Novel stress corrosion test specimen and experiment method

A technology of stress corrosion and test methods, which is applied in the preparation of test samples, weather resistance/light resistance/corrosion resistance, and the use of stable tension/pressure to test the strength of materials, etc. It can solve the problems that are not suitable for stress corrosion tests and WOL samples Complicated processing, high material consumption, etc., to achieve the effect of convenient hanging test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention should not be limited thereby.

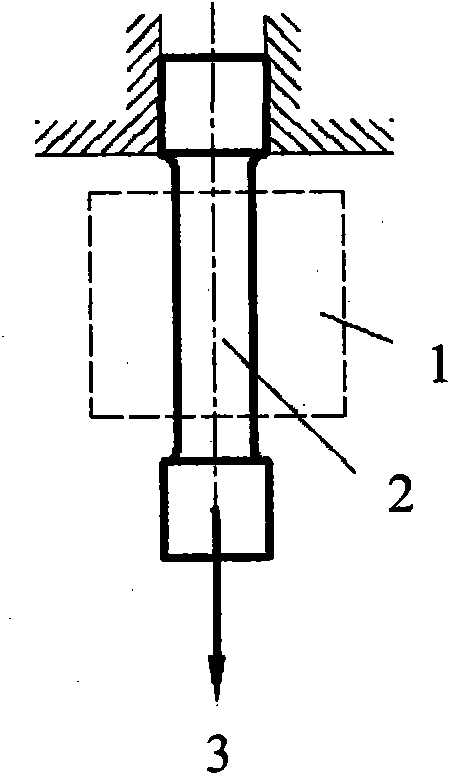

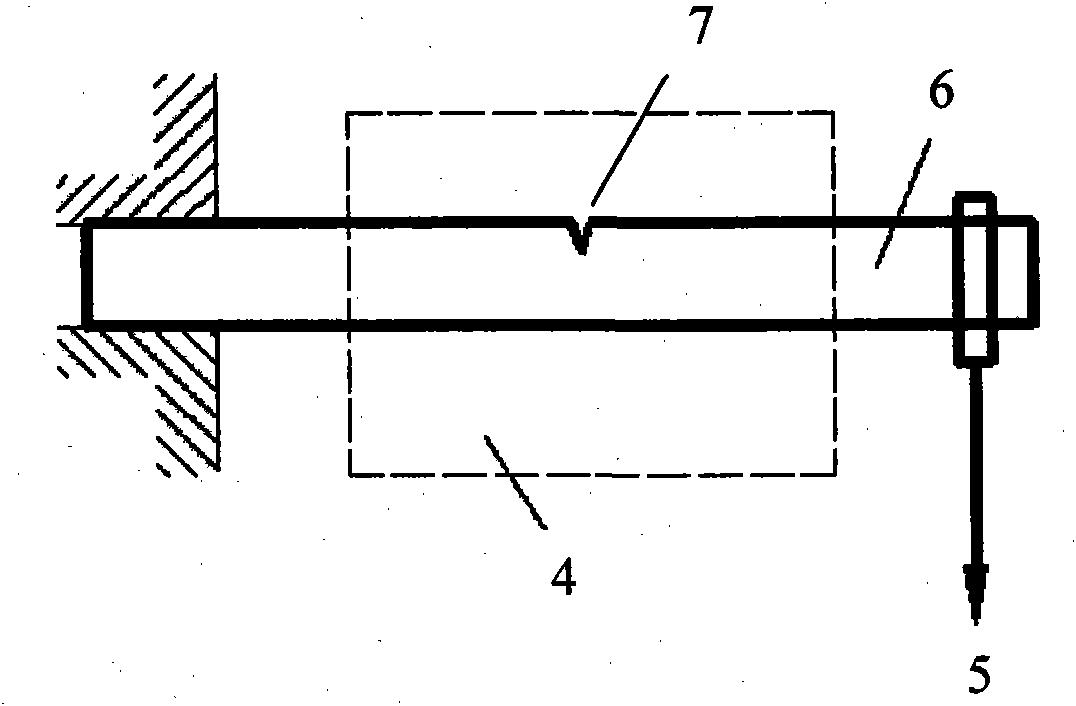

[0035] The invention proposes a new plate-type sample which is cut and shaped by a wire cutting method at one time, then preloaded on a tensile testing machine, and the prestrain value of the tested part is measured and controlled by a displacement sensor. This pre-strain variable can be pre-set according to the test requirements as needed. Then use a special pad that meets the precision requirements to pad it into a specific position. It can be preloaded with a little unloading and ready to use. Even if stress corrosion cracking occurs during use, the displacement at the preload position can always remain unchanged, so this kind of sample should belong to the constant strain stress corrosion test sample.

[0036] see Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com