Patents

Literature

111results about How to "Improve grout quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tunnel information tracing accurate grouting method

ActiveCN101832142AOptimizing the Number of Grouting HolesReduce the amount of waterUnderground chambersTunnel liningGlass fiberGeomorphology

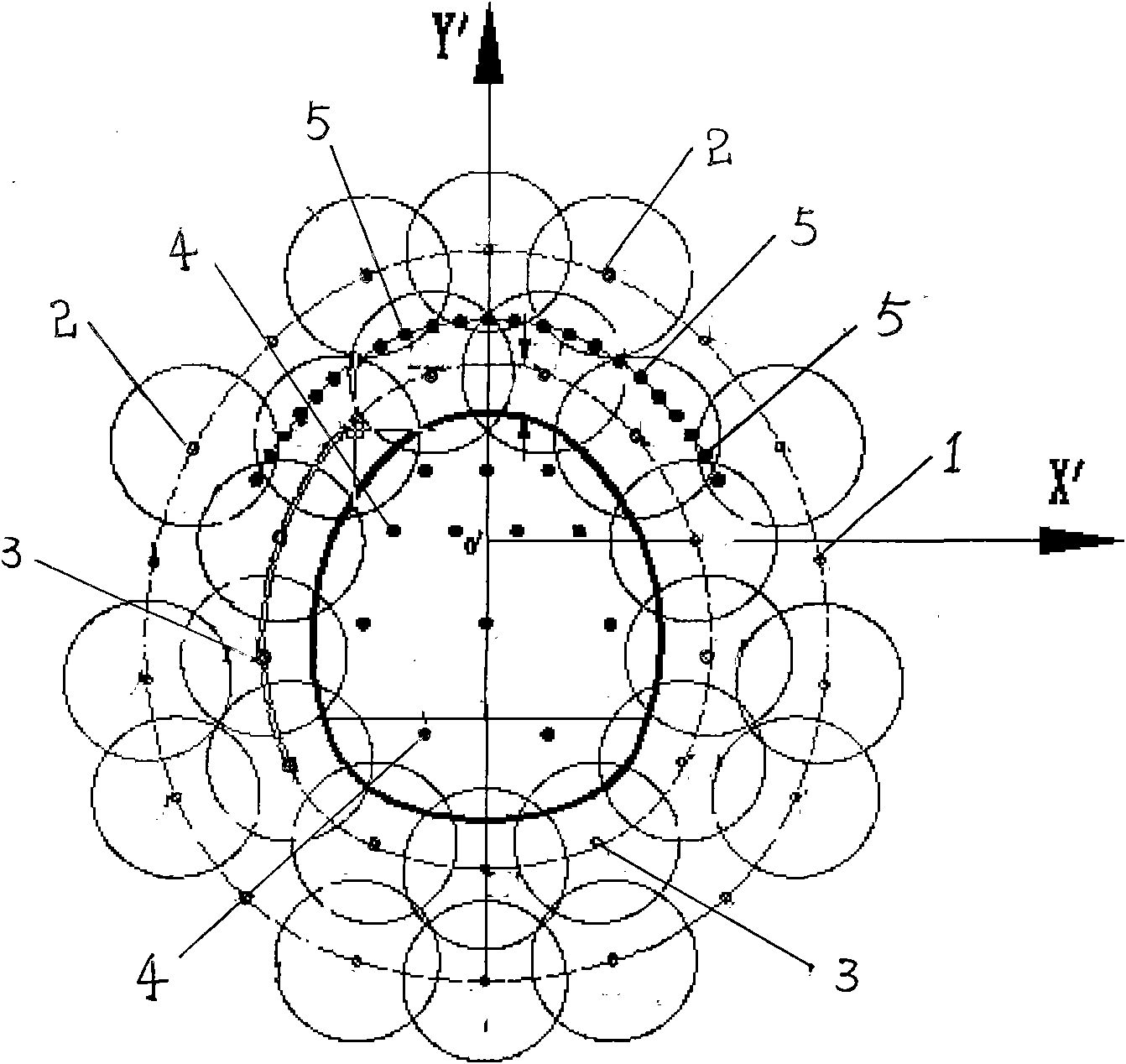

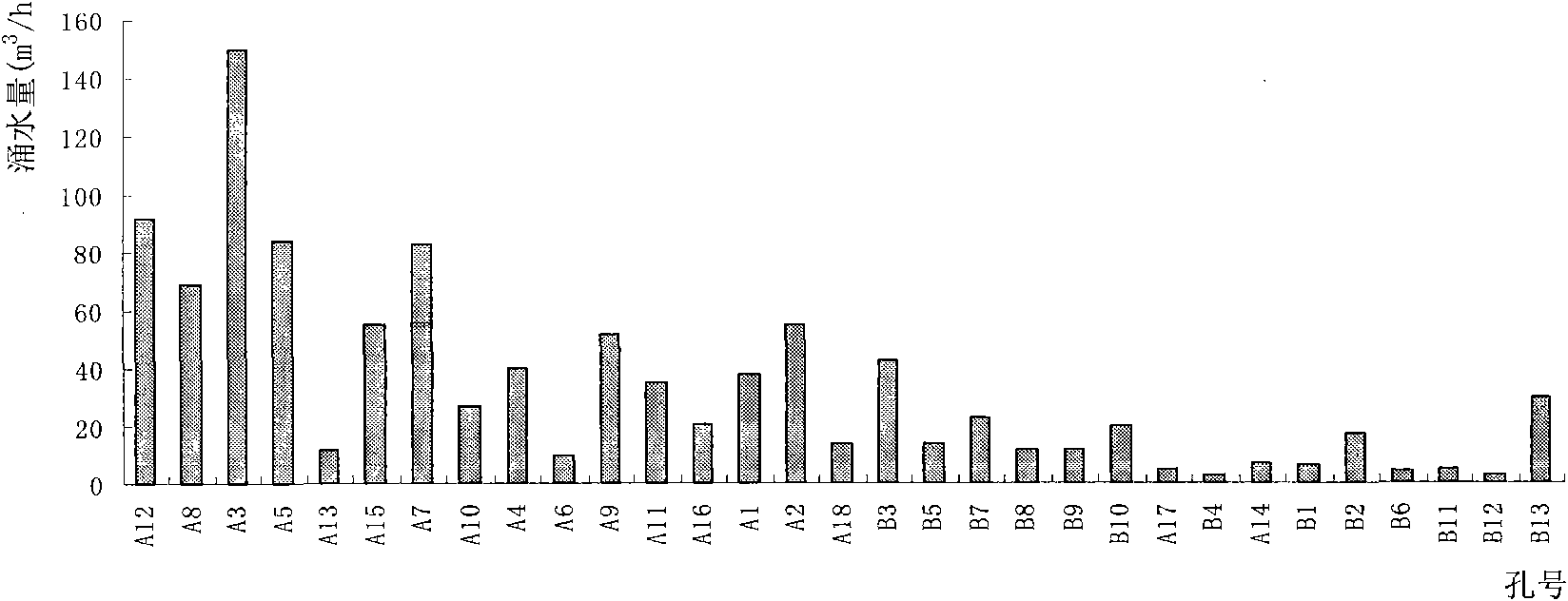

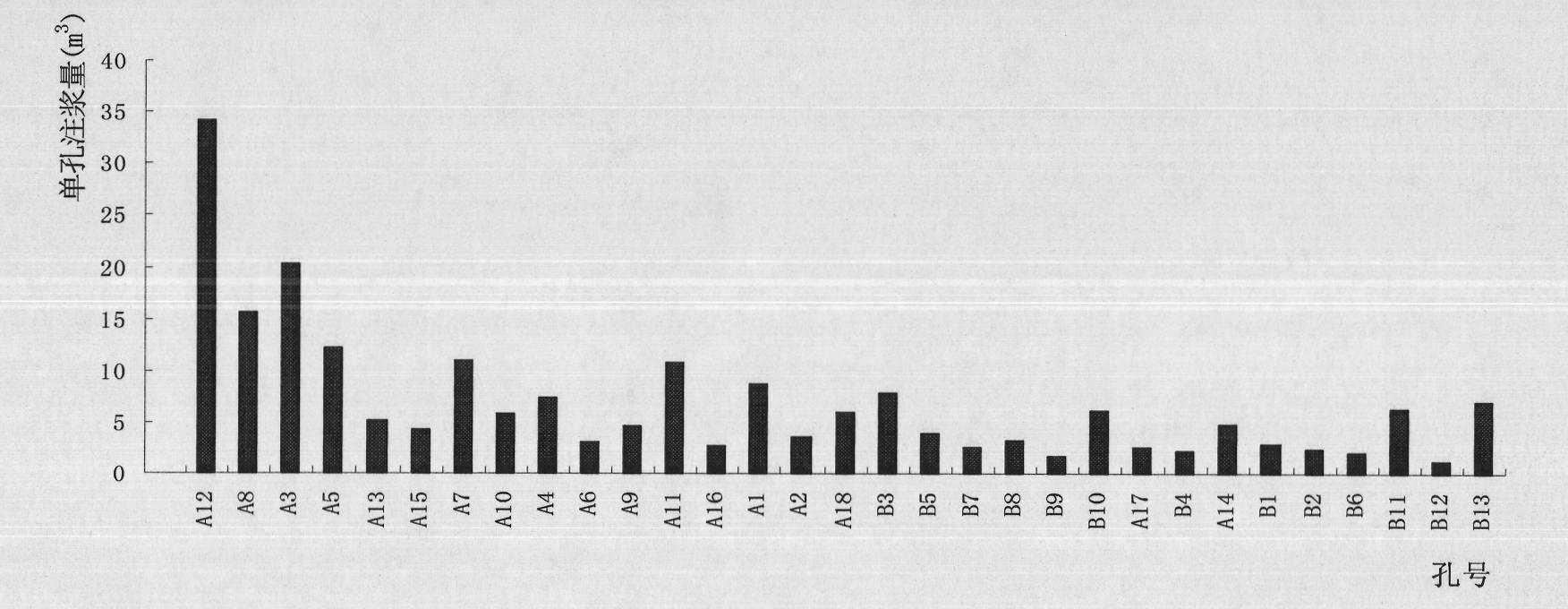

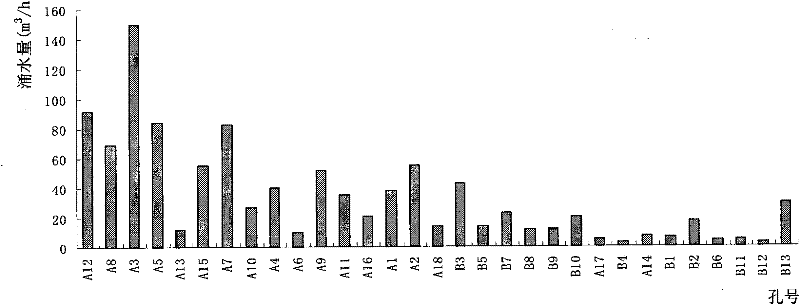

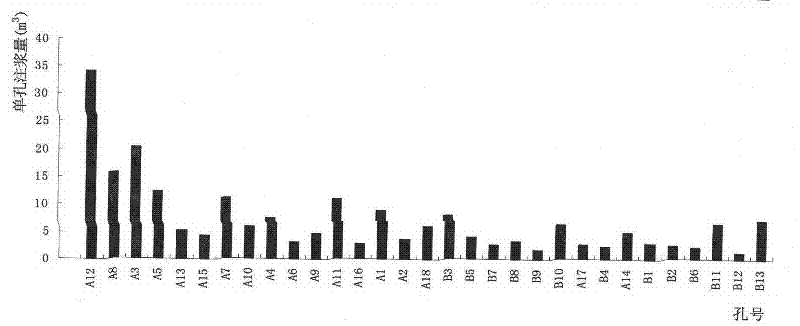

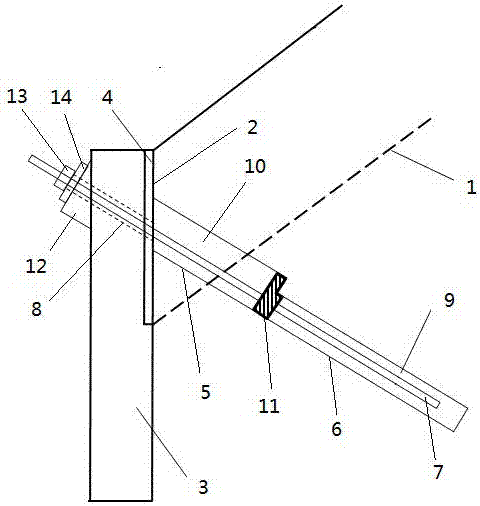

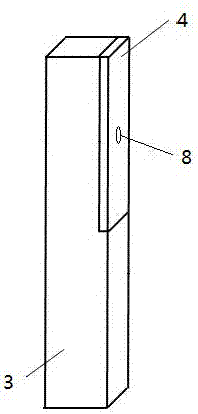

The invention relates to the field of tunnel grouting, in particular to a tunnel information tracing accurate grouting method, which solves the problems of thick reinforcing ring, large number of drilled holes, long construction period and the like of the traditional curtain grouting method adopted in current tunnel grouting. The method comprises the processes of grout stopping wall building, arrangement of orifice tubes and grouting tubes, measurement of the water burst of a drill hole, packer test, hole arrangement, drilling operation and grouting, wherein the hole arrangement and the grouting are performed according to the sequence from an advance geological drill hole to other outer ring holes to an inner ring hole to a working surface stabilizing hole to an access hole to a pipe-shed hole; and steps such as advance big pipe-shed construction of a working chamber and working surface stabilization by using a glass fiber anchor rod are saved. In the invention, a break through is made in the conventional construction philosophy, grouting design and geological change are tightly combined together, a grouting mechanism of 'crack blocking, water reduction, surrounding rock fixation and stratum stabilization' is adopted, the grouting holes are reduced by 30 to 40 percent, grouting quality is improved, the safe and quick construction is guaranteed, major water burst and mud burst accidents are eliminated, and the environment is protected maximally.

Owner:CHINA RAILWAY 12TH BUREAU GRP

Rapid construction method of high-pressure water-rich fault zone of tunnel

ActiveCN101798930AReduce water pressure in tunnelReduce water and mud inrushUnderground chambersTunnel liningWorld classTunnel construction

The invention relates to the field of tunnel construction, in particular to a rapid construction method of a high-pressure water-rich fault zone of a tunnel, which solves a plurality of problems in the construction method of high-pressure water-rich fault zone tunnels under the guide of the traditional knowledge. A draining branch tunnel is additionally arranged between a main tunnel and a parallel heading, the water flow pressure of the hanging wall of a fault interface is reduced progressively, and a large amount of water is discharged from the main tunnel by adopting a guiding and non-clogging mode; when the water pressure of the main tunnel is reduced to 0.3-0.5MPa, an informationized tracking and accurate grouting method is used for grouting and reinforcing the main tunnel; and rapidly excavating and sealing technology is used for excavating the main tunnel and the parallel heading. The invention adopts the technology combining the water distribution and pressure reduction mode, the informationized tracking and accurate grouting method and the rapidly excavating and sealing technology for high-pressure water-rich shattered fault zones for the first time, breaks through the traditional concept that the water distribution and pressure reduction mode is opposite to the grouting and reinforcing construction method, solves the world-class problem of construction of the high-pressure water-rich fault zone of the tunnel, improves the construction progress and the construction efficiency, and ensures safe and rapid perforation of the tunnel.

