Method and device for determining optimal pretension quantity of sphere and cone mixed double-line hub bearing

A technology of wheel hub bearing and determination method, which is applied in the directions of bearing components, shafts and bearings, instruments, etc., can solve the problem that it is difficult to accurately determine the optimal preload of a ball and cone hybrid double-row wheel hub shaft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

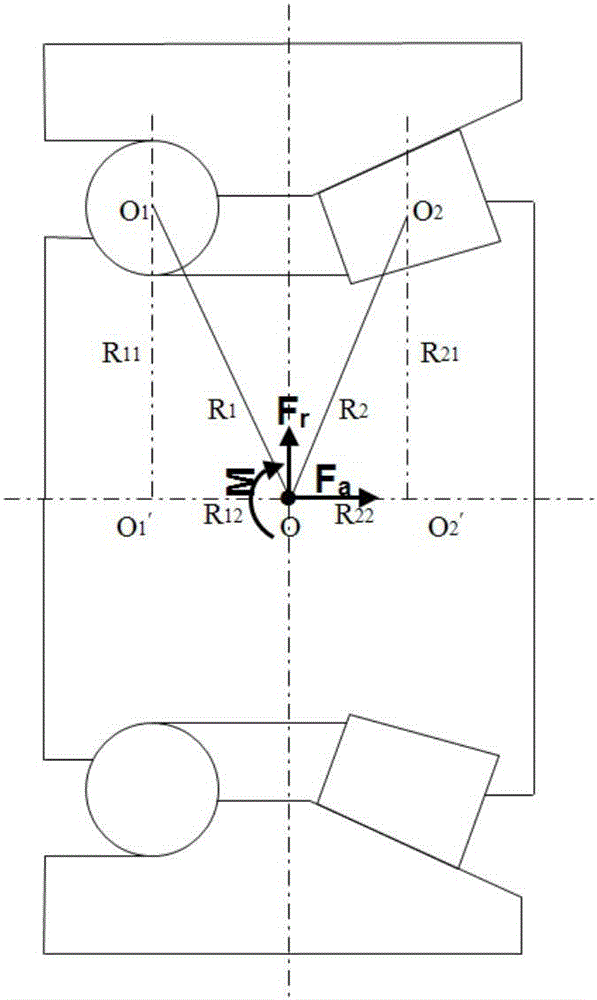

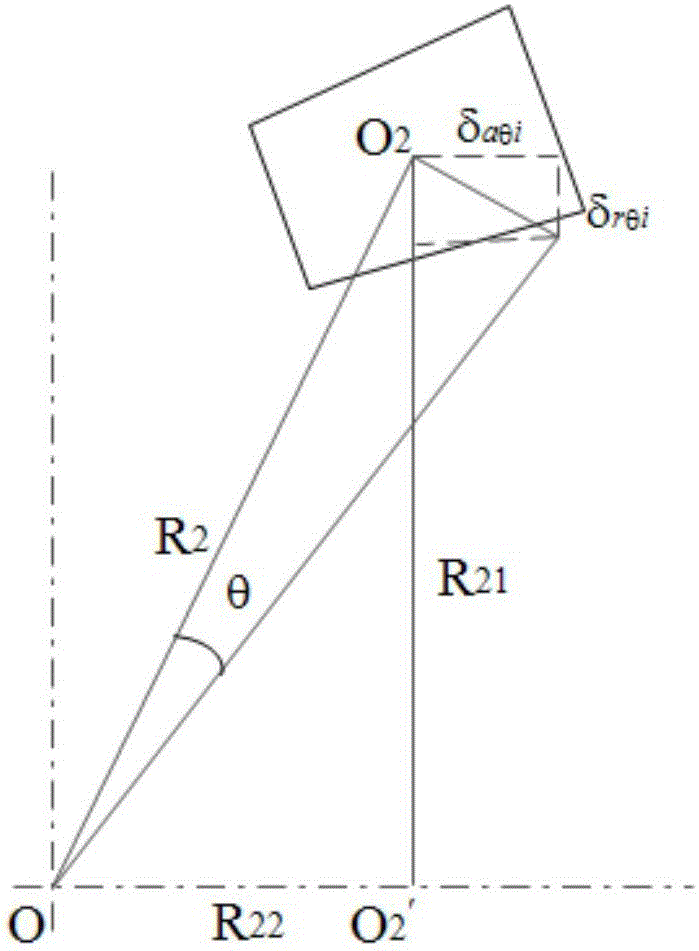

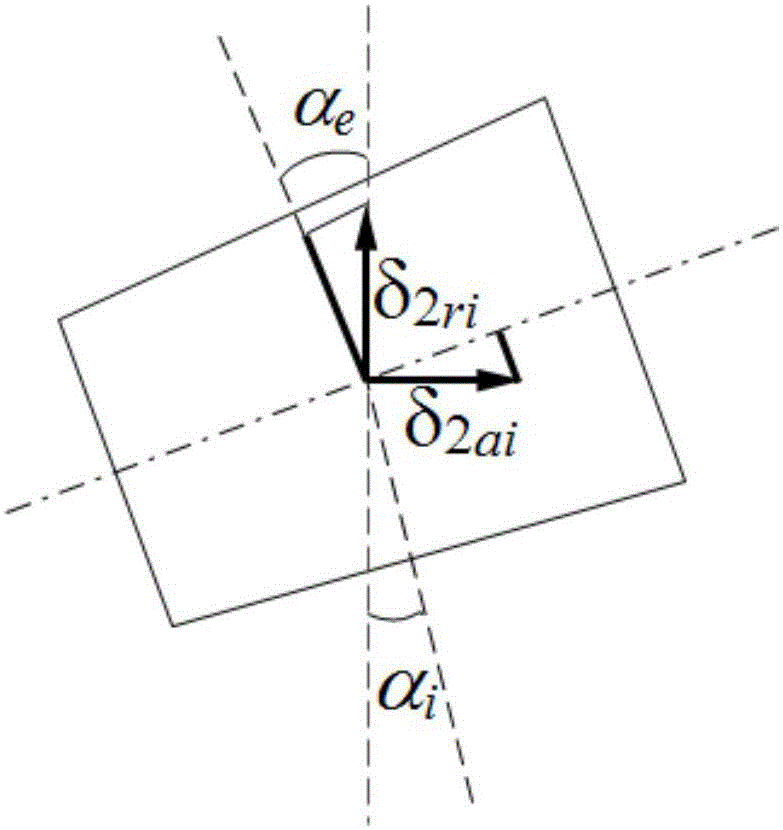

[0062] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0063] Embodiment of the Method for Determining the Optimum Preload of Ball and Cone Mixed Double Row Hub Bearings of the Present Invention

[0064] The invention calculates the radial displacement δ according to the mechanical model of the ball-cone hybrid double-row hub bearing by formulating the unit load spectrum of the ball-cone hybrid double-row hub bearing r , Axial displacement δ a and angular displacement θ, and with the load spectrum as the known condition, and the preload as the analysis variable, the corresponding single-row ring life and comprehensive life of the hub bearing unit are obtained, and the relationship between the preload and the hub bearing unit life is established, and the hub bearing unit The preload corresponding to the longest service life of the single row ferrule and / or the whole hub bearing unit is the optim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com