Dental implant of composite structure and manufacturing method of same

A technology for dental implants and composite structures, which is used in implants, dentistry, prosthetics, etc., can solve problems such as insufficient initial stability, achieve good initial stability, enhance initial stability, and eliminate the need for surface treatment procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

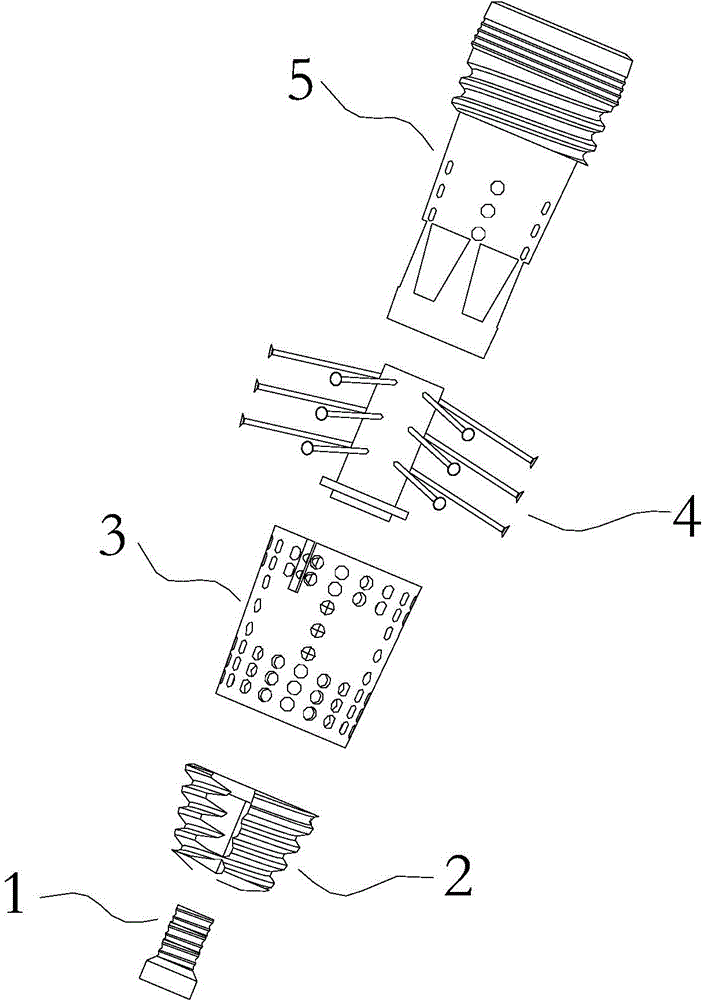

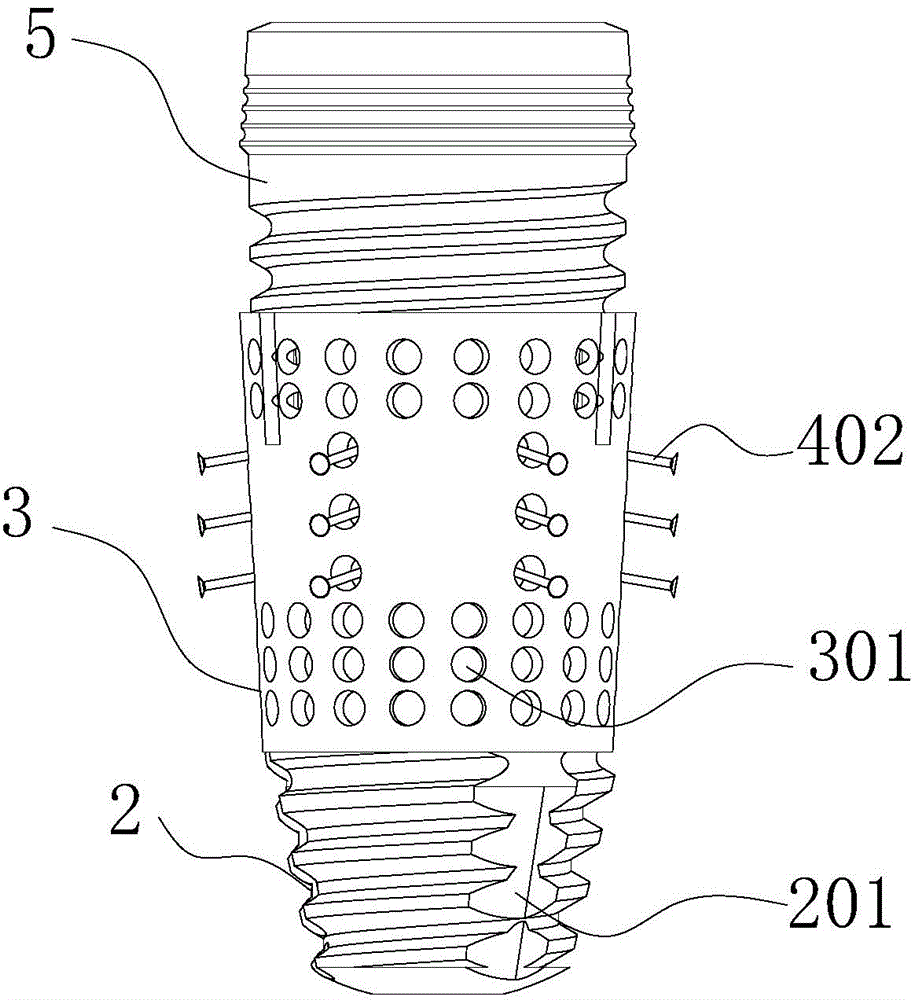

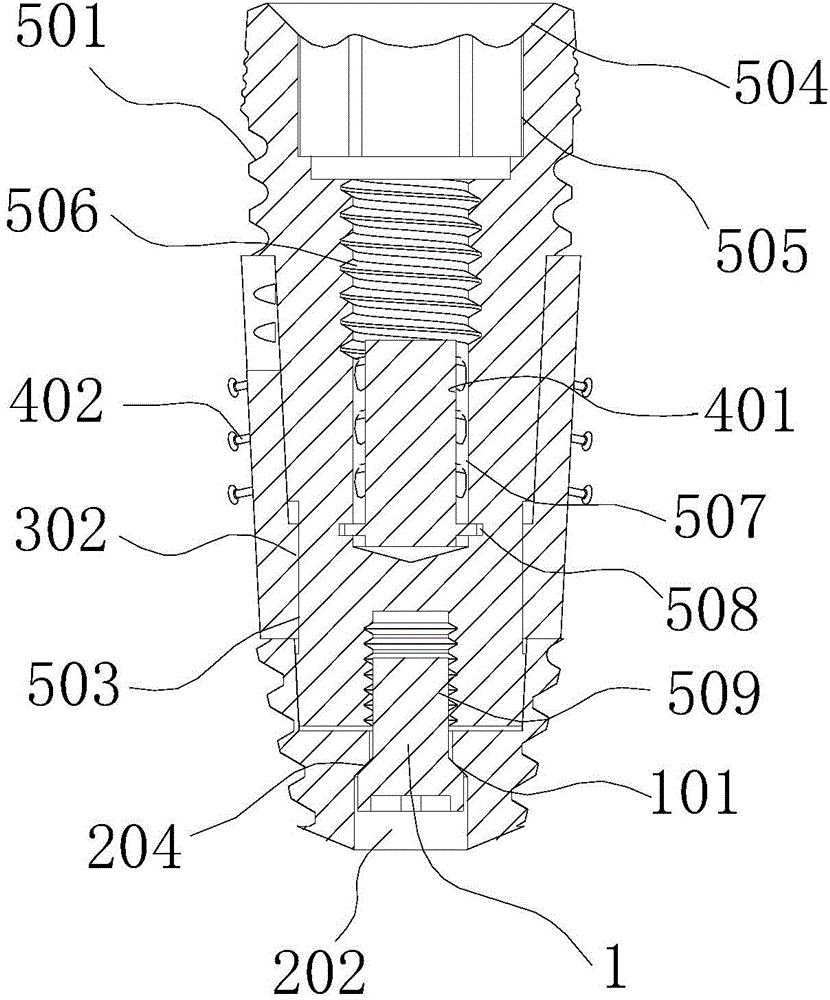

[0050] Figure 1 to Figure 3 An exploded view of a dental implant with a composite structure is shown, including a fastening screw 1 , a threaded implant segment 2 , a porous implant segment 3 , an antenna support structure 4 and an implant body 5 arranged sequentially from bottom to top.

[0051] Figure 4 Shows a cross-sectional view of the thread implantation section 2 of the present invention, the exterior of the thread implantation section 2 is in the shape of a truncated cone, the outer surface is provided with threads, the upper end of the thread implantation section 2 is provided with a first accommodating space 202, and the lower end A second accommodating space 203 is provided, and the first accommodating space 202 and the second accommodating space 203 are connected through a through hole, and the diameter of the through hole is smaller than the diameters of the first accommodating space 202 and the second accommodating space 203 .

[0052] The threaded section and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com