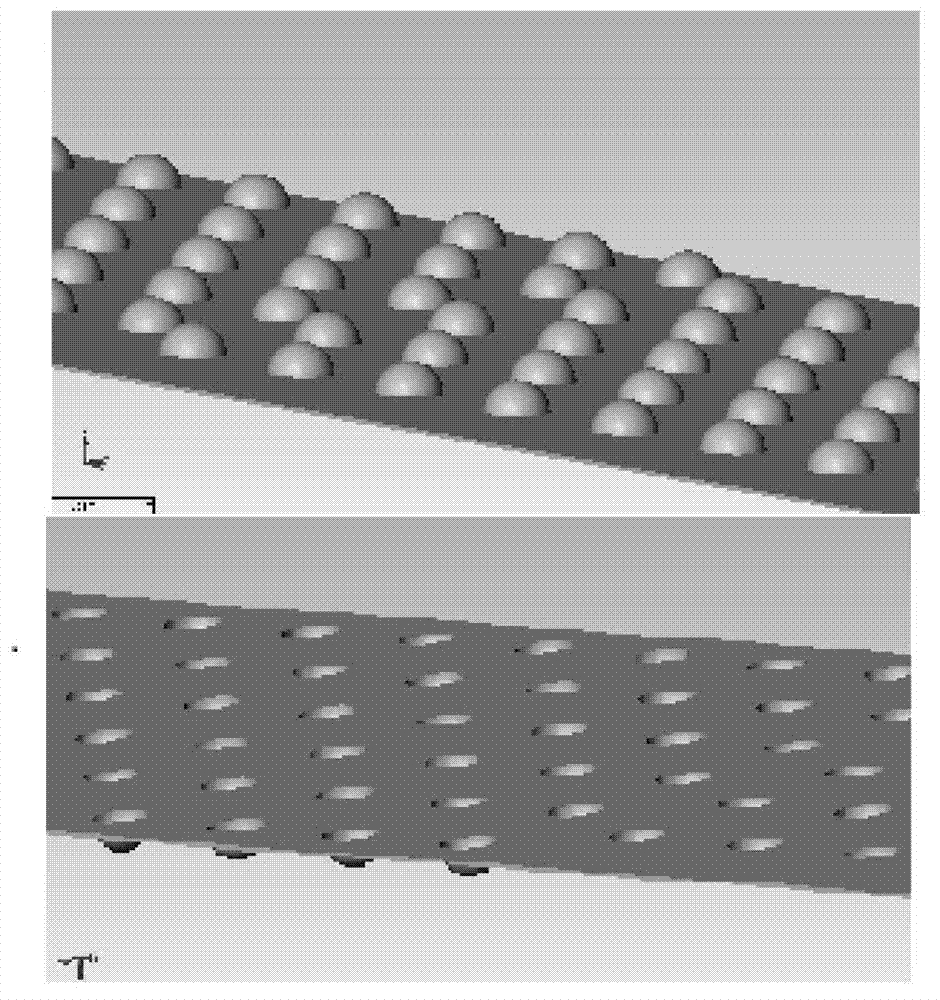

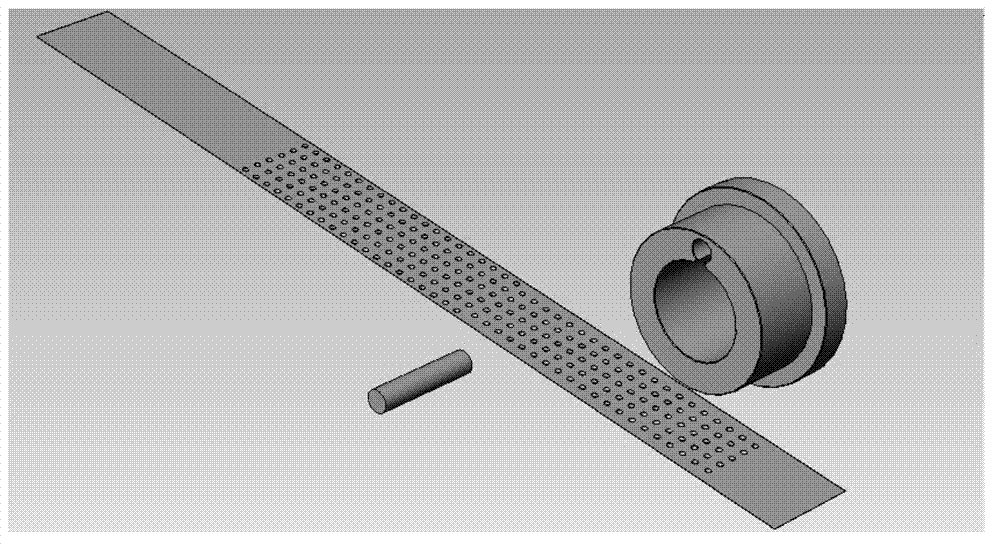

Multi-layer bubbled foil radial dynamic pressure gas bearing

ActiveCN102927124AImprove frictional damageConvenient preloadBearing componentsSliding contact bearingsProduct gasHigh load

The invention discloses a multi-layer bubbled foil radial dynamic pressure gas bearing, which comprises a bearing block and a shaft which is arranged in the bearing block, wherein the inner side of the bearing block is provided with an elastic supporting component; the elastic supporting component comprises multi-layer elastic bubbled elements arranged on the inner side of the bearing block and a top flat foil arranged between the elastic bubbled elements and the shaft; the top flat foil is attached to the elastic bubbled elements; a shell-shaped bulge with a continuous surface fillet is arranged on each layer of elastic bubbled elements; and one end of the elastic supporting component is fixed on the bearing block through a positioning element, and the other end of the elastic supporting component is free. The multi-layer bubbled foil radial dynamic pressure gas bearing is novel in structure, can generate timely and effective deformation, has adjustable local and integral rigidity and damping height, and has high load adaptability and excellent stability.

Owner:XI AN JIAOTONG UNIV

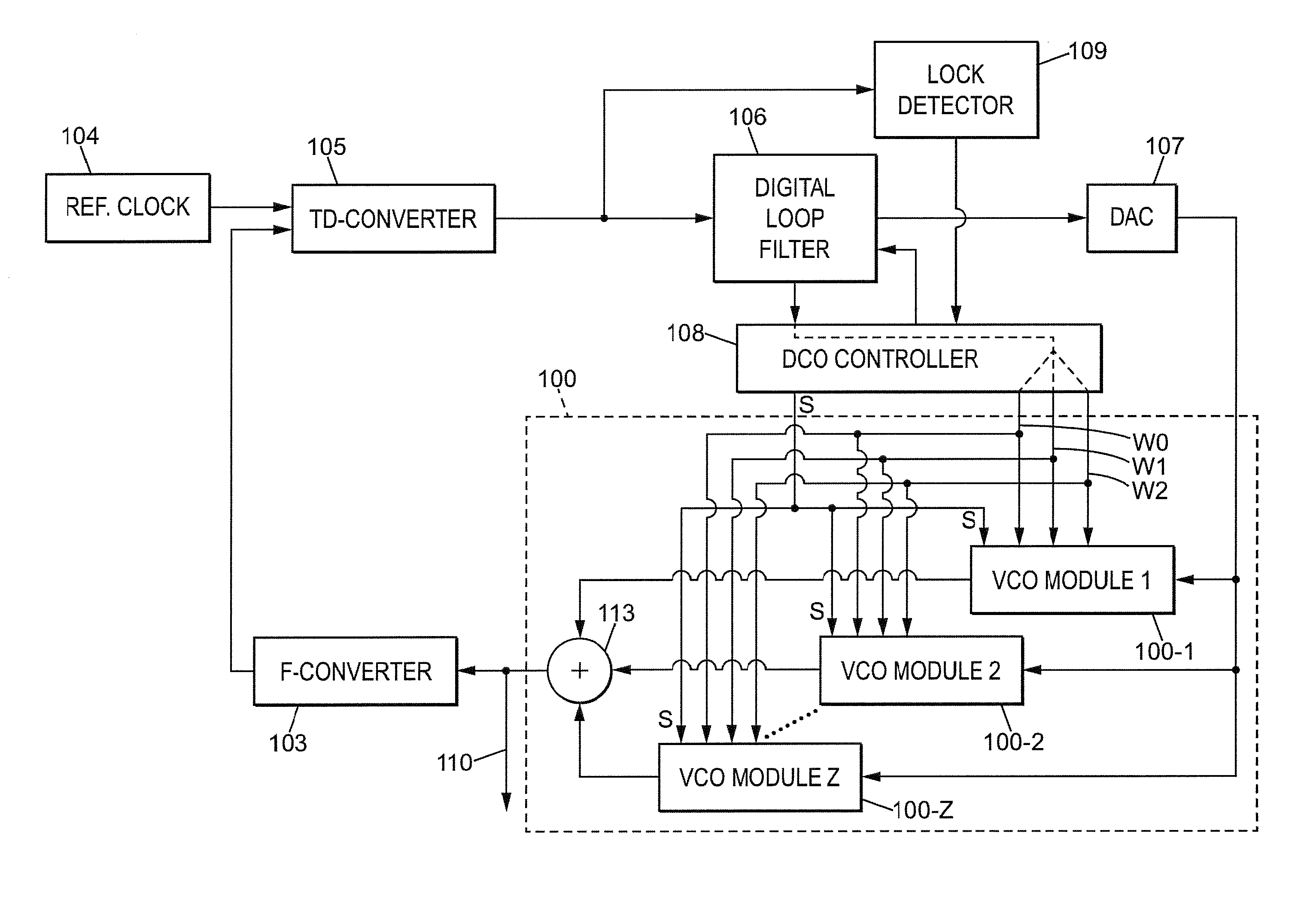

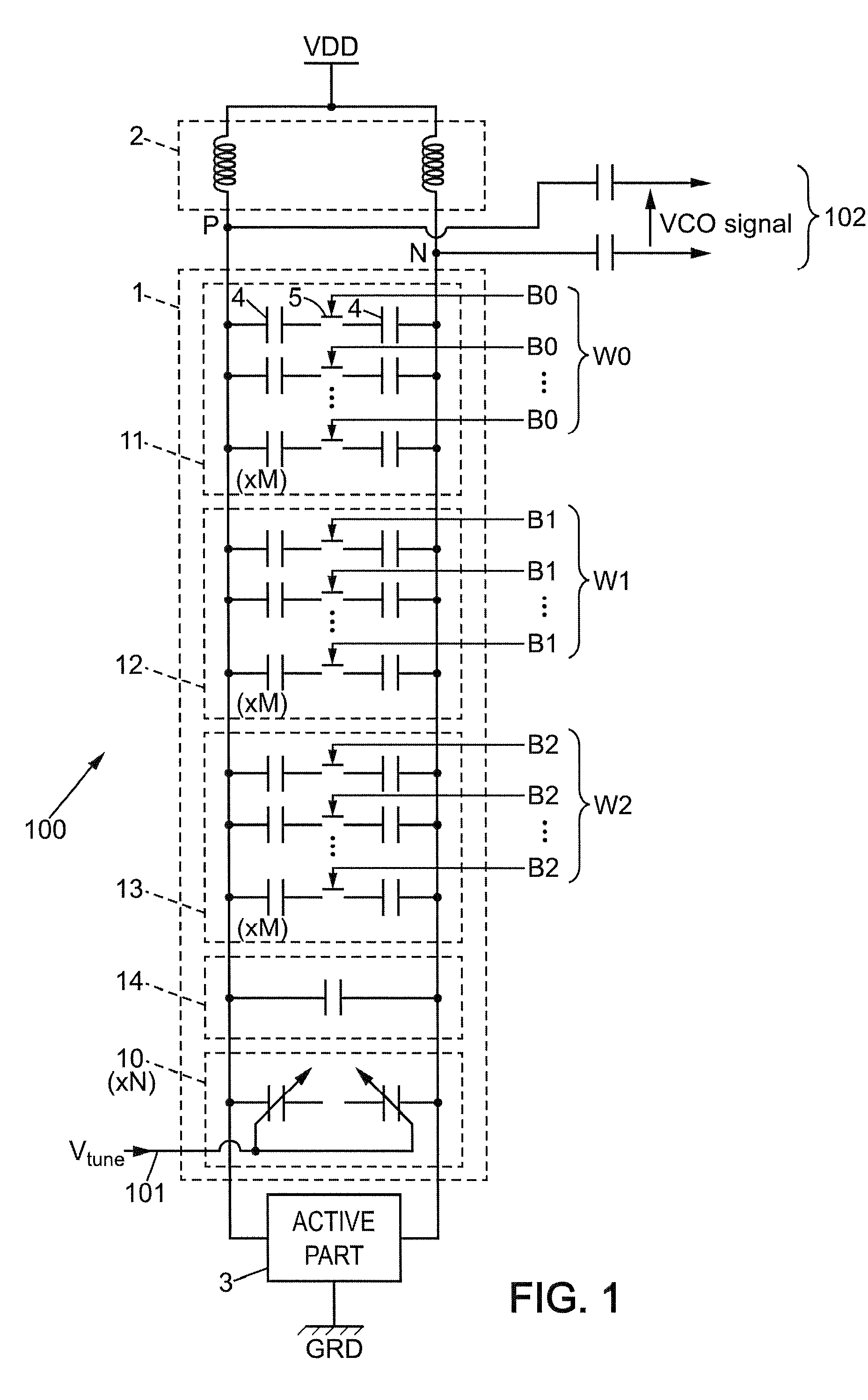

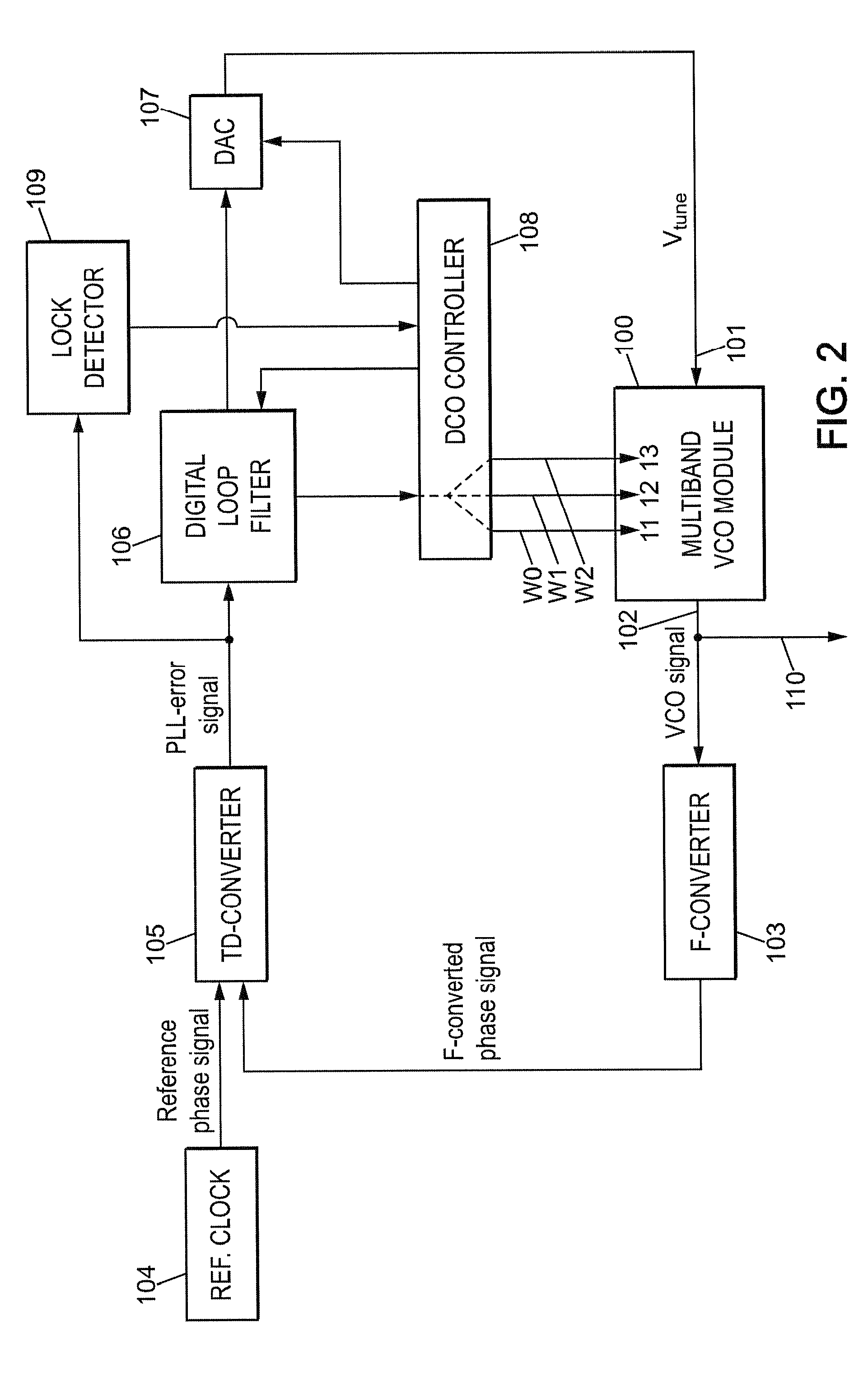

Digital phase-locked loop device with automatic frequency range selection

ActiveUS20140340161A1Fast convergenceShorten the construction periodPulse automatic controlLoop filterDigital filter

A digital phase-locked loop (PLL) device includes a digital loop filter which is provided with both a VCO-loop output and a DCO-loop output. The VCO-loop output is connected to an analog input of a multiband voltage-controlled oscillator (VCO) module for allowing usual operation of the PLL with a direct voltage acting as feedback parameter. The DCO-loop output is connected to a digital control input of the multiband VCO module for allowing automatic frequency range selection. A code value which is produced by the digital loop filter acts as feedback parameter during the frequency range selection. Rapid and precise range selection can thus be performed.

Owner:ASAHI KASEI ELECTRONICS CO LTD

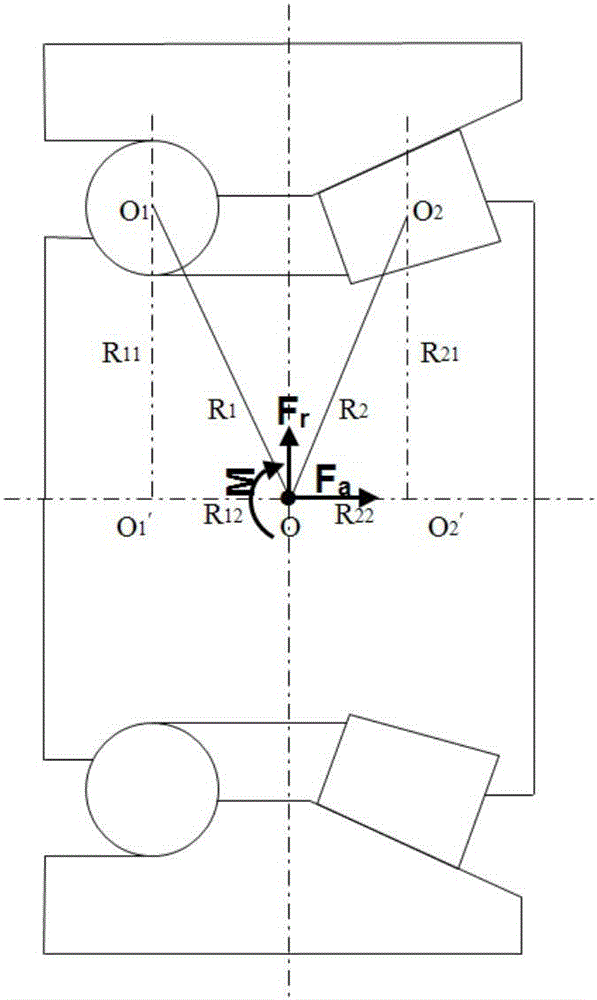

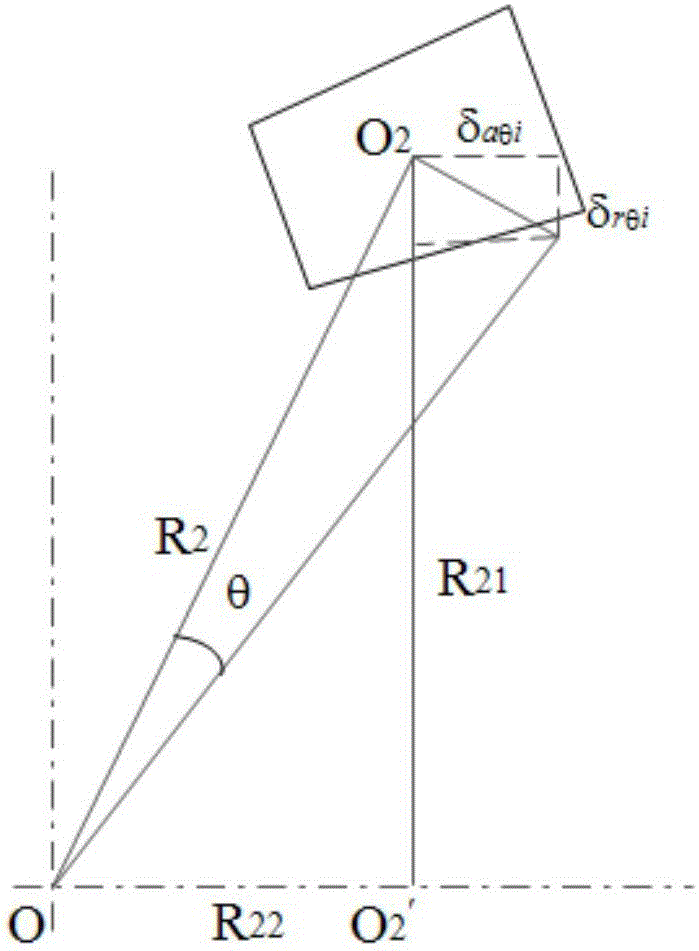

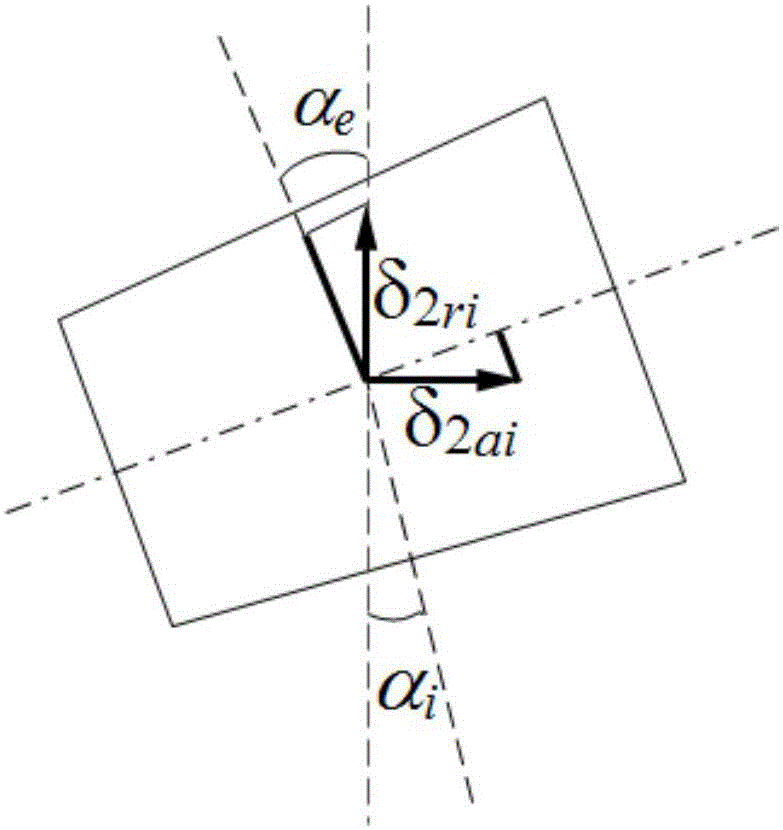

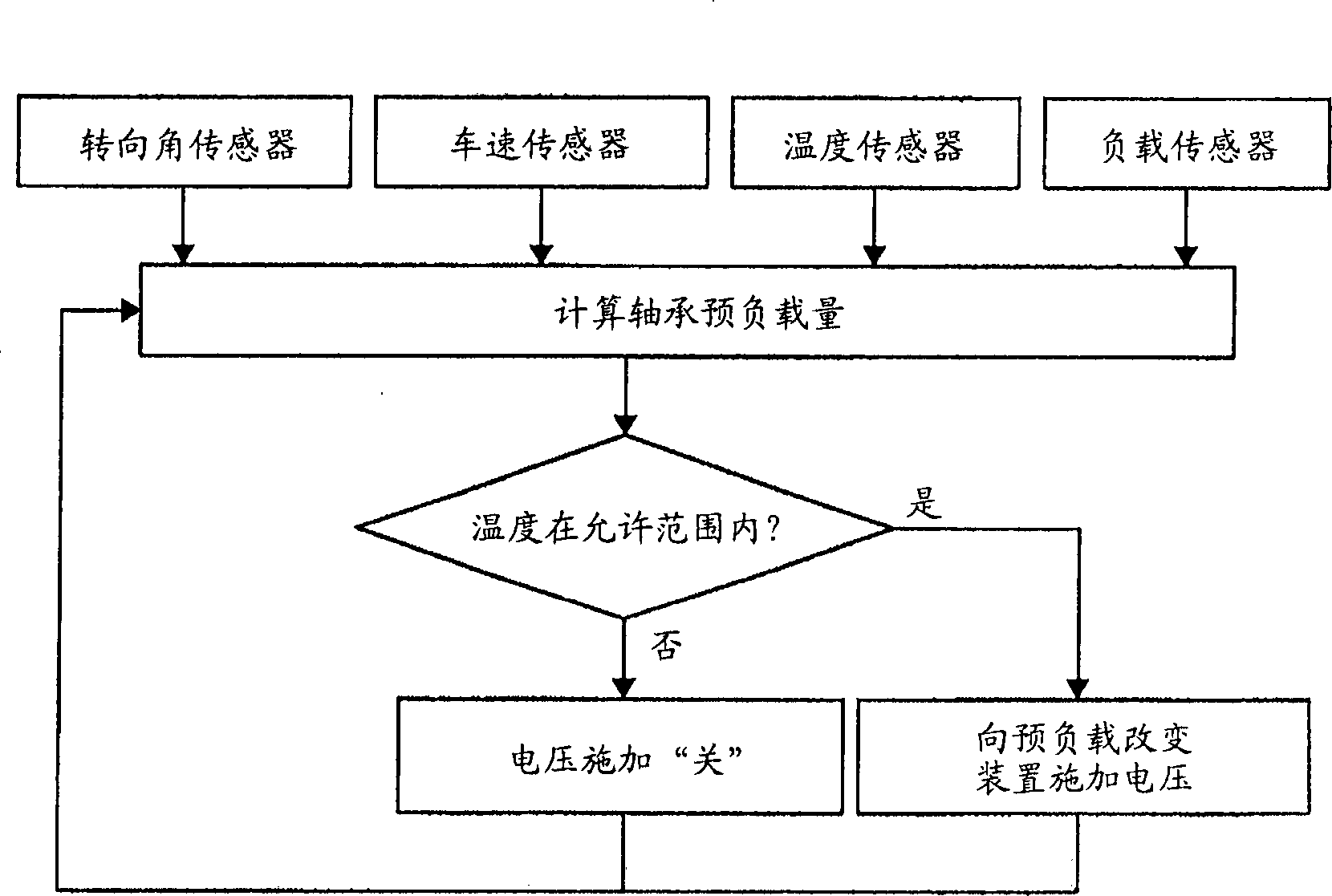

Method and device for determining optimal pretension quantity of sphere and cone mixed double-line hub bearing

ActiveCN106326570AExtended service lifeConvenient preloadGeometric CADBearing componentsLoad spectrumEngineering

The invention relates to a method and a device for determining the optimal pretension quantity of a sphere and cone mixed double-line hub bearing, and belongs to the technical field of bearing design. The method comprises the steps: formulating a load spectrum of a sphere and cone mixed double-line hub bearing unit; calculating radial displacement delta r, axial displacement delta a and angle displacement theta according to a mechanical model of the sphere and cone mixed double-line hub bearing; obtaining corresponding single-line ferrule life and comprehensive life of the hub bearing unit by taking the load spectrum as a known condition and pretension quantity as analysis variable; and establishing a relationship between the pretension quantity and the life of the hub bearing unit and taking the pretension quantity, corresponding to the longest life of the single-line ferrule of the hub bearing unit and / or the whole hub bearing unit, as the optimal pretension quantity. By the method for determining the optimal pretension quantity of the sphere and cone mixed double-line hub bearing based on the load spectrum, which is provided by the invention, the optimal pretension quantity of the sphere and cone mixed double-line hub bearing unit during assembling can be obtained accurately.

