Method for detecting mechanical response of mechanical components by using organic mechanoluminescent material

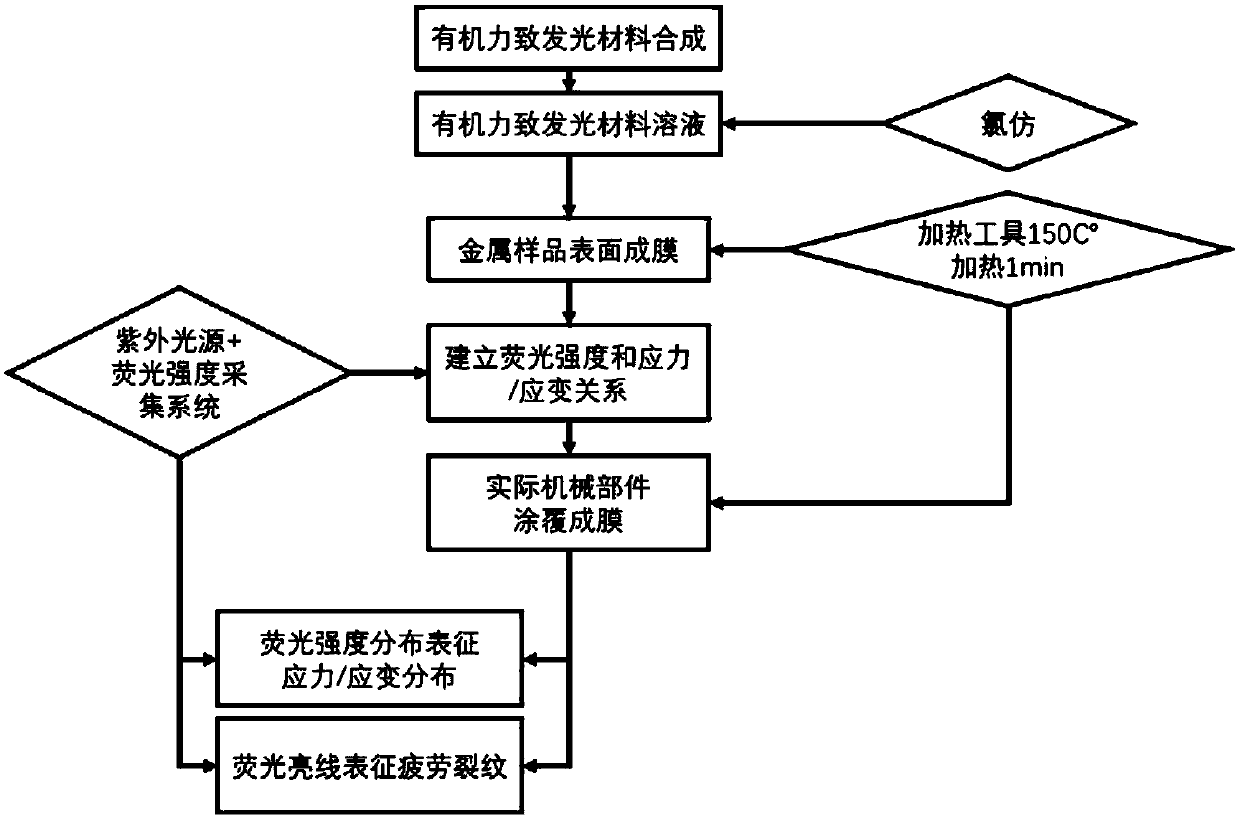

一种机械部件、致发光的技术,应用在通过测量材料受应力时其光学性质的变化力的计量、采用光学装置、使用施加稳定的张力/压力测试材料强度等方向,能够解决非可再生、环氧树脂流动性差、无机材料与金属相容性差等问题,达到准确定性及定量分析、适用范围广、方法简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Dissolve TPE-4N in chloroform to prepare a TPE-4N solution with a concentration of 0.01g / mL, apply the solution on the metal surface with a brush, and heat at 80°C for 20 minutes with a heat gun to form a film.

Embodiment 2

[0049] Example 2: TPE-4N was dissolved in chloroform to prepare a TPE-4N solution with a concentration of 0.3g / mL, and the solution was applied to the metal surface with a brush, and heated at 150°C for 1 minute with a heat gun to form a film.

