Patents

Literature

281results about "Felting apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

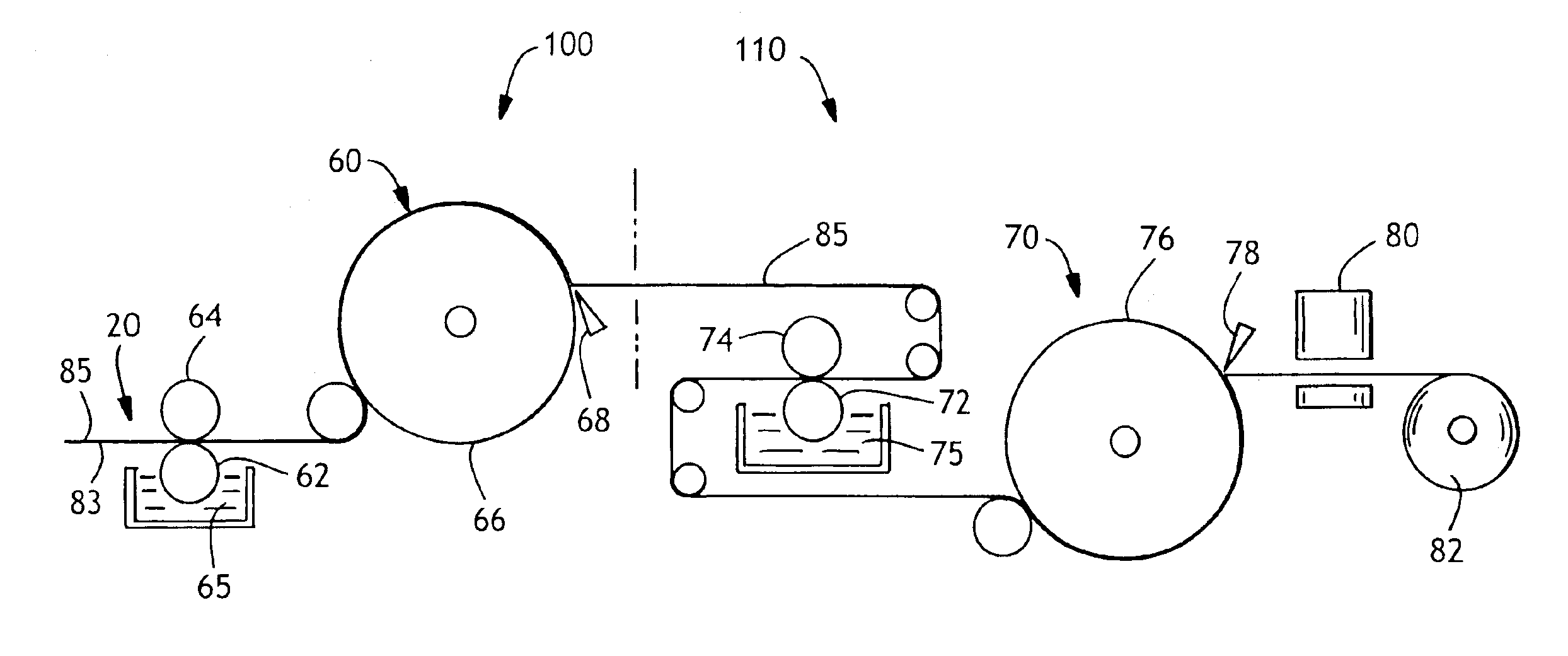

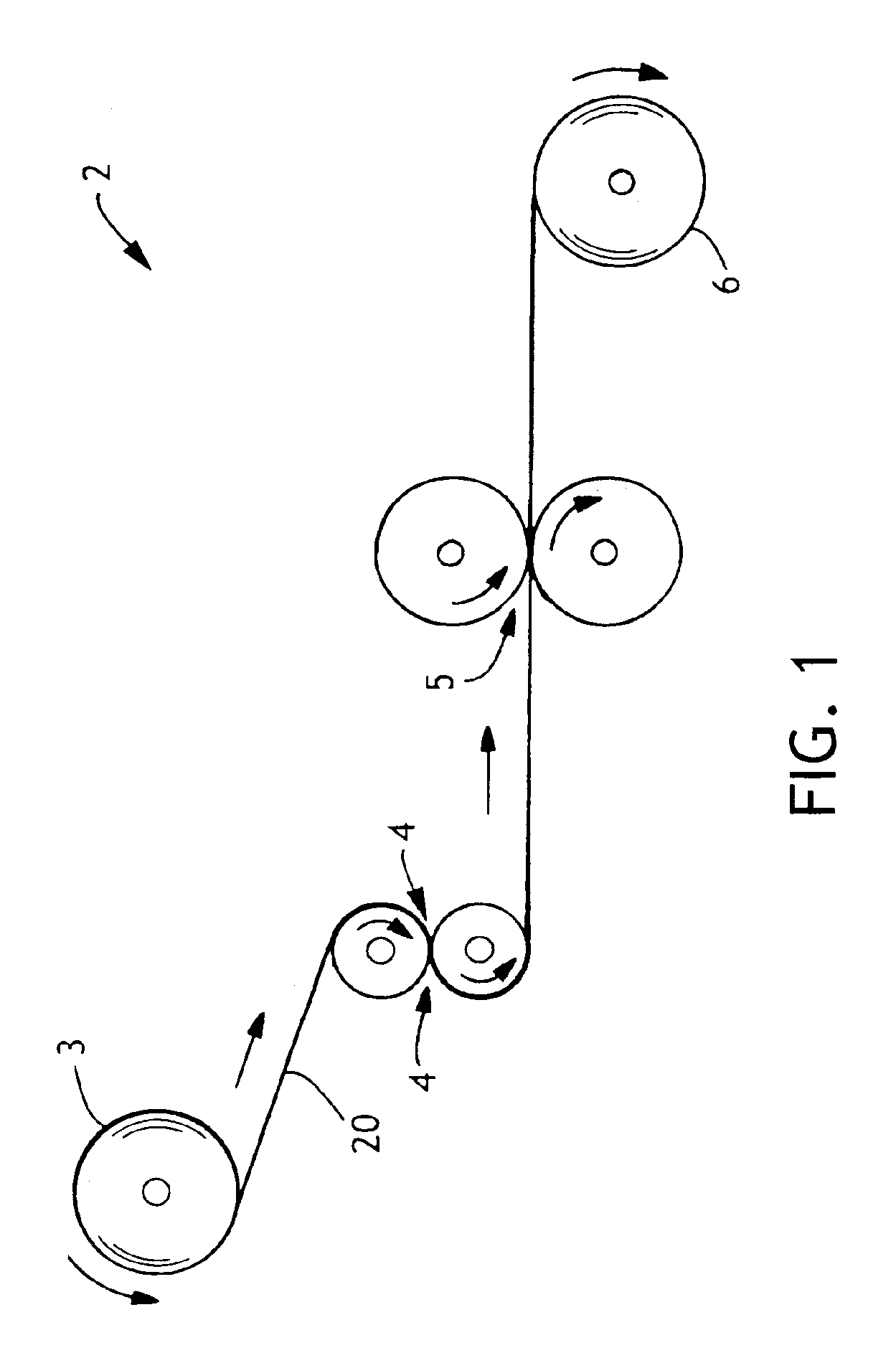

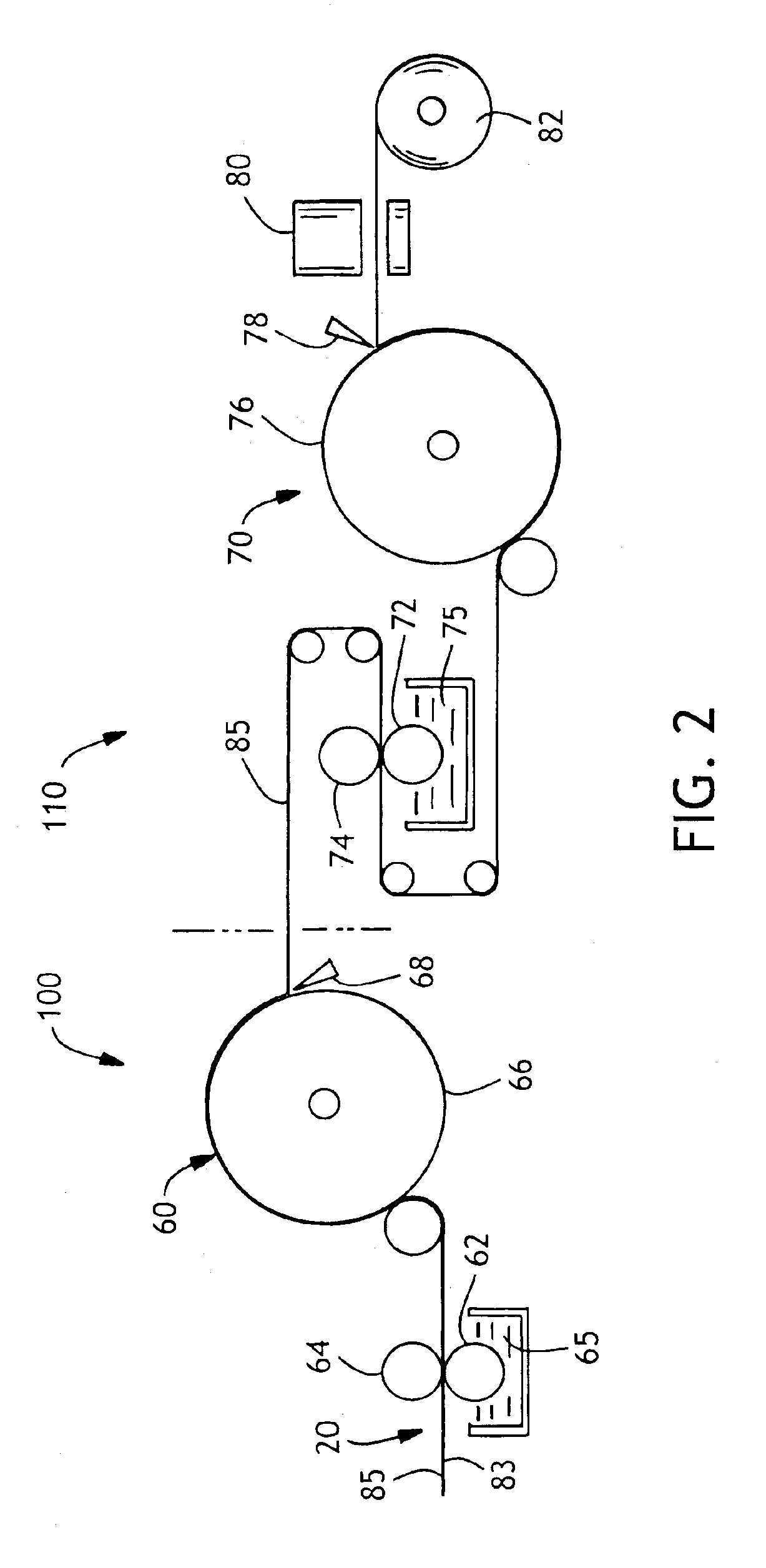

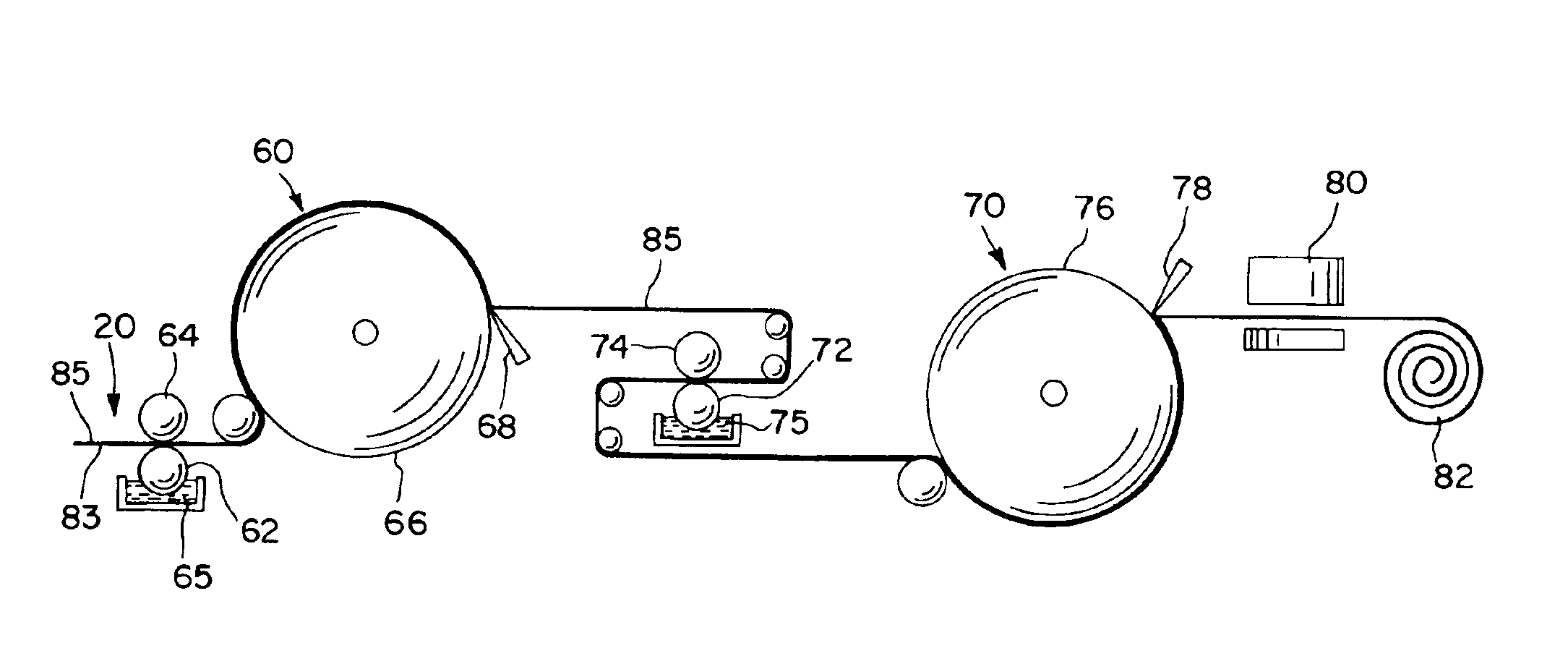

Nonwoven fabrics with advantageous properties

InactiveUS7060149B2Increasing the thicknessIncrease opening spacingEnvelopes/bags making machineryLaminationEngineeringNonwoven fabric

This invention relates to nonwoven fabrics with advantageous characteristics and the method to produce these fabrics. Advantageously, the fabrics of the subject invention have increased thickness (loft) compared to conventional nonwoven fabrics and have high air permeability and open space while maintaining softness and strength at the same basis weight.

Owner:THE PROCTER & GAMBLE COMPANY

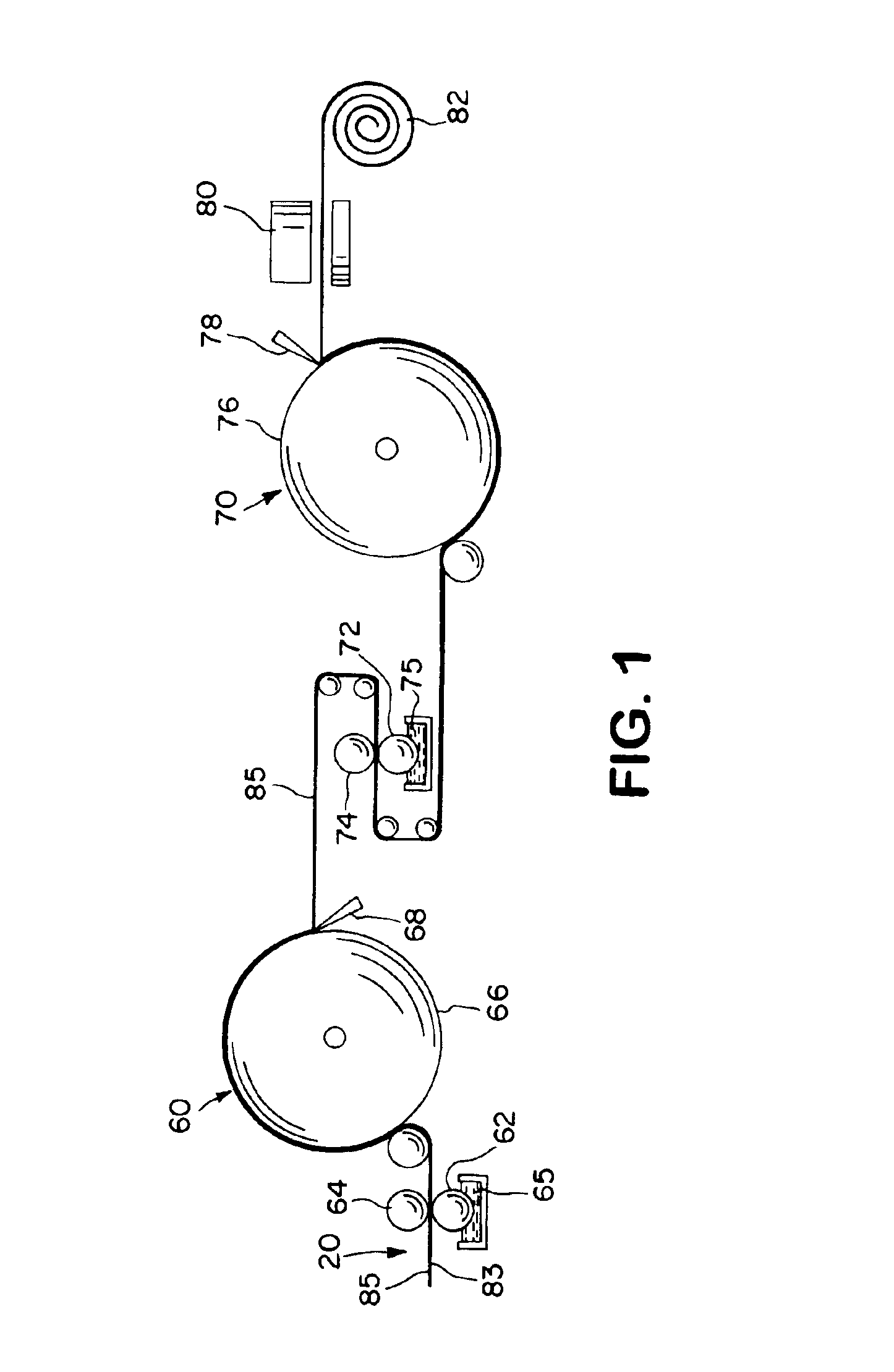

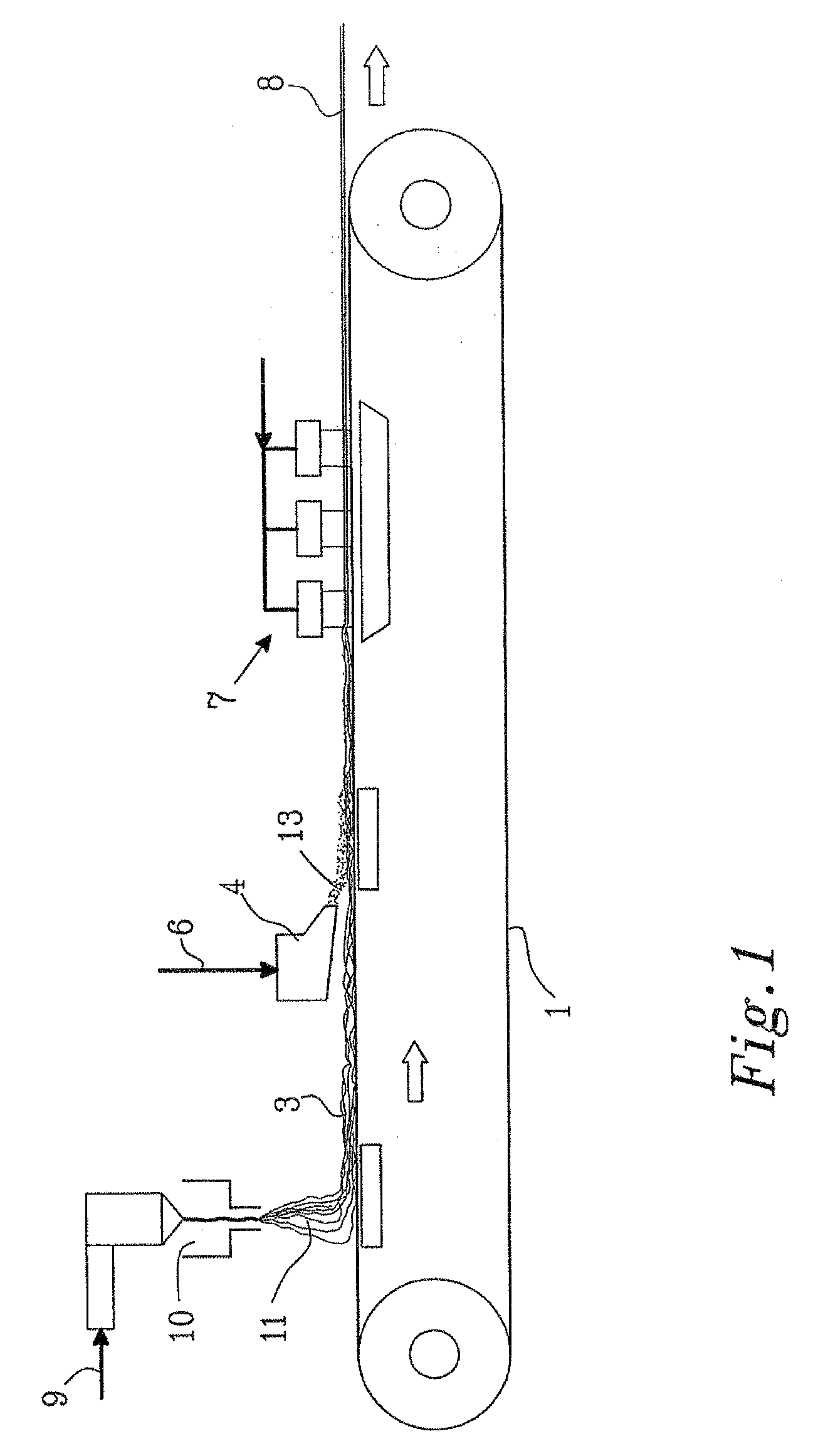

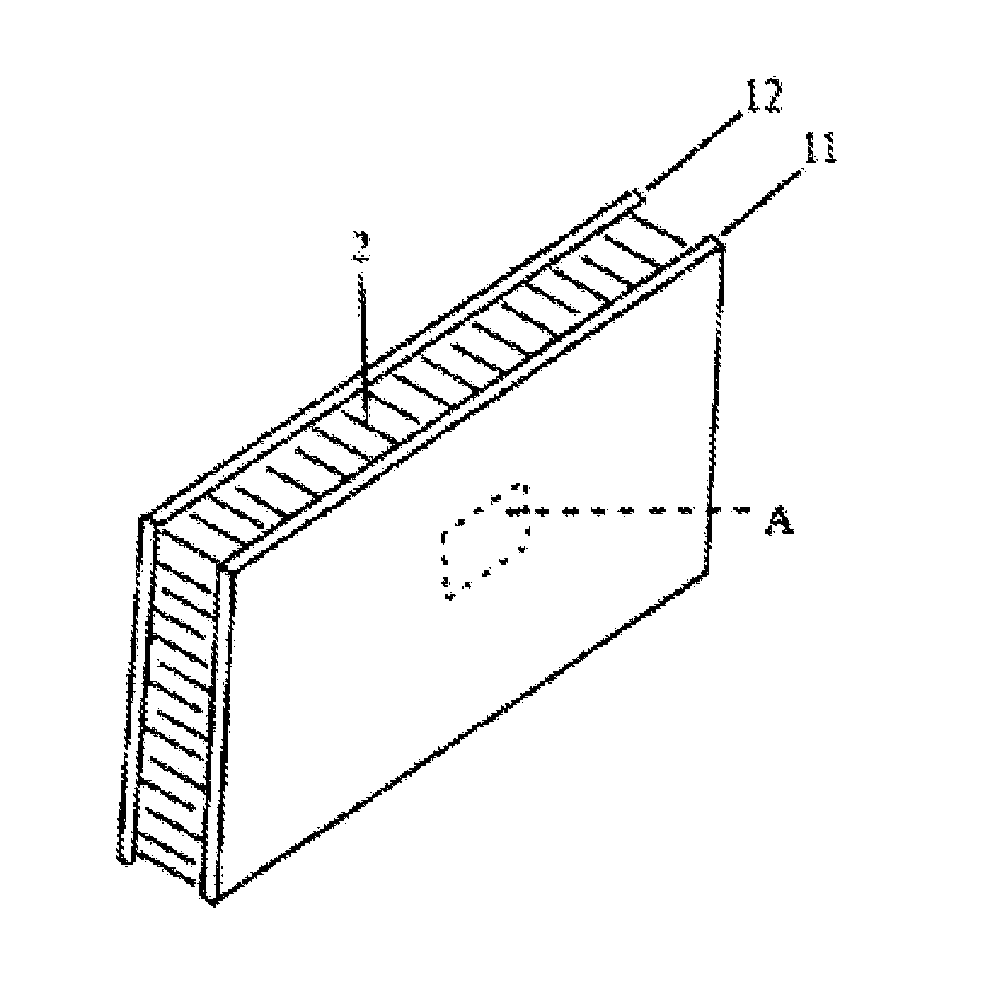

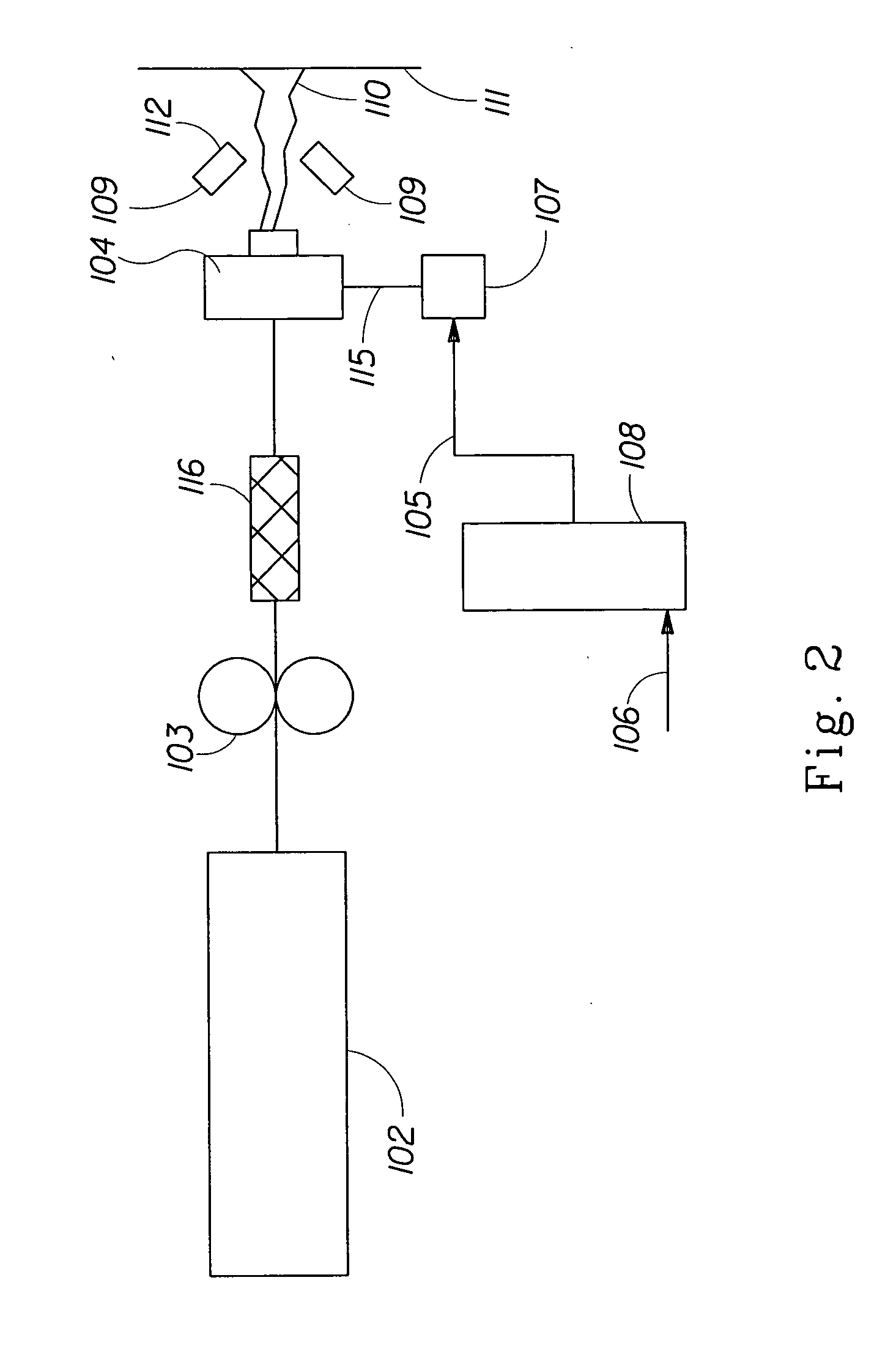

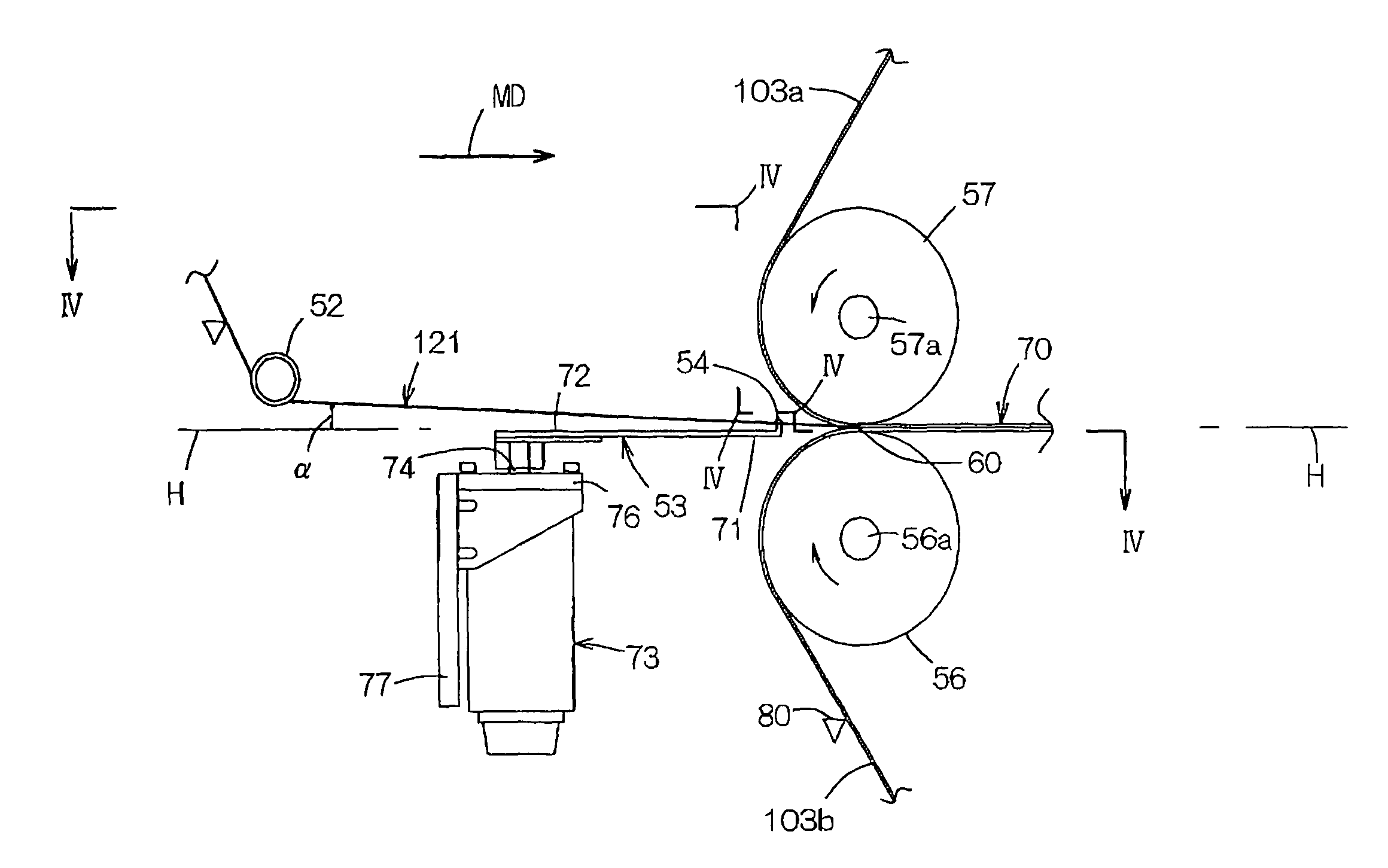

Process and apparatus to attach elastic members to disposable wearing article being continuously manufactured

ActiveUS20060185135A1Efficient use ofEasy to manufactureLaminationLamination apparatusEngineeringServomotor

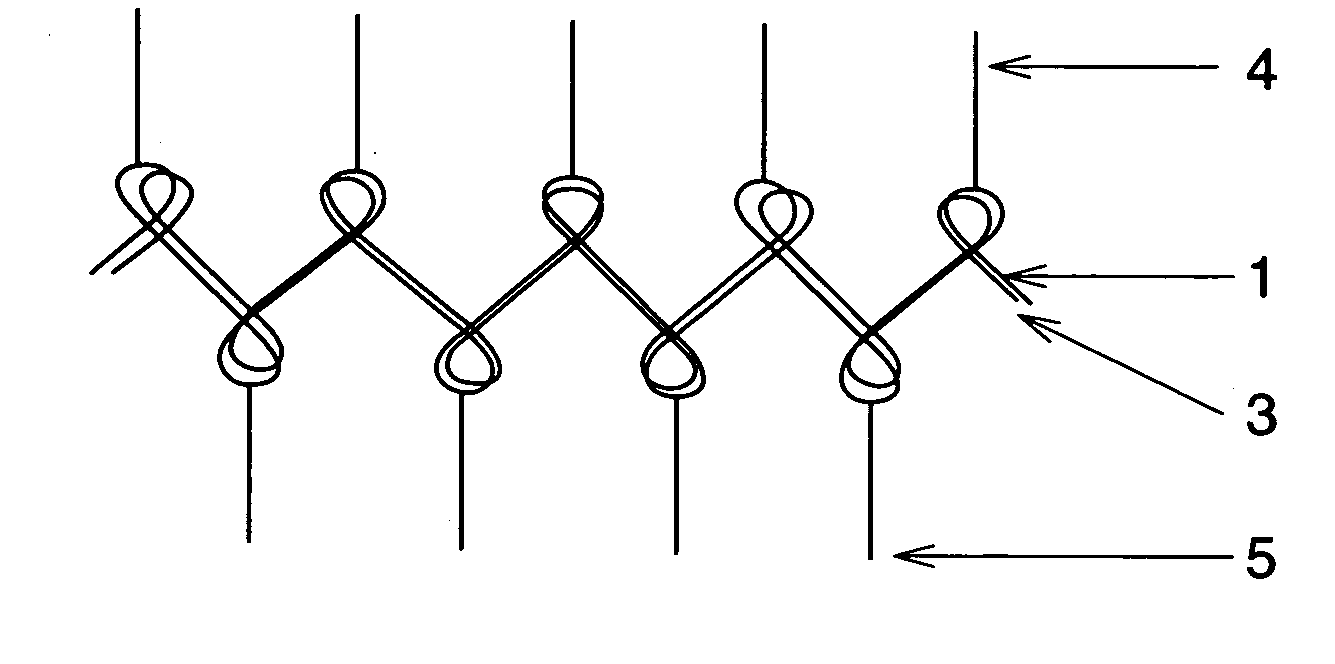

First continuous web as a component of disposable wearing article to be continuously manufactured is fed in a machine direction and first continuous elastic members are fed via guide means adapted to oscillate the elastic members in a cross direction crossing the machine direction and attached thereto. Each of the guide means comprises a first servomotor having a rotary shaft adapted to repeat reversal of its rotational direction, a first arm connected directly with the rotary shaft and extending in a direction crossing the rotary shaft so that the first arm swings around the rotary shaft as the rotary shaft rotates and a first feed member adapted to direct the first continuous elastic members toward guide means formed on the first arm.