Owner:HENAN UNIV OF SCI & TECH

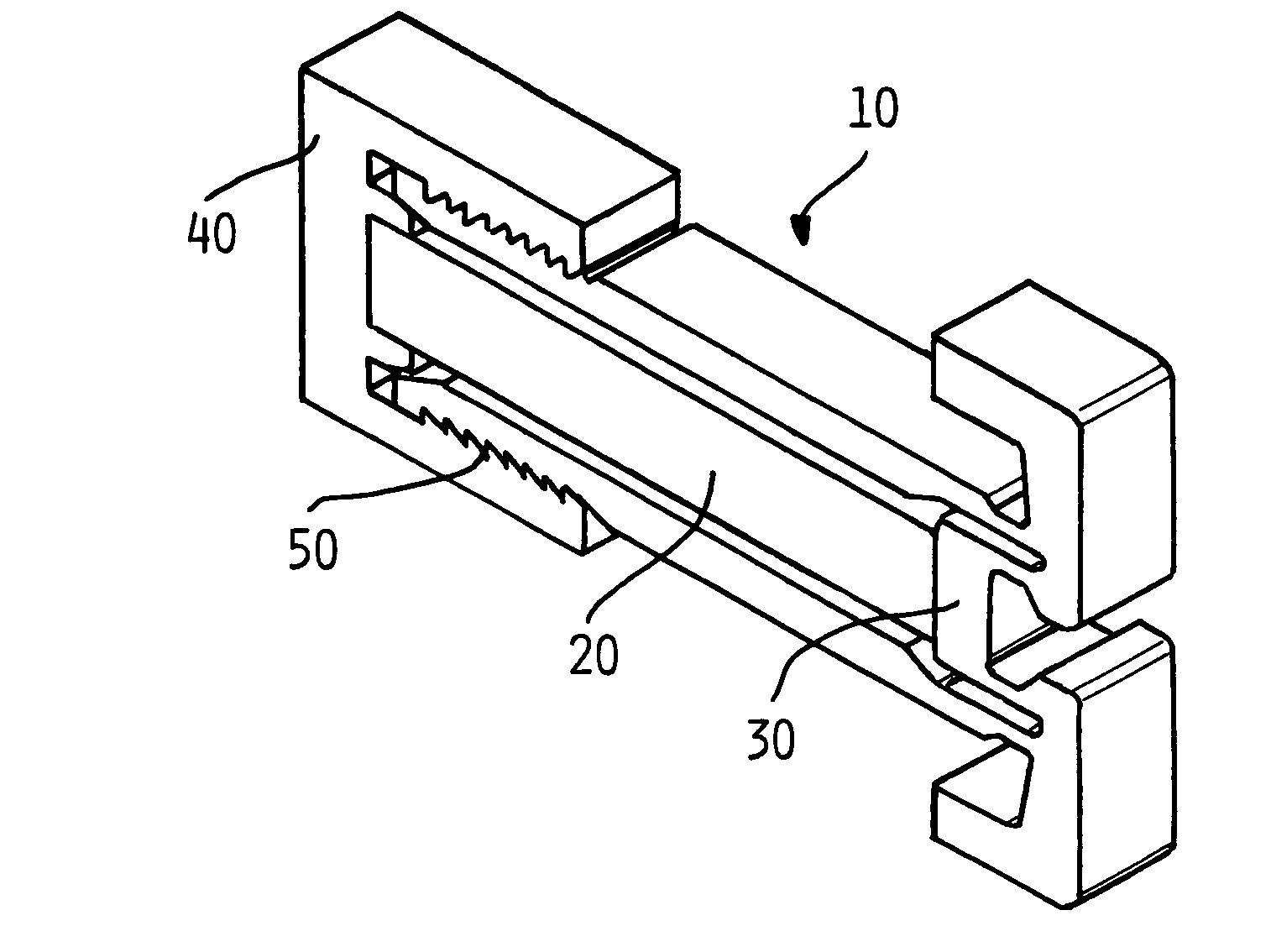

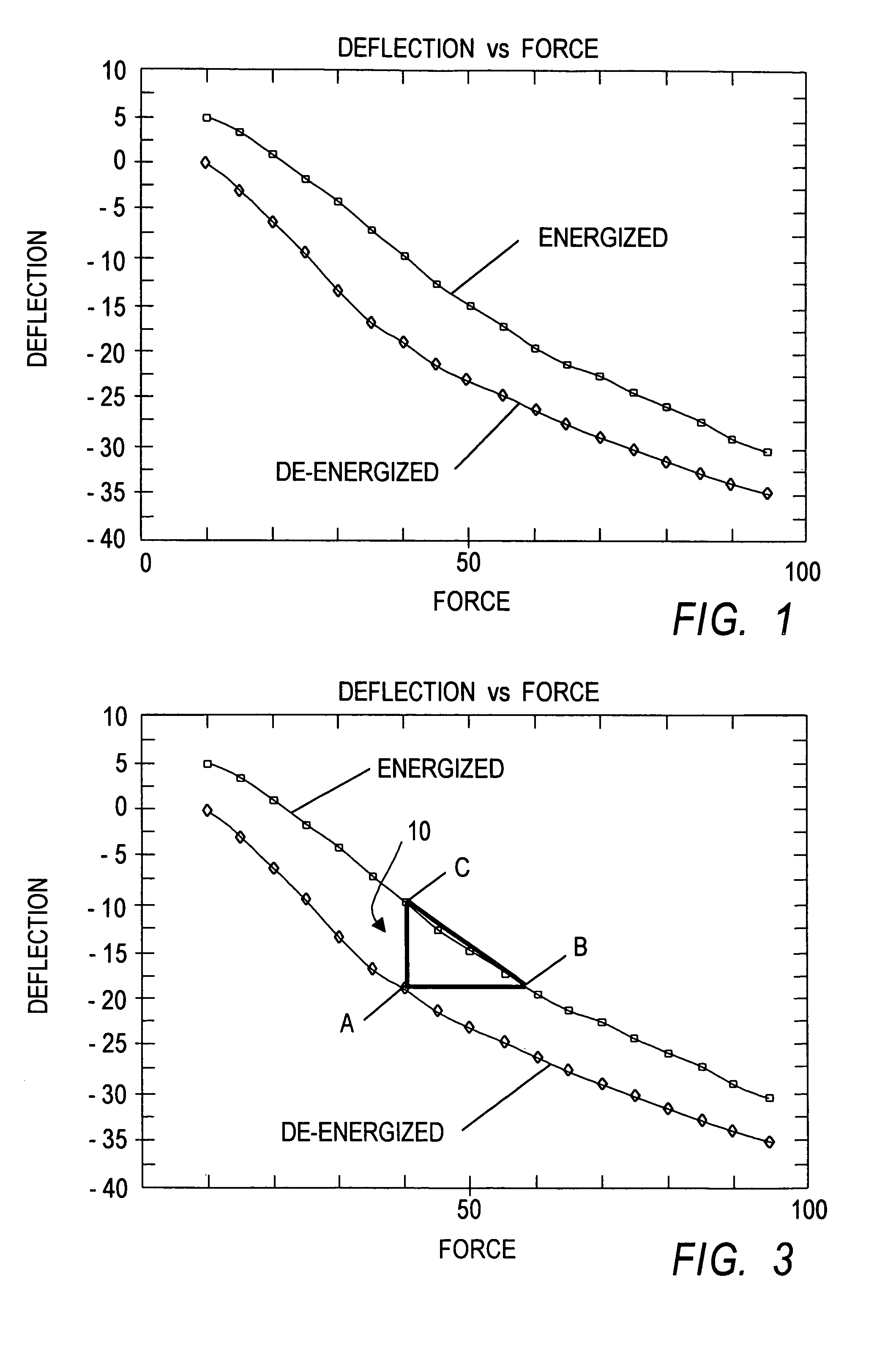

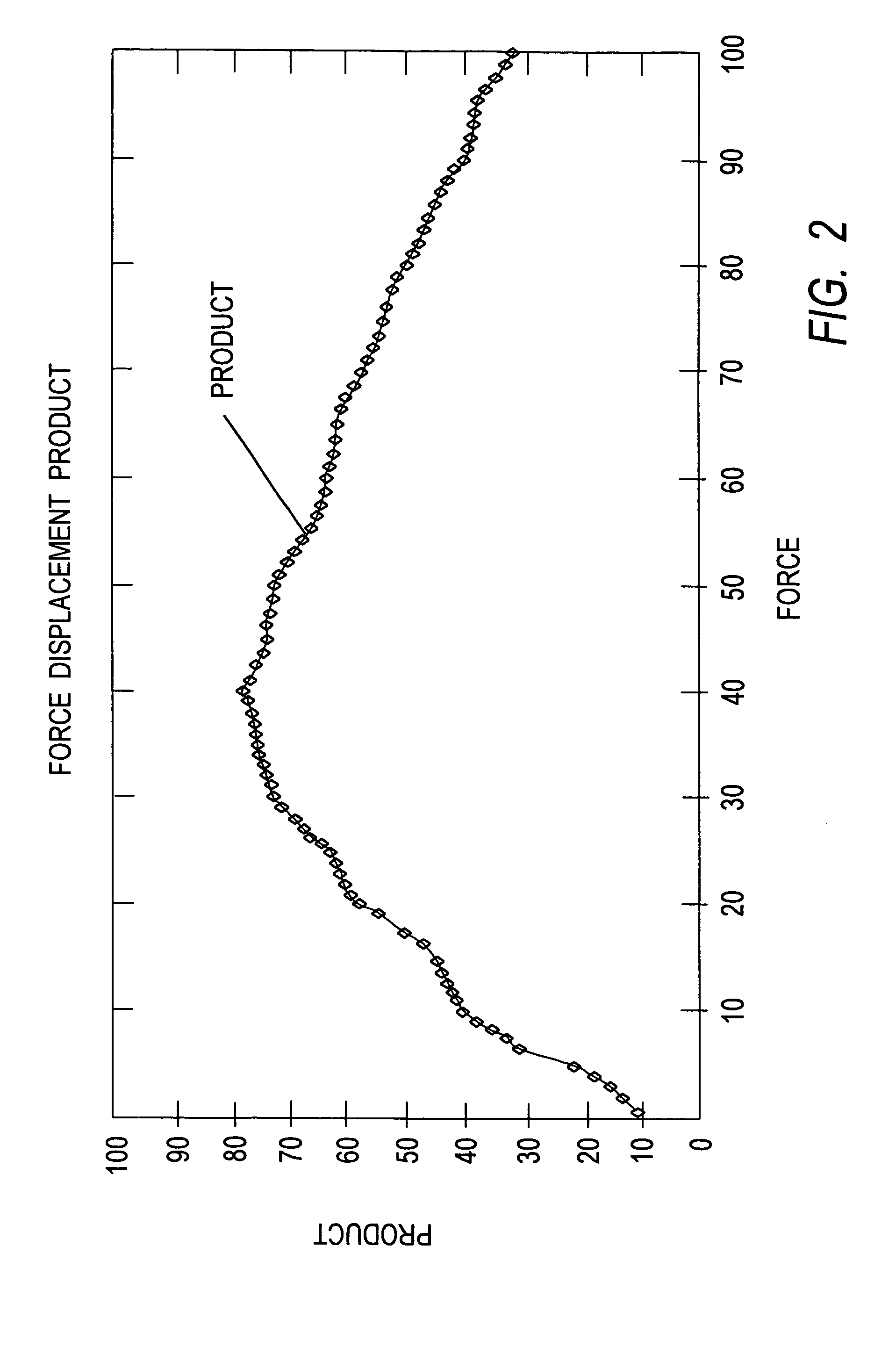

Apparatus and process for optimizing work from a smart material actuator product

InactiveUS7368856B2Improve Smart EffectsShort lifePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionElectricityHysteresis

An apparatus and process for pre-loading an electrically stimulated smart material actuator product to obtain maximum work from the actuator. When a smart material actuator is optimally pre-loaded certain desirable characteristics become apparent, such as work, operational frequency, hysteresis, repeatability, and overall accuracy. When used in conjunction with a mechanically leveraged actuator structure the smart material actuator can be used to its greatest potential. Since the mechanically leveraged actuator can be based on the maximum work provided by the smart material actuator, certain attributes such as the force, and displacement of total system can be adjusted without loss to system efficiency. Pre-loading methods and a determination of the optimal pre-load force are disclosed. Each smart material actuator type has a unique work curve. In the design of an actuator assembly, the process of optimizing uses the unique work curve to optimize the design for the requirements of the particular application. The unique work curve is used by finding the place where the smart material actuator is capable of providing the most work in order to set the optimum pre-load point accordingly. Different mechanical pre-load techniques are provided.

Owner:PARKER INTANGIBLES LLC

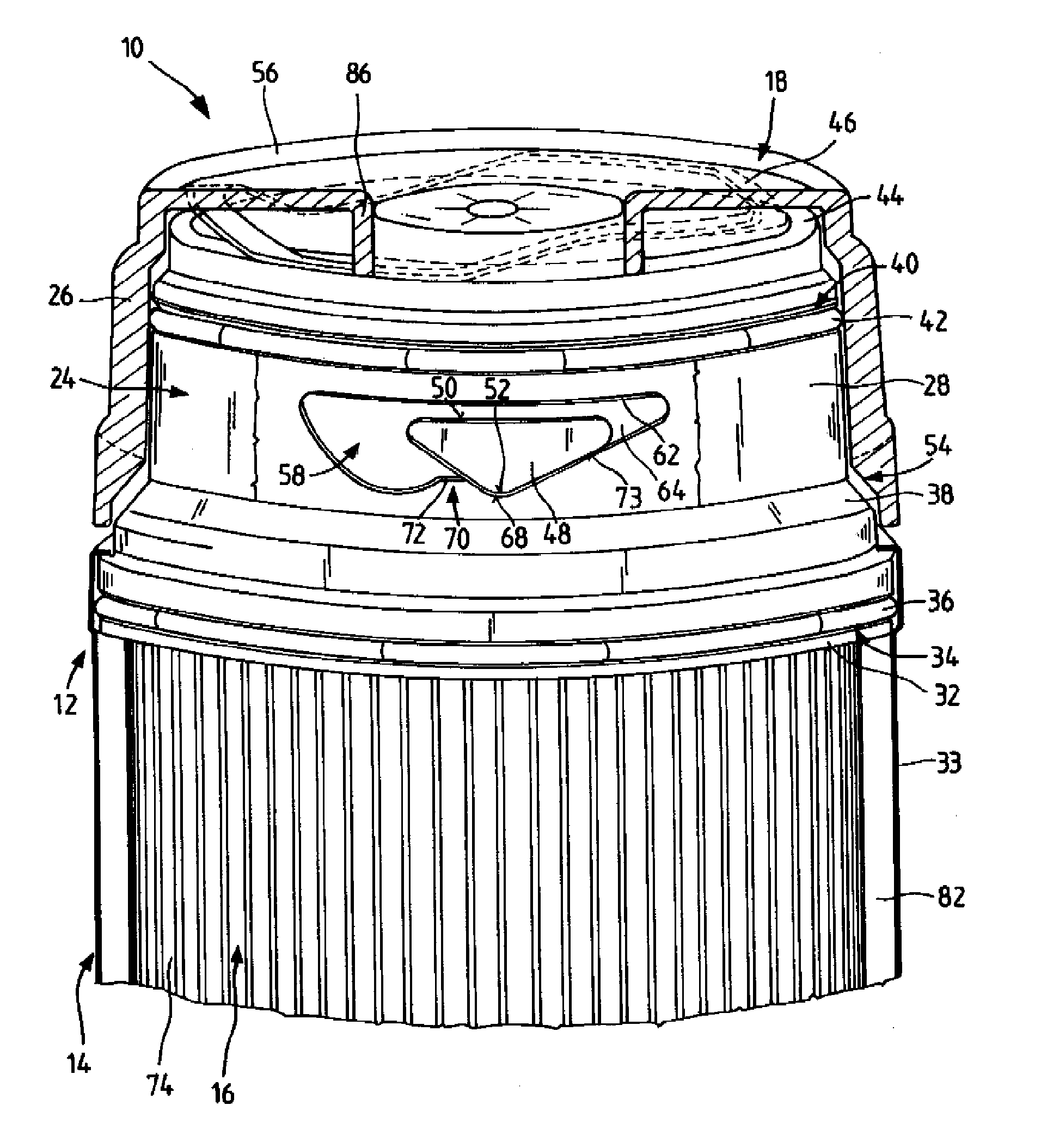

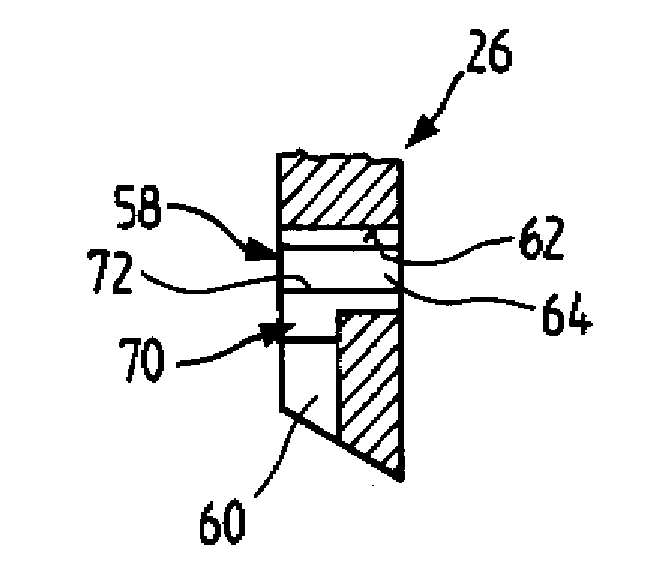

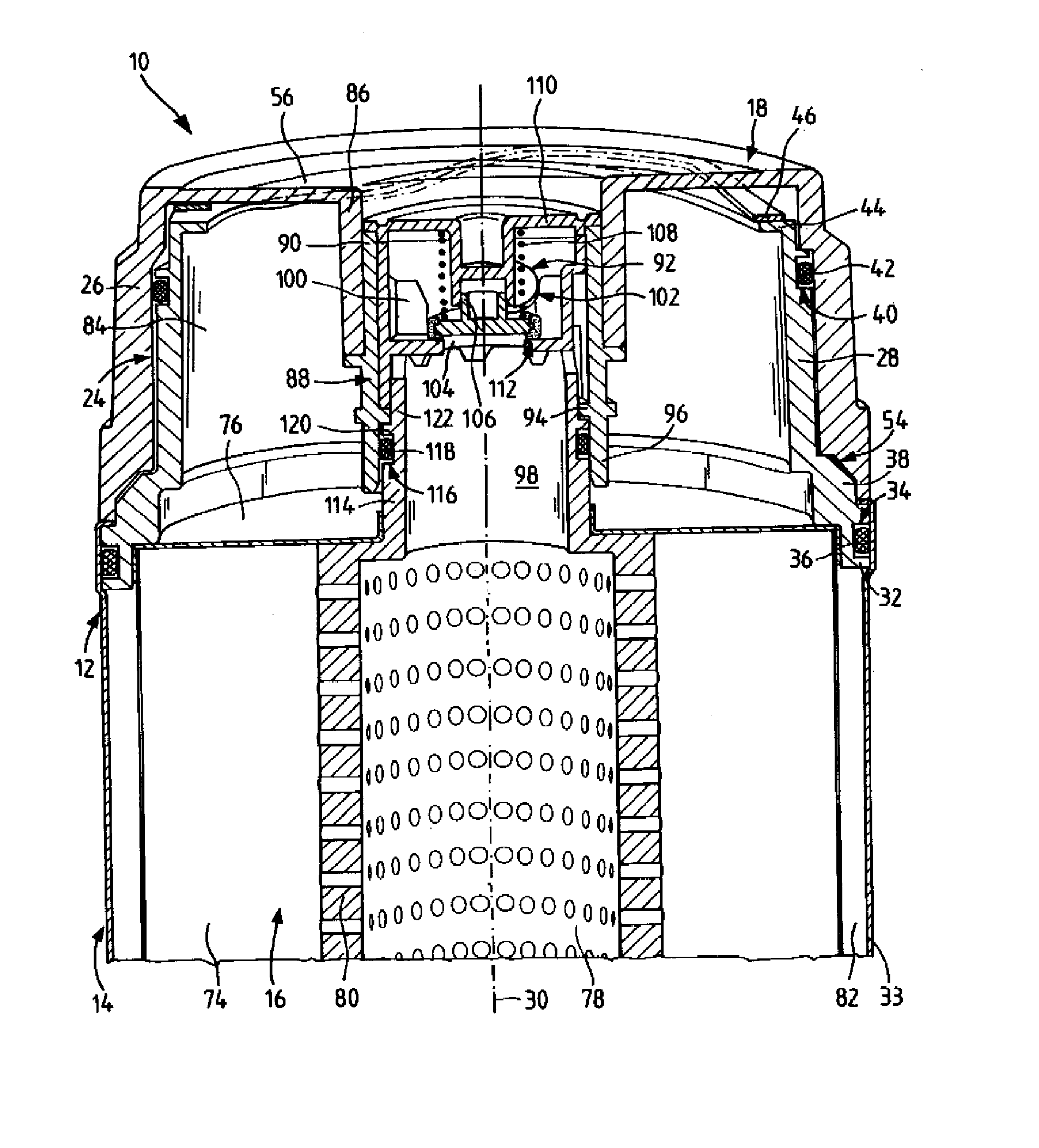

Filter for filtering fluids, filter bowl and filter head

InactiveCN103201007AConvenient preloadEasy to makeDispersed particle filtrationMembrane filtersDetentInternal combustion engine

The invention relates to a filter (10) for filtering in particular liquid fluids, in particular fuel or oil, in particular of an internal combustion engine, comprising a filter bowl (14), in which a filter element (16) is arranged, and a filter head (18), which comprises an inlet and / or an outlet for the fluid. The filter head (18) and the filter bowl (14) are connected to each other by means of a detachable bayonet-like rotary / plug connection (24). The rotary / plug connection (24) comprises at least two cooperating catch components (26, 28), of which one is connected to the filter bowl (14) and the other to the filter head (18). One of the catch components (28) comprises at least one detent (48). One of the catch components (26) comprises at least one recess (58) corresponding to the detent (48) and has an insertion / removal region (60) for joining and separating the detent (48) and recess (58) without resistance and also has a closing region (64) with which the detent (48) engages in a bayonet-like manner. In order to implement a prestress of the detent (48) in the recess (58), a prestressing element (46) that acts between the filter head (18) and the filter bowl (14) is provided. Between the closing region (64) and the insertion / removal region (60), the recess (58) comprises a catch shoulder (70) for the detent (48), wherein said shoulder has a shoulder tip (72) on the side thereof which corresponds to the detent (48). On the side corresponding to the catch shoulder (70), the detent (48) comprises a catch tip (52).