Embodiment 3

[0050] Example 3: TPE-4N was dissolved in chloroform to prepare a TPE-4N solution with a concentration of 1 g / mL, and the solution was applied to the metal surface with a brush, and heated at 300° C. for 30 seconds with a heat gun to form a film. Heating tools can use heat guns, ovens, heating mantles, etc. with consistent results.

[0051] The results of coating the TPE-4N film on the metal surface with any of the solutions prepared above in Examples 1, 2, and 3 are consistent; the TPE-4N solution is stored in a light-shielding low temperature place.

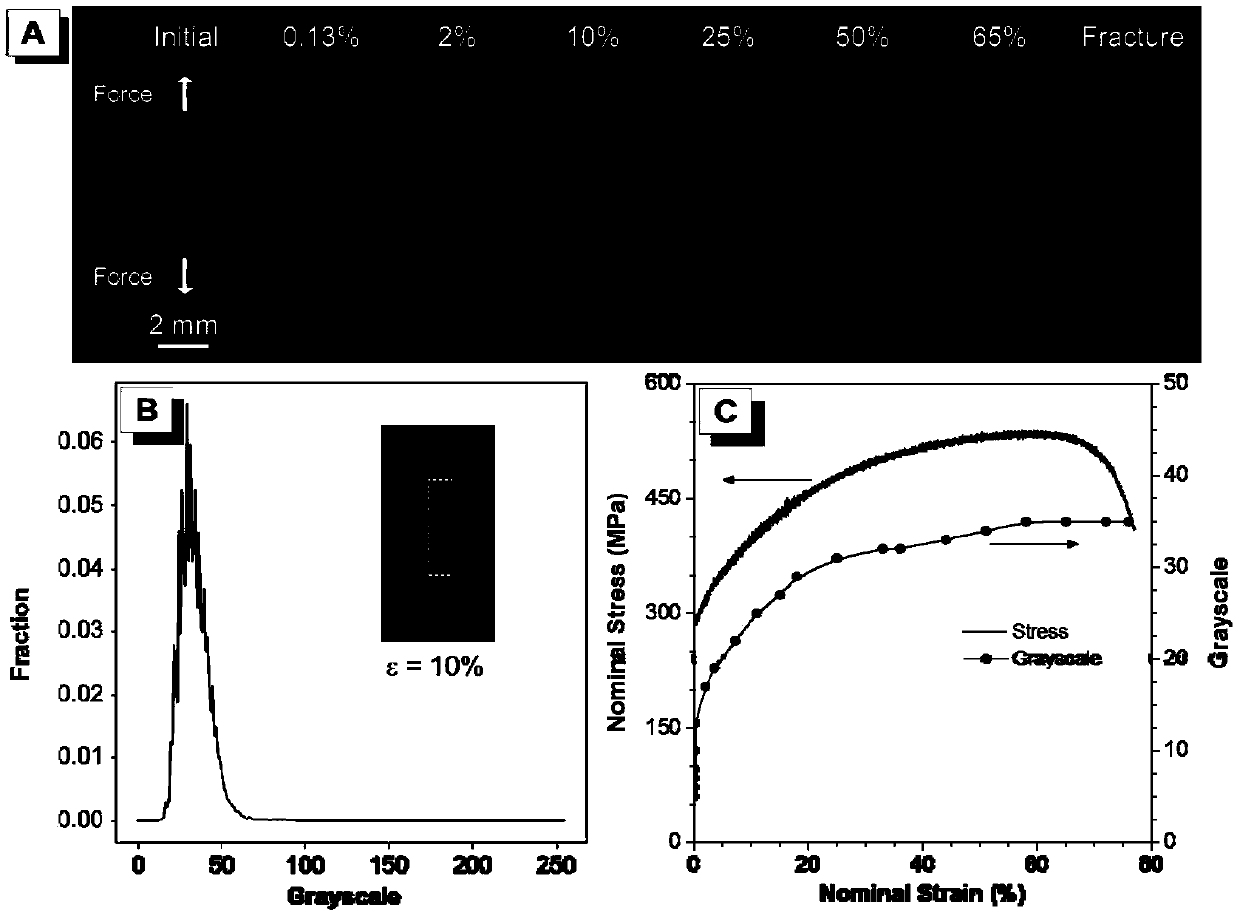

