Filter for filtering fluids, filter bowl and filter head

A filter cover and filter technology, which is applied in the direction of fixed filter element filter, membrane filter, filter separation, etc., can solve problems such as damage and operation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

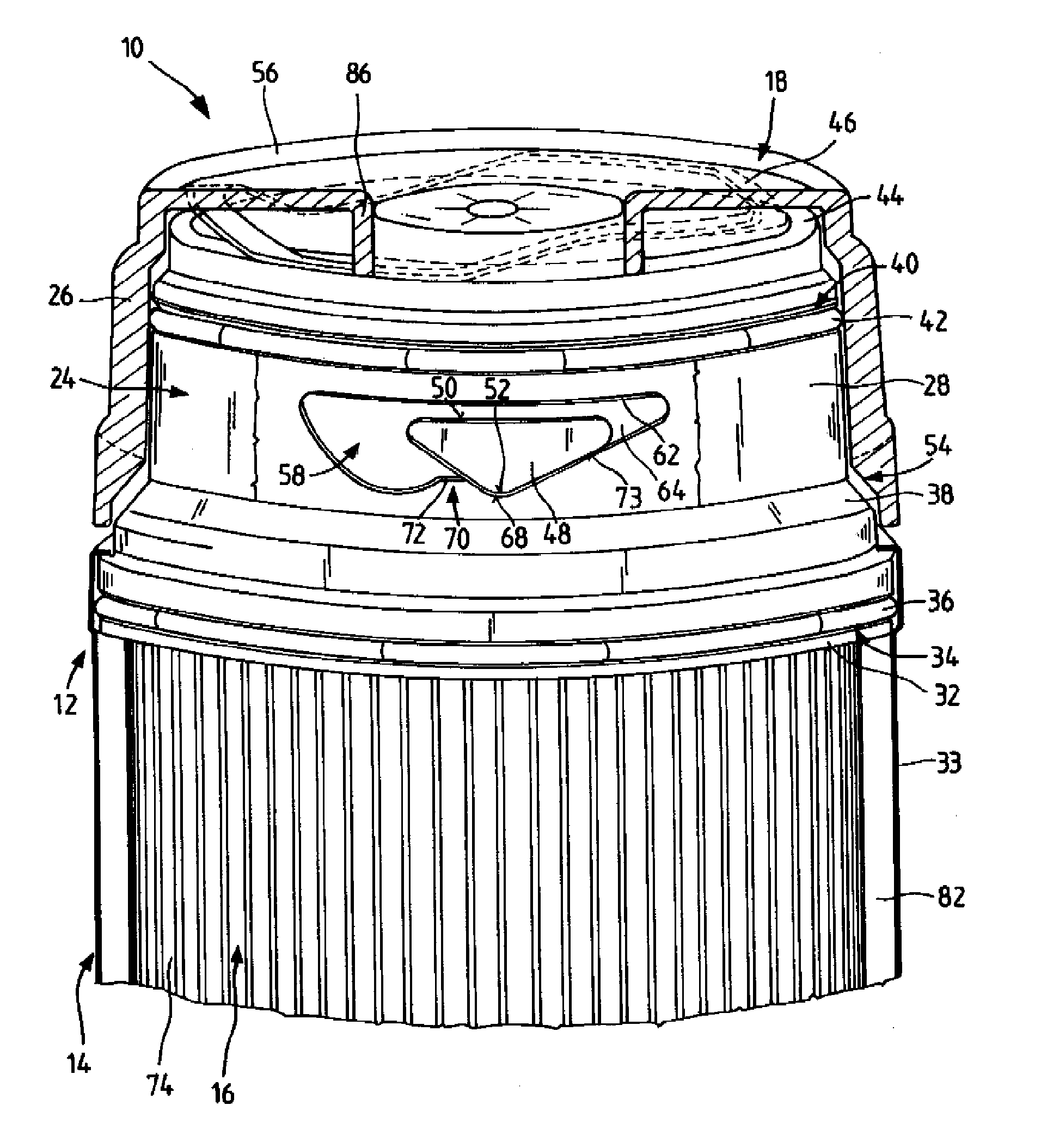

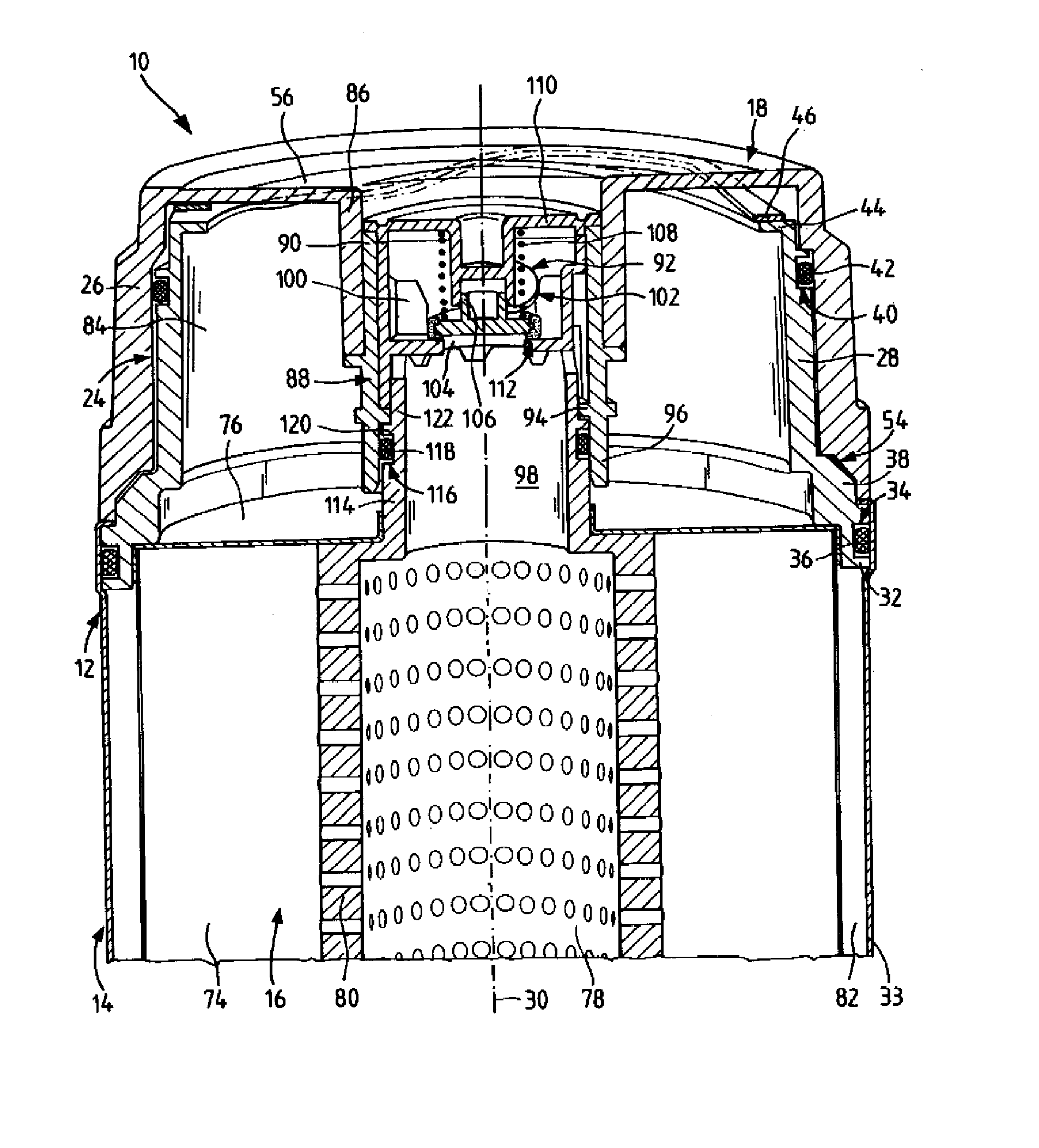

[0030] 1 to 9 show sections of a liquid filter 10 for filtering liquids, for example fuel or oil of an internal combustion engine of a motor vehicle (not shown otherwise), in various assembly stages.

[0031] The liquid filter 10 comprises a filter housing 12 assembled from a cylindrical filter bowl 14 in which a round filter element 16 is arranged and a filter cover 18 .