Owner:UNI CHARM CORP

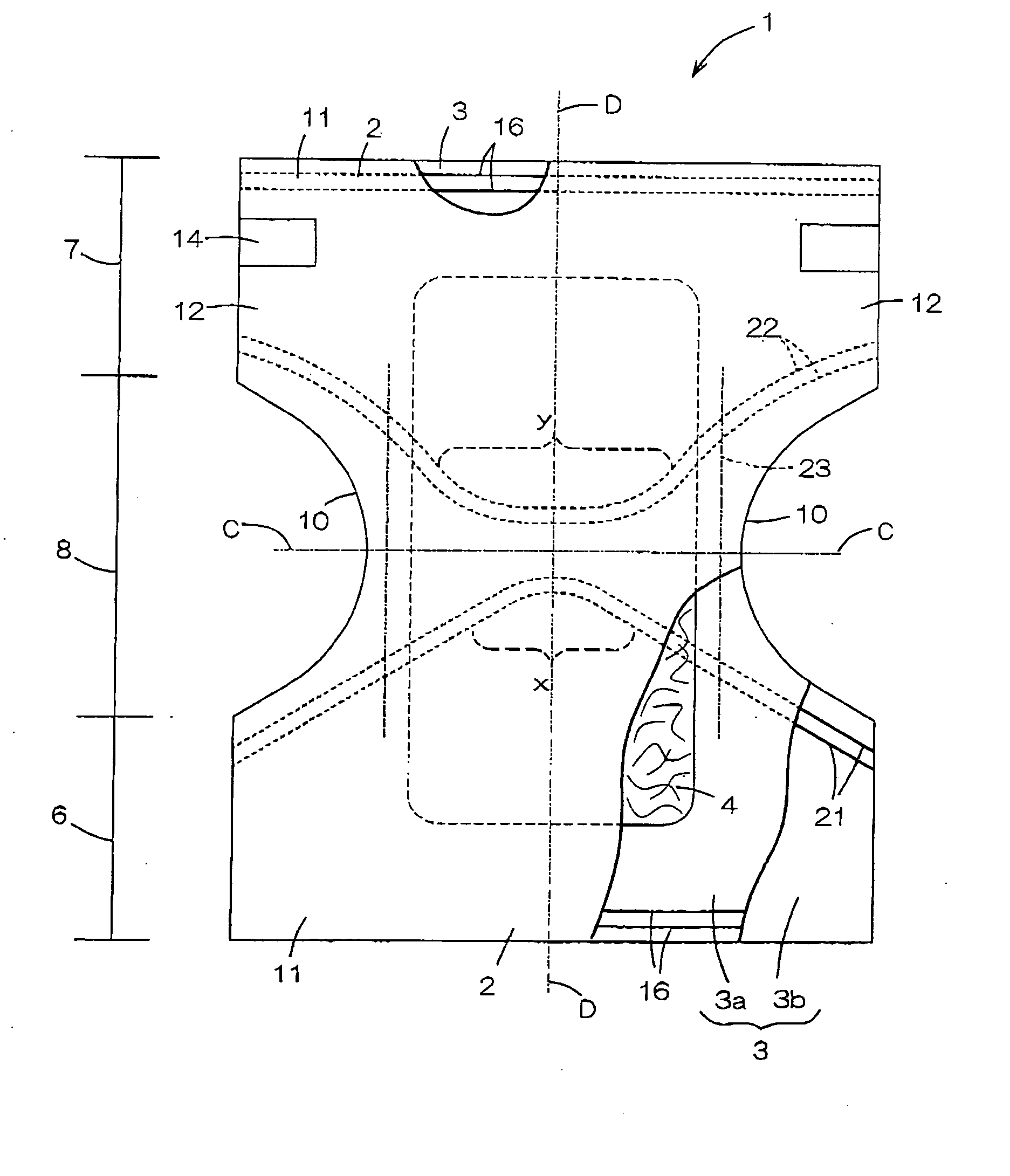

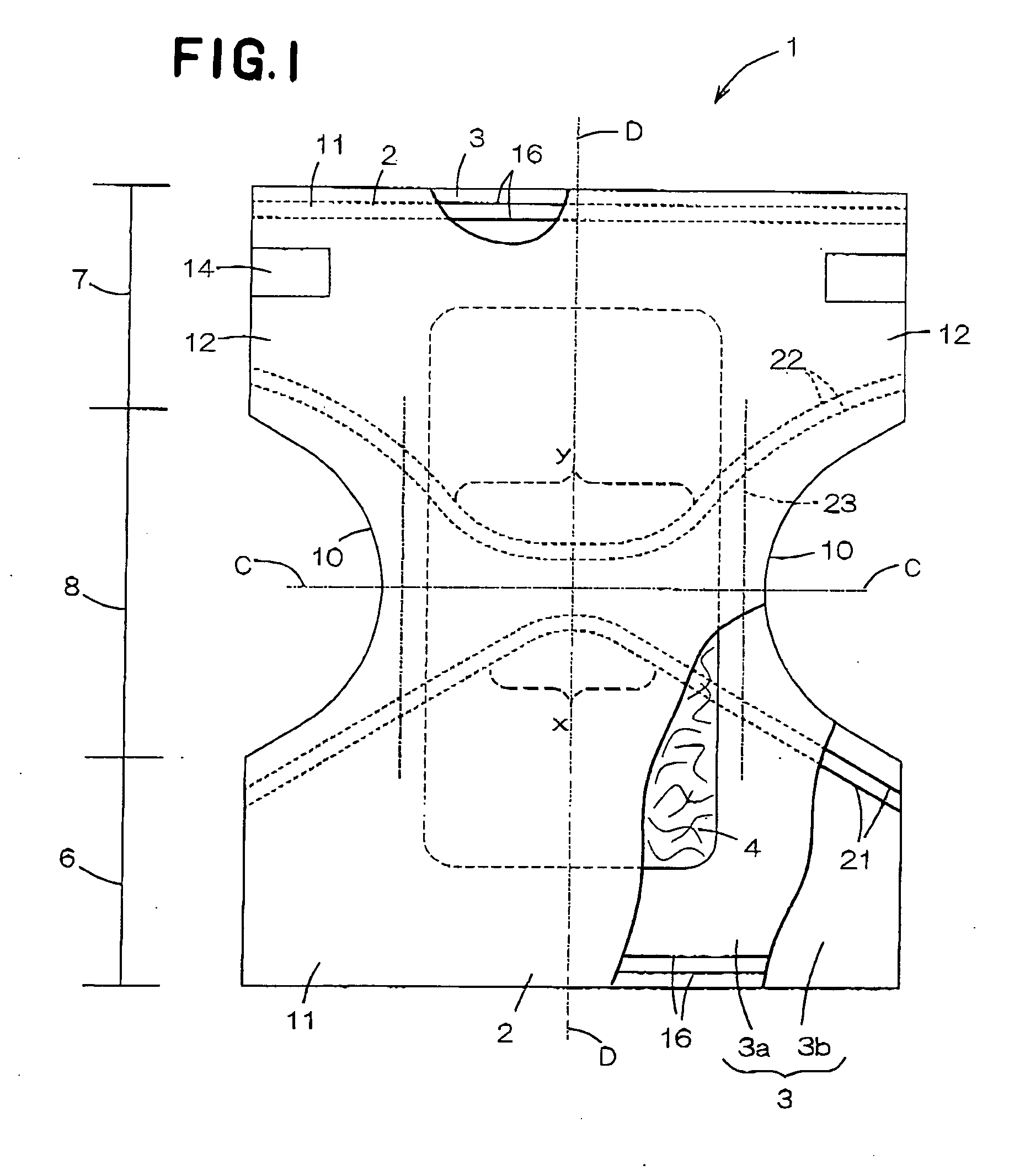

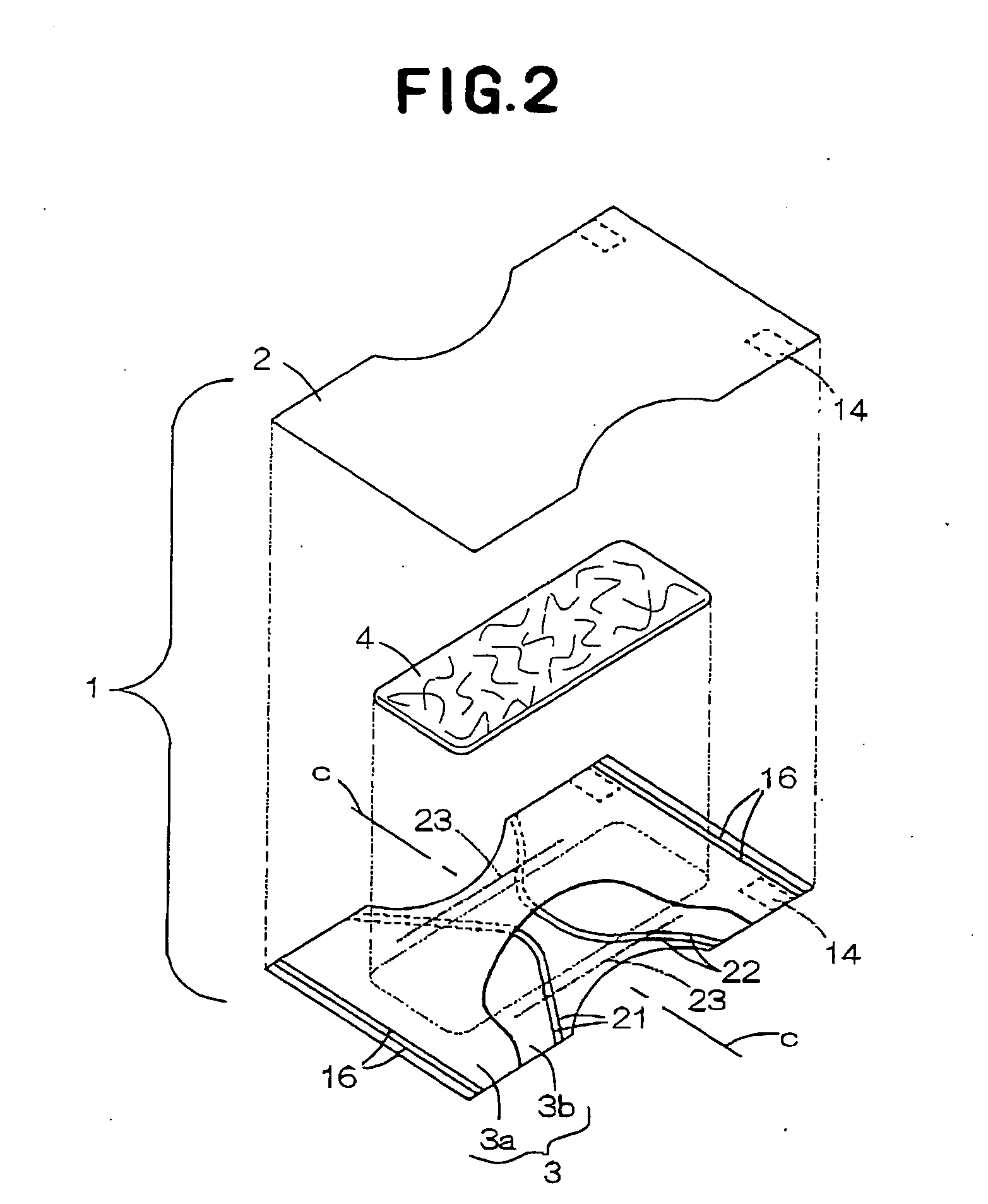

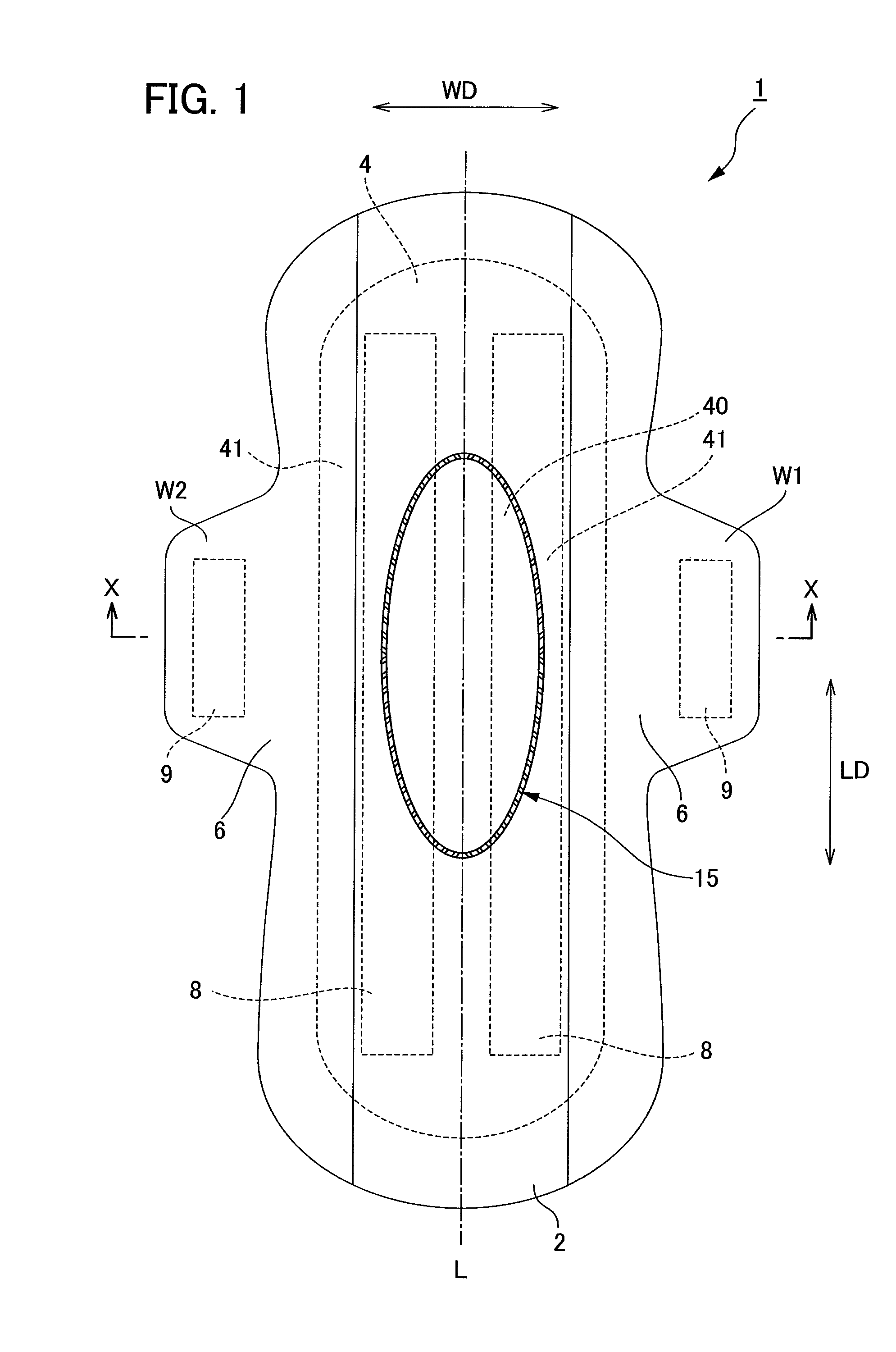

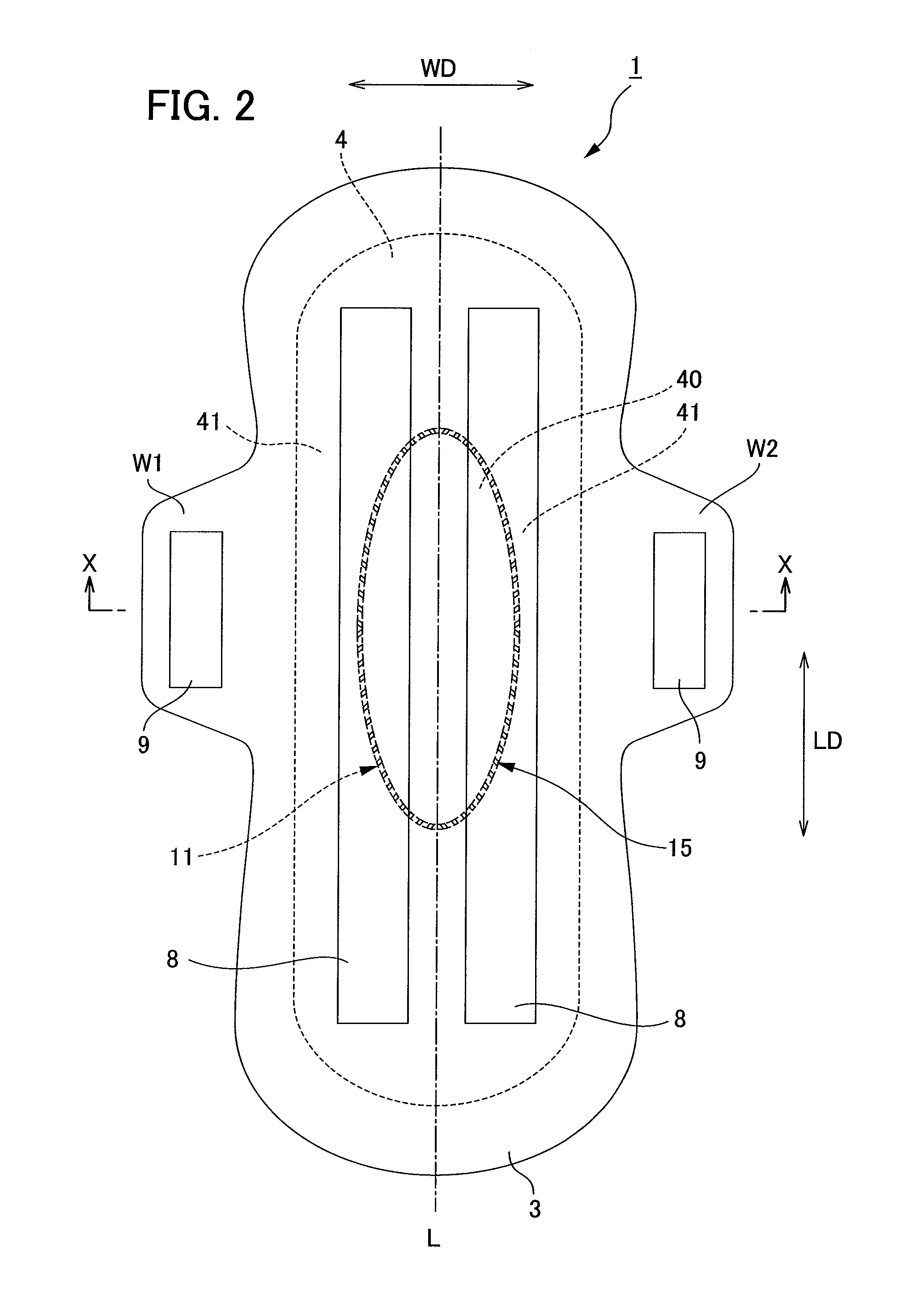

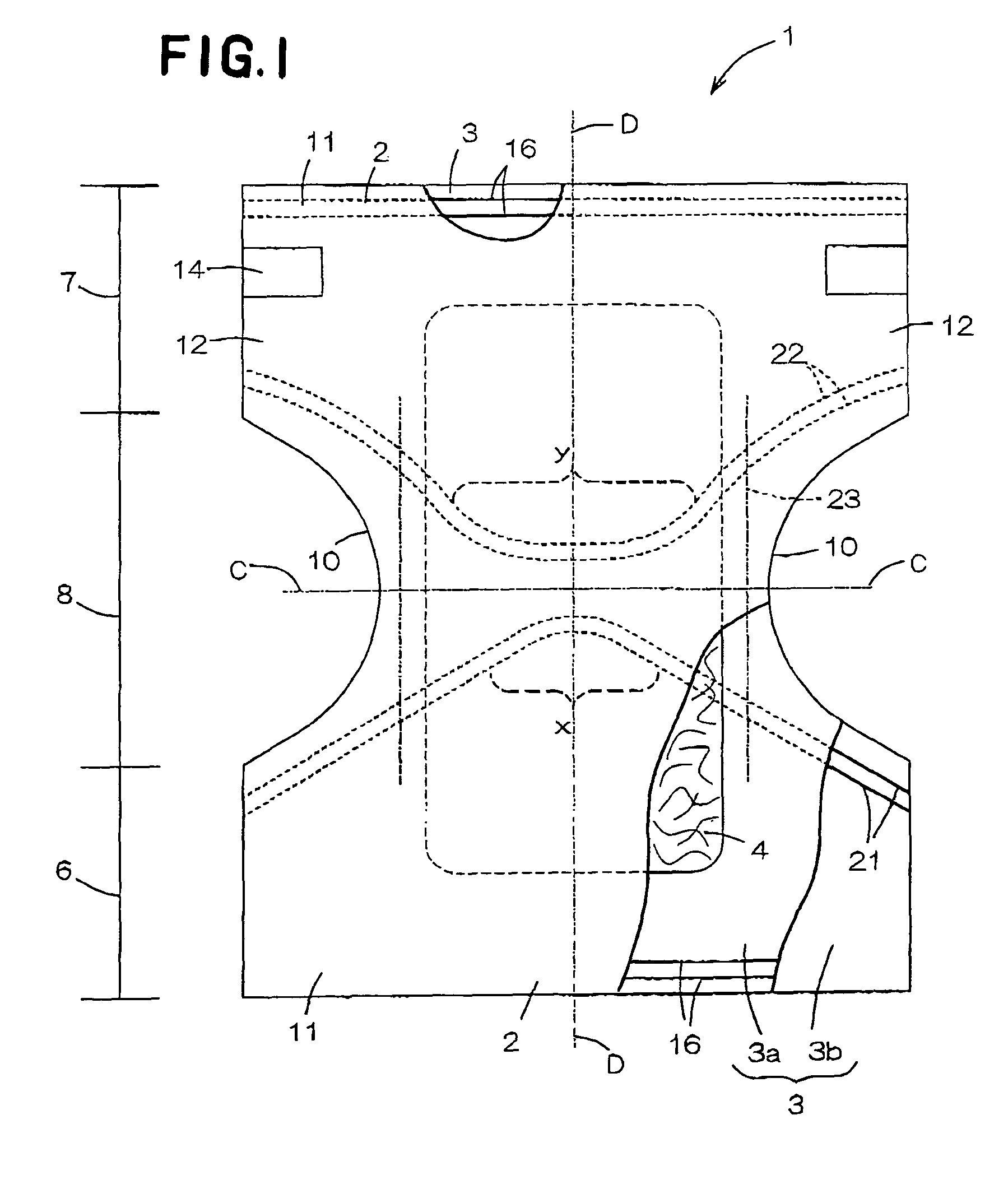

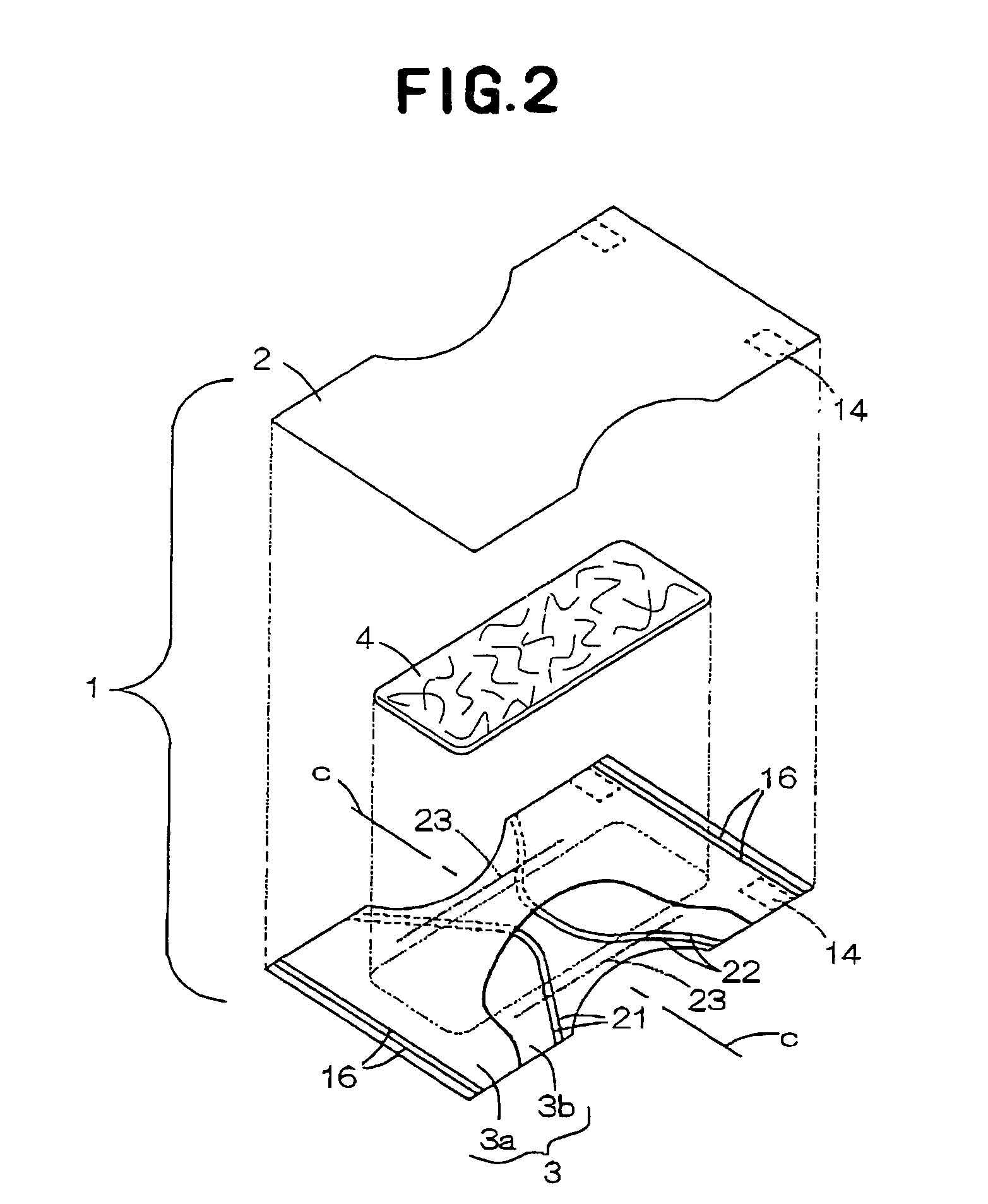

Absorptive article and method of producing the same

Owner:UNI CHARM CORP

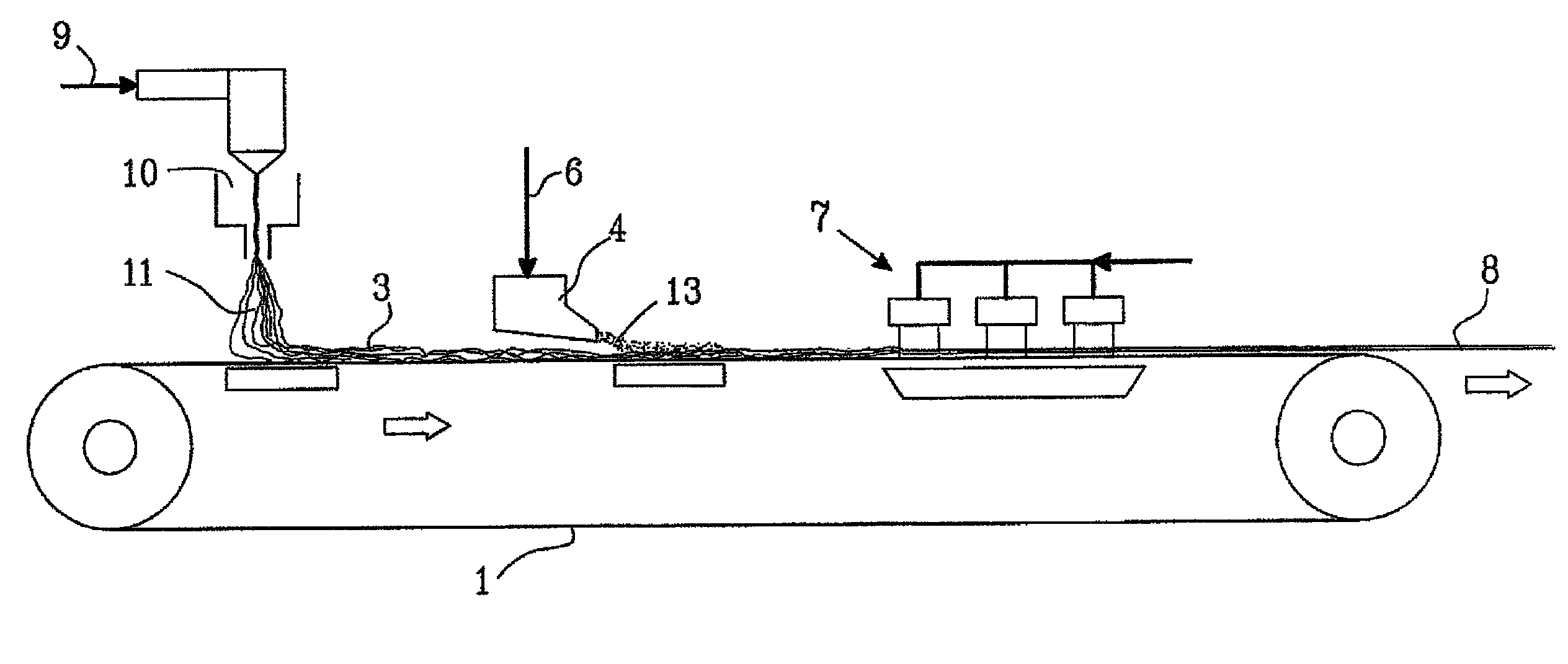

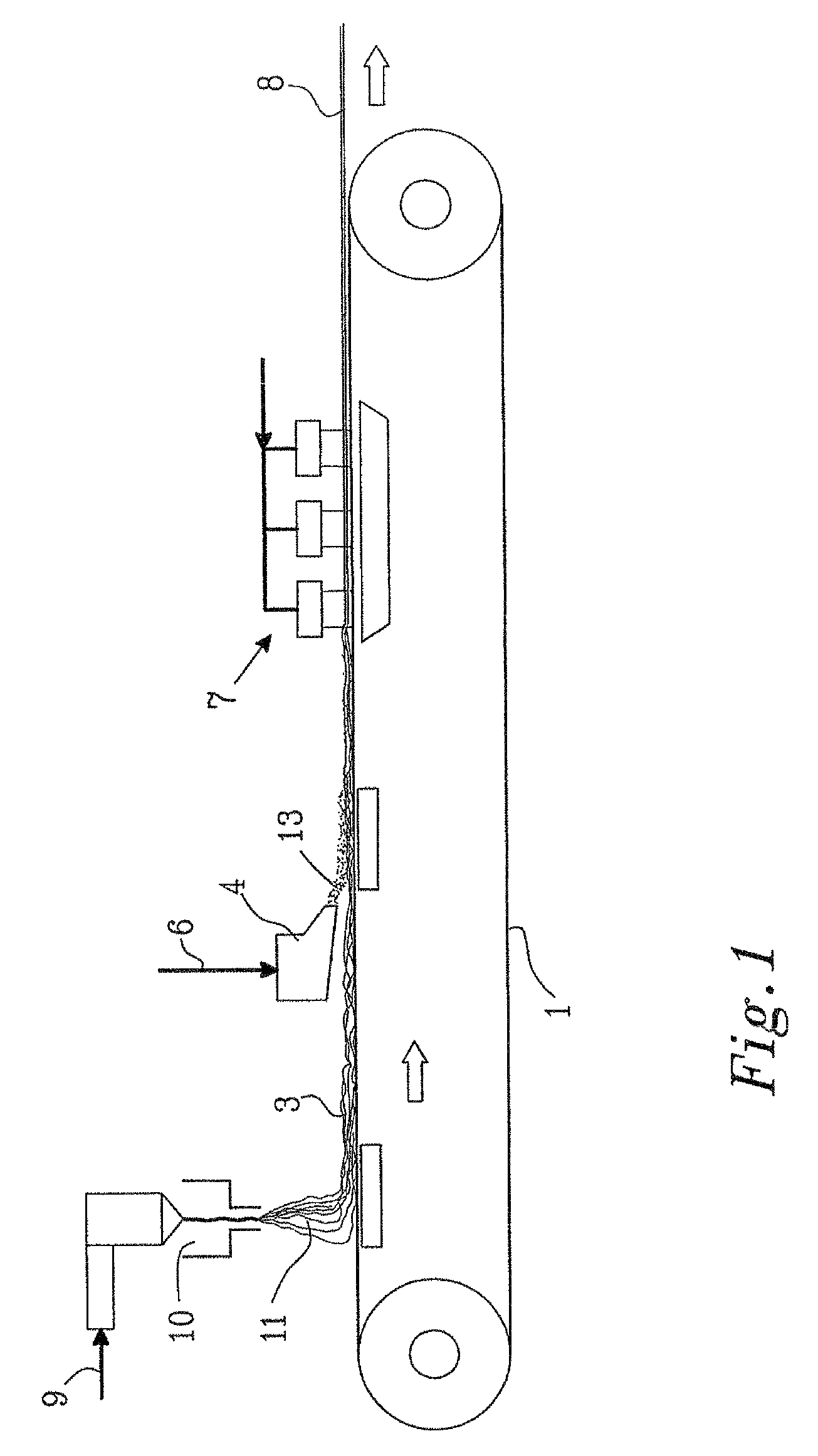

Method and device for producing a composite nonwoven for receiving and storing liquids

Known methods involve applying a layer of particularly highly absorbent fibers such as woodpulp on a carrier nonwoven and then compacting the composite nonwoven with the aid of water entanglement. One disadvantage of the compacting method is the high woodpulp fiber loss and the associated purification of the circulating water for the entanglement device. According to the invention, a fine layer of microfibers is initially applied before applying the woodpulp fibers. The microfibers are evenly distributed on the carrier nonwoven using, for instance, a meltblown process and the woodpulp fibers are only then applied in the separating layer. The water during entanglement can no longer merge the woodpulp fibers into the carrier nonwoven due to the fact that the microfibers act as a barrier.

Owner:FLEISSENER GMBH & CO MASCHFAB & ALBIS SPA +1

Entangled fabric wipers for oil and grease absorbency

InactiveUS7022201B2Enhance certain characteristicNon-fibrous pulp additionNatural cellulose pulp/paperCelluloseFiber

A composite fabric comprising a necked and creped spunbond nonwoven web of monocomponent fibers hydraulically entangled with a fibrous component that comprises cellulosic fibers. The nonwoven web contains thermoplastic fibers and the fibrous component comprises greater than about 50% by weight of the fabric.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Entangled fabrics containing staple fibers

InactiveUS6958103B2Enhance certain characteristicNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

Owner:KIMBERLY-CLARK WORLDWIDE INC

Leather-Like Sheet And Method Of Manufacturing The Same

InactiveUS20090274862A1Dense feelingElegant surface appearanceFibre treatmentSynthetic resin layered productsFiberVitrification

A leather-like sheet composed of a microfine-fiber entangled body made of bundles of microfine fibers and an elastic polymer impregnated therein. The bundles of microfine fibers are composed of microfine monofibers having an average cross-sectional area of 0.1 to 30 μm2 and have an average cross-sectional area of 40 to 400 μm2. The bundles of microfine fibers exist in a density of 600 to 4000 / mm2 on a cross section taken along the thickness direction of the microfine-fiber entangled body. The elastic polymer contains 30 to 100% by mass of a polymer of ethylenically unsaturated monomer. The polymer of ethylenically unsaturated monomer is composed of a soft component having a glass transition temperature (Tg) of less than −5° C., a crosslinkable component, and optionally a hard component having a glass transition temperature (Tg) of higher than 50° C. and another component. The polymer of ethylenically unsaturated monomer is bonded to the microfine fibers in the bundles of microfine fibers. The leather-like sheet has a flexibility and hand such as dense feeling each resembling natural leathers and a high quality appearance. The leather-like sheet is highly stable in quality such as fastness and surface abrasion resistance and excellent in practical performance.

