Tunnel waterproof curtain construction precision-guided grouting method

A technology for water-stop curtains and tunnels, used in construction, infrastructure engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

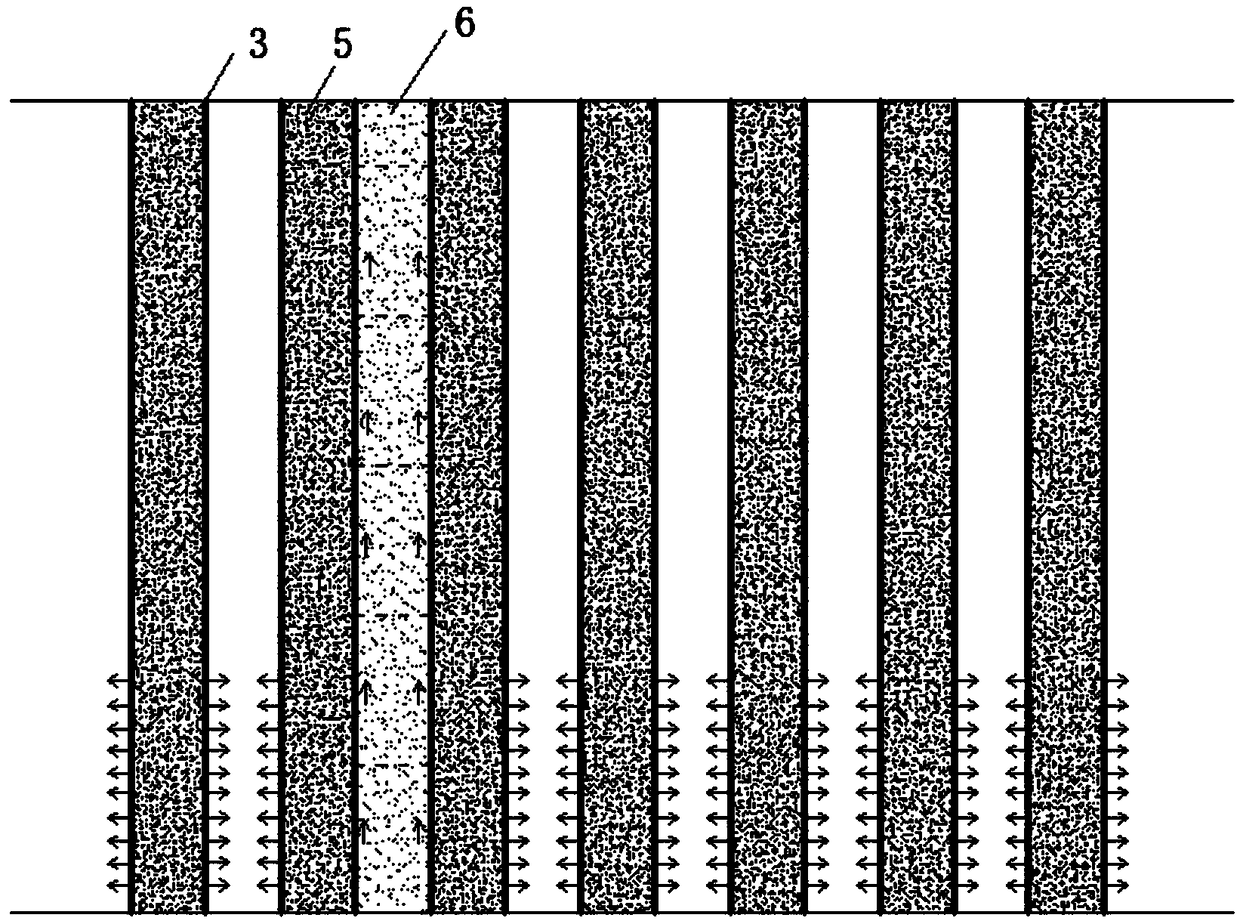

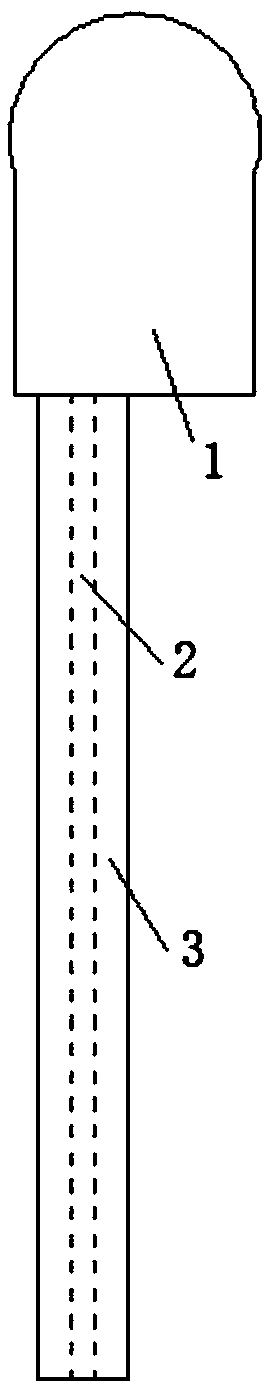

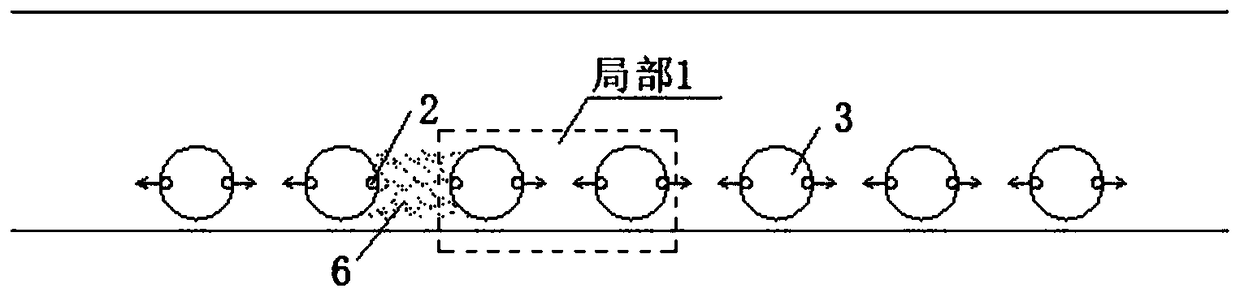

[0032] A precise guided grouting method for constructing a water-tight curtain in a tunnel. When driving piles along the side wall in the tunnel, the pile row drilling is performed first. The guided grouting pipe is lowered together with the reinforcement cage drilled in the row of piles, after which the concrete is poured. After the initial setting of the concrete, a water-stop curtain with an effective thickness of 0.8-1.0D is gradually formed between the piles through the guided grouting pipe from bottom to top, where D is the diameter of the pile row. Key technologies include the following three parts:

[0033] (1) Construction technology of precise guided grouting for water-stop curtain

[0034] 1) The drilling rig is positioned at the drill hole of the pile row, and the drill rig drills the design diameter drill hole at the design drill hole;

[0035] 2) After completing the drilling, connect the guide grouting pipe 2 with a diameter of 100 mm to the outer side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com