Owner:CHINA RAILWAY 12TH BUREAU GRP

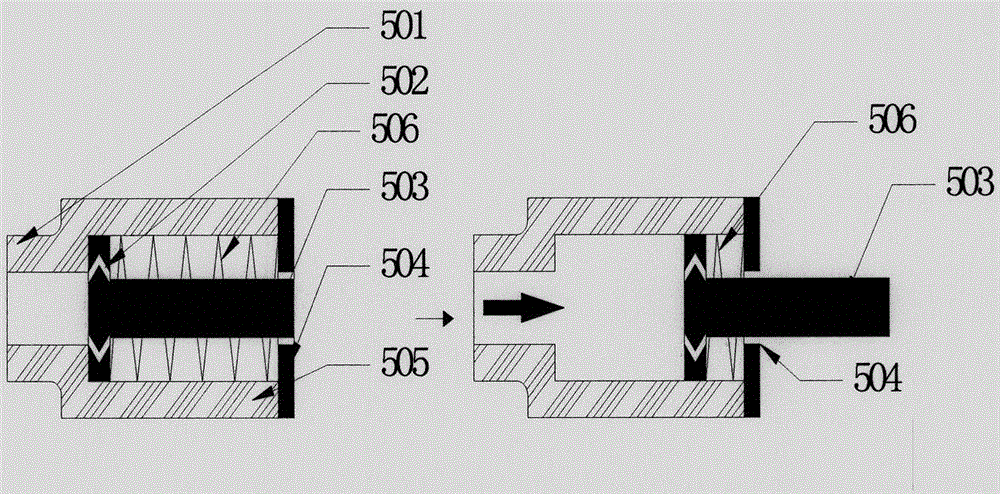

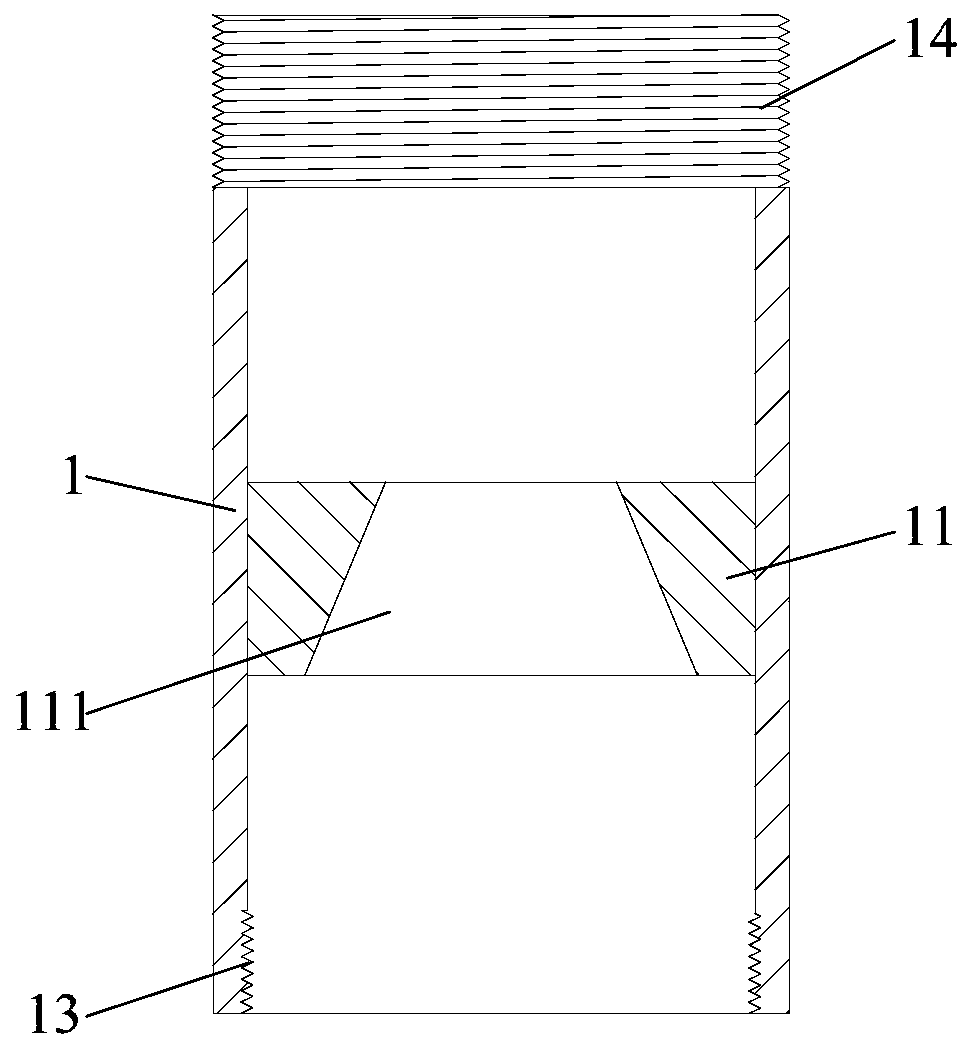

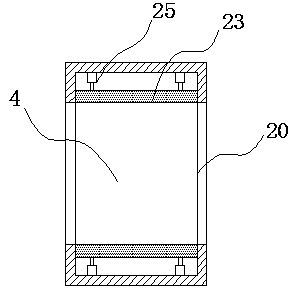

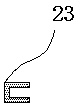

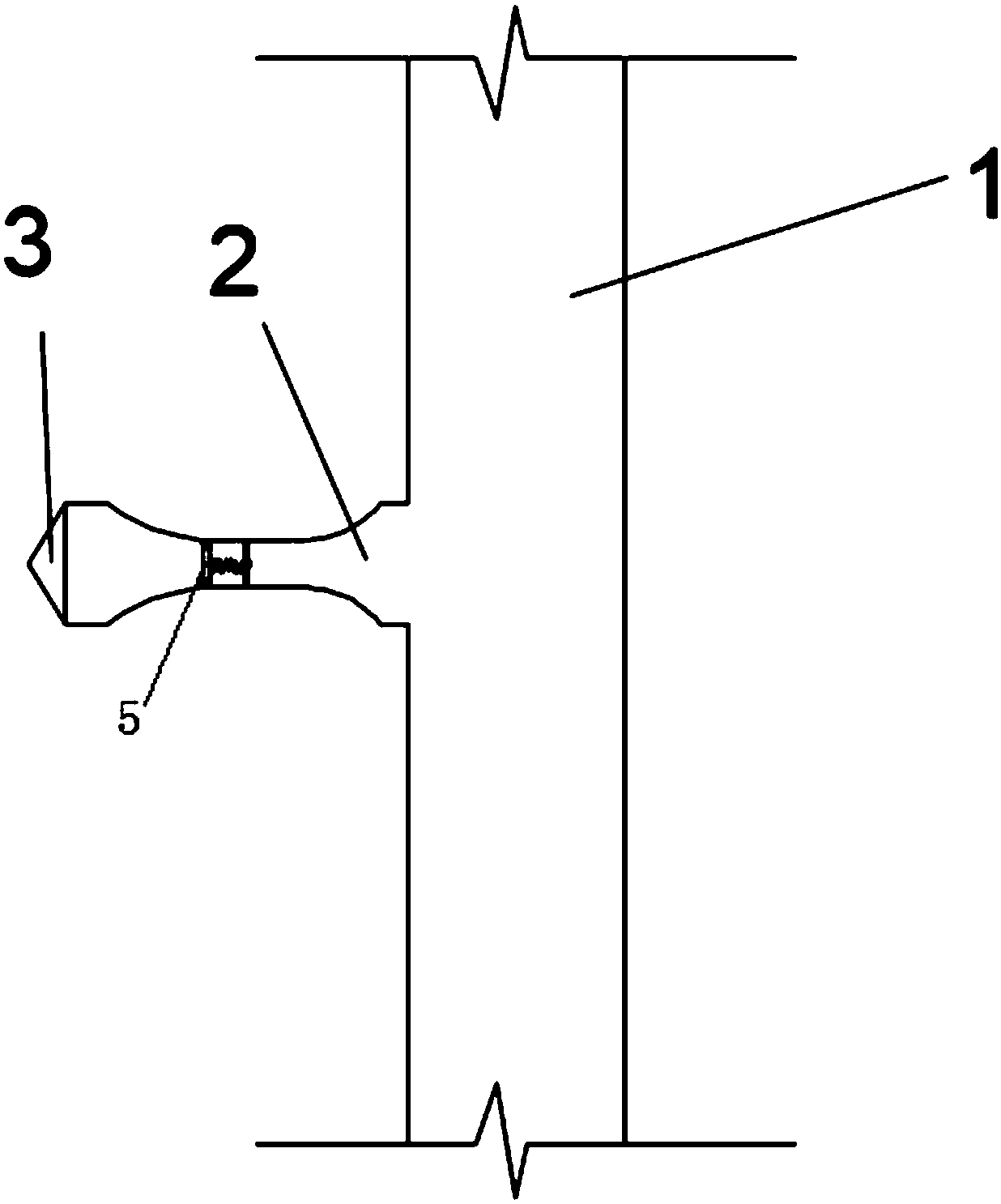

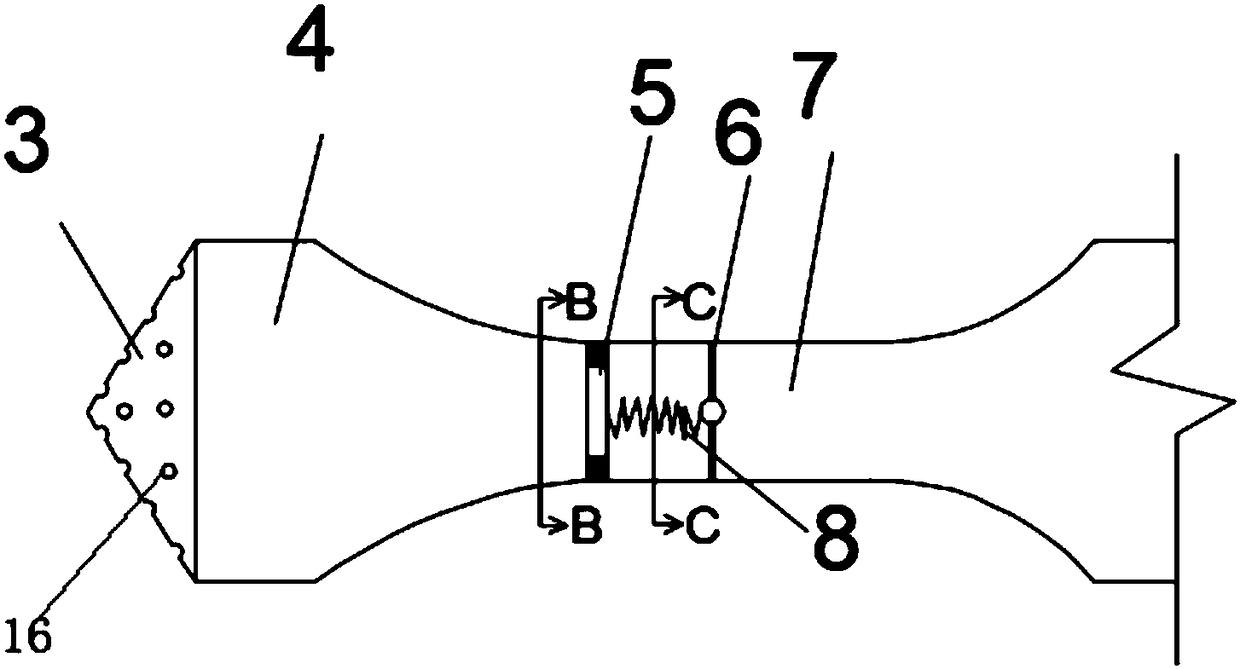

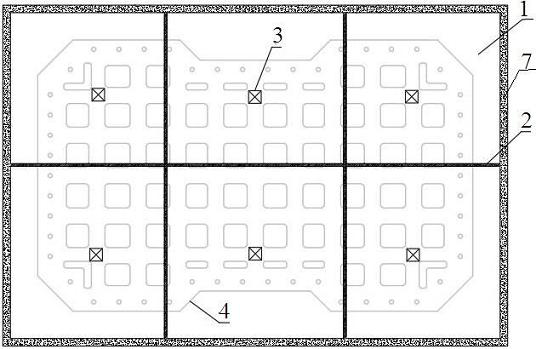

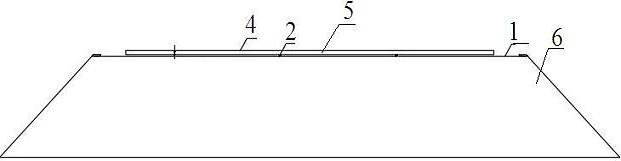

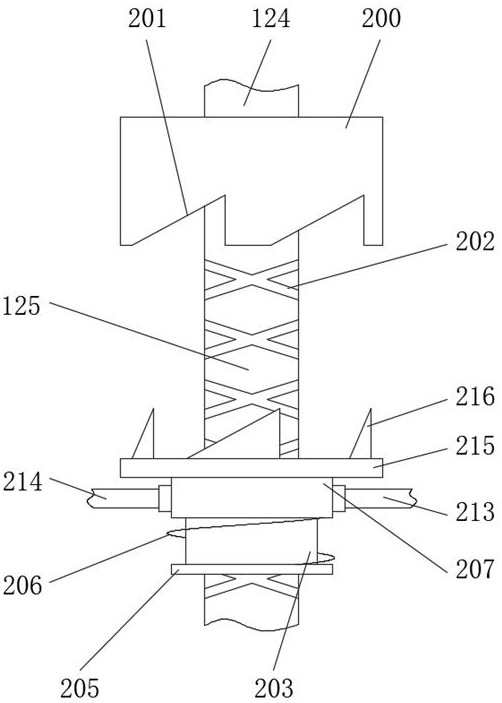

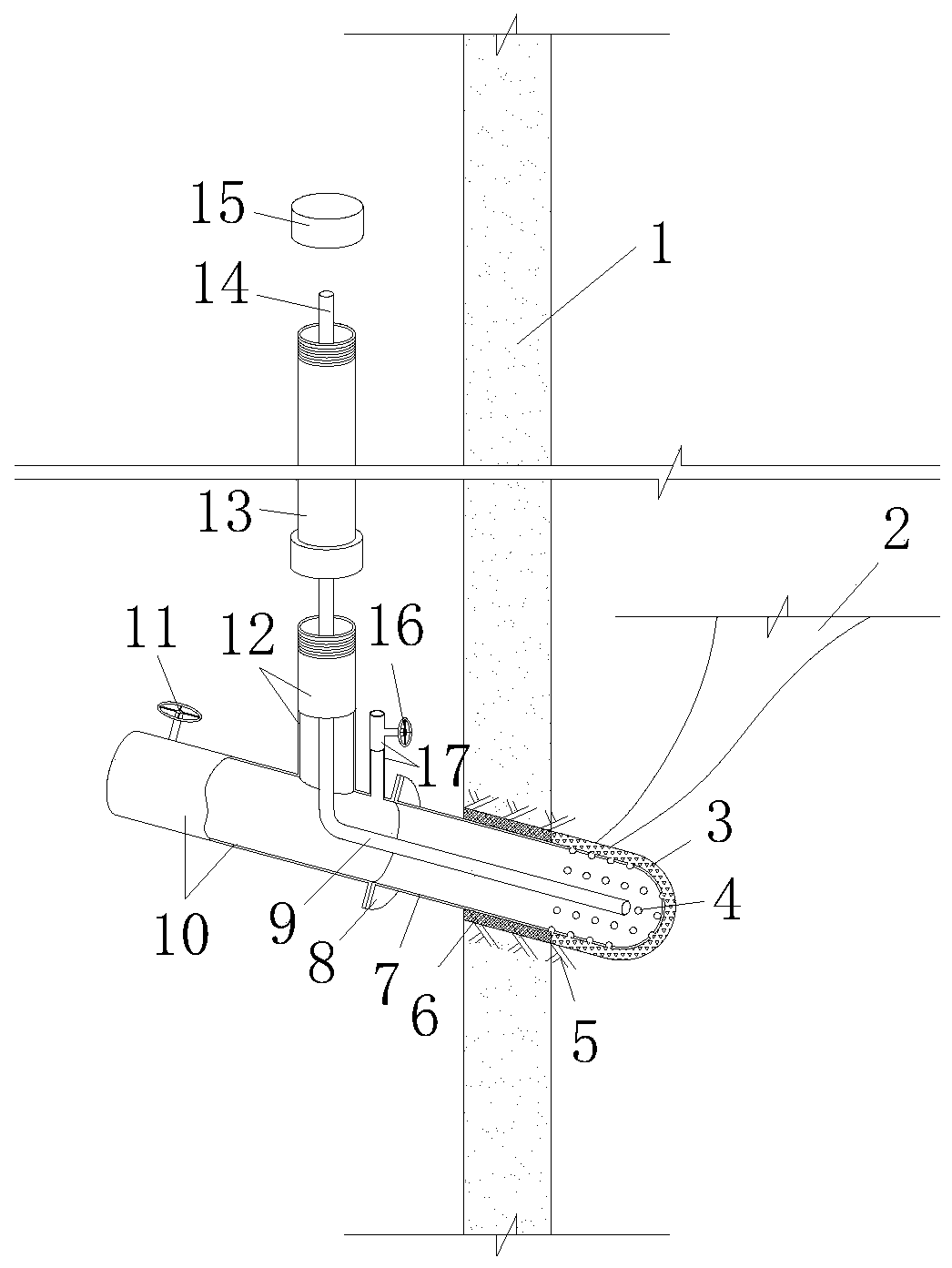

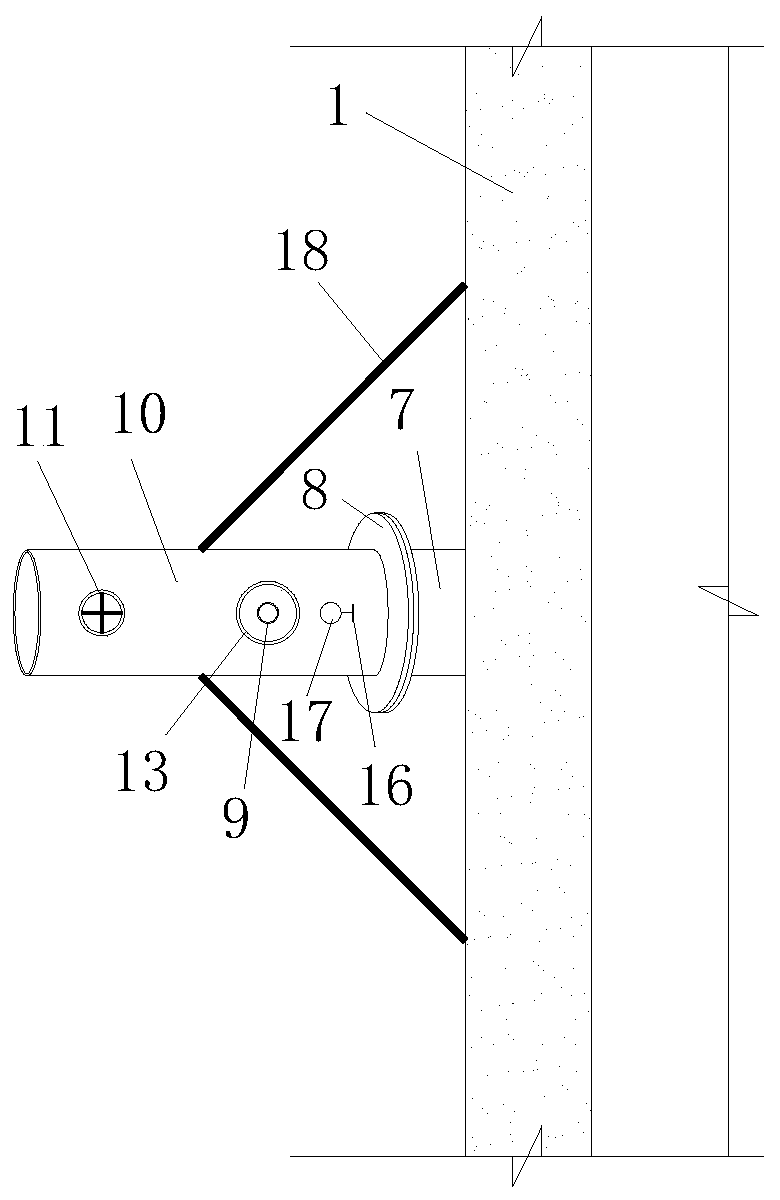

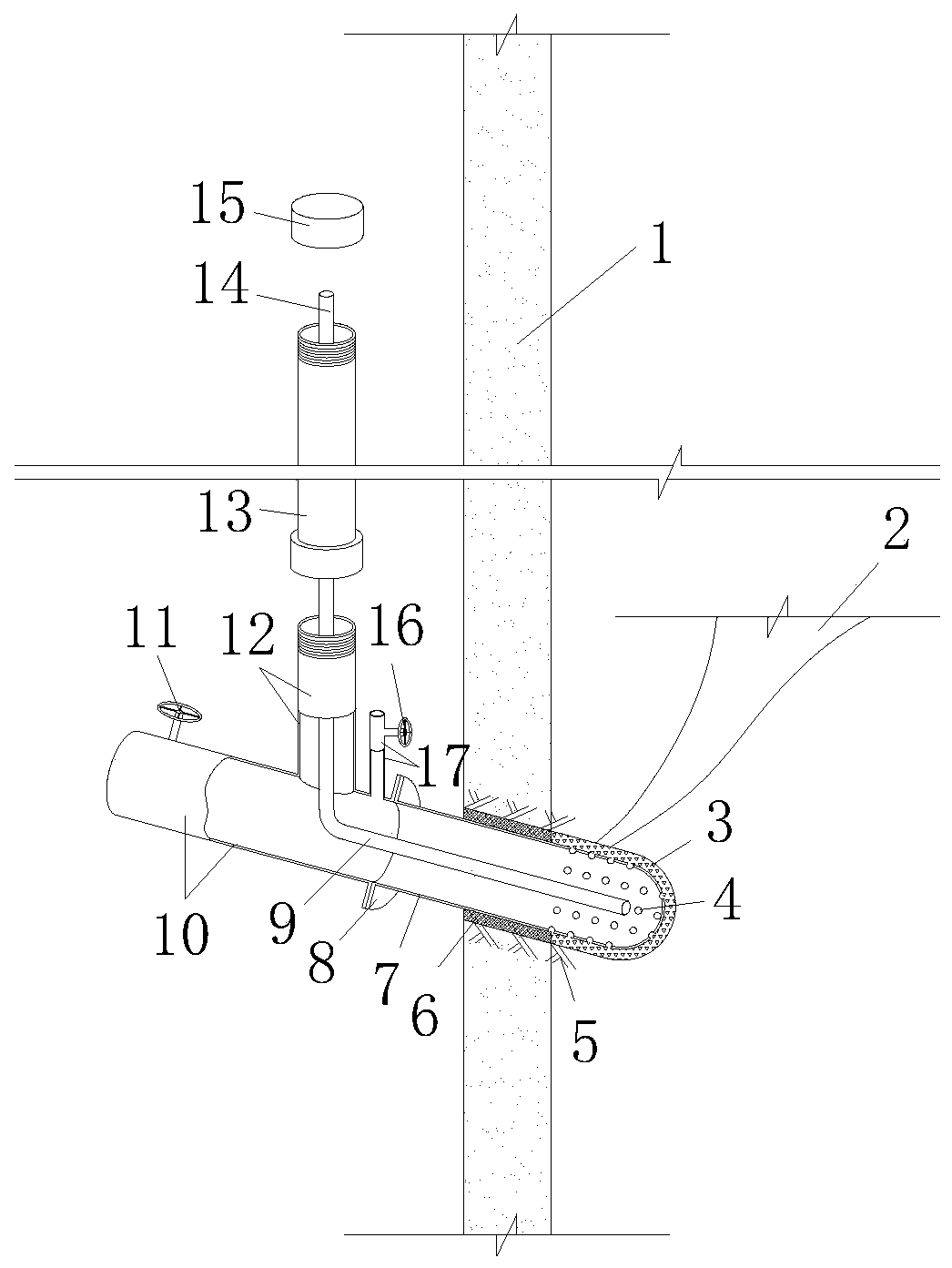

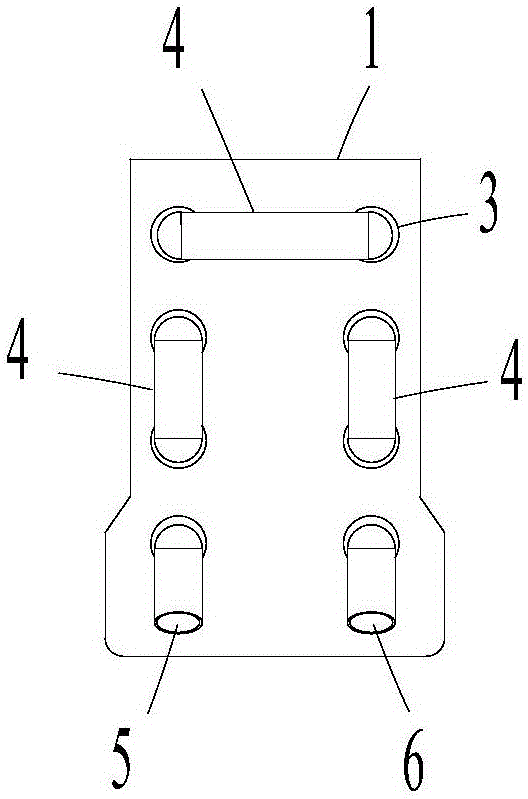

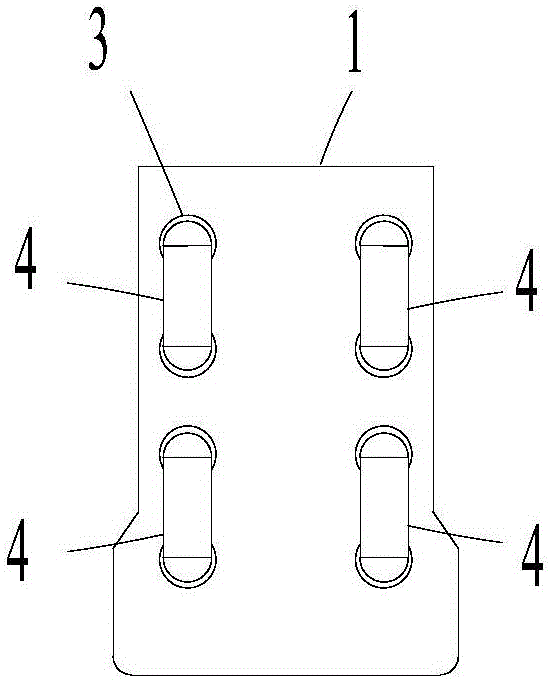

Blocking valve, grouting sleeve and prefabricated component connecting method

PendingCN105781022AImprove grout qualityHigh strengthBuilding reinforcementsLift valveAgricultural engineeringBlocked valves

The invention provides a blocking valve, a grouting sleeve and a prefabricated component connecting method. The steel bar connection grouting sleeve has a sealed space, and can be automatically sealed after grouting, and the grouting degree can be observed in a grouting process. Compared with an existing open sleeve, the grouting sleeve has the advantages that higher pressure can be born in the grouting process, the grouting sleeve can be automatically sealed after grouting, and the grout fullness of the sealed space can be observed in the grouting process, thereby monitoring the grouting quality of the grouting sleeve. The blocking valve, the grouting sleeve and the prefabricated component connecting method can be widely applied to a grouting sleeve connection process in the technical field of building construction.