Owner:MANN HUMMEL GMBH

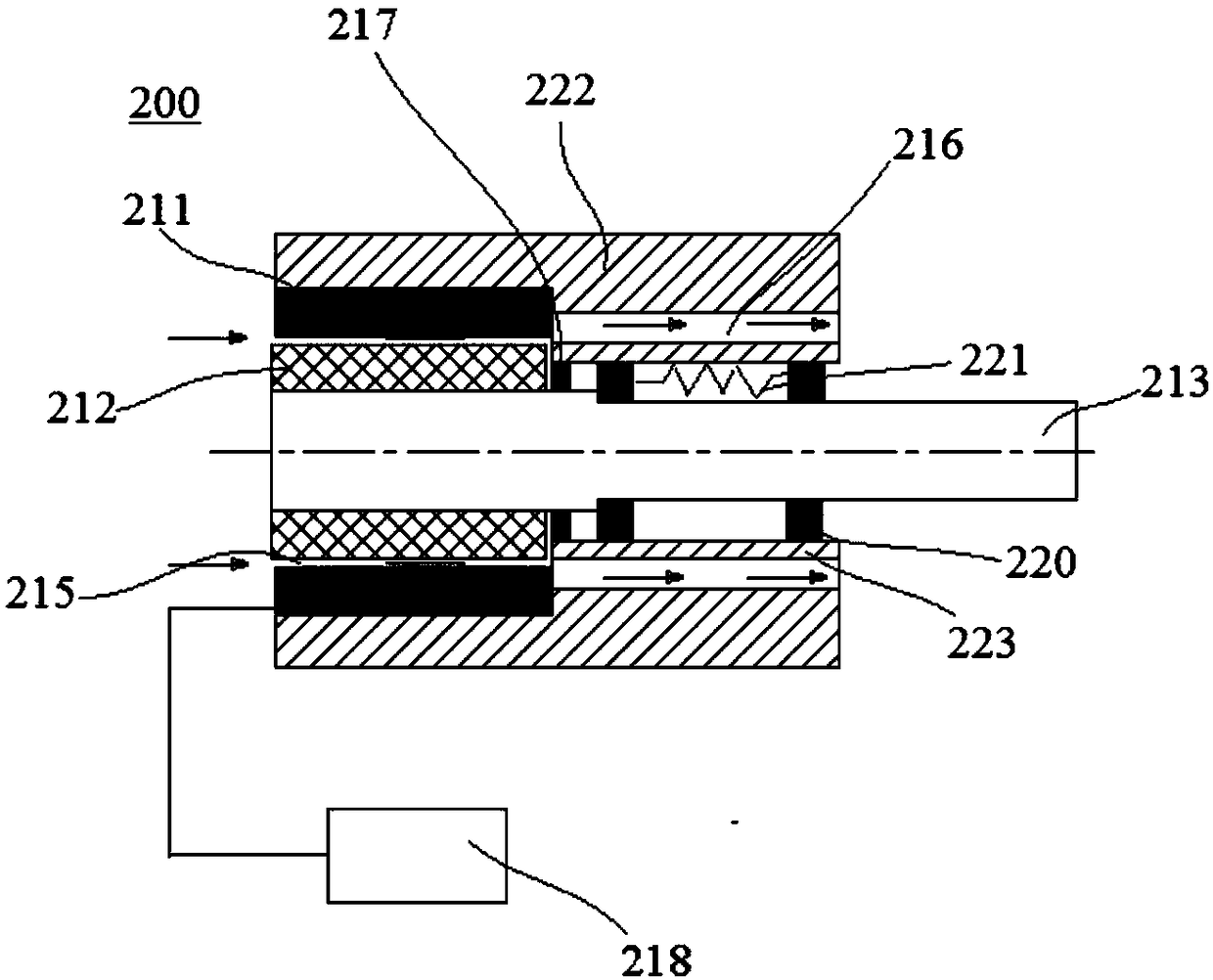

Linear ultrasonic motor stator and electric excitation method thereof

ActiveCN111464070AShorten the lengthReduced Thickness DimensionsPiezoelectric/electrostriction/magnetostriction machinesElectric machineEngineering

The invention discloses a linear ultrasonic motor stator and an electric excitation method thereof. The stator comprises a stator elastic body and piezoelectric ceramic pieces, wherein an open slot isformed in the stator elastic body along the length direction, and the stator elastic body is divided into a driving body and two symmetrical driving legs by the open slot; the piezoelectric ceramic pieces in axial symmetry are attached to the two opposite outer side surfaces of the two driving legs, and driving feet extending outwards are arranged at the upper ends of the two driving legs respectively; and the piezoelectric ceramic pieces are coated with an electrode layer. The electric excitation method comprises the steps of 1) bonding the piezoelectric ceramic pieces; 2) preparing electrifying electrodes; and 3) simultaneously exciting local second-order bending vibration of the driving legs and overall first-order longitudinal vibration of the stator twice by using two paths of same-frequency sinusoidal voltage signals, and finally realizing forward and reverse movement of a driving rotor. According to the invention, the local second-order bending vibration of the two driving legsof the stator and overall first-order longitudinal vibration of the stator are combined and degenerate, and elliptical vibration of the driving feet is achieved.

Owner:HARBIN INST OF TECH

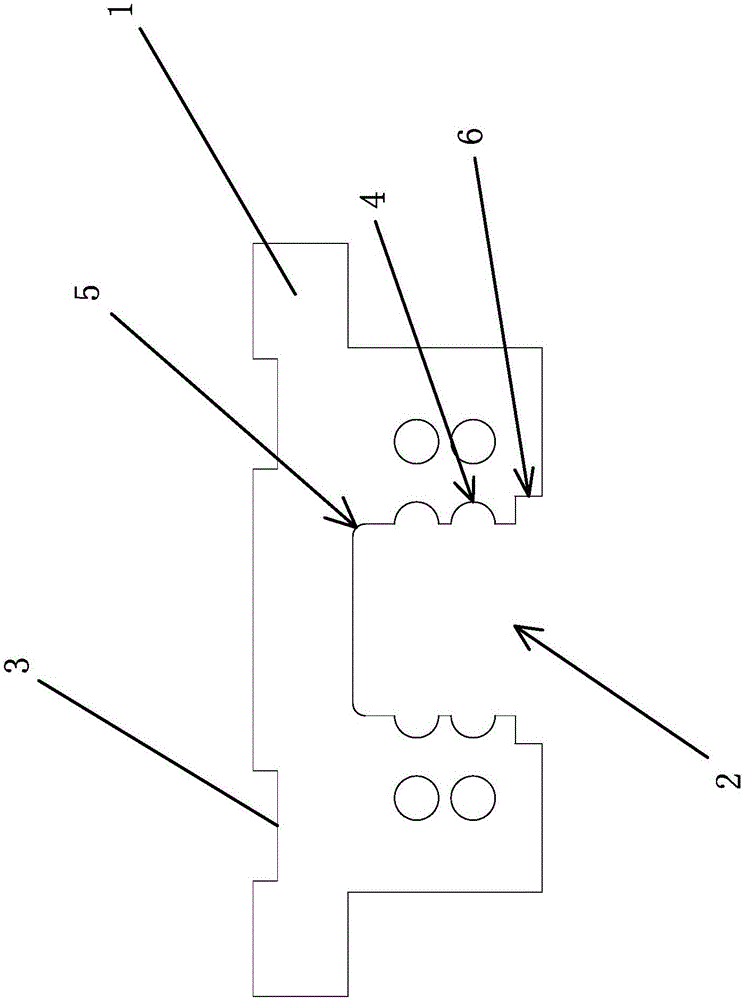

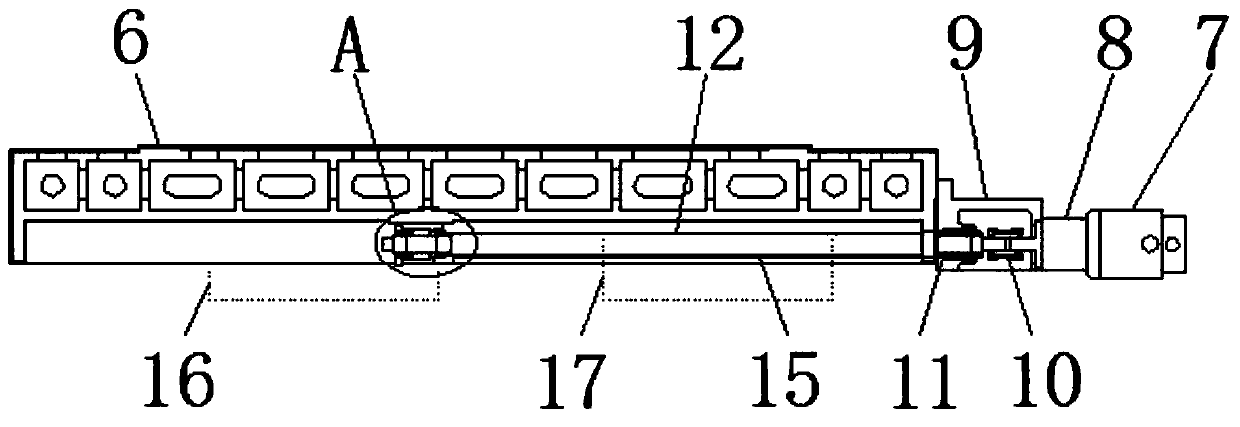

Linear guide rail pair and machining technology thereof

The invention provides a linear guide rail pair and a machining technology thereof, and belongs to the technical field of linear guide rail pairs. The linear guide rail pair comprises a sliding block body. The linear guide rail pair is characterized in that the body is in a U shape; a guide rail groove is formed in the bottom of the body, an installing groove is formed in the upper end face of the body, and two arc load grooves for supporting balls are formed in the inner walls of the two sides of the guide rail groove respectively; the two corners of the bottom of the guide rail groove are circular chamfers; and steps are arranged at the opening ends of the guide rail groove. The machining technology of the linear guide rail pair comprises the following steps of raw material preparing, head cutting, head rolling, head grinding, polishing, parkerising, saponifying and drawing. According to the linear guide rail pair, a unique double-arc structure is adopted in the load grooves, and when the impact load and the heavy load are borne, the bearing contact area is enlarged, and the rigidity of the system is improved. According to the machining technology of the linear guide rail pair, one-time joint forming is achieved during drawing, a plurality of later machining procedures are omitted, and cost, labor and the production time are saved.

Owner:浙江建鑫型钢科技股份有限公司

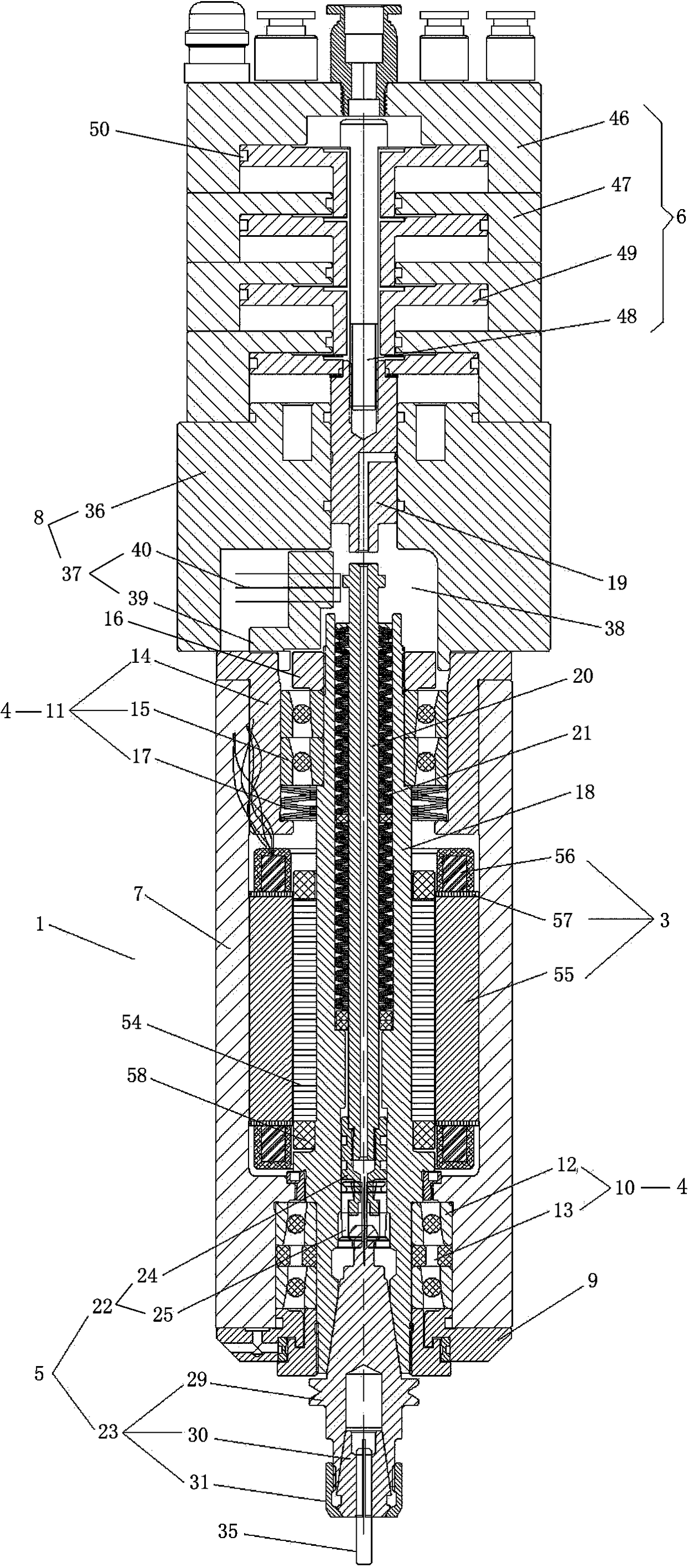

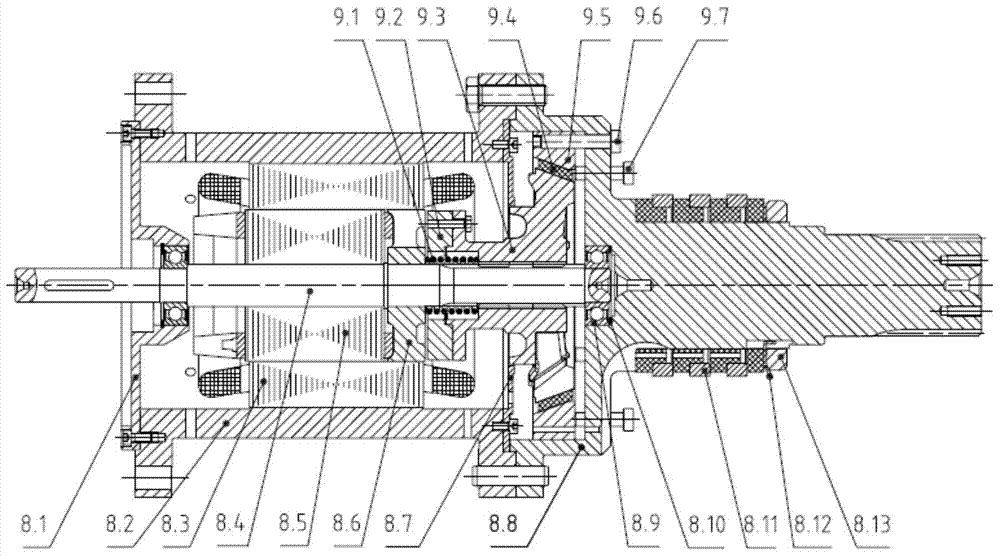

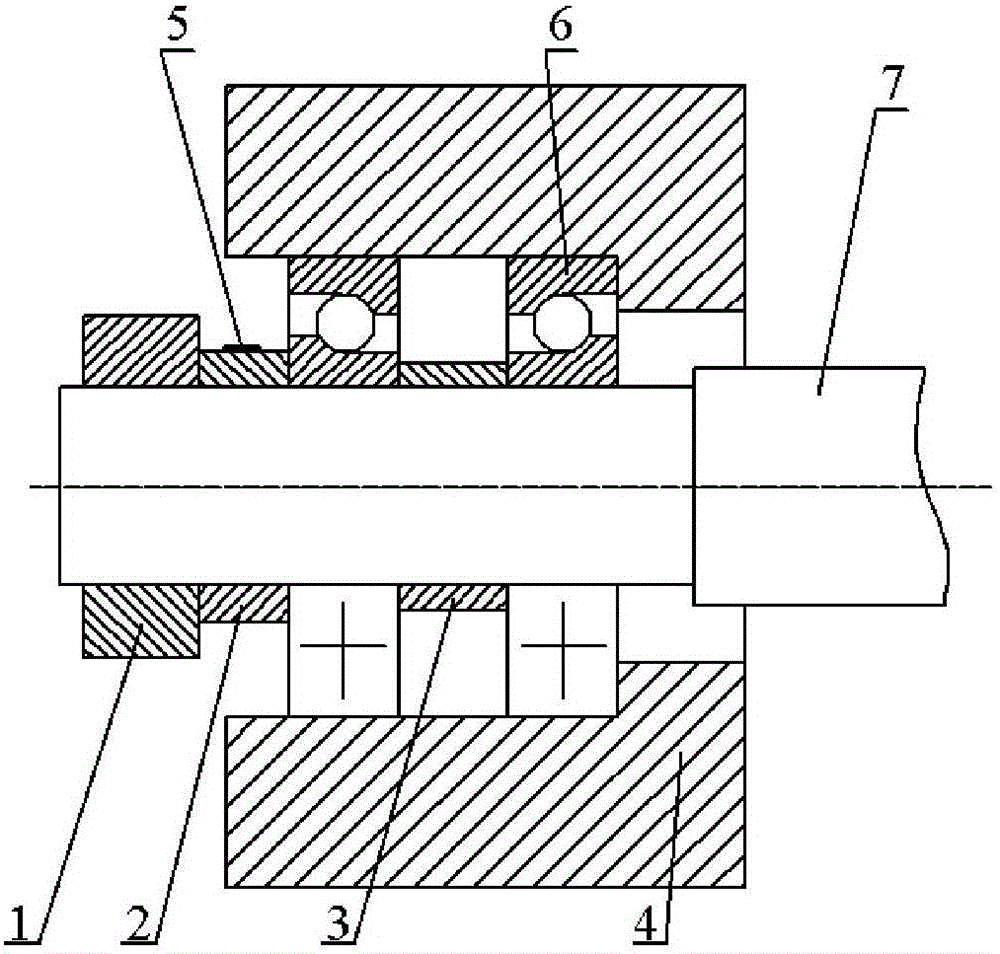

High-speed milling cutter handle type electric spindle

PendingCN109366205AConvenient preloadAxial force stabilityMilling cuttersLarge fixed membersMilling cutterEngineering

The invention relates to a high-speed milling cutter handle type electric spindle which comprises a main body mechanism, a rotor mechanism, a stator mechanism, a bearing mechanism, a broach mechanismand an air cylinder mechanism. The bearing mechanism comprises a front bearing assembly and a back bearing assembly arranged at two ends of the rotor mechanism; the front bearing assembly is providedwith an inner backing ring and an outer backing ring; a backing ring and an adjusting spring located in the same axis are arranged on the upper side and the lower side of the back bearing assembly; and the broach mechanism is detachably arranged on the rotor mechanism. The high-speed milling cutter handle type electric spindle provided by the invention has the beneficial effect that the electric spindle is provided with a position proximity switch connected with a programable logic controller (PLC) control center, so that a function on intelligently monitoring and automatically changing a cutter is realized. With an innovative self-designed cutter handle holding mechanism, the structural strength and the bearing surface are greatly increased, and the cutter holding force, the radial cutting rigidity and the loading force are further greatly improved, so that the high metal removal rate is achieved; and multi-process integrated processing of workpieces can be realized through a machinetool cutter rest, and a power assisting machine tool equipment manufacturer realizes high-intelligent automatic and integrated product functions.

Owner:岳阳市显隆电机有限公司

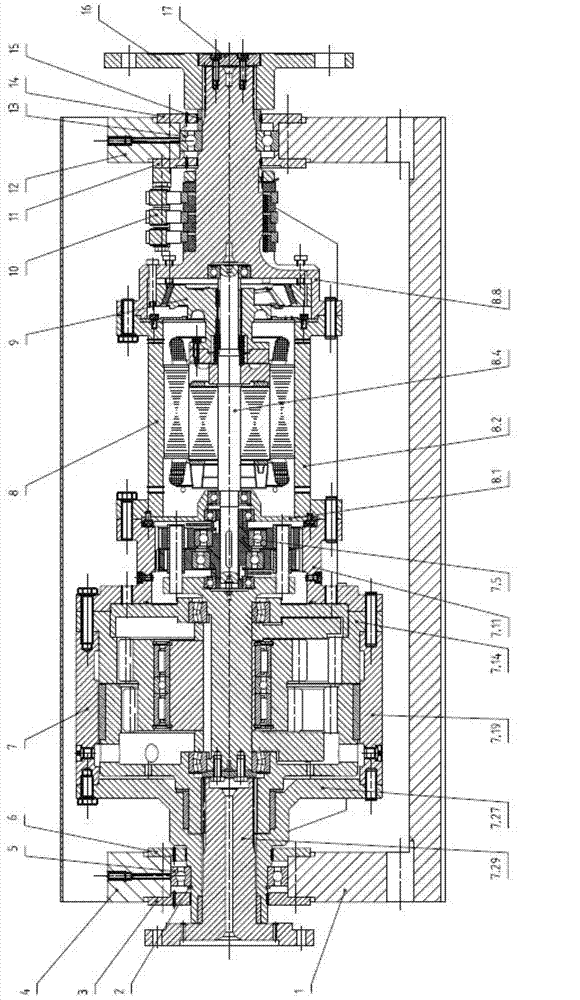

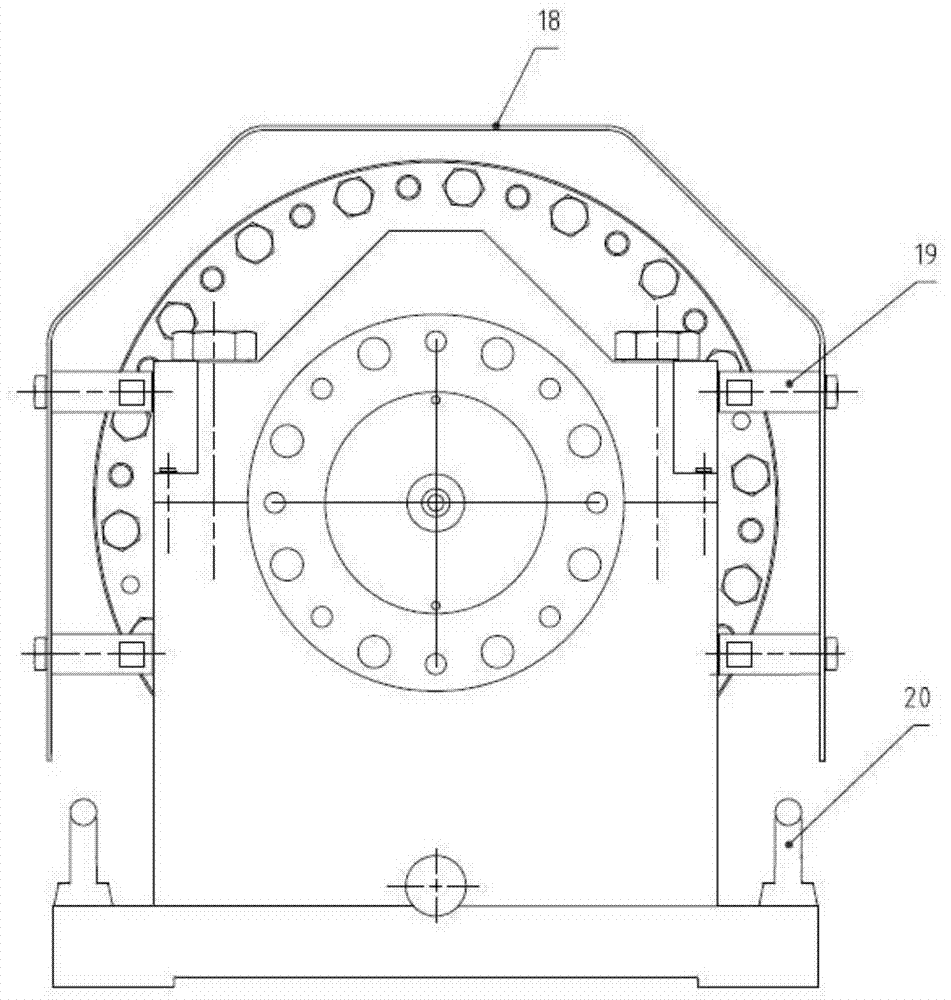

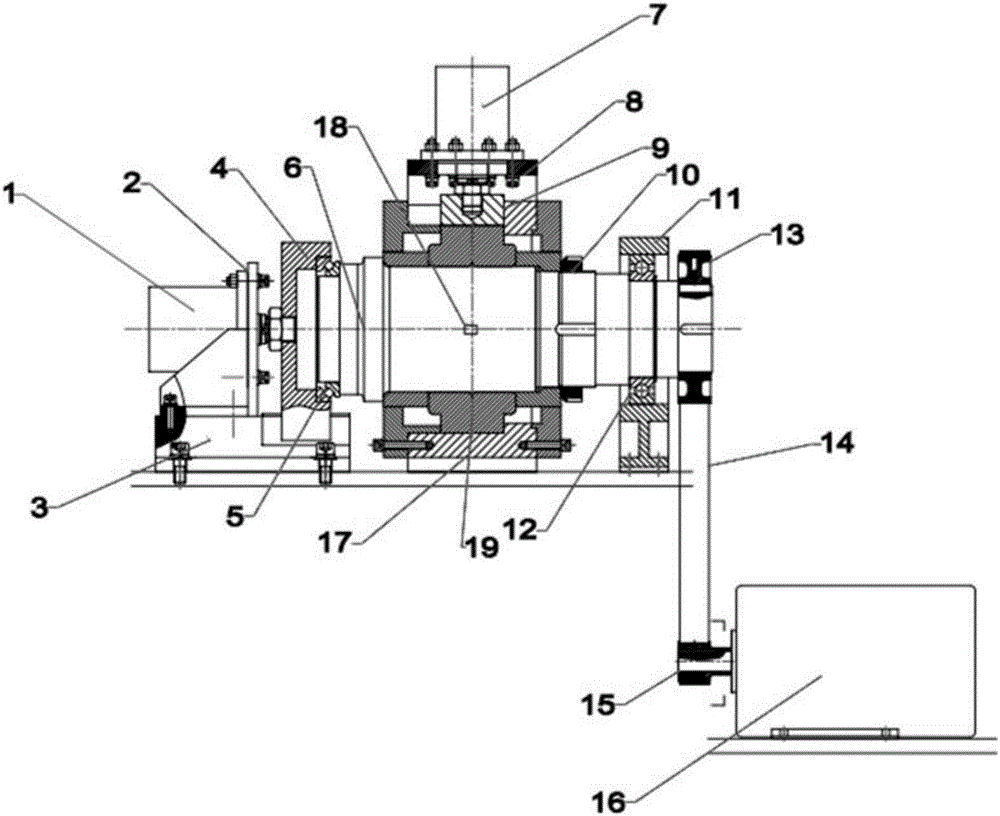

Electric synchronous loader

ActiveCN103528818ACompact structureSmall footprintMachine gearing/transmission testingElectric machineReduction drive

The invention provides an electric synchronous loader which comprises a base, a speed reducer, a loading motor, a brake, a braking frame assembly and a second left end cover, wherein the speed reducer comprises a first-stage casing, a fixed inner tooth ring, a second-stage casing and an output-end supporting seat which are connected in sequence to form a rotary housing of the speed reducer; the loading motor comprises a motor housing and a rear cover which form a rotary housing of the loading motor; the brake is arranged in a tail inner cavity of the loading motor and integrally combined with the loading motor; the braking frame assembly is arranged on the second left end cover and connected with an external lead wire for introducing an external three-phase power supply. The electric synchronous loader can be used for realizing no-load starting of a test device and freely changing the size and the direction of a torque in a running process, and is infinite in loading travel angle, high in loading precision, automatic in load locking, stable in running, allowable in high-speed rotation, large in loading torque, small in external contour size, high in reliability, low in loading motor power, low in use cost and good in economy.

