Float gauge with vernier or buoy display

A liquid level gauge and float type technology, applied in the field of liquid level measurement, can solve the problems of complex structure of magnetic coupling or vernier or buoy, affecting accuracy and sensitivity, and large friction coefficient, so as to achieve eye-catching and intuitive display, improve accuracy and reduce The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

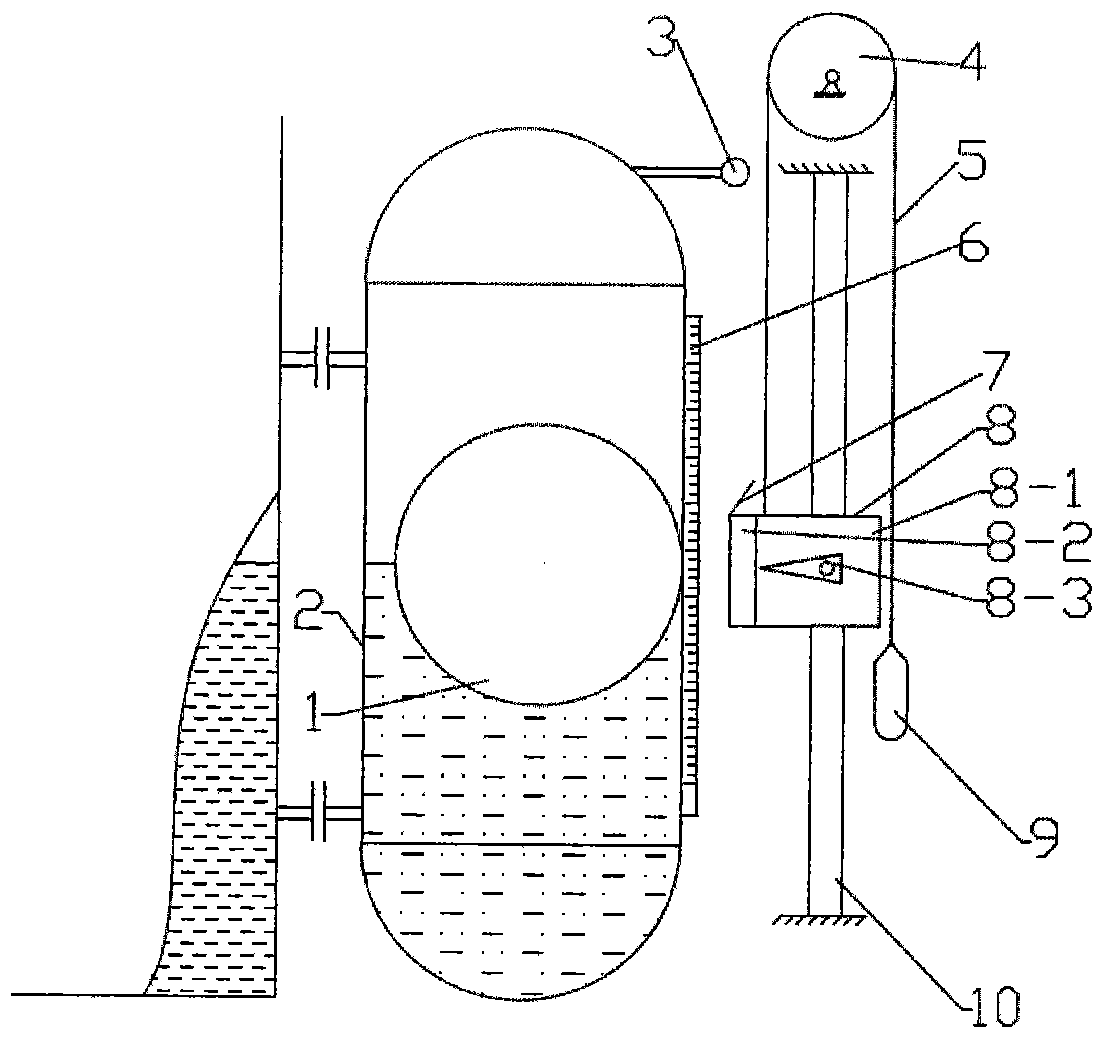

[0075] Such as figure 1 The float type liquid level gauge shown includes a float chamber 2 made of non-ferromagnetic material, a spherical float 1 made of ferromagnetic material, and a cursor 8 outside the float chamber;

[0076] It is characterized by:

[0077] The vernier 8 includes a magnetic steel 8-2 and a linear bearing 8-1, the magnetic steel 8-2 is fixed on the linear bearing 8-1, and the outside of the float chamber 2 is adjacent to the axis parallel to the float chamber Fix a linear guide rail 10, the linear bearing 8-1 is worn on the linear guide rail 10, the magnetic steel 8-2 is located between the linear bearing 8-1 and the float chamber 2, its magnetic pole is facing the float 1, the linear bearing 8 -1 is closely attached to the linear guide rail 10 through the magnetic coupling force between the magnetic steel 8-2 and the float 1.