Owner:KURARAY CO LTD

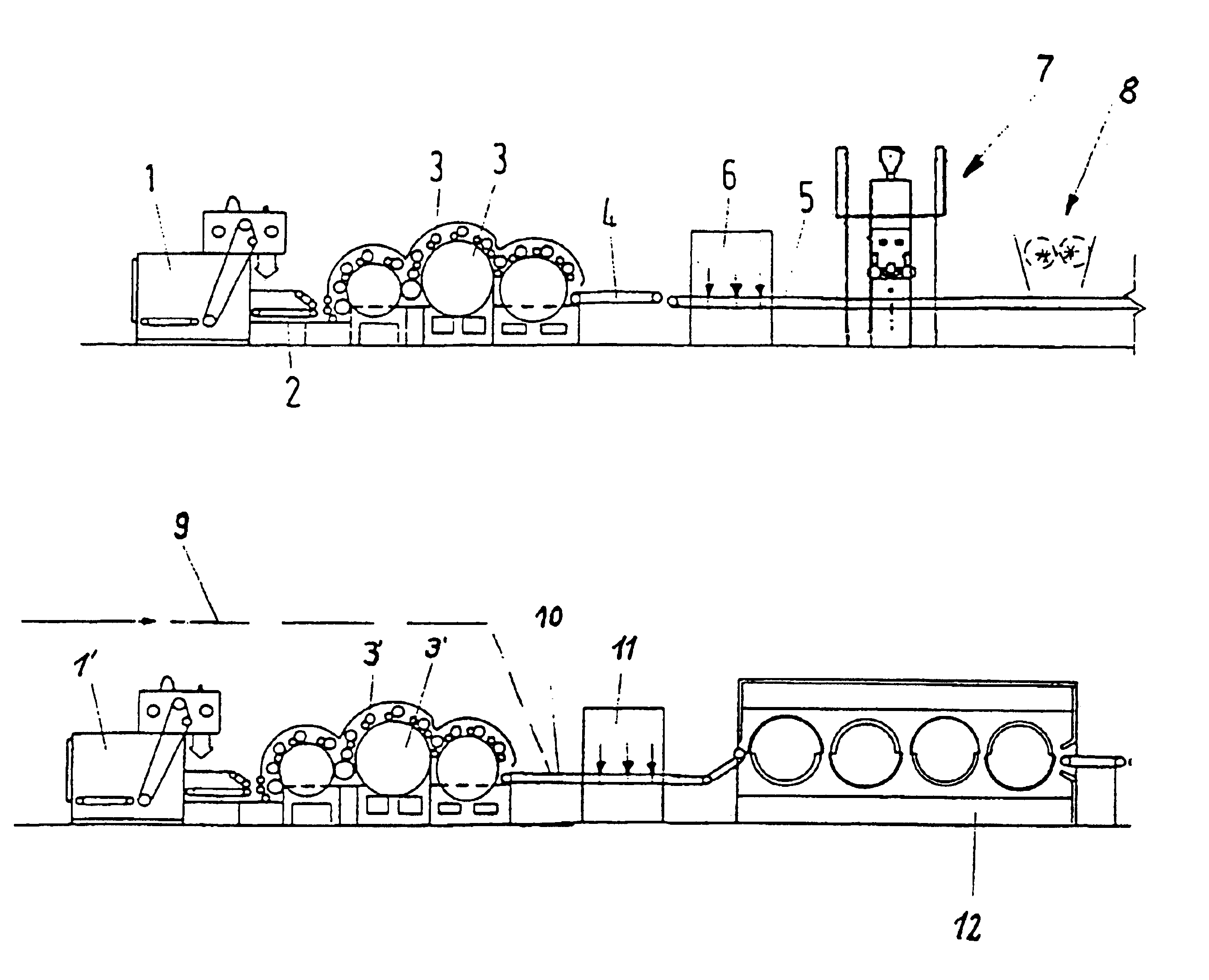

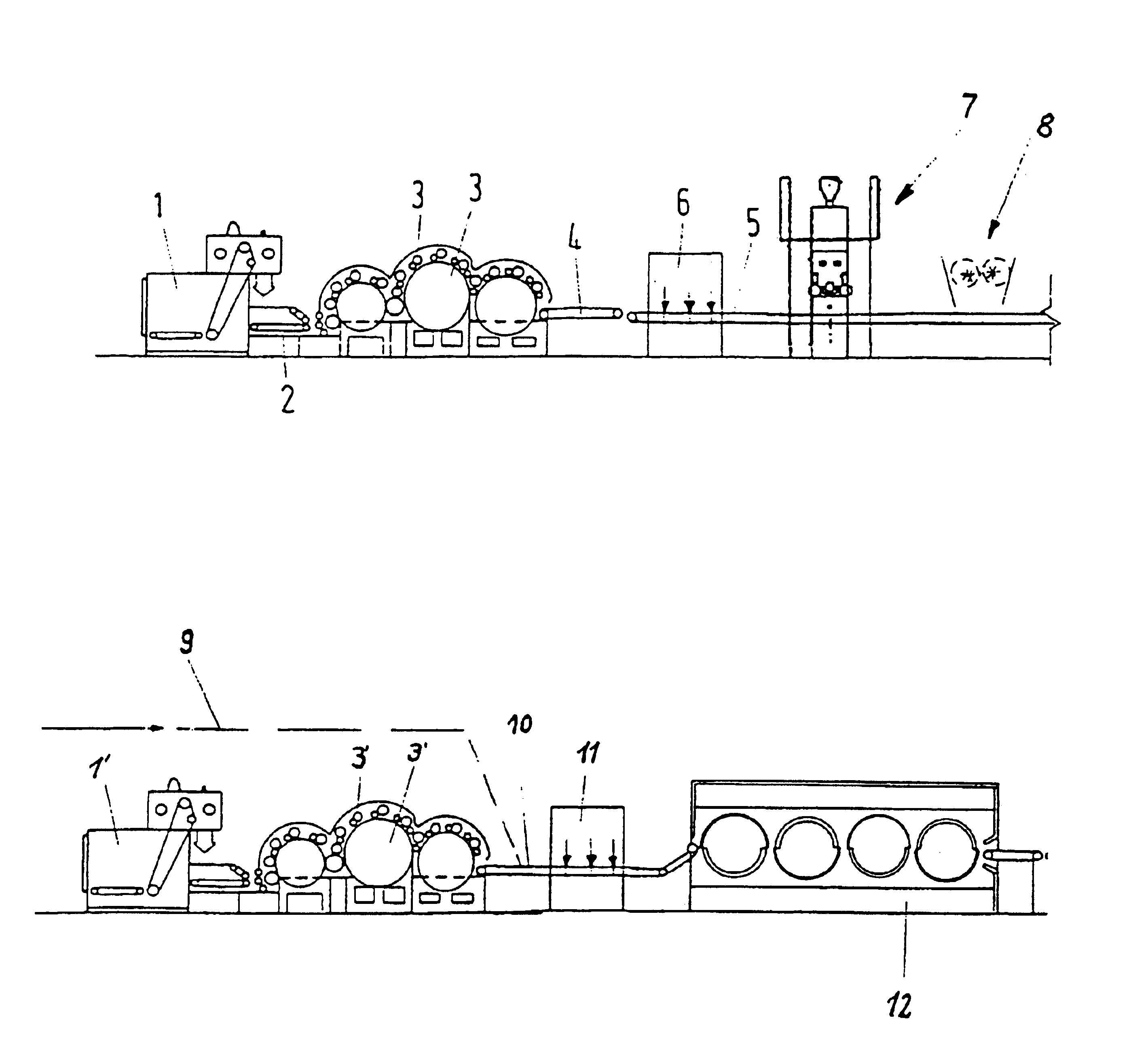

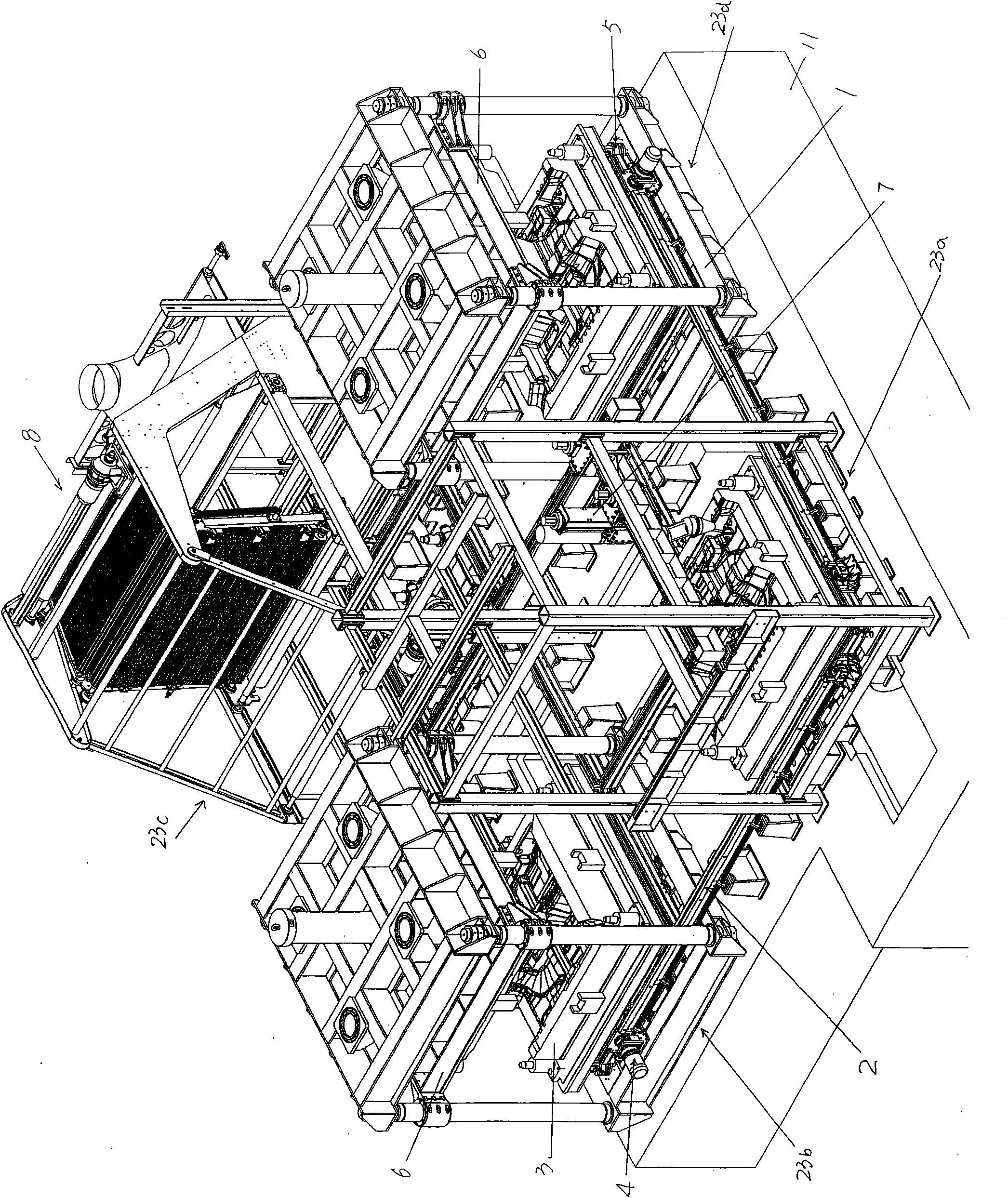

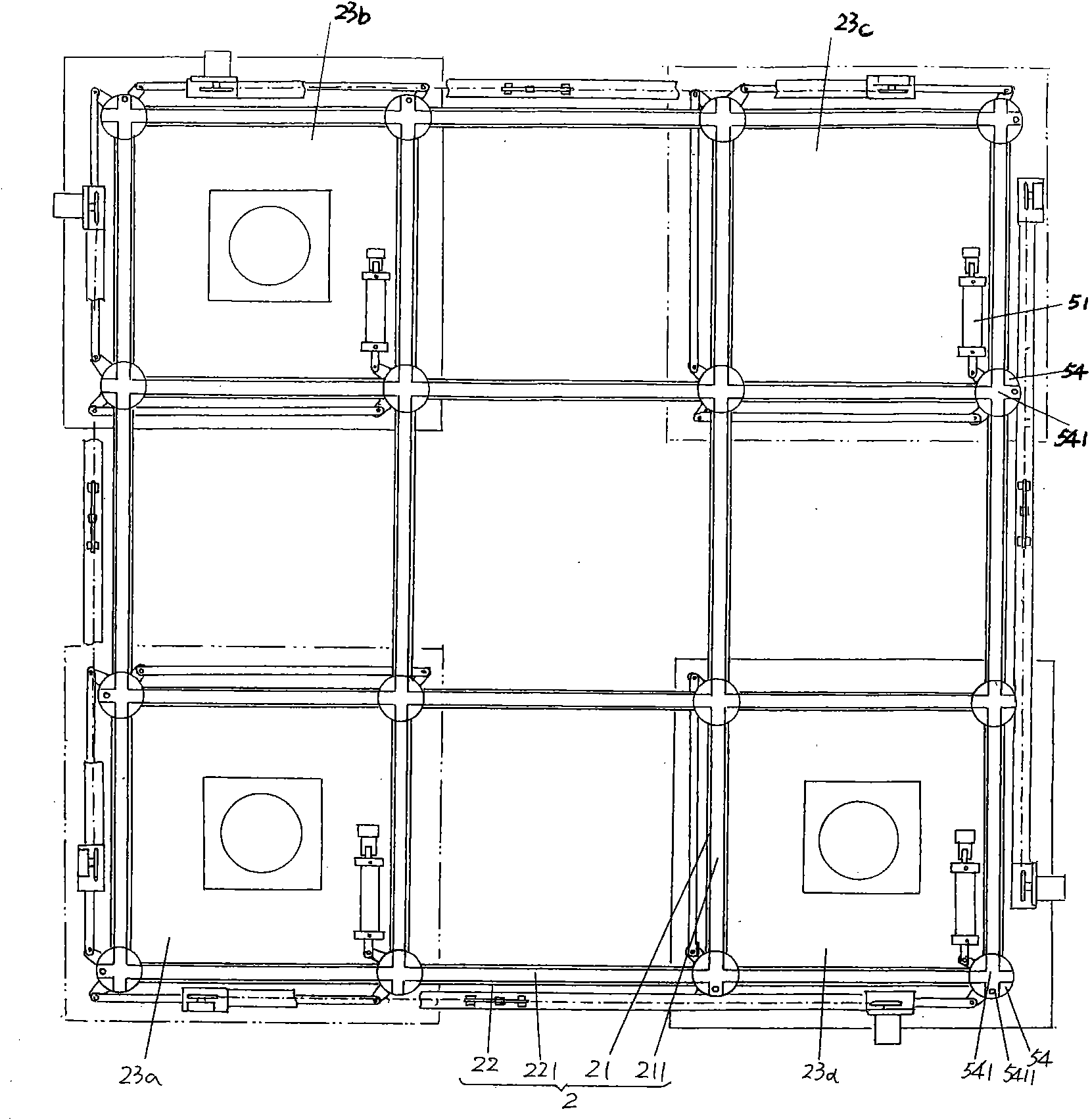

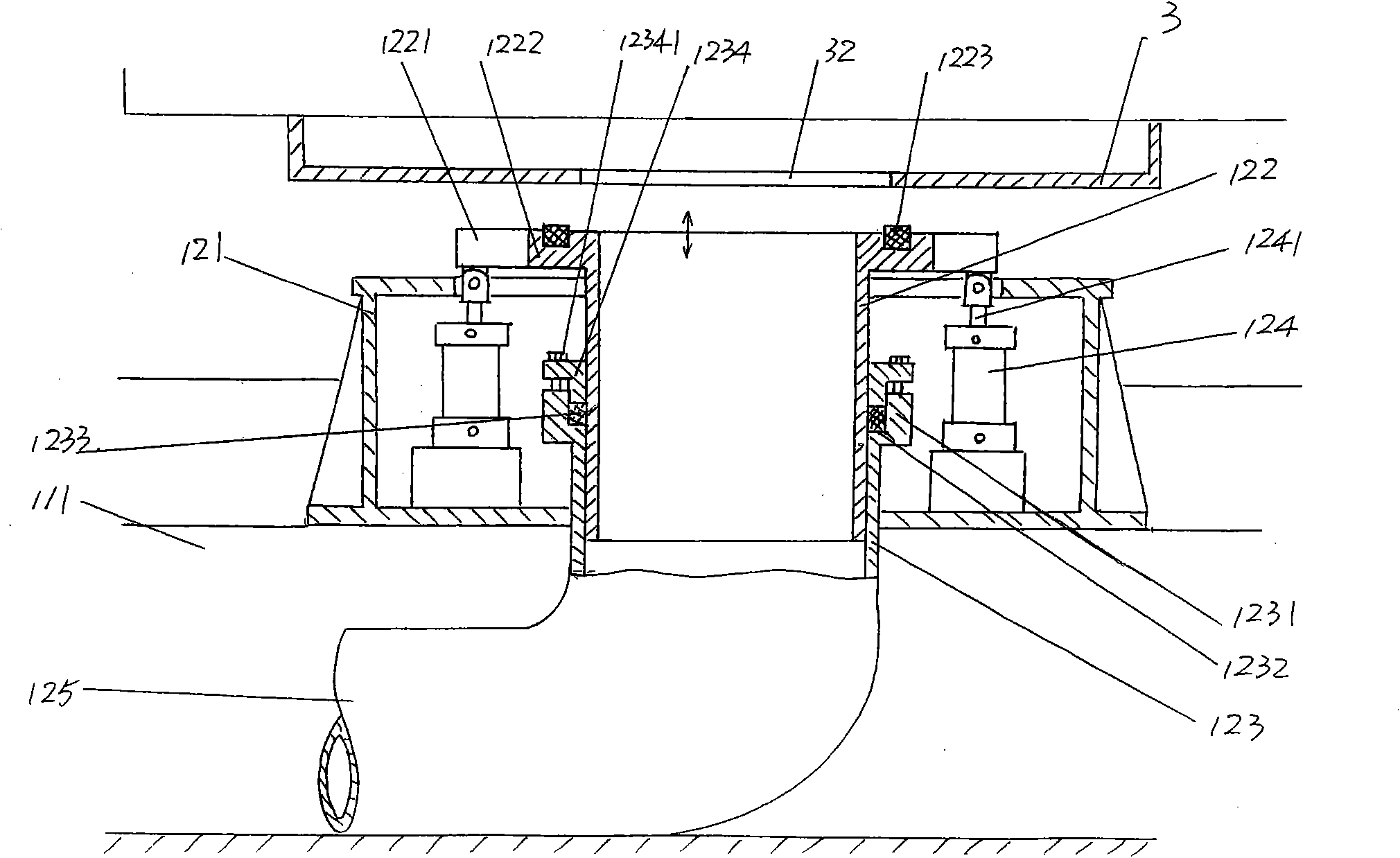

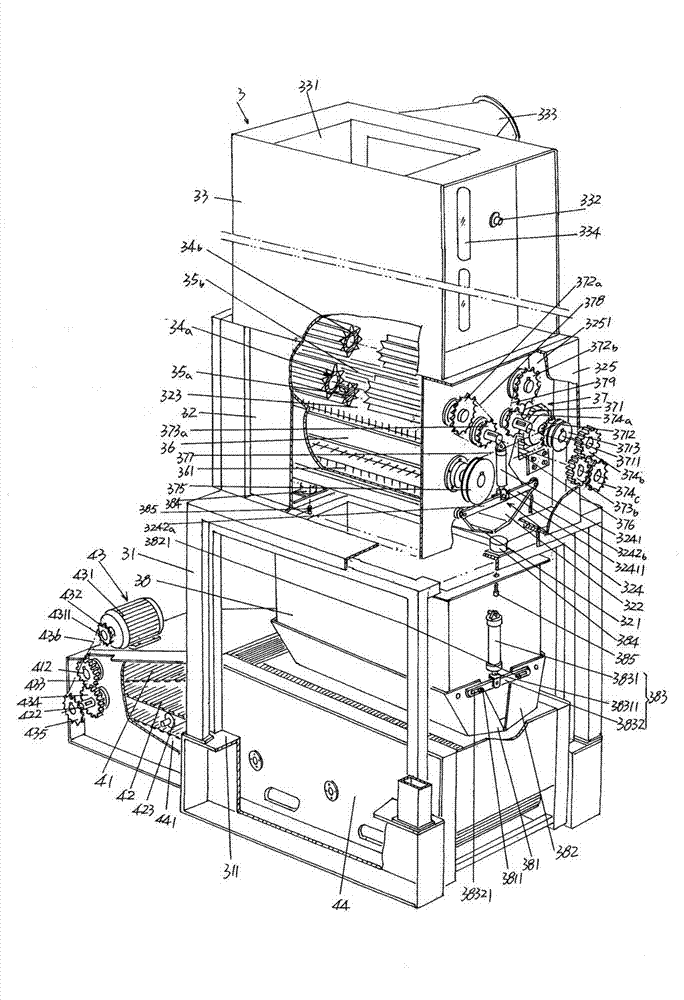

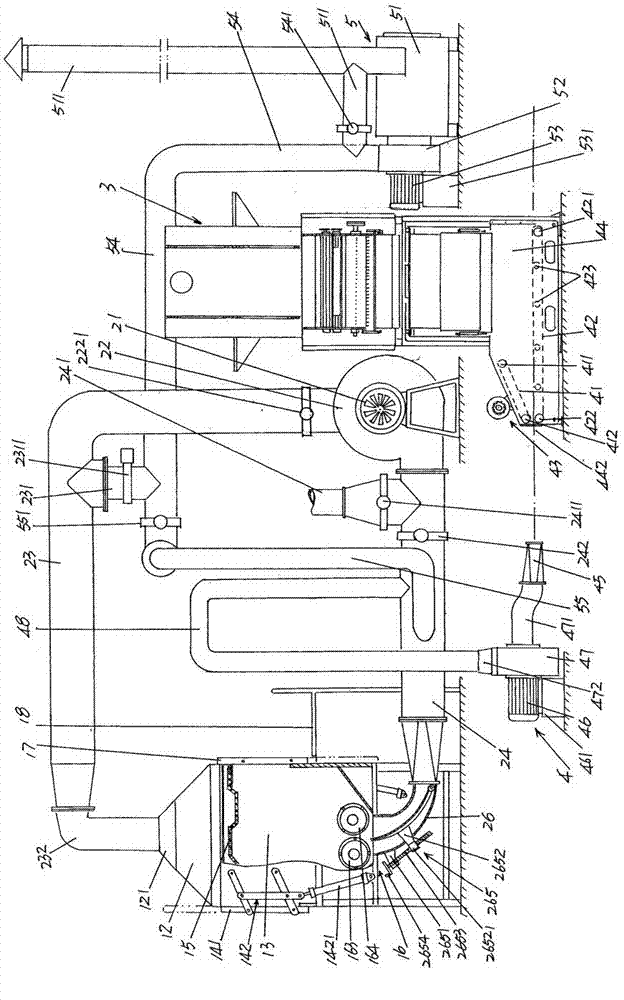

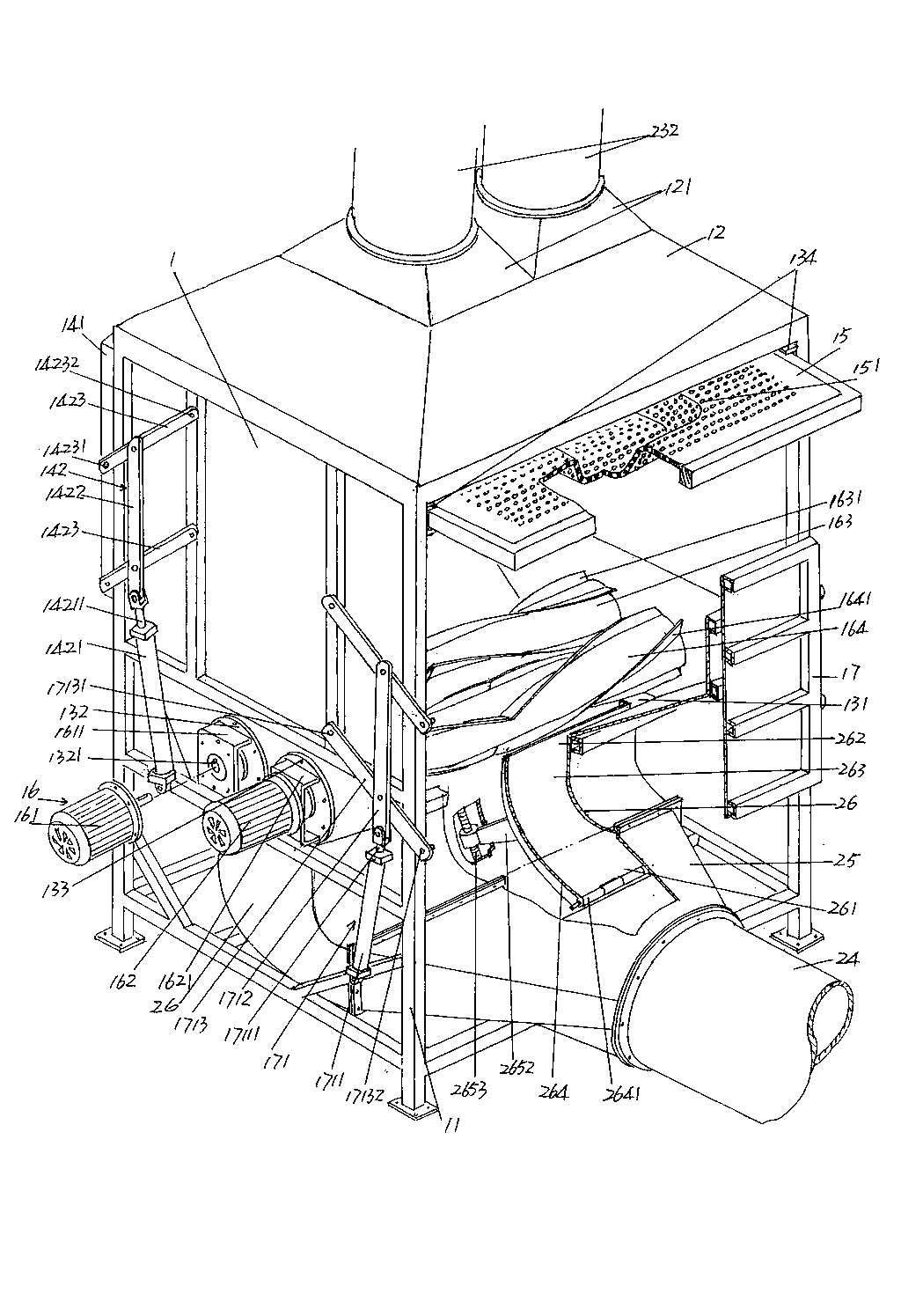

Automatic molding machine for automobile interior part felt

InactiveCN101775708AHigh degree of collectionIncrease productivityFelting apparatusFrame basedMolding machine

The invention discloses an automatic molding machine for an automobile interior part felt and belongs to molding machinery of automobile interior parts. The automatic molding machine comprises a frame base, a rail assembly, three lower molds, a group of lower mold station moving mechanisms, a group of lower mold station reversing mechanisms, a pair of pressing upper molds, a feed supplementing mechanism and a net laying mechanism. The rail assembly consists of a group of longitudinal guide rails and a group of transverse guide rails, and is arranged on the frame base, and the longitudinal guide rails and the transverse guide rails are vertically staggered to form a feed complementing station, a pre-pressing station, a net laying station and a molding station. The three lower molds which are provided with a lower mold base are arranged on the rail assembly. The group of lower mold station moving mechanisms are arranged on the frame base. The group of lower mold station reversing mechanisms are arranged on the frame base and matched with the intersection formed by vertically intersecting the transverse guide rails and longitudinal guide rails. The pair of pressing upper molds which is provided with the upper mold base is arranged on the frame base, wherein one pressing upper mold corresponds to the upper part of the pre-pressing station, and the other pressing upper mold corresponds to the upper part of the molding station. The feed complementing mechanism is arranged on the frame base and corresponds to the upper part of the feed complementing station. The net laying mechanism is arranged on the frame base and corresponds to the upper part of the net laying station. The automatic molding machine for the automobile interior part felt has the advantages of high integration degree, small occupancy area, a few on-line workers, high production efficiency and energy conservation.

Owner:常熟市双龙无纺设备有限公司

Micro staple fiber nonwoven fabric and leather-like article in sheet form, and method for their production

InactiveUS20060234587A1Good strength performanceQuality improvementSynthetic resin layered productsAbsorbent padsApparent densityPolymer science

To provide a nonwoven fabric containing ultra-fine fibers suitable as a leather-like sheet, and also a leather-like sheet with an excellent compactness. A nonwoven fabric containing ultra-fine fibers, characterized in that it contains staple fibers with a fiber fineness of 0.0001 to 0.5 decitex and a fiber length of 10 cm or less, and has a weight per unit area of 100 to 550 g / m2, an apparent density of 0.280 to 0.700 g / cm3, a tensile strength of 70 N / cm or more, and a tear strength of 3 to 50 N.