Owner:HUNAN NANFANG AVIATION HIGH ACCURATE DRIVE

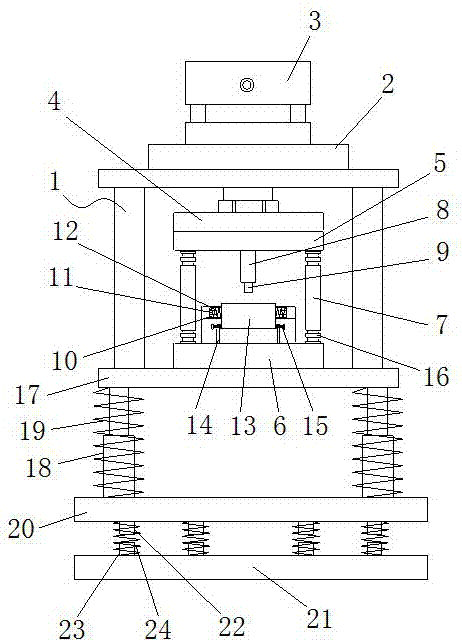

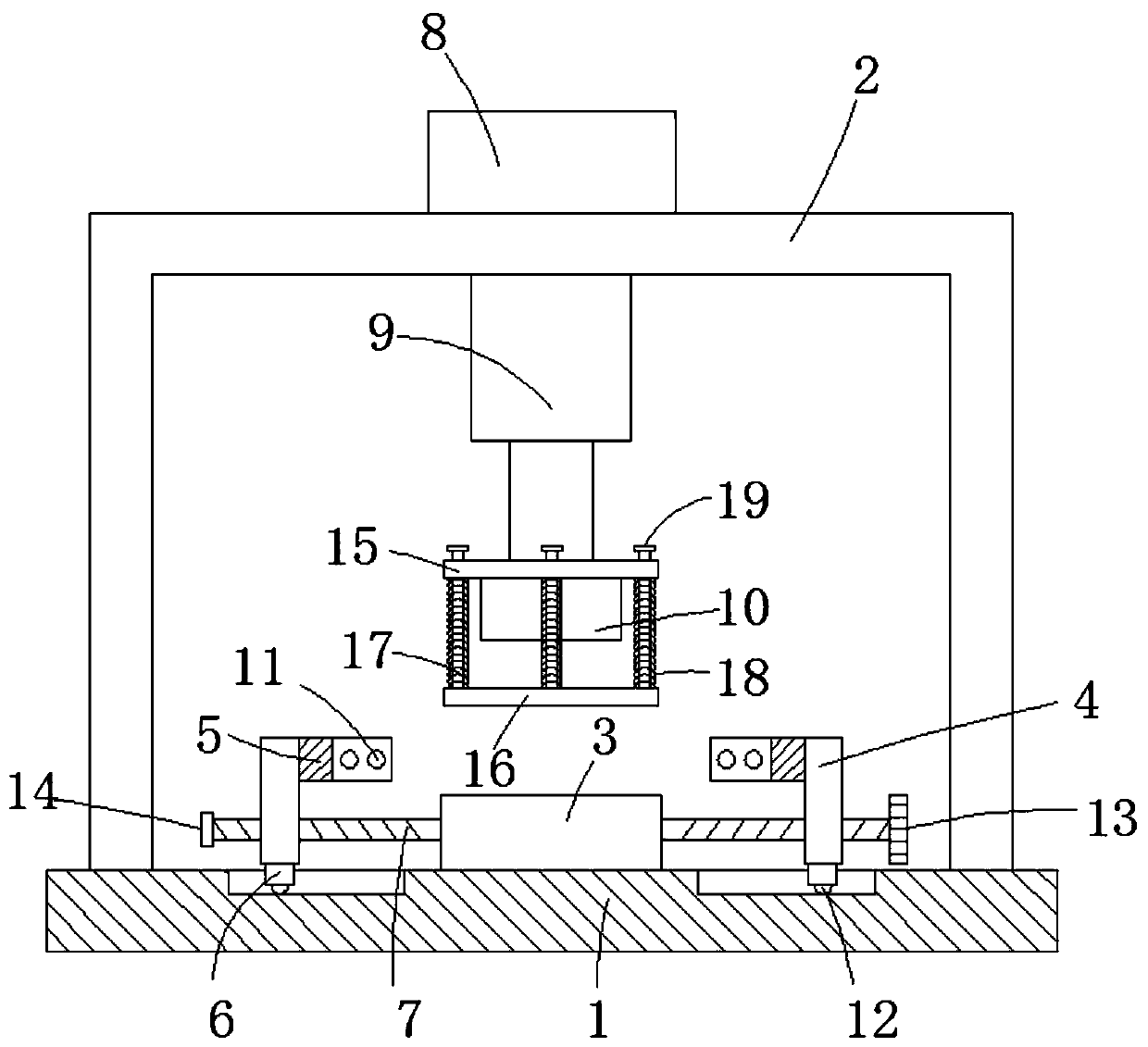

Shock absorption performance improved punching device

InactiveCN107498633AEasy to preloadAvoid offsetNon-rotating vibration suppressionMetal working apparatusHydraulic cylinderPunching

The invention discloses a shock absorption performance improved punching device. The punching device comprises a punching frame, a hydraulic cylinder fixing seat, a hydraulic cylinder, a top plate, a male die, a female die and guide posts. A punching column is mounted under the male die. The lower portion of the punching column is detachably provided with a punching head through threads. The lower end of a bottom plate of the punching frame is provided with four telescopic rods. Each telescopic rod is sleeved with a damping spring A. The bottom ends of the four telescopic rods are mounted on the upper surface of a supporting plate body. An elastic plate body is arranged under the supporting plate body. The supporting plate body and the elastic plate body are arranged in parallel. The lower surface of the supporting plate body is fixedly provided with a plurality of spring seat bodies A. The upper surface of the elastic plate body is fixedly provided with a plurality of spring seat bodies B. The spring seat bodies A and the spring seat bodies B are in one-to-one correspondence. Damping springs B are mounted between the spring seat bodies A and the corresponding spring seat bodies B.

Owner:嘉兴新博信息科技有限公司

Inertial rotation piezoelectric motor

ActiveCN109861582AImprove exercise efficiencyFirmly connectedPiezoelectric/electrostriction/magnetostriction machinesFriction lossPrism

The invention relates to an inertial rotation piezoelectric motor. The inertial rotation piezoelectric motor comprises a base, a rotor mechanism and a pretightening mechanism, wherein the base comprises a quadrangular prism and a cantilever-shaped mounting pipe; the rotor mechanism comprises a rotor, a mounting plate, a pair of piezoelectric plates and a pair of mass blocks, the piezoelectric plates are fixedly arranged on the two side surfaces of the middle part of the mounting plate respectively, and the mass blocks are fixedly arranged on the two side surfaces of the upper part of the mounting plate; the pretightening mechanism comprises a pretightening shaft, a screw and a spring; in working hours, an electric signal with corresponding frequency is applied onto the piezoelectric plates, the mounting plate begins to swing, due to the existence of a flexible hinge, the mounting plate is of micro deflection around the flexible hinge, under the effect of the mass blocks, alternating conversion states of clamping and loosening appear, and the inertial rotation piezoelectric motor integrally rotates at a micro angle theta in the loosening state; and one-way rotational motion of the inertial rotation piezoelectric motor is realized through continuous motion. The friction loss during working is low, and the motion efficiency is improved by 5% to 10%.

Owner:HEFEI UNIV OF TECH

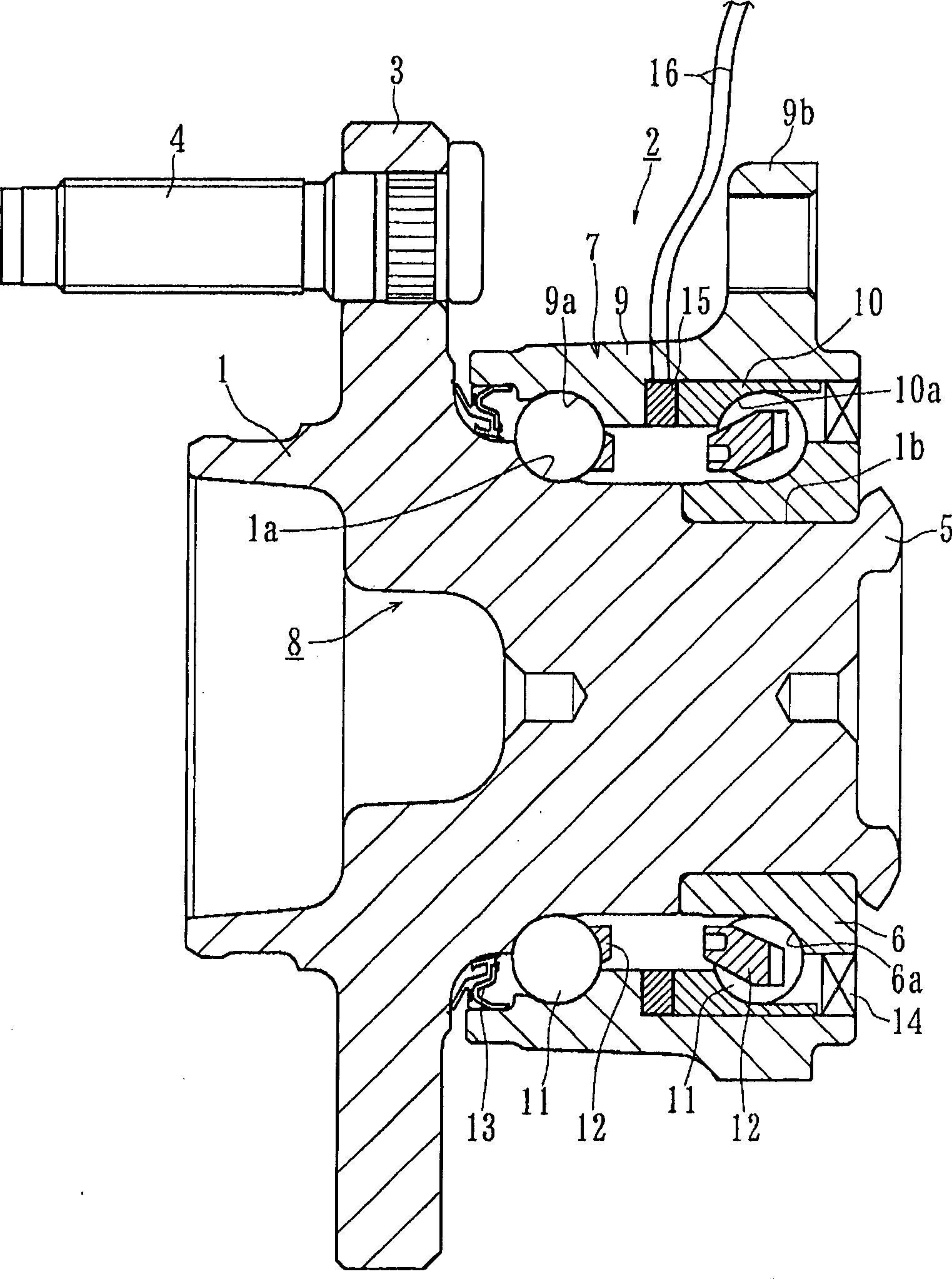

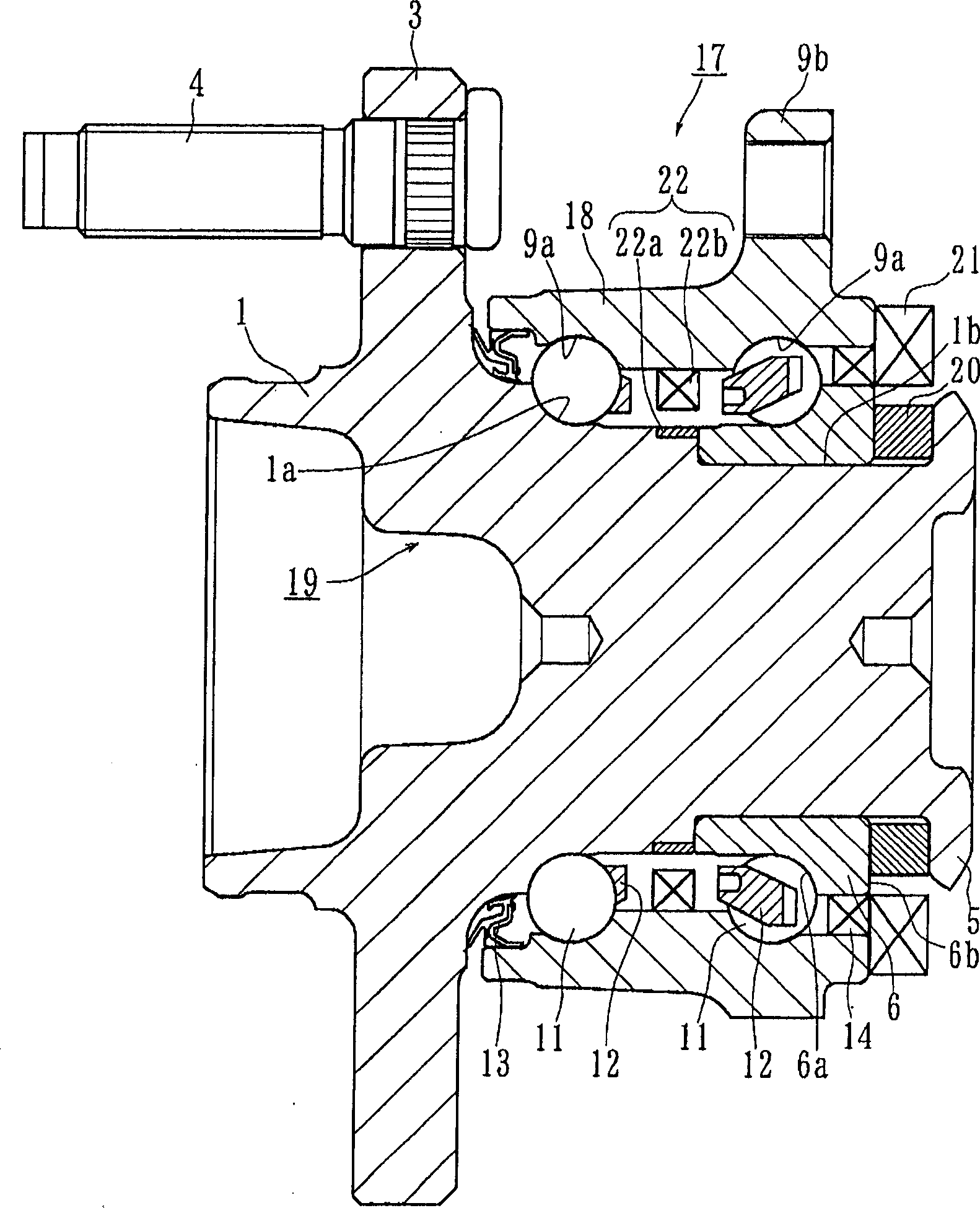

Bearing device for wheel

InactiveCN1802517AReduce friction lossCurb tiltRolling contact bearingsBearing assemblyRolling-element bearingEngineering

A bearing apparatus for a wheel of vehicle comprising a hub wheel integrally formed therewith a wheel mounting flange on the periphery at one end thereof, and a double row rolling bearing, the double row rolling bearing comprising an outer member integrally formed therewith a body mounting flange on the periphery thereof and also formed therewith double row outer raceway surfaces, an inner member including said hub wheel and formed therewith double row inner raceway surfaces each arranged opposite to each of said double row outer surfaces, and double row rolling elements freely rotatably contained between said double row outer and second raceway surfaces, said double row rolling bearing being adapted to be applied a predetermined preload characterized in that: there are arranged a separate outer or inner ring on at least one of said outer and inner members, and a preload varying means arranged at an abutting portion between said outer and inner members for varying the preload applied to the bearing, said preload varying means can be extended or contracted based on an output signal from a detecting sensor for detecting the running condition of vehicle.