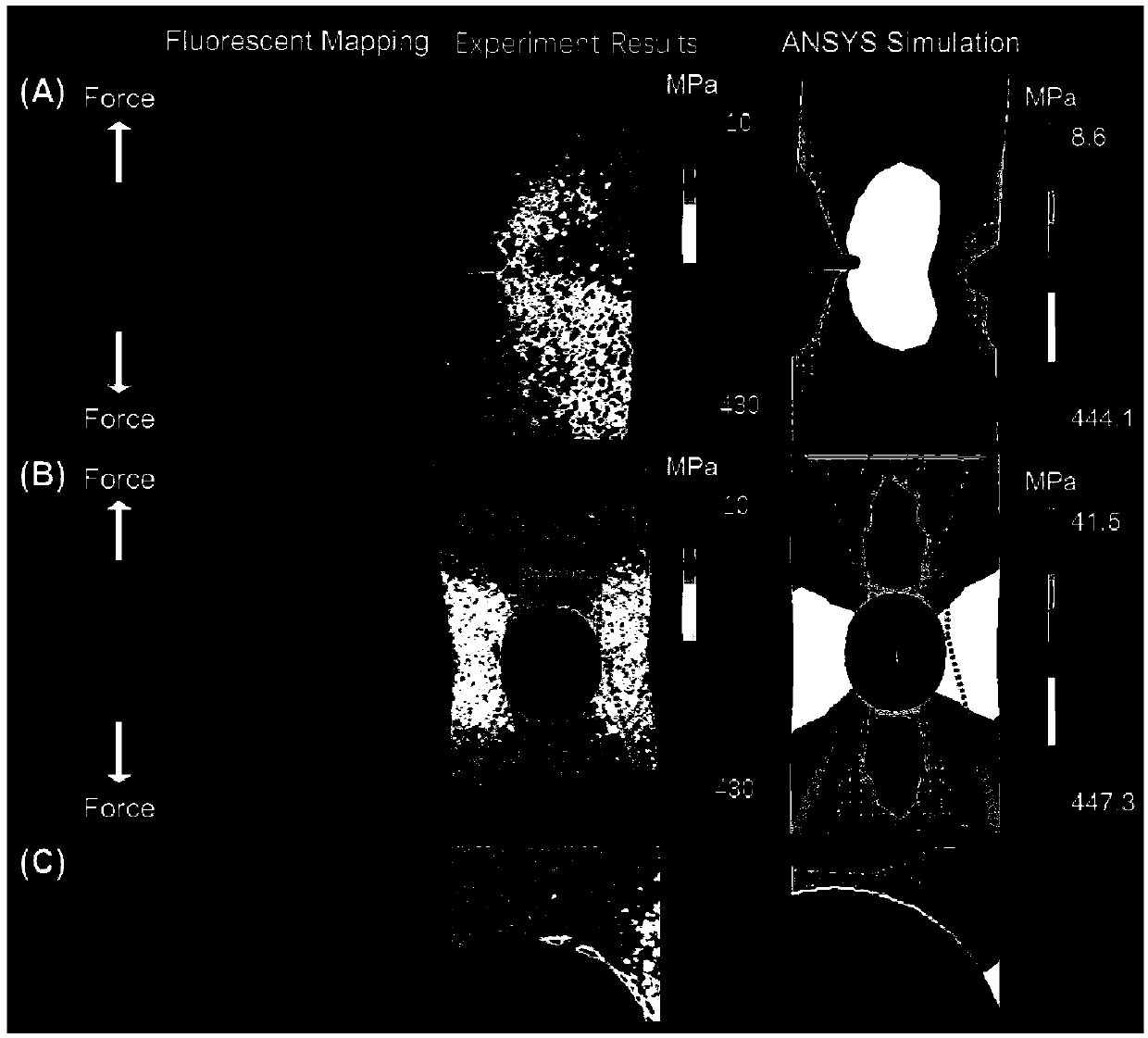

[0052] (4) Fluorescence intensity calibration. Such as figure 2 As shown, a uniaxial tensile test was carried out on a 316L stainless steel metal sample coated with TPE-4N, and an ultraviolet light source was used as an excitation light source to irradiate the coating on the sample. In different stress / strain response stages, a CCD camera system was used to obtain And record the fluorescent photos on the sample ( figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

| composition ratio | aaaaa | aaaaa |

| composition ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com