Linear ultrasonic motor stator and electric excitation method thereof

A linear ultrasonic motor and stator technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve bending vibration weakening, complex pre-tensioning mechanism, length or width Direction restrictions and other issues, to achieve the effect of increasing energy input density, increasing drive power, and easy miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

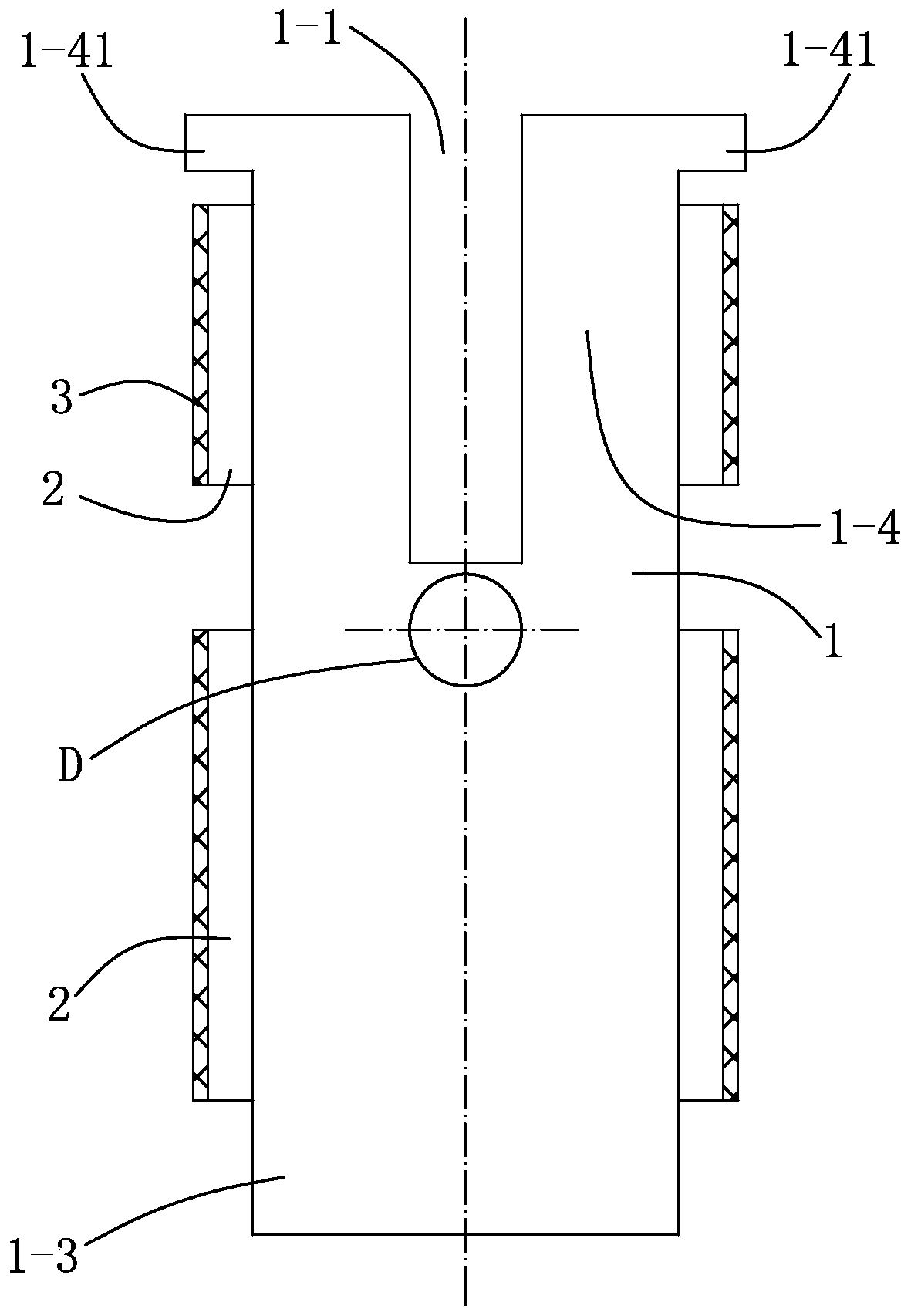

[0065] Embodiment 1, as figure 1 As shown, this embodiment further defines that: the cross-section of the opening groove 1-1 is a rectangle. It is processed into a regular rectangular slot with a straight bottom, easy to manufacture, guaranteed in size, and easy to miniaturize. Due