Bearing device for wheel

A technology for bearing devices and wheels, which is applied in bearing assembly, bearing components, shafts and bearings, etc., can solve the problems of not developing bearing devices, and achieve the effects of improving fuel consumption and suppressing inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

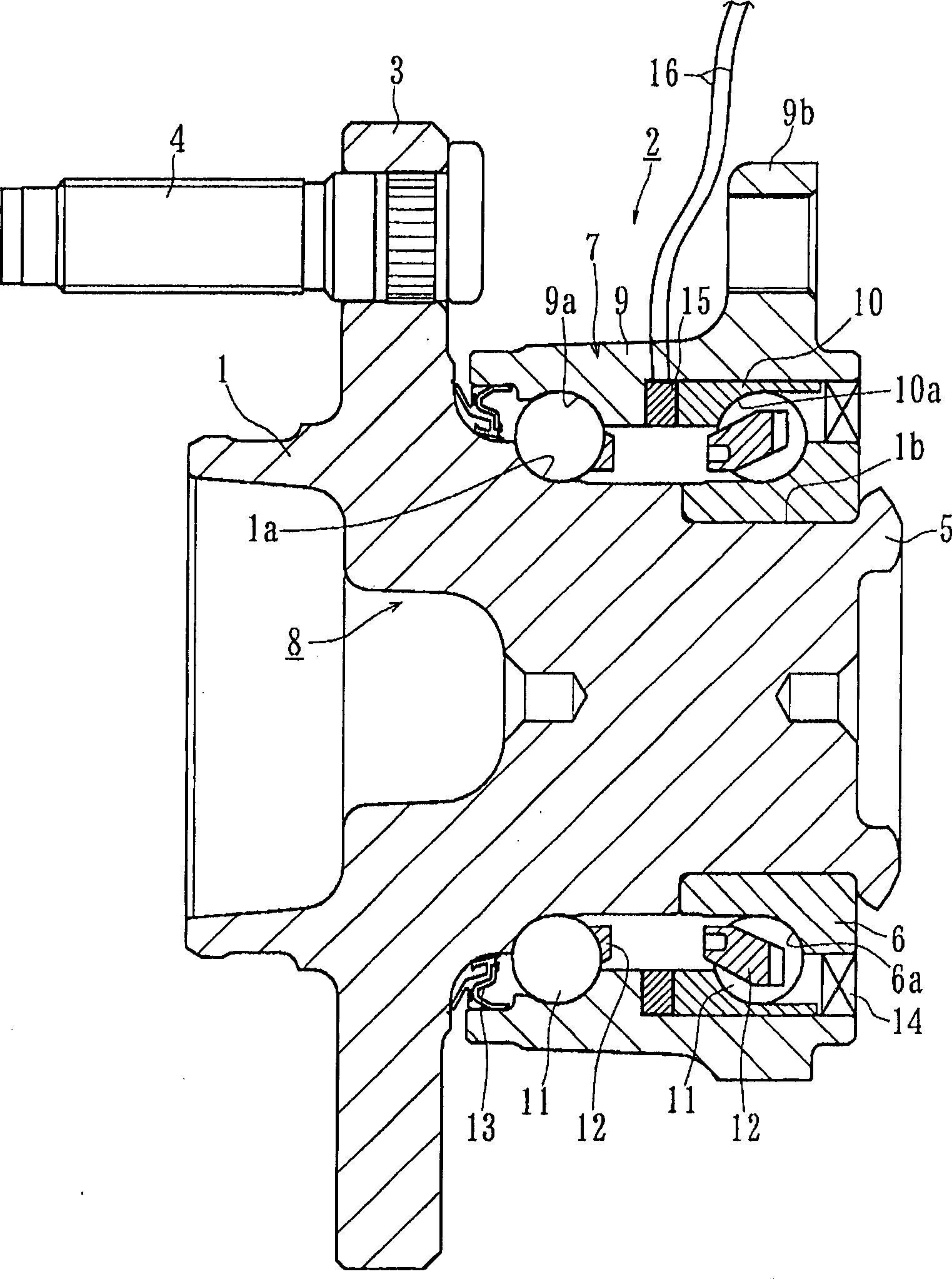

[0041] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 A first embodiment of the bearing device for a wheel of the present invention is shown.

[0042] The bearing device for a wheel is used for a driven wheel, and includes a wheel hub 1 and a double row rolling bearing 2 . In the following description, the term "outside" of the device (left-hand side in the figure) refers to the side that is located outside the vehicle body when the bearing device is installed on the vehicle body, while the term "inside" of the device (inside the The right-hand side in ) refers to the side that is located inside the vehicle body when the bearing unit is installed on the vehicle body.

