Slurry pocket slurry-injecting anchorage rod with control system and using method

A grouting bolt and control system technology, which is applied in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problem of lack of precise control of grouting amount and grouting pressure, complicated grouting engineering and low pullout resistance. and other problems, to achieve the effect of solving the excessive return pressure of the slurry, improving the quality of grouting, and enhancing the anti-pulling ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

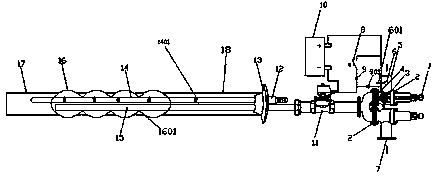

[0026] A grouting anchor with a control system, including a rod body part and a control part, and also includes a housing 18 outside the rod body part, and the control part includes a parallel grouting part, a grout return part and an activity above the grout return part In the connected control circuit part, the grouting part has a grouting port 7 with an opening downward, and the grouting part has a grouting port 5 with an upward opening, and there are flanges 2 on both sides of the grouting port 7 and the grouting port 5. There is a regulator 1 at the right end of the part and the return part, and the return part also includes an adjustment structure. The adjustment structure includes the regulator 1 and the spring 3 and the piston piece 4 between the flanges 2 at both ends of the return port 5, and one end of the spring 3 It is fixedly connected with the regulator 1, and the other end is fixedly connected with the piston piece 4, and the movement of the spring 3 is controll...

Embodiment 2

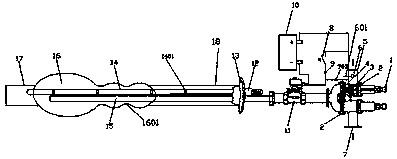

[0036] The difference between this embodiment and Embodiment 1 is that the main reinforcement is composed of five short main reinforcements. The slurry bag 16 is in the shape of two consecutive small beads and a large one. It is made of geotextile material. The retractable restraining band 1601 of the embodiment 1, the slurry bladder bag 16 of the present embodiment is stretched from the leftmost restraining band 1601 of Embodiment 1 into a large string of beads.

Embodiment 3

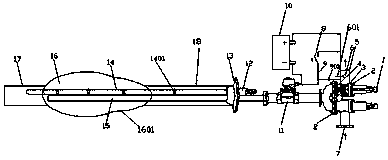

[0038] The difference between this embodiment and Embodiment 2 is that the pulp capsule bag 16 is in the shape of continuous beads, one small and one large, and is made of plastic film material. The restraint strap 1601 is elongated as a large bead.

[0039] The products of the three embodiments of embodiment 1, embodiment 2 and embodiment 3 are used for grouting, after testing, there is no situation that the grouting pressure is too large and accidents occur; The precise control of grouting pressure is obviously superior to that of ordinary grouting anchors, which solves the technical problems of excessive return pressure of ordinary grouting anchors, easy grout running, and grout leakage. It has simple structure, low cost, quick installation, and repeatability. It is suitable for the geological conditions of weak surrounding rocks such as coal mines and tunnels that need to be reinforced by grouting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com