Owner:BEIJING JIEYANTE ENG TECH

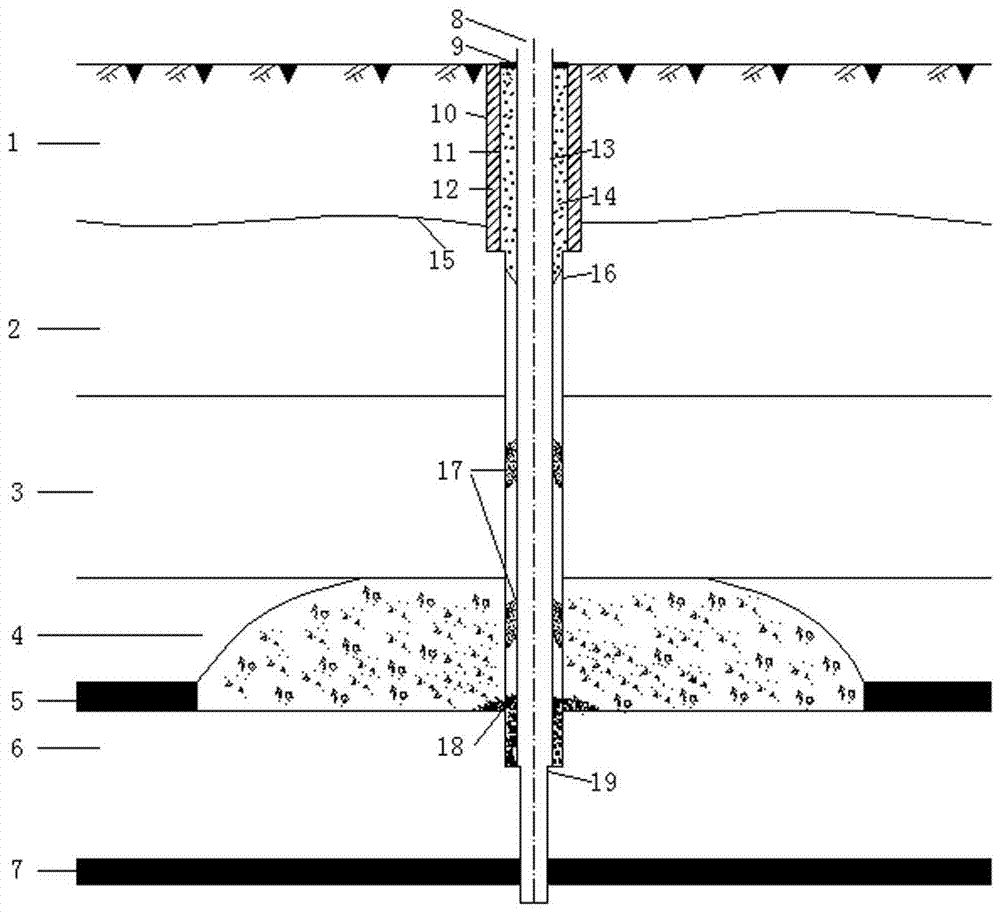

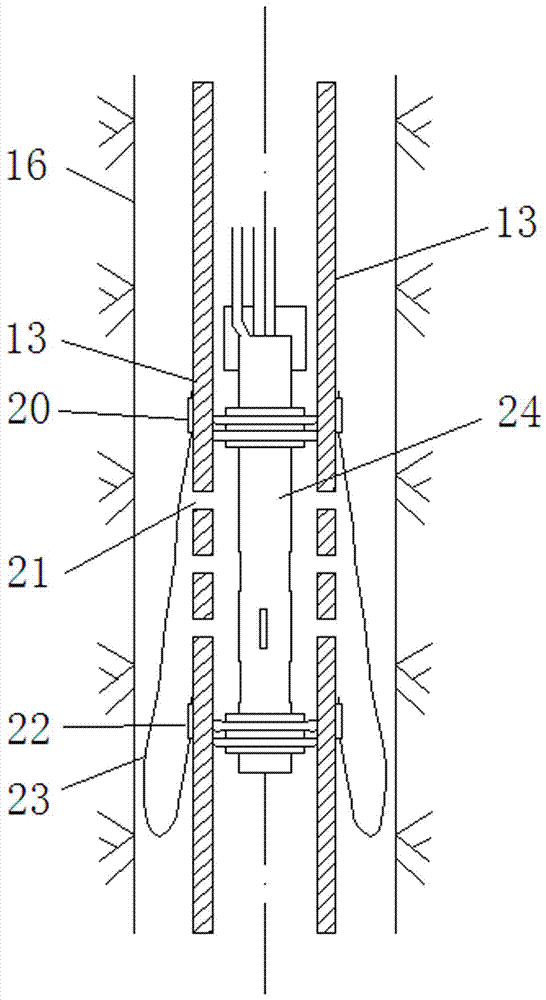

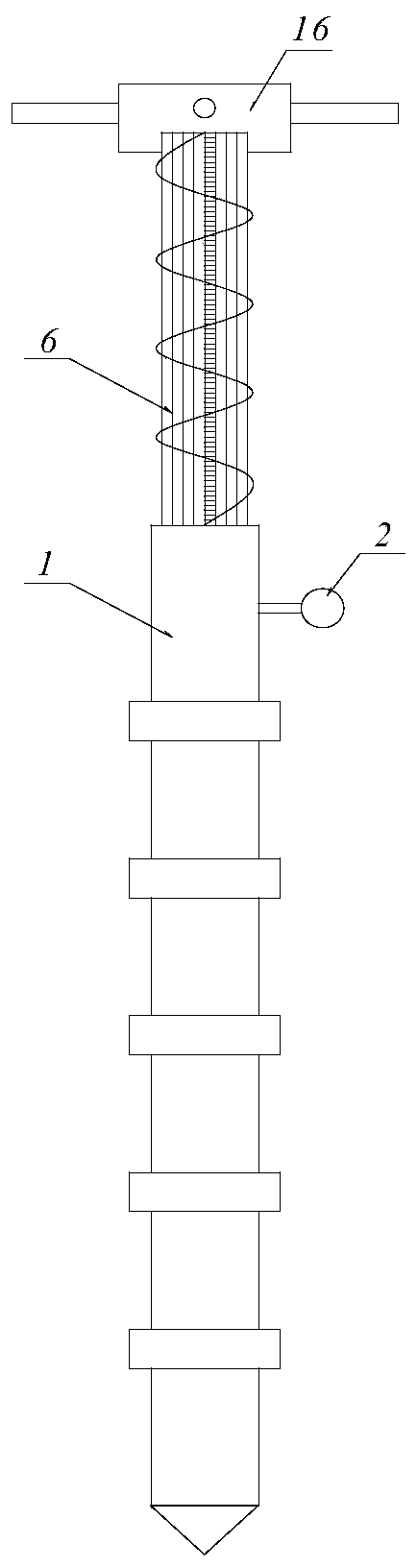

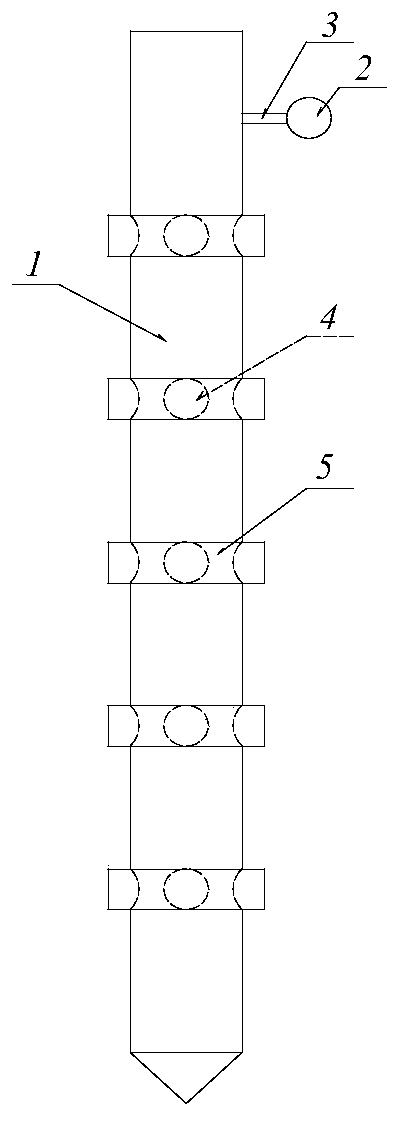

Multi-joint intensive grouting well-reinforcing method for reinforcing coal-bed gas well penetrating through goaf

ActiveCN107313745AImprove long-term stabilityGuaranteed flowSealing/packingWell drillingWell cementing

The invention belongs to the technical field of coal-bed gas exploitation and provides a multi-joint intensive grouting well-reinforcing method for reinforcing a coal-bed gas well penetrating through a goaf. According to the method, the problems that during passing-through of the goaf, the third spud-in well-drilling construction process is complex, and the stability of a third spud-in well body structure is poor are solved. The third spud-in drilling construction process is adopted; a well body of the coal-bed gas well is composed of a first spud-in drilled hole, a surface casing, a second spud-in drilled hole, an intermediate casing and a third spud-in drilled hole; when third spud-in drilling is constructed, multi-joint grouting reinforcing is conducted on well wall surrounding rock outside the intermediate casing, so that the strength of the well wall surrounding rock is improved, long-term stability of the coal-bed gas well is guaranteed, and the stabilized intermediate casing is directly used as the production casing of the coal-bed gas well. A multi-joint cement paste wrapped body supporting structure is formed between the intermediate casing and the well wall surrounding rock, the long-term stability of the well wall surrounding rock of the coal-bed gas well and the well body structure can be strengthened greatly.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD +2

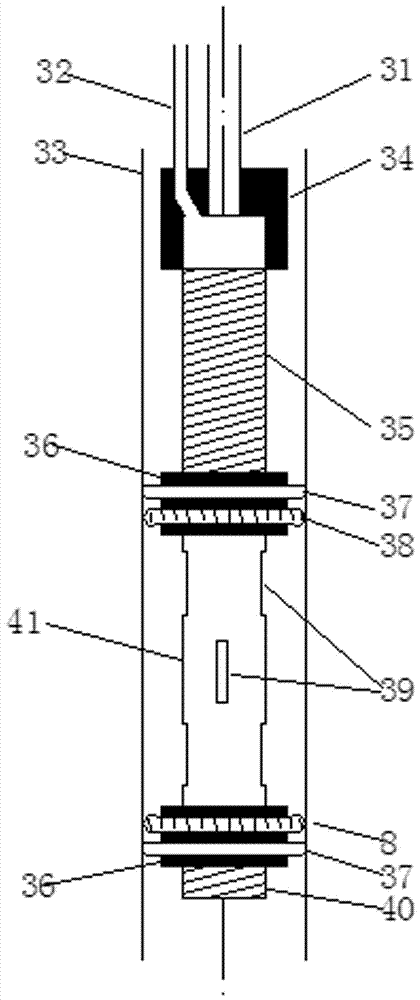

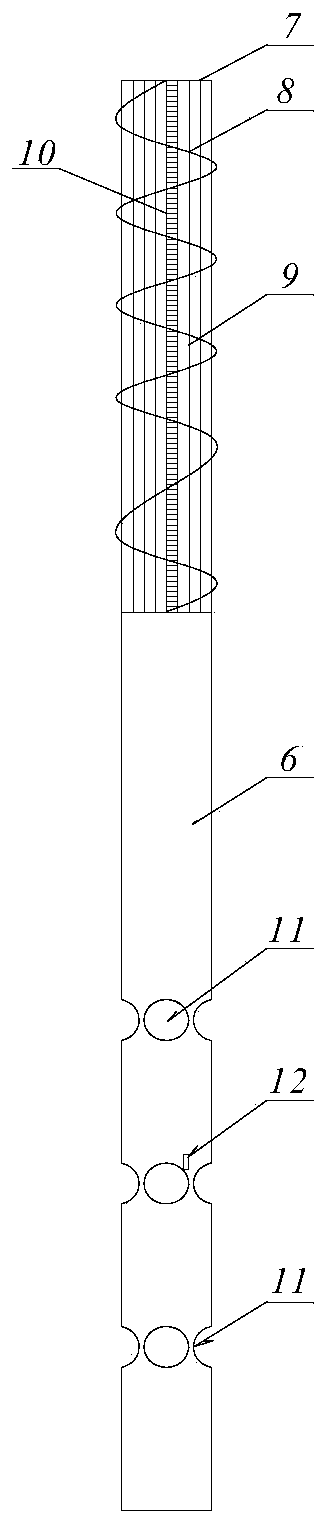

Pressure-controllable layered grouting type sleeve valve tube and grouting method

The invention discloses a pressure-controllable layered grouting type sleeve valve tube and a grouting method. Controllable pressure and accurate layered grouting are realized, and grouting quality iseffectively improved. The pressure-controllable layered grouting type sleeve valve tube comprises an outer tube, an inner tube, a rotating handle and a pressure measuring device, wherein the lower end of the outer tube is closed, and the upper-part inner wall is provided with an inner threaded segment; multiple layers of outer tube grout outlet holes are longitudinally and equidistantly formed inthe lower-part tube wall in a spaced mode, and each layer of the outer tube grout outlet holes is composed of at least two grout outlet holes uniformly distributed in the circular direction; and rubber one-way valves for covering all the outer tube grout outlet holes are arranged on the outer wall of the outer tube; the lower end of the inner tube is closed, and multiple layers of inner tube grouting holes are longitudinally and equidistantly formed in the lower-part tube wall of the inner tube in a spaced mode; the center distance of adjacent two layers of the inner tube grouting holes is equal to the center distance of adjacent two layers of the outer tube grout outlet holes, and each layer of outer tube grouting holes is composed of at least two grouting holes with corresponding to thegrout outlet holes in number and position; and a rotating handle communicating with the inner tube longitudinally is fixedly installed at the upper end of the inner tube and used for inserting the inner tube main body into the outer tube, and an outer threaded segment on the upper part of the rotation is connected with the inner threaded segment of the outer tube in a threaded mode. The pressuremeasuring device comprises a pressure sensor fixedly installed on the outer wall of the inner tube at the positions of the grouting holes.

Owner:POWERCHINA RAILWAY CONSTR +2

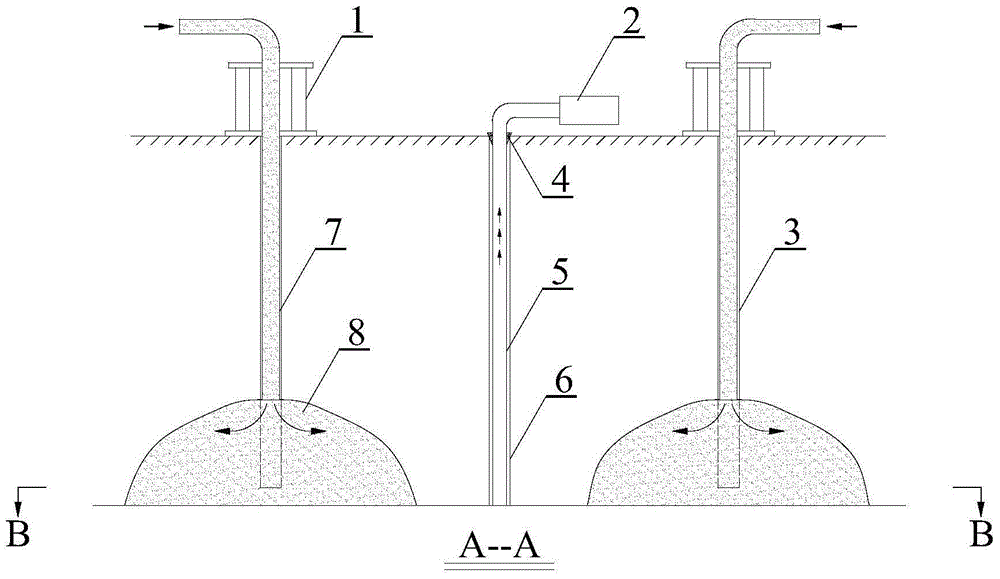

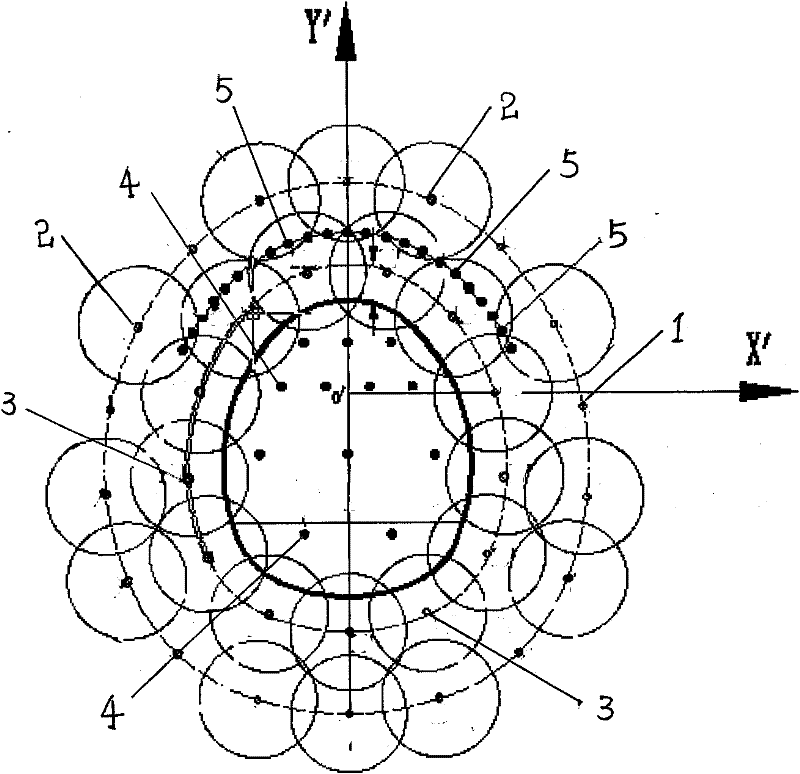

Method for widening grouting reinforcement and seepage and blockage prevention range of rock and soil

The invention discloses a method for widening the grouting reinforcement and seepage and blockage prevention range of rock and soil. Grouting holes and water drainage holes are distributed in the place where reinforcement and seepage prevention need to be conducted at intervals according to a certain form through combination of static pressure grouting and vacuum negative pressure water drainage. By means of vacuum negative pressure water drainage, the underground water level is lowered, underground water and air in holes of rock and soil are discharged, and dilution of underground water on grouting fluid is reduced. Negative pressure is formed at the water drainage positions, under the same grouting pressure condition, a forward pressure field is formed, the grouting speed is increased, and the grout expansion radius is increased. When a vacuum negative pressure pump works, underground water in holes of rock and soil surrounding the water drainage holes is collected towards the water drainage holes, dynamic water pressure is formed, and the grouting expansion radius is further increased. The grouting reinforcement and seepage and blockage prevention range of rock and soil is widened, the grouting effect is improved, the grouting quality is improved, and the grouting speed is increased. The method has the remarkable beneficial effects of being small in work amount, high in safety, good in grouting effect, wide in reinforcement and seepage prevention range, and the like.

Owner:CENT SOUTH UNIV

Variable pressure grouting pump and grouting method

PendingCN109667390AGuaranteed StrengthHigh saturationBuilding reinforcementsBuilding material handlingEngineeringSlurry

The invention relates to the field of rebar sleeve grouting and specifically discloses a variable pressure grouting pump and a grouting method. The grouting pump comprises a feeding part, a grouting part and an output part; the grouting part is connected with a discharging port of the feeding part; the output part is connected with a slurry outlet of the grouting part; the output part comprises acontrol valve and a conveying pipe; the control valve comprises a first valve inlet, a second valve inlet and a valve outlet; one end of the conveying pipe is connected with the valve outlet; the slurry outlet comprises a variable pressure slurry outlet and a normal pressure slurry outlet; the variable pressure slurry outlet is connected with the first valve inlet through a variable pressure device; the normal pressure slurry outlet is connected with the second valve inlet. According to the invention, the variable pressure slurry outlet is added and the variable pressure device is arranged between the variable pressure slurry outlet and the control valve, so that the technical problem of influences on slurry discharging pressure and flow of the grouting pump caused by untight closing of aslurry discharging valve block in the prior art can be solved, and the saturability, evenness and airtightness of slurry in the sleeve can be promoted.

Owner:广州建筑产业研究院有限公司

Grouting device for prefabricated component and construction method thereof

PendingCN108590189AAvoid wastingEfficient dischargeBuilding reinforcementsBuilding material handlingSlurryPrecast concrete

The invention discloses a grouting device for a prefabricated component. The grouting device comprises a precast concrete wallboard, a precast concrete beam, a grouting sleeve pre-buried at the bottomof the precast concrete wallboard, and a slurry circulation conveyor mechanism connected with the grouting sleeve. A sleeve outlet is arranged at the top of the grouting sleeve, and a sleeve inlet isarranged at the bottom of the grouting sleeve. The slurry circulation conveyor mechanism comprises a mixing device and a booster pump connected with the mixing device, a slurry inlet and a slurry outlet are formed in the mixing device, the slurry outlet is connected with a conveyor channel, the conveyor channel communicates with the sleeve inlet, the slurry inlet is connected with a backflow channel, and the backflow channel communicates with the sleeve outlet. The slurry circulation conveyor mechanism is arranged to realize the purpose of circulation grouting, the problems such as insufficient grouting inside the sleeve, incomplete bubble elimination, incomplete grouting at the joint or leakage of grouting at a seal chamber are effectively solved, and the connection quality between precast concrete components is improved.

