Laser scaleplate endoscopic sleeve grouting defect detecting device and method

A sleeve grouting and defect detection technology, which is used in measuring devices, optical testing of defects/defects, material analysis by optical means, etc. , to achieve the effect of intuitive and accurate test results, convenient operation, high economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

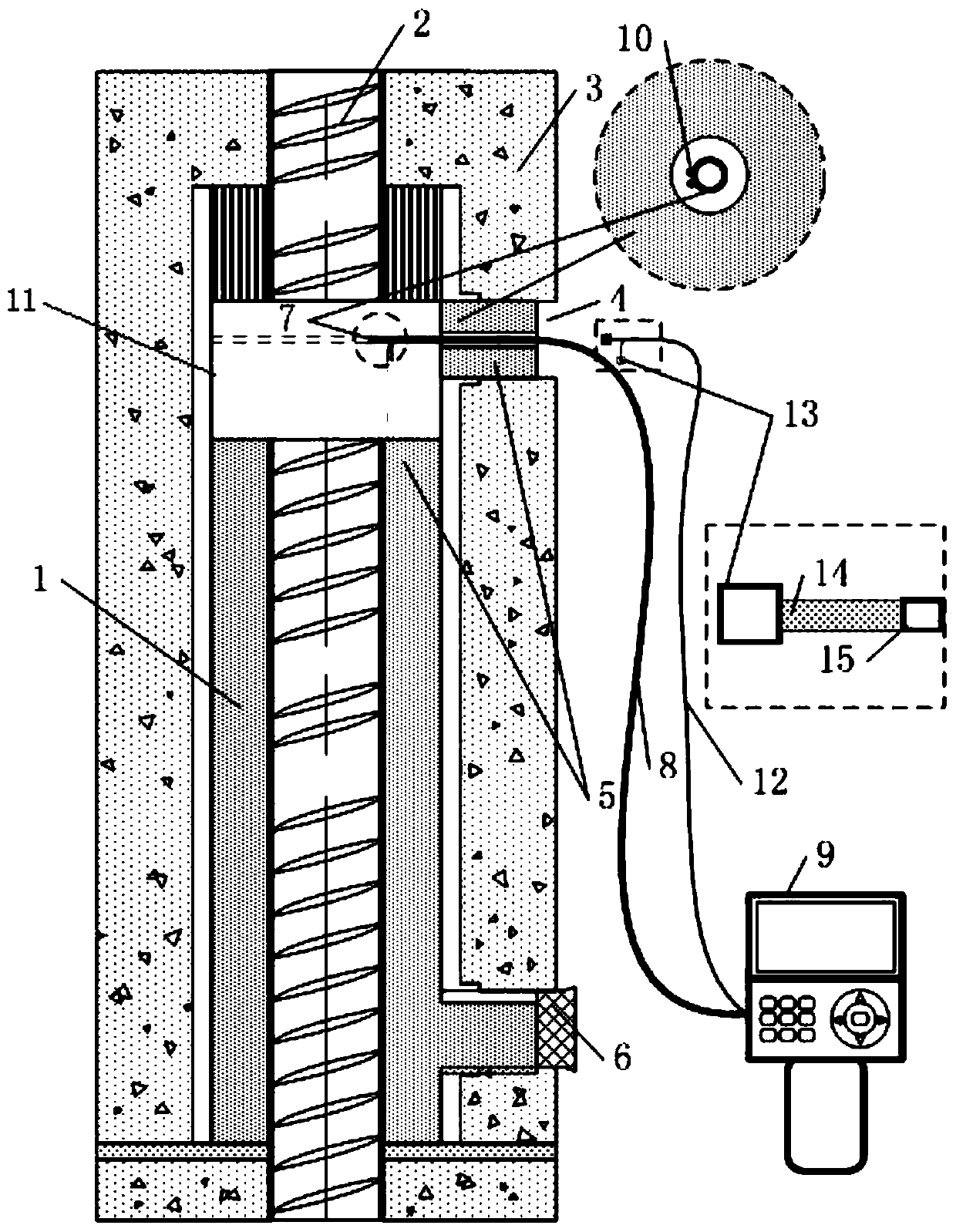

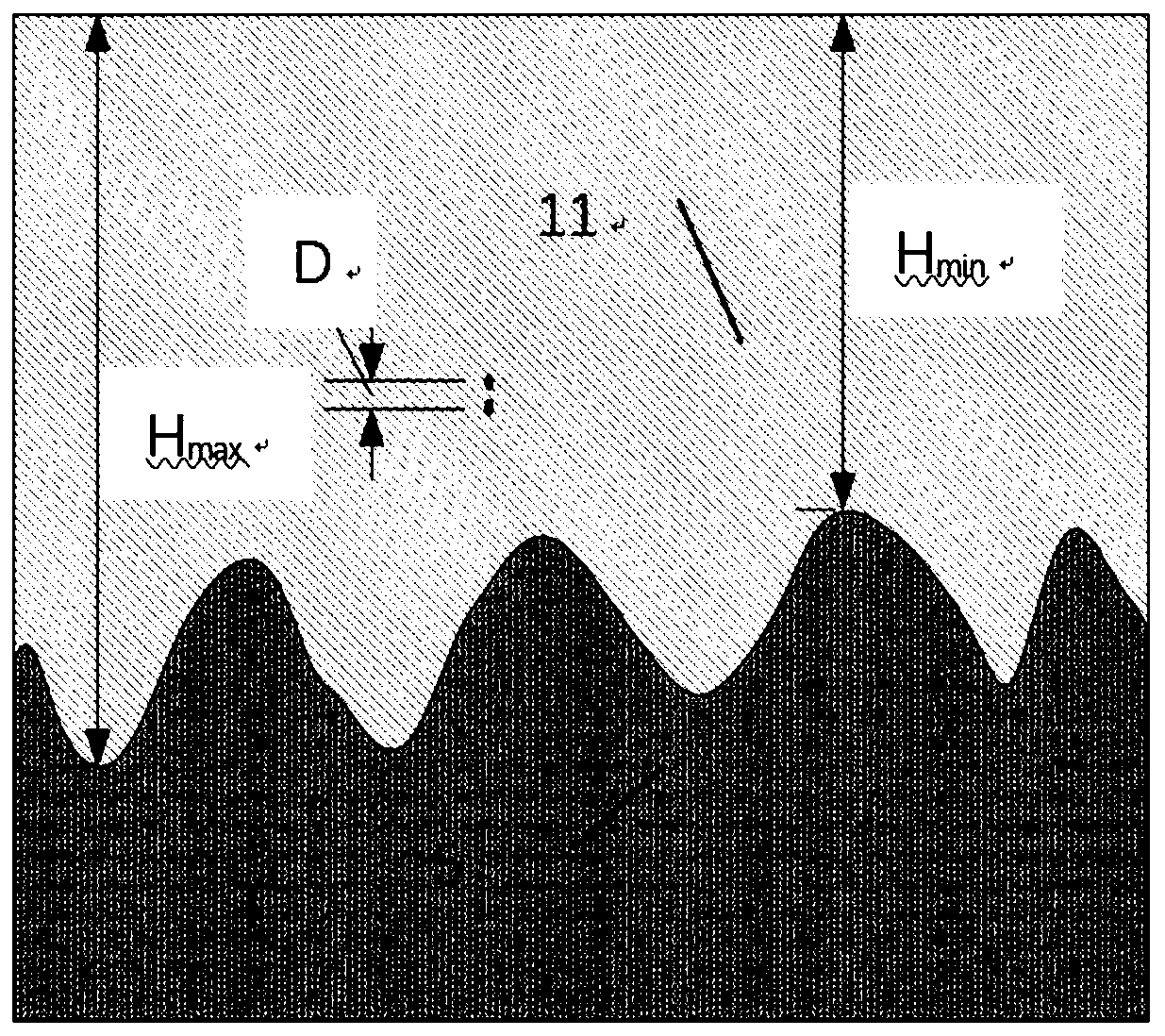

[0046] Embodiment one: if image 3 The sleeve 1 shown has defects in its internal grouting. Using the detection method of the present invention to image 3 The specific process of detecting grouting defects inside the sleeve 1 shown is as follows:

[0047] Step 1. Provide the detection device, requiring the probe 7 to have a diameter of 3.5 mm; the probe 7 is equipped with a visible light lens, using high-brightness LED lighting technology, the depth of field of the lens is continuously adjustable from 2 to 100 mm, and the wide angle is 120°; two sets of laser transmitters 10 The emitted laser beam is parallel; and the diameter of the laser beam is 0.10mm, and the distance d is 1.0mm;

[0048] Step 2. Arrange the detection holes as required: you can use a drill with a drill bit diameter of 4.5mm to drill holes, or use a plastic conduit to directly reserve detection holes during grouting;

[0049] Step 3. Set the detection position of the probe 7 in the detection hole, and ...