[0078] In order to indicate clearly and accurately, it is characterized in that an eye-catching pointer 8-3 is fixed outside th...

Embodiment 2

[0081] still as figure 1 As shown, for example, in the case of high temperature and high pressure or high pressure and low density medium, because the wall thickness of the float 1 is relatively thick, the specific gravity of the float 1 is greater than the specific gravity of the measured medium. In order to balance the gravity of the float 1, an upward lifting force is given to the float 1 , On the basis of the above-mentioned scheme, fixed pulley 4 and counterweight 9 and connecting rope or connecting belt 5 have been added. The fixed pulley 4 is fixed above the outer side of the float chamber 2, the connecting rope or belt 5 bypasses the fixed pulley 4, and the two ends are respectively connected with the counterweight 9 and the vernier 8.

[0082] Under normal circumstances, the weight of the counterweight 9 is greater than that of the vernier 8 so that the float 1 and the vernier 8 always form a tension between the upper and lower sides, so as to avoid the formation of a...

Embodiment 3

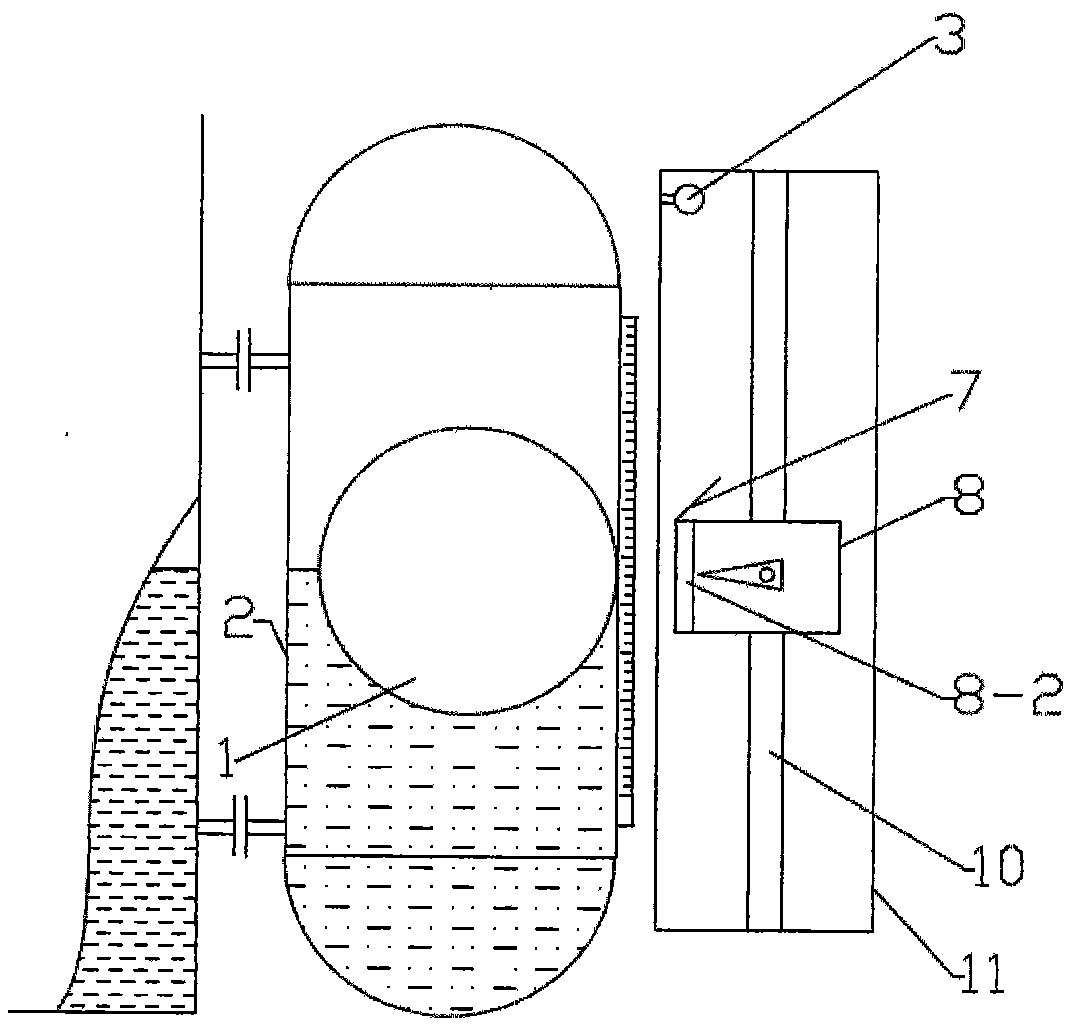

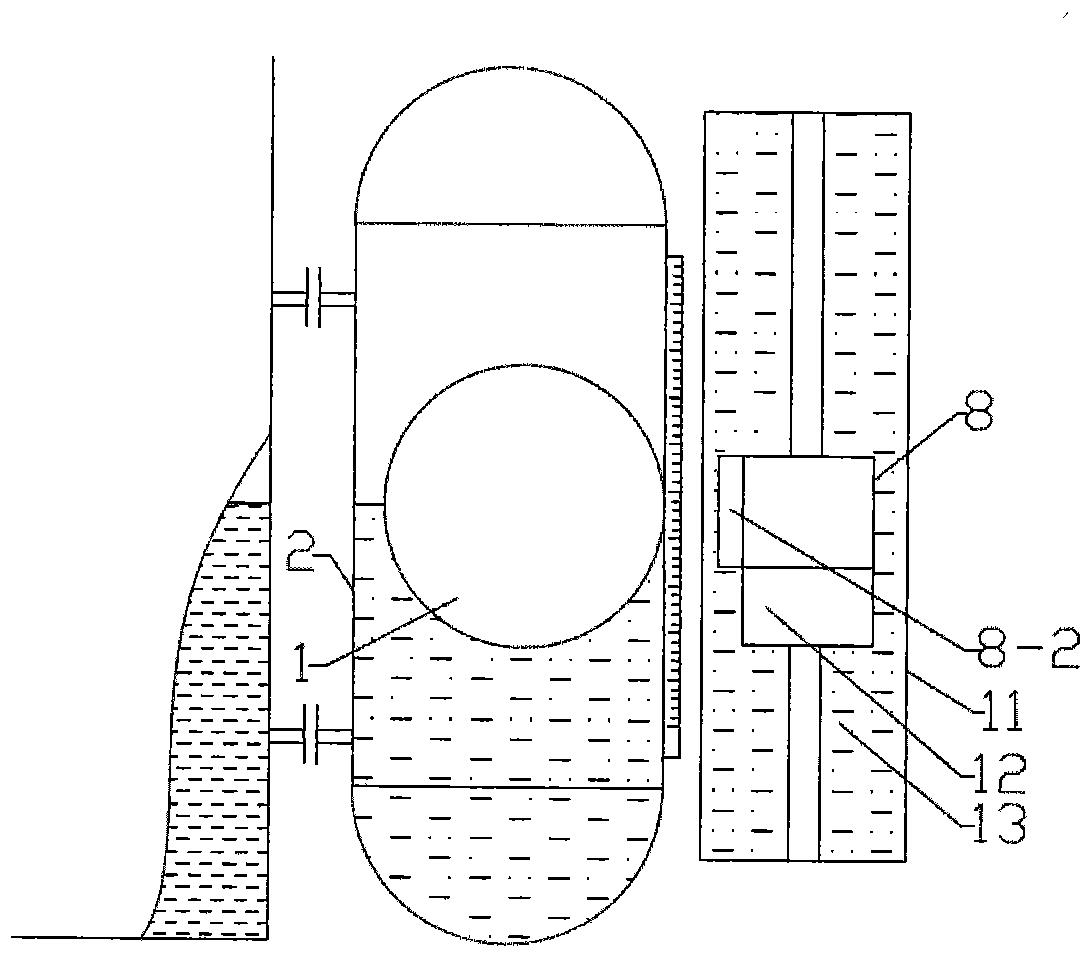

[0084] Such as figure 2 As shown, in order to prevent dust and water, a transparent cursor chamber 11 made of non-ferromagnetic material is adjacent to the float chamber 2, and the cursor 8, the linear guide rail 10 and the laser lamp 3 are fixed in the cursor chamber 11, and the cursor 8 The reflective plate 7 is also fixed on it. The cursor chamber 11 is airtight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com