[0043] The wheel hub 1 is integrally formed with: a wheel mounting flange 3 at one end on the outer side; an outer side inner raceway surface 1a of a double row rolling bearing 2 on its outer peripheral surface; and a column axially ...

no. 2 example

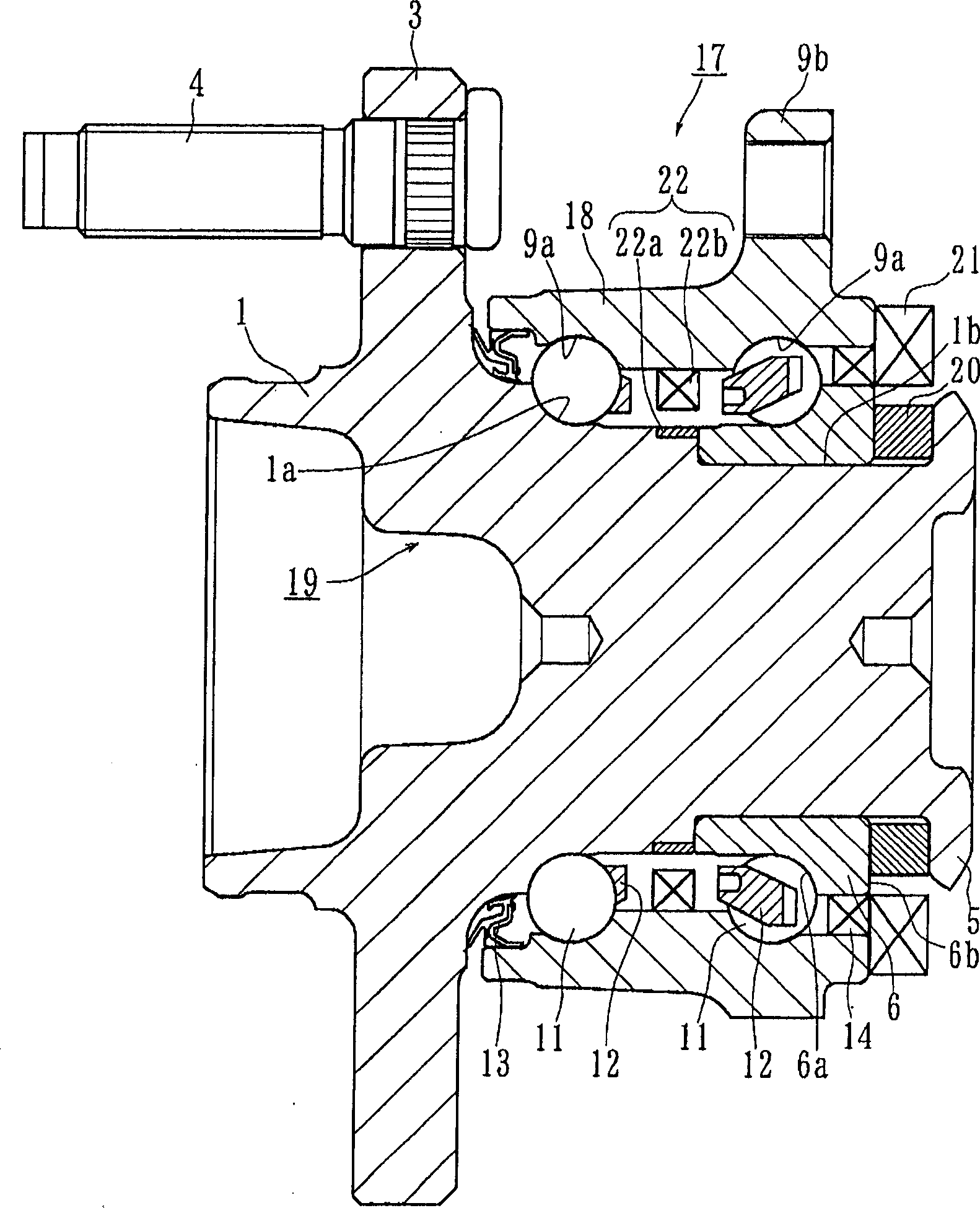

[0048] figure 2 It is a longitudinal sectional view showing a second embodiment of the bearing device for a wheel according to the present invention. In this embodiment, the same reference numerals are used to denote the same components having the same functions as those used in the first embodiment.

[0049] This bearing arrangement for a wheel comprises a wheel hub 1 and a double row rolling bearing 17 comprising an outer part 18 , an inner part 19 and double row rolling elements 11 and 11 . The outer member 18 is integrally formed on its outer peripheral surface with a main body mounting flange 9b for mounting the bearing device on a vehicle body (not shown), and on its inner peripheral surface is formed with a double-row outer raceway surface 9a and 9a.

