Rapid construction method of high-pressure water-rich fault zone of tunnel

A construction method and fault technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., to reduce risks, reduce water pressure in front tunnels, and strengthen construction organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

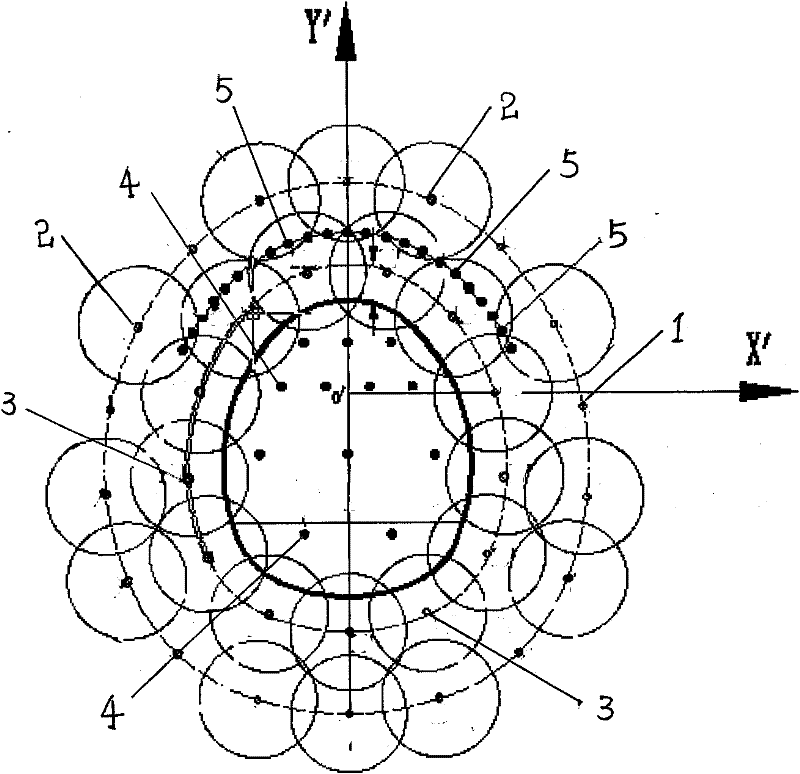

Method used

Image

Examples

Embodiment Construction

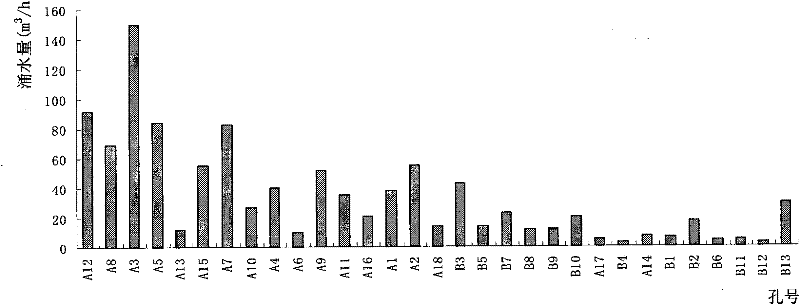

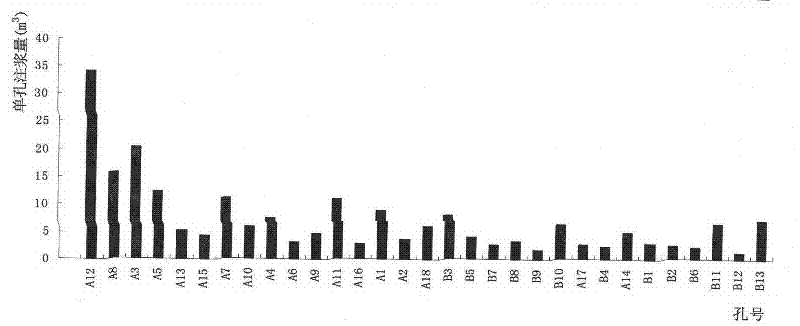

[0046] List the following engineering examples to further illustrate the construction method of the present invention

[0047] 1. Brief introduction of the project. The F11 fault of Qiyueshan Tunnel is exposed on the surface DK364+950~+180 segment, and it develops in the hard soluble rock dominated by T1j4 dolomite and the soft non-ferrous rock dominated by T2b1 calcareous shale and mudstone. The junction of soluble rocks, the tunnel range DK365+110~+340 is the main fault zone, with multi-phase, secondary structure development, complex lithological composition, loose cementation, broken rock mass, and deterioration of rock and soil properties due to saturated water .

[0048] The F11 fault is divided into the upper and lower wall broken rock mass contact zone and the core broken and weak zone, with well-developed structural fissures and strong water permeability; the middle core zone is dominated by soft materials similar to gravel-containing silty clay or gravel-like soil, sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com