Double-layer channel variable-section turbine control device

A technology of control device and variable cross-section, which is applied in the direction of gas turbine devices, mechanical equipment, engine components, etc., to achieve the effect of changing cross-sectional area, solving cost problems, and simply controlling valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

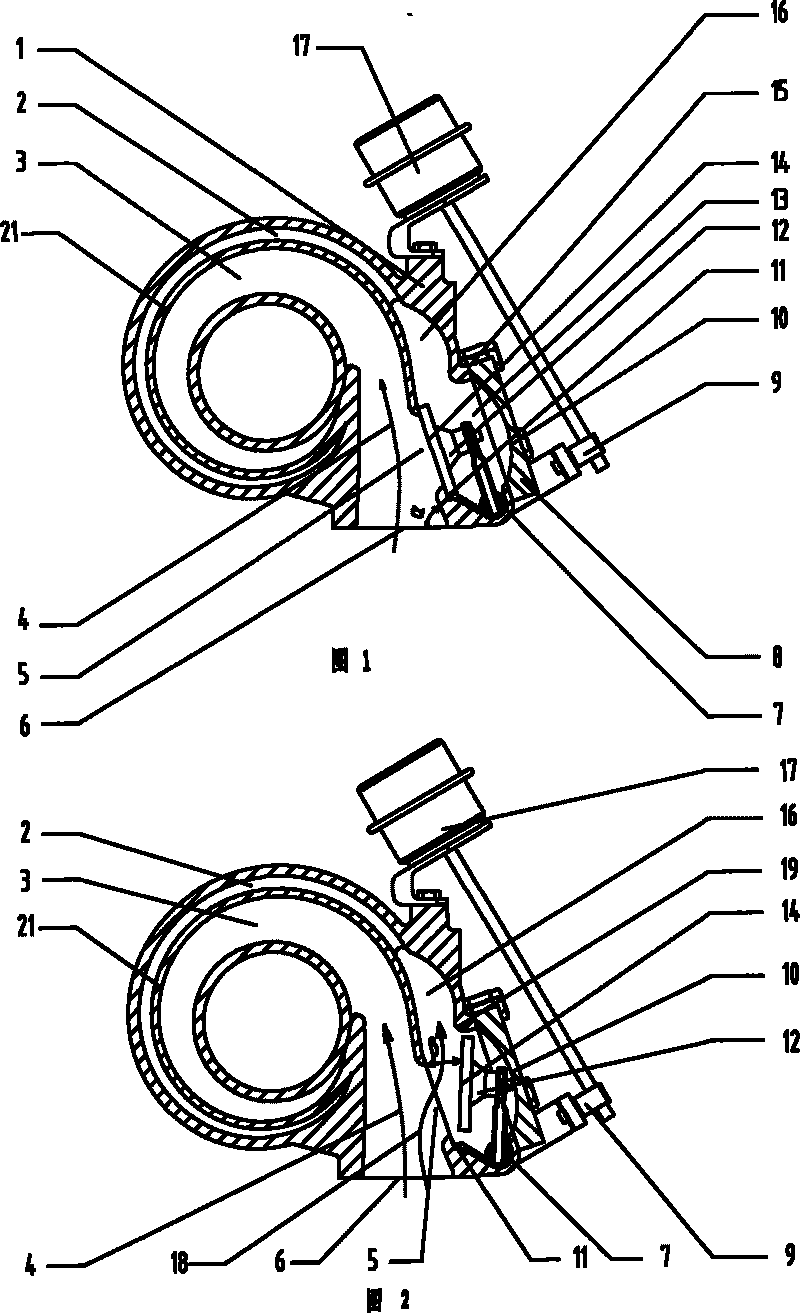

[0035] Example 1, such as figure 1 As shown, a double-layer channel variable cross-section turbine control device includes a single-inlet turbine shell 1, and the single-inlet turbine shell 1 is provided with an intake outer flow channel 2 and an intake inner flow channel 3, and the intake air flows out The channel 2 is located on the circumferential outside of the air intake inner flow channel 3, and a partition wall 21 is provided between the air intake outer flow channel 2 and the air intake inner flow channel 3. The air intake inner flow channel 3 has an air inlet 6 between which An outer runner air inlet 5 is provided near the air inlet 6 on the next wall, and an air inlet control device is arranged at the outer runner air inlet 5 .

[0036] The front end of the intake inner runner 3 is directly connected to the air inlet 6, and the high-temperature exhaust gas discharged from the engine directly enters the intake inner runner 3 along the inlet 6 and then provides power t...

