Adjustable ejector

An injector, adjustable technology, applied in the direction of injection device, liquid injection device, etc., can solve the problems of difficult adjustment process, section ratio change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

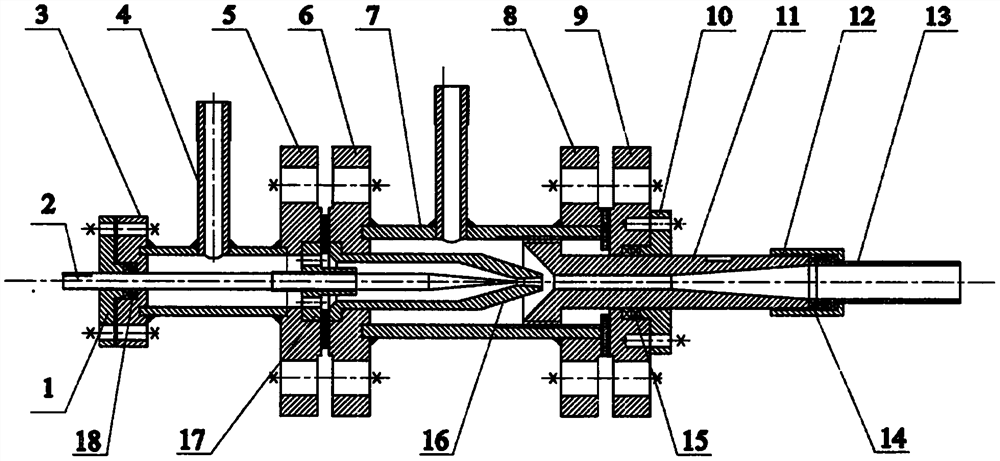

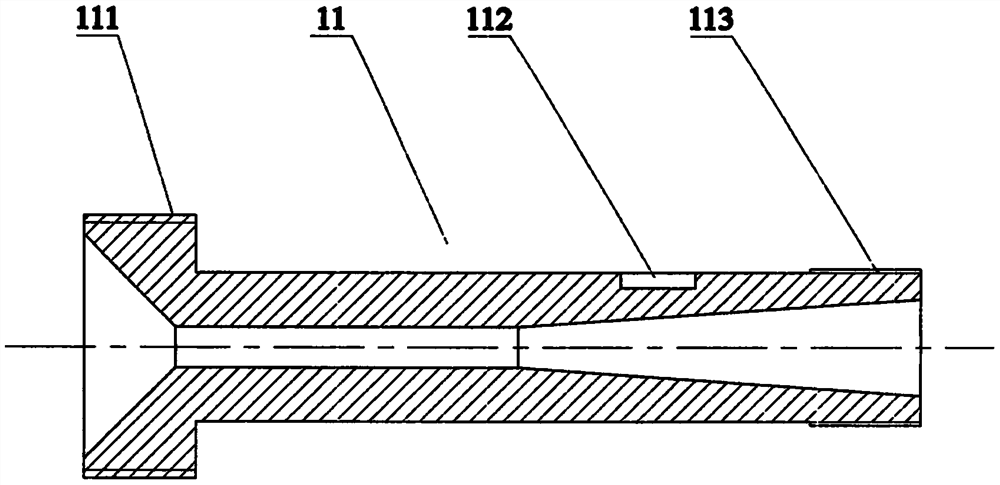

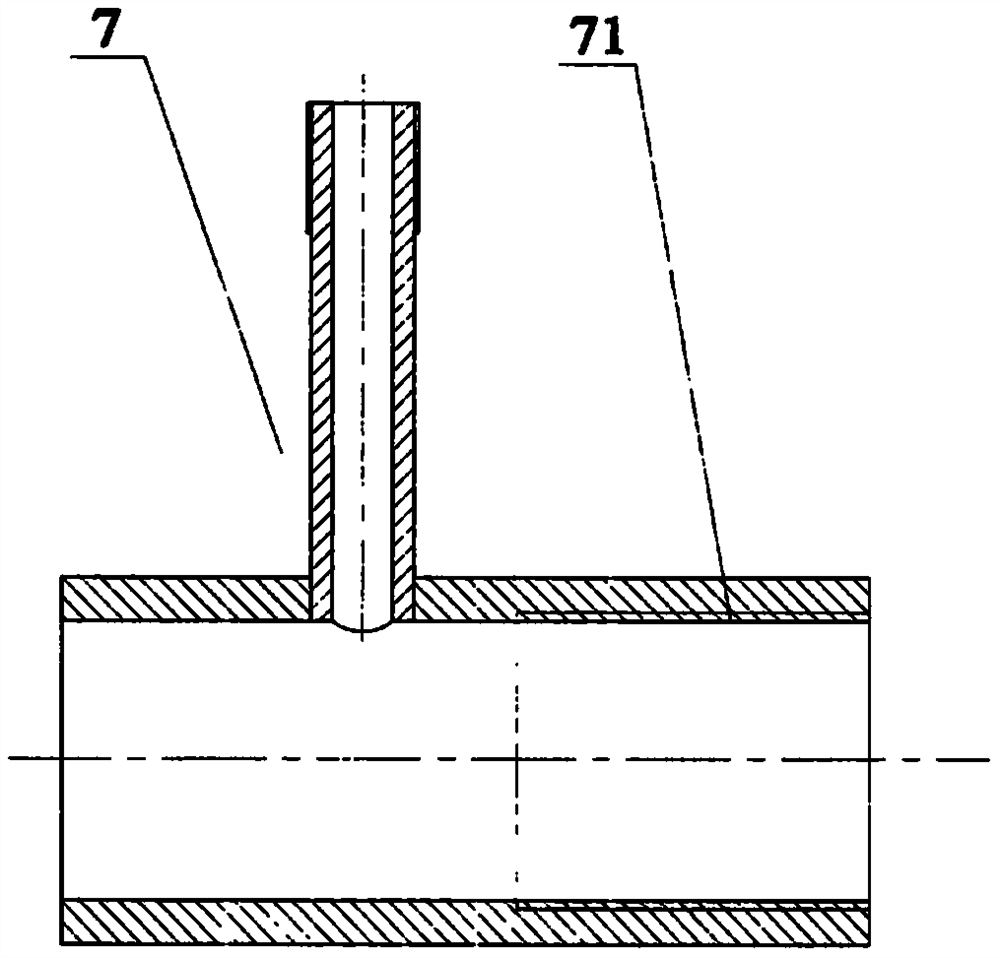

[0031] Such as Figure 1 to Figure 11 As shown, an adjustable injector according to a specific embodiment of the present invention includes a high-pressure tee 4 , a low-pressure tee 5 , a mixing diffuser 11 , a nozzle adjusting cone 2 , and a nozzle 16 . The mixing diffuser 11 is connected with the internal thread 71 at the front end of the low-pressure tee 7 through the external thread 111 at the rear end, and the front end of the mixing diffuser 11 is connected with the metal braided hose 13 through a joint 12, and the mixing diffuser 11 can be turned to realize The axial displacement of the mixing diffuser 11 relative to the low-pressure tee 7 causes a change in the axial distance from the outlet section of the nozzle 16 to the inlet section of the mixing diffuser 11 (namely, the nozzle distance), which changes the performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com