Assembling stress testing platform for structural member of heavy type machine tool

A test platform, assembly stress technology, applied in the testing of machine/structural components, testing of mechanical components, measuring devices, etc., can solve problems such as the dynamic stiffness of unsimulated guide rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

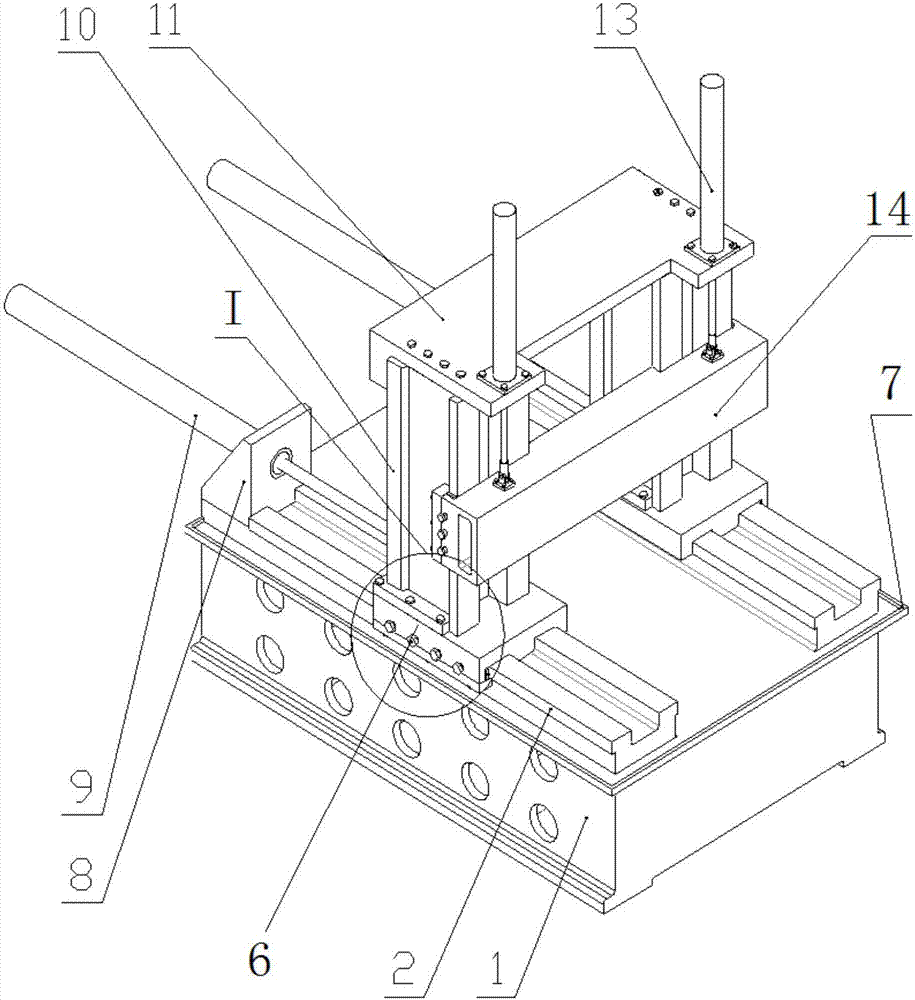

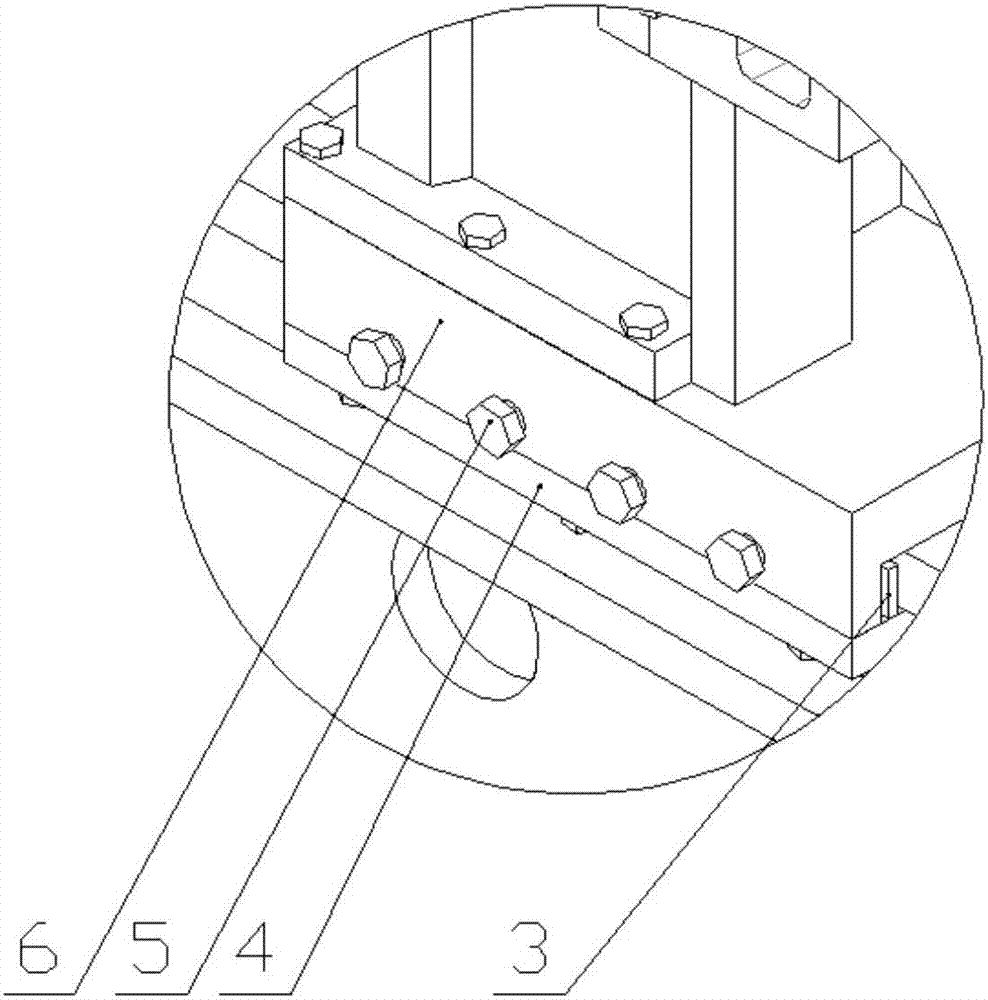

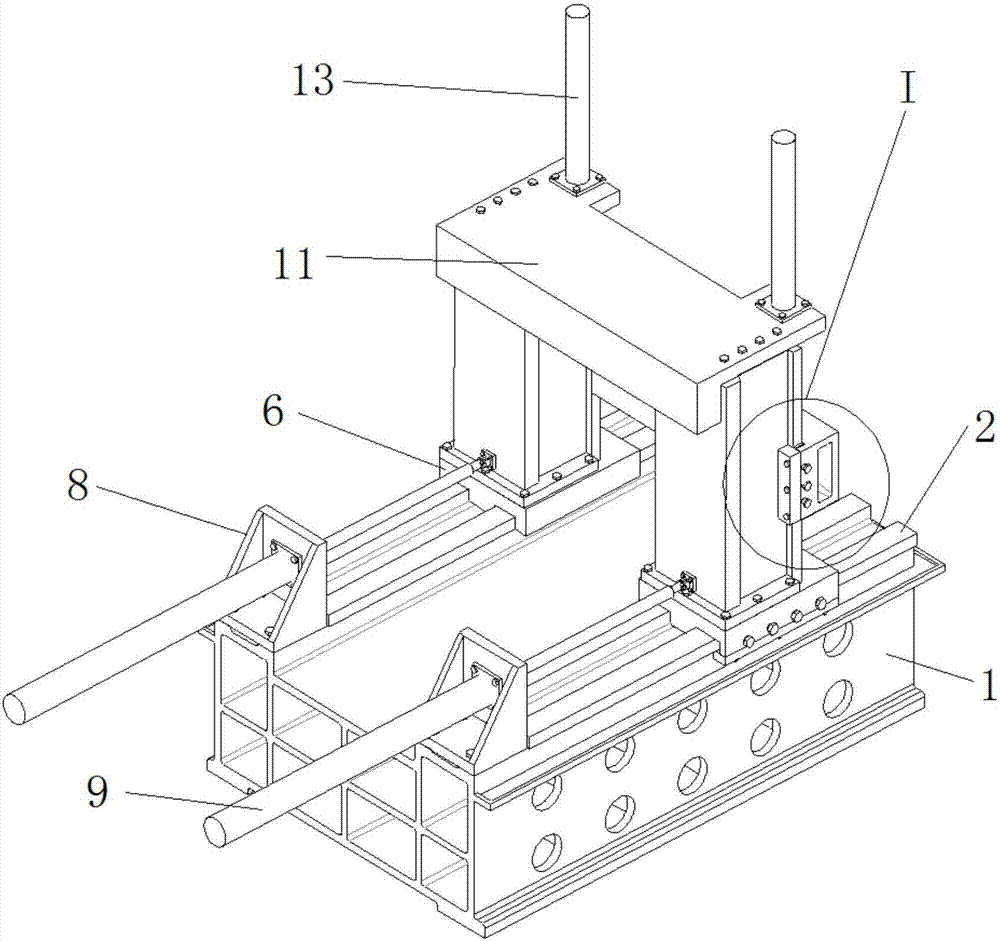

[0024] The invention provides a test platform for stress testing of the assembly stress of heavy machine tool structural parts (referred to as the test platform, see Figure 1-10 ), including base 1, horizontal guide rail 2, slide block 6, rear support 8, horizontal hydraulic cylinder 9, column 10, balance connecting plate 11, vertical hydraulic cylinder 13 and movable beam 14; described horizontal guide rail 2, slide block 6 , rear bracket 8, horizontal hydraulic cylinder 9, column 10 and vertical hydraulic cylinder 13 are two; two horizontal guide rails 2 are symmetrically arranged on the base 1; two sliders 6 are respectively installed on the respective horizontal guide rails 2 , there is a gap between the side contact surface of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com