Embodiment 2

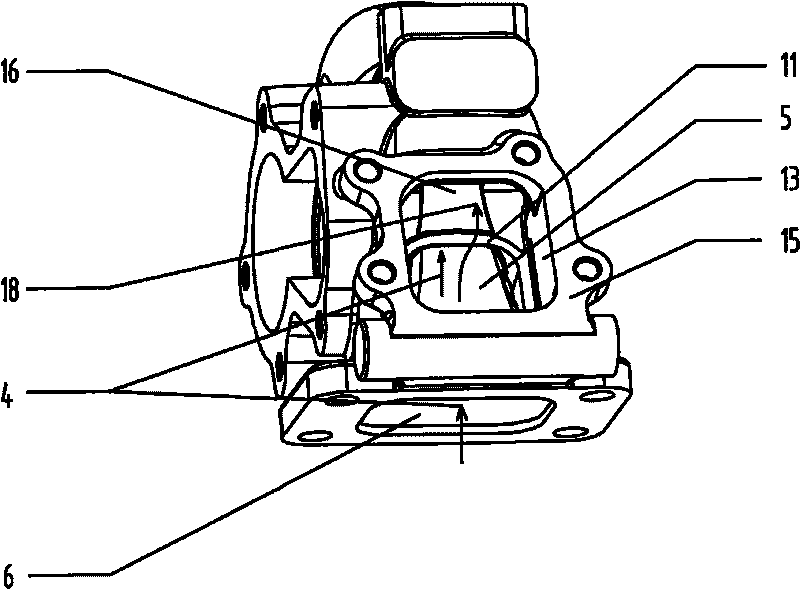

[0044] Example 2, such as Figure 4 As shown, a double-layer channel variable cross-section turbine control device includes a double-inlet turbine housing 1, and the double-inlet turbine housing 1 is provided with an air inlet 6 located on the right side of the double-inlet volute, and the turbine housing 1 is equipped with There are intake outer flow channel 2 and intake inner flow channel 3 located on the right side of the double inlet volute, the intake outer flow channel 2 is located on the circumferential outer side of the intake inner flow channel 3, the front end of the intake inner flow channel 3 is connected to the air inlet 6 is directly connected, and the high-temperature exhaust gas discharged from the engine directly enters the intake inner flow channel 3 on the right side of the double-inlet volute along the air inlet 6, and then provides power to the turbine rotor, forming an internal flow on the right side of the double-inlet volute Road flow direction 4.

[0...

Embodiment 3

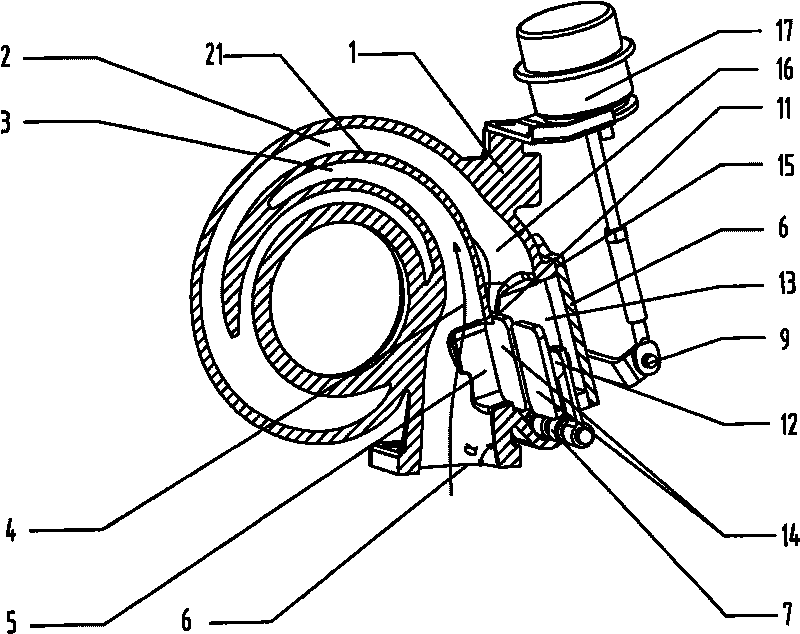

[0053] Example 3, such as Figure 7 As shown, in embodiment 2, the vent valves 12 respectively provided at the outer runner air inlet on the left side of the double-inlet volute and the outer runner air inlet on the right side of the double-inlet volute can also be provided by two sets of valves respectively. The air intake control device is controlled, wherein, the exhaust valve 12 at the inlet of the outer runner on the right side of the double inlet volute is controlled by the original inlet control device, and the air inlet valve 12 at the inlet of the outer runner on the left side of the double inlet volute is controlled by the original inlet control device. The air discharge valve 12 at the position is controlled by the left air intake control device, which includes a control actuator 17 arranged on the left side outside the volute, and the control actuator 17 controls the air discharge valve through the valve transmission pin 9 Exercise alone.

[0054] These two sets o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com