Owner:TORAY IND INC

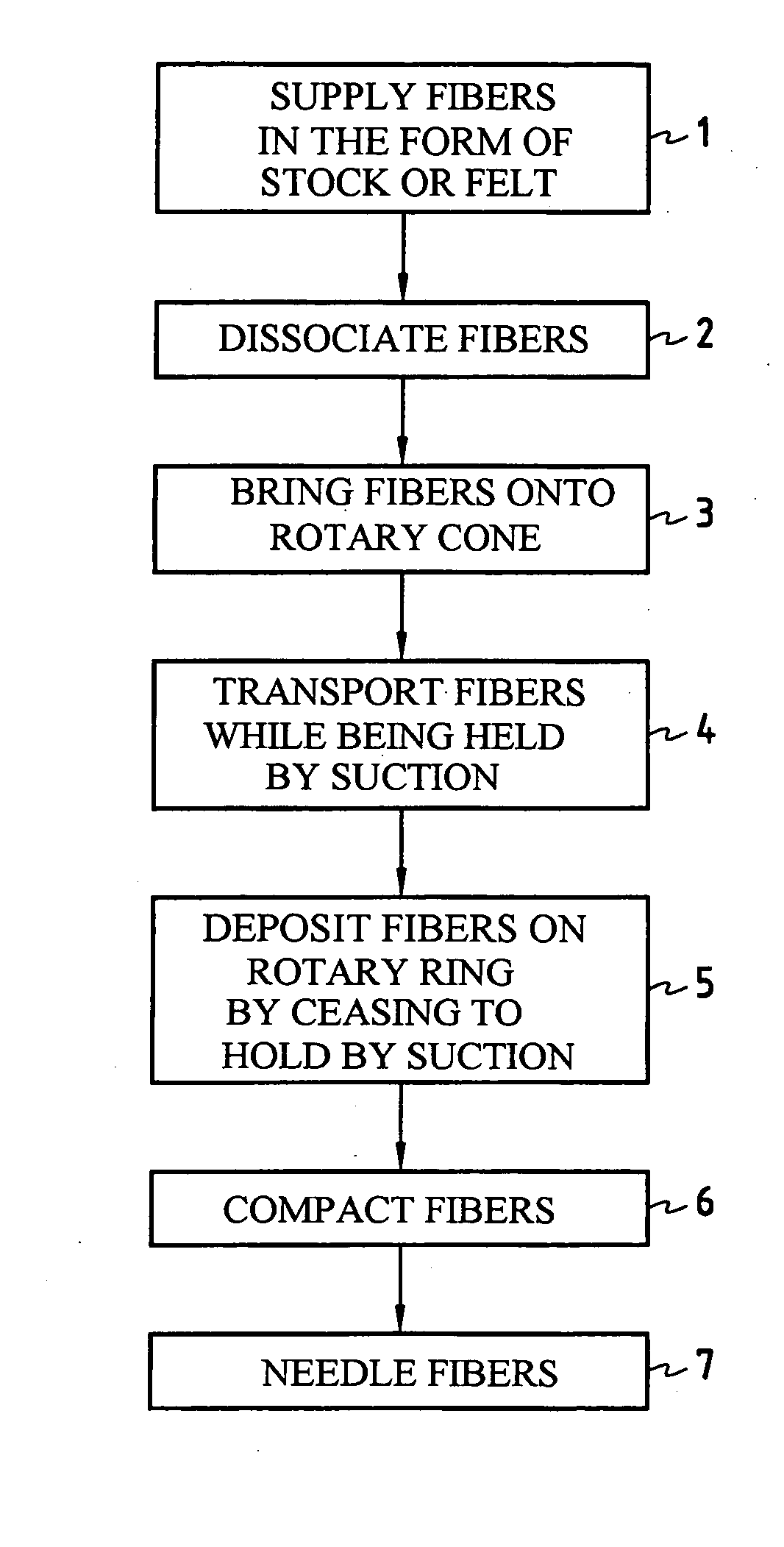

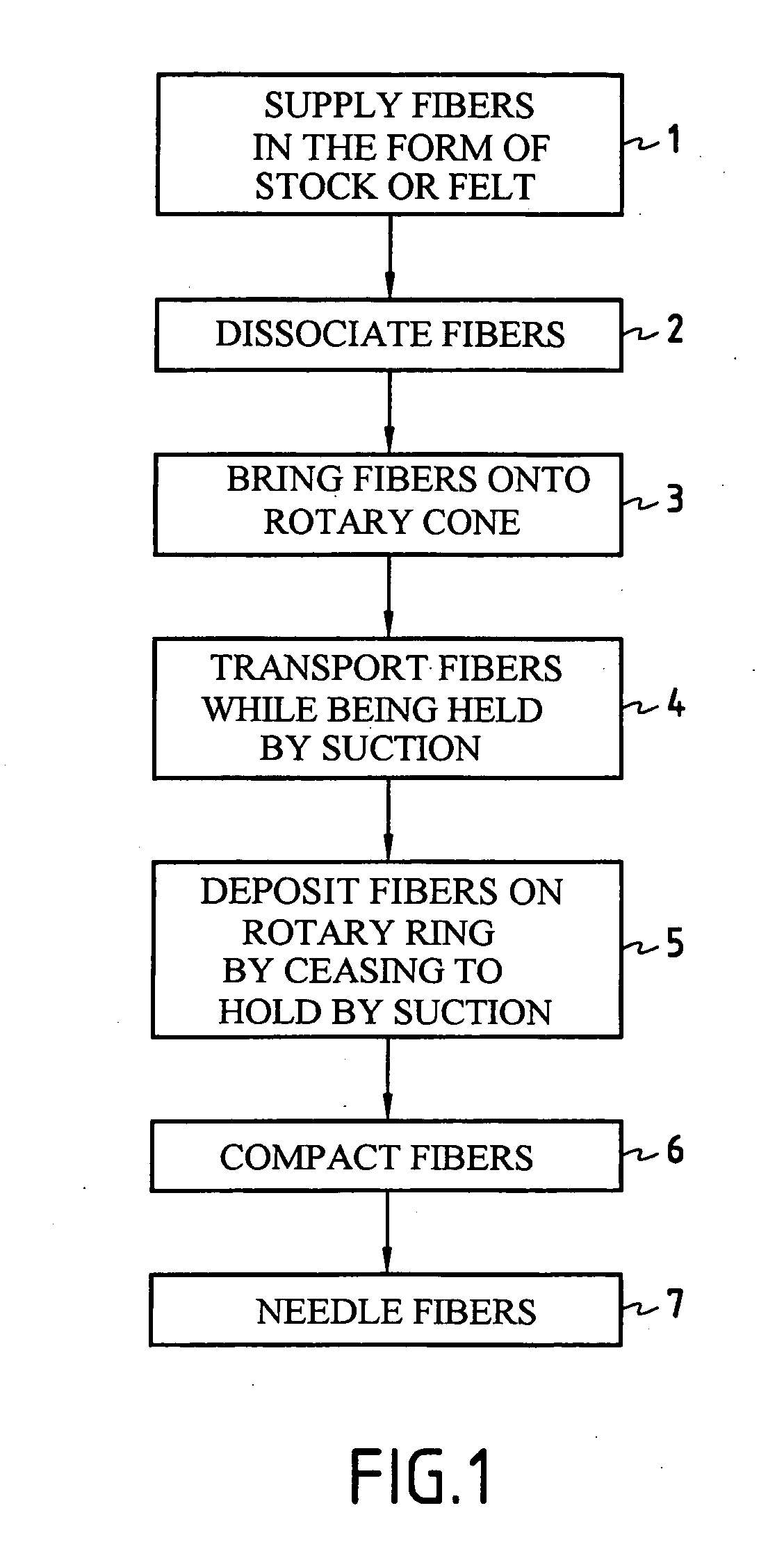

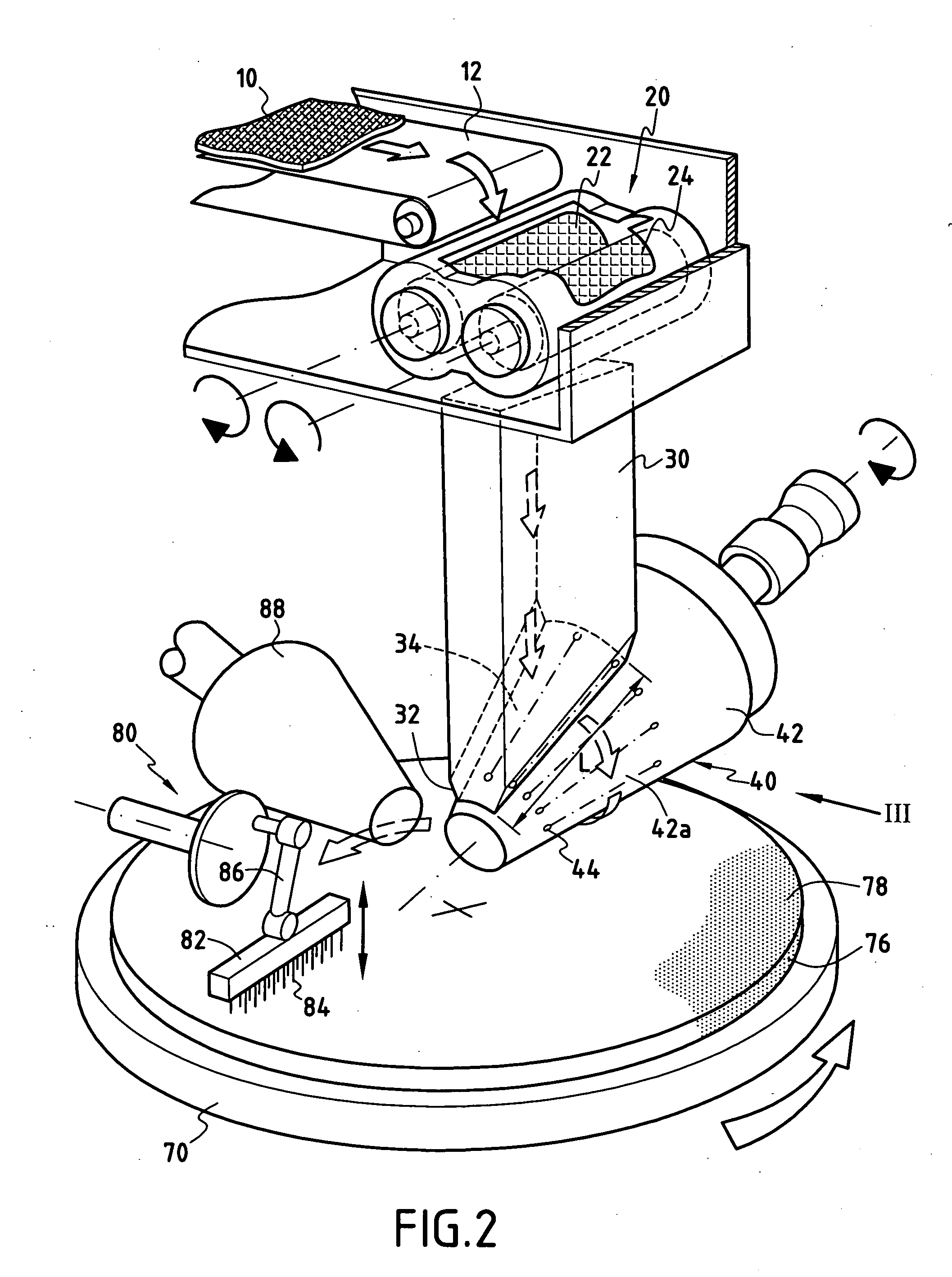

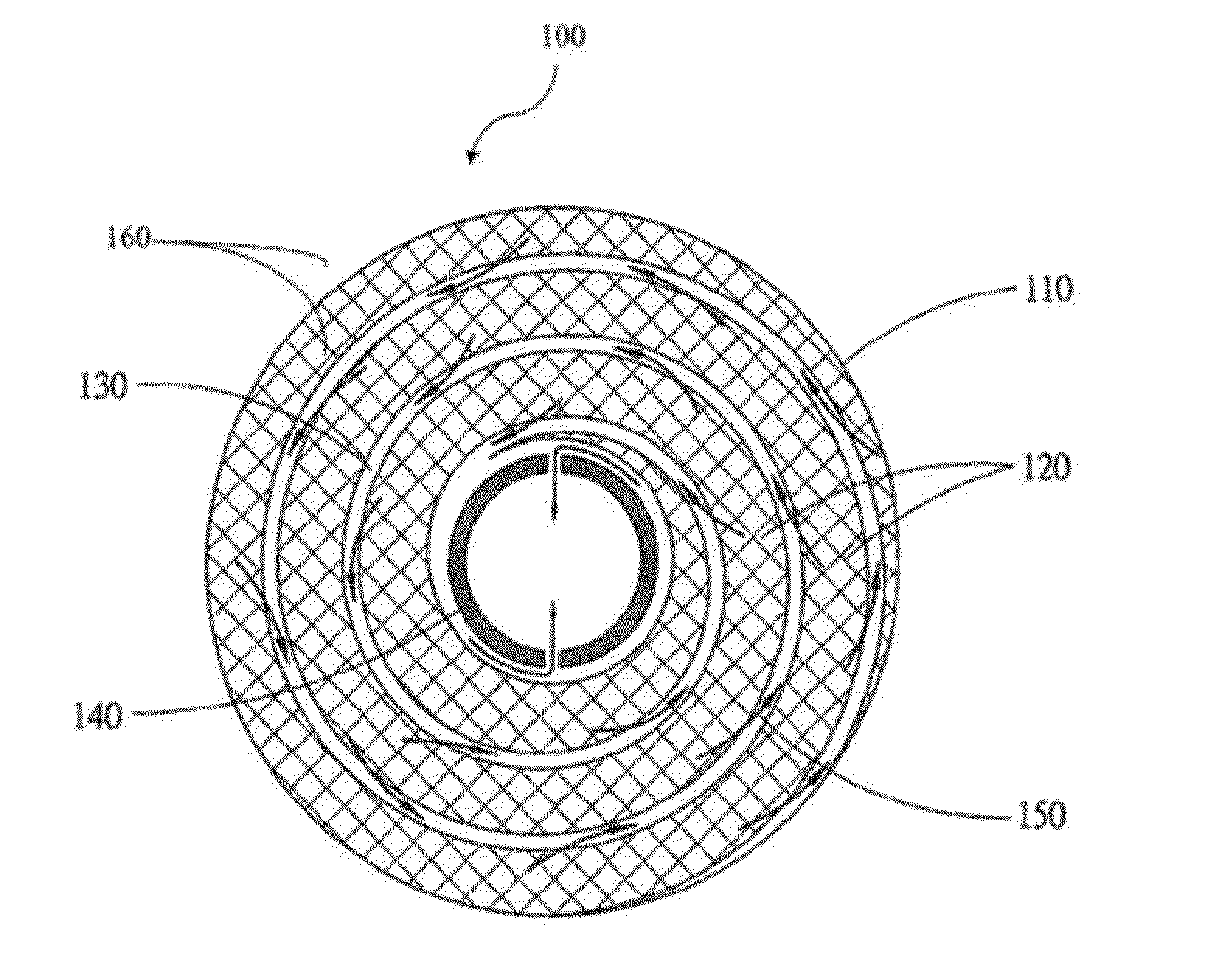

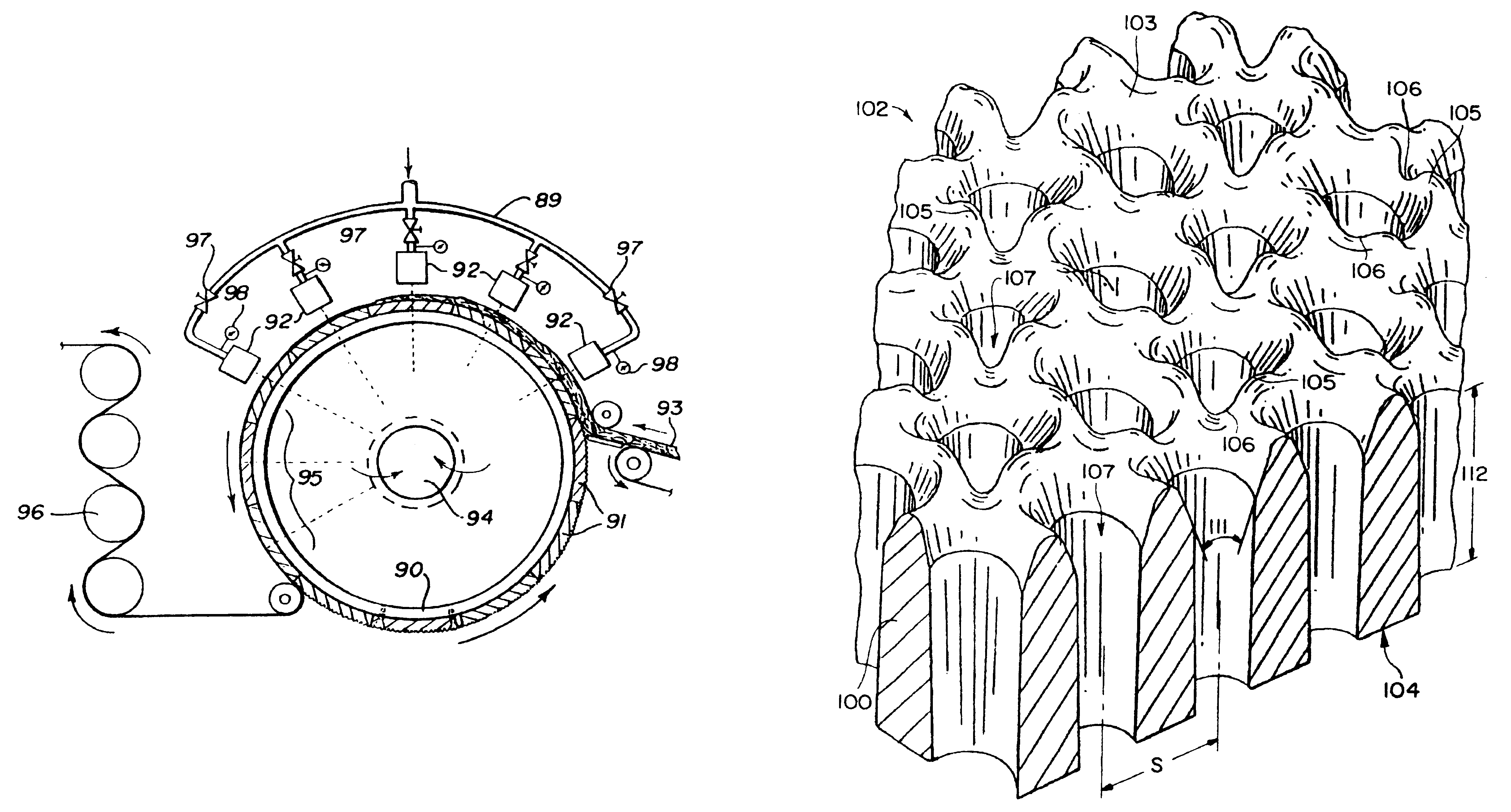

Method and system for the manufacture of annular fibrous preforms

Owner:MESSIER BUGATTI INC

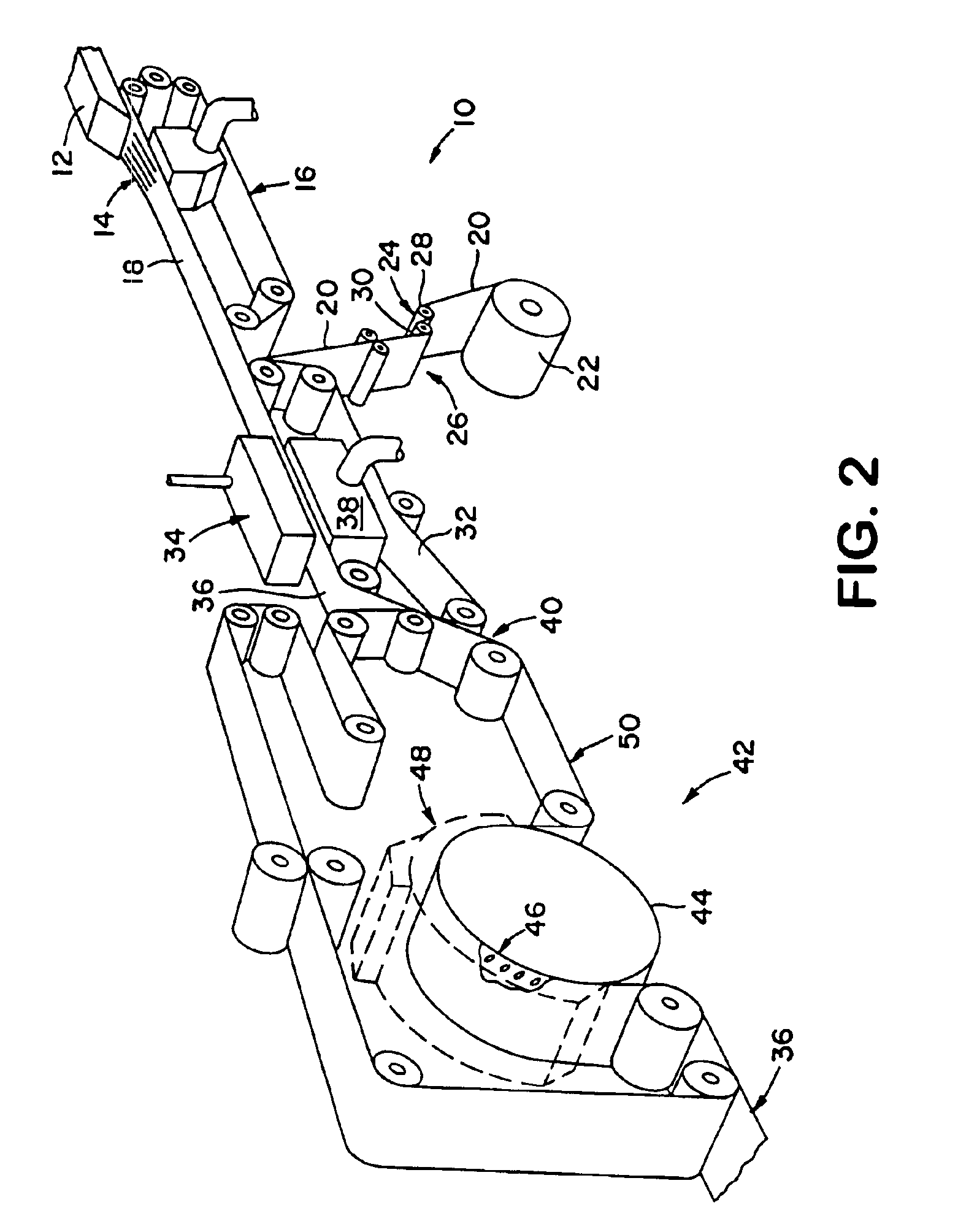

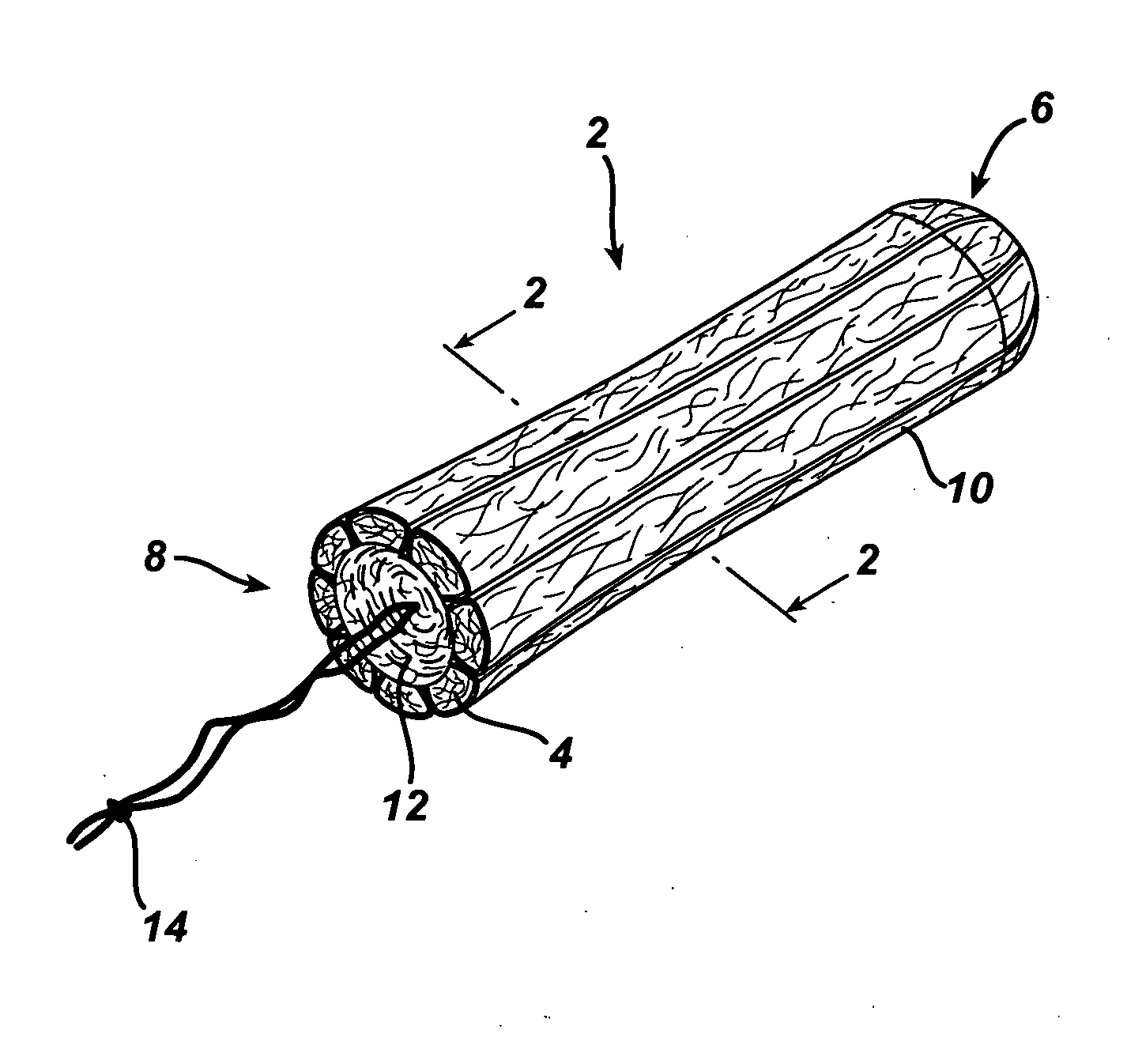

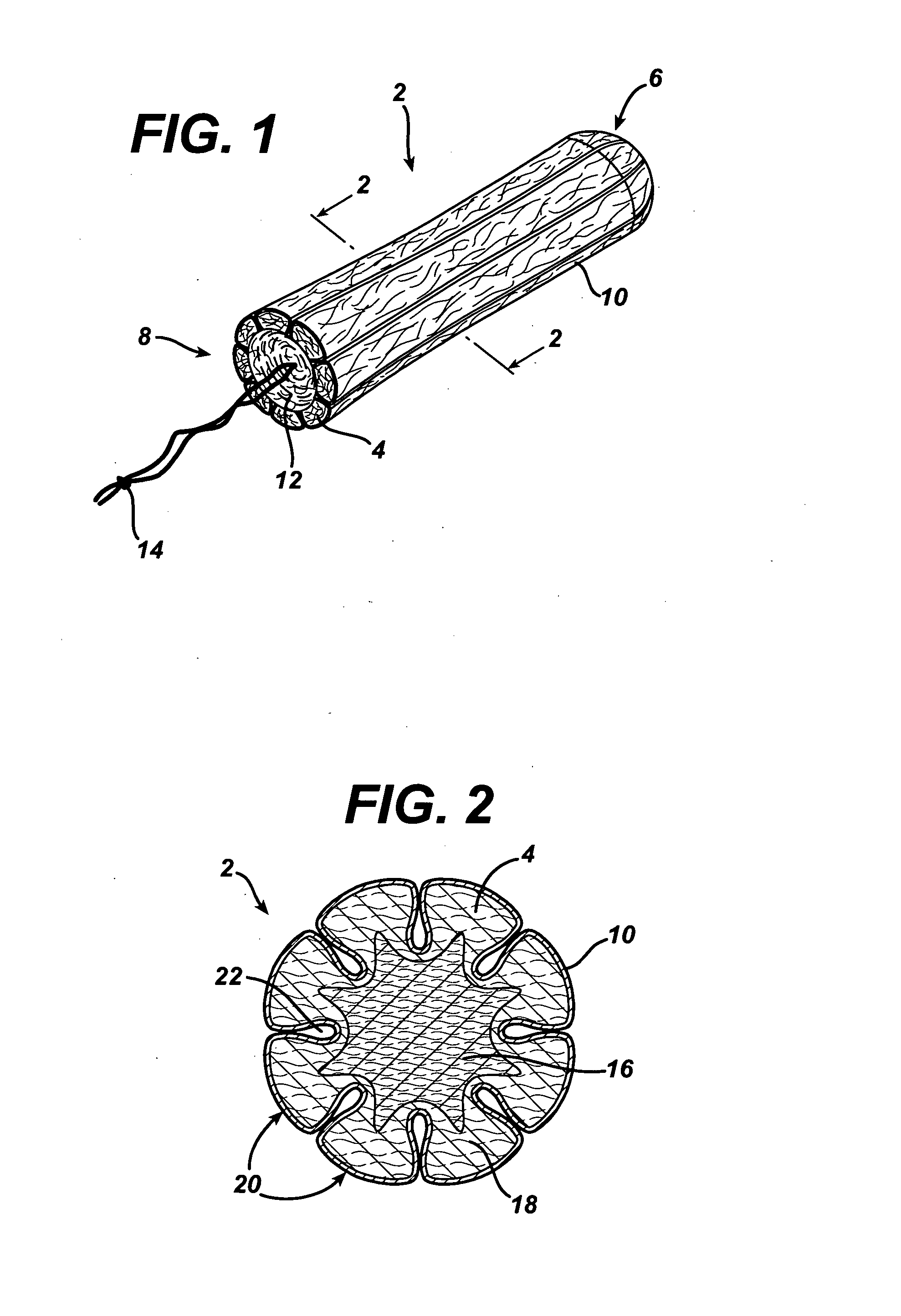

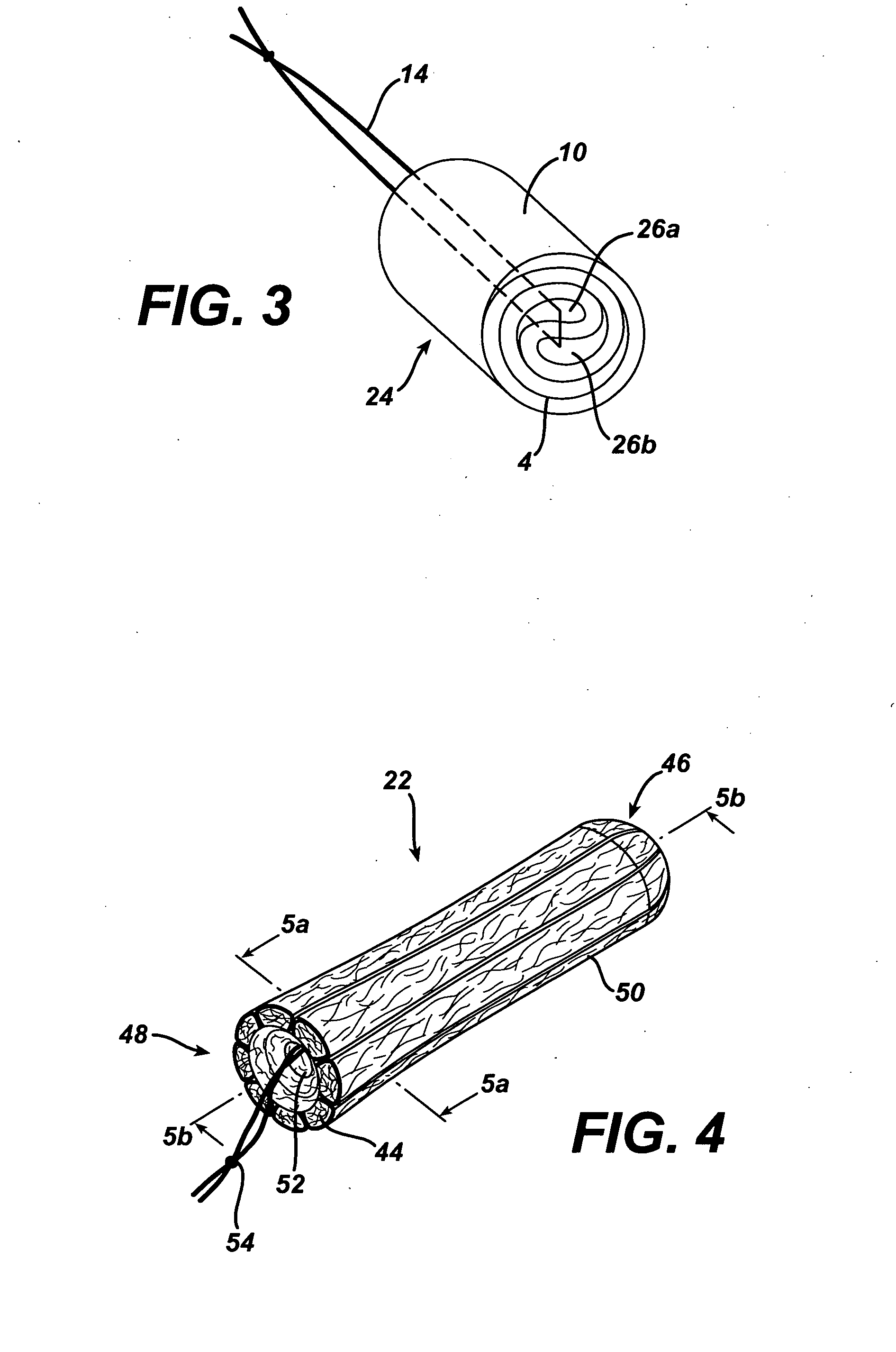

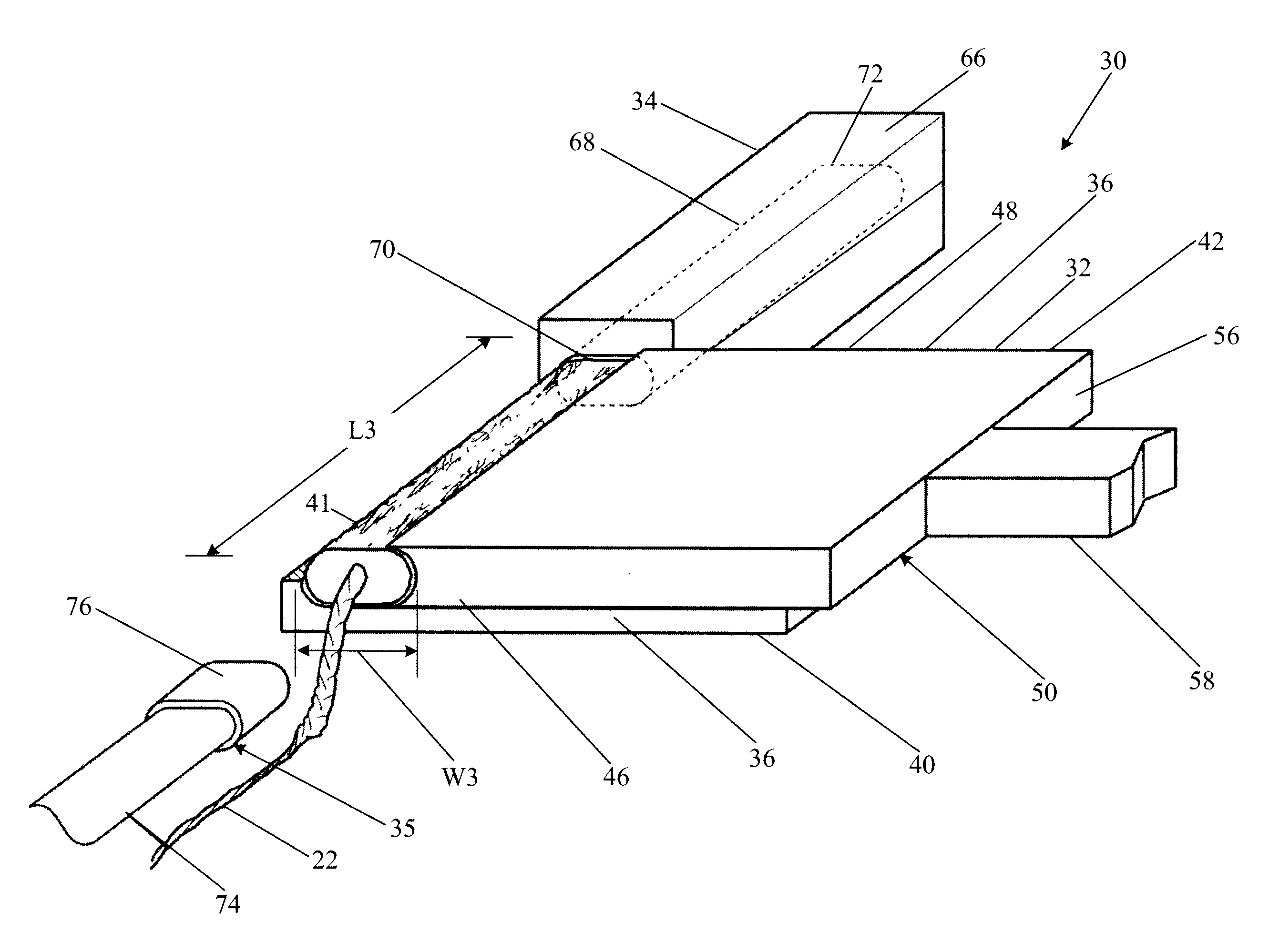

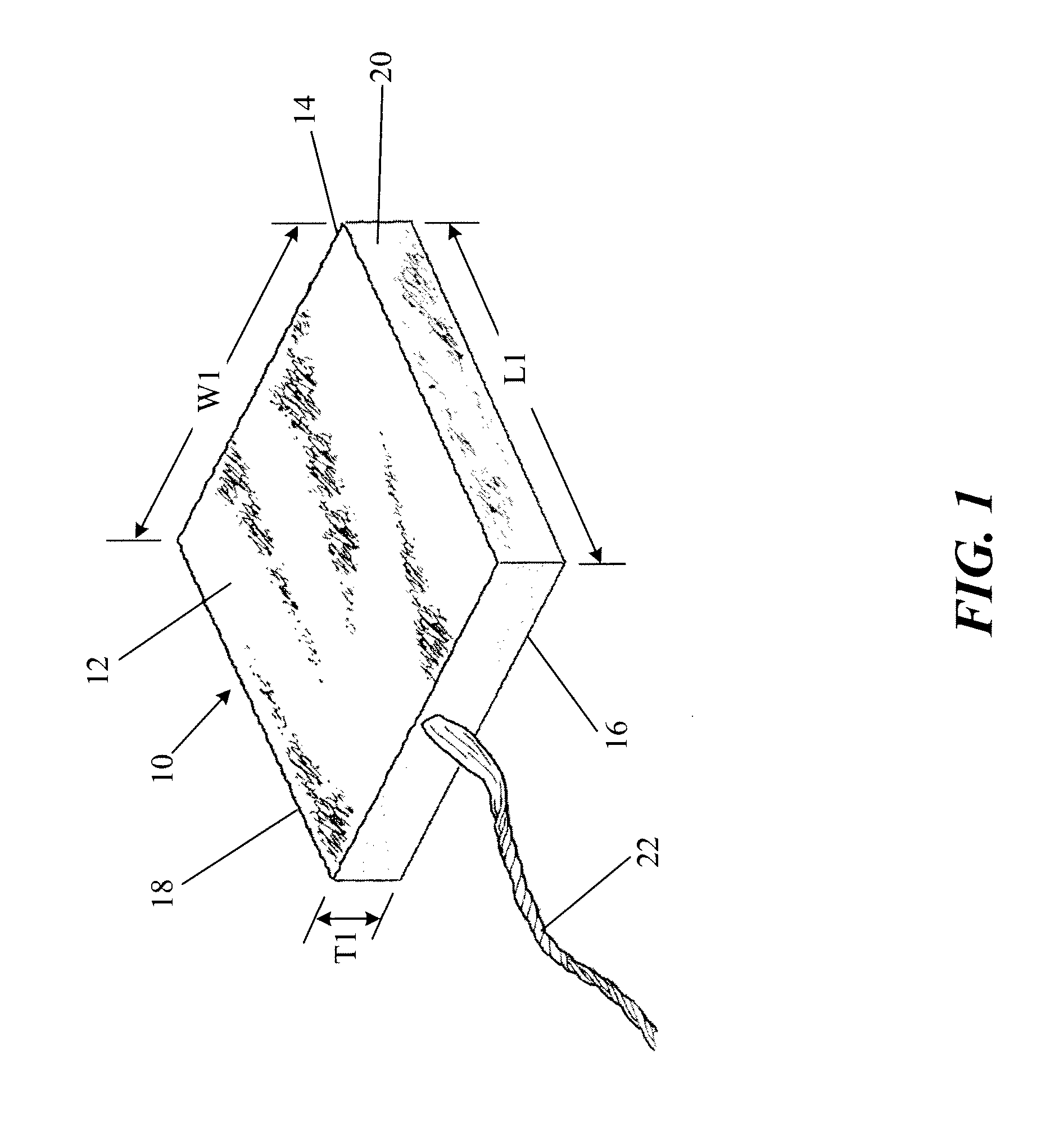

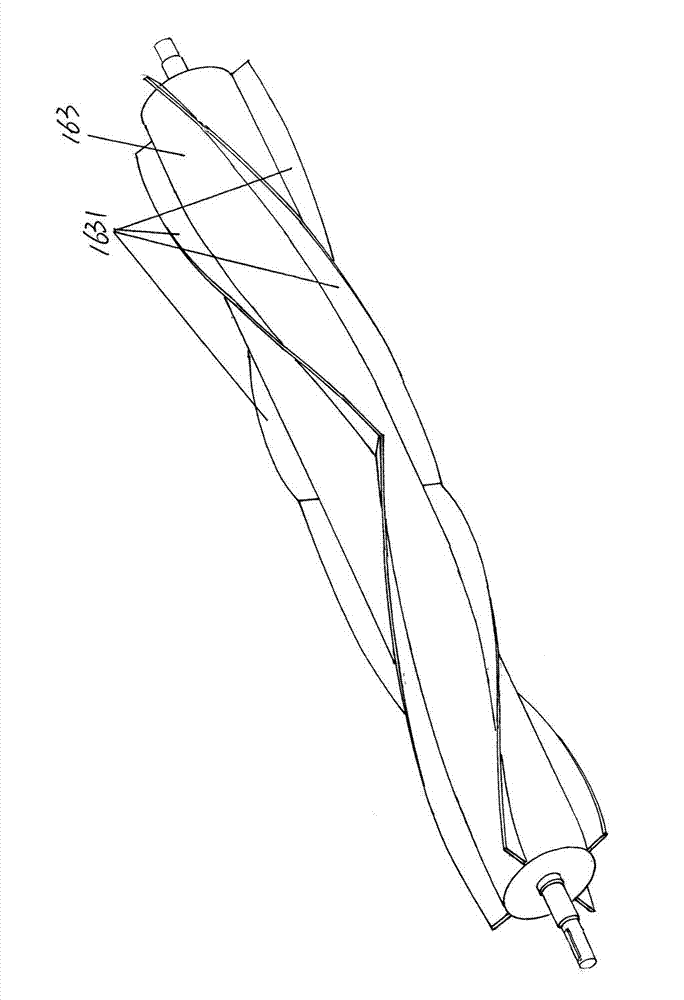

Absorbent Tampon Providing Clean Digital Insertion

A tampon has a generally uniform fiber distribution along its length, an insertion end, a withdrawal end, and a longitudinal axis. A finger recess having a depth of at least about 5 mm is formed into the withdrawal end. Nonetheless, a column strength of at least about 10 Newtons (N) can still be achieved. The tampon can be formed by winding an absorbent fibrous web around a winding mandrel; transferring the blank into a press; inserting a forming mandrel into one end of a tampon blank while the tampon blank is positioned in the press; moving a plurality of press jaws toward a central longitudinal press axis to compress the tampon blank and to form a compressed tampon having a finger recess formed into the one end of the tampon; and ejecting the compressed tampon from the press.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