to the symmetry of the structure, the acoustic node of the stator (the point that does not vibrate, has neither displacement nor corner) Clearly, a mounting hole D can be opened at this acoustic node to fix the stator, which does not affect the effects of longitudinal and bending vibration modes, and can be fixed reliably.

[0066] Optionally, the width W of the opening groove 1-1 is 0.2-10 mm, and the depth H is 0.5-10 mm.

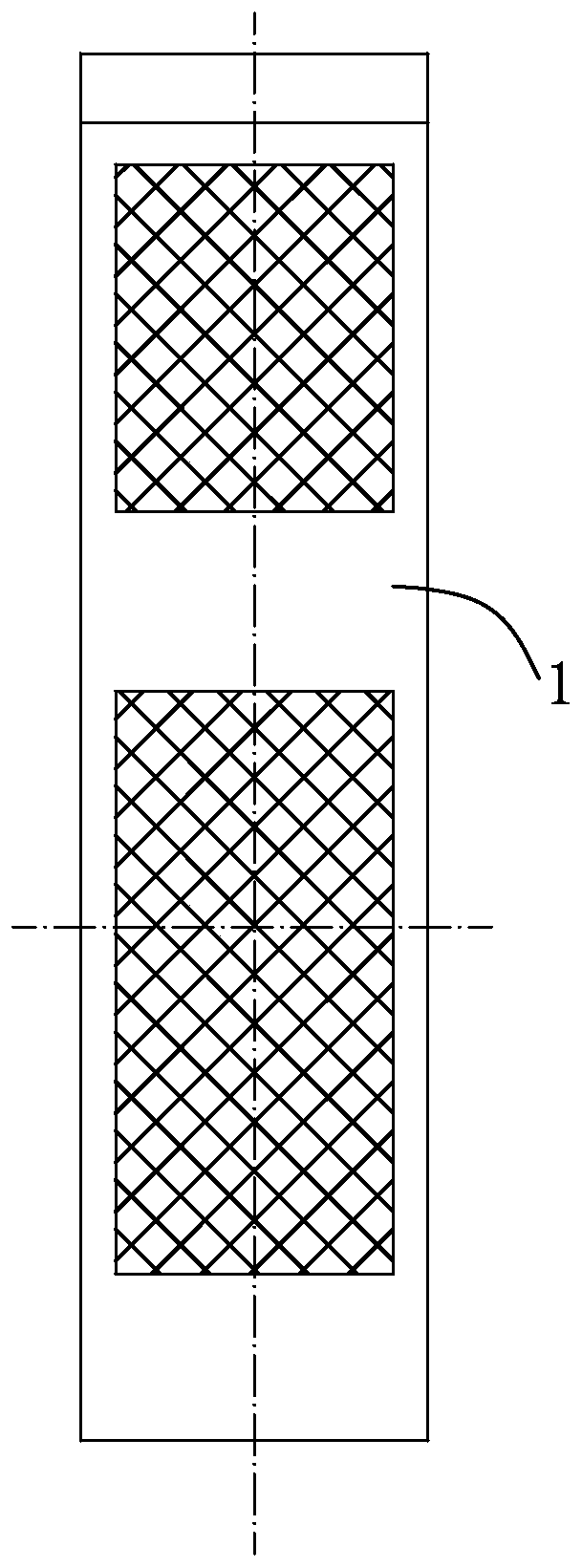

[0067] Optionally, the stator is mainly composed of a rectangular thin-plate stator elastic body 1 and a piezoelectric ceramic sheet 2. The piezoelectric ceramic sheet is a rectangular sheet structure, and the rectangular parallelepiped driving foot 3 extended from the stator ...

