Shearing-resistant and not-pull-resistant friction-type shearing force connection part and construction method thereof

A technology of connectors and components, which is applied in the direction of architecture and building construction, etc., can solve the problems of composite structure system performance, long-term performance and durability adverse effects, concrete internal force cannot be released, cannot be deformed or slipped, etc., to avoid direct Damage, changes in shear capacity and stiffness, effects of a high degree of prefabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solution of the present invention will be described in detail below in conjunction with the drawings.

[0057] Figure 1a with Figure 1b A schematic diagram of a stud shear connector provided for a beam or plate in the prior art. The figure shows that the shear connector needs to be welded to the beam or plate, which is labor-intensive and wastes materials.

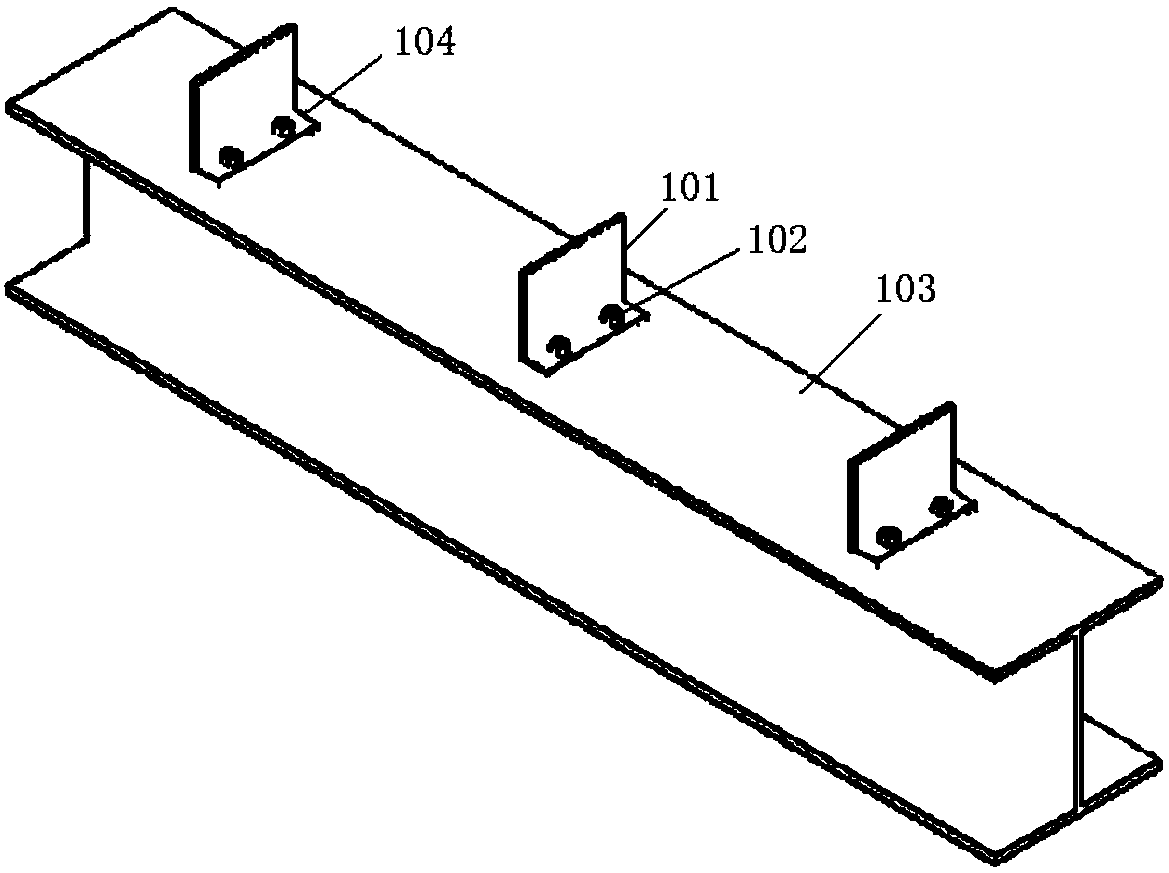

[0058] Such as figure 2 Shown is a friction-type shear connector, which includes a connector body 101 and a high-strength bolt assembly 102. The connector body is installed on the H-shaped steel main beam 103 through a high-strength bolt assembly, and the bolt holes 104 are long bolt holes. . The main girder can be replaced with any section steel or between the plates where shear connectors are needed. Install the main body of the connector on the H-shaped steel main beam at intervals according to the required shear resistance. The main body of the connector is an angle steel, which does not have an em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com