Grouting unit flowmeter calibration device and method

A technology of flow meter and slurry volume, which is applied in the direction of measuring device, testing/calibrating device, testing/calibrating volumetric flow, etc. It can solve the problems that the field flow of the system does not reach the screen slurry flow rate, cannot be completed normally, and the workload is heavy. Achieve the effects of reducing unnecessary grouting time, preventing human interference, and improving the automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

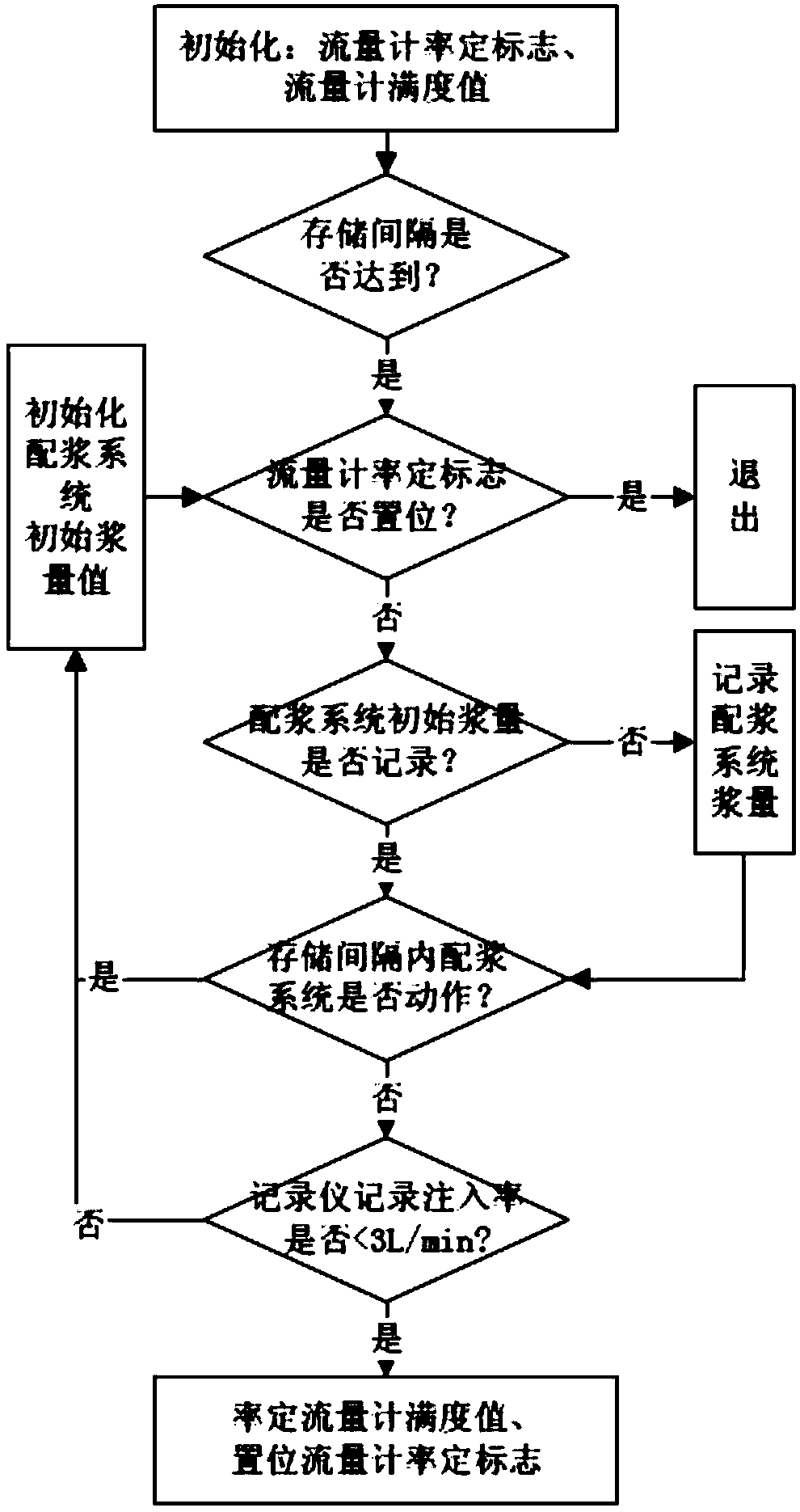

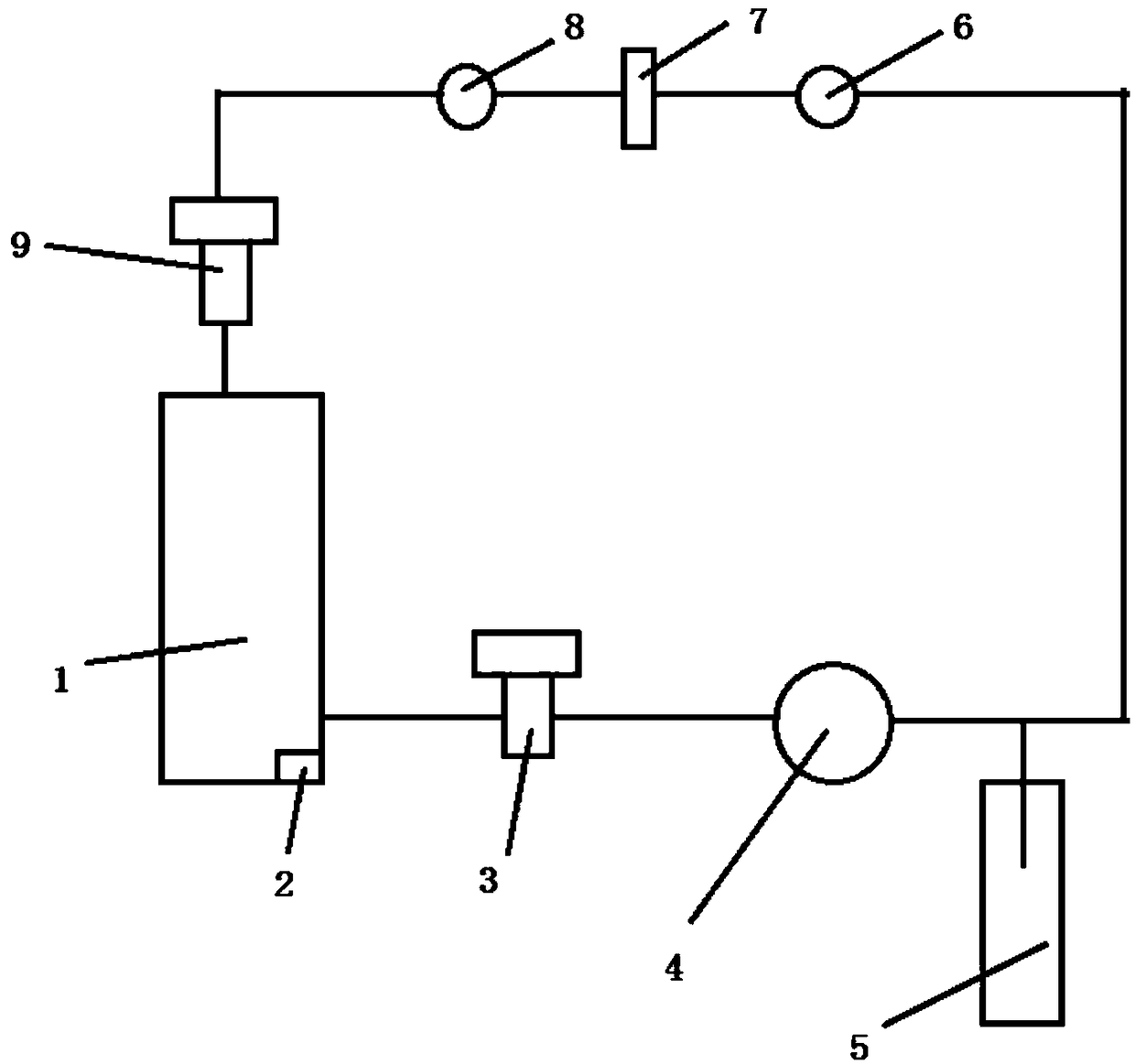

[0032] Refer to attached Figures 1 to 2 , the embodiments of the present invention will be described in detail.

[0033] The device and method for calibrating a flowmeter of a grouting unit include the following steps:

[0034] Step 1: Initialize the calibration flag of the flowmeter and the full scale value of the flowmeter;

[0035] Step 2: When the storage interval of the recorder is reached, calculate the actual injection rate in the storage interval according to the reading of the low pressure sensor;

[0036] Step 3: Judging whether the slurry mixing system operates in the storage interval, if the slurry mixing system operates, initialize the initial slurry volume of the slurry mixing system and return to step 2;

[0037] Step 4: Determine whether the slurry volume injection rate of the system is a small injection rate. If it is not a small injection rate, return to step 2. If it is a small injection rate, set the full value of the slurry return flowmeter and set the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com