Ball float type liquidometer with vernier display

A float type, liquid level gauge technology, applied in the direction of buoy liquid level indicator, etc., can solve the problems of inability to use, increase the weight of the float, large friction coefficient, reduce the cost of use and maintenance, overcome the difficulty of reading values Overcoming the effect of high friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] (1) Basic type

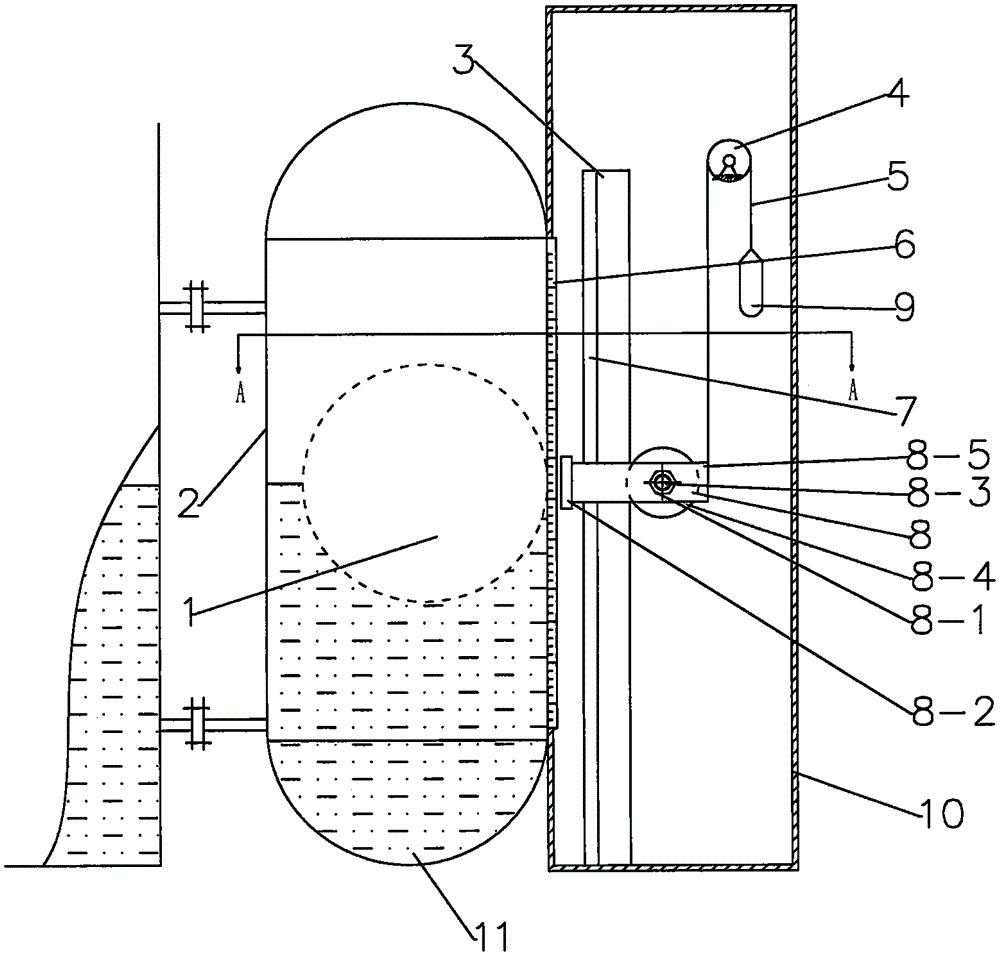

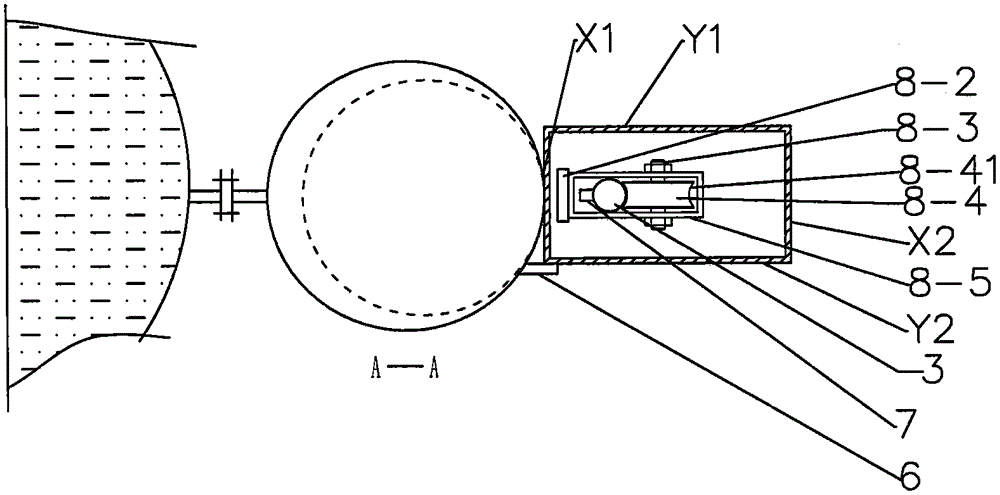

[0085] A float type liquid level gauge displayed by a vernier, such as figure 1 and figure 2 As shown, it includes a float chamber 2 made of non-ferromagnetic material, a spherical float 1 made of ferromagnetic material in the float chamber 2, a scale 6 adjacent to the float chamber 2, a cylindrical guide rail 3, and a closed non-ferrous The cursor chamber 10 of magnetic transparent material, the scale 6, the axis of the cylindrical guide rail 3 and the axis of the cursor chamber 10 are parallel to each other and parallel to the axis of the float chamber 2, and the vernier 8 and the cylindrical guide rail 3 are respectively arranged on Inside the cursor chamber 10;

[0086] The cylindrical guide rail 3 is provided with a guide rail reinforcing rib plate 7 from top to bottom on the side close to the float chamber 2;

[0087] Wherein, described vernier 8 comprises magnetic steel 8-2, rectangular frame 8-5 and rolling system, and described rolling syst...

Embodiment 2