Embodiment 2

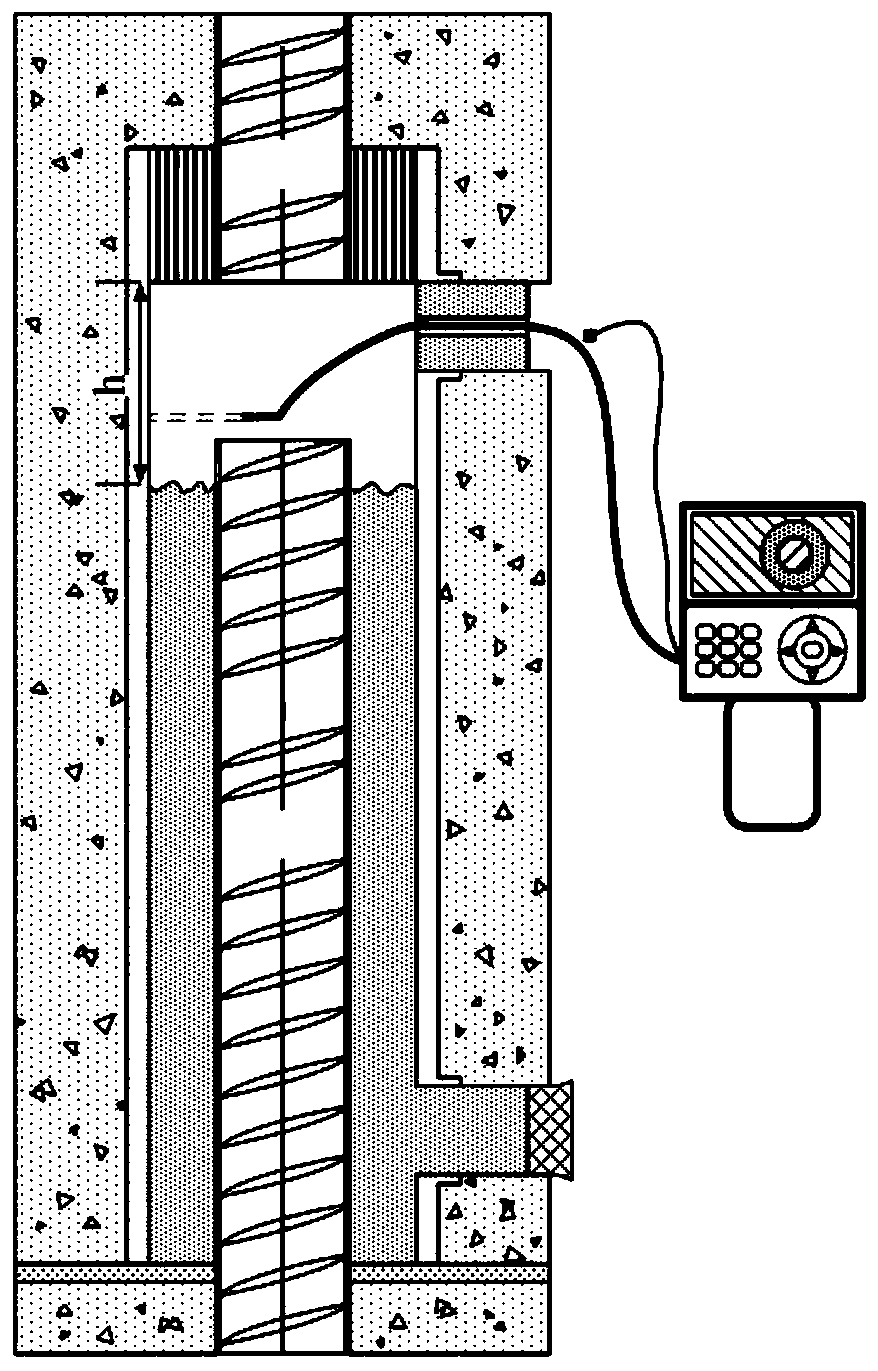

[0054] Embodiment two: if Figure 4 Shown is a schematic diagram of the inspection of sleeve 1 with no defects in internal grouting. Steps 1 to 4 in this embodiment are the same as in Embodiment 1. In step 5, the probe 7 extends into the detection hole to reach the detection position, and the captured image is a uniform and dense structure, such as Figure 5 As shown, it is considered that the sleeve 1 is full of grouting and has no defects, and the defect size is 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com