Owner:NTN CORP

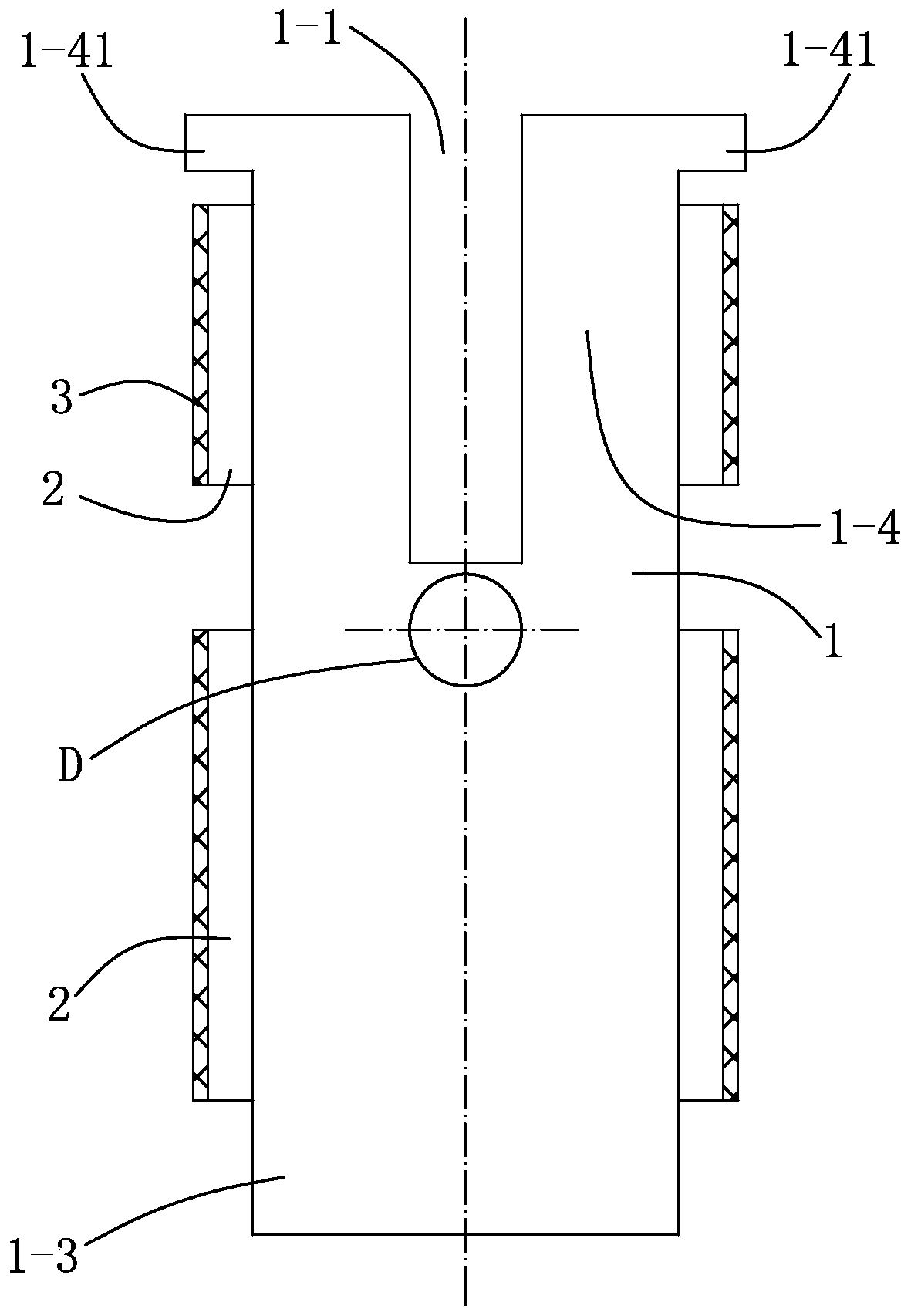

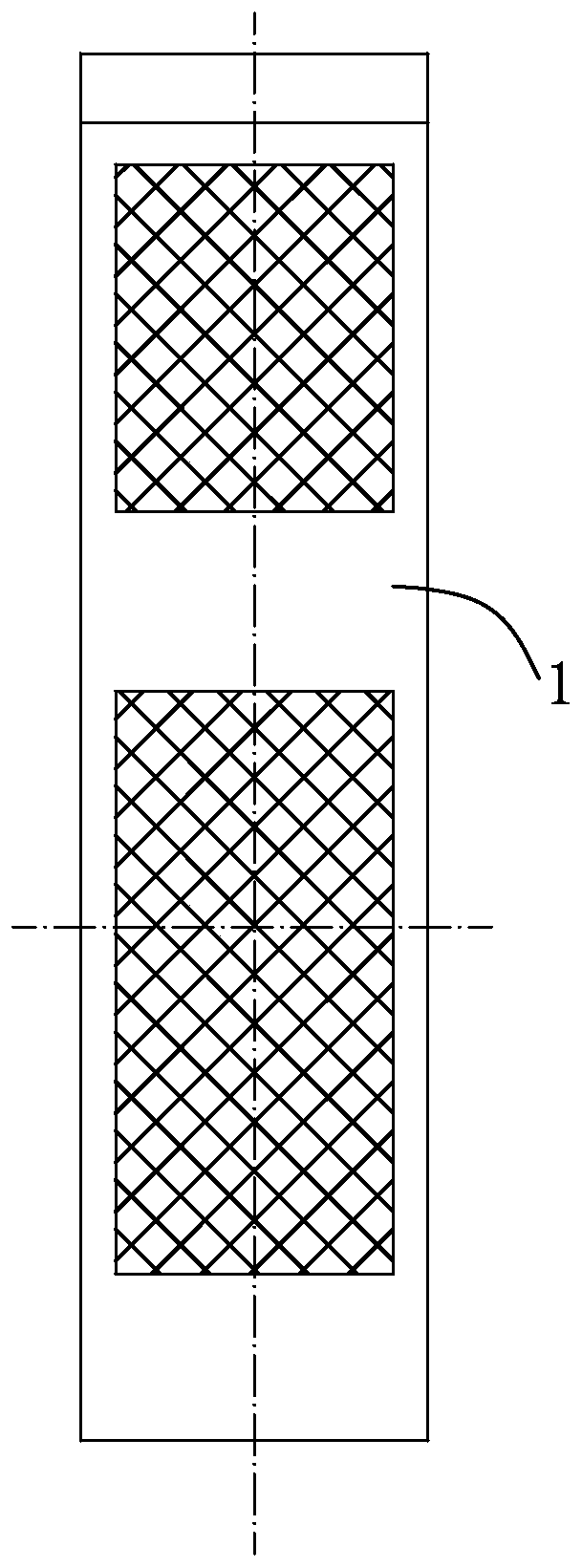

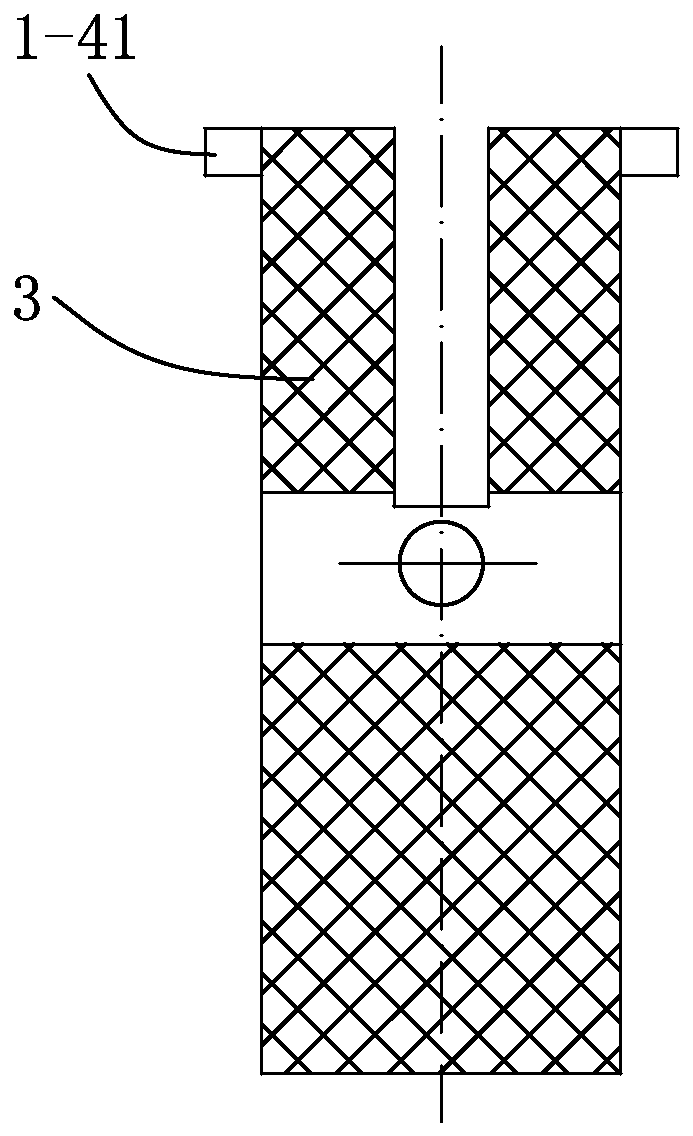

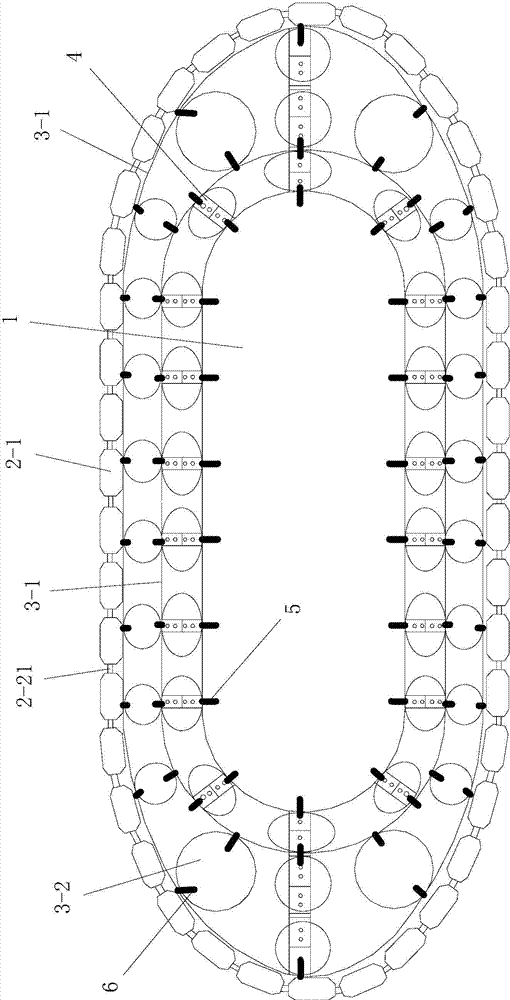

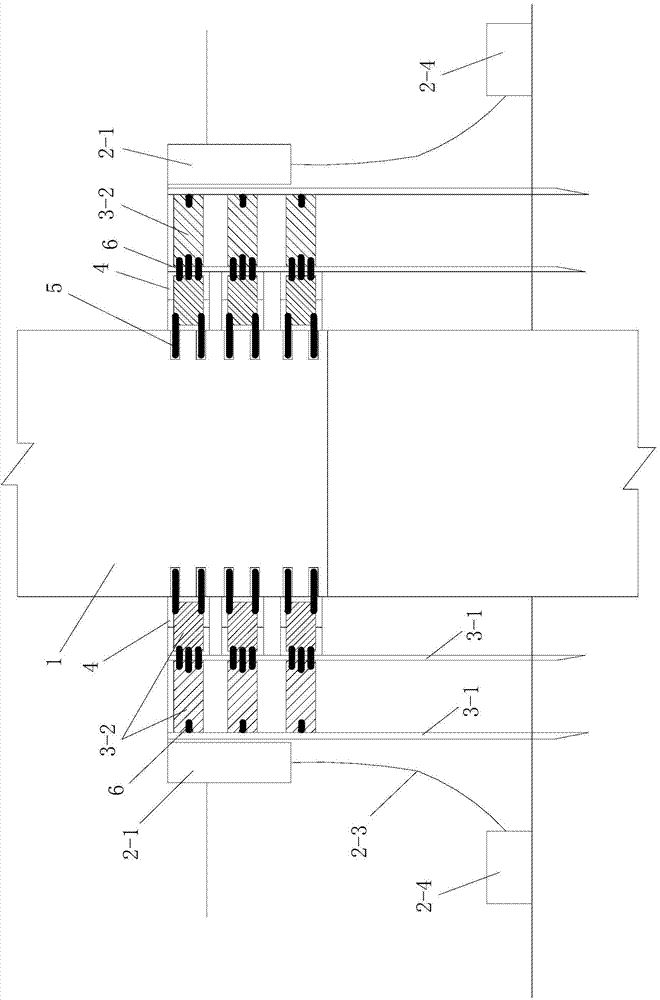

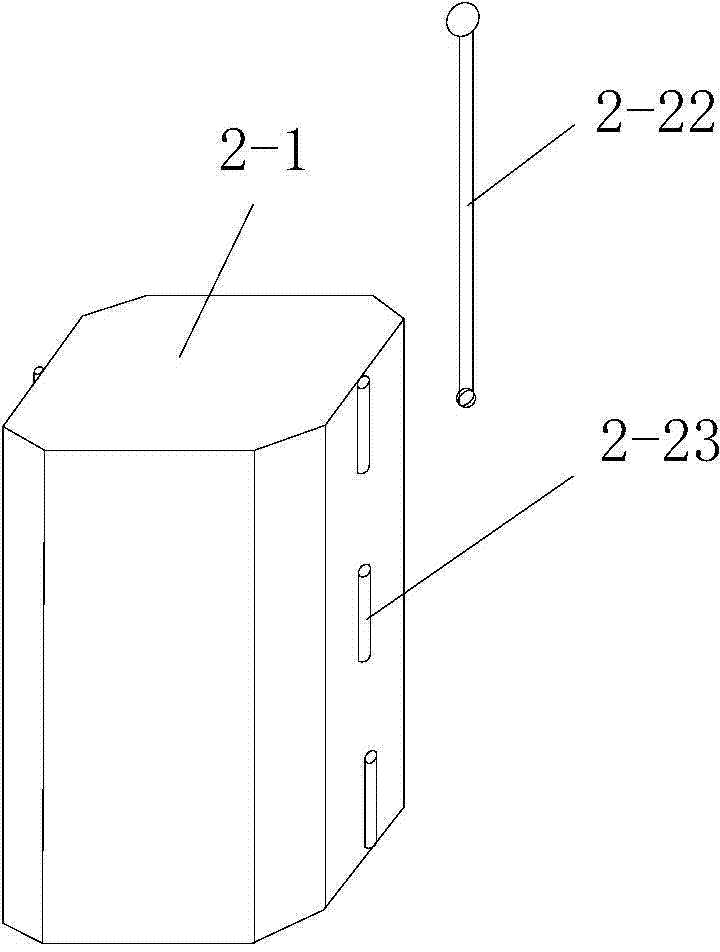

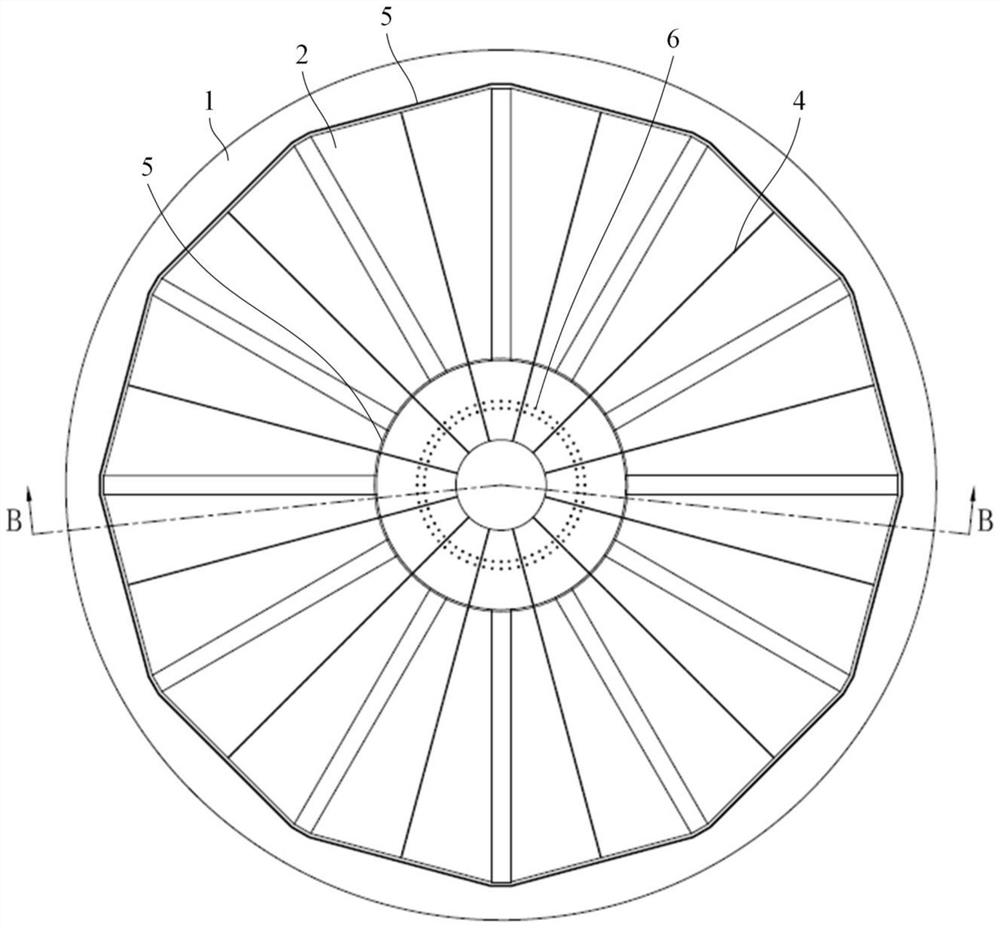

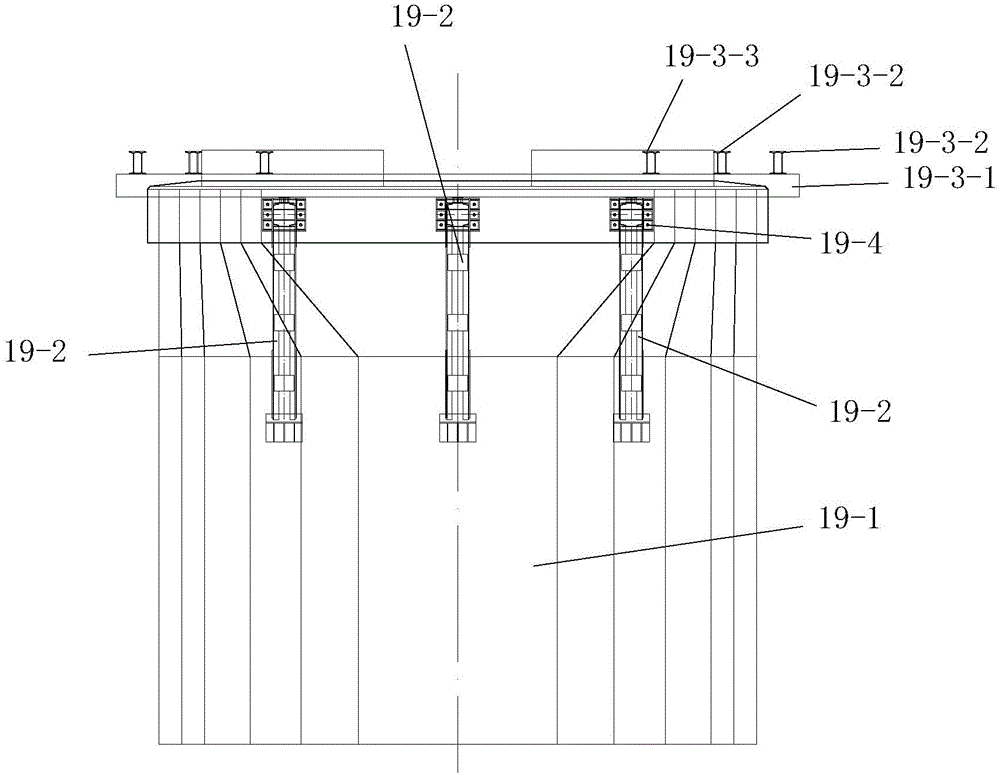

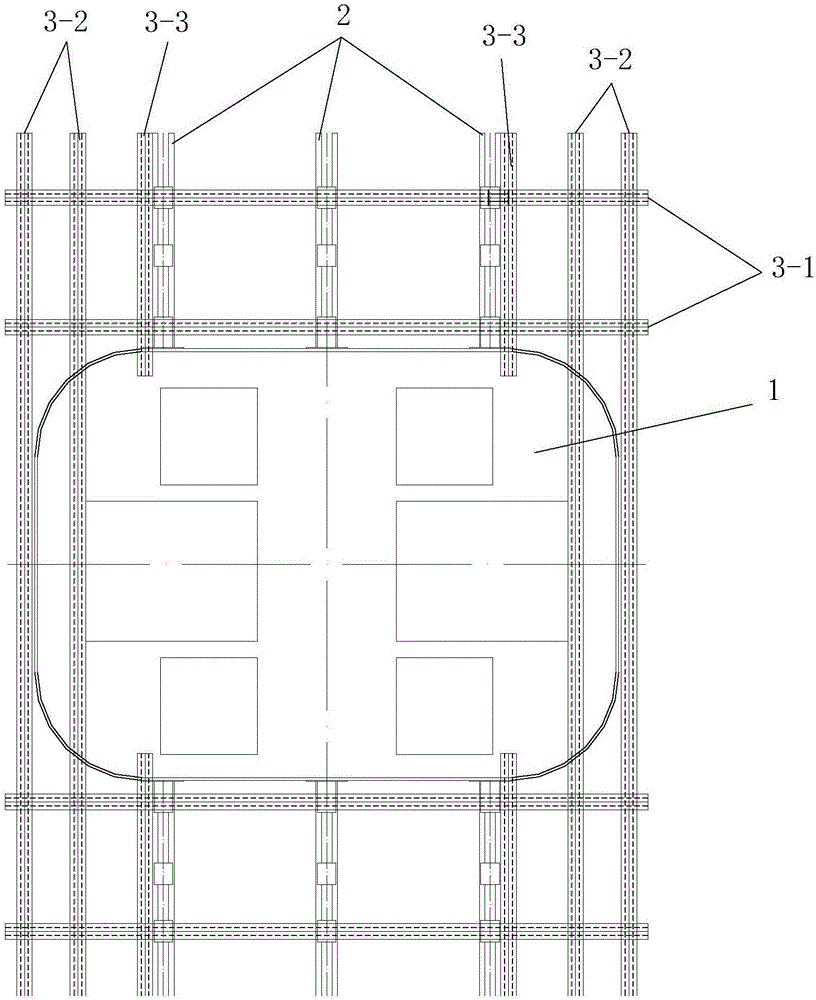

Date-pit-type composite anti-collision system for pier and construction method for date-pit-type composite anti-collision system for pier

InactiveCN104775355ASimple structureReasonable designClimate change adaptationBridge structural detailsArchitectural engineeringCofferdam

The invention discloses a date-pit-type composite anti-collision system for a pier and a construction method for the date-pit-type composite anti-collision system for the pier. The composite anti-collision system comprises a prepressing-type anti-collision device which is arranged at the outer side of the pier, and a floating-type external retaining device which sleeves the outer side of the prepressing-type anti-collision device, wherein the floating-type external retaining device is in a date pit shape, and is formed by connecting a plurality of anti-collision boxes which float on the water surface; the prepressing-type anti-collision device comprises one or a plurality of date-pit-type anti-collision structures; each date-pit-type anti-collision structure comprises an external cofferdam, and an energy consumption layer which is arranged at the inner side of the external cofferdam and is composed of a plurality of energy consumption rings; each external cofferdam is in the date pit shape; each energy consumption ring comprises an elastic ring which is formed through prepressing, and an external protective sleeve which sleeves the outer side of the elastic ring. The construction method comprises the following steps of (1) building a horizontal construction platform; (2) conveying parts in place; (3) constructing fixing elements at the outer side of the pier; (4) constructing the prepressing-type anti-collision device; (5) constructing the floating-type external retaining device. The date-pit-type composite anti-collision system for the pier and the construction method for the date-pit-type composite anti-collision system for the pier have the advantages that the design is reasonable, the construction is simple and convenient, the use effect is good, and the pier can be effectively protected.

Owner:XIAN UNIV OF SCI & TECH

Annular prefabricated assembly beam plate type fan foundation and installation method

PendingCN114108685AImprove grout qualityRing structure reinforcementFoundation engineeringEarthquake resistantElectric generator

The invention relates to the technical field of wind driven generator foundation structures, and discloses an annular prefabricated assembly beam plate type fan foundation which is characterized in that an annular prefabricated assembly beam plate type fan foundation cushion layer is poured at the bottom of a corresponding area of a wind driven generator foundation; the annular structure is formed by annularly distributing a plurality of precast beam and slab units, the annular structure is arranged above the cushion layer, the annular structure and the cushion layer are in filling connection through a bottom grouting body, and any two adjacent precast beam and slab units are in filling connection through an abutted seam grouting body; the annular prestressed cable is arranged on the outer side of the annular structure in a surrounding mode, and the annular prestressed cable is tightly attached to the outer side of the annular structure and tensioned; and the anchor bolt assemblies are arranged on the precast beam and slab units respectively and used for being connected with a bottom flange of the fan tower drum. The overall strength of the assembly type fan foundation can be improved, and the shock resistance of the fan foundation is improved. Meanwhile, the invention further provides an installation method of the annular prefabricated assembly beam plate type draught fan foundation.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP +1

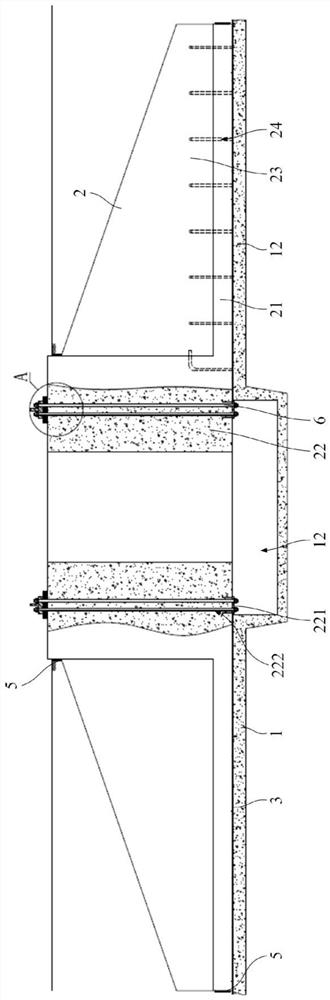

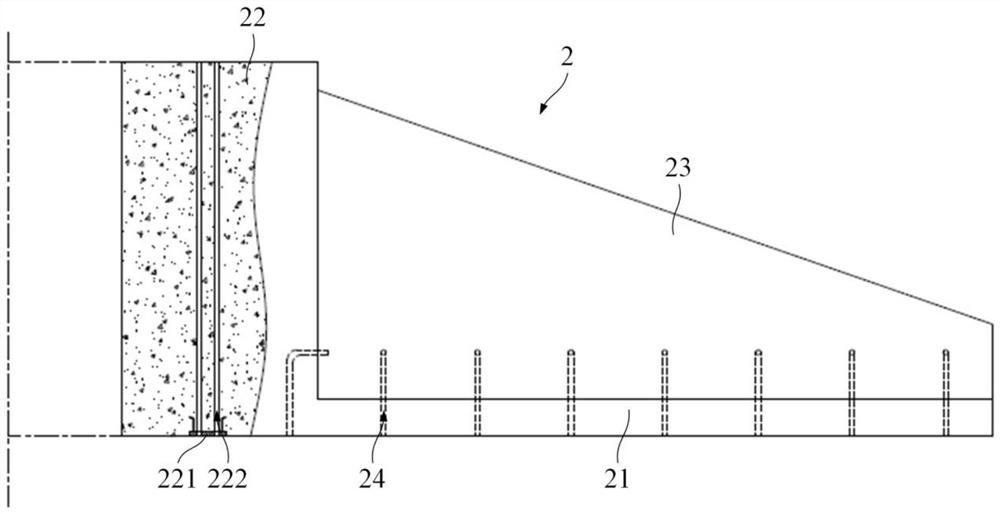

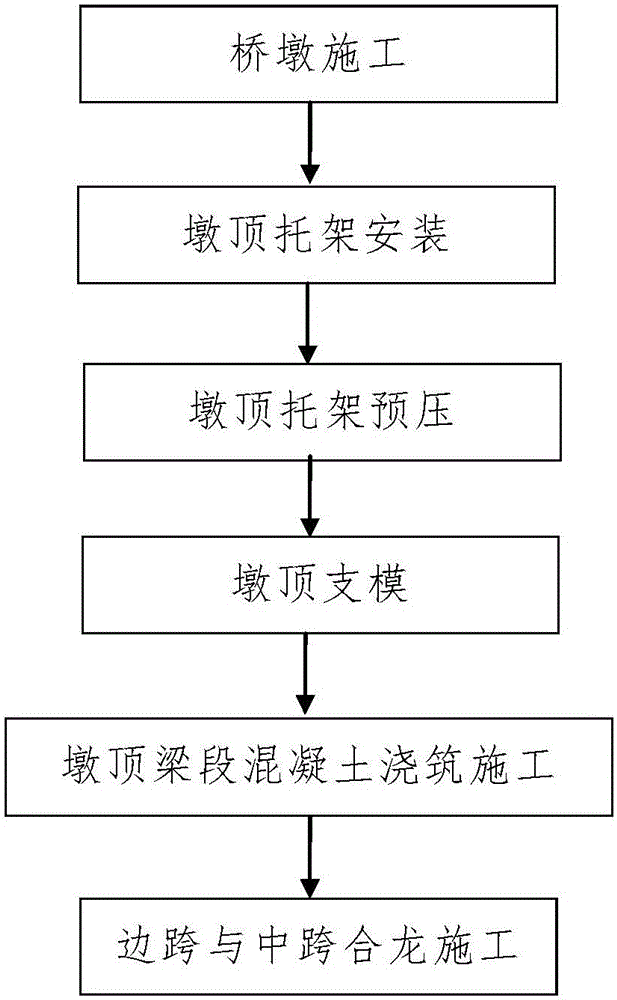

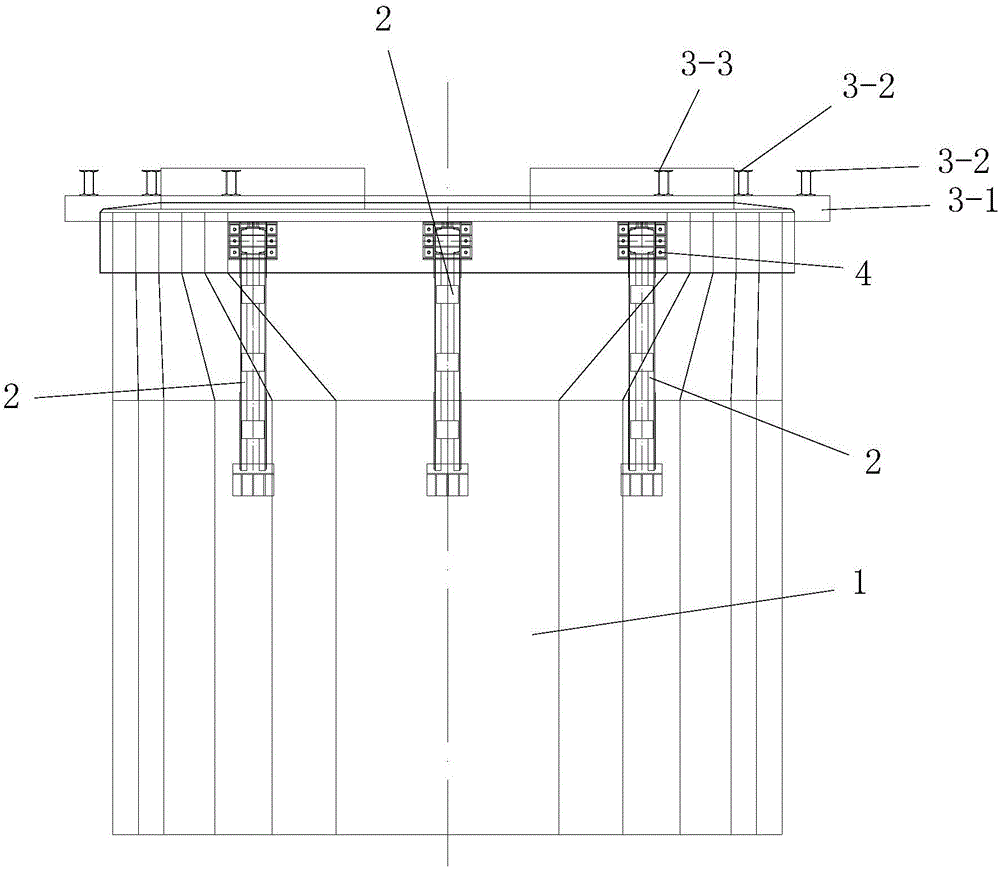

Construction method of large-span continuous beam closely next to existing line deep water foundation

ActiveCN106284085AThe method steps are simpleReasonable designBridge erection/assemblyContinuous beamRebar

The invention discloses a construction method of a large-span continuous beam closely next to an existing line deep water foundation. The large-span continuous beam to be constructed is a reinforced concrete box beam located on one side of an existing railway line, and is formed by splicing two side-span beam segments, a middle-span beam segment and two pier top beam segments. The construction method of the large-span continuous beam to be constructed comprises the steps that 1, bridge piers are constructed; 2, the pier top beam segments are constructed, specifically, pier top brackets are installed and pre-pressed, formworks are erected on the pier tops, and concrete is poured to the pier top beam segments; and 3, side-span and middle-span closure construction is carried out, specifically, after construction of the two pier top beam segments is completed, closure construction is carried out on the middle-span beam segment and the two side-span beam segments through a hanging basket. According to the method, the steps are simple, design is reasonable, construction is easy and convenient, the using effect is good, construction of the large-span continuous beam closely next to the existing line deep water foundation can be completed easily, conveniently and quickly, and the construction process is safe and reliable.

Owner:NO 1 ENG LIMITED OF CR20G

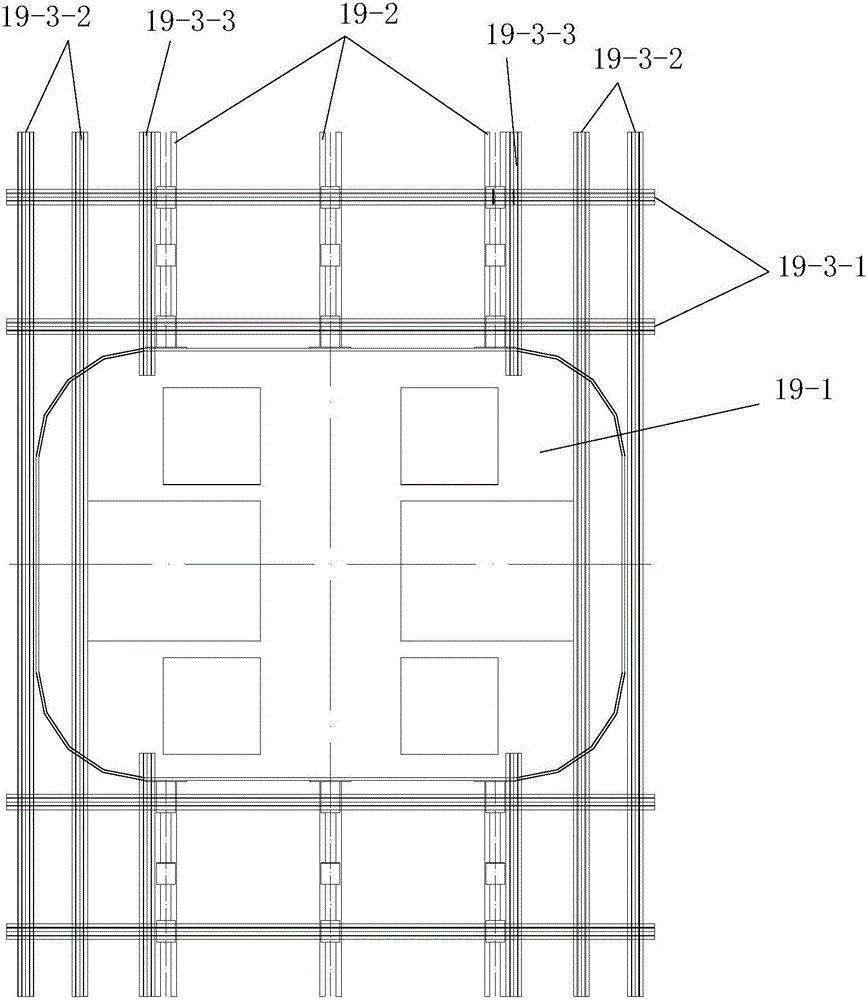

Novel vertical numerical control turning and grinding composite machine tool

PendingCN110434616AImprove rigiditySmall footprintOther manufacturing equipments/toolsElectric machineryEngineering

The invention discloses a novel vertical numerical control turning and grinding composite machine tool. The novel vertical numerical control turning and grinding composite machine tool comprises a base and an alternating current servo motor, wherein the top end of the base is provided with a workbench, the upper surface of the base is provided with a stand column, the alternating current servo motor is arranged on the outer side of a protective shell, the tail end of a rotating shaft is connected with a coupler, the tail end of the coupler is connected with a transmission lead screw, and the front side of a cross beam is sequentially provided with a grinding tool rest and a turning tool rest from left to right. The novel vertical numerical control turning and grinding composite machine tool is convenient to install, can conveniently adjust the pretightening of an X-axis screw rod and a Z-axis screw rod, can increase the rigidity of the screw rods, saves the occupied area, improves theautomation degree, improves the depth of a ground inner hole, increases the range of the ground inner hole, reduces the vibration of a grinding wheel in the grinding process, accordingly improves thegrinding precision, has the characteristics of high positioning precision, stability, reliability, compact structure and the like and can ensure normal work of a spindle under the conditions of largecutting depth and large feeding.