[0050] A separate inner ring 6 is press-fitted on the axially extending portion 1b of the wheel hub 1 and fixed thereto by means of the caulked portion 5 . Double-row rolling elements 11 and 11 are accommodated betwee...

no. 3 example

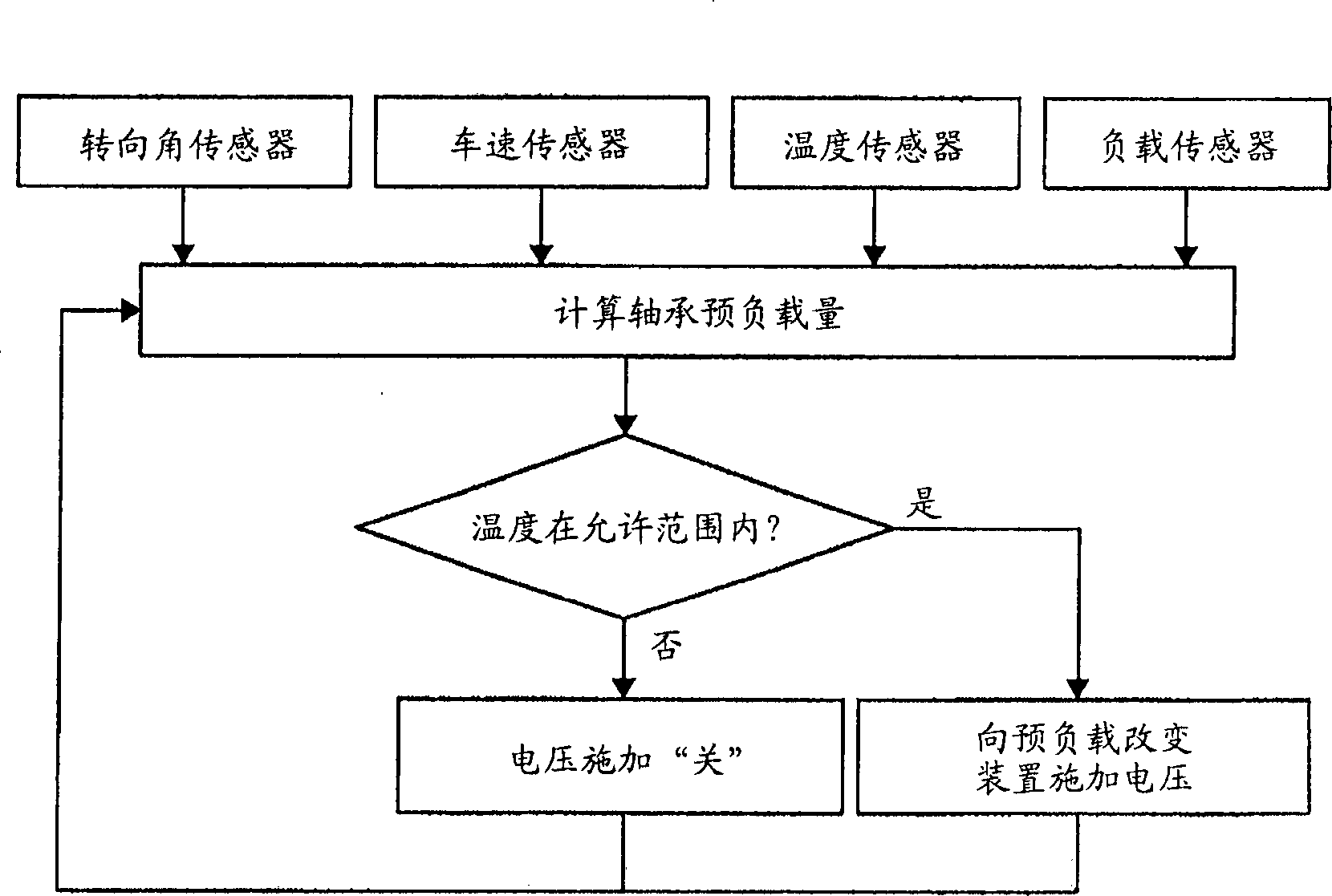

[0056] Figure 4 It is a longitudinal sectional view showing a third embodiment of the bearing device for a wheel according to the present invention. In this embodiment, the same reference numerals are used to denote the same components having the same function as those used in the second embodiment, since this embodiment differs from the second embodiment only in its preload application structure.

[0057] This bearing arrangement for a wheel comprises a hub wheel 23 and a double row rolling bearing 24 , and this double row rolling bearing 24 comprises an outer part 18 , an inner part 25 and double row rolling elements 11 and 11 . The outer member 18 is integrally formed on its outer peripheral surface with a main body mounting flange 9b for mounting the bearing device on a vehicle body (not shown), and on its inner peripheral surface is formed with a double-row outer raceway surface 9a and 9a. A separate inner ring 6 is press-fitted on the axially extending portion 1 b of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com