Patents

Literature

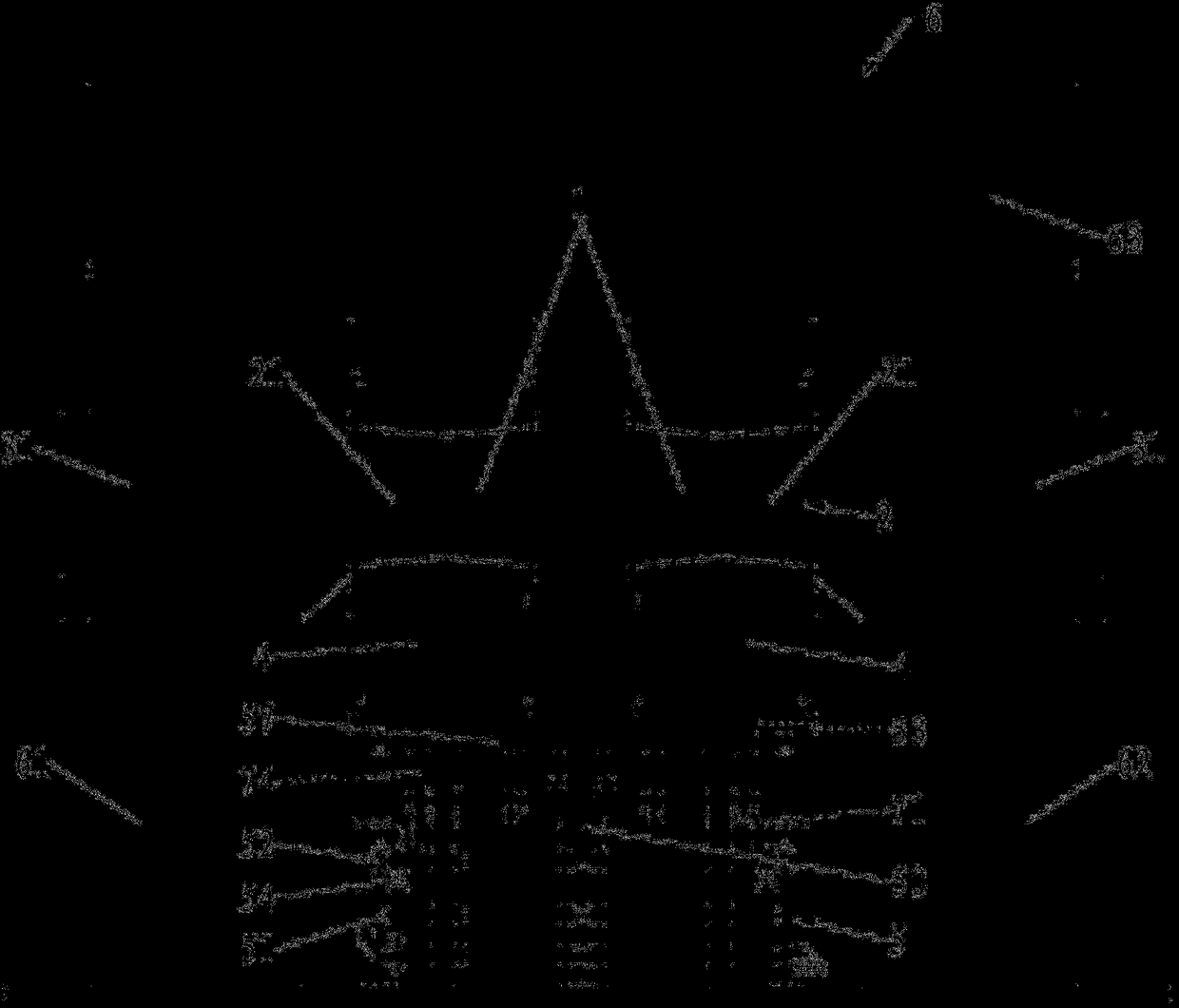

43results about How to "Reduce grouting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