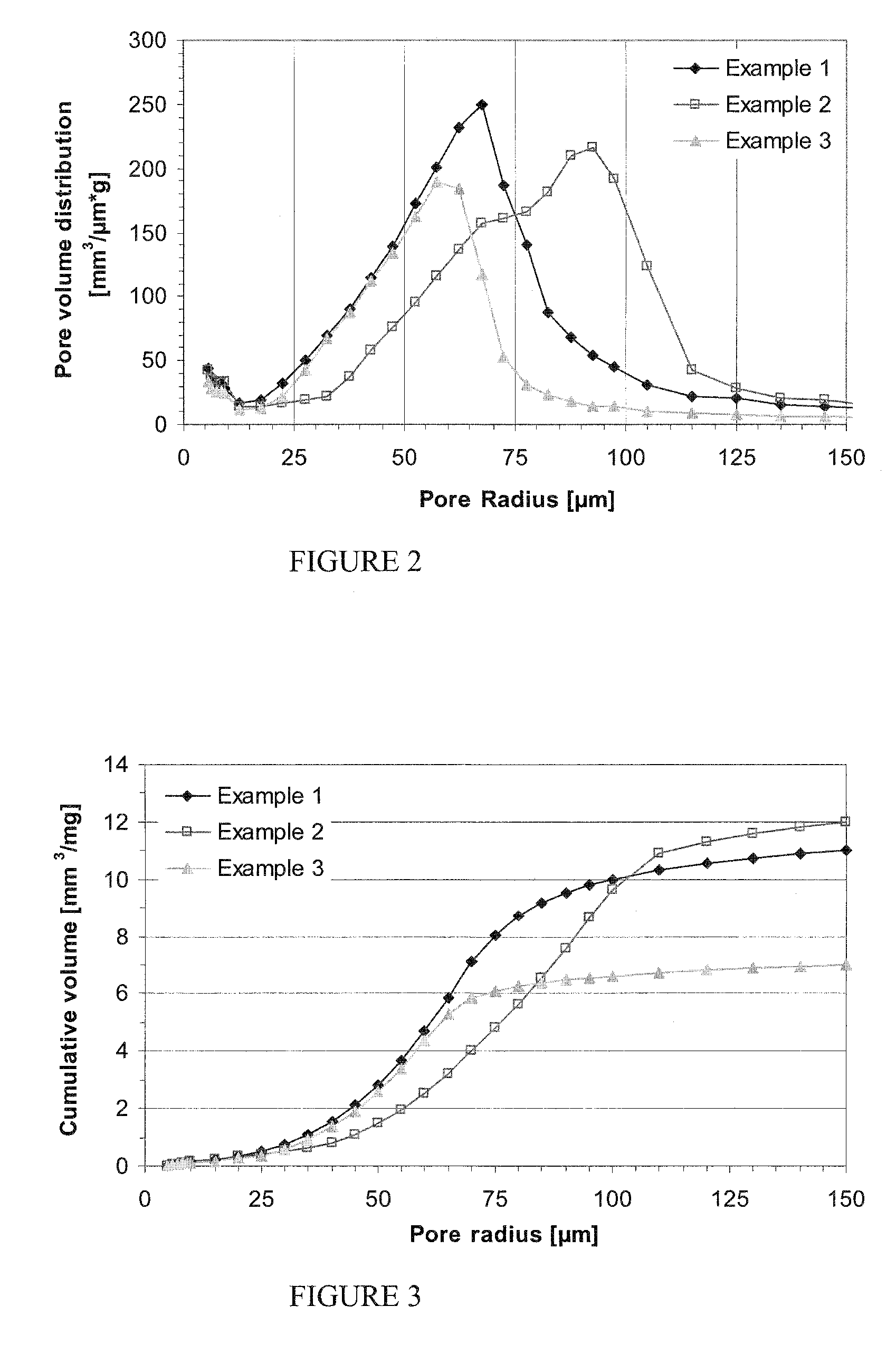

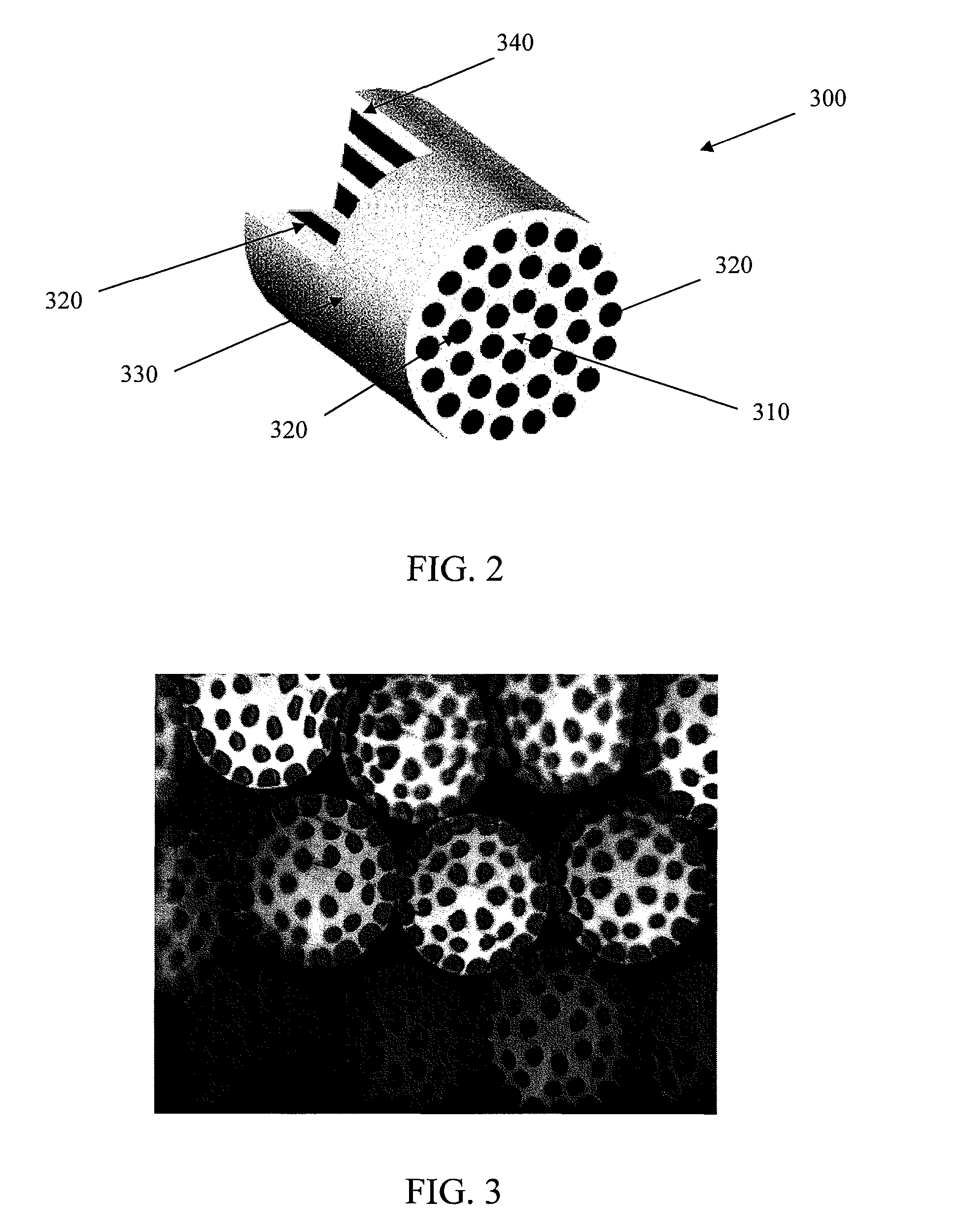

Hydroentangled integrated composite nonwoven material

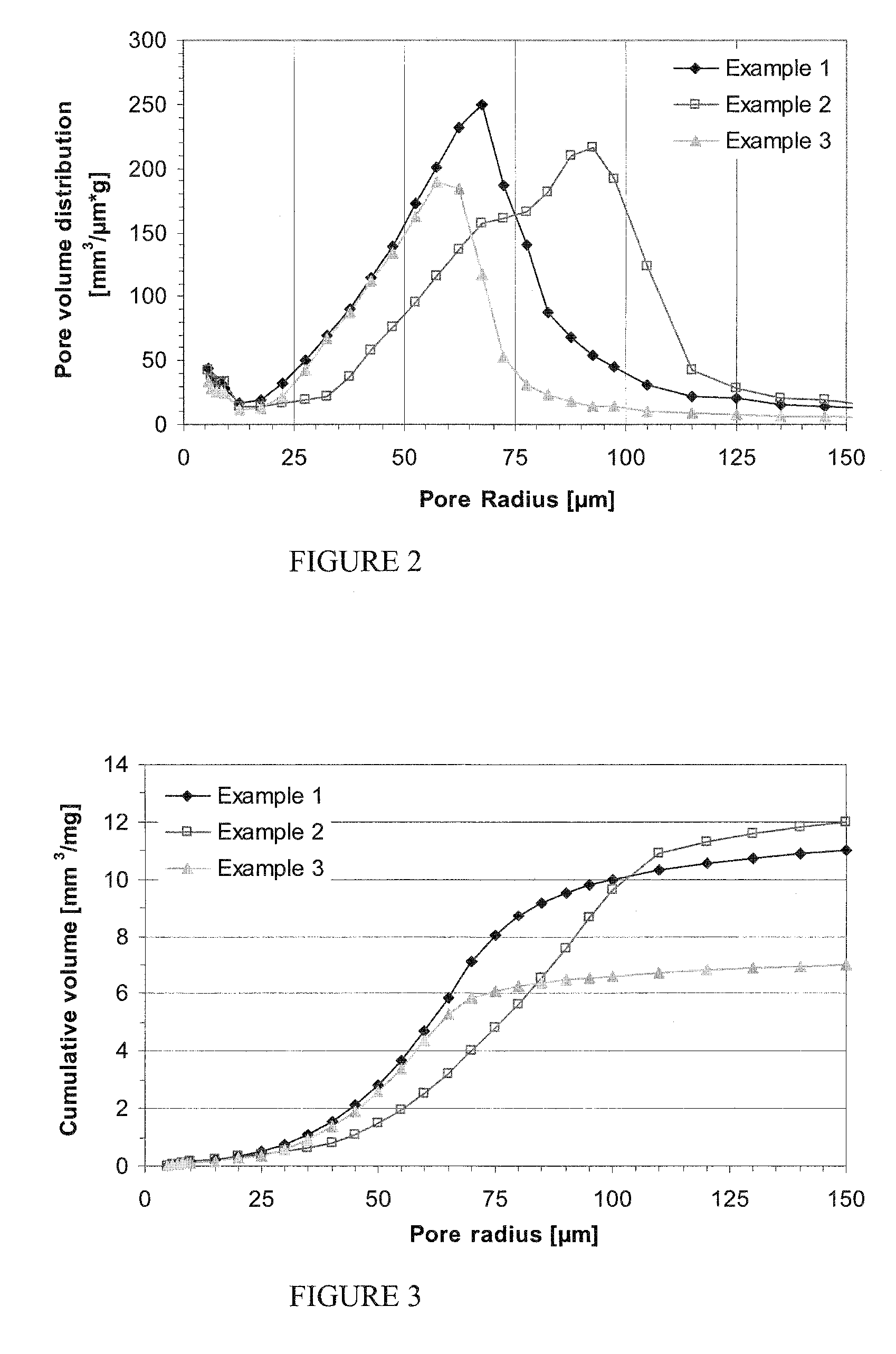

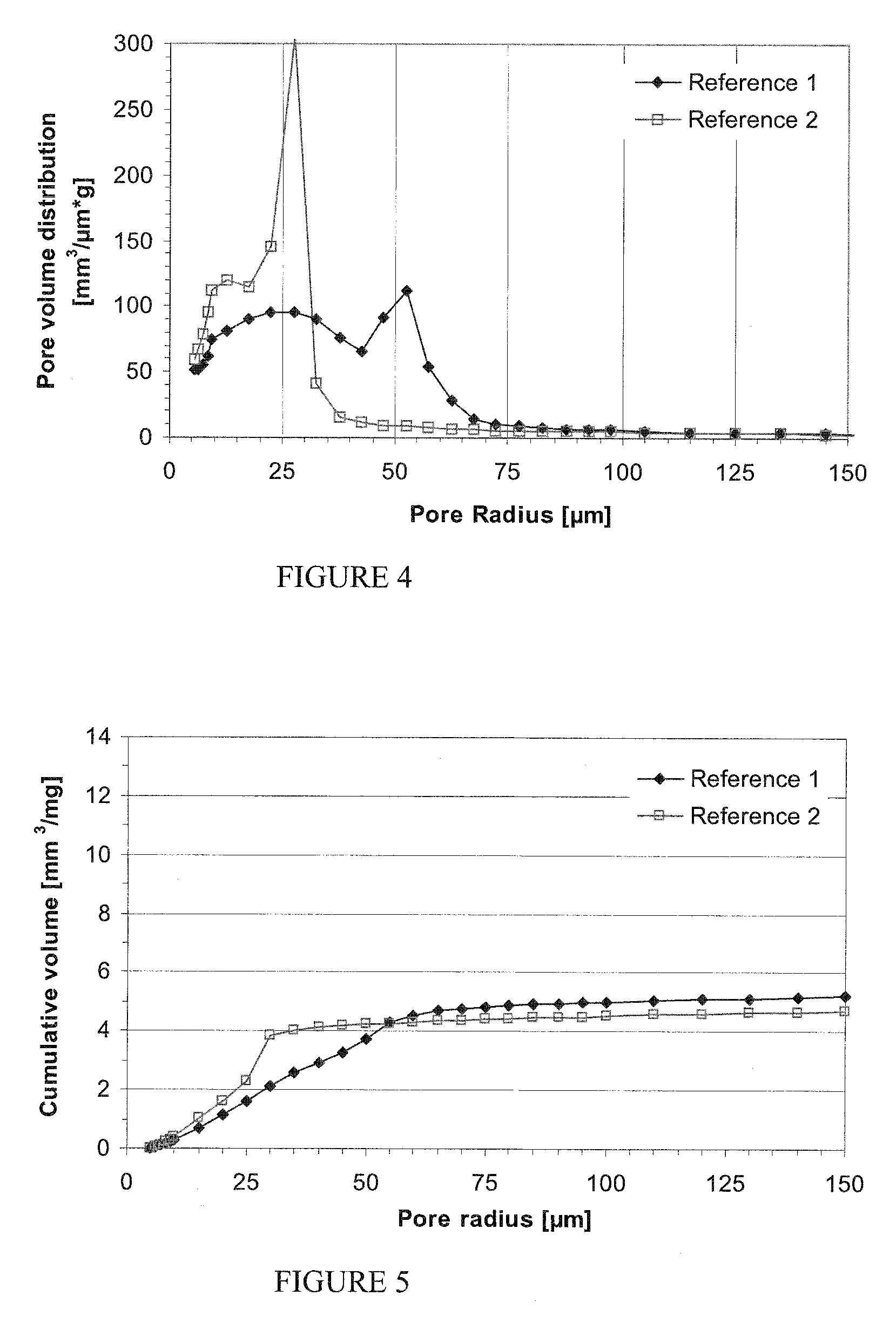

InactiveUS20080050996A1Facilitated releaseLarge hole volumePattern makingLayered productsPolyesterPolymer science

An hydroentangled integrated composite nonwoven material, includes a mixture of randomized continuous filaments, and synthetic staple fibers, where there are no thermal bonding points between the continuous filaments. The nonwoven material exhibits a cumulative pore volume, measured by PVD in n-hexadecane, in the pore radius range 5-150 μm, where at least 70% of the cumulative pore volume is in the pores with a pore radius above 45 μm. The nonwoven material also exhibits a cumulative pore volume, which when the synthetic staple fibers are chosen from the group of polyethylene, polypropylene, polyester, polyamide, and polylactide staple fibers is at least 9 mm3 / mg, and when the synthetic staple fibers are lyocell staple fibers is at least 6 mm3 / mg.

Owner:SCA HYGIENE PROD AB

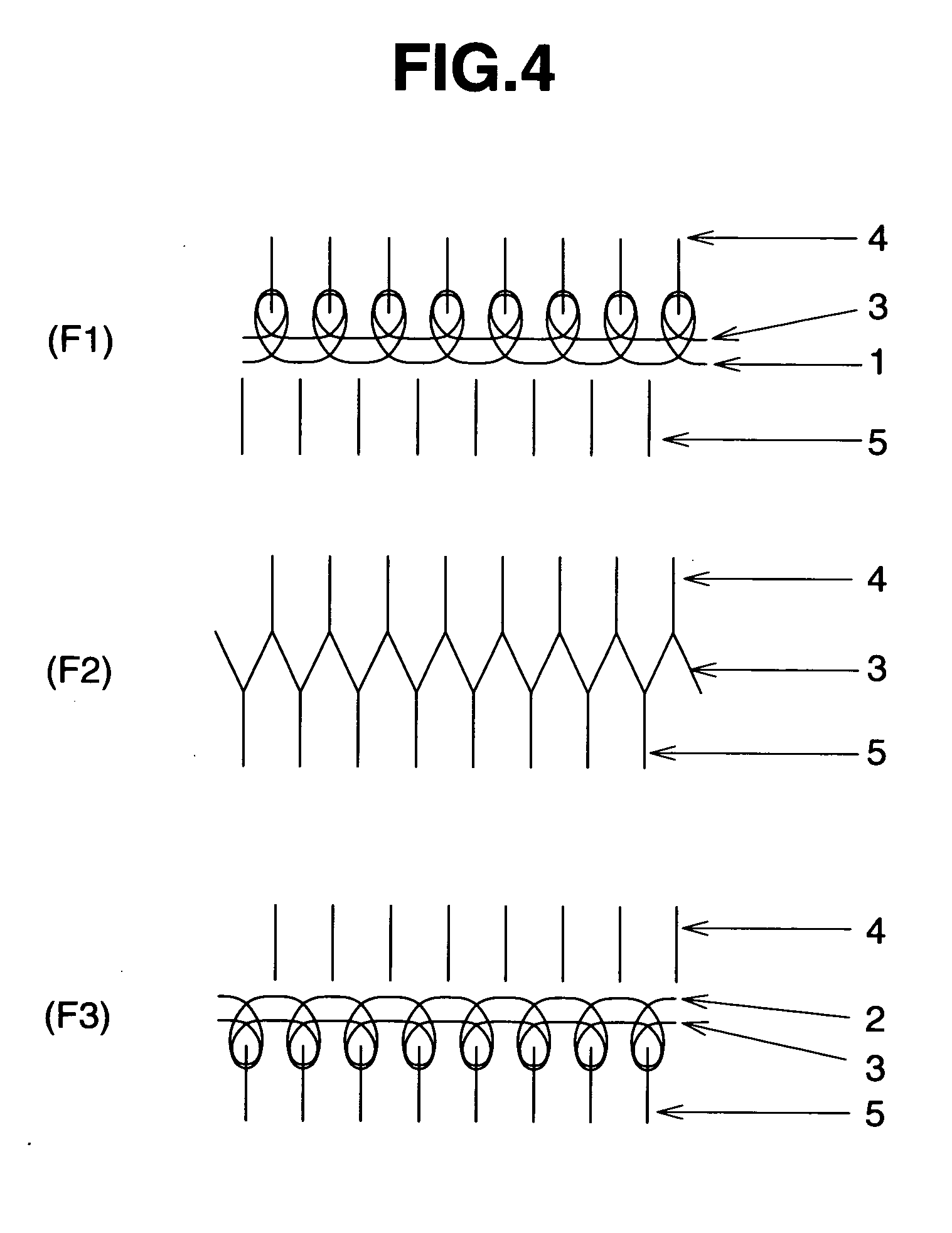

Weft Knitted Fabric Including Polyurethane Elastomer Fiber and Process for Producing the Same

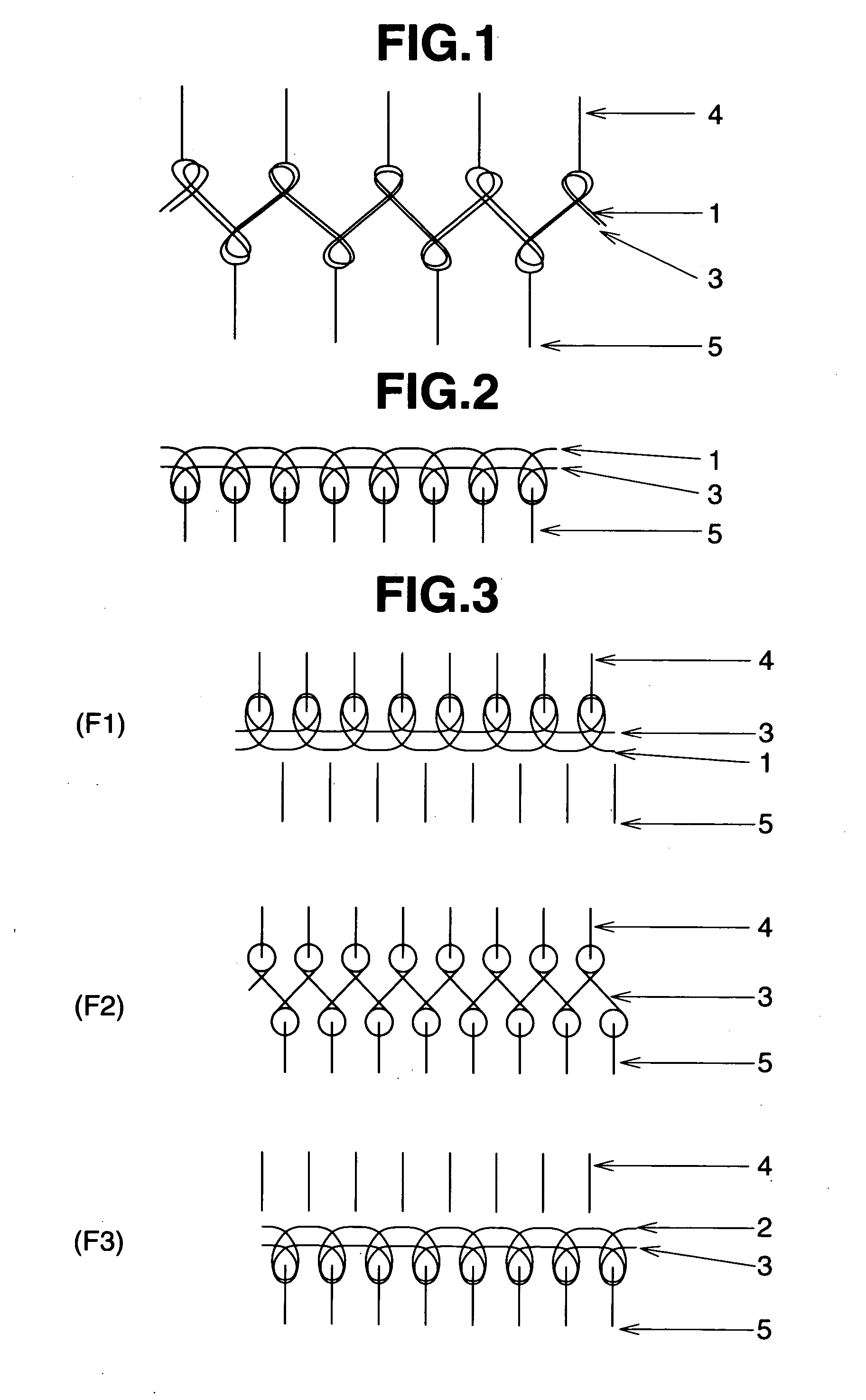

ActiveUS20080032580A1Good extensibilityPromote recoveryOrnamental textile articlesWarp knittingYarnPolyurethane elastomer

A polyurethane elastomeric filament-containing weft knit fabric is obtained by plating a bare yarn of highly fusible, alkali-resistant polyurethane elastomeric filament having at least 50% retention of tenacity following dry heat treatment under 100% extension at 150° C. for 45 seconds, a melting point of 180° C. or below, and at least 60% retention of tenacity following treatment in a 2 g / L aqueous sodium hydroxide solution under 100% extension at 100° C. for 60 minutes at every loop of a weft knit fabric having a 1×1 rib. knit structure or a center yarn-containing reversible knit structure composed of at least one type of non-elastomeric yarn, then heat setting the plated structure so as to thermally fuse the highly fusible, alkali-resistant polyurethane elastomeric filaments to each other or to the non-elastomeric yarns at crossover points therebetween.

Owner:NISSHINBO TEXTILE INC +1

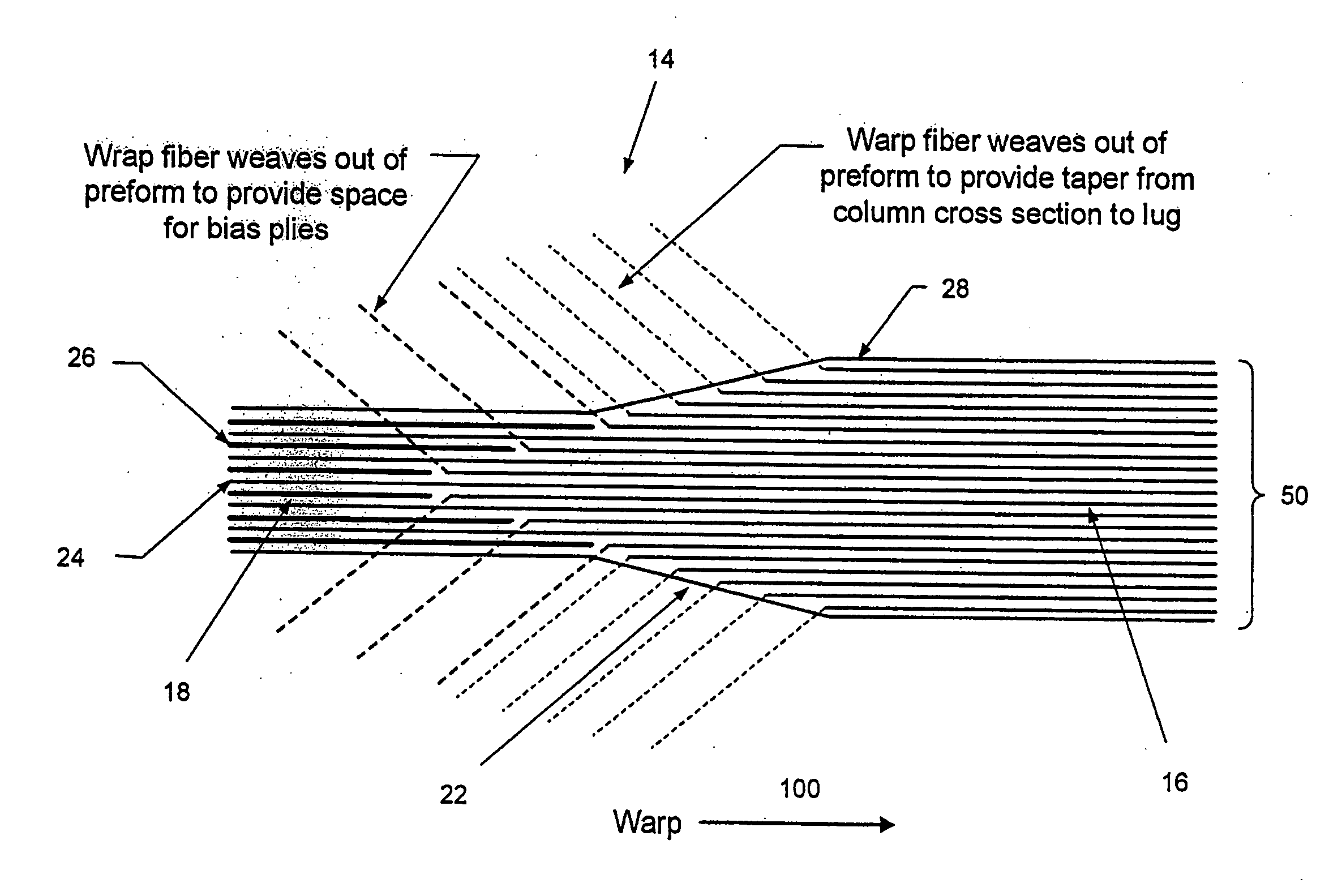

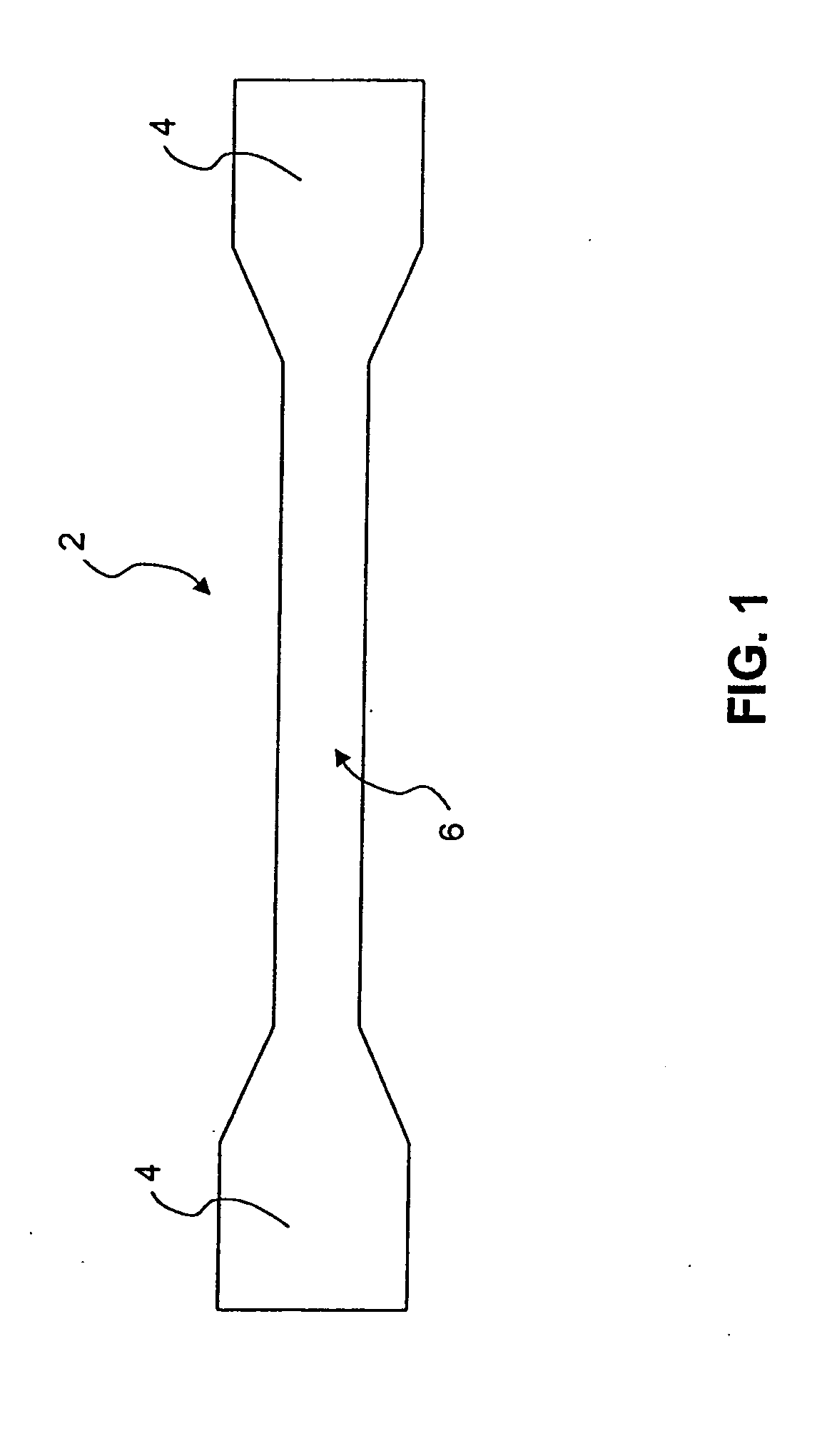

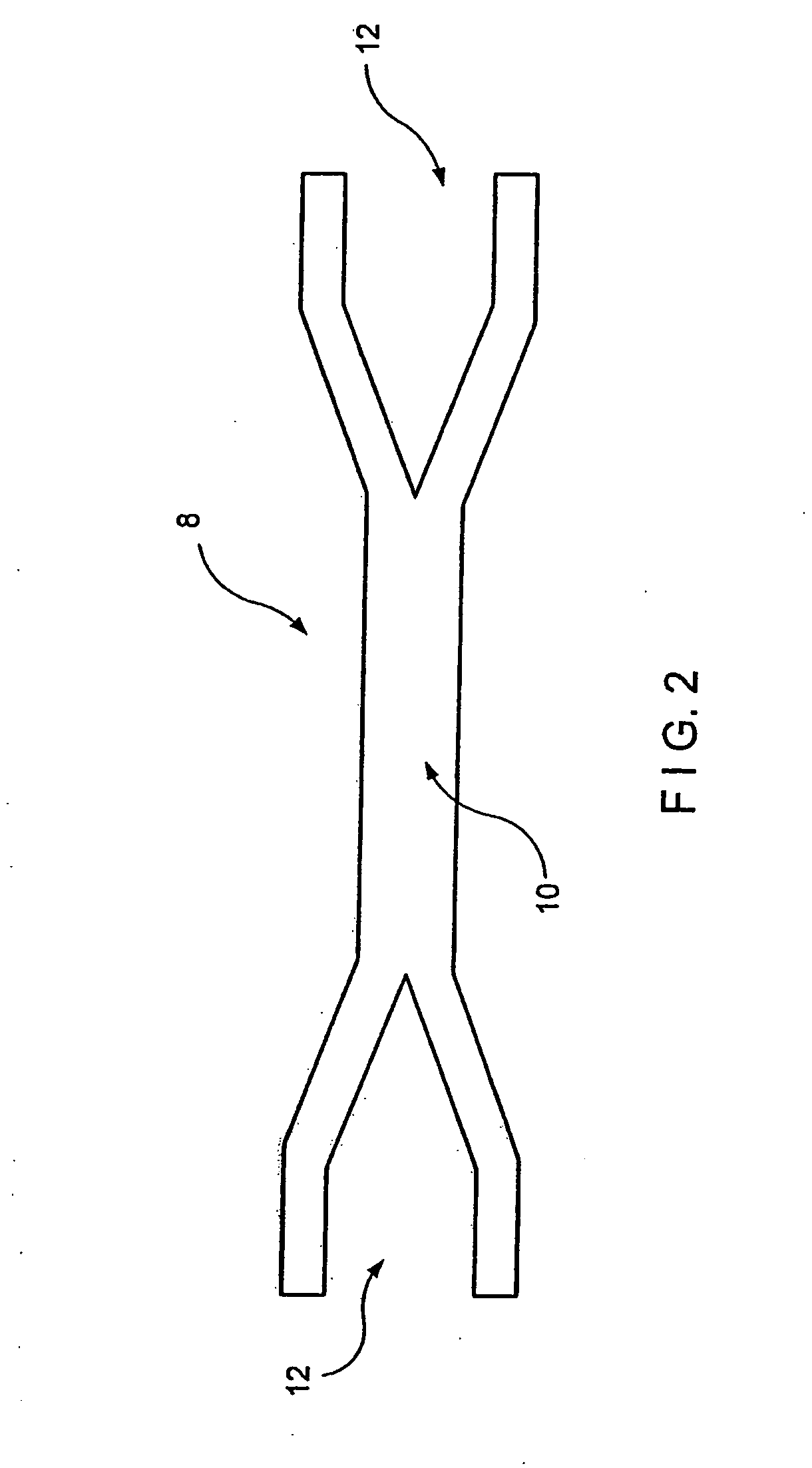

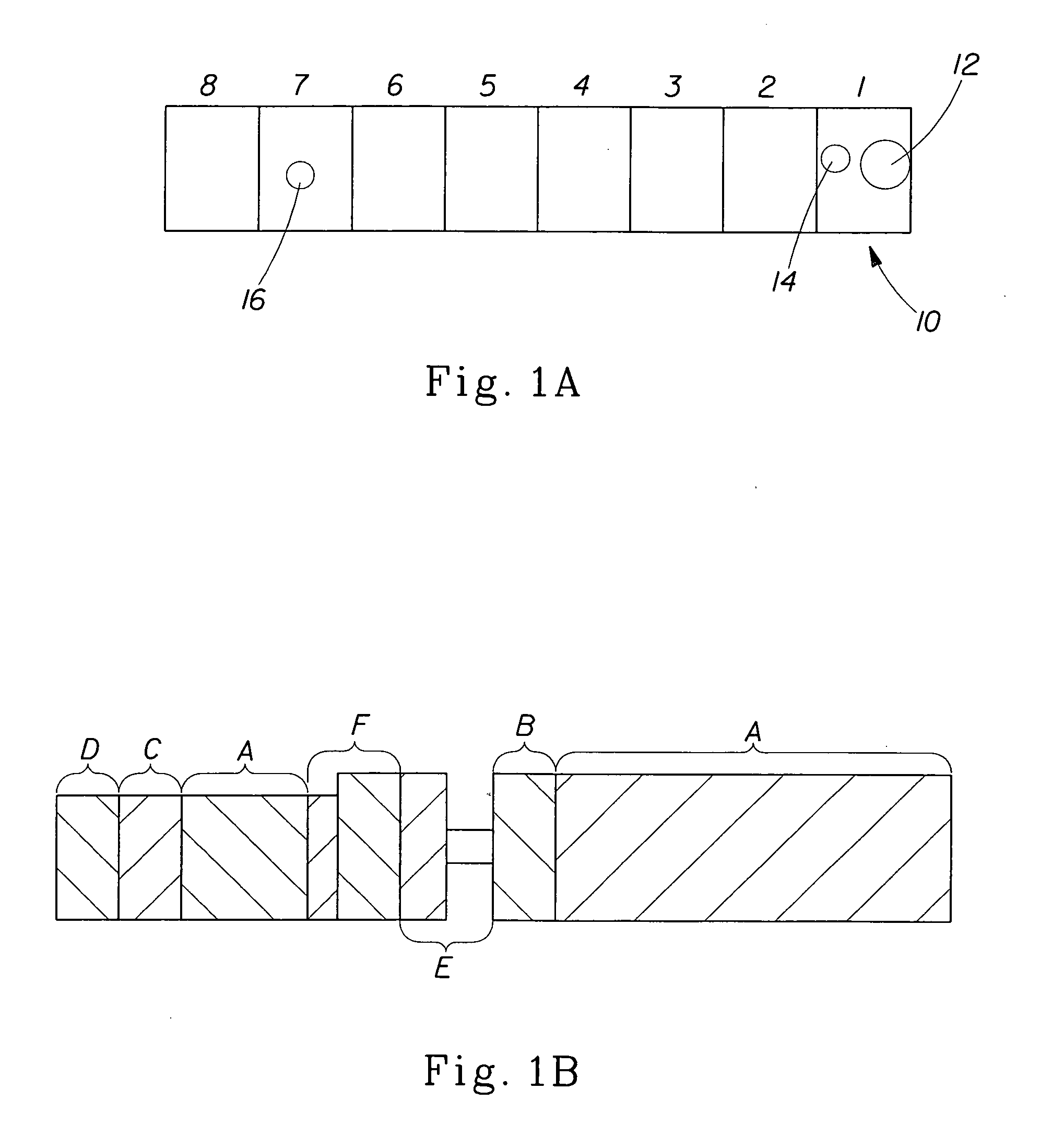

Hybrid Three-Dimensional Woven/Laminated Struts for Composite Structural Applications

ActiveUS20080261474A1High damage toleranceImprove through thickness propertySewing-machine elementsLoomsFiberEngineering

A woven preform used to reinforce a composite structure which includes a central portion having a plurality of interwoven layers. The preform also includes first and second end portions having a plurality of independent woven layers that are integrally woven with the plurality of interwoven layers in the central portion and which extend along the entire length the preform. Interspersed between the plurality of independent woven layers in the first and second end portions are bias plies. The first and second end portions can have through thickness reinforcements comprising reinforcement fibers that traverse through the independent woven layers and the bias plies, locking them together.