Owner:NINGBO PRECA CONSTR TECH CO LTD

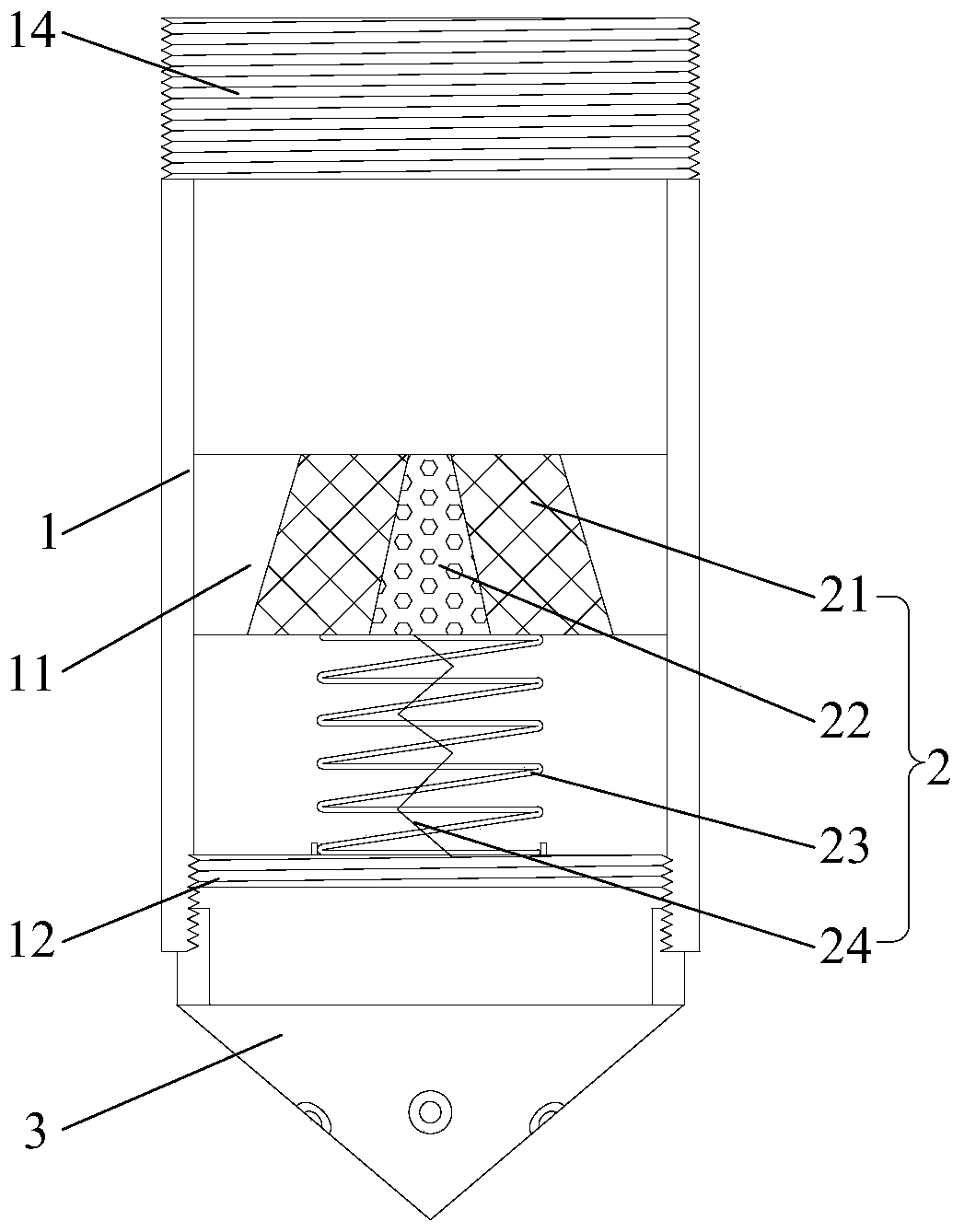

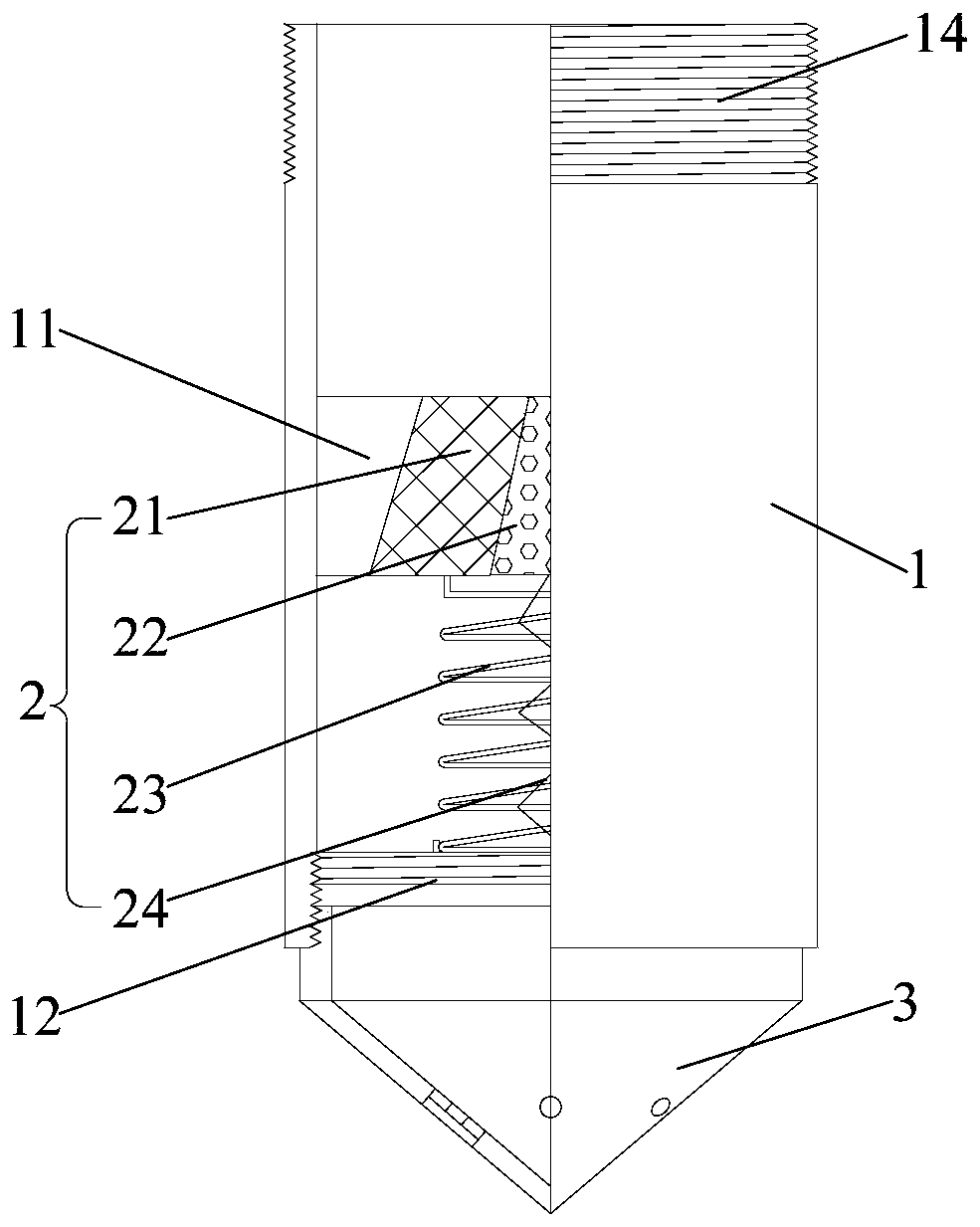

Pile end grouting spray head

PendingCN110499765AConstruction safetyEfficient constructionFoundation engineeringArchitectural engineeringPiston

The invention provides a pile end grouting spray head. The pile end grouting spray head comprises a grouting pipe, an adjusting assembly and a grouting head, wherein a baffle and a base are connectedin the grouting pipe in the grouting direction in a spaced mode; the baffle is provided with a first grout outlet hole, and the base is provided with grout passing holes; the adjusting assembly can bemovably arranged in the first grout outlet hole; the adjusting assembly comprises at least two pistons arranged in a sleeving mode from inside to outside in sequence; the pistons are connected with the base through corresponding elastic parts, and the elastic force of the elastic parts connected with the corresponding pistons increases progressively in sequence from inside to outside; the grouting head is connected to the grout outlet end of the grouting pipe and is provided with grouting holes. Through the pile end grouting spray head provided by the invention, under the condition that grouting pressure meets the using requirement, the first grout outlet hole can be opened smoothly to complete grouting operation. The pile end grouting spray head can adjusting the grout flow according tothe grouting pressure to ensure that the grout flow meets the using requirement.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

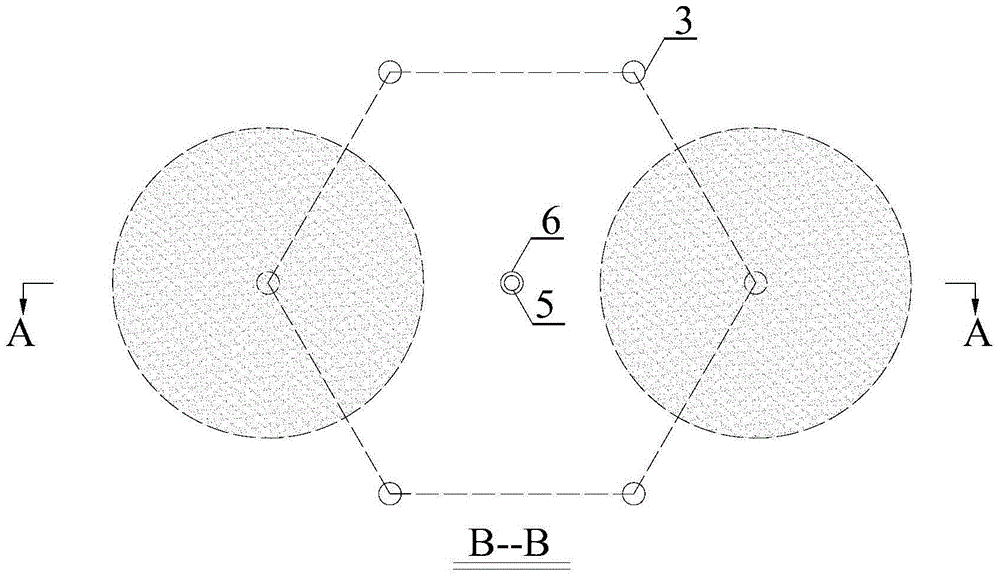

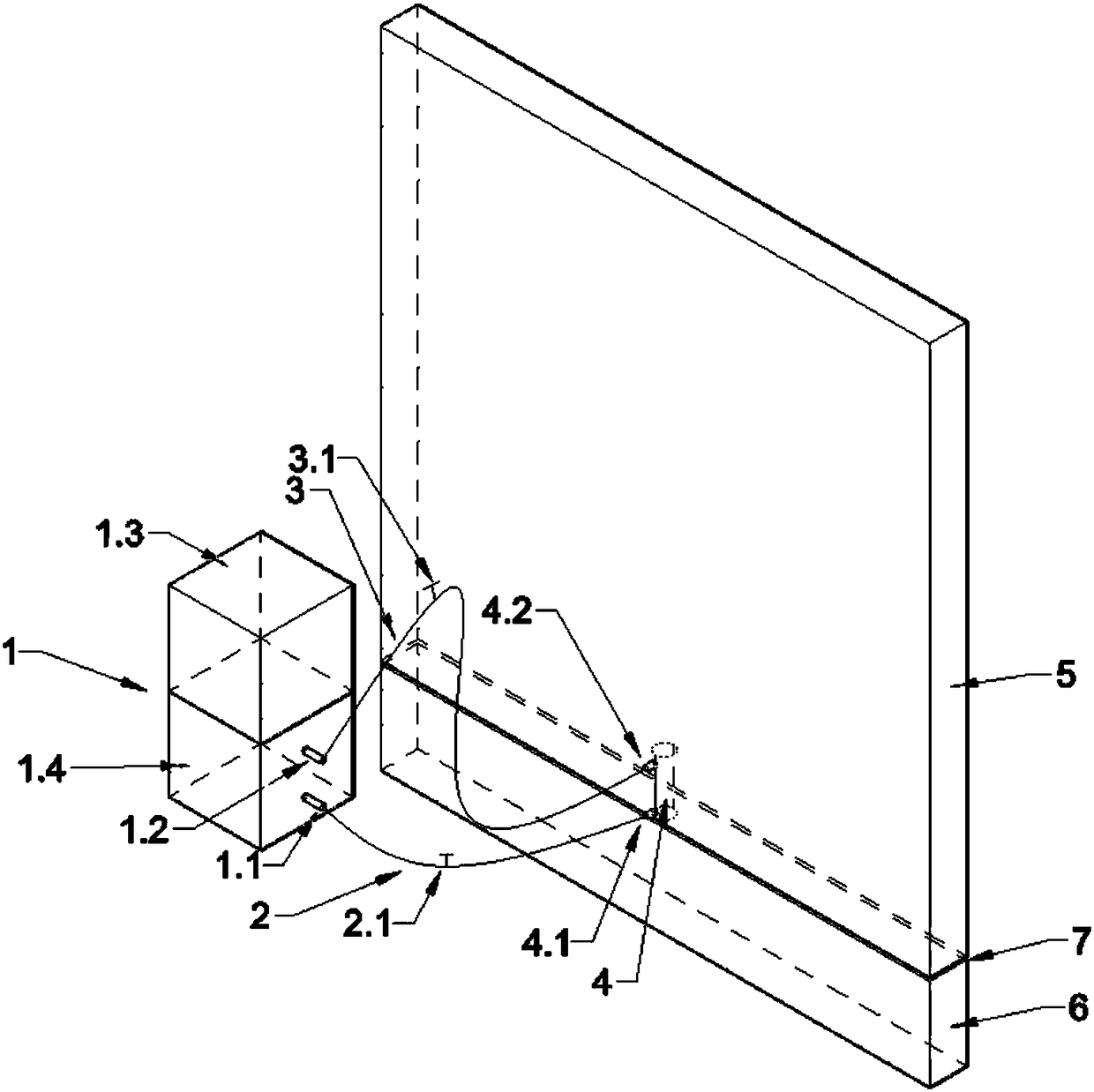

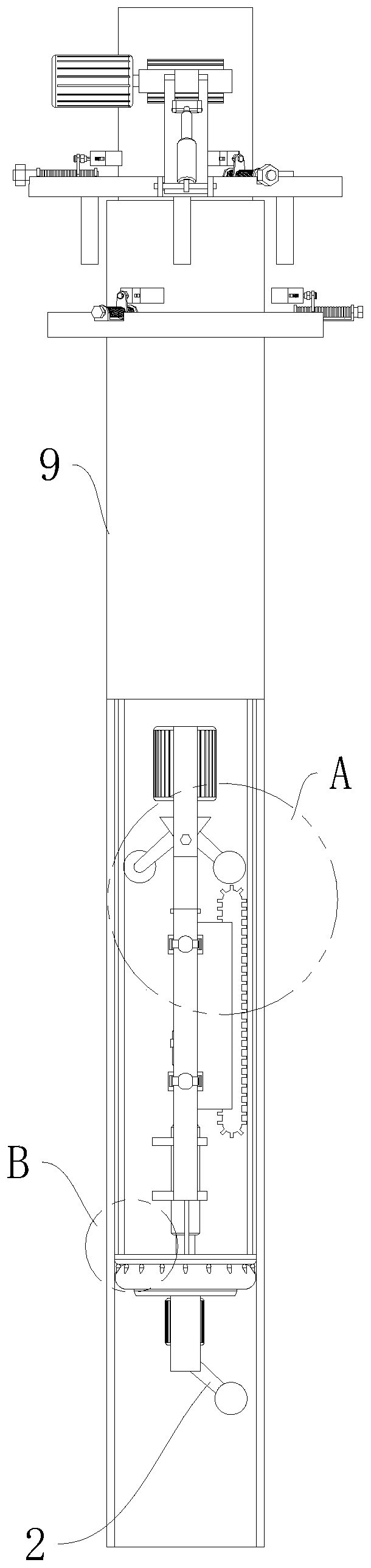

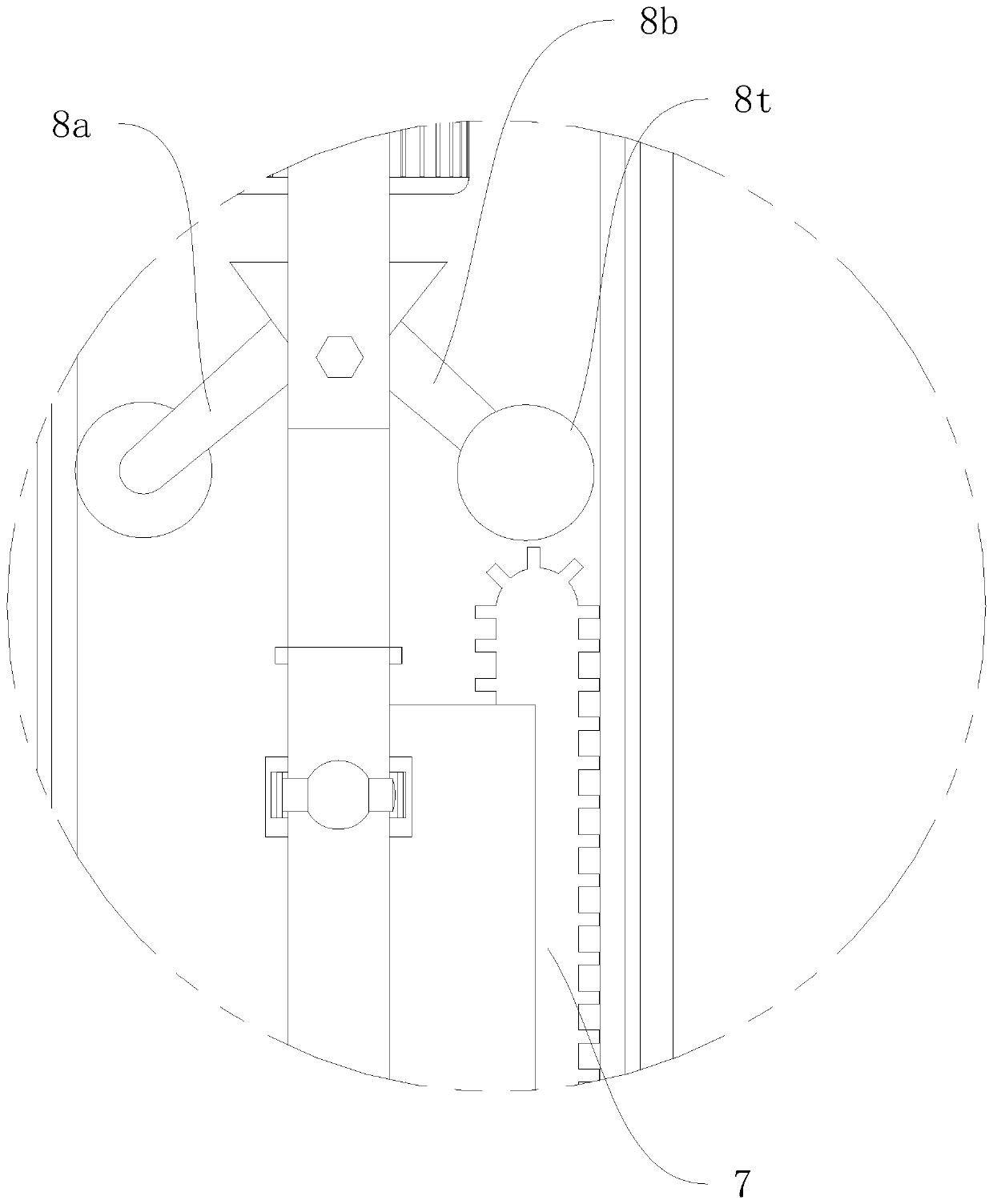

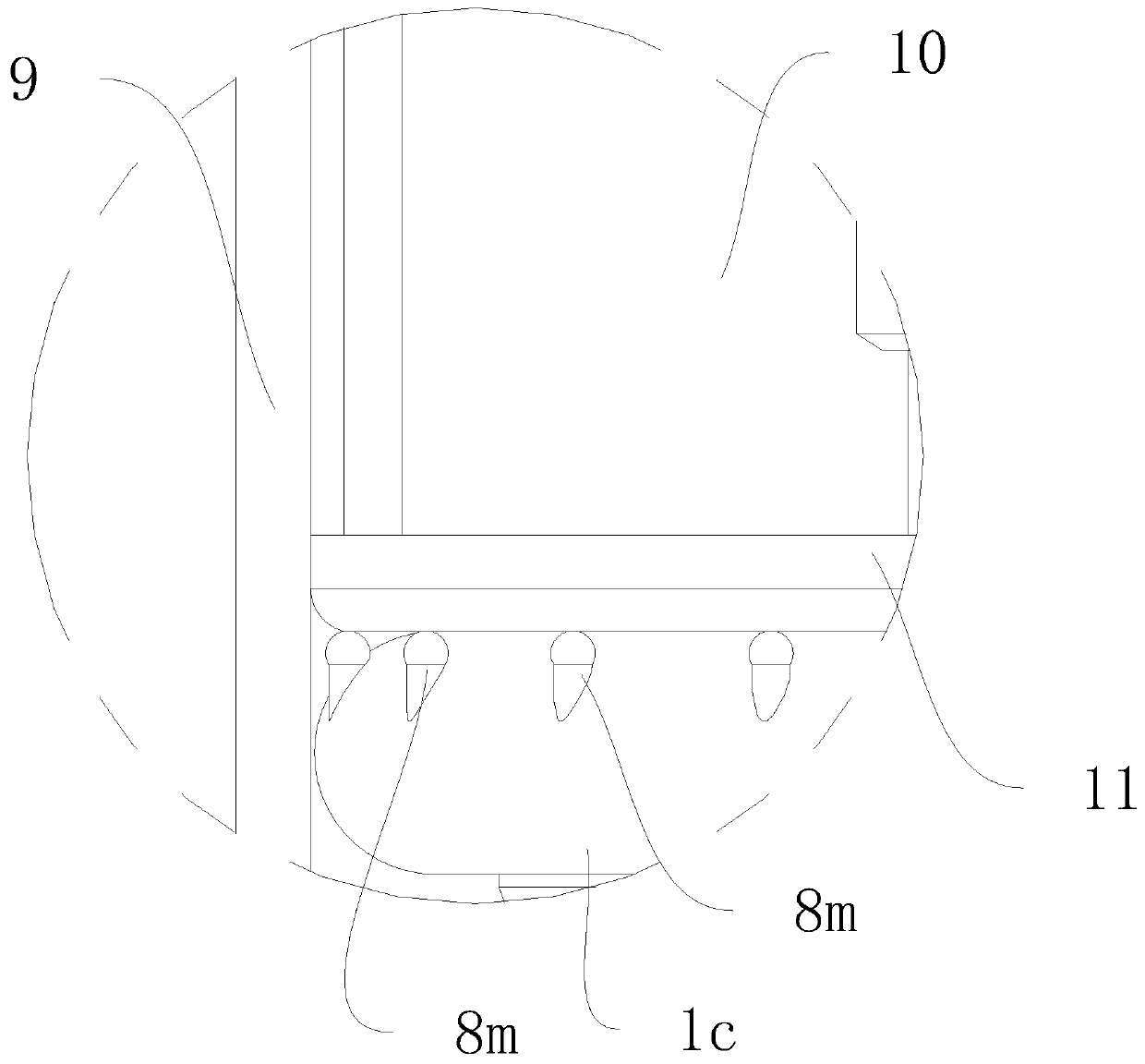

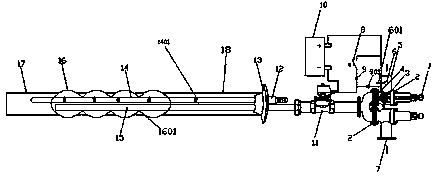

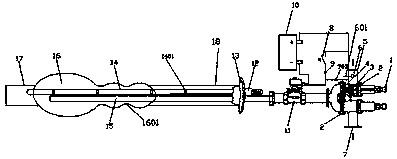

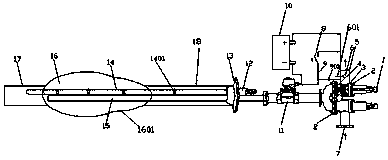

Circular pipeline feeding type overall rehabilitation equipment and rehabilitation method thereof

ActiveCN111594694AExtended service lifePromote expansionPipe elementsPhysical medicine and rehabilitationEngineering

The invention relates to the technical field of pipeline maintenance equipment, in particular to circular pipeline feeding type overall rehabilitation equipment and a rehabilitation method thereof. The equipment comprises a concentric positioning device, feeding devices, a sealer, an advancing device and a pressurizing oil rod; the concentric positioning device comprises a main ring body and a secondary ring body which are coaxial and are connected with each other; a group of fastening members are arranged on the front side face of the main ring body and on the front side face of the secondaryring body respectively; two feeding devices are provided and the two feeding devices are symmetrically arranged on the rim of the secondary ring body; each of the feeding devices is flexibly matchedwith the secondary ring body via a container; the sealer comprises a hollow disc and a rubber airbag; an inwardly concave installation groove is formed in the outer surface of the hollow disc; the rubber airbag wraps the outer part of the hollow disc via the installation groove; the backside of the hollow disc is horizontally and flexibly arranged at the front end of the advancing device via the pressurizing oil rod; and a suspended guider is arranged on the front side of the hollow disc. The equipment and the method can improve the quality of grouting and thereby improves the service life ofa pipeline after rehabilitation.