Owner:FUJIAN CHENGGONG MACHINE TOOL CO LTD

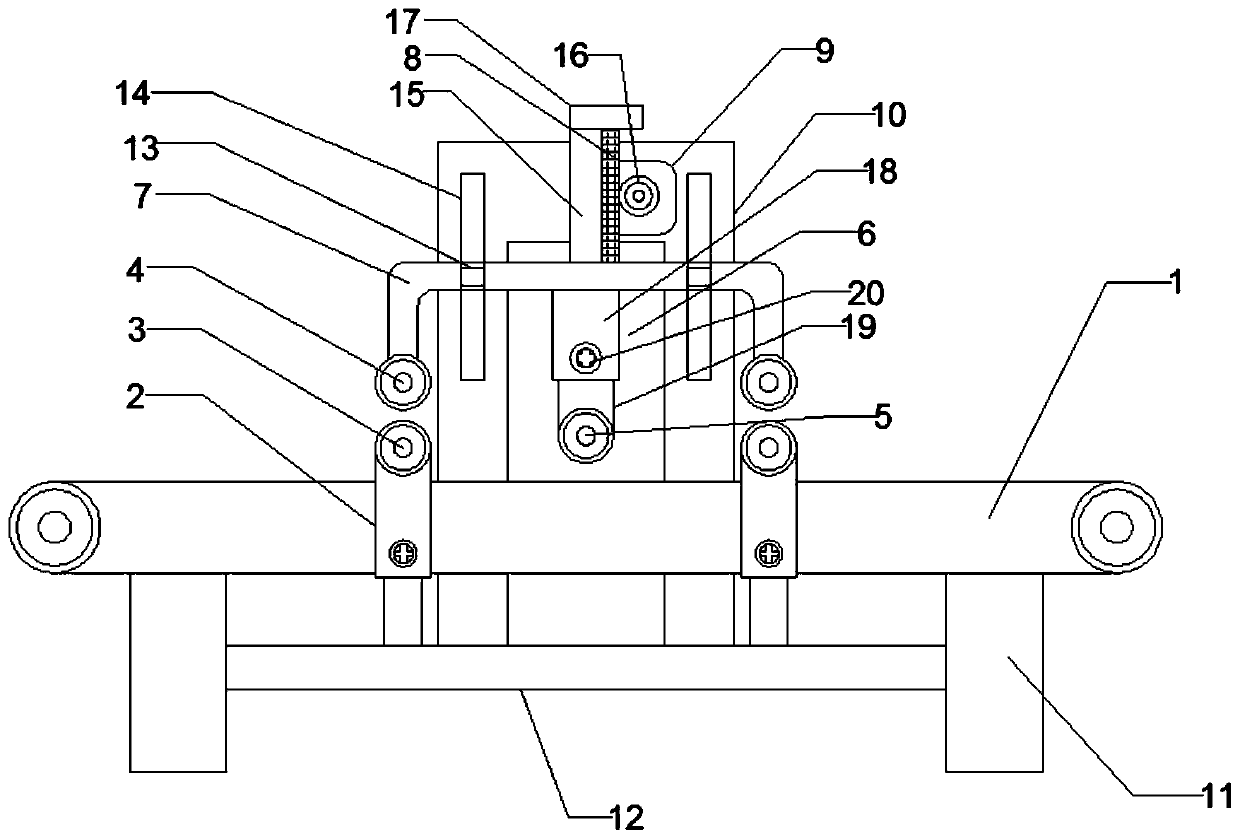

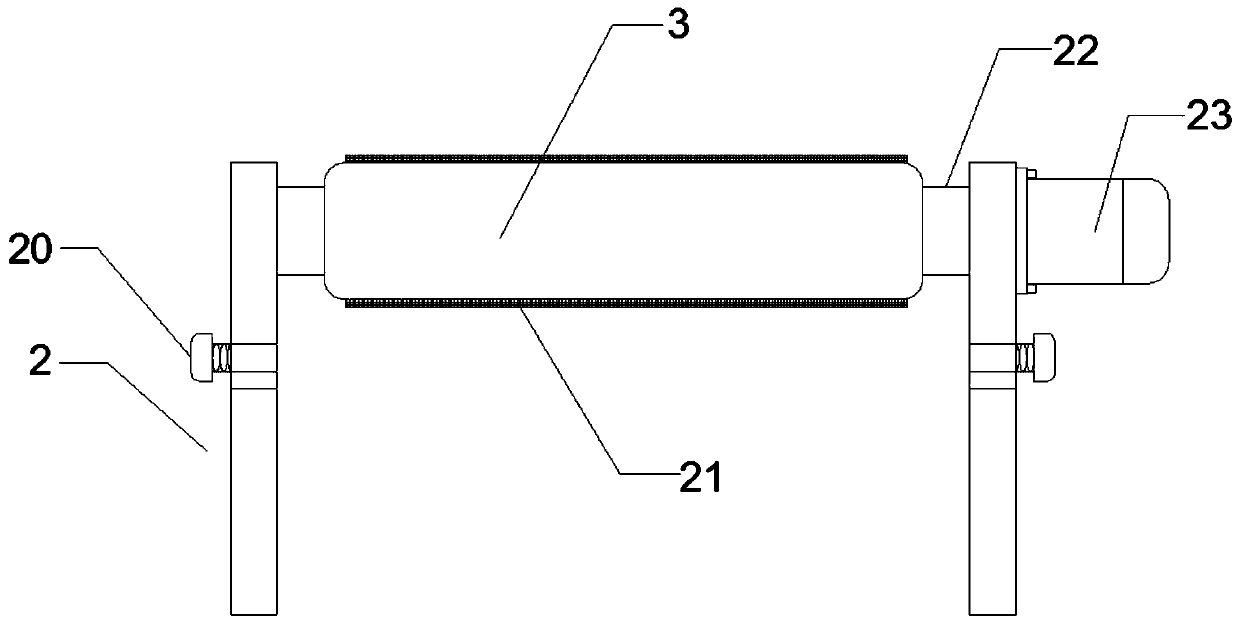

Non-woven cloth pre-pressing conveying device

The present invention discloses a non-woven cloth pre-pressing conveying device. The device comprises a conveying belt, first lifting brackets, driving guide rollers, auxiliary pressing rollers, a driving pressing roller, a second lifting bracket, a transmission bracket, a rack, a speed reduction motor and a supporting frame, wherein the left and right sides of the bottom of the conveying belt areprovided with supporting legs, a connecting plate is arranged between the supporting plates, the left side and the right side of the connecting plate are provided with the first lifting brackets, thetops of the first lifting brackets are provided with the driving guide rollers, the auxiliary pressing rollers are arranged above the driving guide rollers, the auxiliary pressing rollers are arranged on the left side and the right side of the bottom of the transmission bracket, and the second lifting bracket is arranged at the lower part of the middle of the transmission bracket and is connectedwith the driving pressing roller. The device is simple in structure; by arranging the multiple driving guide rollers, the auxiliary pressing rollers and the driving pressing roller, non-woven cloth is convenient to pre-press, and working positions of the driving guide rollers, the auxiliary pressing rollers and the driving pressing roller can be adjusted according to the requirements to better perform the required pre-pressing work so as to achieve the required working effect and improve the product quality.

Owner:JIANGYIN BINGDA ELECTRIC APPLIANCE IND CO LTD

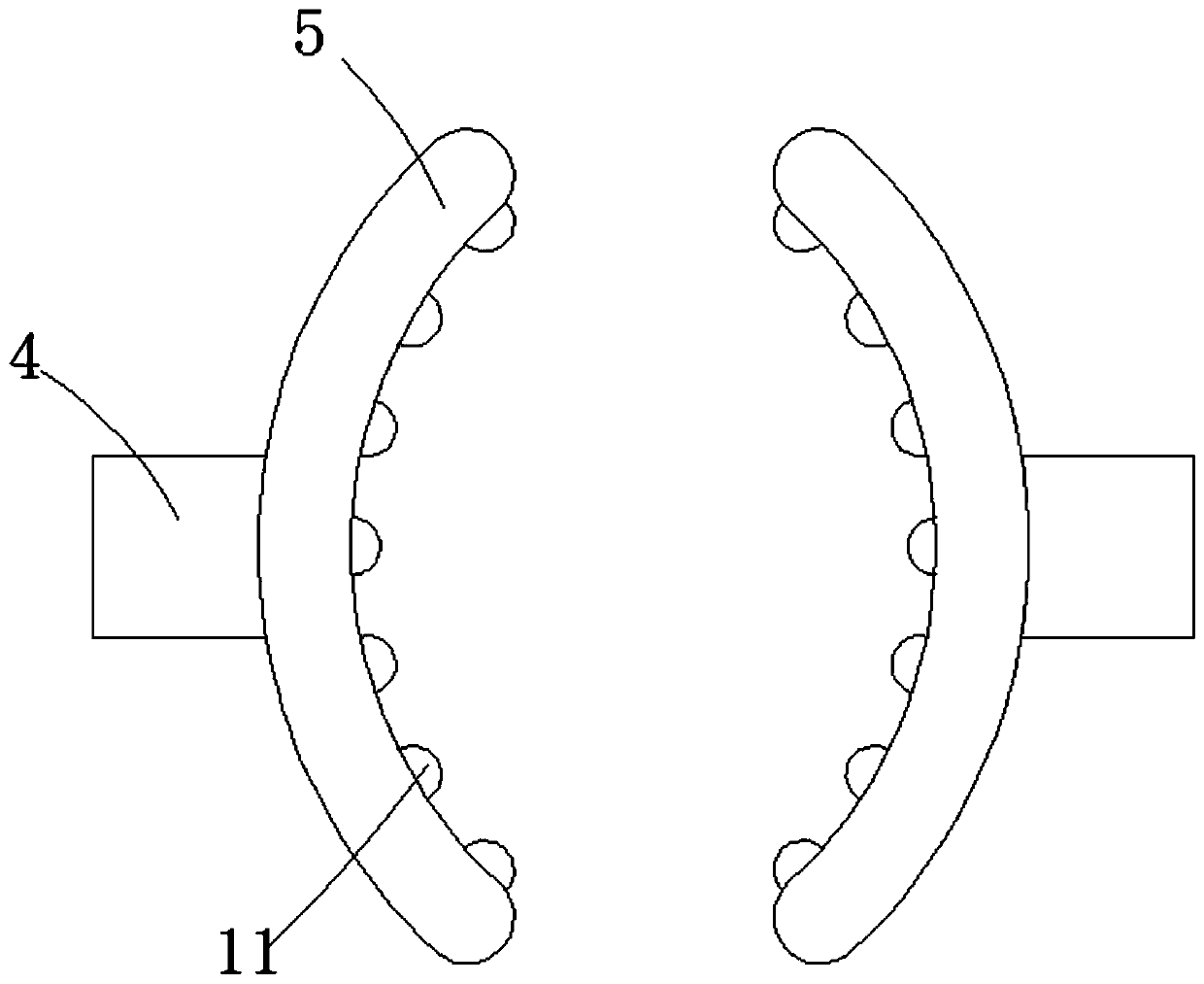

Alloy die casting clamping device capable of preventing offsetting

InactiveCN110666055AAvoid offsetAvoid displacementMetal-working feeding devicesPositioning devicesRolling-element bearingDie casting

The invention relates to the alloy die casting technology field, and discloses an alloy die casting clamping device capable of preventing offsetting. The alloy die casting clamping device capable of preventing offsetting comprises a bottom seat and a U-shaped support frame, wherein a support seat is fixedly connected with the middle of the upper end of the bottom seat, two clamping rods verticallyarranged are arranged on the left side and the right side of the support seat, arc rods are fixedly connected with upper ends of rod walls on two opposite sides of the two clamping rods, sliding blocks are fixedly connected with lower ends of the two clamping rods, sliding chutes matched with the sliding blocks are formed in the left side and the right side of the upper end of the bottom seat, abidirectional threaded rod transversely arranged is rotatably inserted into the support seat through a rolling bearing, the two clamping rods respectively run through the left end and the right end ofthe bidirectional threaded rod, and the left end and the right end of the bidirectional threaded rod are connected with the two clamping rods through threads. The alloy die casting clamping device capable of preventing offsetting can apply multidirectional force to alloy pending for die casting so as to clamp the alloy, enables the position of the alloy to correspond to the position of a die casting head, can perform pre-compression on the peripherical edge of the alloy in the die casting, and prevents the alloy from offsetting in the die casting.

Owner:巢湖宜安云海科技有限公司

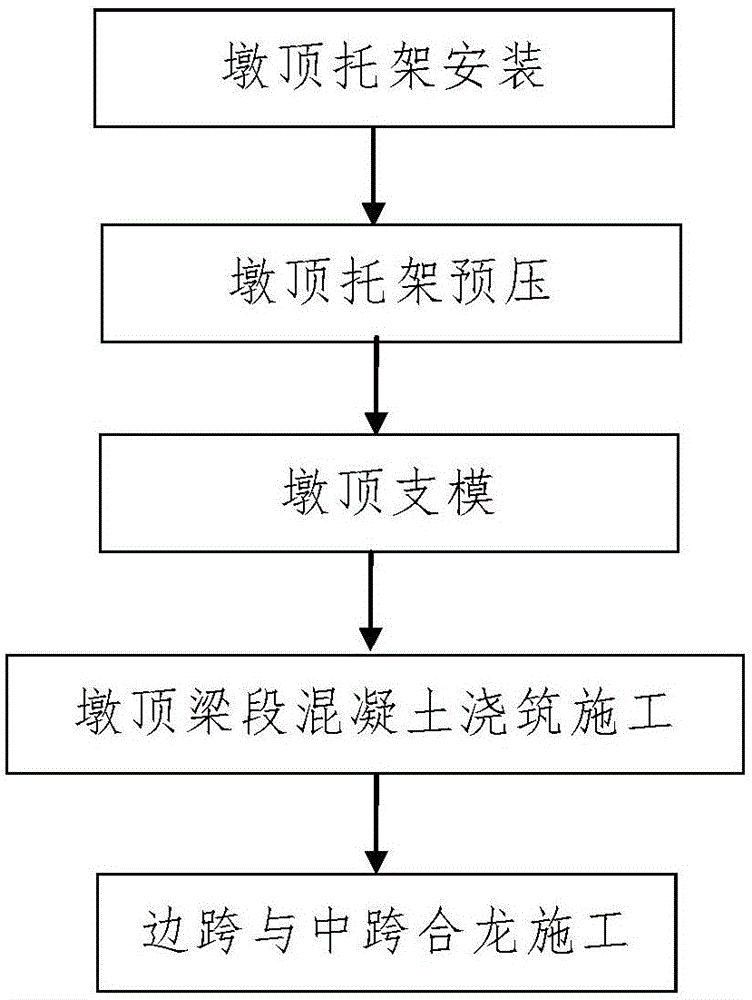

Construction method for long-span continuous beam neighboring existing lines

ActiveCN106351129AThe method steps are simpleReasonable designBridge erection/assemblyReinforced concreteContinuous beam

The invention discloses a construction method for long-span continuous beam neighboring existing lines. The long-span continuous beam in construction refers to reinforced concrete box girder located on one side of existing railway lines; the long-span continuous beam in construction is jointed by two side span beam sections, one medium span beam section and two pier top beam sections and the medium beam section is connected with the side span beam sections by two pier top beam sections; the construction of the long-span continuous beam comprises the steps of 1, pier top beam section construction in the process of pier top bracket installation, pier top bracket prepressing, pier top formwork and pier top beam section concrete pouring construction; 2, side span and median span in closure construction: after construction of two pier top beam sections is completed, cradle is applied to make closure construction of the median span beam section and the two side span beam sections. The construction method for long-span continuous beam neighboring existing lines has simple steps, reasonable design, convenient construction, and good effects of application, which can conveniently and quickly complete long-span continuous beam construction in safe and reliable process of construction.

Owner:CHINA RAILWAY 20 BUREAU GRP

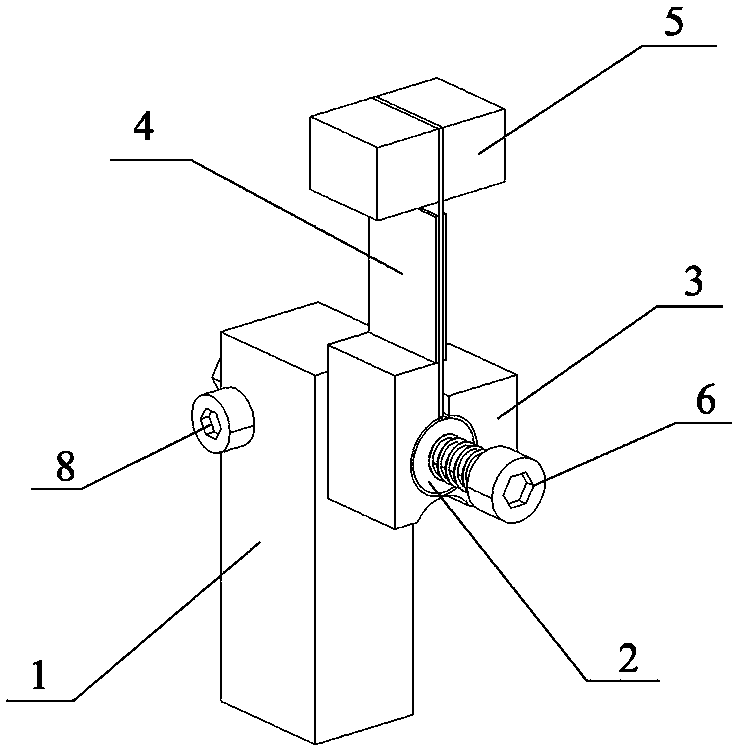

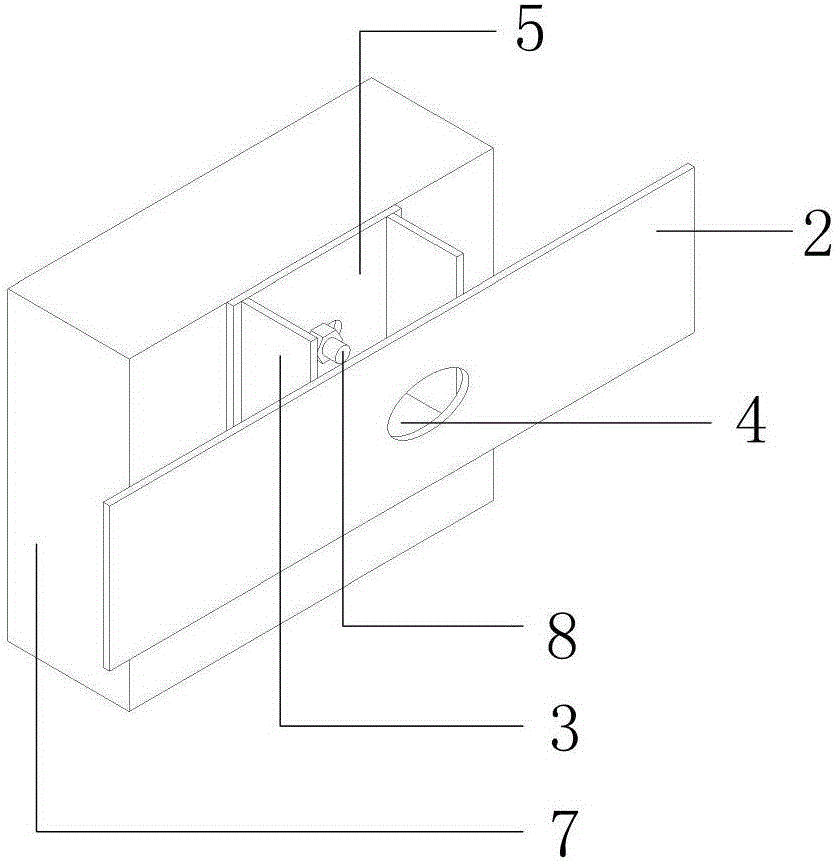

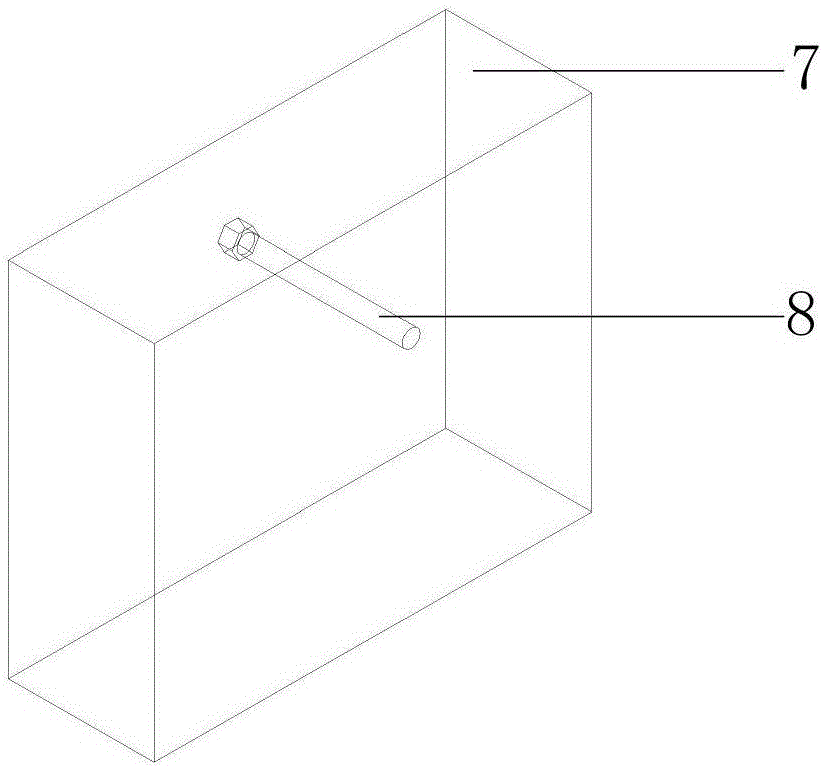

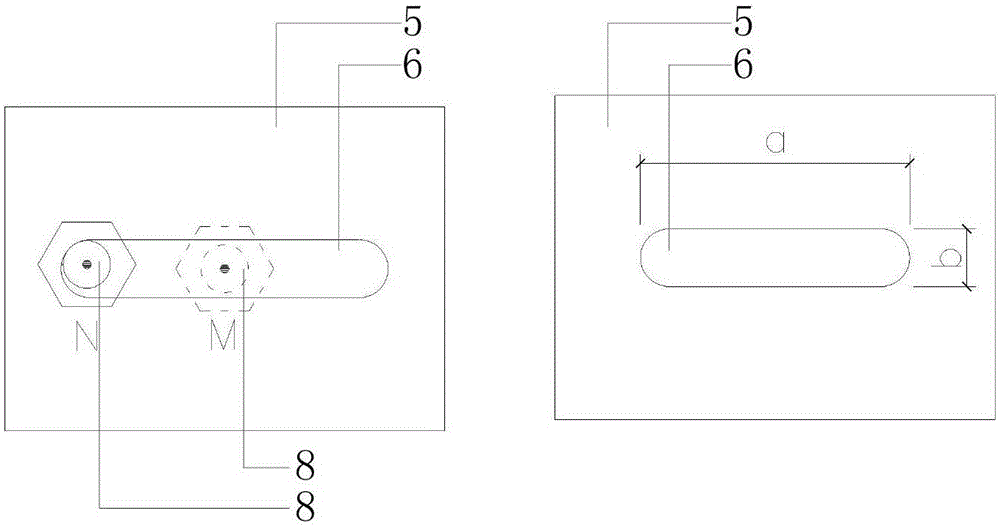

Controllable slippage node for fabricated prefabricated externally-hung wall body

The invention discloses a controllable slippage node for a fabricated prefabricated externally-hung wall body. The controllable slippage node comprises a pre-buried high-strength bolt, a connecting piece, a stiffening rib and a steel beam with a hole. The prefabricated externally-hung wall body and part of the pre-buried high-strength bolt are integrated in a pouring way in a factory on site. The connecting piece is welded to a main body steel frame beam, a long slot hole is formed in the center of the connecting piece, and the prefabricated externally-hung wall body is connected with the main body steel frame beam through the pre-buried high-strength bolt and the connecting piece. A circular or an oval hole is formed in the center of a web of the main body steel frame beam so as to conveniently apply pre-tightening force to the pre-buried high-strength bolt. According to the controllable slippage node for the fabricated prefabricated externally-hung wall body, it is ensured that the wall body and a main body structure can laterally move together under the effect of small load such as wind load or a small earthquake, cracks do not occur between the wall body and the main body structure, repairing of the wall body after the effect of small load such as wind load or the small earthquake is reduced, and the effect that the wall body slips through the long slot hole during a medium earthquake and a large earthquake can be achieved; and meanwhile, by controlling the length of the long slot hole, the controllable slippage node can play a role in the later period of earthquakes while integrity of the wall body is ensured.

Owner:BEIJING UNIV OF TECH

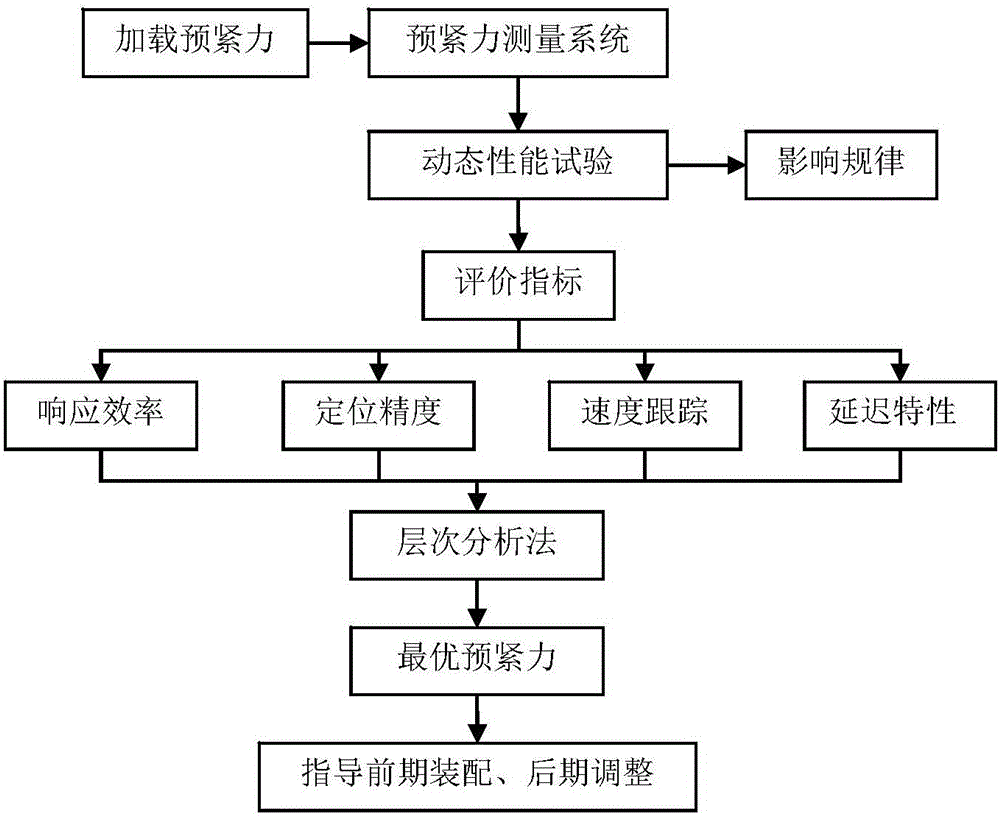

Test optimization method for pre-tightening force of ball screw of feeding system of numerical control machine tool

ActiveCN105893709AConvenient preloadAccurate and easy preloadGeometric CADSpecial data processing applicationsNumerical controlBall screw

The invention relates to a test optimization method for the pre-tightening force of a ball screw of a feeding system of a numerical control machine tool. The test optimization method comprises the following steps: establishing a measuring system for the pre-tightening force of the ball screw; establishing an evaluation index system for the dynamic performance of the feeding system; designing a test variable according to an evaluation index, performing dynamic performance test by utilizing a laser interferometer and analyzing the rule of influence of the change of the pre-tightening force on the dynamic performance of the feeding system according to a test result; analyzing the dynamic performance of the feeding system by adopting a layering analysis method, thereby accurately acquiring the pre-tightening force corresponding to the optimal dynamic performance of the feeding system. According to the test optimization method provided by the invention, the measuring system for the pre-tightening force of the ball screw and the evaluation index system for the dynamic performance of the feeding system are combined for acquiring the rule of influence of the change of the pre-tightening force on the dynamic performance of the feeding system by analyzing the test result on the basis of repeated dynamic performance test of the feeding system, so that the optimized pre-tightening force can be accurately, simply and conveniently acquired and the earlier stage assembly and the later stage adjustment of the ball screw can be guided.