Owner:ALBANY ENGINEERED COMPOSITES

Hydroentangled integrated composite nonwoven material

InactiveUS7998889B2Facilitated releaseMaximum effectivePattern makingLayered productsPolyesterPolymer science

An hydroentangled integrated composite nonwoven material, includes a mixture of randomized continuous filaments, and synthetic staple fibers, where there are no thermal bonding points between the continuous filaments. The nonwoven material exhibits a cumulative pore volume, measured by PVD in n-hexadecane, in the pore radius range 5-150 μm, where at least 70% of the cumulative pore volume is in the pores with a pore radius above 45 μm. The nonwoven material also exhibits a cumulative pore volume, which when the synthetic staple fibers are chosen from the group of polyethylene, polypropylene, polyester, polyamide, and polylactide staple fibers is at least 9 mm3 / mg, and when the synthetic staple fibers are lyocell staple fibers is at least 6 mm3 / mg.

Owner:SCA HYGIENE PROD AB

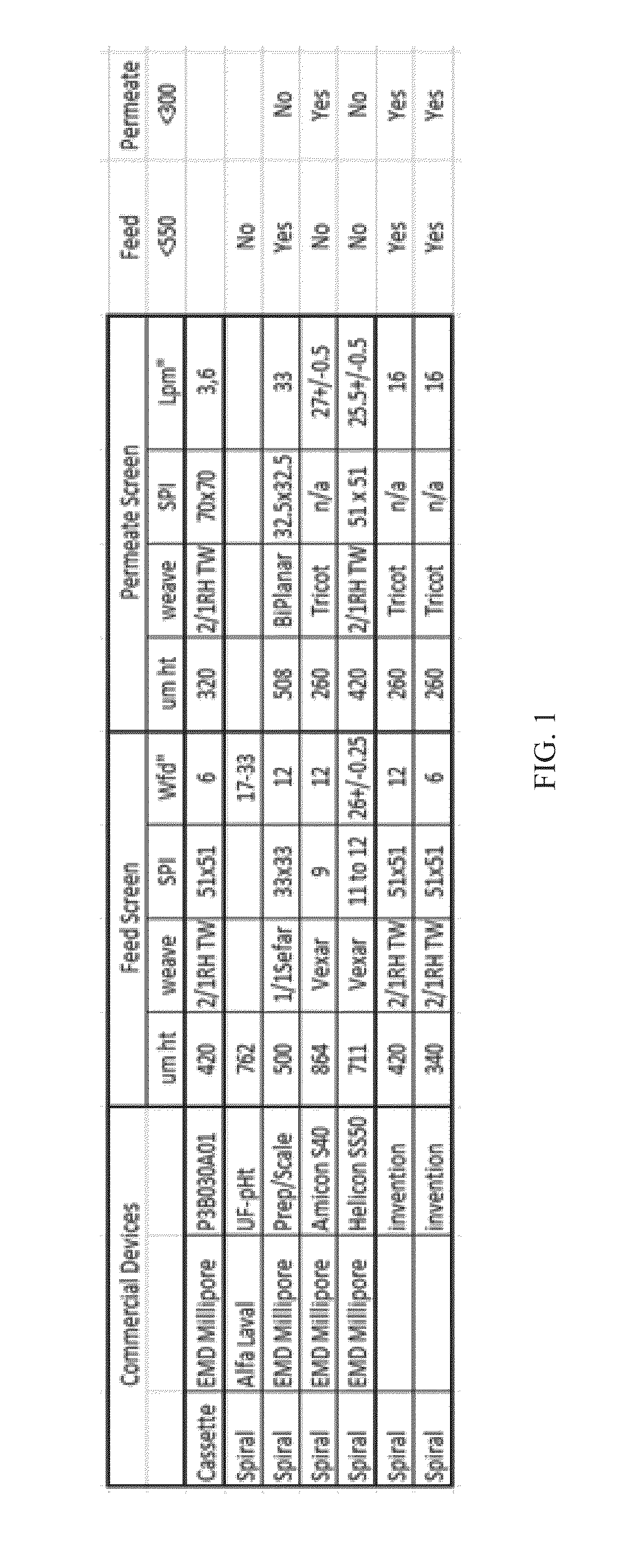

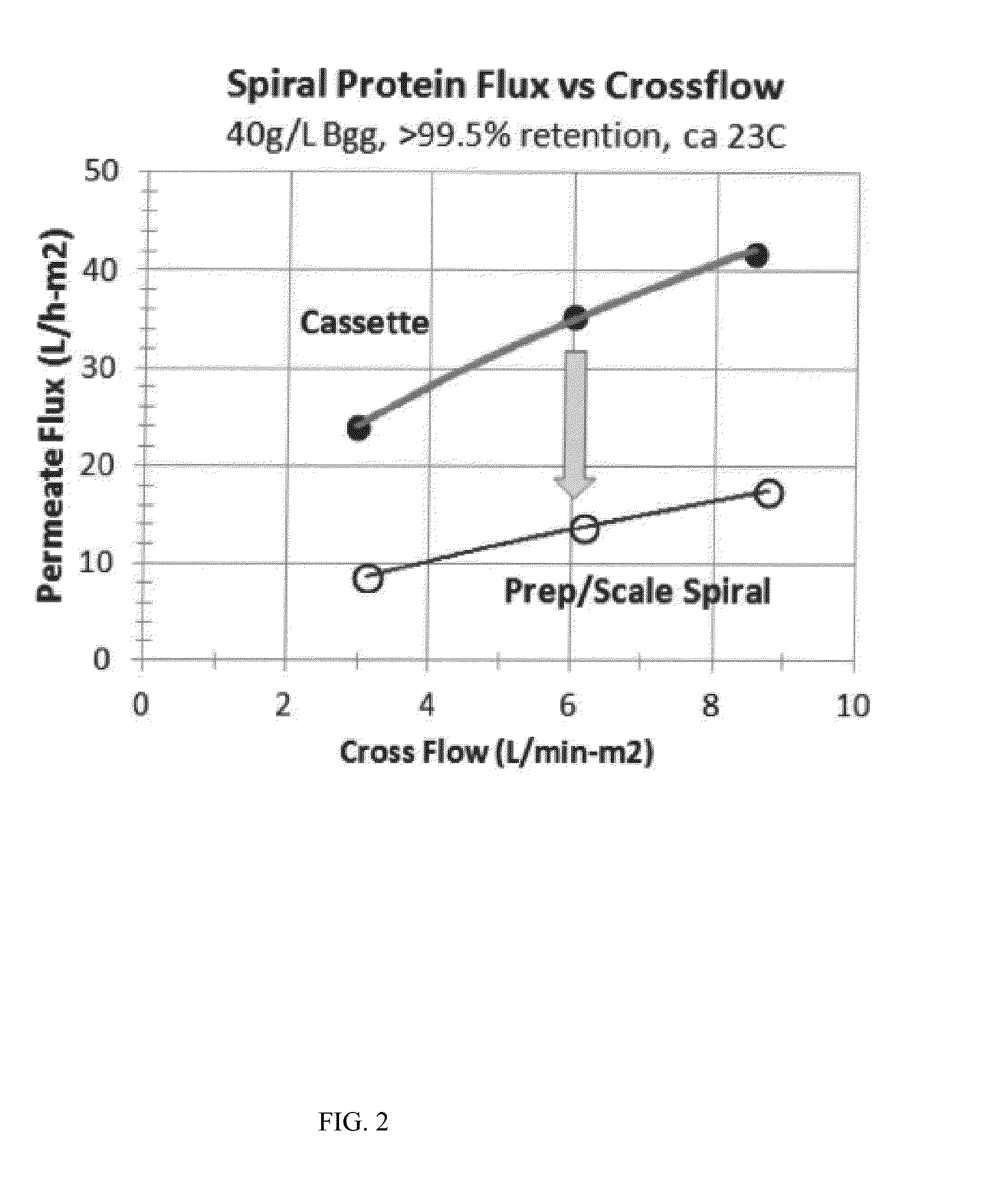

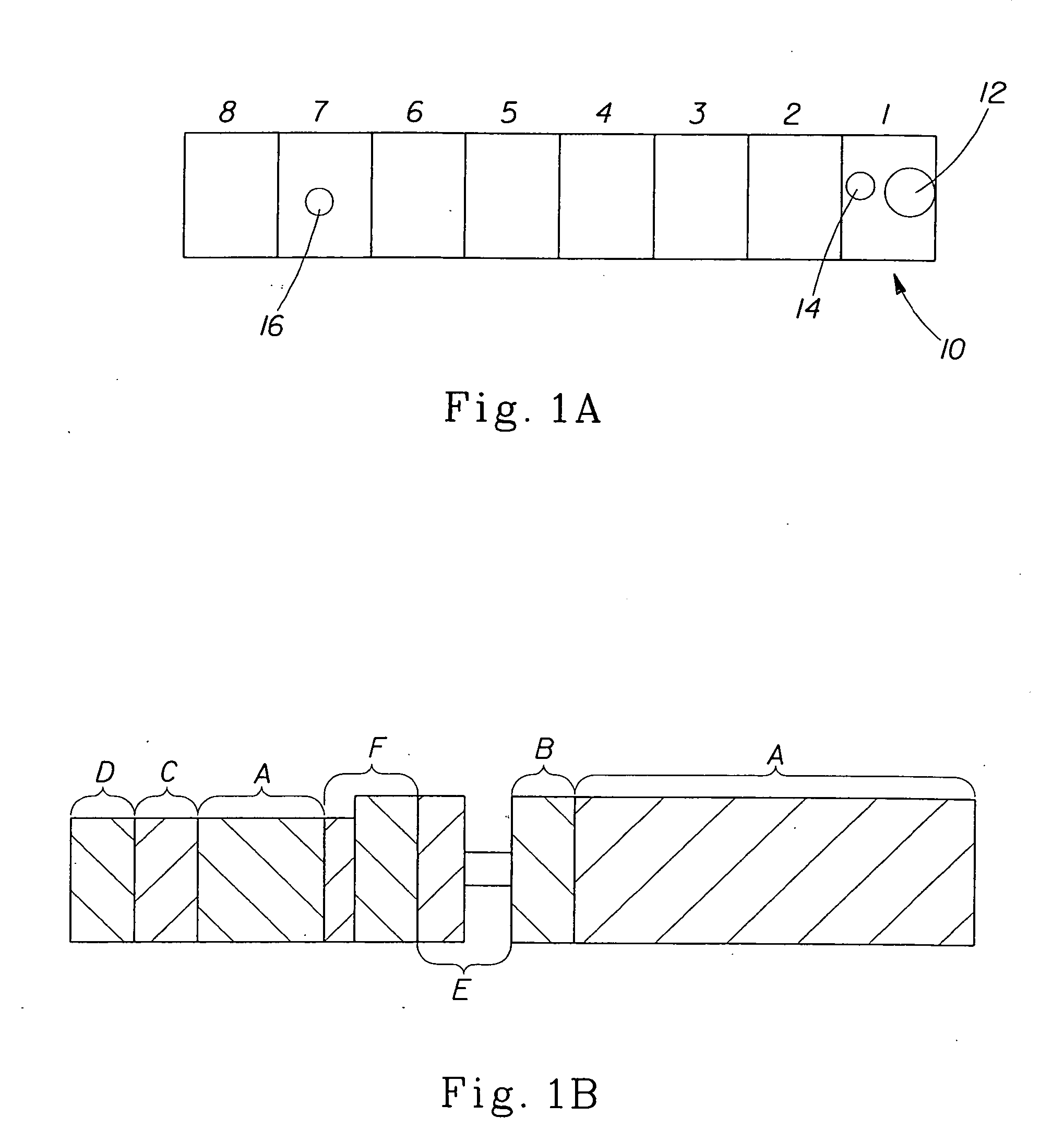

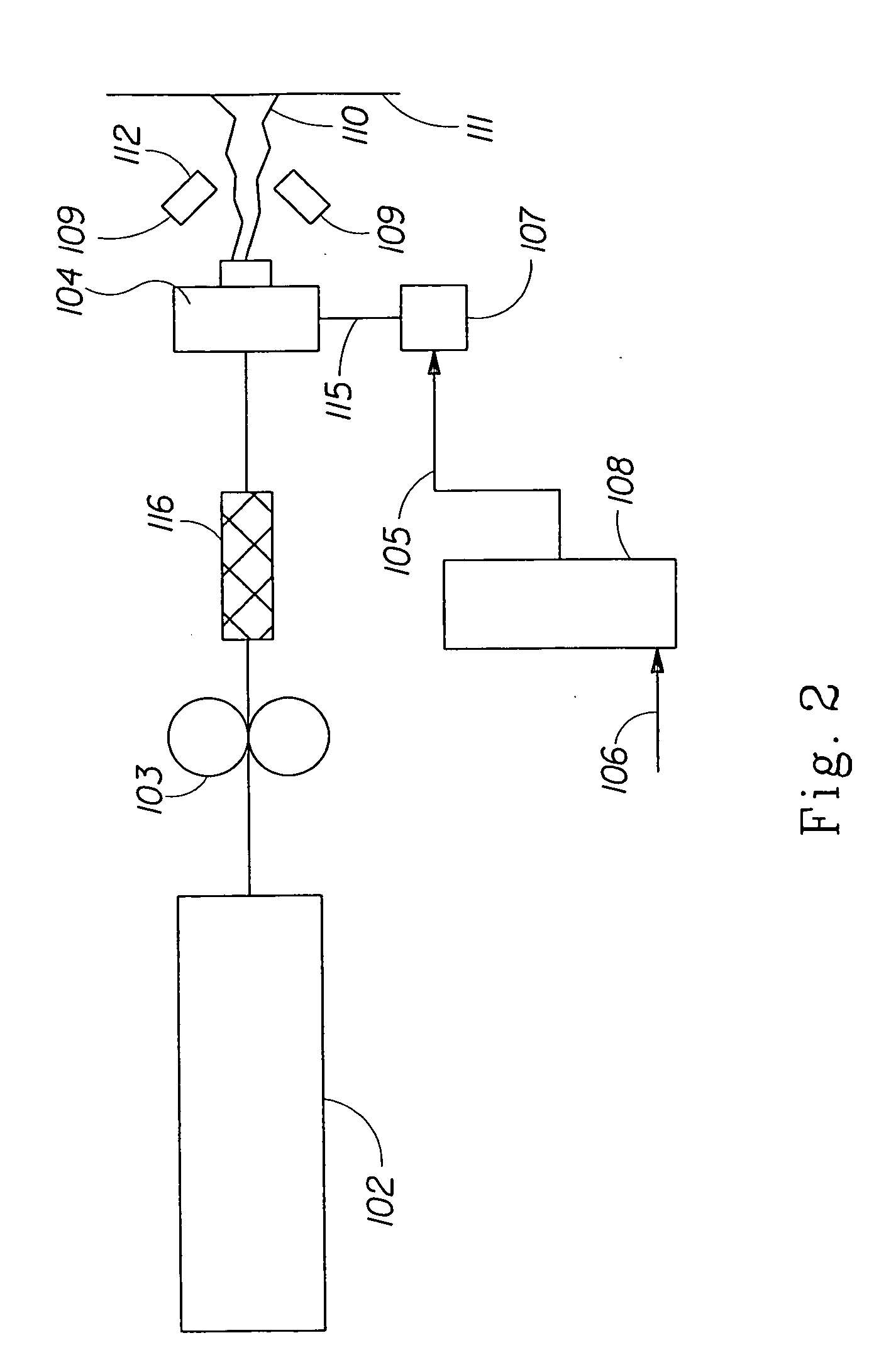

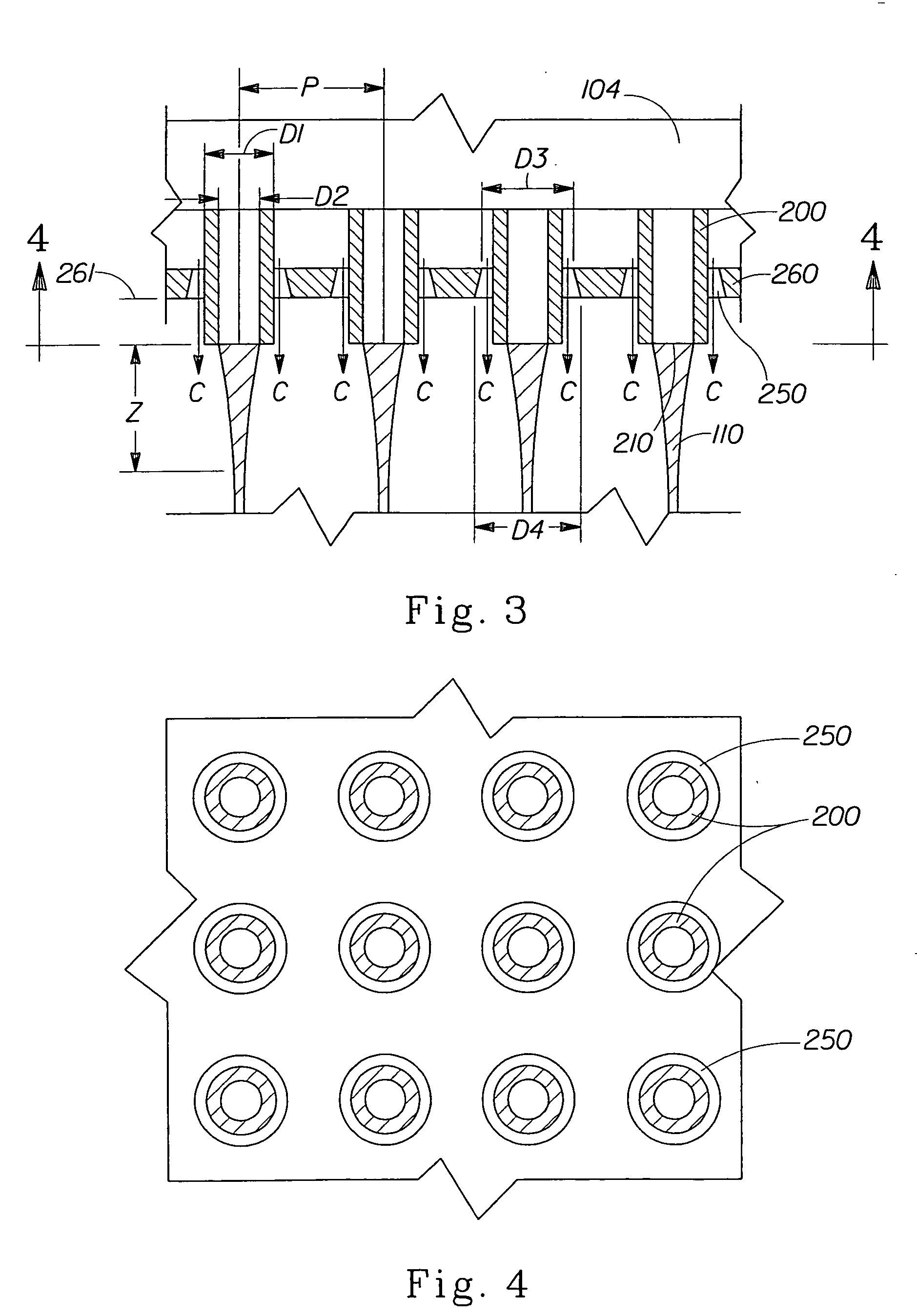

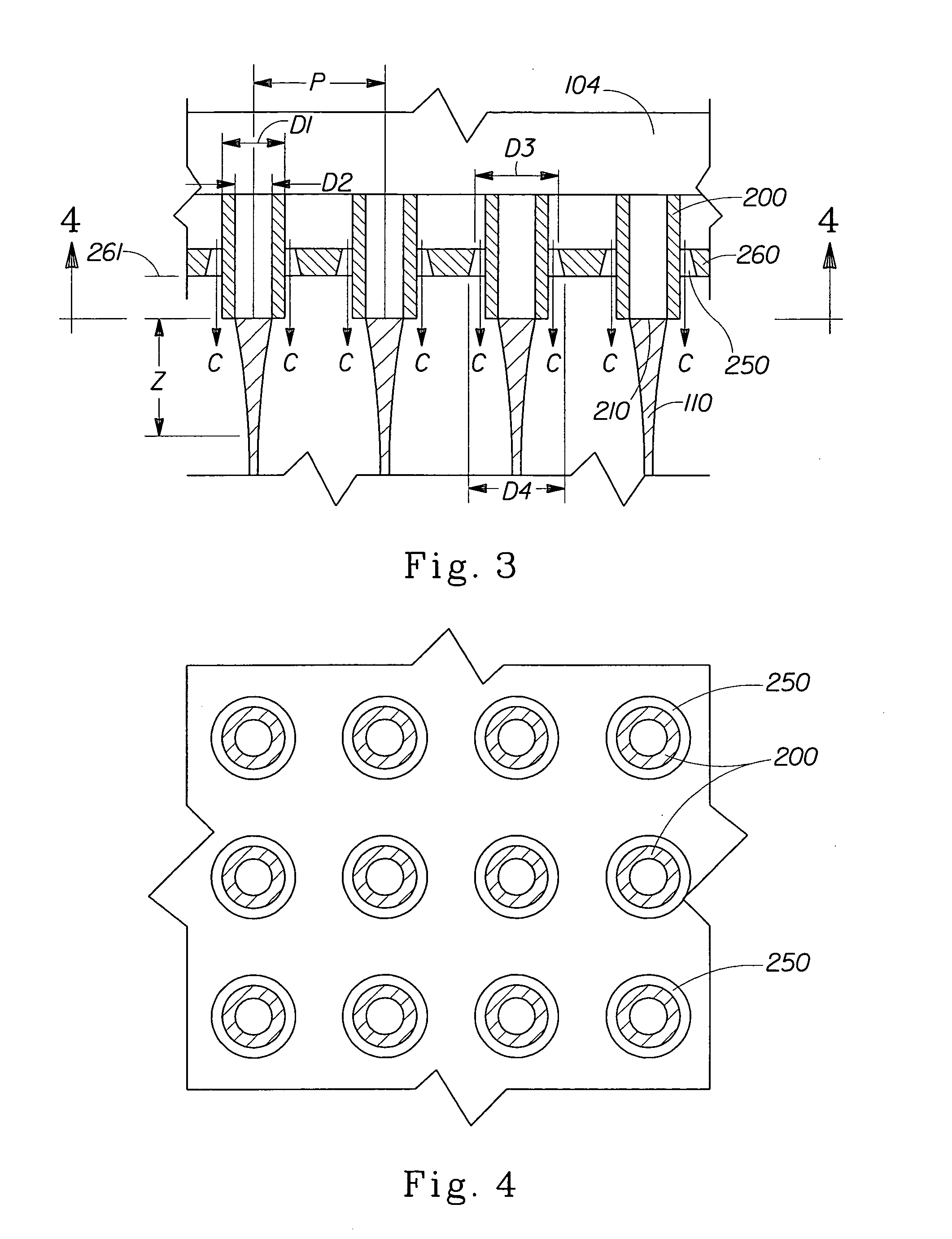

Compact spiral-wound filter elements, modules and systems

ActiveUS20150375173A1Increased feed channel pressure dropEasy to mergeUltrafiltrationReverse osmosisFiltrationSpiral wound

The present invention provides compact spiral-wound filter elements having cassette-like performance. The invention further provides filtration systems (e.g., TFF systems) and processes (e.g., SPTFF processes) employing compact spiral-wound filter elements having cassette-like performance.

Owner:MILLIPORE CORP

Polymeric structures comprising a hydrophile/lipophile system

InactiveUS20050137330A1Good dispersionMonocomponent protein artificial filamentNon-fibrous pulp additionCrystallographyFiber

Owner:THE PROCTER & GAMBLE COMPANY

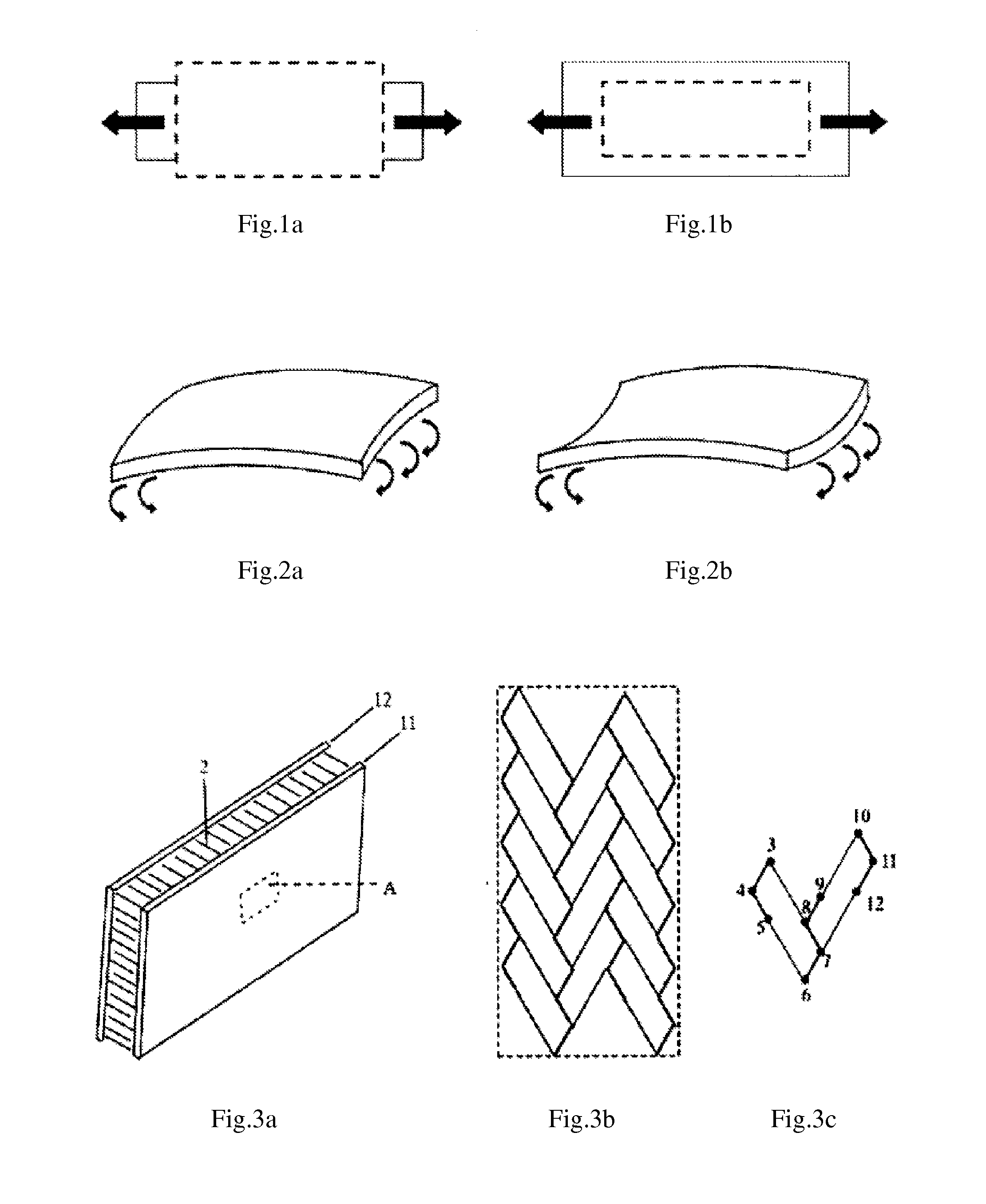

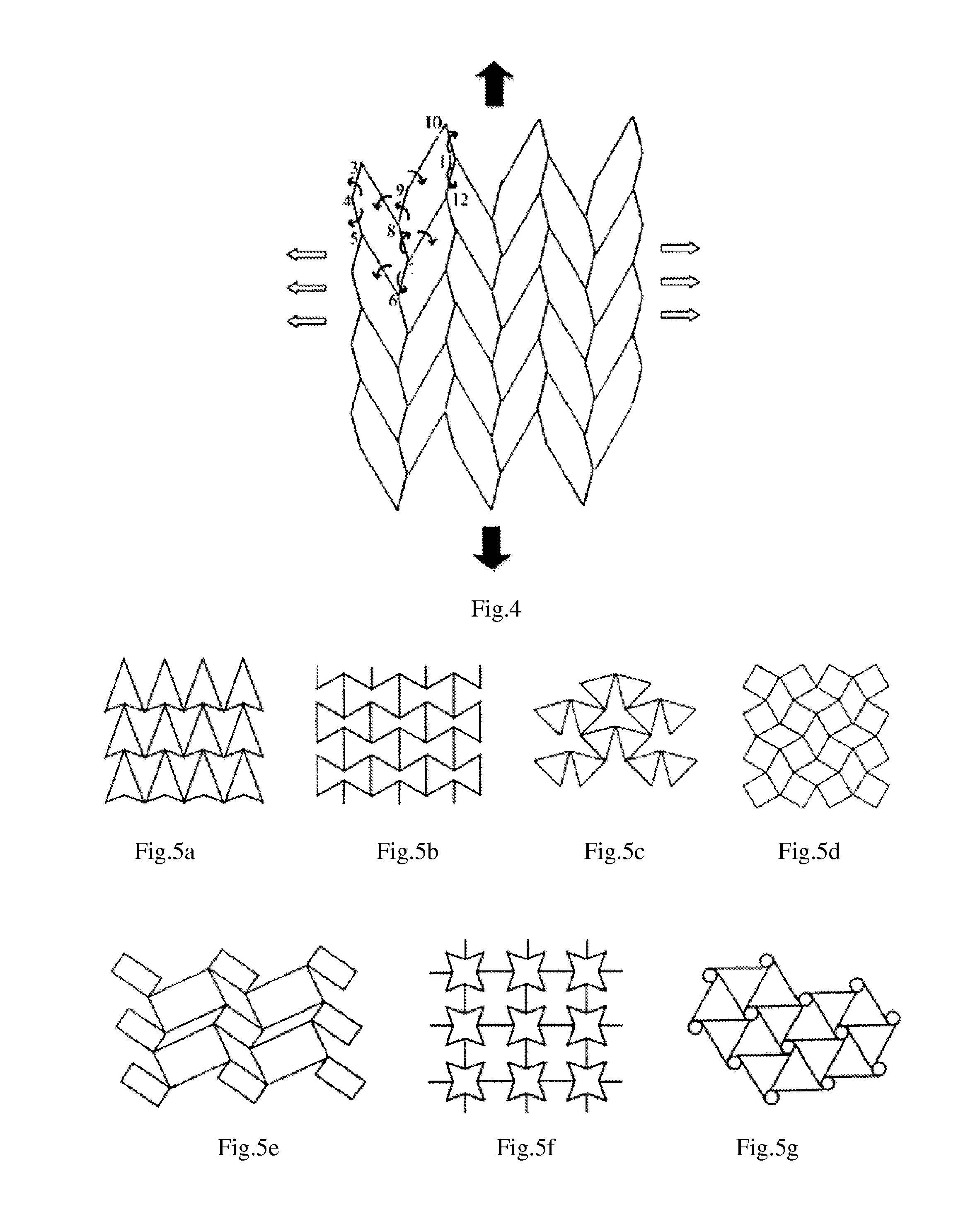

Three dimensional negative poisson's ratio spacer knitted fabric and method for making the same

ActiveUS20140205795A1Low costEasy to operateOrnamental textile articlesLayered productsYarnSurface layer

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

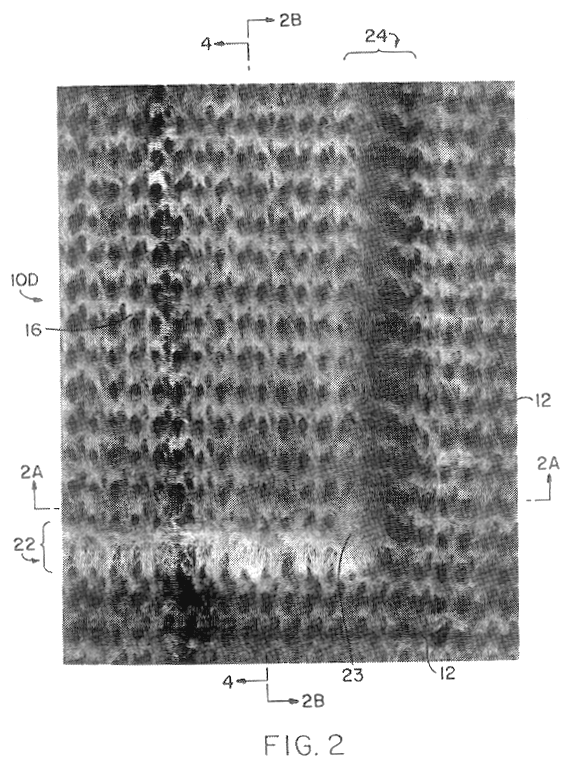

Apparatus for making nonwoven fabrics having raised portions

A topographical support member and a method of forming a topographical support member for use in producing nonwoven fabrics with raised portions, especially intaglio and slub type portions. The topographical support member comprises a body having a top surface including a first micro-sized topographical pattern and a pattern of apertures extending through the body. At least one macro-sized region recessed below the top surface is provided. The micro-sized pattern produces a background portion of the fabric and the macro-sized recessed regions produce the raised portions of the fabric. Multiple levels may be provided in the macro-sized region to produce multiple level raised portions.