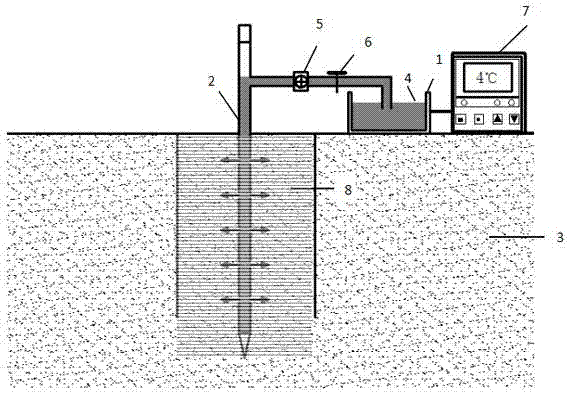

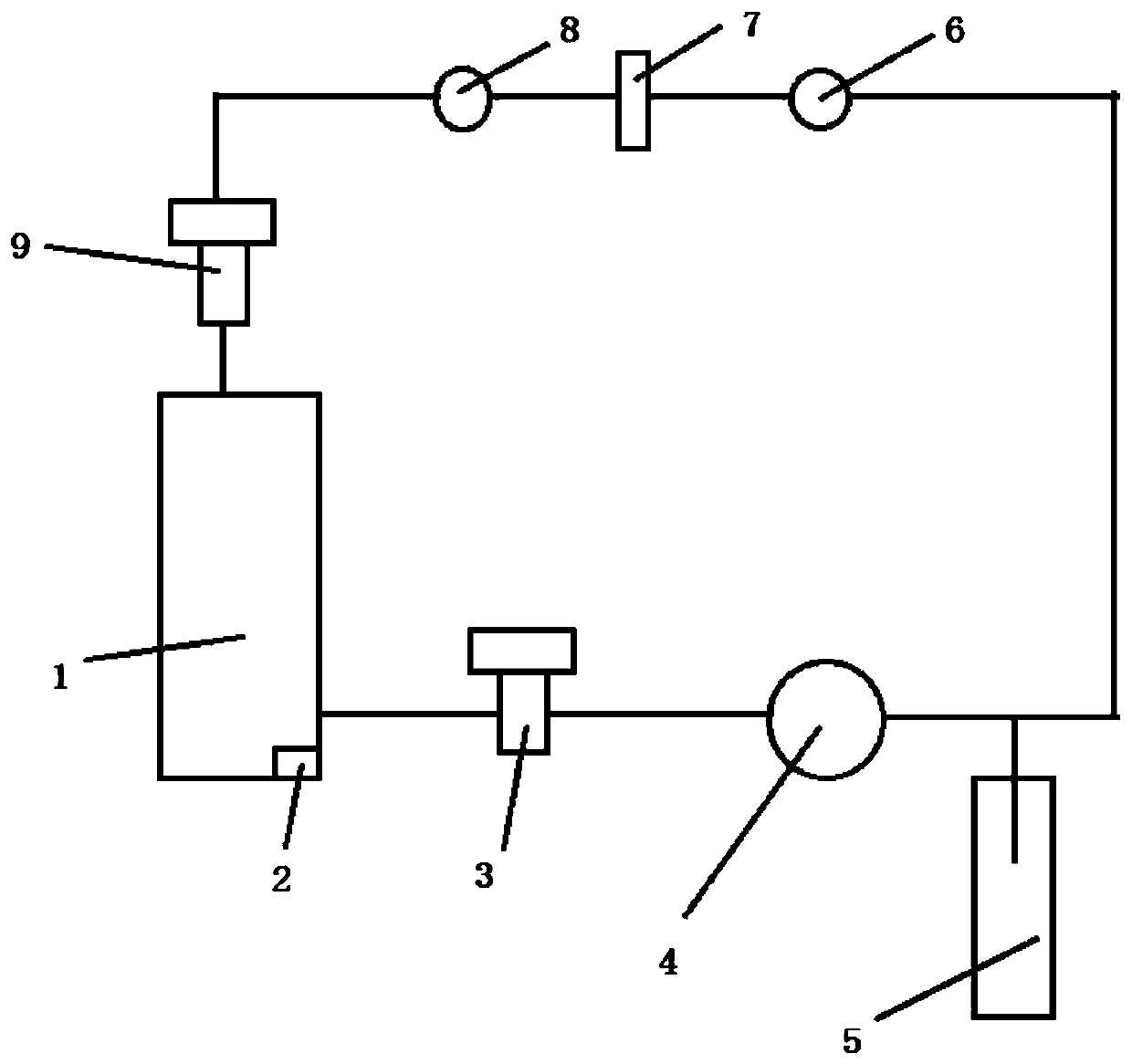

Microorganism low-temperature grouting and soil reinforcing method

ActiveCN105714765AImprove uniformityOvercome the problem of easy cloggingBuilding constructionsOrganic fertilisersMicroorganismChloride