Owner:湖北铭瀚机电工程有限公司

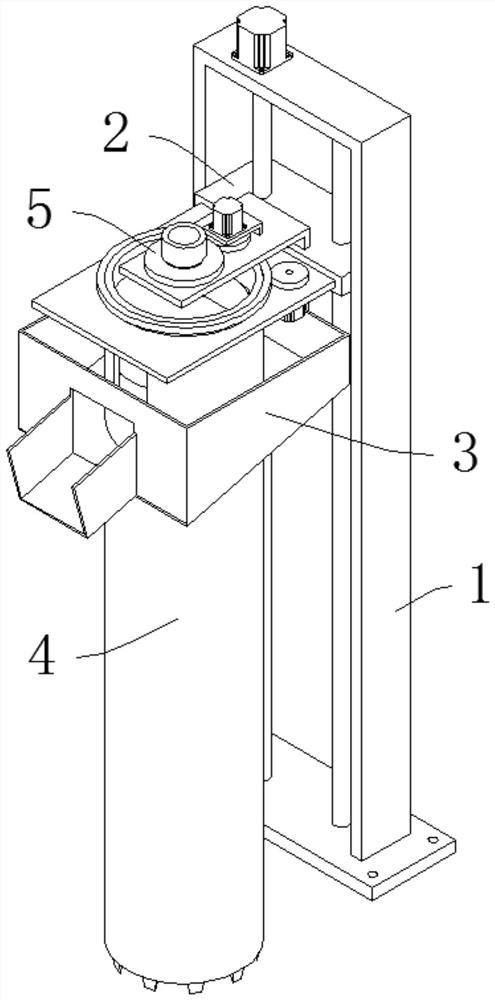

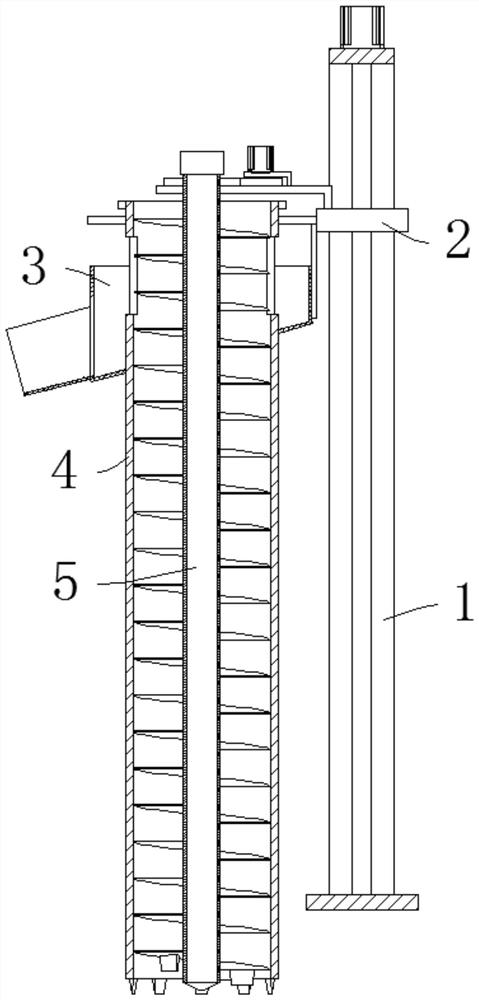

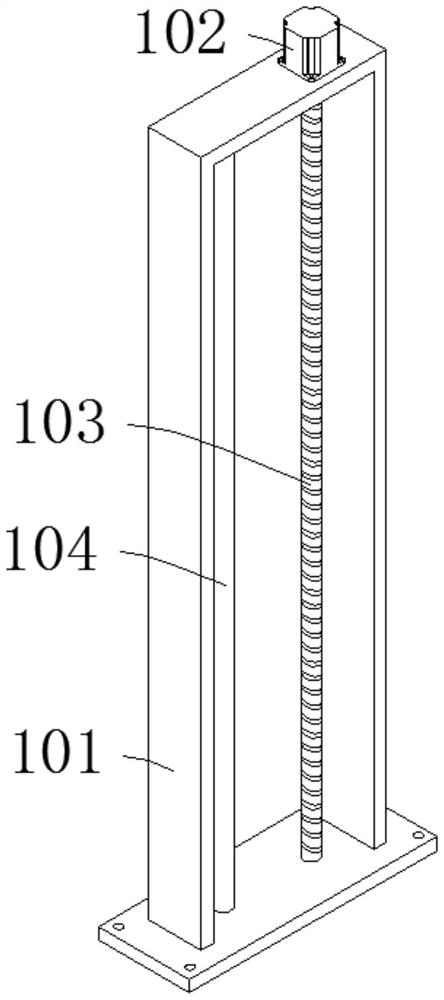

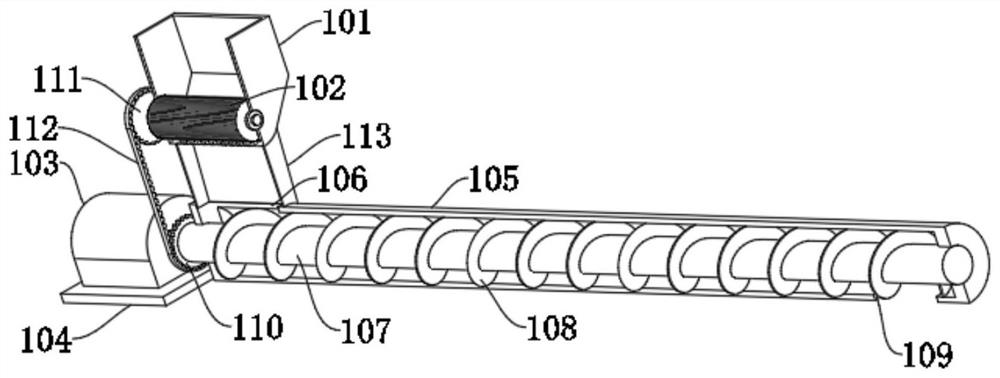

Grouting device for building pile foundation construction

PendingCN111926804ASpeed up groutingReduce labor intensityEarth drilling toolsDrilling rodsSpiral bladeArchitectural engineering

The invention discloses a grouting device for building pile foundation construction. The grouting device comprises a rack device used for supporting up-down lifting and further comprises a lifting device used for moving up and down, wherein a drilling barrel device used for supporting the outer wall is installed in the middle of the lifting device, a conveying device used for grouting and conveying muck is arranged in the drilling barrel device, and a flow guiding device used for guiding the muck is installed below the lifting device. According to the grouting device, through integrated arrangement of drilling and grouting, the grouting speed of a building pile foundation is increased, the labor intensity of workers is reduced, through arrangement of reverse rotation of spiral blades during grouting, uniform stirring and downward pressing of concrete are facilitated, the grouting quality is improved, and through arrangement of the drilling barrel device, the strength of the wall face is improved, and outward discharging of the muck is guaranteed.

Owner:JIANGSU HAI HENG BUILDING MATERIAL MACHINERY CO LTD

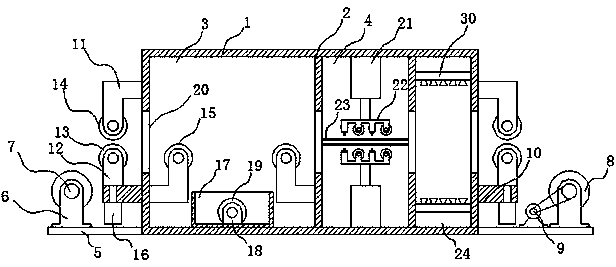

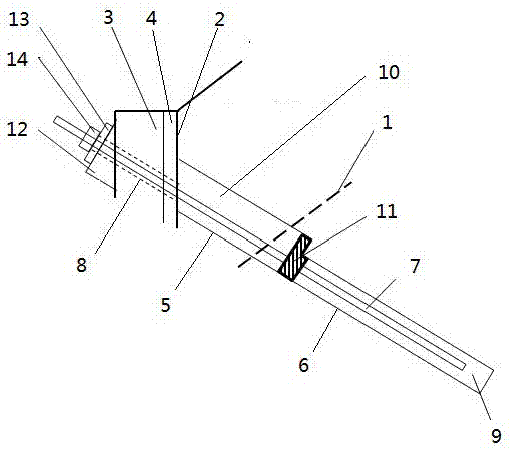

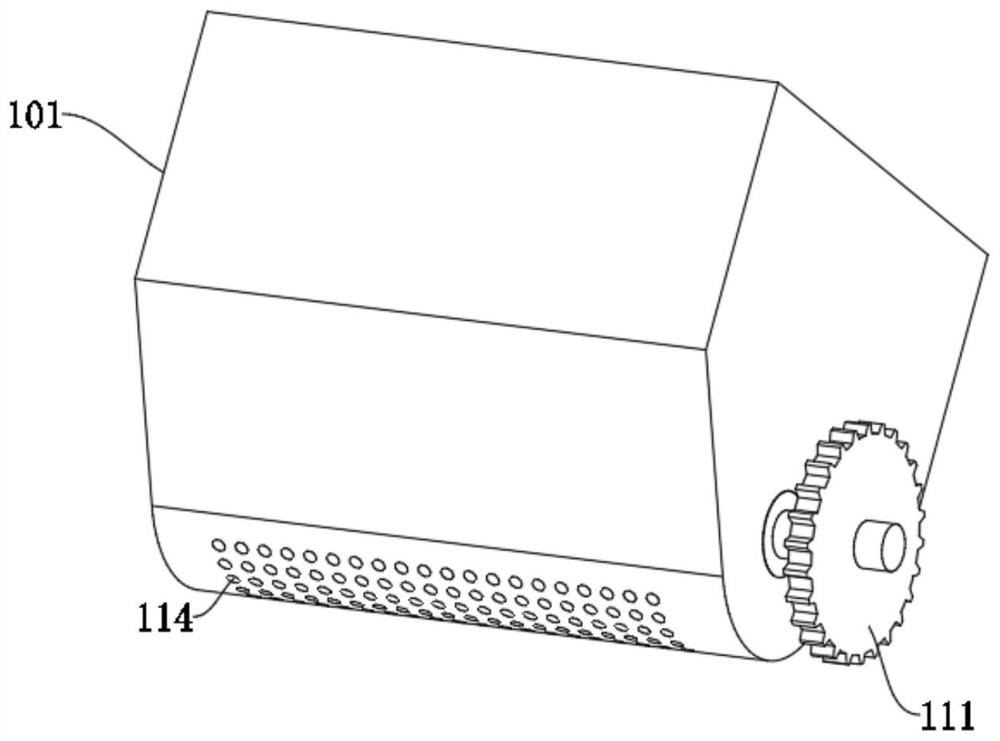

Cloth coating process and device for producing woven cloth

InactiveCN109385779AImprove efficiencyQuality improvementTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsSlurry coatingEngineering

The invention discloses a cloth coating process and device for producing woven cloth. The device comprises a box chamber, and the box chamber is internally partitioned into a coating chamber, a slurryscraping chamber and a drying chamber by partition plates; a cloth releasing roller and a cloth collecting roller are installed on a first bracket on a base plate separately, first guide rollers areinstalled on the two side walls in the coating chamber through fourth brackets, a slurry groove is formed in the portion, between the two first guide rollers, of the bottom in the coating chamber, anda second guide roller is connected to the middle in the slurry groove through a fifth bracket; two opposite brackets are connected to the upper and lower portions in the slurry scraping chamber through second air cylinders, two scrapers and two pressing rollers are installed on the brackets, limiting guide rails are connected to the front and rear portions in the slurry scraping chamber through third air cylinders, and air pipes are installed at the upper and lower portions in the drying chamber. By means of the cloth coating process and device, the efficiency and quality of cloth coating areimproved, roller pressing and flat scraping are continuously conducted twice, the slurry coating unevenness and the movement deflection are avoided, and even and stable scraping is ensured.

Owner:广东彩诗纺织有限公司

Cast-in-place pile side post-grouting device and method

ActiveCN108457266AAvoid Corrosion HazardsInto the uniformPhotovoltaic energy generationBulkheads/pilesRebar corrosionSurface layer

The invention discloses a cast-in-place pile side post-grouting device and method. A high pressure grouting manner is adopted for a pile body through a longitudinal grouting main pipe, a horizontal grouting branch pipe, a taper grouting head and a one-way non-return pressure valve, a pile body mud cake and soil around a pile are strengthened, and the aim of improving the pile foundation bearing force is achieved. The taper grouting head with holes is kept outside the pile body all the time or located on the surface layer of pile body concrete, and reinforcement corrosion hidden dangers causedby excessive damage of the pile body concrete in the grouting process can be avoided; variable cross-section design is adopted for the horizontal grouting branch pipe; the one-way non-return pressurevalve can be controlled to be opened or closed according to the grouting pressure, and silt regurgitation is prevented; and the cast-in-place pile side post-grouting device and the implementation method are suitable for cast-in-place piles with various soil layers, different pile diameters and different pile lengths, the construction technology is simple, the construction method and materials usedby construction are flexible and varied, and popularization and spreading are facilitated.

Owner:HEFEI UNIV

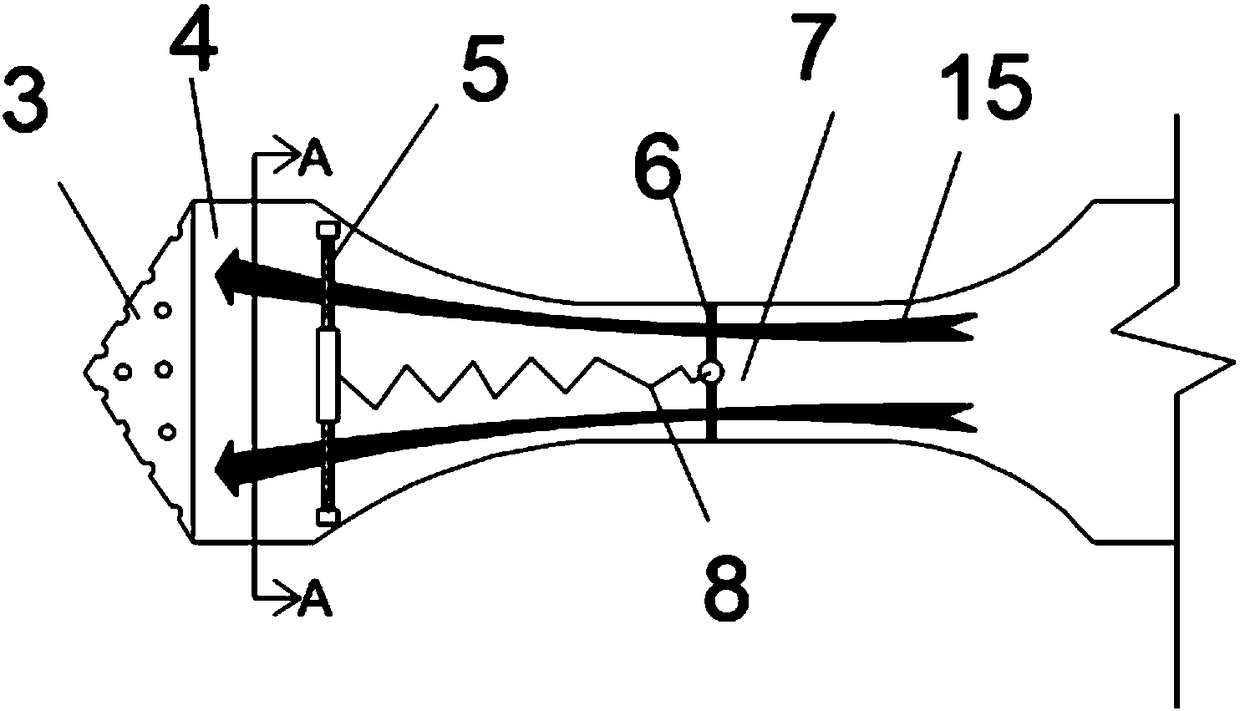

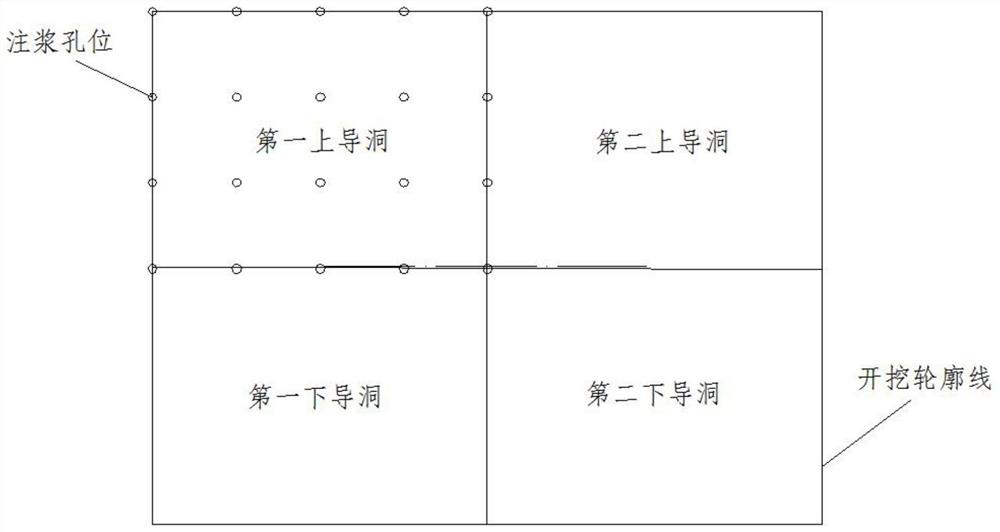

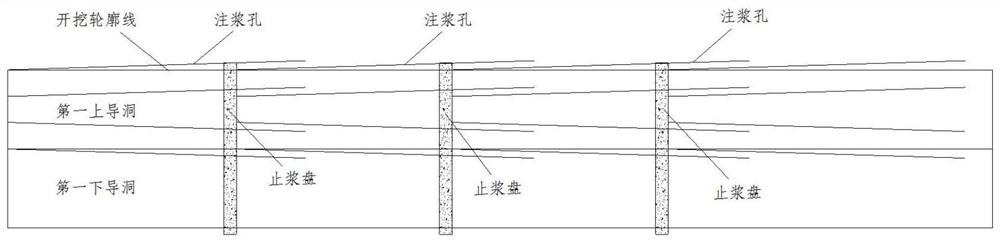

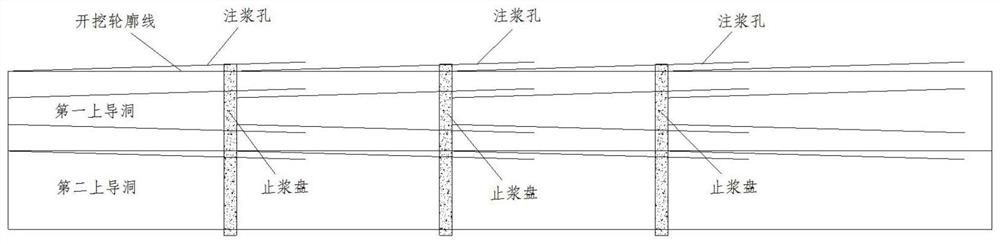

Advanced grouting construction method for underground excavated tunnel

InactiveCN111878083AReduce workloadShorten working timeUnderground chambersTunnel liningArchitectural engineeringTunnel construction

The invention discloses an advanced grouting construction method for an underground excavated tunnel. The method comprises the steps of step I, dividing the section of the tunnel into a first upper pilot tunnel, a second upper pilot tunnel, a first lower pilot tunnel and a second lower pilot tunnel; step II, after pipe shed advance support, performing advanced grouting on the first upper pilot tunnel in the tunnel excavation direction, and excavating and supporting the first upper pilot tunnel; step III, performing grouting reinforcement on the to-be-excavated areas of the first lower pilot tunnel and the second upper pilot tunnel from the first upper pilot tunnel through the excavated and supported space of the first upper pilot tunnel; step IV, excavating and supporting the first lower pilot tunnel, performing grouting reinforcement on the to-be-excavated area of the second lower pilot tunnel from the first lower pilot tunnel through the excavated and supported space of the first lower pilot tunnel; step V, excavating and supporting the second upper pilot tunnel, and then excavating and supporting the second lower pilot tunnel; and step VI, repeating the step II, the step III, the step IV and the step V, and completing tunnel construction. The construction method can shorten the construction period, improve the grouting effect and reduce the construction cost.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

Ultra-large-area grouting construction method for steel-concrete combined section of cable-stayed bridge

InactiveCN111648245AGuarantee the quality of groutingQuality improvementCable-stayed bridgeBridge structural detailsArchitectural engineeringTower

The invention provides an ultra-large area grouting construction method for a steel-concrete combined section of a cable-stayed bridge. The ultra-large area grouting construction method comprises thesteps of chiseling a notch, arranging a partition wall, arranging cushion blocks, installing a first section of steel tower and grouting a bearing plate. Notch chiseling comprises the step of pouringa tower base to the top surface of a grouting layer in the tower base construction process; except for tower base concrete with the width of 30 cm reserved on the periphery of the top face of the tower base, overpoured concrete with the width of 5 cm is chiseled away in a roughening mode, area division is conducted by arranging a partition wall, cushion blocks are arranged to support the first section of the steel tower, and grouting is achieved by directly conducting grouting from the hole position of a pressure bearing plate. Due to the fact that concrete around the tower base is used as a fence, a formwork does not need to be erected, pollution to the inclined face of the tower base during grouting is avoided, and the grouting quality is improved. As the partition wall adopts a groutingmaterial and a rubber strip, the leakproofness is enhanced; by means of the construction method, high-quality and high-efficiency construction of ultra-large-area grouting of the steel-concrete combined section of the cable-stayed bridge is guaranteed.