Owner:PGI POLYMER

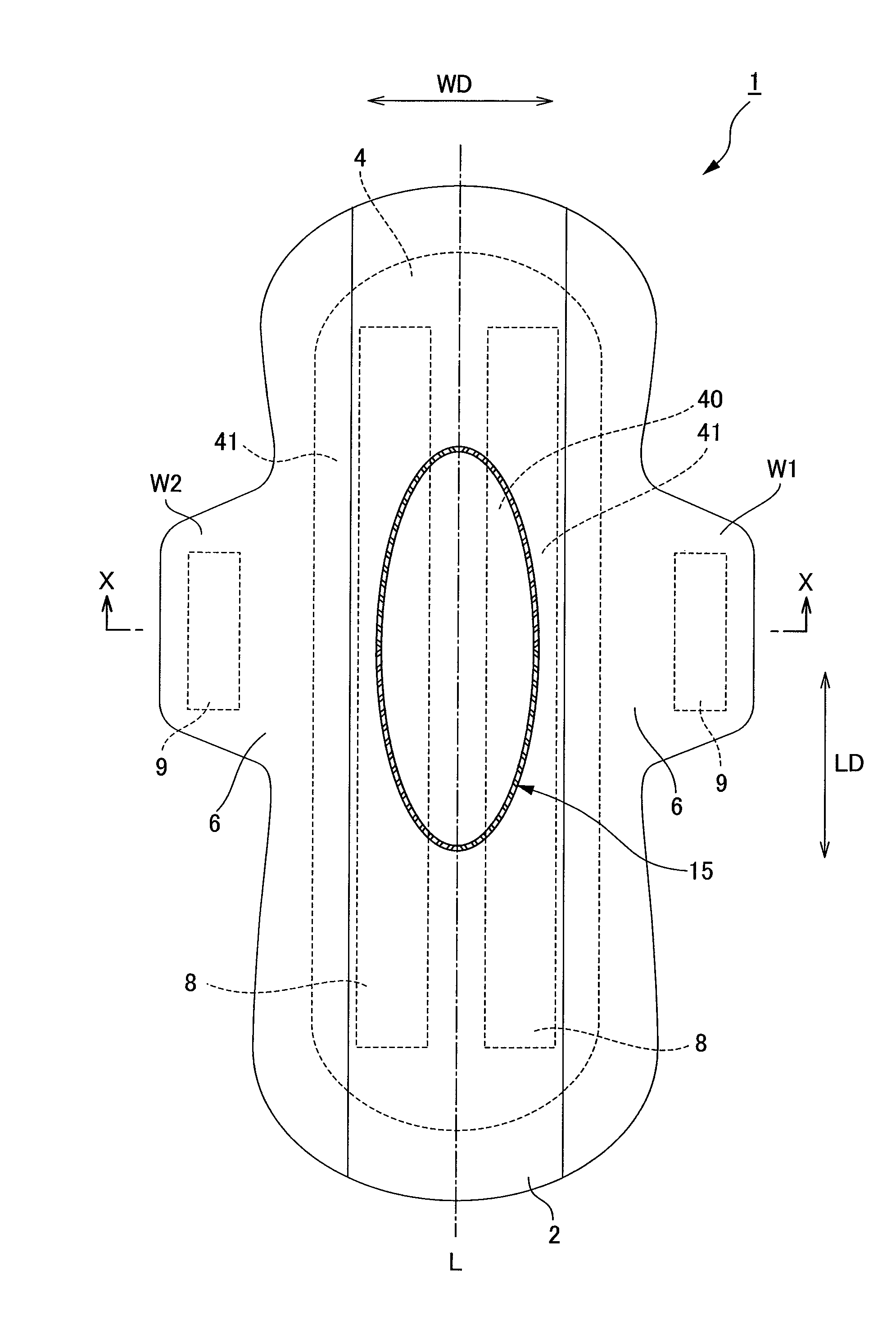

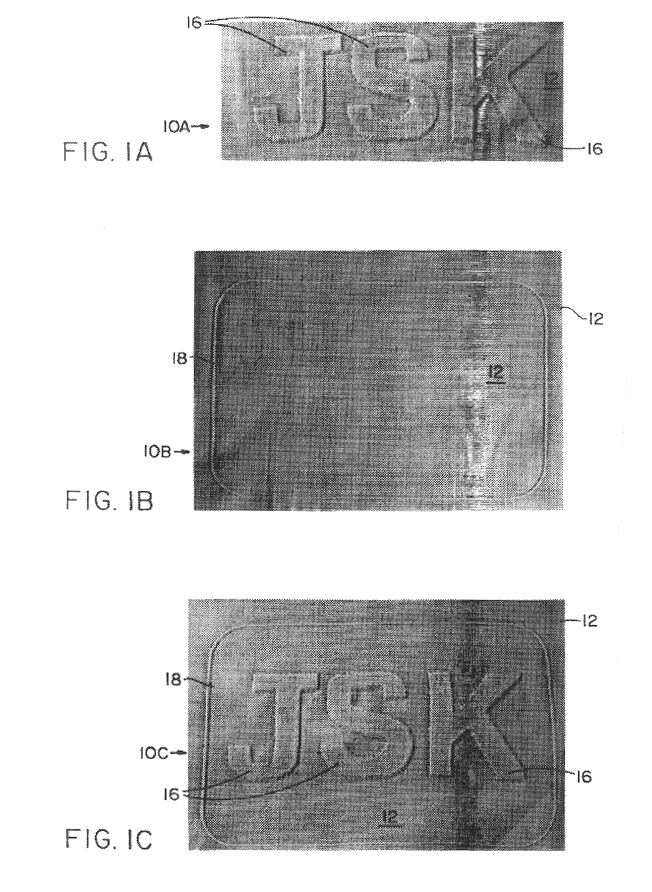

Patterned tampon and method of making

A tampon including a compressed pledget of absorbent material. The tampon has a body portion and a longitudinal axis, wherein the tampon includes at least one patterned impression with one or more design elements oriented substantially perpendicular to the longitudinal axis, wherein at least one design element is formed by contact with at least one corresponding pattern including at least one lead in portion. A method and apparatus for making the tampon are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

Polymeric structures comprising a hydrophile/lipophile system

ActiveUS20050137331A1Good dispersionNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer melt

Owner:THE PROCTER & GAMBLE COMPANY

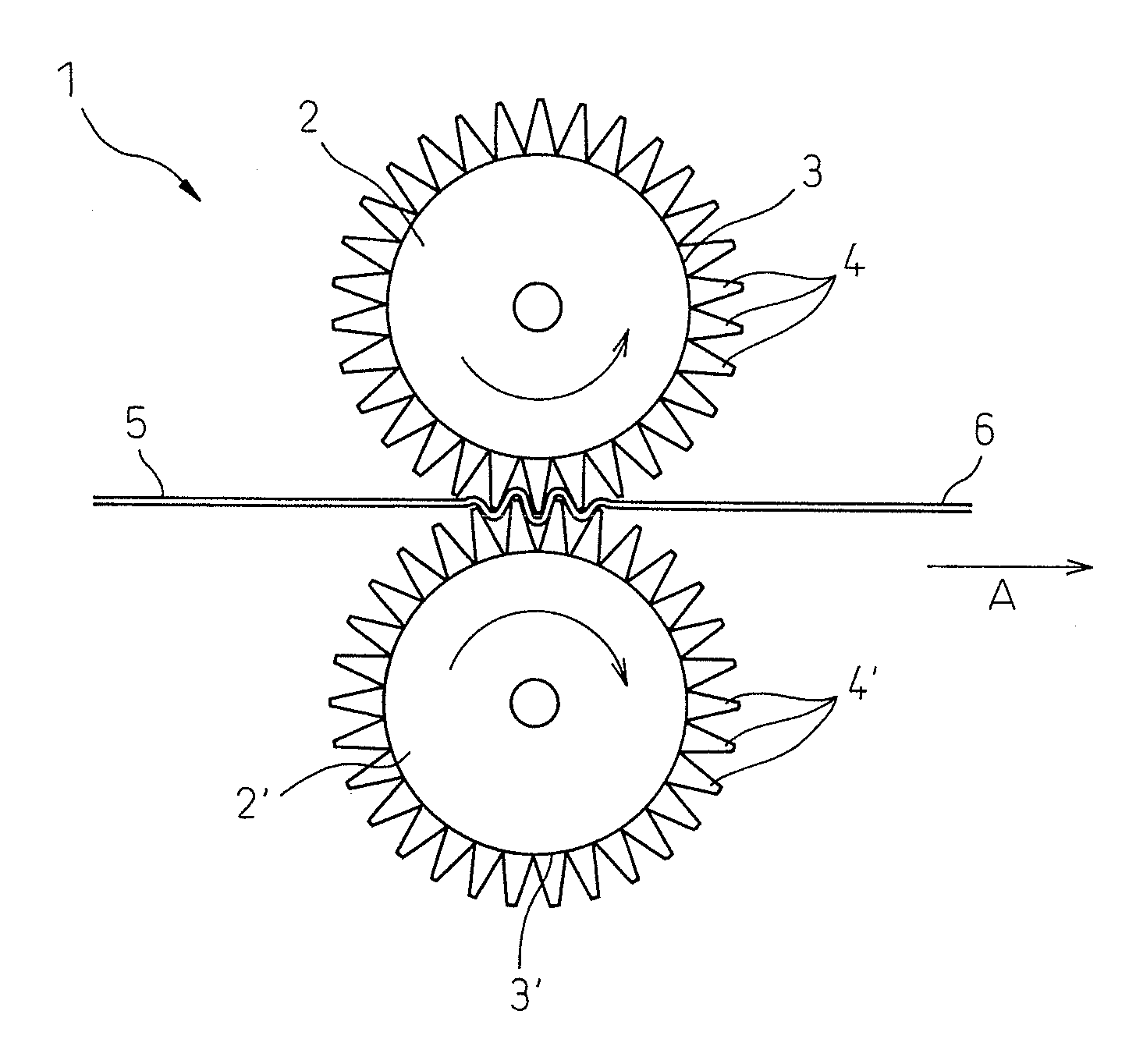

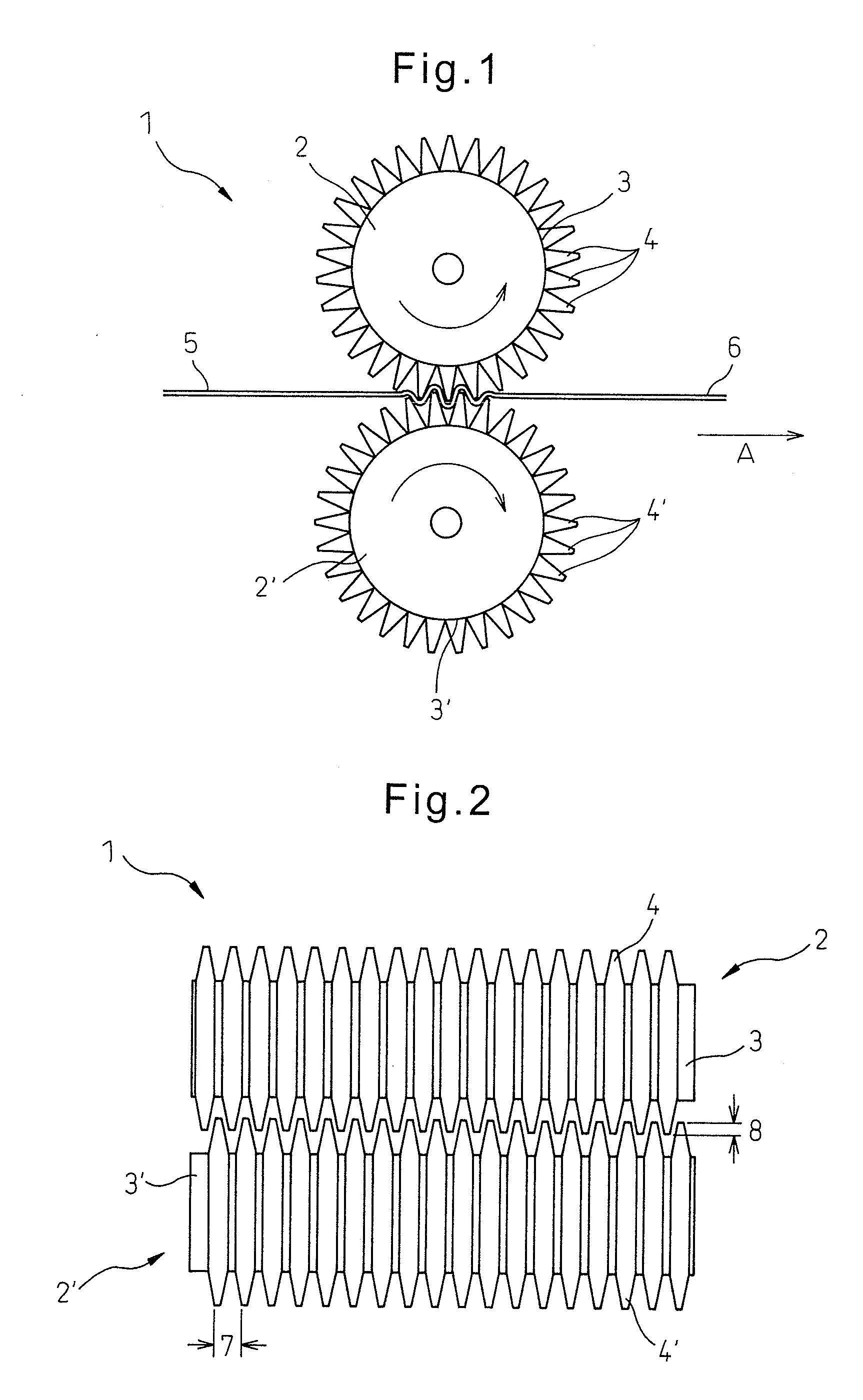

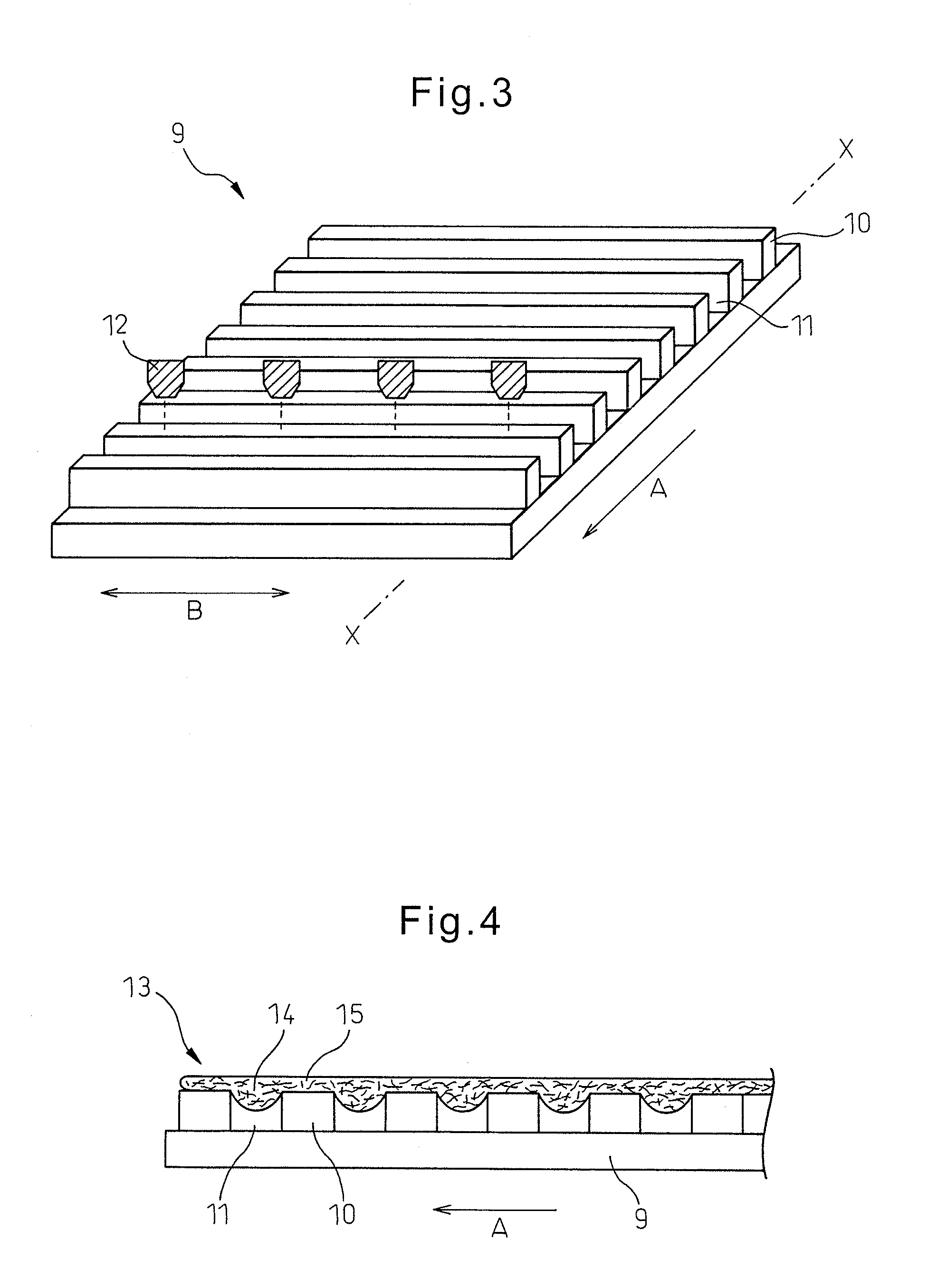

Method of easy production of nonwoven fabric having at least one projection and at least one recess, and method of easy processing of nonwoven fabric

It is an object of the invention to provide a method of easy production of a nonwoven fabric having at least one projection and at least one recess and to a method of easy processing of a nonwoven fabric.A method of producing a nonwoven fabric having at least one projection and at least one recess, comprising the steps of non-homogeneous stretching a nonwoven fabric so as to form a nonwoven fabric with high-stretch regions and low-stretch regions, and forming a nonwoven fabric having at least one projection and at least one recess by placing the nonwoven fabric with high-stretch regions and low-stretch regions on a support and spraying a fluid onto the nonwoven fabric with high-stretch regions and low-stretch regions for treatment.

Owner:UNI CHARM CORP

Nonwoven fabrics containing yarns with varying filament characteristics

InactiveUS20040221436A1Good lookingIncrease stiffnessPaper/cardboardPaper/cardboard layered productsYarnPolymer science

The subject invention provides non-woven fabrics having yarns of varying characteristics. In a preferred embodiment the subject invention provides nonwoven fabrics that comprise yarns of different deniers or cross sections. The use of these yarns gives the nonwoven fabric a unique appearance and advantageous properties. The subject invention further pertains to the processes used to produce these fabrics.

Owner:CEREX ADVANCED FABRICS

High-temperature resistant carbon fiber heat insulation felt

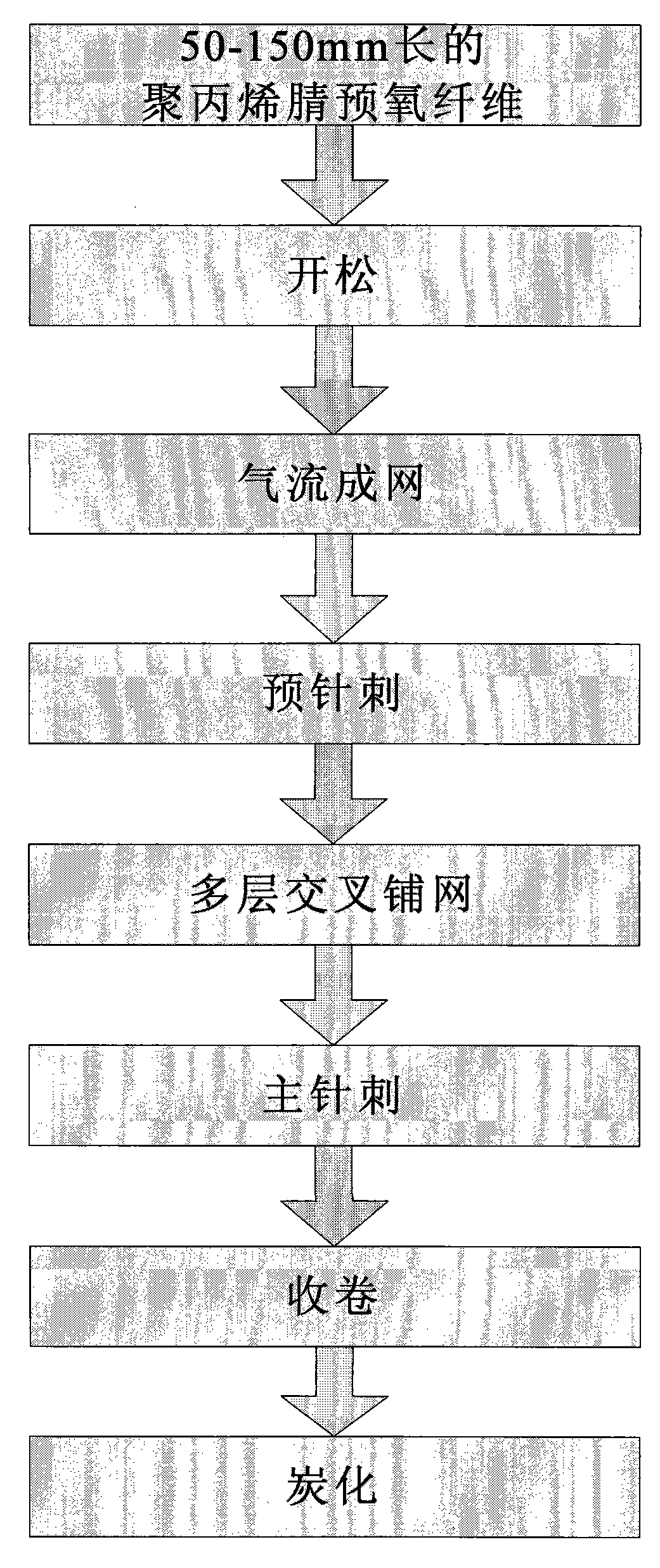

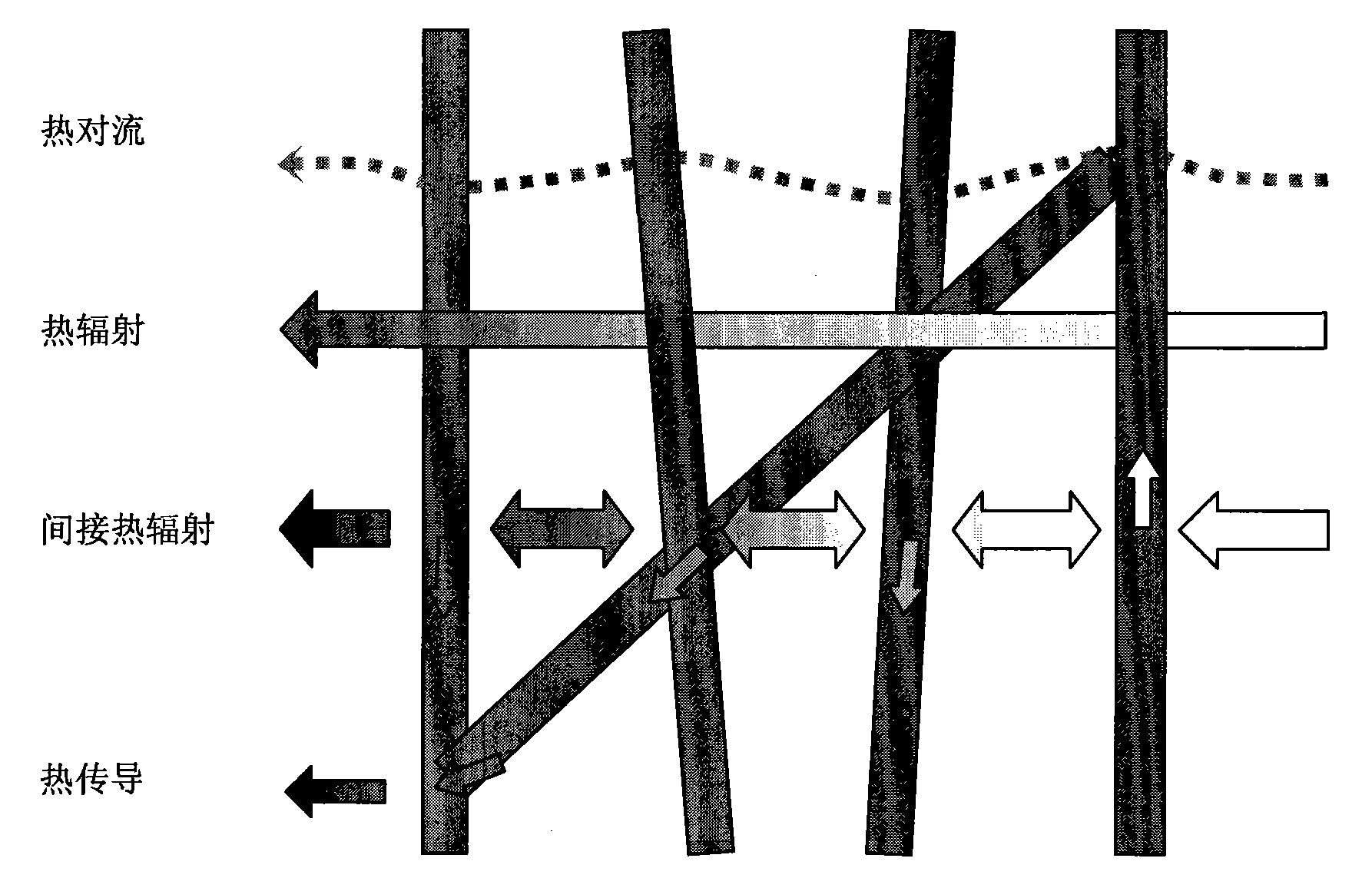

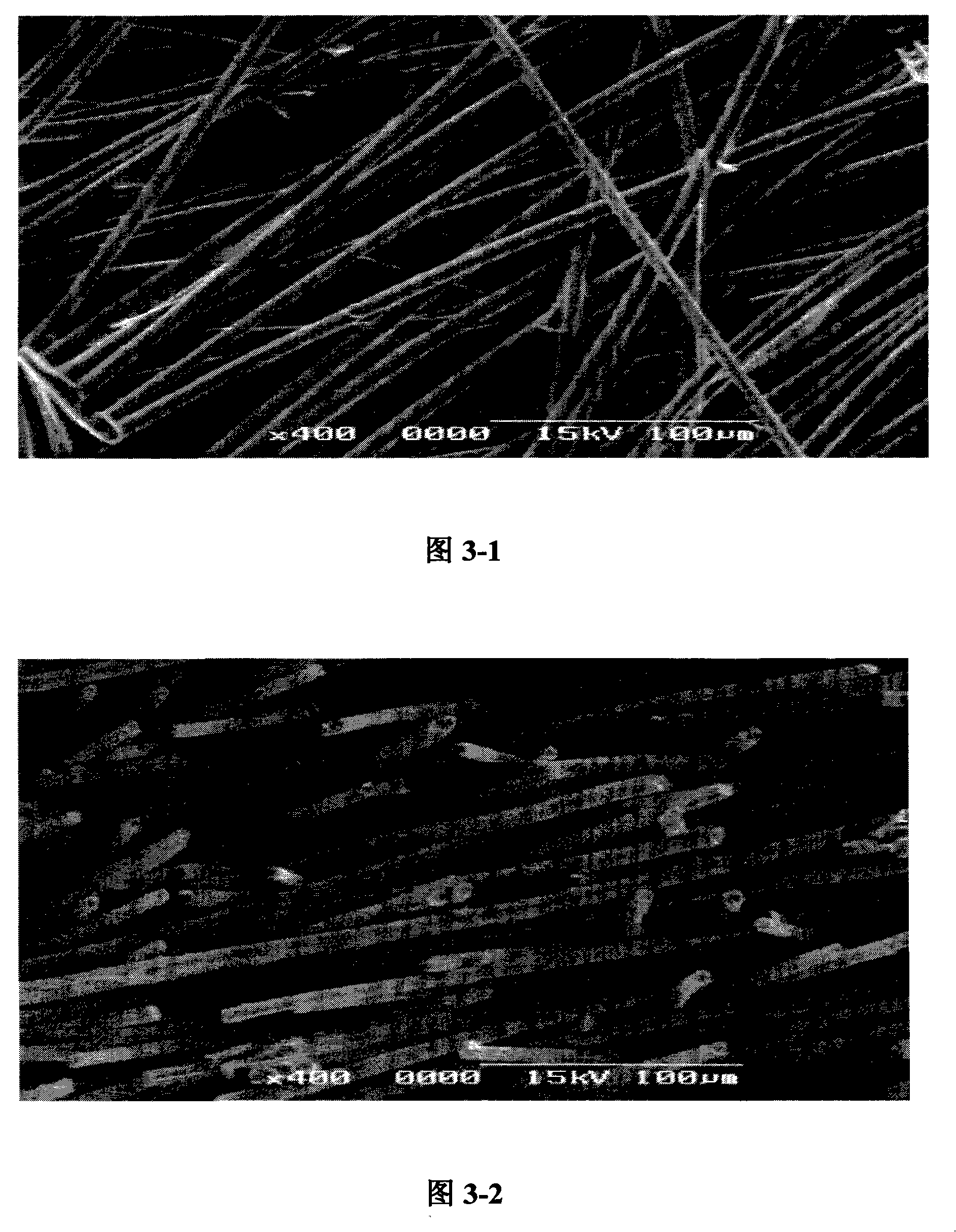

InactiveCN101899748AControl the amount of fiberClimate change adaptationInsulation improvementCarbon compositesCarbon fibers

The invention relates to a high-temperature resistant polyacrylonitrile-based carbon fiber heat insulation felt, a preparation method and the use thereof. The ratio of fiber parts on X-Y planes to those in Z direction of the high-temperature resistant polyacrylonitrile-based carbon fiber heat insulation felt is 50:1-250:1; and polyacrylonitrile-based carbon fiber substrate with a chop length of 50 to 150mm is prepared into the polyacrylonitrile-based carbon fiber heat insulation felt with a thickness of 8 to 12mm, a gram weight of 500 to 700g / cm<2>, and a tensile strength of 12 to 50N / 2cm. The polyacrylonitrile-based carbon fiber heat insulation felt can be used for preparing carbon / carbon composite heat insulation plates.

