Ultra-large-area grouting construction method for steel-concrete combined section of cable-stayed bridge

A technology with super large area and construction method, applied in cable-stayed bridges, bridges, bridge parts, etc., can solve problems such as poor grouting effect, low construction efficiency, and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

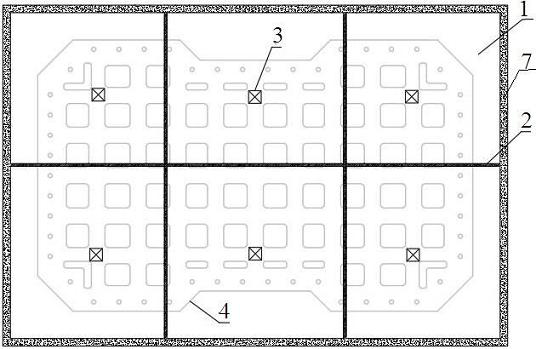

[0033] In order to solve the technical problems of the super-large-area grouting construction method of the steel-concrete joint section of the cable-stayed bridge in the prior art, the construction process is relatively complicated, the construction efficiency is low, and the grouting effect is not good when the top surface of the tower base has no slope. This embodiment provides a super-large-area grouting construction method for a steel-concrete joint section of a cable-stayed bridge, including the following steps:

[0034] Step 1) Dig notch 1;

[0035] Step 2) Set partition wall 2;

[0036] Step 3) Set pad 3;

[0037] Step 4) Install the steel tower of the first section;

[0038] Step 5) Grouting of bearing plate 4.

[0039] The super-large-area grouting construction method of the steel-concrete joint section of the cable-stayed bridge provided by the present invention is to form an enclosure 7 by reserving tower concrete around the top surface of the tower, and chiseli...

Embodiment 2

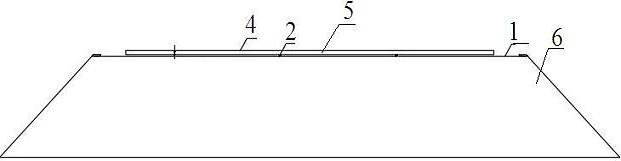

[0041] On the basis of Example 1, this example provides a super-large-area grouting construction method for the steel-concrete joint section of a cable-stayed bridge. To the top surface of the grouting layer 5, then reserve 25-35cm thick tower concrete around the top surface of the tower base, and chisel off the rest of the top surface of the tower base by chiseling to form a notch with a depth of 5-10cm 1.

[0042] The notch 1 is to pour the tower base to the top surface of the grouting layer 5 during the construction of the tower base, and then remove the overcast concrete by chiseling to form a notch 1 with a depth of 5 cm. Surface flatness and grouting quality. During the chiseling process, 30cm thick tower concrete is reserved around the tower as a fence 7 to prevent the grout from overflowing.

Embodiment 3

[0044] On the basis of Example 1, this example provides a super-large-area grouting construction method for the steel-concrete joint section of a cable-stayed bridge. Step 2) The process of setting the partition wall 2 is as follows: The partition wall 2 divides the notch 1 into multiple grouting areas of equal area.

[0045] The present invention is aimed at grouting area greater than 270m2 2 , in order to avoid the problem of insufficient grouting in the super large grouting area, the super large grouting area is divided into equal areas by setting a partition wall 2, and then the grouting is performed to ensure the grouting quality and improve the grouting efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com