Owner:CCCC SHEC SECOND ENG

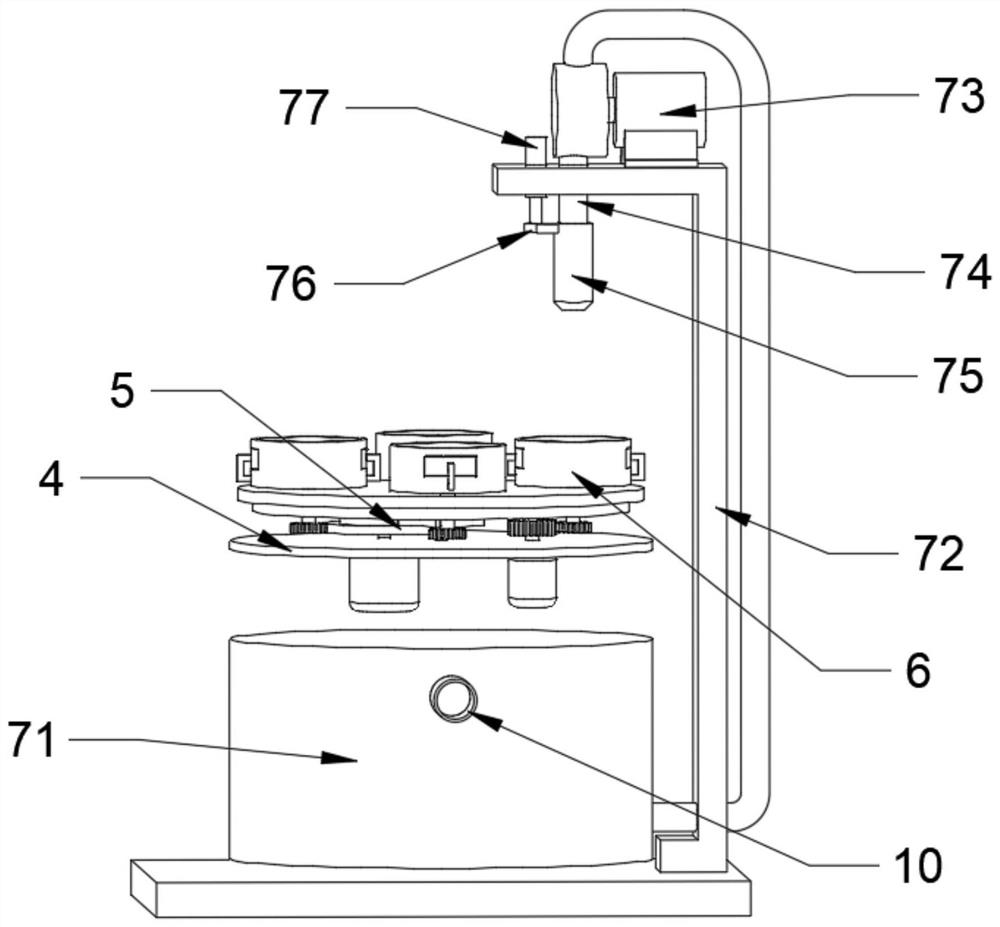

Grouting device for hydraulic engineering construction

InactiveCN113550316AImprove practicalityEasy to replaceMixing operation control apparatusMarine site engineeringArchitectural engineeringProcess engineering

The invention discloses a grouting device for hydraulic engineering construction. The grouting device comprises a pulping device, wherein an up-down reciprocating device is arranged in the pulping device. Through the pulping device, the grouting device can prefabricate slurry in advance, the concentration of the slurry is convenient to change, the situation that the grouting process is interrupted due to the change of the concentration of the slurry is avoided, and the grouting efficiency is improved; through the cooperation of the pulping device, the up-down reciprocating device, a weighing device, an accommodating device and a linkage device, the grouting device can detect the concentration of the prefabricated slurry in real time, water and aggregate with specified proportional quantity do not need to be manually measured, the workload is small, the accuracy is high, and the grouting efficiency and quality are improved; and through a discharging device, the prefabricated slurry can be put into grouting operation; through the cooperation of the pulping device, a beating device and a transmission device, the aggregate can be gradually scattered into water in a waterfall mode, the water and the aggregate can form homogeneous slurry, and the practicability of the grouting device for hydraulic engineering construction is improved.

Owner:付建利

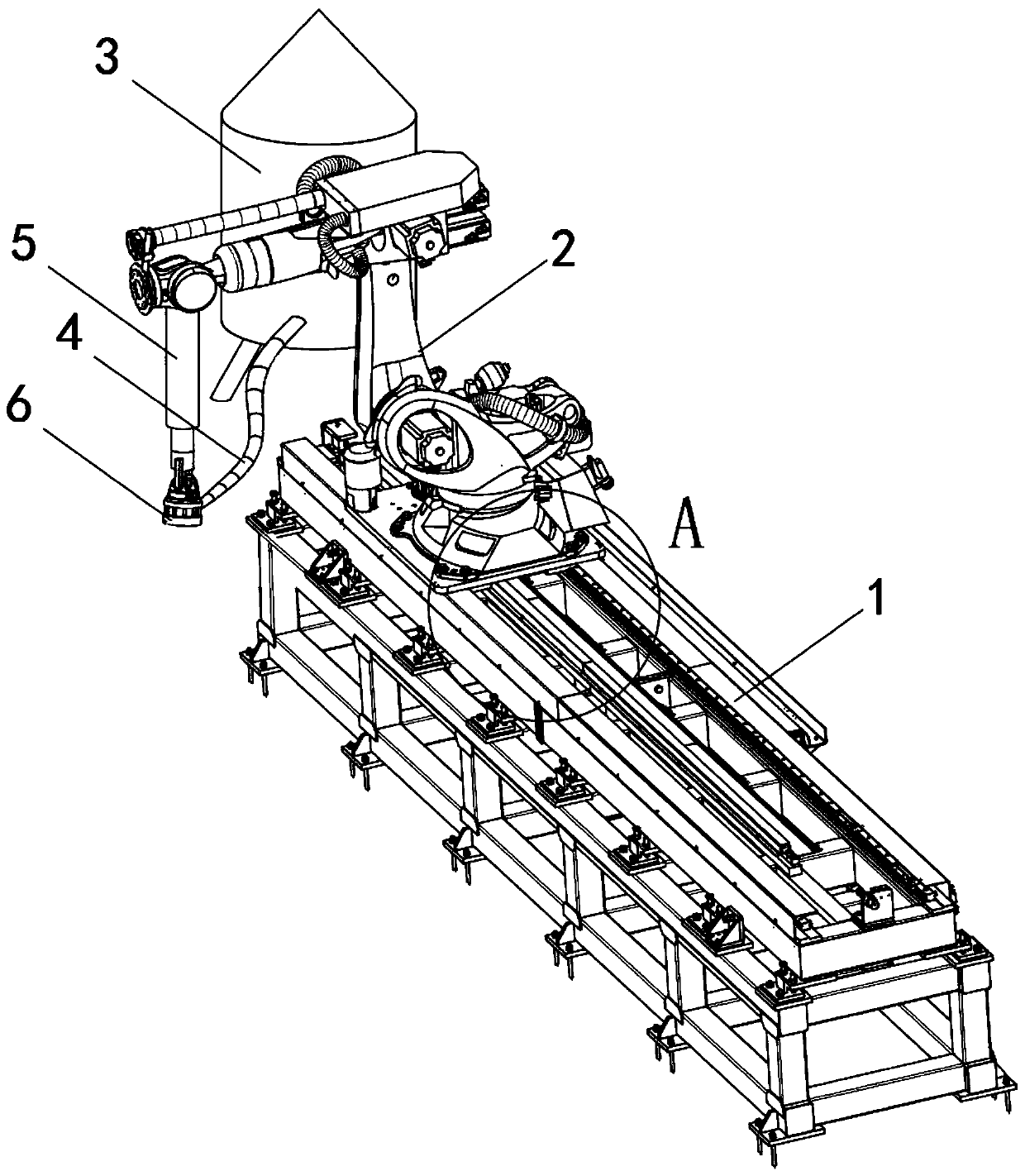

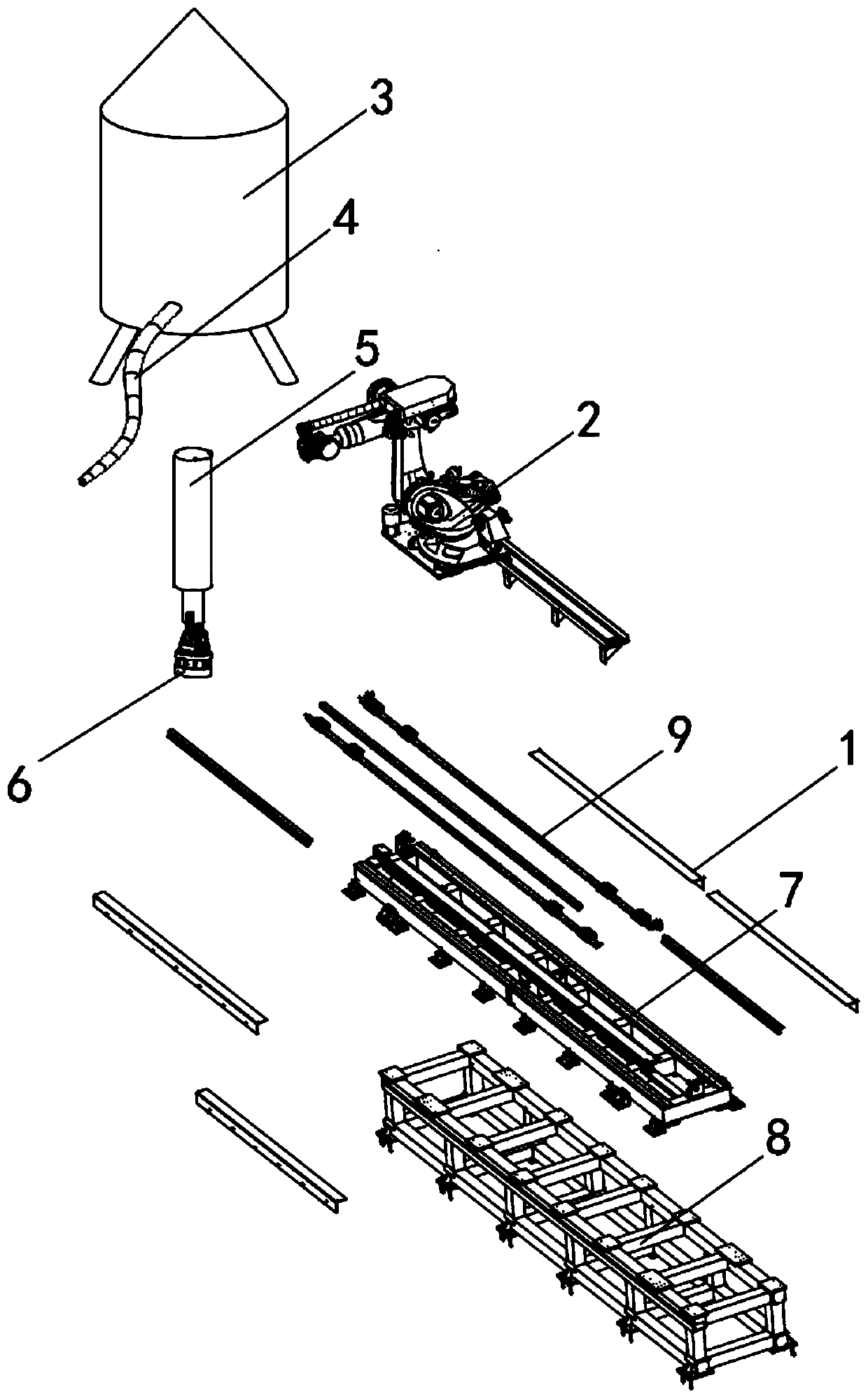

Concrete grouting equipment for building construction and operation method of equipment

ActiveCN109958132AReduce jitter amplitudeHeight adjustableFoundation engineeringArchitectural engineeringHydraulic pump

The invention discloses concrete grouting equipment for building construction and an operation method of the equipment. The concrete grouting equipment for the building construction comprises a sliding installing platform, a transmission disk, a grout box, a grout dredging pipe and a grouting cylinder; and the transmission disk is installed above the sliding installing platform, the grout box is arranged on one side of the sliding installing platform, and the grout dredging pipe is arranged at one end of the grout box in a penetrating mode. The concrete grouting equipment for the building construction and the operation method of the equipment have the beneficial effects that a second hydraulic pump drives a first hydraulic pump and the grouting cylinder to move back and forth horizontallythrough a hydraulic rod, so that the position of the horizontal grouting in front of a building foundation and behind the building foundation is flexibly adjusted by the device, and it is ensured thatthe equipment makes the horizontal grouting position of the building foundation be more accurate; and a stretching sliding column is matched with the hydraulic rod in the second hydraulic pump and synchronously moves horizontally back and forth, it is ensured that the hydraulic rod drives the grouting cylinder to move more smoothly and firmly, the jitter amplitude is reduced when the grouting cylinder is adjusted to move forward and backward, the grouting cylinder is prevented from wasting or polluting resources due to the fact that grout is shed into non-grouting areas when the grouting cylinder moves forward and backward, and the working stability of the equipment is ensured.

Owner:ANHUI TONGJI CONSTR GRP

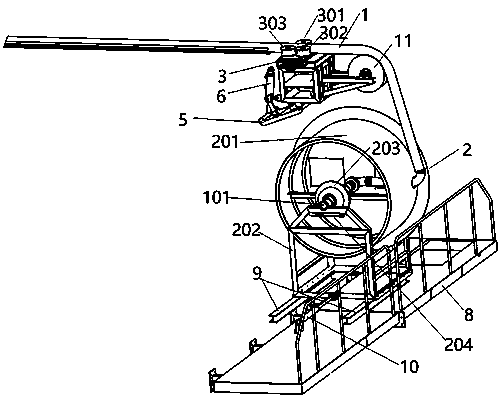

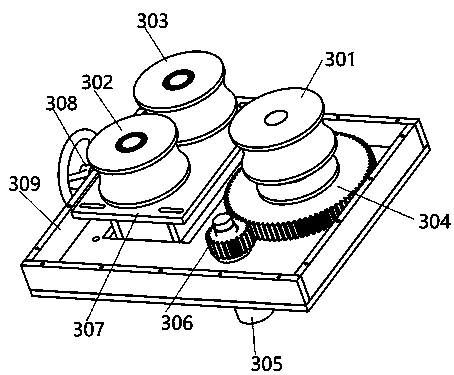

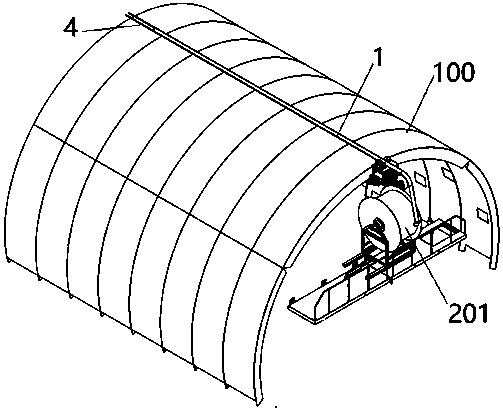

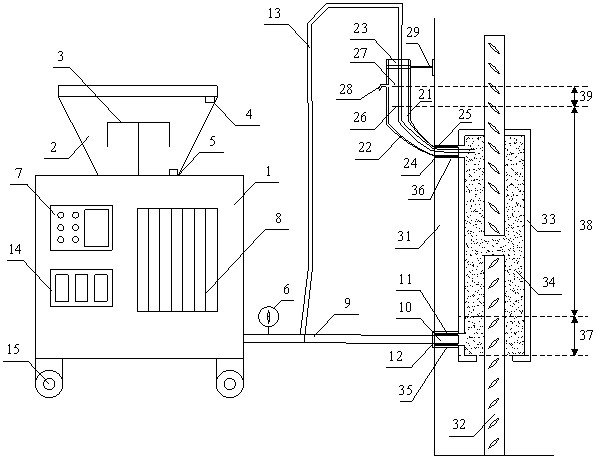

Pouring construction device for vault of secondary lining of tunnel and construction method

PendingCN111156029AImprove grout qualityAvoid cavitiesUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a pouring construction device for a vault of a secondary lining of a tunnel and a corresponding construction method. The device comprises a flexible pipeline, a pipeline conveying mechanism and a pipeline retracting and releasing mechanism, wherein the pipeline conveying mechanism comprises a first guide wheel and a second guide wheel, the flexible pipeline is driven by thefirst guide wheel and the second guide wheel to move, and the pipeline retracting and releasing mechanism comprises a coiling block, can be coiled by the coiling block and can penetrate from the sidesurface of the coiling block with a steel pipeline connected to the flexible pipeline. By carrying out vault pouring by employing the device, concrete is poured to the vault from top to bottom, so that a jet grouting mode from bottom to top is avoided, generation of cavities, cracks and the like is reduced advantageously, and the pouring construction quality is improved.