[0101] Another float type liquid level gauge displayed by the vernier, such as Figure 4 and Figure 5 As shown, it is different from the protective type of embodiment 1 in that the vernier guide rail is a rectangular parallelepiped guide rail 3'; correspondingly, the radial groove of the scroll wheel 8-4 is a rectangular groove 8-42 , the distance between the two inner parallel surfaces of the rectangular groove 8-42 is greater than the distance between the two outer surfaces corresponding to the guide rail 3'. Under the magnetic coupling effect of the magnetic steel 8-2 on the vernier 8 and the floating ball 1, the rolling wheel 8-4 rolls along the working surface of the cuboid guide rail 3'.

[0102] Further, in order to avoid the trouble of replacing the magnetic steel 8-2 after the magnetic steel 8-2 is demagnetized, the liquid level gauge is provided with a spare vernier 14 at the upper position in the vernier chamber 10, and correspondingly outside the vernier chamber ...

Embodiment 3

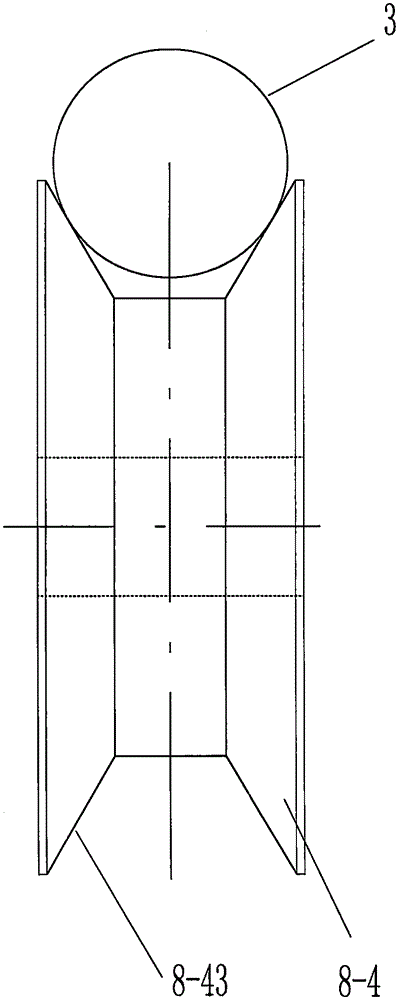

[0104] Another float-type liquid level gauge with a vernier display, on the basis of the aforementioned liquid level gauge, has improved its vernier 8, that is, the vernier 8 includes two sets of the rolling system, that is, includes two scroll wheels 8 -4, 8-4' and their respective shafts 8-3, 8-3' and rolling bearings 8-1, 8-1', such as Image 6 shown. The two sets of rolling systems are arranged in parallel up and down in the same rectangular frame 8-5, and the plane formed by the two shafts 8-3, 8-3' is perpendicular to the ground, so as to prevent the cursor 8 from The rotation around the axis is generated during the up and down movement, which improves the accuracy and reliability of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com