[0032] The filter cover 18 has an inlet 20 for the liquid to be filtered and an outlet 22 for the filtered liquid. Inlet 20 and outlet 22 are only indicated in FIG. 2 for better clarity. The filter cover 18 is connected in a manner not of further interest here via an outlet 22 and an inlet 20 to the not shown fluid system of the internal combustion engine.

[0033] The filter bowl 14 is connected to the filter cover 18 from below by means of a releasable bayonet-like swivel / socket connection 24 .

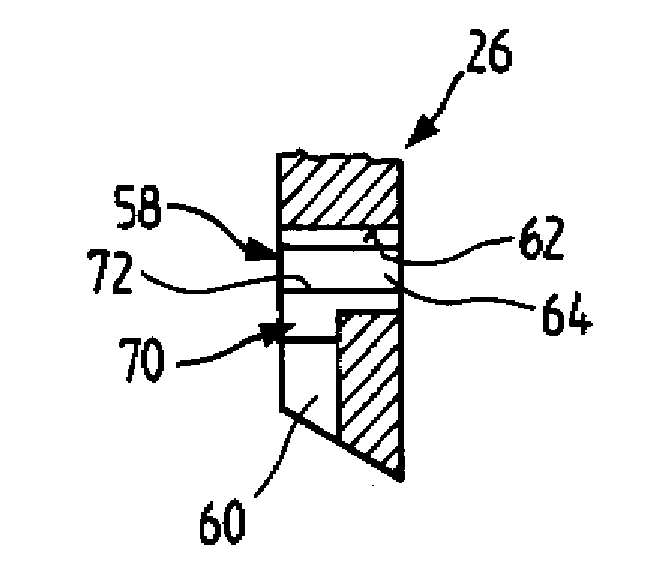

[0034] On the filter cover 18 , the swivel / plug connection 24 has a post holder 26 into which a coaxial coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com