Construction method of large-span continuous beam closely next to existing line deep water foundation

A deep-water foundation and construction method technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of easy cracking on the beam surface and large span of continuous beams, and achieve fast fixed installation, good stress effect, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

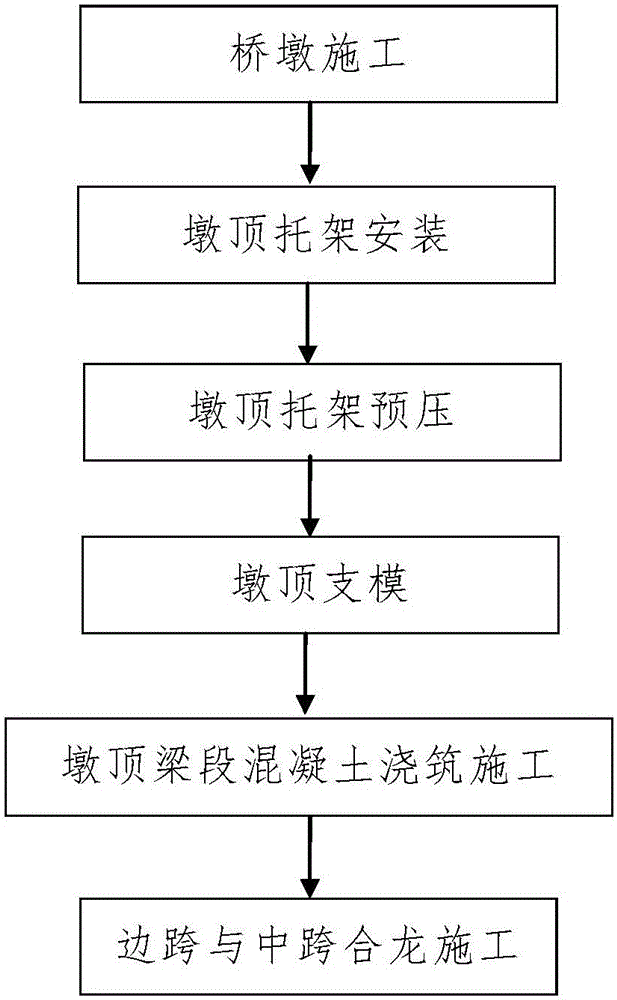

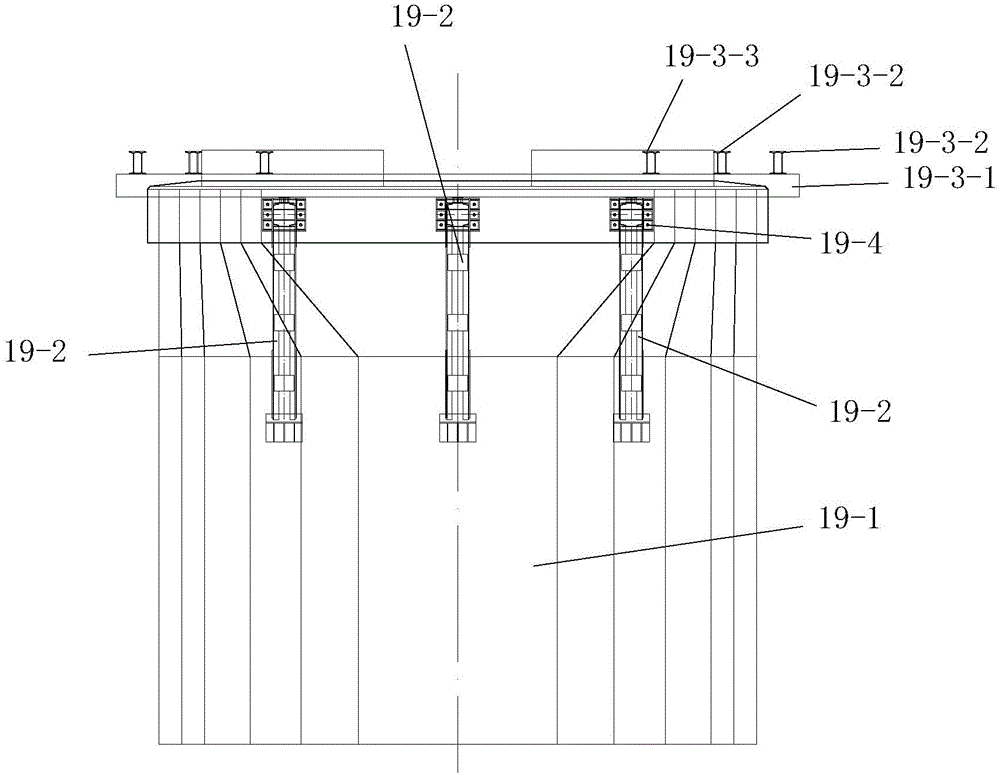

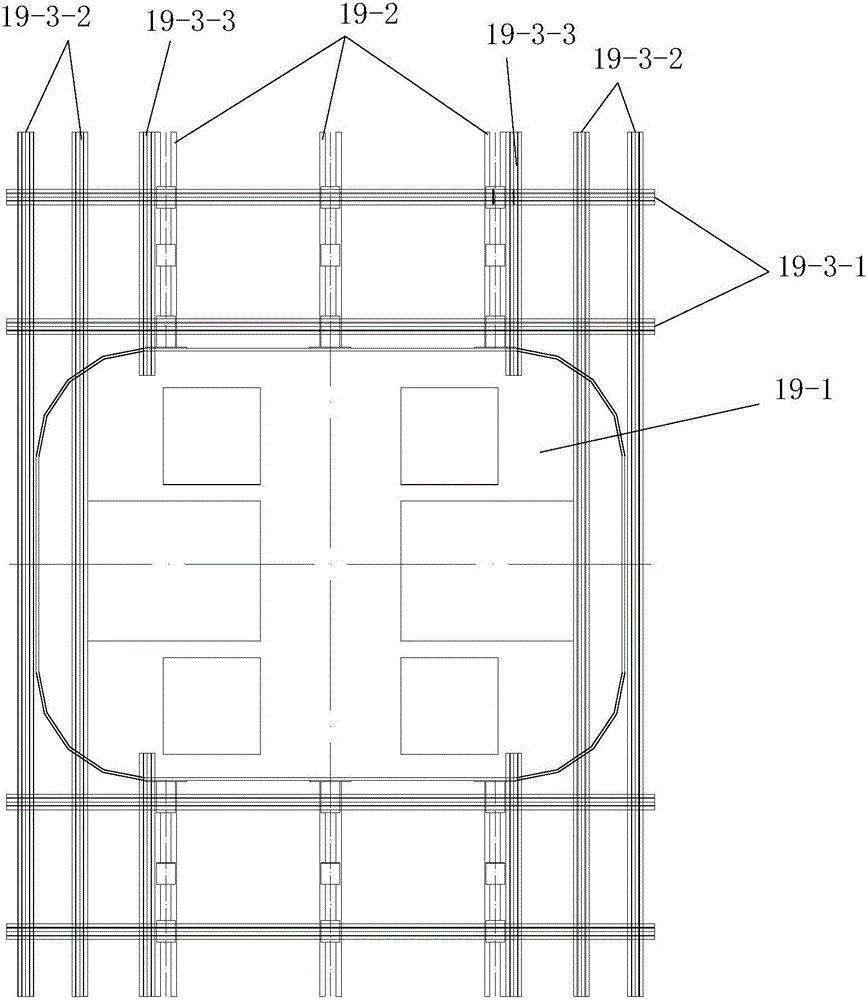

[0084] Such as figure 1Shown is a construction method of long-span continuous beams close to the existing deep-water foundation. The long-span continuous beams constructed are reinforced concrete box girders located on one side of the existing railway line; the front and rear ends of the long-span continuous beams constructed are respectively supported On the first pier and the fourth pier, a second pier and a third pier are arranged between the first pier and the fourth pier, the first pier, the second pier, the first pier The three piers and the fourth piers are laid out from front to back along the longitudinal bridge direction of the constructed large-span continuous beam, and they are all reinforced concrete piers; the length of the constructed large-span continuous beam is greater than 100m and consists of two A side-span beam section, a mid-span beam section, and two pier top beam sections 19-5 are spliced together, and the mid-span beam section is located between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com