Embodiment 2

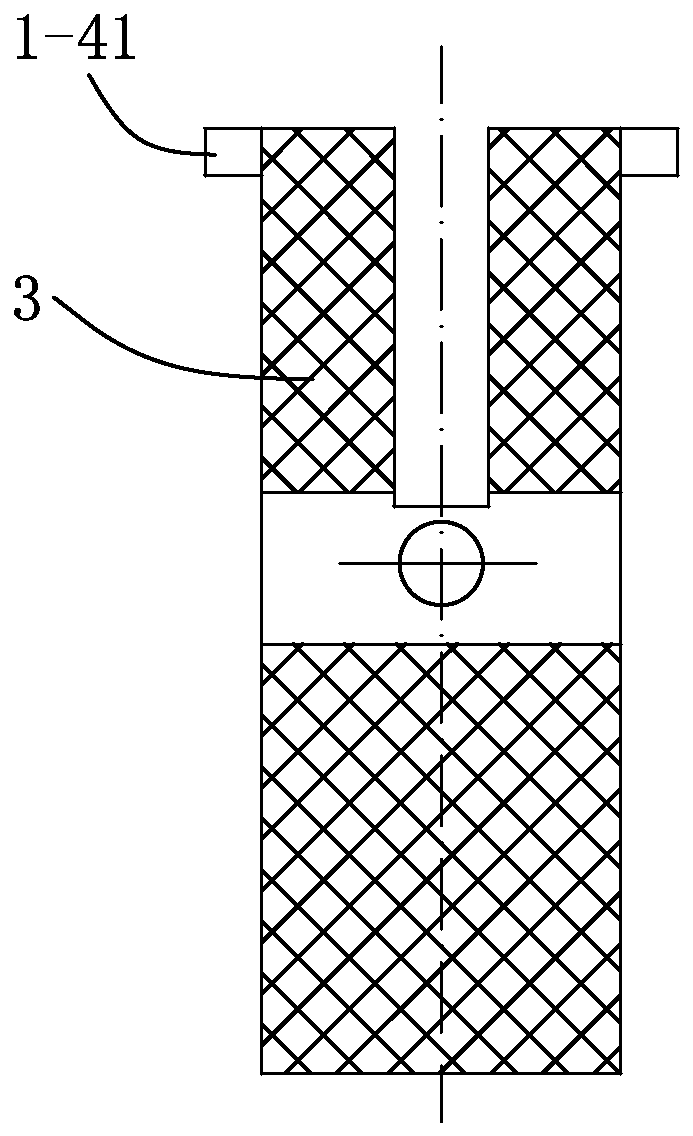

[0068] Embodiment 2, as image 3 and Figure 4 As shown, the body of the piezoelectric ceramic material stator in this embodiment is a cuboid, and it is further defined that the electrode layer 3 is sprayed on the two wide sides of the entire piezoelectric ceramic material stator in the length direction, so as to facilitate the polarization of the piezoelectric ceramic material in the thickness direction. Excitation of the material stator. Such as Figure 5 As shown, this embodiment further defines that the electrode layer 3 is sprayed on the two thick sides of the piezoelectric ceramic material stator in the length direction, so as to facilitate the excitation of the piezoelectric ceramic material stator polarized in the width direction.

Embodiment 3

[0069] Embodiment 3, this embodiment 3 is further defined in embodiment 1 and / or embodiment 2: the bottom corner of the open groove 1-1 is vertically opened with axisymmetric narrow groove 1- 2. The combined design of open slots and narrow slots has a better effect on adjusting the degeneracy of the local second-order bending vibration modes of the two driving legs of the stator and the first-order longitudinal vibration mode of the stator as a whole. Figure 6 Given the narrow slots on the stator elastic body 1, the body of the whole piezoelectric ceramic material stator in embodiment 2 has narrow slots and Figure 6 Same, omitted and not drawn.

[0070] The size combination of the open slot 1-1 and the narrow slot 1-2 degenerates (same or close to) the frequency of the bending vibration and the longitudinal vibration, and can obtain a better effect of driving the elliptical motion of the foot. Optionally, the width K of the narrow groove 1-2 is 0.1-1 mm, and the depth L is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com