Owner:TIANJIN UNIV

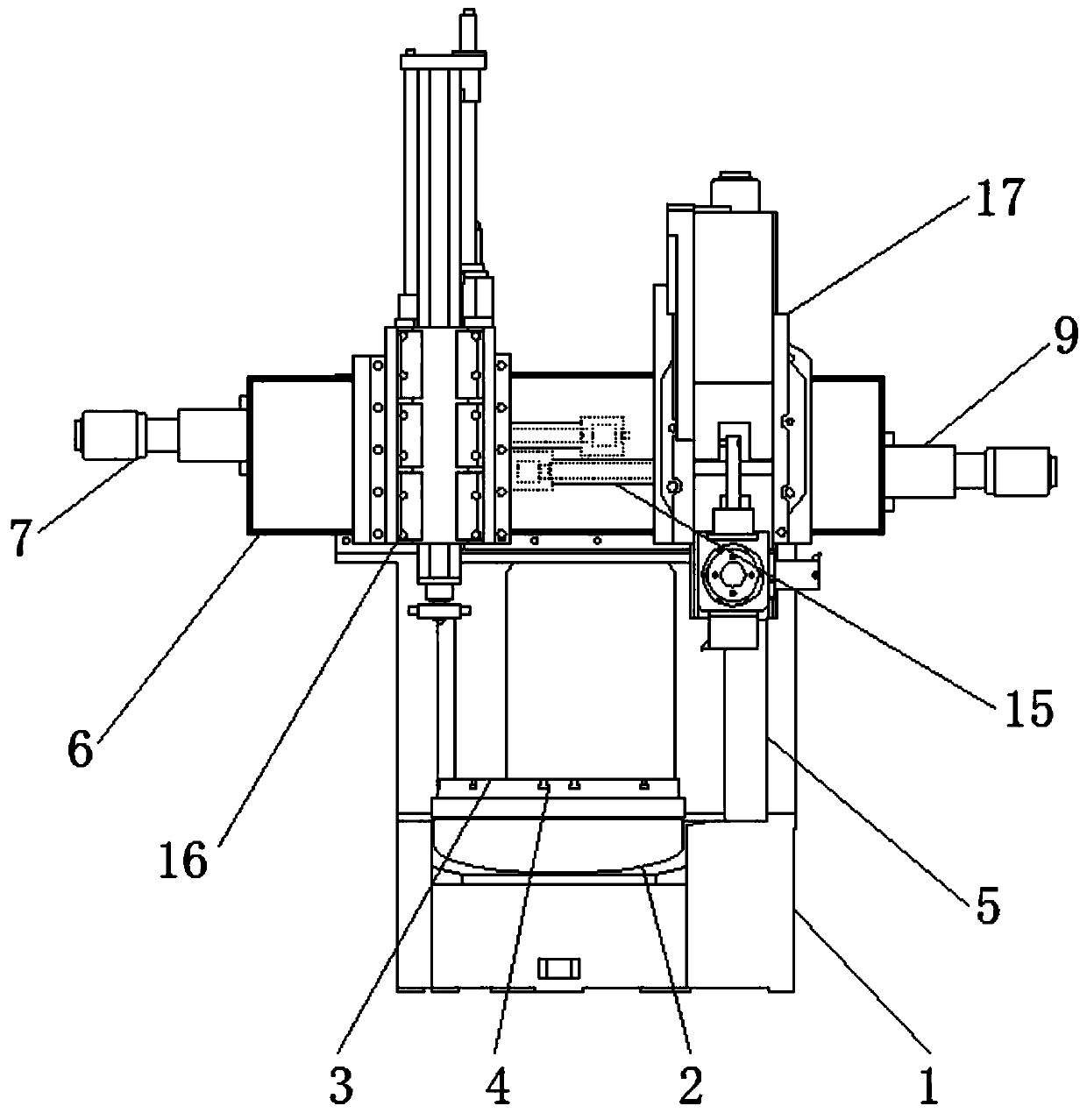

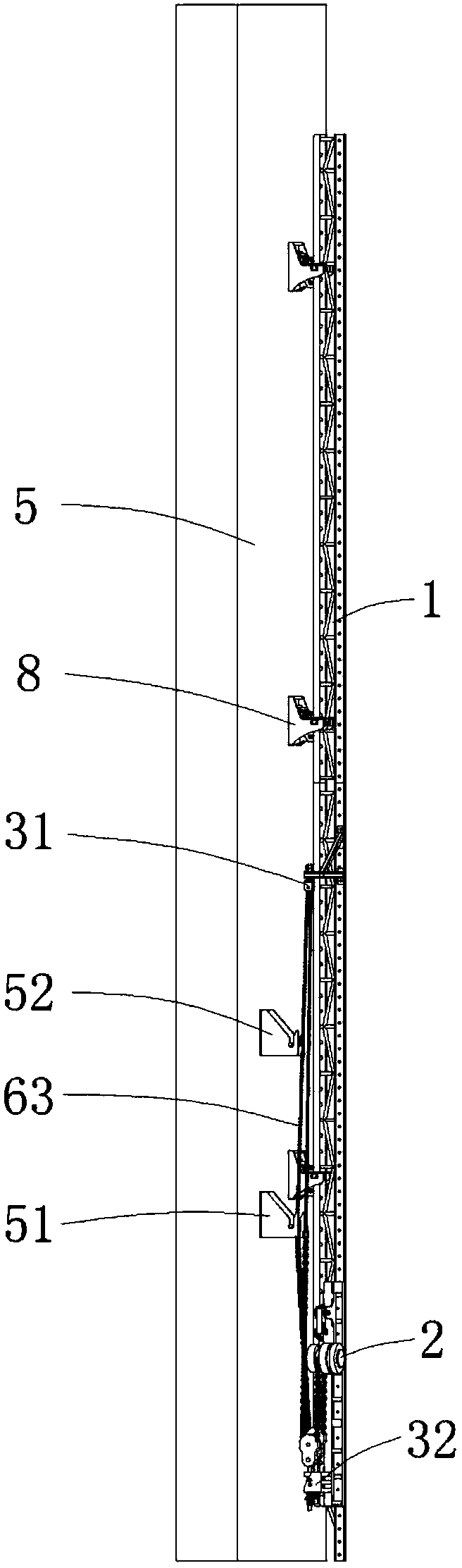

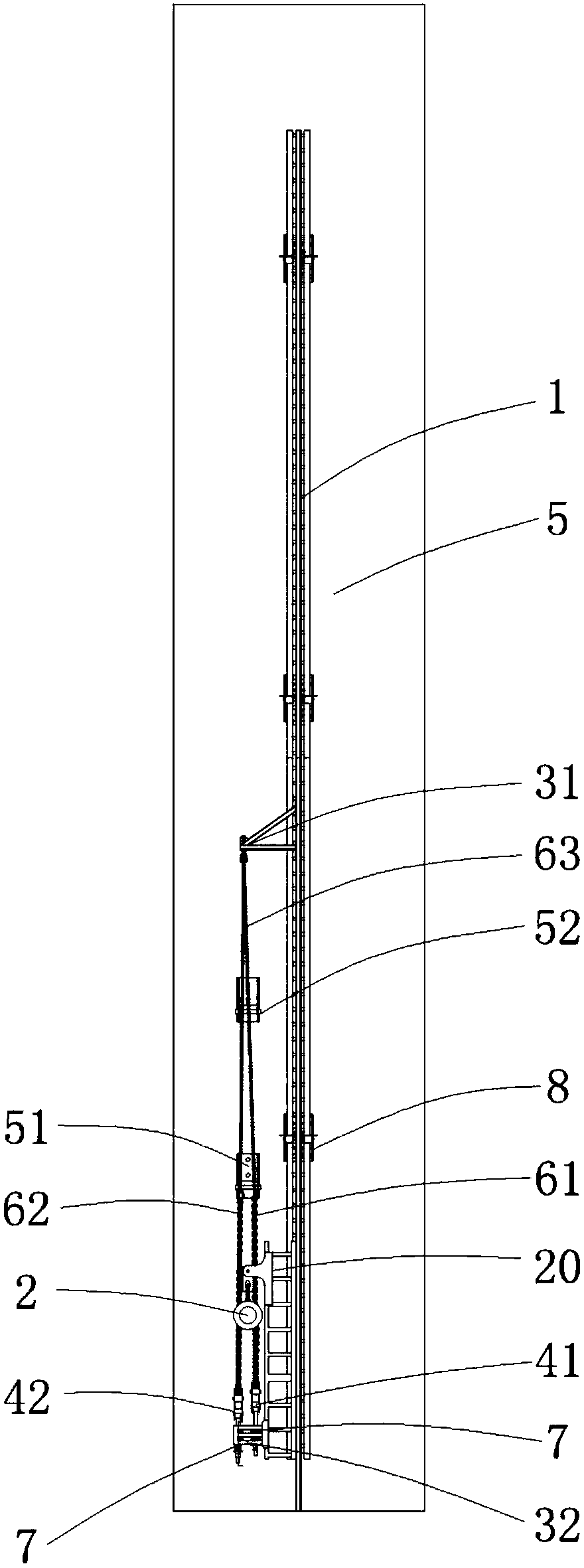

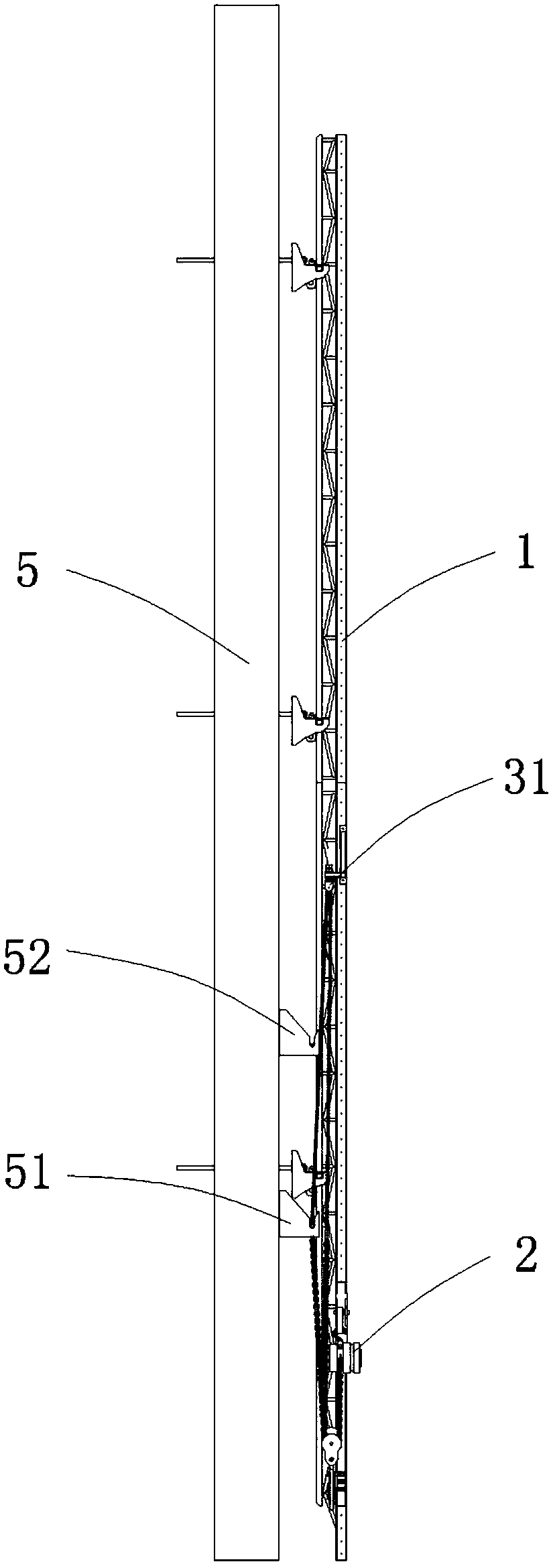

All-steel adhesion type lifting scaffolding positive and negative rotation simultaneous lifting system and method

ActiveCN108149914AConvenient preloadLifting devicesBuilding support scaffoldsClosed loopIndustrial engineering

The invention discloses an all-steel adhesion type lifting scaffolding positive and negative rotation simultaneous lifting system and method. The all-steel adhesion type lifting scaffolding positive and negative rotation simultaneous lifting system comprises a climbing frame and a lifting rope chain, and an electric hoist is fixedly installed at the lower part of the climbing frame; an upper lifting point is mounted at a high-order position of the climbing frame, and a lower lifting point is mounted at a low order of the climbing frame; a first guide wheel and a second guide wheel are arrangedon the lower lifting point, and a first wall-attaching lifting point and a second wall-attaching lifting point are separately installed on the upper and lower parts of the neutral position of a building wall; and the lifting rope chain comprises a first chain and a second chain and forms a closed loop with a guiding fine chain, and the closed loop bypasses the electric hoist, the first guide wheel, the second guide wheel, the upper lifting point and the wall-attaching lifting points in sequence. According to the all-steel adhesion type lifting scaffolding positive and negative rotation simultaneous lifting system and method, the climbing frame can be driven by the positive and negative rotation of the electric hoist to run upwards, and the lower parts of the first guide wheel and the second guide wheel are provided with a chain pre-tightening mechanism for facilitating the pre-tightening operation of the chains, thereby achieving the effects of bi-directional lifting and two-way pre-tensioning.

Owner:厦门安科科技有限公司

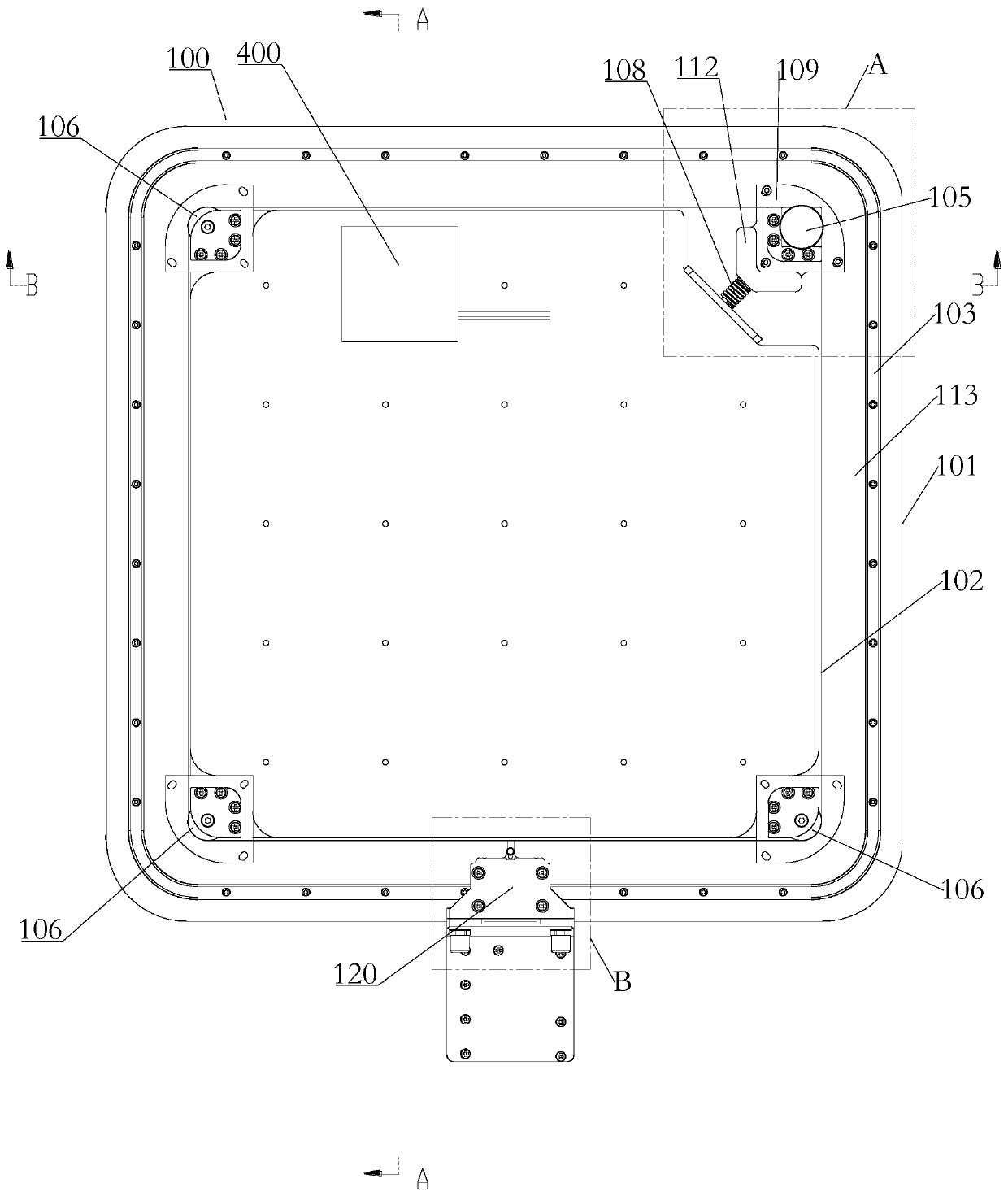

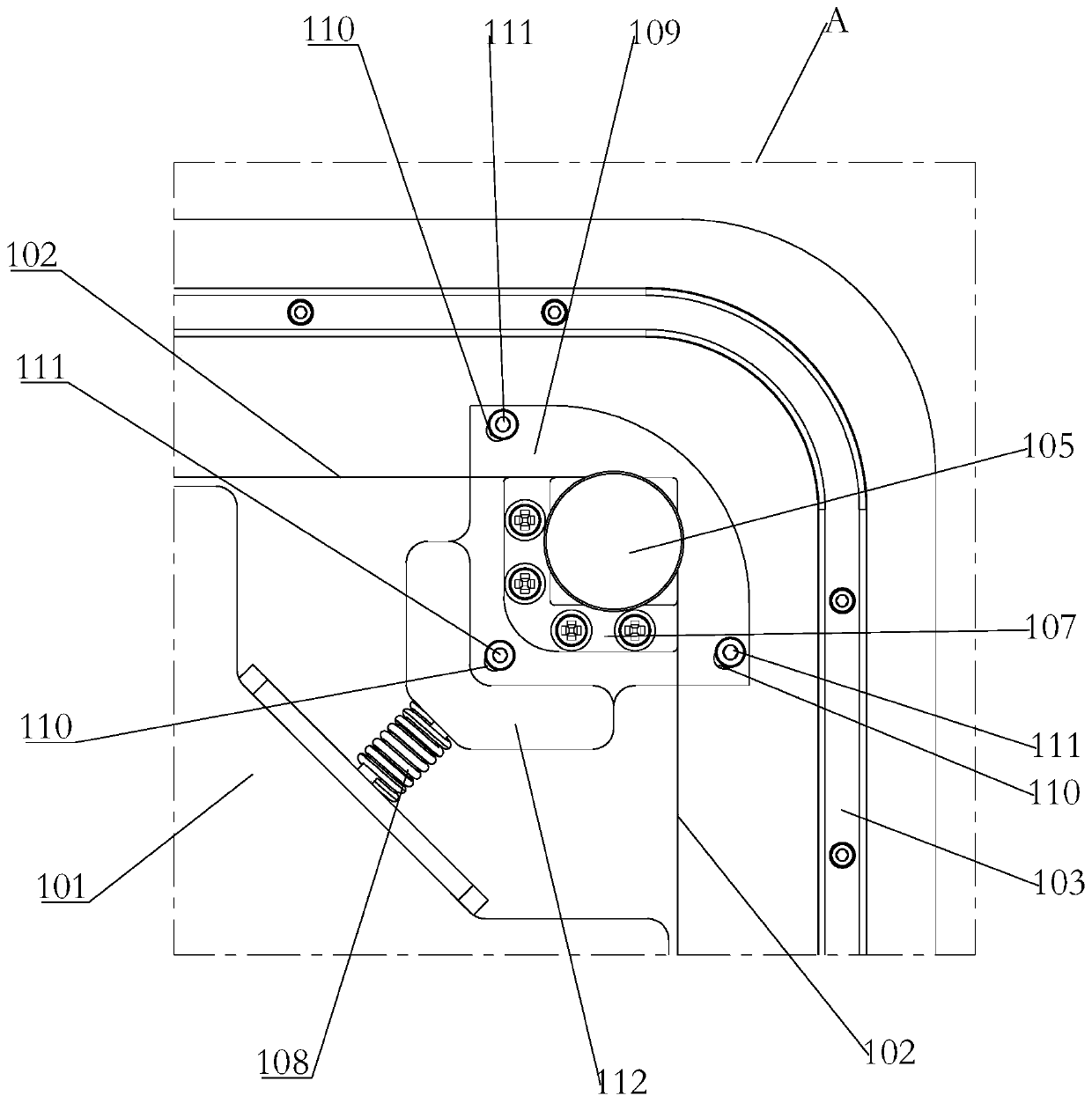

Material outboard annular inspection device with cable arrangement function

ActiveCN111114855AOrderly managementSports real-time monitoringTelevision system detailsCosmonautic vehiclesClassical mechanicsStructural engineering

The invention relates to a material outboard annular inspection device with a cable arrangement function, and the device comprises an installation platform which is provided with a steel belt drivingmechanism, wherein the peripheral side of the installation platform is provided with an annular groove for accommodating a cable; an annular steel belt which is driven by the steel belt driving mechanism to do annular motion around the peripheral side of the mounting platform; an annular guide rail which is annularly arranged around the installation platform; a bearing sliding block which is usedfor bearing an annular inspection mechanism, is connected to the annular steel belt and is arranged on the annular guide rail in a sliding manner; and a cable telescopic device which is mounted on theinstallation platform, wherein a cable of the annular inspection mechanism is arranged along the annular groove and is connected with the cable telescopic device. The steel belt driving mechanism drives the annular steel belt to move in an annular mode and drives the annular inspection mechanism on the steel belt driving mechanism to perform annular inspection, and a cable on the annular inspection mechanism achieve synchronous take-up and pay-off under the action of the cable telescopic device. According to the invention, the cable telescopic device can follow the movement position of the annular inspection mechanism to release or withdraw the cable.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