Owner:SHANGHAI DINGYI INDAL

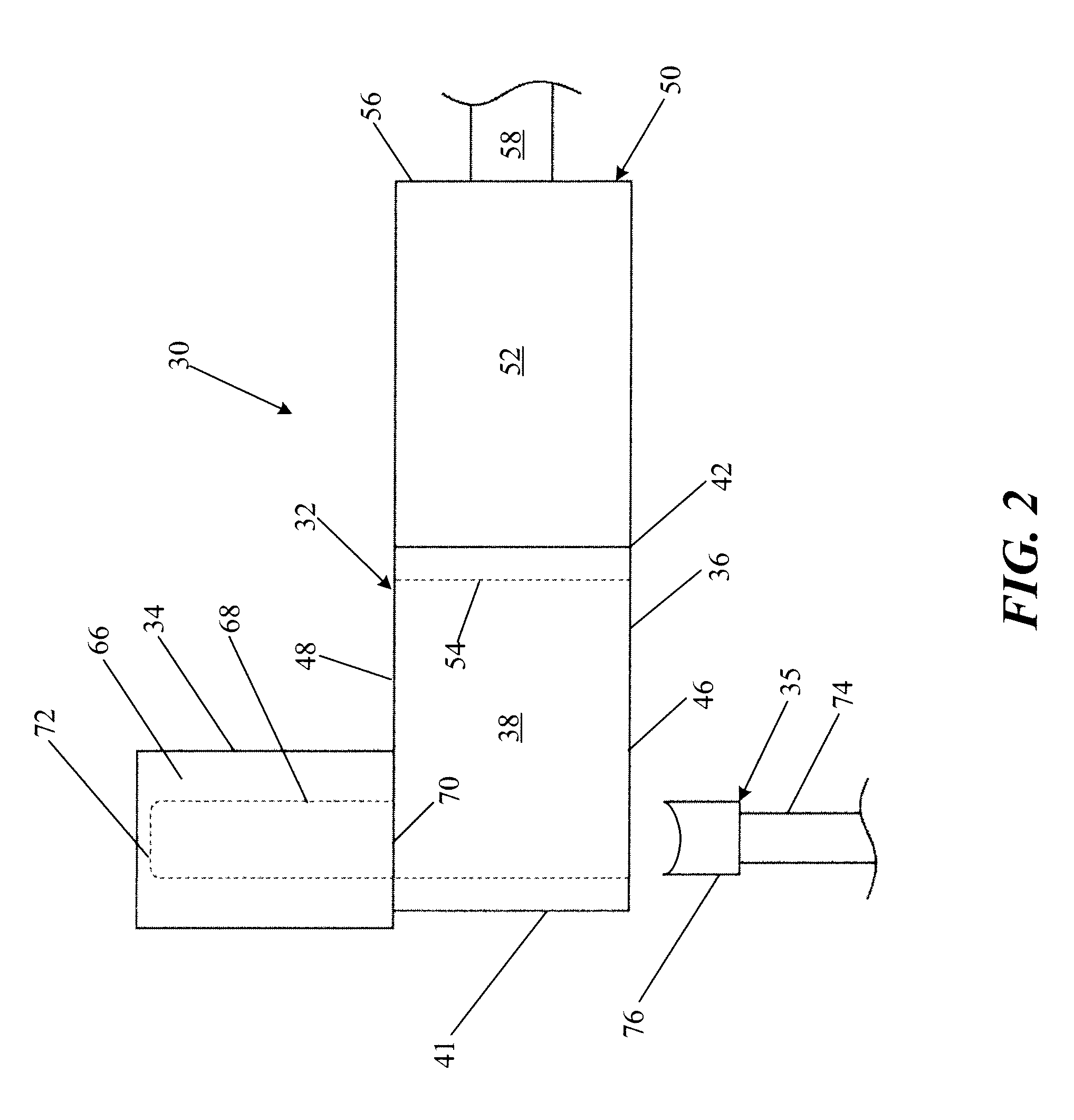

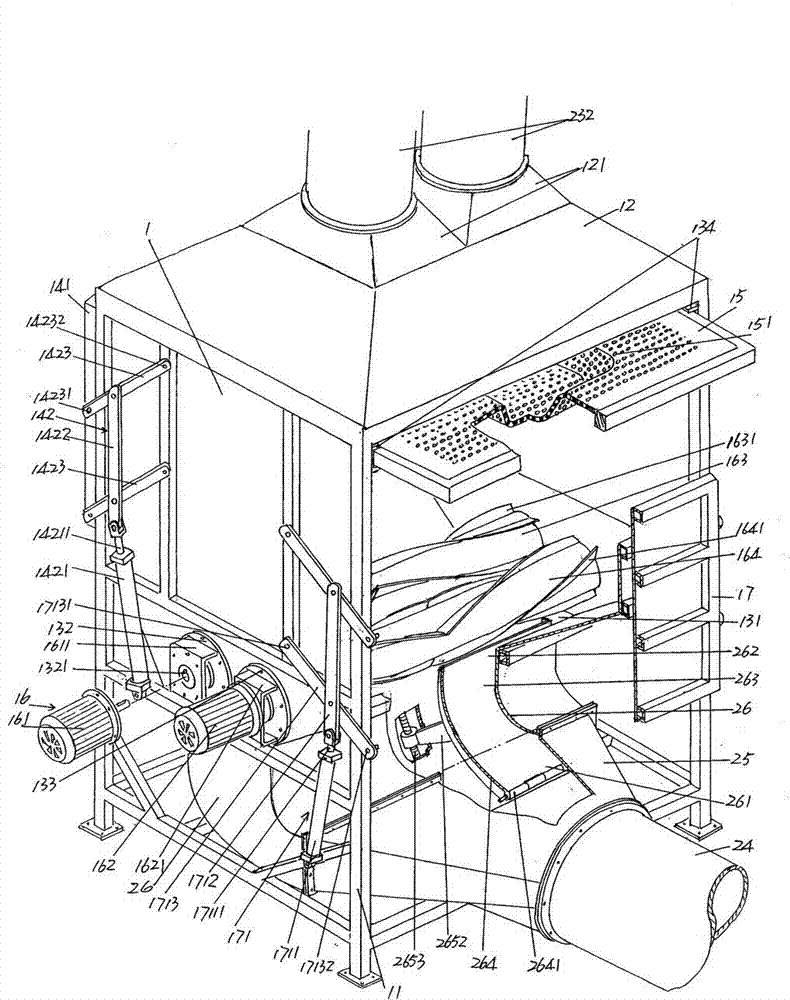

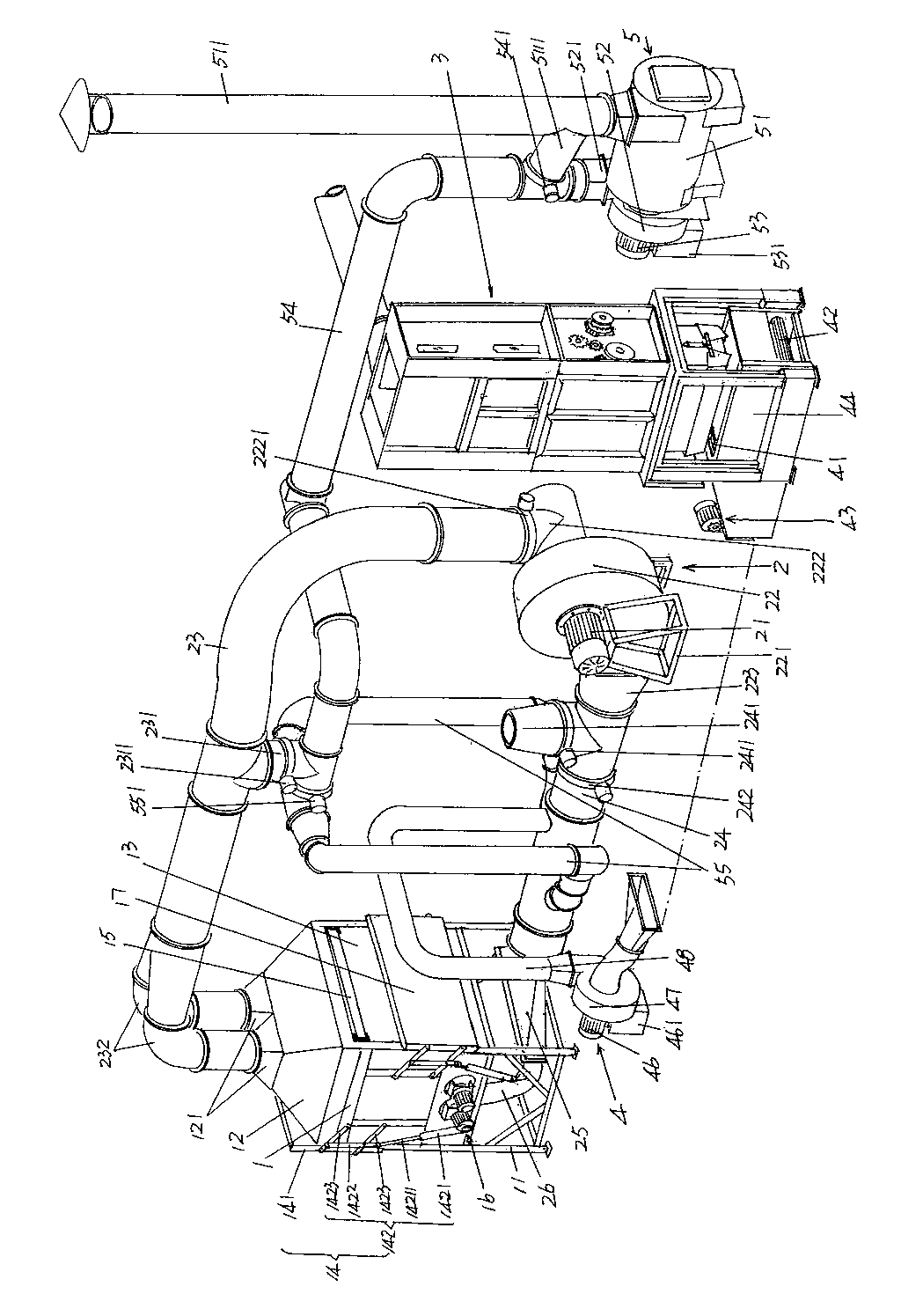

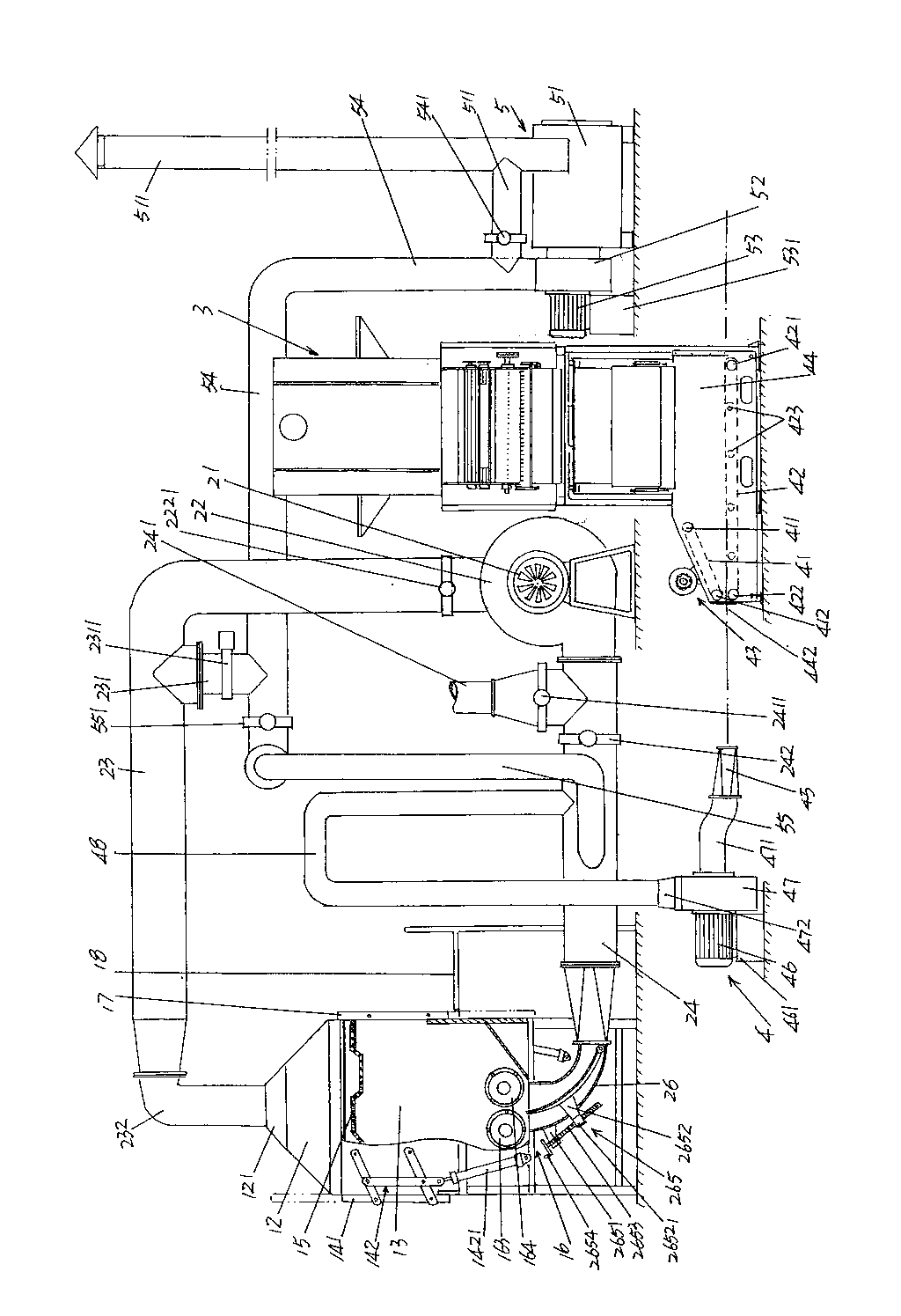

Automotive upholstery pre-shaping machine adopting air filling method

The invention provides an automotive upholstery pre-shaping machine adopting an air filling method, belonging to the technical field of automotive upholstery production devices. The automotive upholstery pre-shaping machine adopting the air filling method comprises a pre-shaping box, an airflow circulation mechanism, a fiber weighing and measuring mechanism, a fiber conveying mechanism and a hot air generation mechanism, wherein a box cover is formed on the top part of the pre-shaping box; an aspiration pipe adapting port is connected with the top of the box cover in a matching way; a box chamber opening / closing mechanism is arranged on one side of the pre-shaping box; a pre-shaping mould is arranged on the top of a box chamber; an aspiration hole is opened in the pre-shaping mould; a fiber feeding mechanism is arranged on the bottom of the pre-shaping box; the hot air generation mechanism is connected with the airflow circulation mechanism by a pipeline; and the airflow circulation mechanism comprises a working motor, a fan, an aspiration pipe, an air supply pipe, a connection cotton box and a cotton guide box. The automotive upholstery pre-shaping machine adopting the air filling method has the advantages that the quality of automotive upholsteries which are pressed and shaped by subsequent pressing processes can be reliably guaranteed, the overall structure is simple, and the labor intensity is decreased for workers; the processing efficiency is high and the energy is saved; and in addition, fibers with a low melting point are vitrified, so that the prototypes of the automotive upholsteries are formed.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

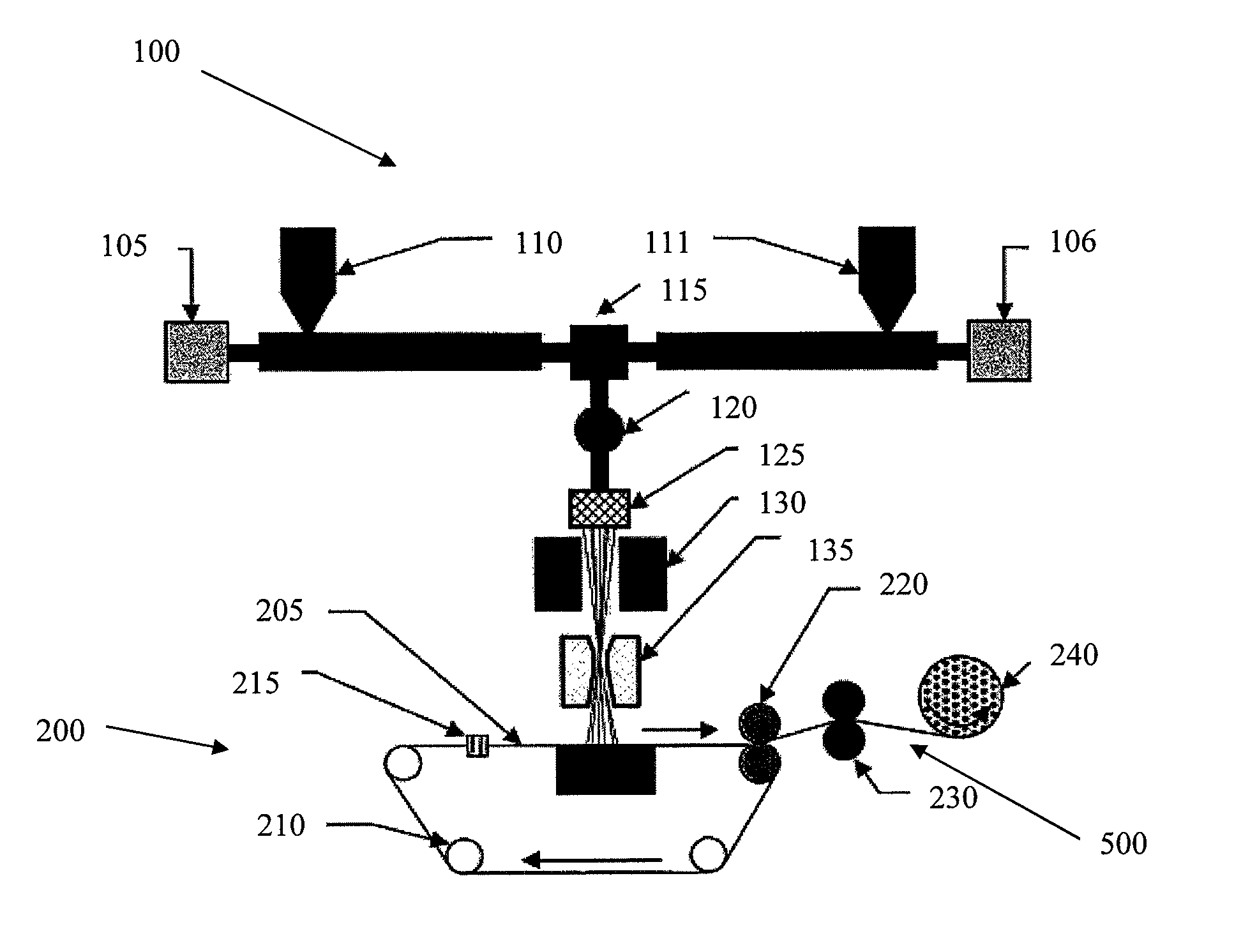

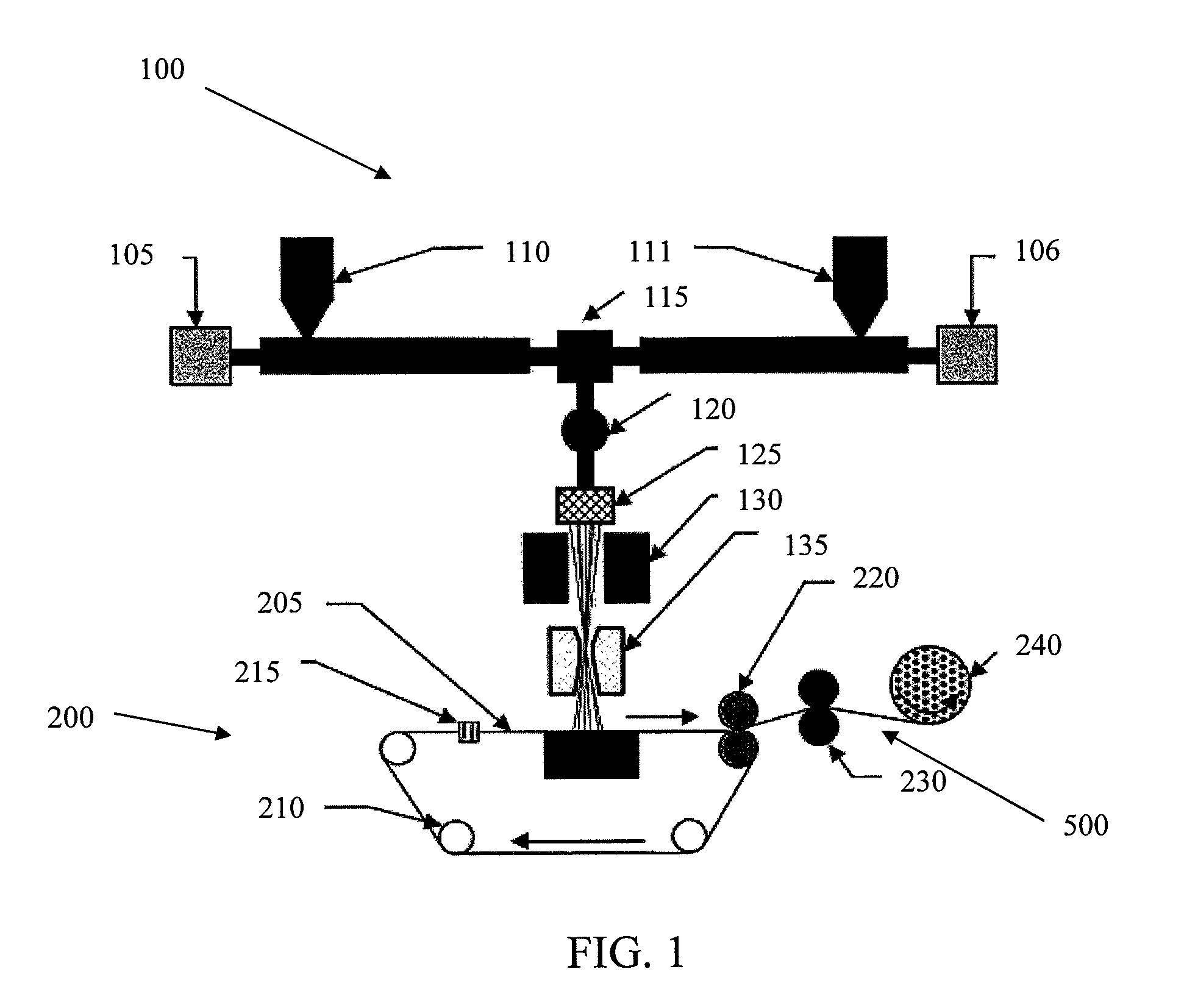

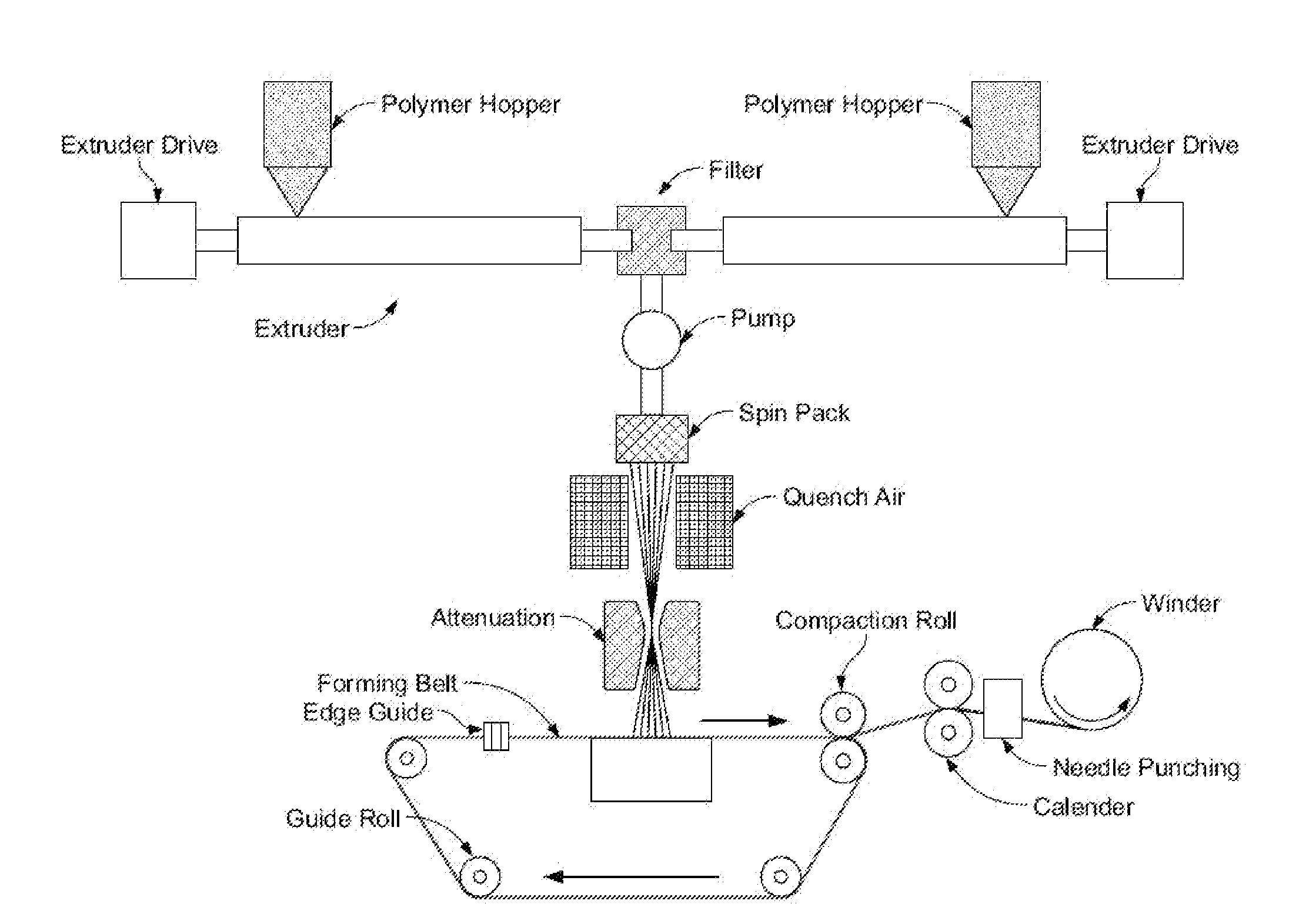

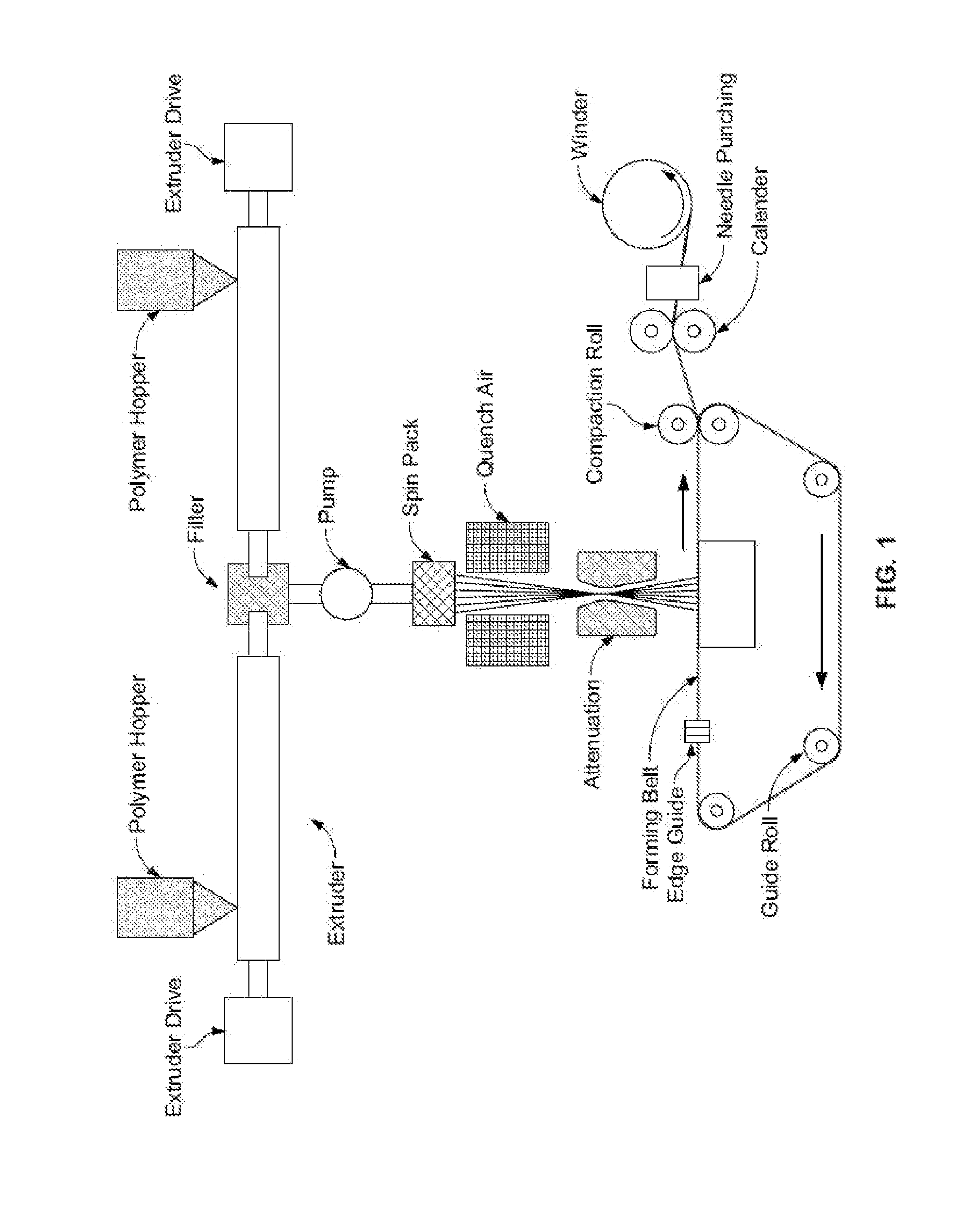

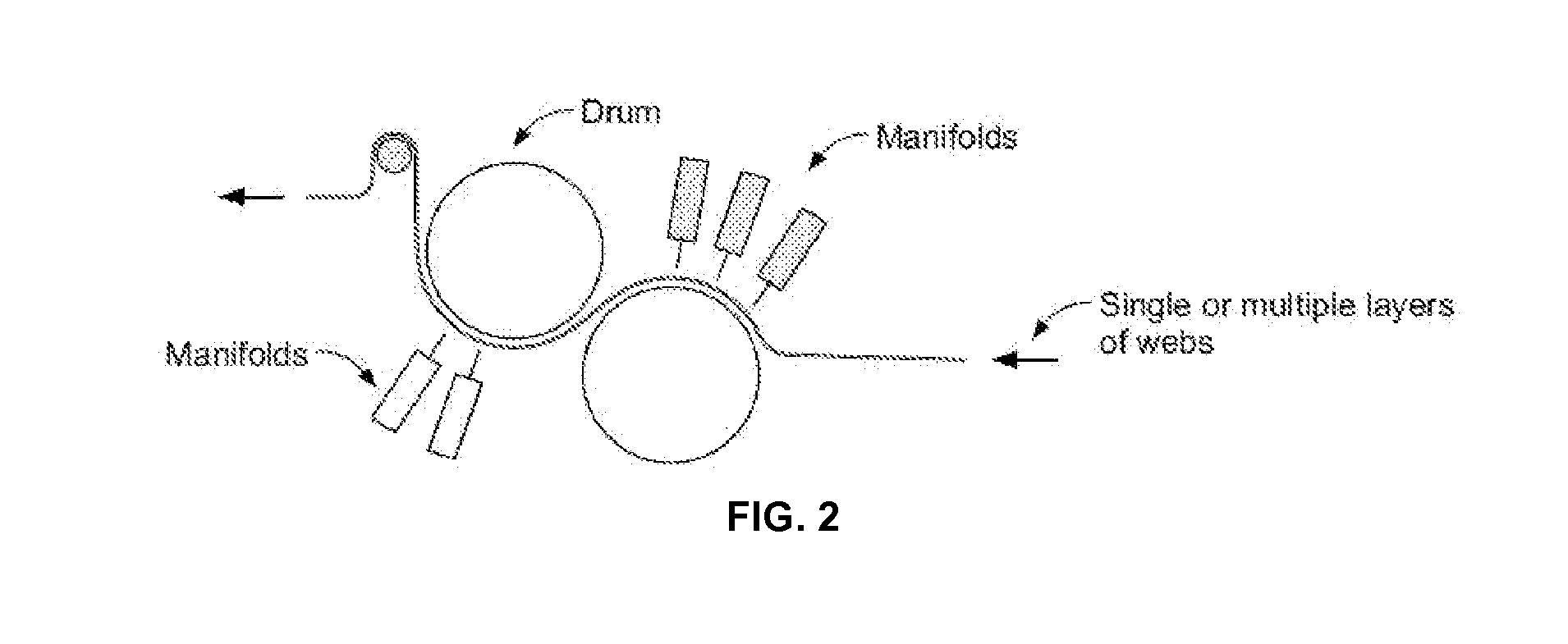

Micro and nanofiber nonwoven spunbonded fabric

The invention provides methods for the preparation of nonwoven spunbonded fabrics and various materials prepared using such spunbonded fabrics. The method generally comprises extruding multicomponent fibers having an islands in the sea configuration such that upon removal of the sea component, the island components remain as micro- and nanofibers. The method further comprises mechanically entangling the multicomponent fibers to provide a nonwoven spunbonded fabric exhibiting superior strength and durability without the need for thermal bonding.

Owner:NORTH CAROLINA STATE UNIV

Process and apparatus to attach elastic members to disposable wearing article being continuously manufactured

A continuous web as a component of a disposable wearing article is fed in a machine direction and first continuous elastic members are fed via guide elements adapted to oscillate the elastic members in a cross direction. Each of the guide elements has a first servomotor having a rotary shaft adapted to repeat reversal of its rotational direction, a first arm connected directly with the rotary shaft and extending in a direction crossing the rotary shaft so that the first arm swings around the rotary shaft as the rotary shaft rotates, and a first feed member adapted to direct the first continuous elastic members toward the guide element formed on the first arm.

Owner:UNI CHARM CORP

Multicomponent fibers and microdenier fabrics prepared by fibrillation thereof

Multicomponent fibers and fabrics made therefrom are provided. The fibers include a multilobal sheath fiber component surrounding a core fiber component, wherein the fibers can be fibrillated to provide a plurality of intertwined microdenier fiber components. Methods of providing such fabrics are also disclosed.

Owner:NORTH CAROLINA STATE UNIV

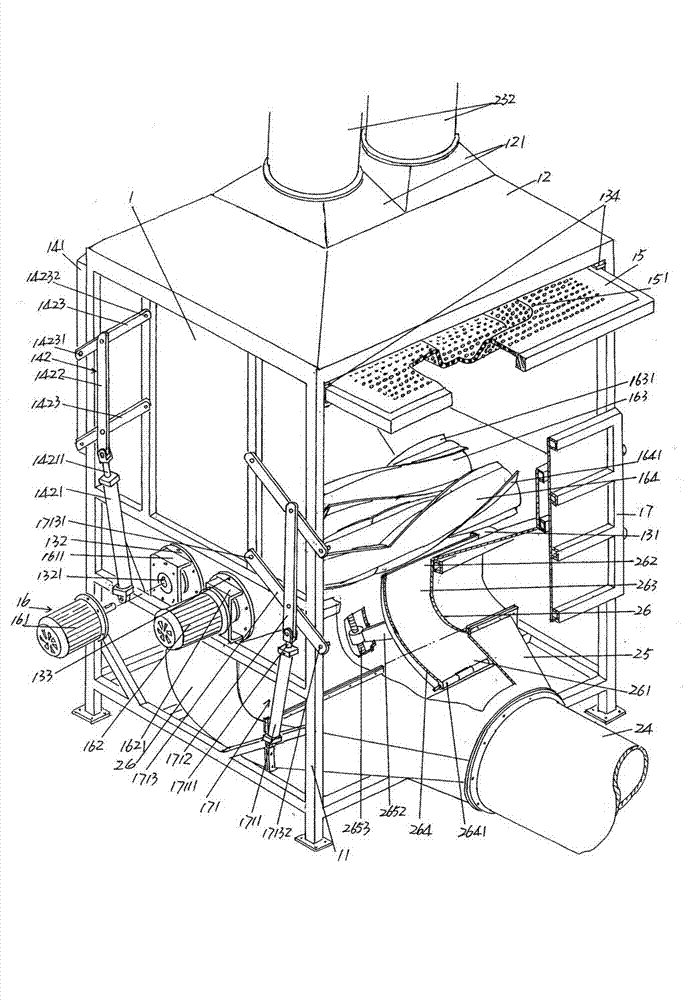

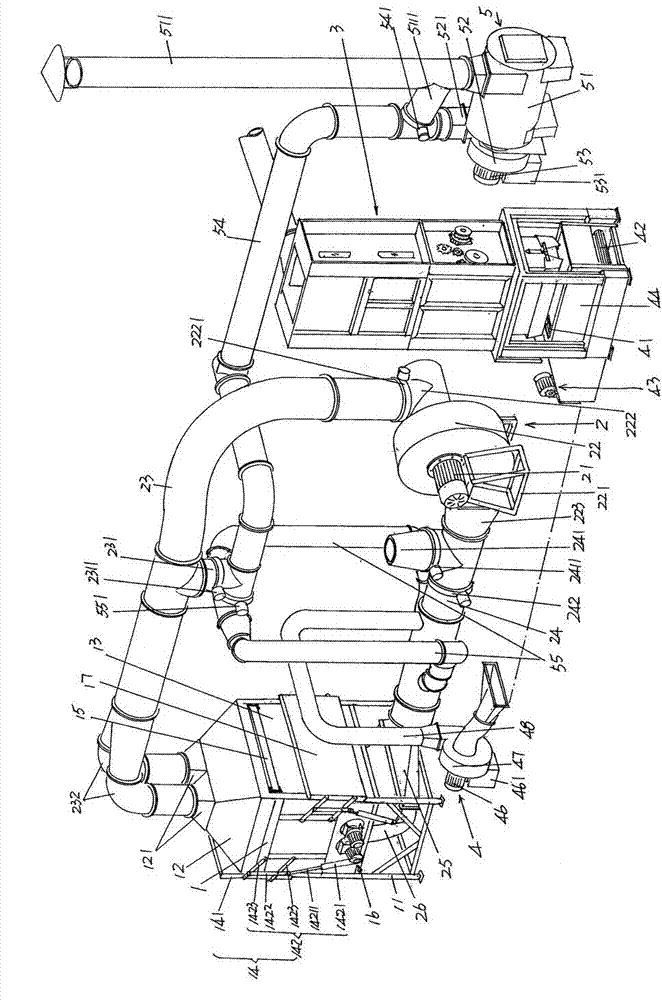

Airflow filling type automotive interior preforming machine

The invention provides an airflow filling type automotive interior preforming machine and belongs to the technical field of automotive interior production devices. The airflow filling type automotive interior preforming machine comprises a preforming box, an airflow circulating mechanism, a fiber conveying mechanism, a hot air generating mechanism and a fiber weighing and metering mechanism, wherein a box cover is formed on the top; a box cavity opening / closing mechanism is arranged on one side of the preforming box, and the other side of the preforming box is provided with an access door; a preforming mold is arranged on the top of the box cavity; a suction hole is formed on the preforming mold; a fiber feeding mechanism is arranged at the bottom of the preforming box; the airflow circulating mechanism is connected with the box cover in a matching mode; the fiber weighing and metering mechanism comprises a frame, a cotton loosening box, a cotton storage box, a first upper star-shaped roller, a second upper star-shaped roller, a first lower star-shaped roller, a second lower star-shaped roller, a cotton shifting roller, a roller shaft power transmission device and a weighing and metering hopper. The airflow filling type automotive interior preforming machine has the advantages that: the density consistency of a fiber cotton layer adsorbed to the preforming mold can be ensured; the whole structure is simple, and the labor intensity of a worker is lightened; ideal processing efficiency is achieved, and energy is saved; and moreover, according to the fiber weighing and metering mechanism, the metering effect can be guaranteed.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

Automotive upholstery pre-forming machine by using airflow filling method

The invention provides an automotive upholstery pre-forming machine by using an airflow filling method, and belongs to the technical field of automotive upholstery producing devices. The automotive upholstery pre-forming machine comprises a pre-forming box, a fiber weighing and measuring mechanism, a fiber conveying mechanism and a hot air generating mechanism, wherein a box cover is formed on the top of the pre-forming box; a box cavity opening and closing mechanism is assembled on one side of the pre-forming box; an access door is assembled on the other side of the pre-forming box; a pre-forming mold is assembled on the top of a box cavity; an induced draft hole is arranged on the pre-forming mold; and a fiber feeding mechanism is assembled at the bottom of the pre-forming box. The automotive upholstery pre-forming machine is characterized by further comprising an airflow circulating mechanism comprising a working motor, a fan, an induced draft tube, an air supply tube, a connected cotton box and a cotton guiding box. The automotive upholstery pre-forming machine has the advantages that density consistency of a fiber cotton layer absorbed on the pre-forming mold can be ensured; the integral structure is simple, and the labor intensity of workers is reduced; processing efficiency is perfect, and energy conservation is facilitated; and the airflow circulating mechanism can realize effects of supplying cotton under positive pressure, absorbing fibers under negative pressure and guiding high-temperature air in the box cavity.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com