Material outboard annular inspection device with cable arrangement function

An outer ring and cable technology, which is applied in the field of material outer ring inspection devices, can solve the problems of real-time monitoring of the surface morphology of materials that cannot be exposed, affect the smooth progress of exposure experiments, and affect the normal progress of on-orbit inspections, so as to prevent interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not used to limit the scope of the present invention.

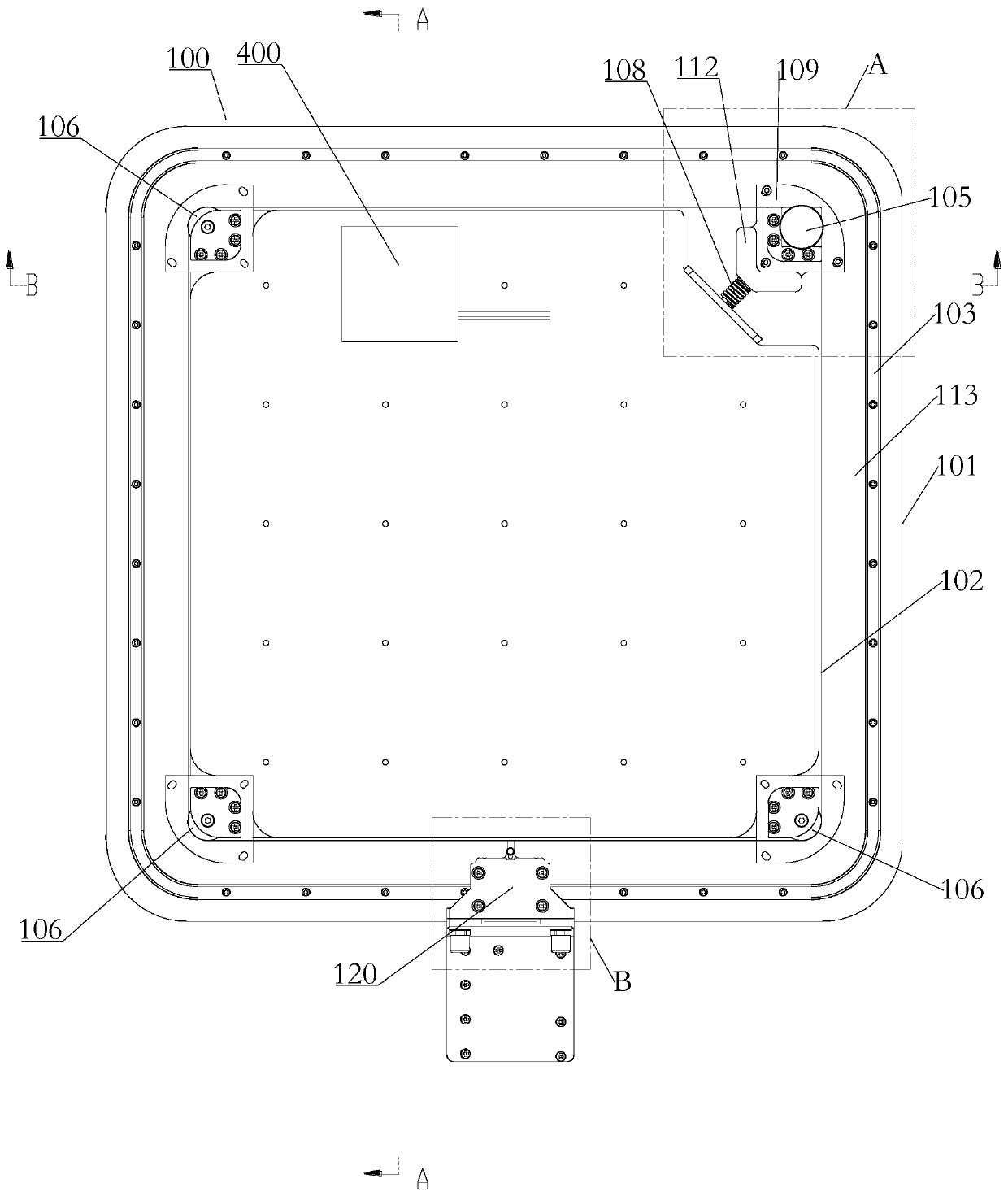

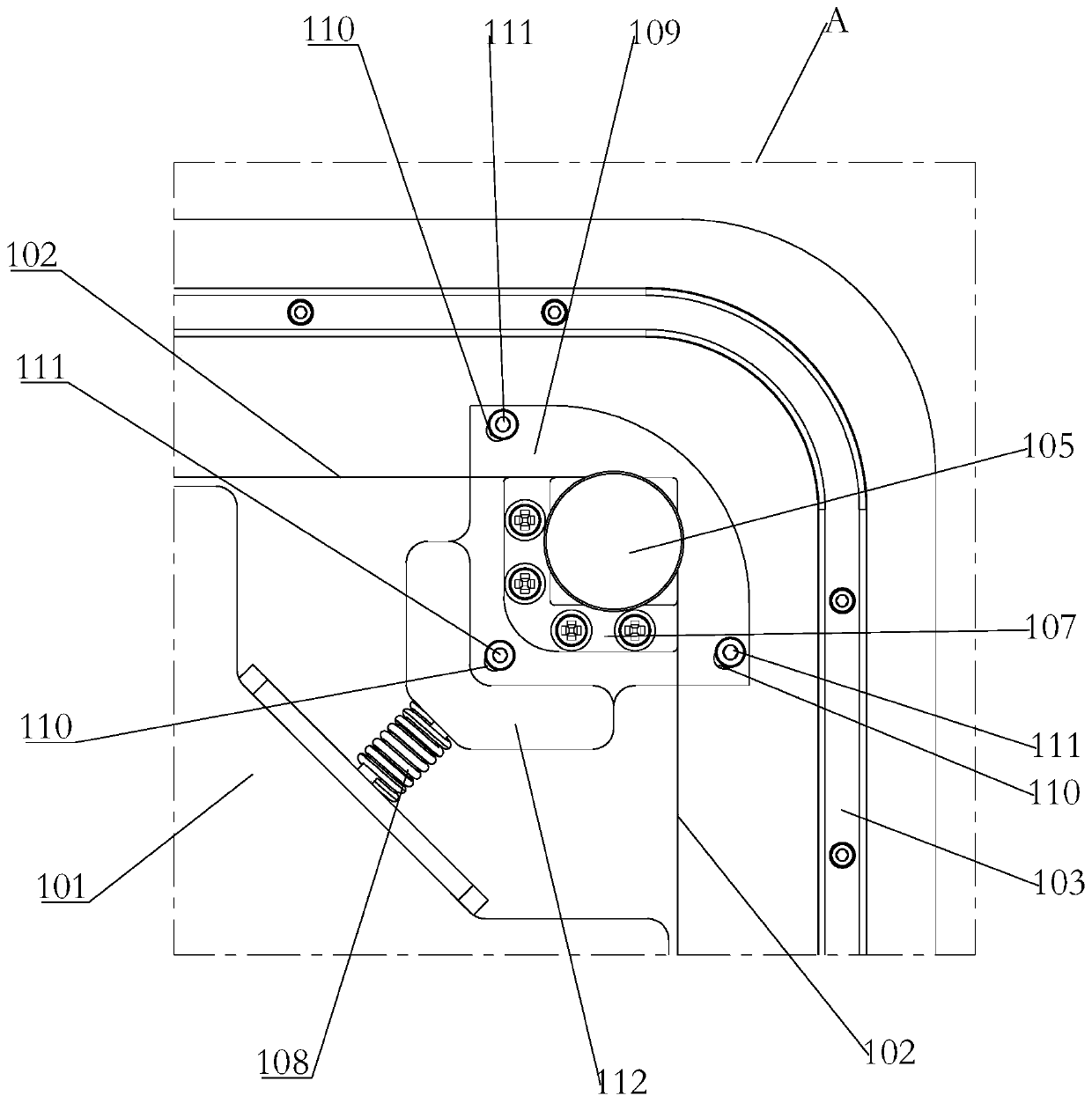

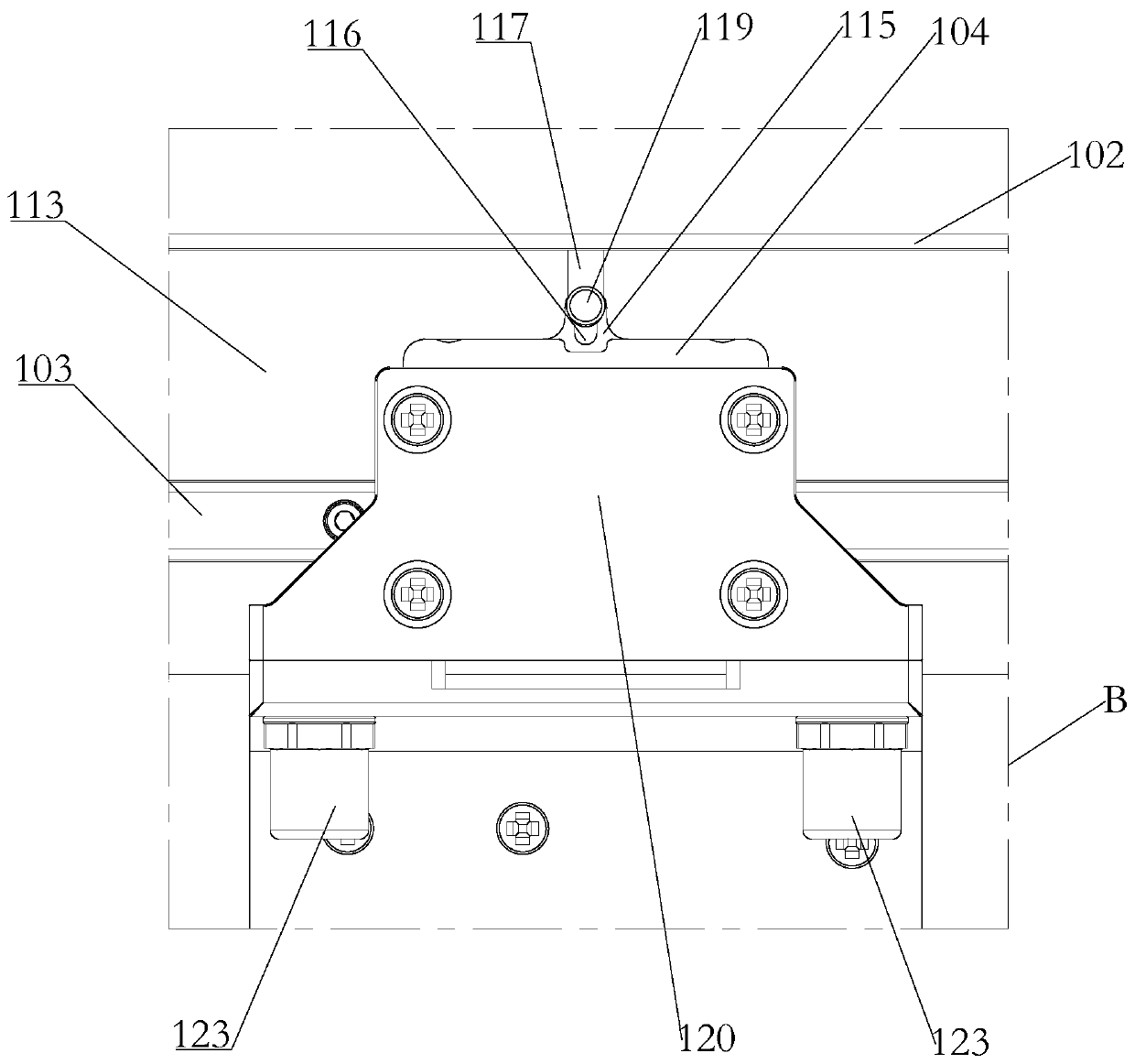

[0091] like Figure 1-Figure 11 As shown, a circular inspection device for materials outside the cabin with a cable finishing function in this embodiment includes:

[0092] The installation platform 101 is provided with a steel belt driving mechanism, and the peripheral side of the installation platform is provided with an annular groove 125 for accommodating cables 406;

[0093] The endless steel belt 102 is arranged around the installation platform 101 and moves in a circular motion around the installation platform 10 under the drive of the steel belt driving mechanism;

[0094] The ring guide rail 103 is arranged around the installation platform 101 and is located on the outer peripheral side of the ring steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com