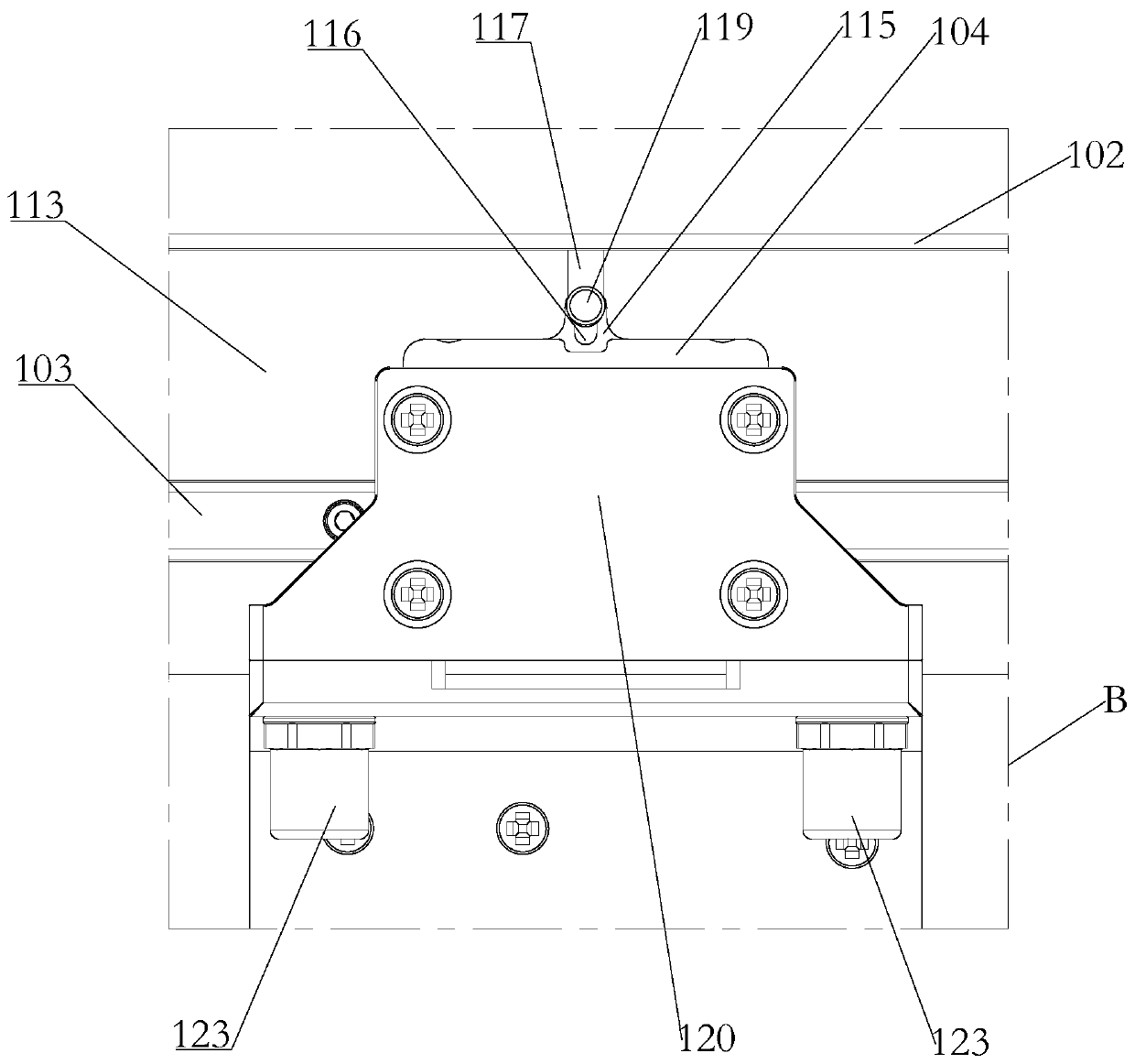

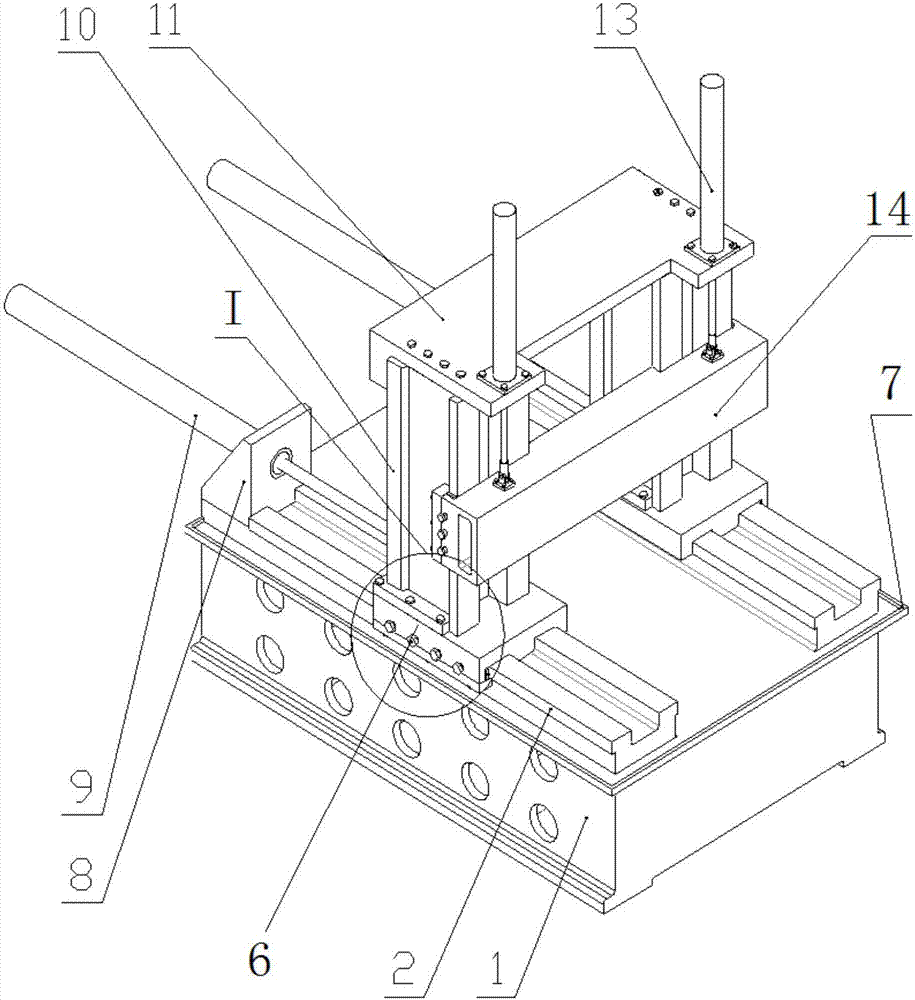

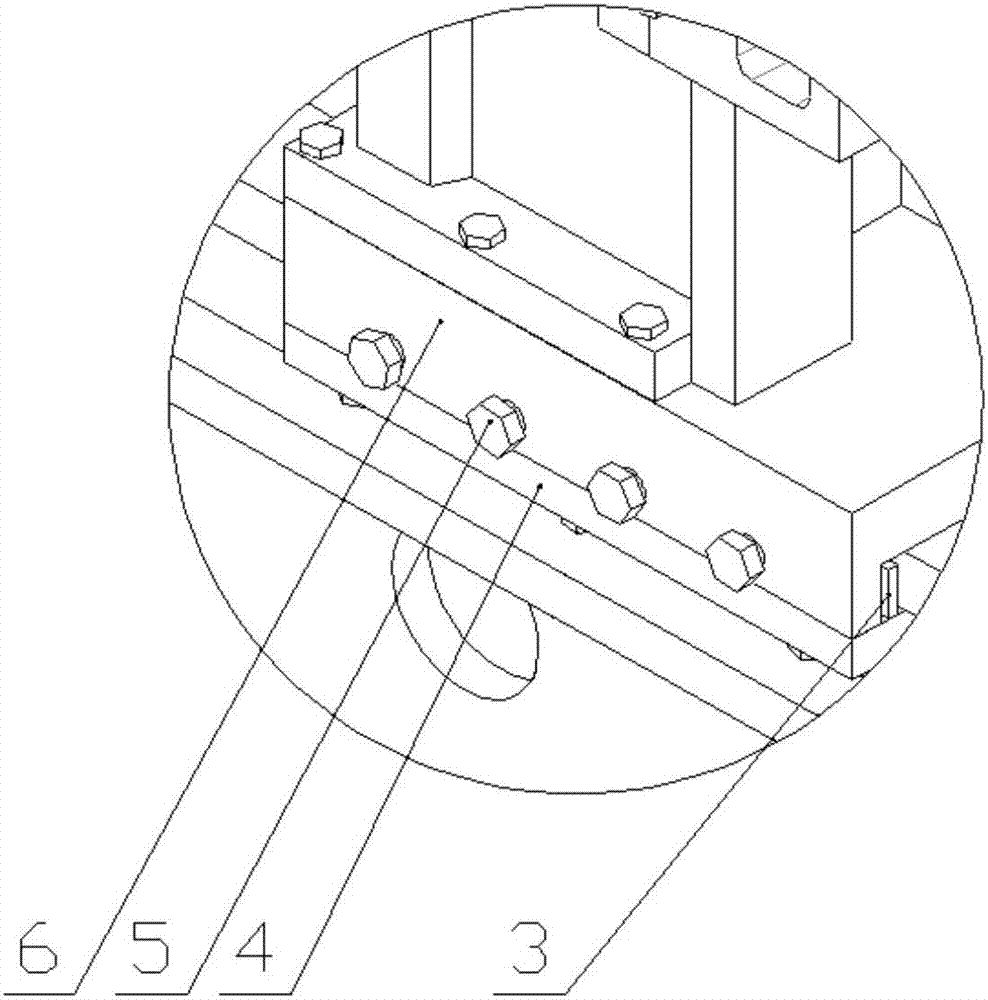

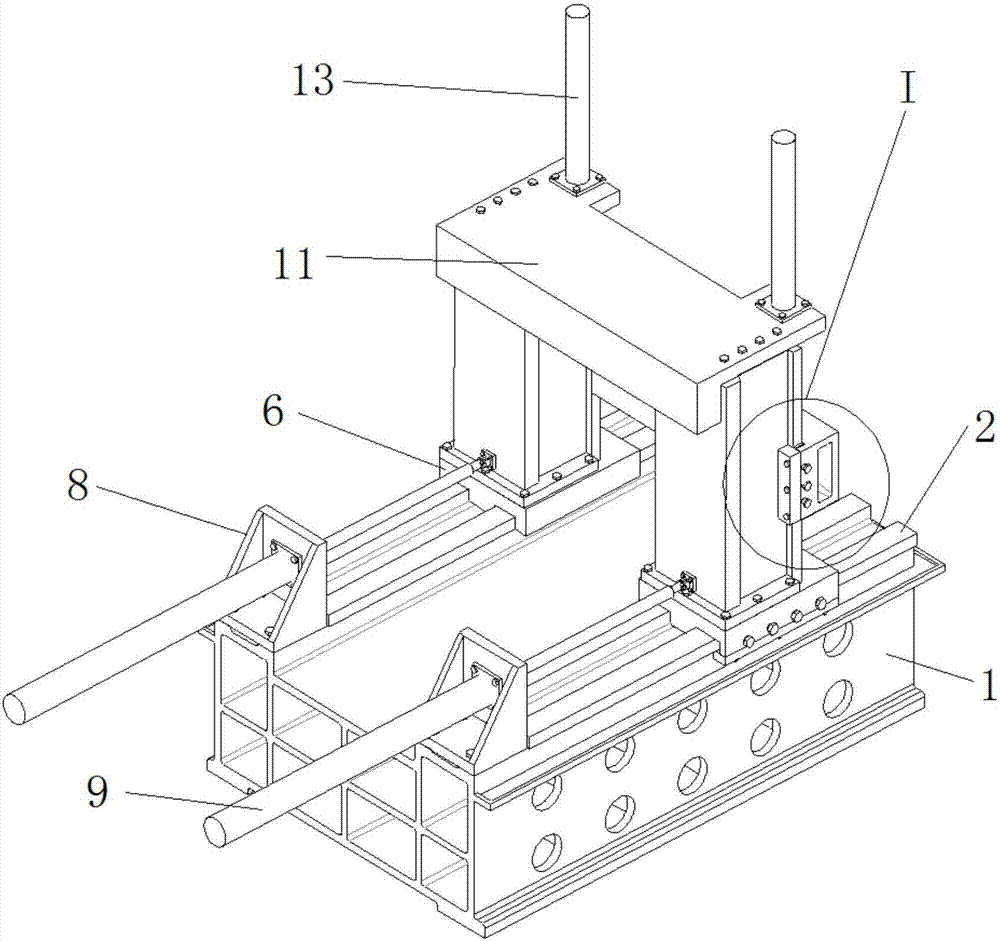

Assembling stress testing platform for structural member of heavy type machine tool

The invention discloses an assembling stress testing platform for a structural member of a heavy type machine tool. The testing platform is characterized by comprising a pedestal, horizontal guide rails, slide blocks, rear supports, horizontal hydraulic cylinders, columns, a balancing connection plate, vertical hydraulic cylinders and a movable crossbeam. The testing platform can test influence on assembling stress and precision when two drivers of the heavy type machine tool are asynchronous, influence of deadweight of the movable crossbeam of the heavy time machine tool on the assembling stress, and influence of parallelism and flatness errors of the guide rails on the assembling stress and precision; and testing results can provide bases for optimizing assembling of the guide rails, optimizing pretightening forces of the slide blocks and optimizing the parallelism of the guide rails of the heavy type machine tool.

Owner:TIANJIN POLYTECHNIC UNIV

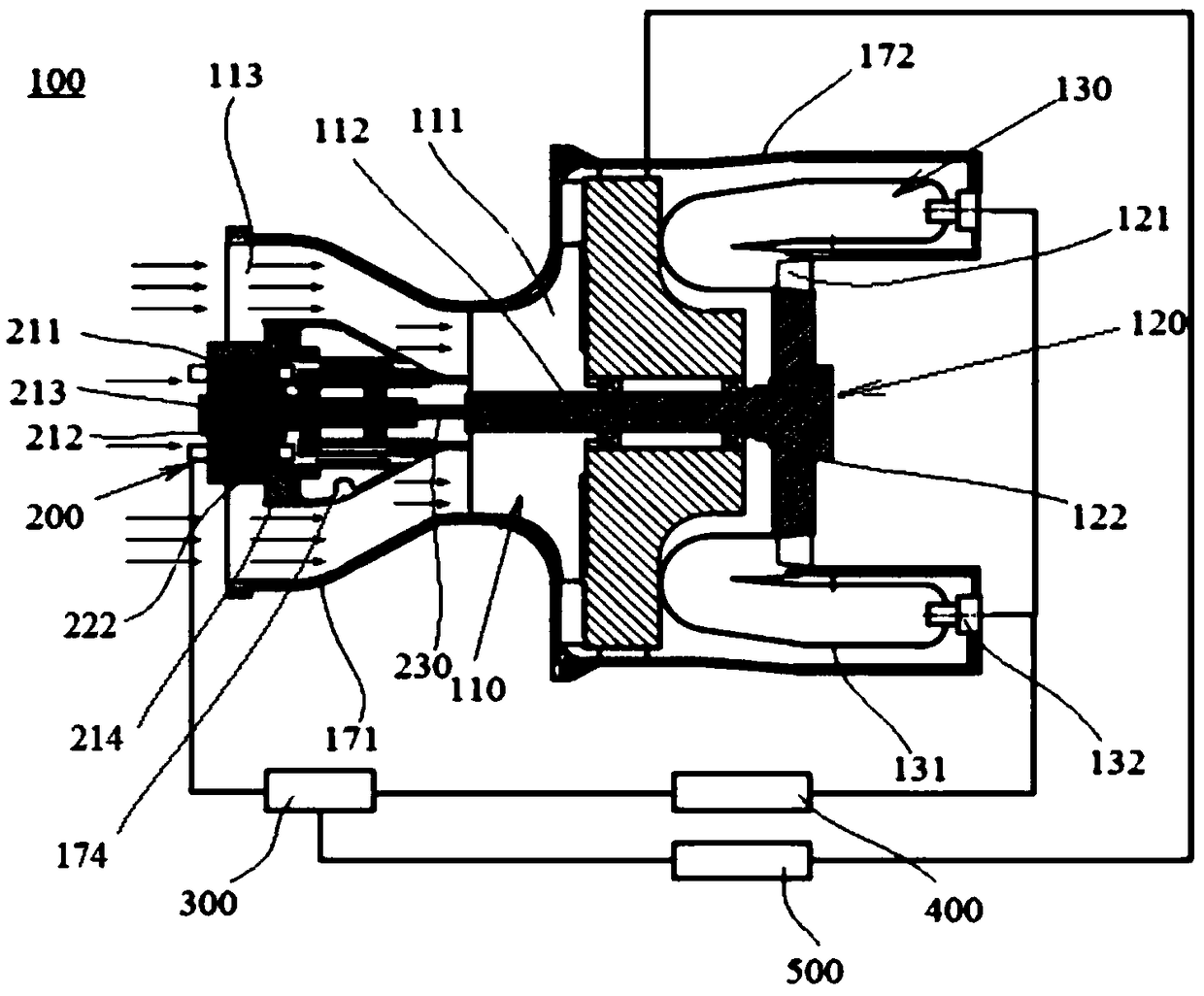

Bearing testing machine with adjustable pre-tightening force

Owner:HUAZHONG UNIV OF SCI & TECH

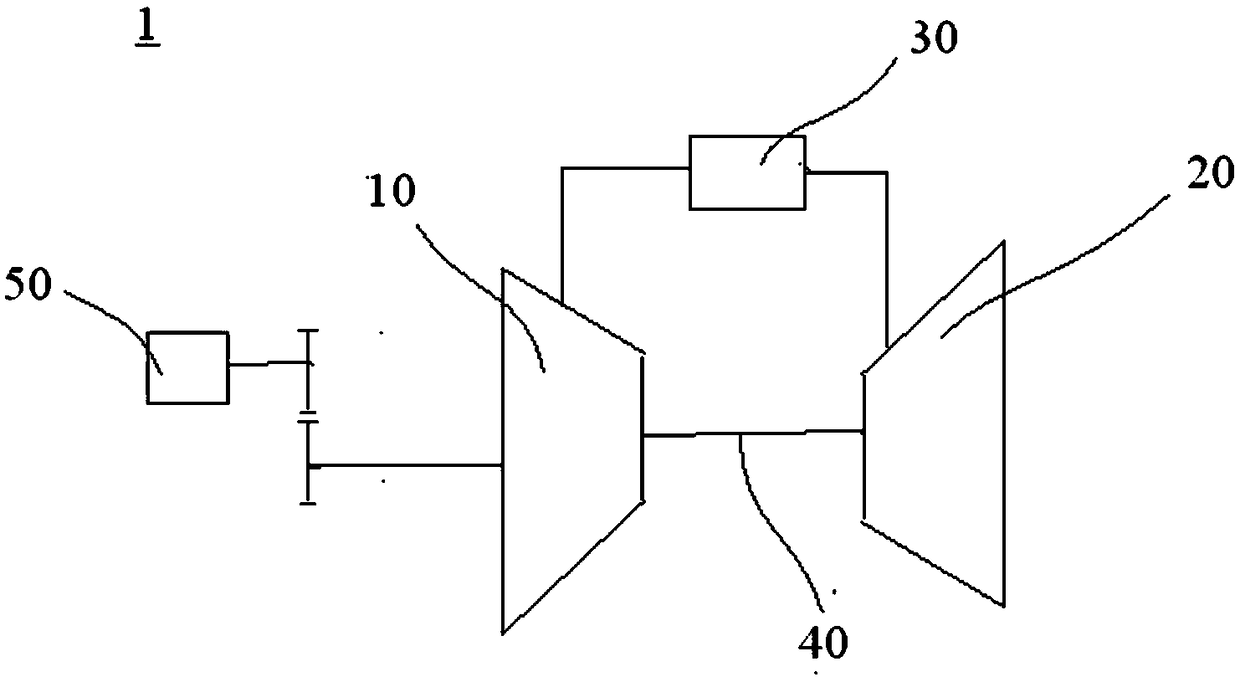

Motor and gas turbine including same

PendingCN108964305AImprove operational safetyReduced sealing costsMagnetic circuit rotating partsGas turbine plantsMotor shaftStator

Owner:潍坊云深机械科技有限公司

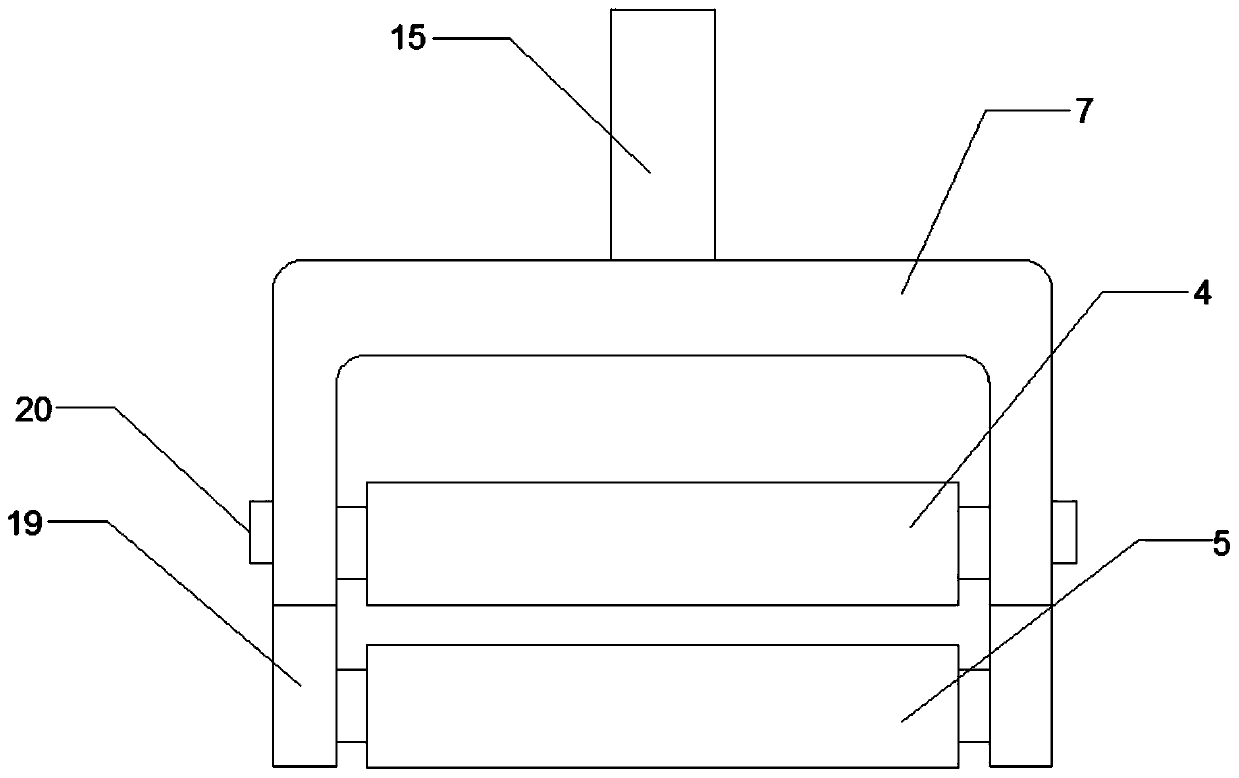

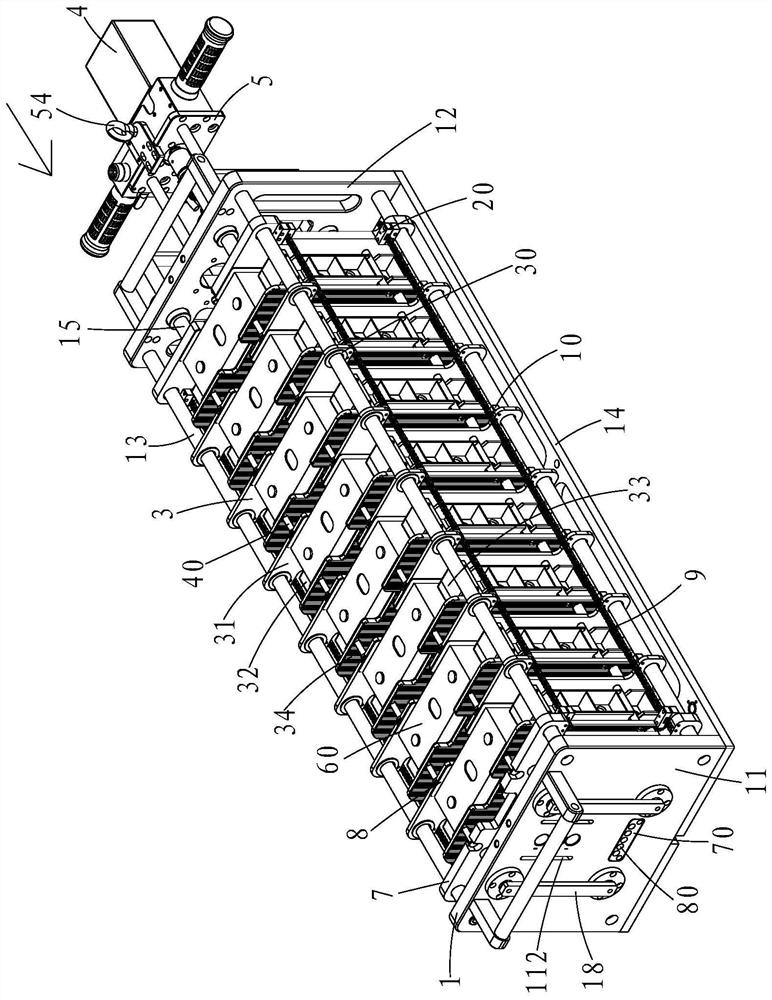

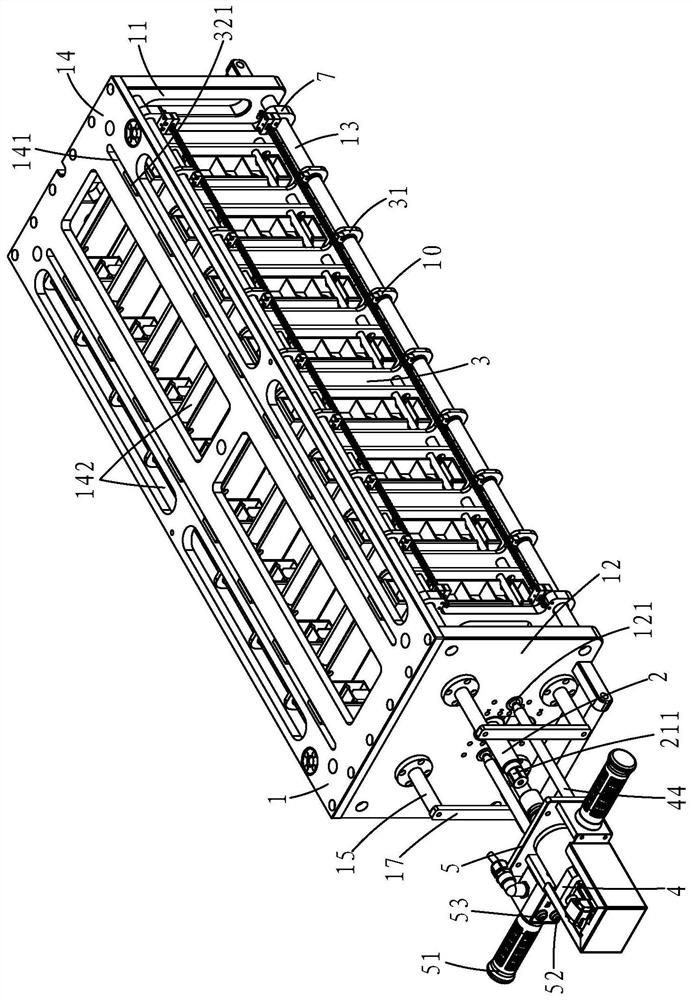

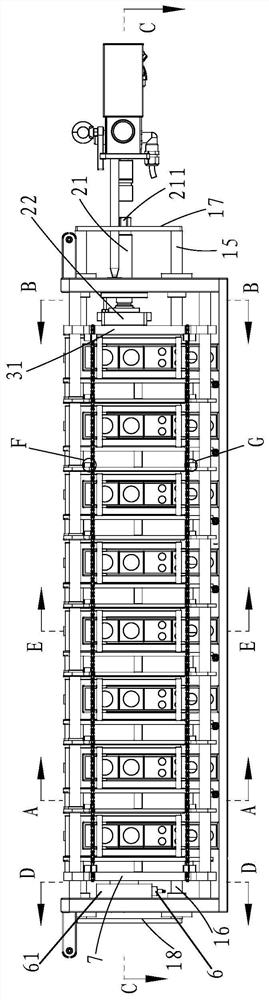

Clamp type pressurizing device for formation and capacity grading ofsquare battery cell

PendingCN112993424AAdjust the pressure in timeA pressure detection device for detecting the pressure on the tray and adjusting it in timeElectrical testingSecondary cells charging/dischargingEngineeringBattery cell

The invention provides a clamp type pressurizing device for formation and capacity grading of a square battery cell. The clamp type pressurizing device comprises a clamp type tray, a support frame, a pressurizing connecting mechanism and a plurality of trays, the plurality of trays are movably connected to the support frame, and the plurality of trays are connected together to realize linkage; the pressurizing connecting mechanism is connected to one of the trays; the pressurizing device comprises a driving device and a fixed seat; the driving device is fixedly connected to the fixed seat; the output end of the driving device is detachably connected to the pressurizing connecting mechanism; and the pressure detection device is used for detecting the pressure borne by the tray. The tray is pressurized through the pressurizing device, the pressure on the tray is detected through the pressure detection device, and the pressure applied by the pressurizing device can be adjusted in time, so that the applied pre-tightening force is more uniform, more stable and optimal.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com