Owner:保定市宇航机械科技有限公司

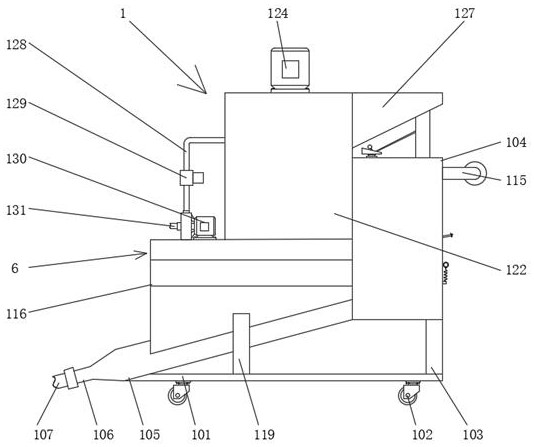

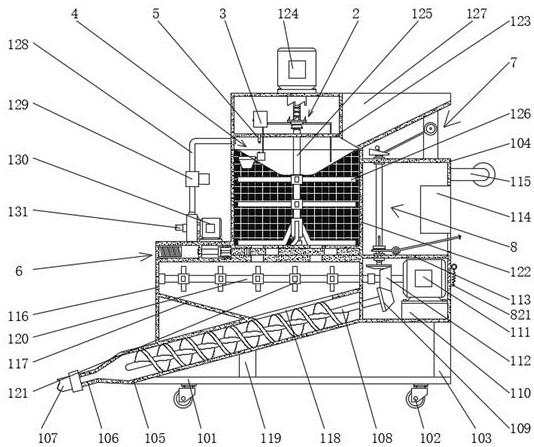

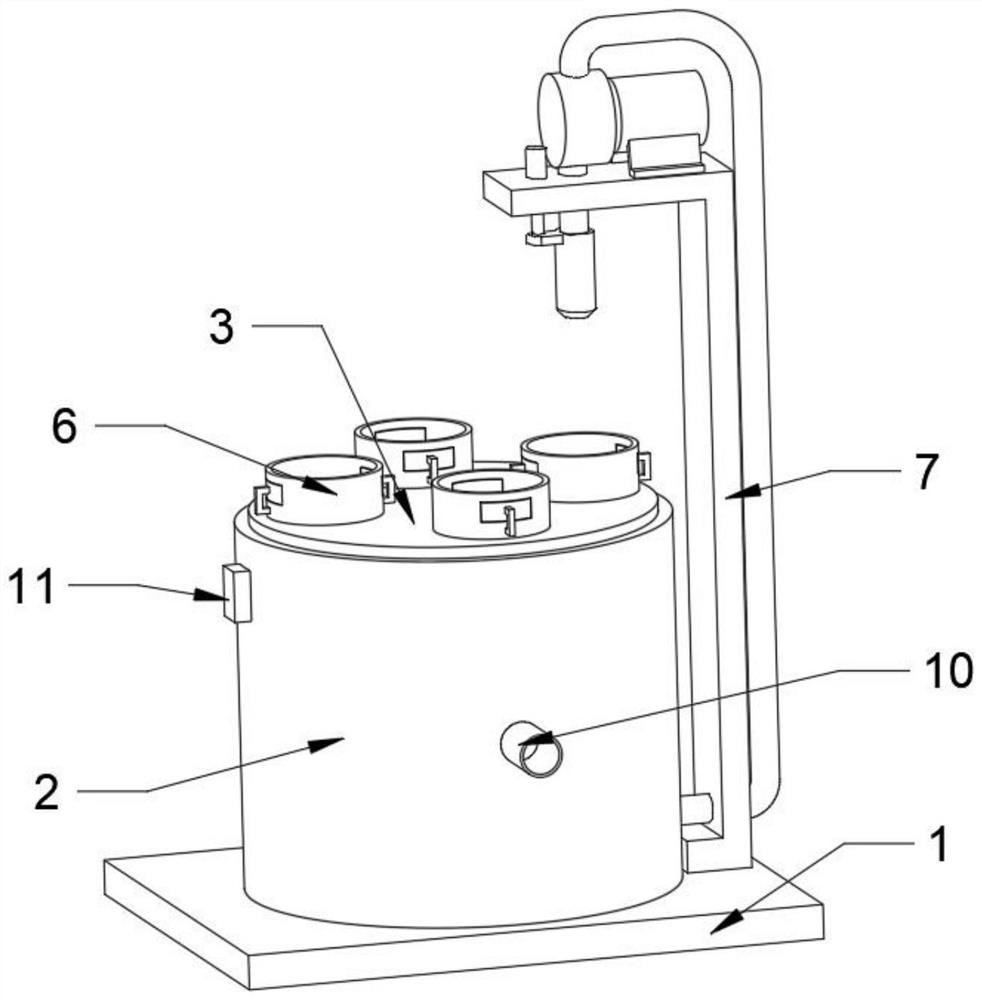

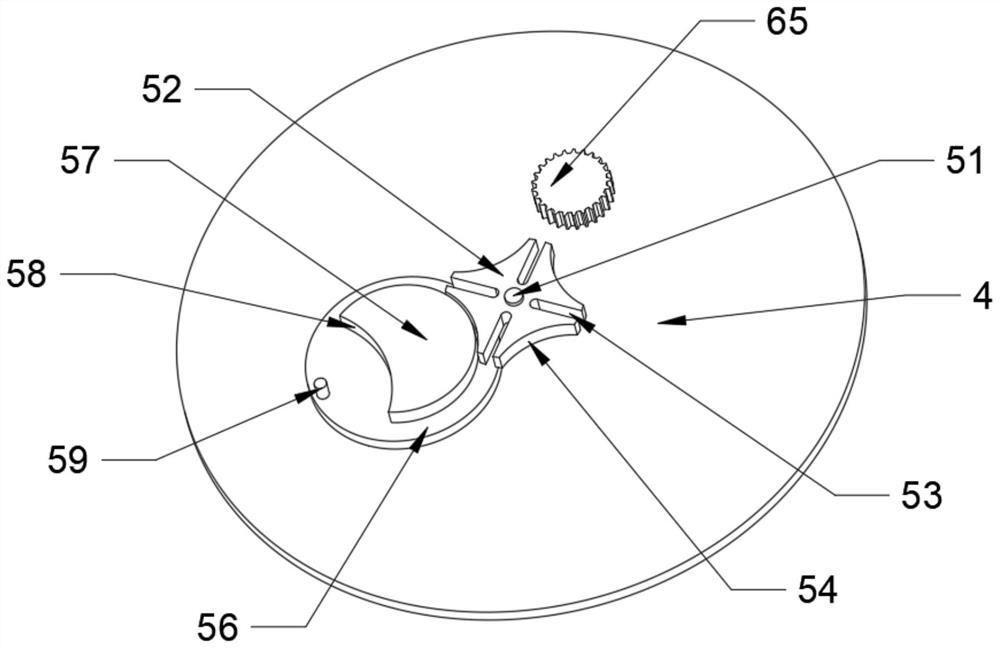

Automatic grouting molding equipment for ceramic wine bottle

InactiveCN112356224AImprove grouting efficiencyReduce manufacturing costFeeding arrangmentsAuxillary shaping apparatusWine bottleEngineering

The invention discloses automatic grouting molding equipment for a ceramic wine bottle. The automatic grouting molding equipment comprises a bottom plate and an equipment box, and the equipment box isfixed to the upper surface of the bottom plate; the top of the equipment box is rotatably connected with a workbench through a bearing, and a partition plate is fixed to the upper end of the inner wall of the equipment box; a rotating mechanism which can be rotated at a fixed angle is fixed to the middle of the partition plate; rotatable fixing mechanisms are symmetrically installed on the surface of the workbench, and a grouting mechanism for preventing splashing is fixed to one end of the bottom plate; the rotating mechanism comprises a fixing shaft, a rotating plate, stirring grooved, locating grooved, a first servo motor, a rotating disc, a locating disc, an avoidance groove and a stirring column, and the fixing shaft is fixed to the middle of the workbench; and the bottom of the fixing shaft is rotatably connected with the middle of the partition plate through a bearing, and the rotating plate is fixed to the middle of the fixing shaft; and the stirring grooves and the locating grooves are formed in the surface of the rotating plate at equal intervals. According to the automatic grouting molding equipment, the mold grouting efficiency is higher, the cost is lower, the grouting quality is higher, and people can use the the automatic grouting molding equipment conveniently.

Owner:黄佳怡

Grouting device and grouting method for sleeve grouting

ActiveCN114150873AEasy groutingImprove construction efficiencyBuilding reinforcementsBuilding material handlingClassical mechanicsPipe

The invention discloses a grouting device and method for sleeve grouting. The grouting device comprises a grouting pump and a pressurizing pipe. The grouting pump comprises a grouting charging barrel, a controller, a fluctuation pressure pump and a grouting pipe; the controller is used for controlling the slurry pumping pressure of the fluctuation pressure pump during grouting, so that the fluctuation pressure pump generates waveform slurry pumping pressure with different amplitudes and / or different frequencies in at least three time periods in the grouting process; one end of the grouting pipe is connected with the fluctuation pressure pump, and the other end of the grouting pipe is connected with the grouting hole of the sleeve and used for conveying a grouting material mixture into the sleeve; the pressurizing pipe comprises a semi-rigid section, a rigid section and a supporting bracket. The method has the advantages of simple grouting operation, high construction efficiency and the like. The grouting material mixture moves up and down in the sleeve by fluctuating the slurry pumping pressure to generate vibration, so that the grouting material mixture is vibrated and bubbles are extruded, and the compactness of grouting is effectively ensured.

Owner:SOUTHEAST UNIV

Danger removing and strengthening seepage control method for barrier lake natural rock-fill dam

ActiveCN111119128AImprove anti-seepage effectImprove stabilityFoundation engineeringEarth-fill damsLandslide damSlurry

The invention belongs to the technical field of seepage control in hydraulic engineering, and particularly relates to a danger removing and strengthening seepage control method for a barrier lake natural rock-fill dam. The method comprises the steps of pouring a concrete cap weight layer of the rock-fill dam; installing a borehole orifice-pipe; performing boring construction; and performing grouting construction. According to the danger removing and strengthening seepage control method for the barrier lake natural rock-fill dam, consistence of grouting slurry is adjusted at any time during thegrouting construction, so that a better seepage control effect can be achieved and stability is improved; the pipe fixation problem is solved by an employed small diameter boring and grouting technology; and construction cost is effectively reduced by the employed grouting slurry material.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Rapid construction method of high-pressure water-rich fault zone of tunnel

ActiveCN101798930BSolve world-class problemsGood effect of water separation and pressure reductionUnderground chambersTunnel liningWater flowEngineering

The invention relates to the field of tunnel construction, in particular to a rapid construction method of a high-pressure water-rich fault zone of a tunnel, which solves a plurality of problems in the construction method of high-pressure water-rich fault zone tunnels under the guide of the traditional knowledge. A draining branch tunnel is additionally arranged between a main tunnel and a parallel heading, the water flow pressure of the hanging wall of a fault interface is reduced progressively, and a large amount of water is discharged from the main tunnel by adopting a guiding and non-clogging mode; when the water pressure of the main tunnel is reduced to 0.3-0.5MPa, an informationized tracking and accurate grouting method is used for grouting and reinforcing the main tunnel; and rapidly excavating and sealing technology is used for excavating the main tunnel and the parallel heading. The invention adopts the technology combining the water distribution and pressure reduction mode, the informationized tracking and accurate grouting method and the rapidly excavating and sealing technology for high-pressure water-rich shattered fault zones for the first time, breaks through the traditional concept that the water distribution and pressure reduction mode is opposite to the grouting and reinforcing construction method, solves the world-class problem of construction of the high-pressure water-rich fault zone of the tunnel, improves the construction progress and the construction efficiency, and ensures safe and rapid perforation of the tunnel.

Owner:CHINA RAILWAY 12TH BUREAU GRP

Shear-yielding and pressure-yielding cable-anchored pile structure and construction method thereof

ActiveCN107489156AAchieve pre-hardeningIncreased shear strengthExcavationsBulkheads/pilesStructural engineeringDrill hole

The invention discloses a shear-yielding and pressure-yielding cable-anchored pile structure which comprises a pressure-yielding slide-resistant pile structure and a pile block shear-yielding anchoring structure. The pressure-yielding slide-resistant pile structure comprises an slide-resistant pile, wherein a pressure-yielding layer is arranged on a side face where the slide-resistant pile is in contact with a slope; the pile block shear-yielding anchoring structure comprises a free section drill hole, and an anchoring section drill hole is formed in the bottom face of the inner side of the free section drill hole; the free section drill hole extends inward to the inner side of a potential slip face of the slope, an outer orifice of the free section drill hole is located in a contact face of the slope and the pressure-yielding layer, through holes communicating with the free section drill hole are formed in the slide-resistant pile and the pressure-yielding layer, the inner side end of an anchor bar extends inward to be located in the anchoring section drill hole, and the outer side end of the anchor bar extends outward out of the slide-resistant pile; mortar fills the anchoring section drill hole, a low compression modulus grouting material fills the free section drill hole, and an anchorage device for tensioning and fixing the anchor bar is arranged on the outer orifice of each of the through holes. The invention also provides a construction method of the shear-yielding and pressure-yielding cable-anchored pile structure.

Owner:CHONGQING JIAOTONG UNIVERSITY

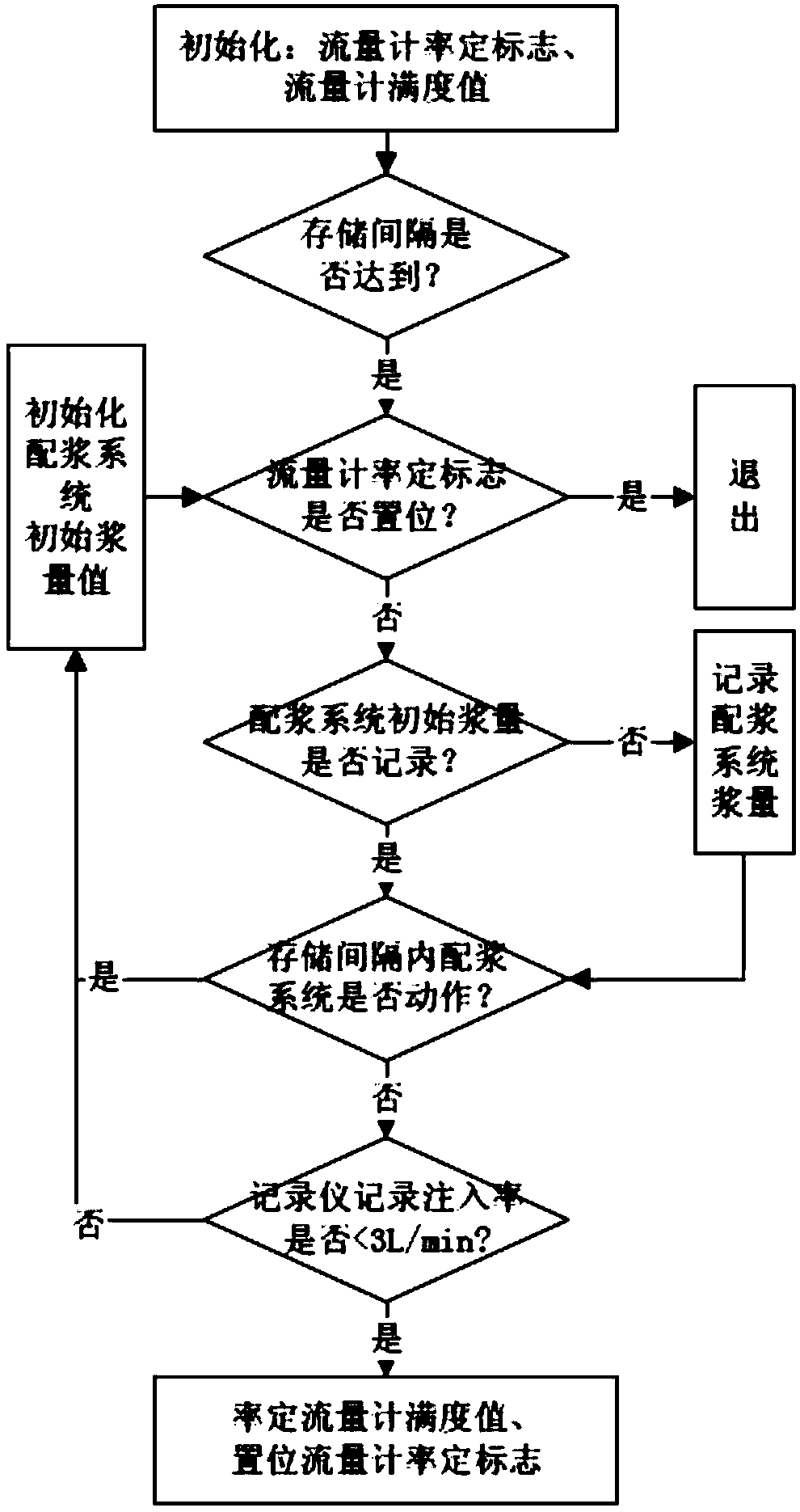

Grouting unit flowmeter calibration device and method

ActiveCN108801404AIncrease the level of automationReduce supervisory interventionTesting/calibration for volume flowFull scaleUltimate tensile strength

The invention discloses a grouting unit flowmeter calibration device and method. The method includes the following steps that a flowmeter calibration mark and a flowmeter full-scale value are initialized; when the storage interval of a recorder is reached, the grouting amount during the storage interval is recorded; whether a pulp preparation system runs during the storage interval is judged, if the pulp preparation system runs, the initial pulp amount of the pulp preparation system is initialized, and returning to the step 2 is executed; whether the pulp injection rate of the system is a small injection rate or not is judged, if the pulp injection rate of the system is not the small injection rate, returning to the step 2 is executed, if the pulp injection rate of the system is the smallinjection rate, the flowmeter full-scale value is calibrated and the flowmeter calibration mark is set. According to the device and the method, machines can be used for automatically measuring the grouting amount of a grouting barrel, the flowmeter is automatically calibrated, the automation level of a site can be improved, supervision interference and work intensity are reduced, key quality points of grouting are controlled, the grouting quality is improved, the unnecessary grouting time is reduced and the grouting progress is improved.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +1

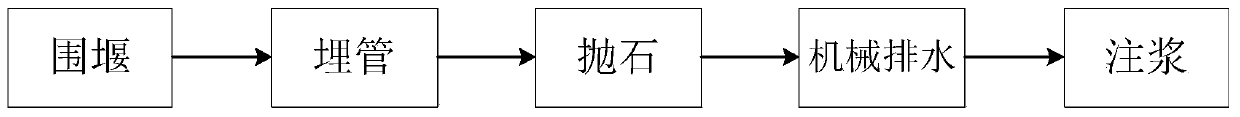

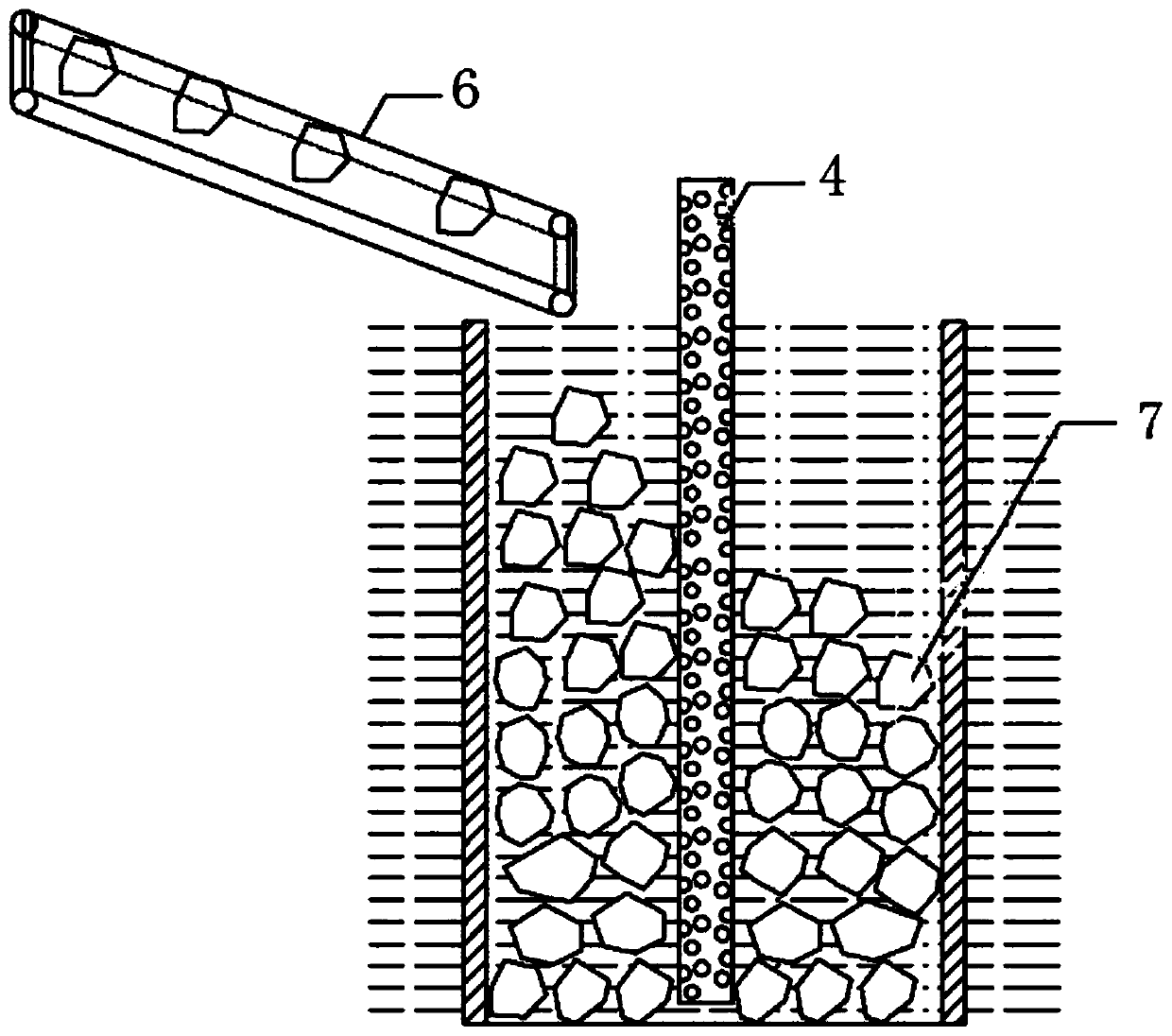

Construction method of underwater concrete grouting

ActiveCN110241827ALarge displacementHigh cost of drainageFoundation engineeringEngineeringUnderwater

The invention belongs to the technical field of cement base material underwater foundation construction, and particularly relates to a construction method of underwater concrete grouting. The construction method includes the following steps of cofferdams, pipes burying, enrockment, mechanical drainage and grouting. According to the technical scheme, compared with the prior art, the construction method has the following advantages that lateral supports do not need to be pre-arranged in the cofferdams; the amount of the mechanical drainage is reduced, and the cost is lowered; and the qualities of stone piling and grouting are high, and the cost is low.

Owner:智连空间测绘技术(苏州)有限公司

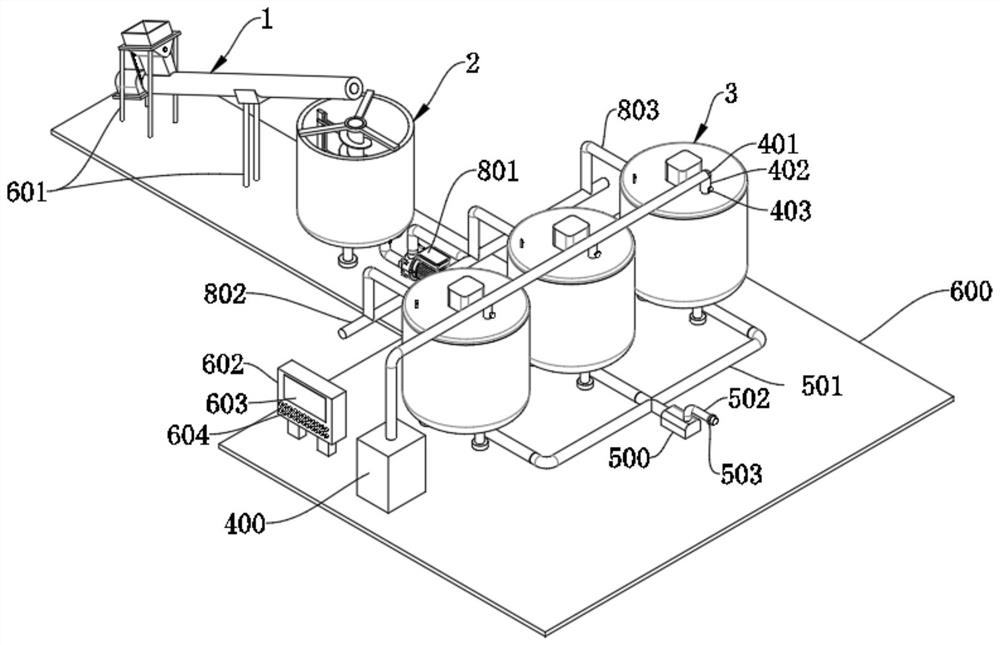

Grouting device for preventing coal spontaneous combustion

InactiveCN114633373AAvoid cloggingLow costDischarging apparatusMixing operation control apparatusCoal spontaneous combustionAuger

The invention provides a grouting device for preventing spontaneous combustion of coal, the grouting device comprises a crushing and feeding mechanism, the crushing and feeding mechanism is used for crushing and scattering grouting raw materials, and the crushing and feeding mechanism is used for automatic feeding, so that the functions of crushing, scattering and automatic feeding of the grouting raw materials are realized; the crushing roller and the auger motor are matched with the driving gear and the driven gear, so that the functions of crushing and automatic feeding can be completed only through one motor, the cost is saved, and meanwhile the phenomenon that a grouting pipe is blocked due to the fact that grouting raw material particles are large is avoided; the interior of the stirring tank is subjected to air exhaust treatment in the stirring and slurrying period, the air content in grouting materials is effectively reduced, the phenomenon that after the grouting materials are cooled, holes are formed in the grouting materials is effectively avoided, the grouting quality is further improved, the mixing mechanism is matched with the multiple stirring mechanisms, uninterrupted slurrying and grouting operation is achieved, and the grouting efficiency is improved. And the grouting continuity is effectively improved, and the grouting quality is improved.

Owner:CHONGQING VOCATIONAL INST OF ENG

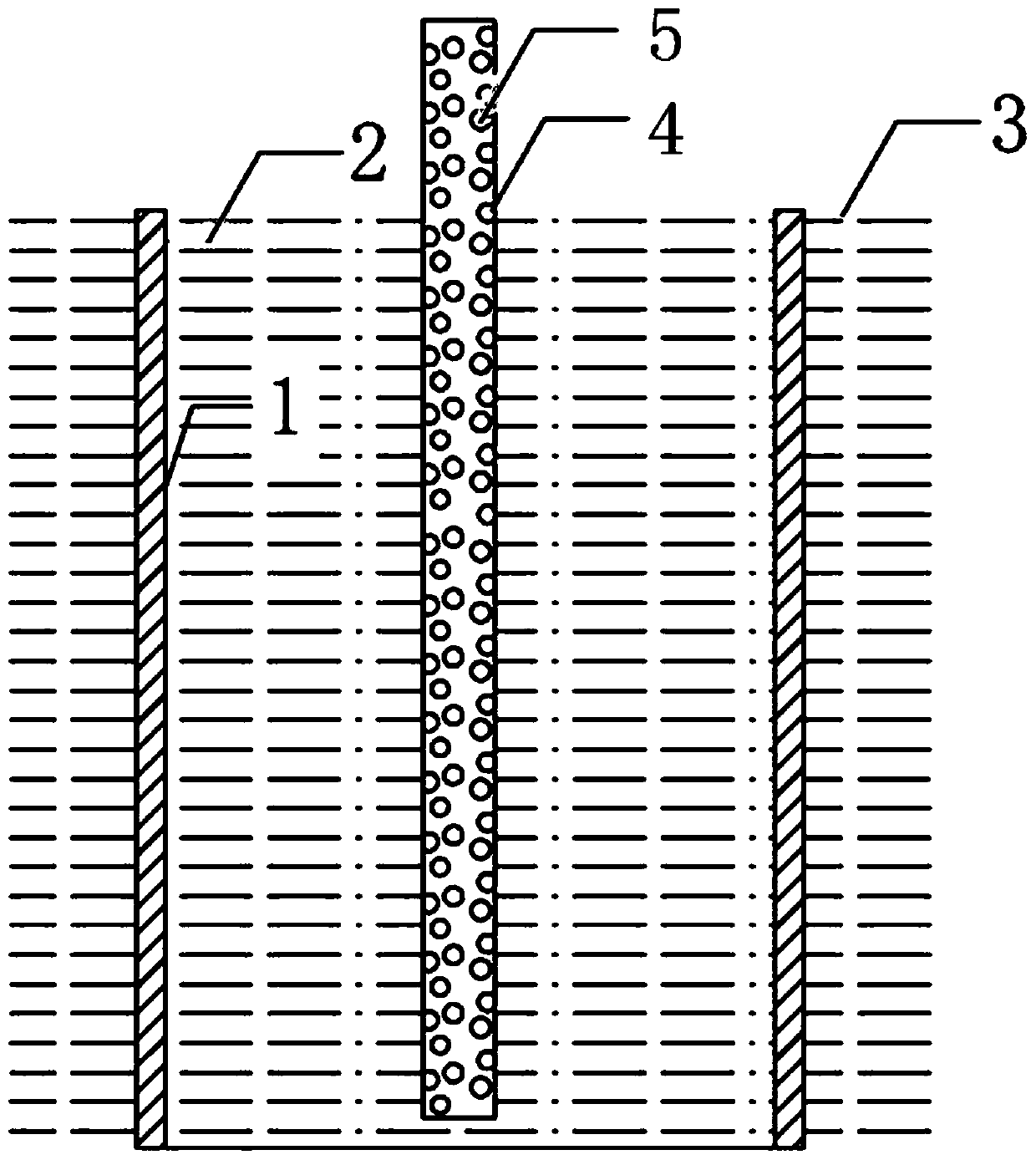

Curtain grouting water plugging device in confined water stratum and working method of curtain grouting water plugging device

PendingCN109706934AAvoid scourImprove grout compactnessFoundation engineeringWater leakageConfined water

The invention relates to a curtain grouting water plugging device in confined water stratum and a working method of the curtain grouting water plugging device. The curtain grouting water plugging device comprises a water guiding pipe, a water distribution pipe, a water pressure balancing pipe, a diagonal brace and a grouting pipe. Water at a water leakage point is drained into the water pressure balancing pipe through the water guiding pipe, the water distribution pipe and the water pressure balancing pipe which communicate with each other, so that the water head pressure in the pipes is balanced with the water pressure in a water leakage hole. Then the water in the guiding pipe is blocked by grouting at the bottom of the hole and grouting at a hole opening. The curtain grouting water plugging device is simple in principle and convenient to operate, static water grouting can be realized in curtain water gushing holes, and the plugging quality of a leaking curtain is greatly improved.

Owner:山东建勘集团有限公司

Slurry pocket slurry-injecting anchorage rod with control system and using method

PendingCN108104856AGood for adjusting grouting effectMeet the needs of different grouting volumesAnchoring boltsSolenoid valveControl system

The invention discloses a slurry pocket slurry-injecting anchorage rod with a control system and a using method and belongs to the technical fields of engineering construction and anchorage rod fixing. The slurry pocket slurry-injecting anchorage rod comprises a rod body part, a control part and a shell, the control part comprises a slurry injecting part and a slurry returning part which are connected in parallel and further comprises a control circuit part, and the slurry returning part comprises an adjusting structure. The control circuit part comprises a first bulb, a second bulb and a power source, a normally open switch is arranged above the first bulb, and the power source is connected with a normally open solenoid valve. The rod body part comprises a shell body, a main reinforcement, a slurry pocket and a pocket interior slurry-injecting pipe, a metal ball is arranged above a slurry returning opening, and the metal ball is connected with the normally open switch of the circuit part in parallel through an electric conducting metal bar. The slurry pocket slurry-injecting anchorage rod with the control system and the using method have the beneficial effects that the extraction-resisting capacity of the anchorage rod can be reinforced through control over the slurry-injecting shape, the slurry-injecting pressure can further be accurately controlled through the control system, and the technical problems that as for an ordinary slurry-injecting anchorage rod, the slurry backflow pressure is overlarge and slurry run-out and leaking are prone to occurring are solved; and theslurry pocket slurry-injecting anchorage rod has the advantages of being simple in structure, low in cost, rapid in mounting, capable of being reused and the like.

Owner:NORTH CHINA INST OF SCI & TECH +1

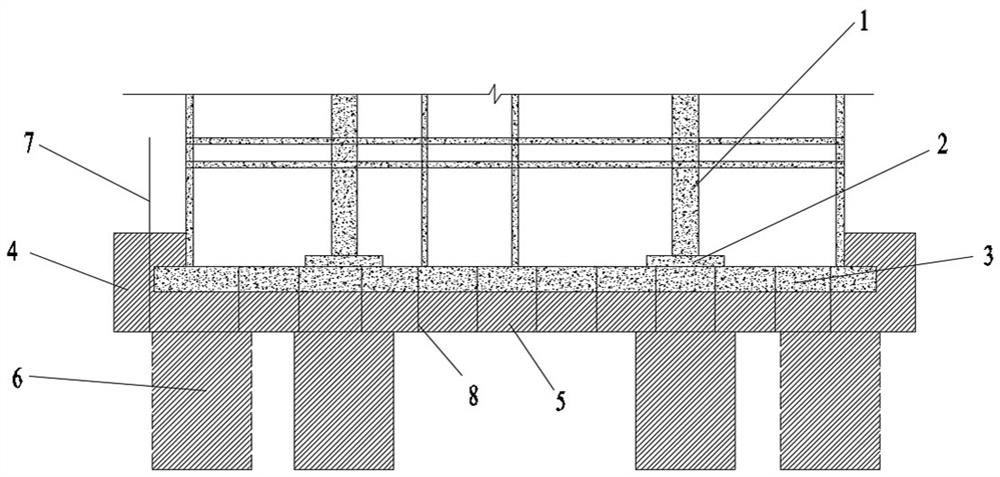

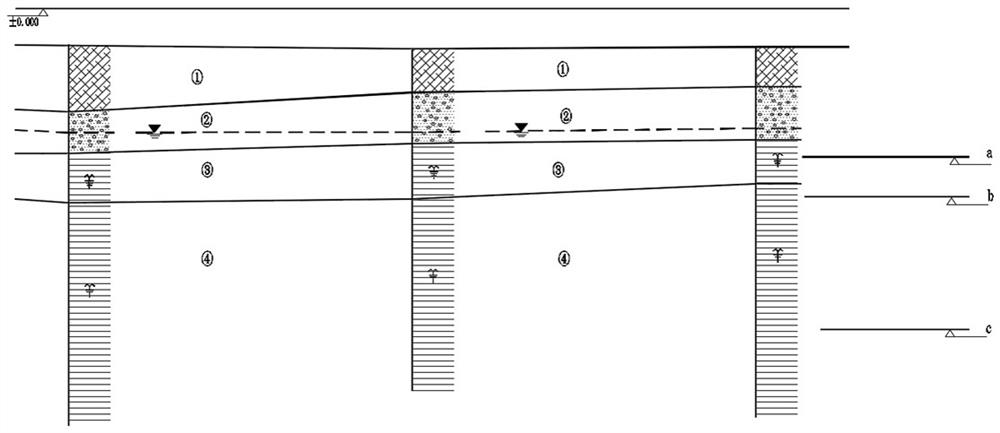

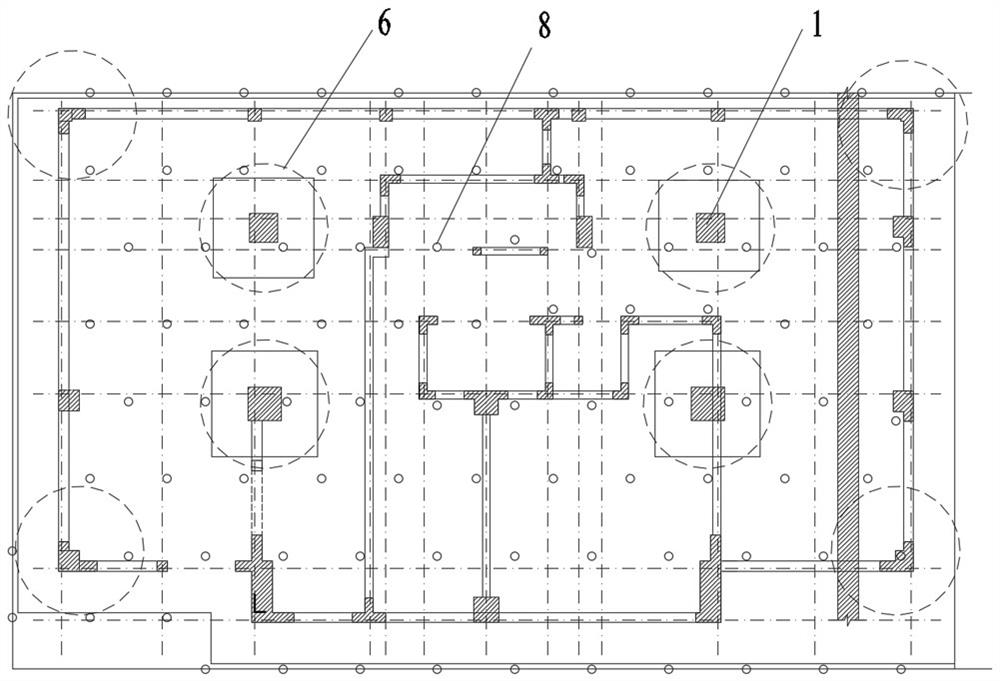

Raft foundation building uplift reinforcement structure and method in corrosive geological environment

ActiveCN110965595BImprove barrier propertiesGuaranteed not to leakProtective foundationArchitectural engineeringStructural engineering

The invention discloses a raft foundation building uplift and reinforcement structure and method in a corrosive geological environment. The uplift and reinforcement structure includes an existing building lower column, a raft foundation connected to the bottom of the column, and a composite foundation connected below the raft foundation The reinforced layer, the composite pile foundation connected under the reinforced layer of the composite foundation, and the water-stop curtain connected to the periphery of the raft foundation. During construction, by setting up the water-stop curtain, it is beneficial to block the water in the aquifer and prevent the outflow of slurry and in-situ water and soil. The inverted L-shaped design of the water-stop curtain can further avoid the further corrosion of the raft foundation and ensure the lateral Displacement limitation; through the setting of composite foundation strengthening layer and composite pile foundation, it is beneficial to locally lift the raft foundation and overall reinforcement, and improve the overall bearing capacity in combination with water-stop curtains; through the setting of groundwater monitoring holes, it is convenient for on-site monitoring during construction The level of groundwater level is conducive to maintaining the stability of water and soil pressure in the underground environment.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

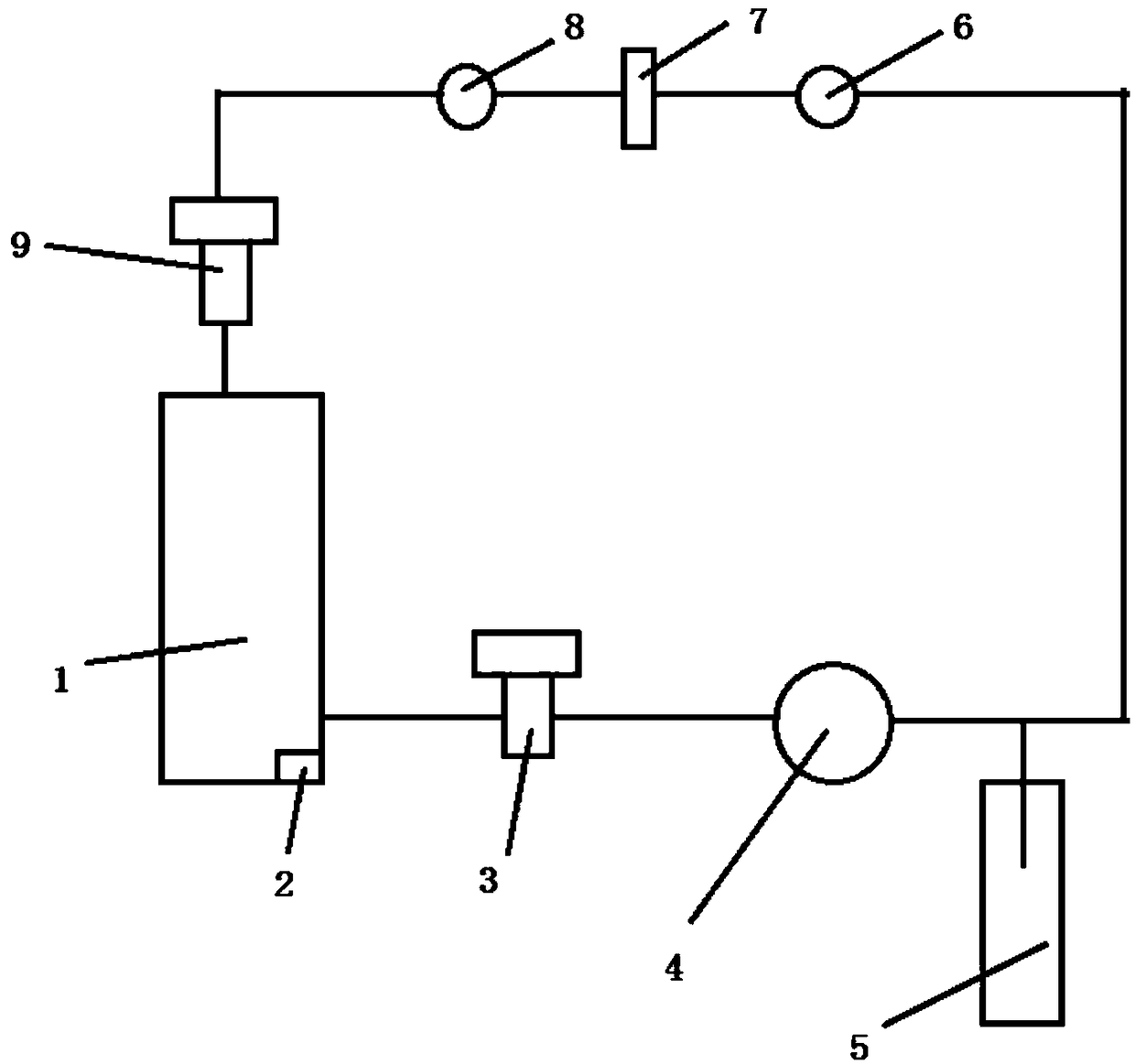

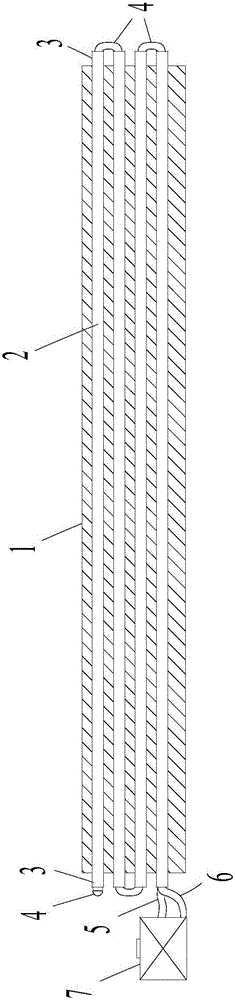

Intelligent mud jacking system for magnetic levitation track beam

InactiveCN105002826APrevent defects of uneven strengthShorten the timeBridge erection/assemblyEngineeringUltimate tensile strength

The invention discloses an intelligent mud jacking system for a magnetic levitation track beam. The system comprises corrugated pipes arranged in all reserved pore passages in the track beam, wherein a mud inlet pipe and a mud outlet pipe are connected with one ports of the two different corrugated pipes, respectively; other ports of all corrugated pipes are communicated with each other through a plurality of connecting pipes to form a mud injection passage; the mud inlet pipe and the mud outlet pipe are connected with a mud jacking device, respectively; and the mud jacking device is used for jacking cement mud for the track beam into the mud injection passage from the mud inlet pipe and enabling the cement mud to flow out from the mud outlet pipe and enter the mud jacking device; therefore, a mud jacking circulation is formed. According to the intelligent mud jacking system for the magnetic levitation track beam, disclosed by the invention, sealed circulated mud jacking for each corrugated pipe of the track beam can be achieved; a defect of non-uniform strength of the track beam caused by non-uniform mud filling in the corrugated pipes of the track beam can be effectively prevented; the mud can be filled into the track beam at one time; the time and cost are saved; and the mud injection efficiency is increased.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com