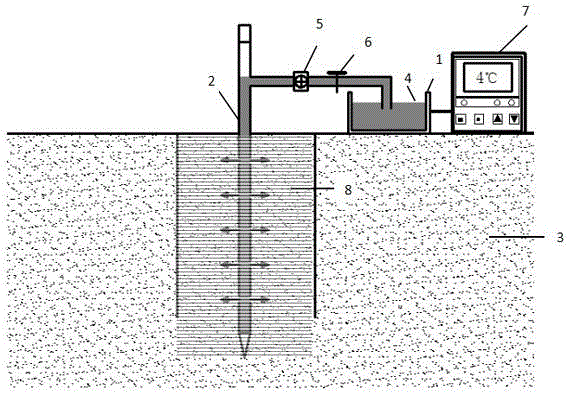

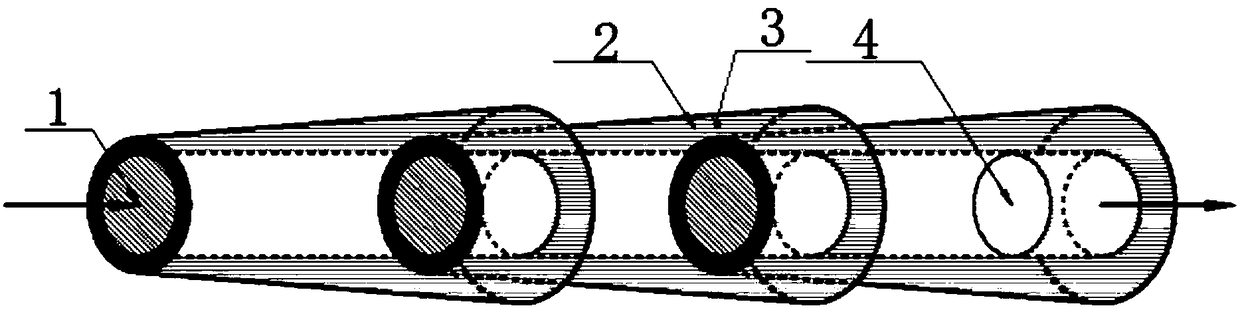

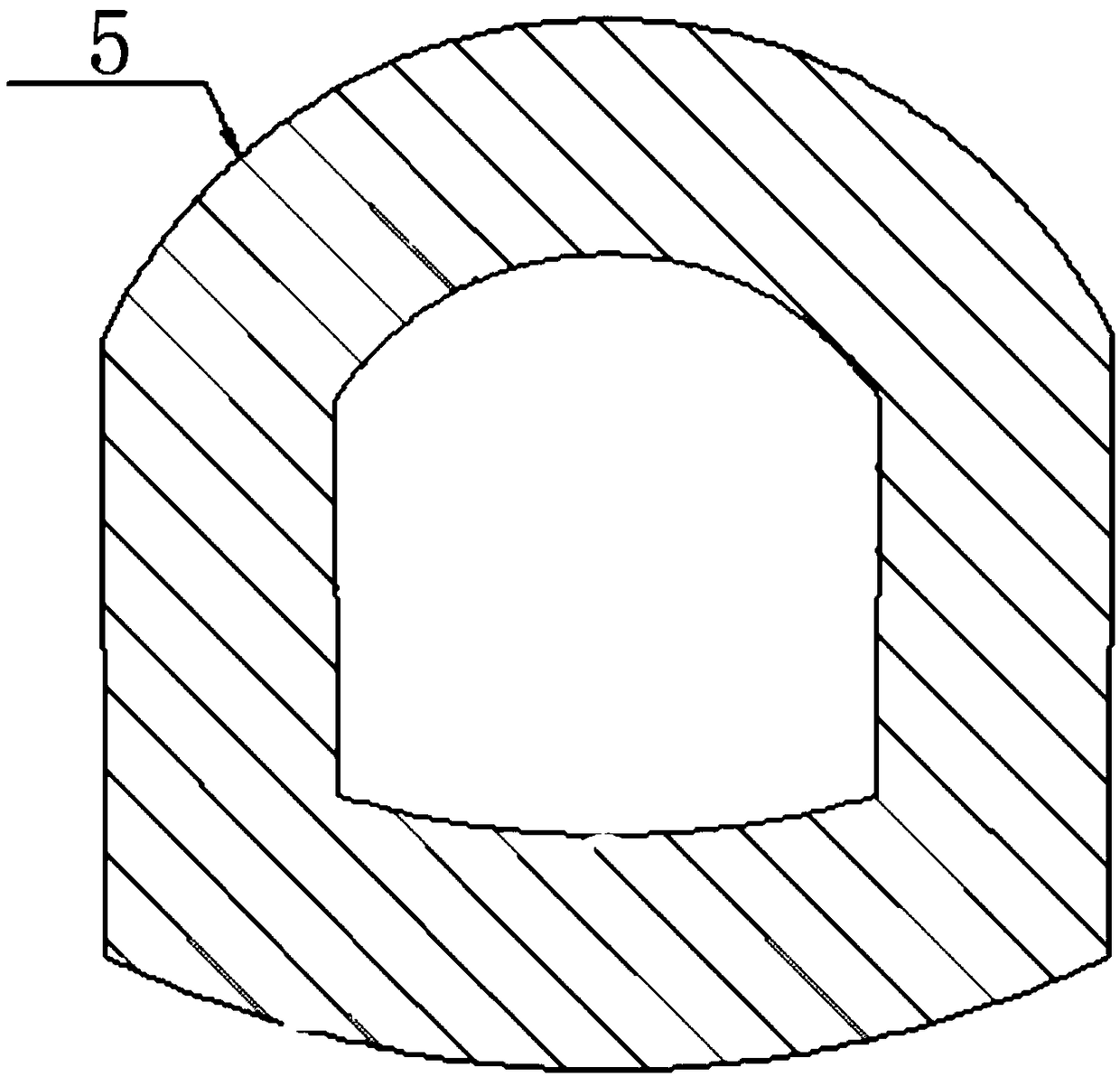

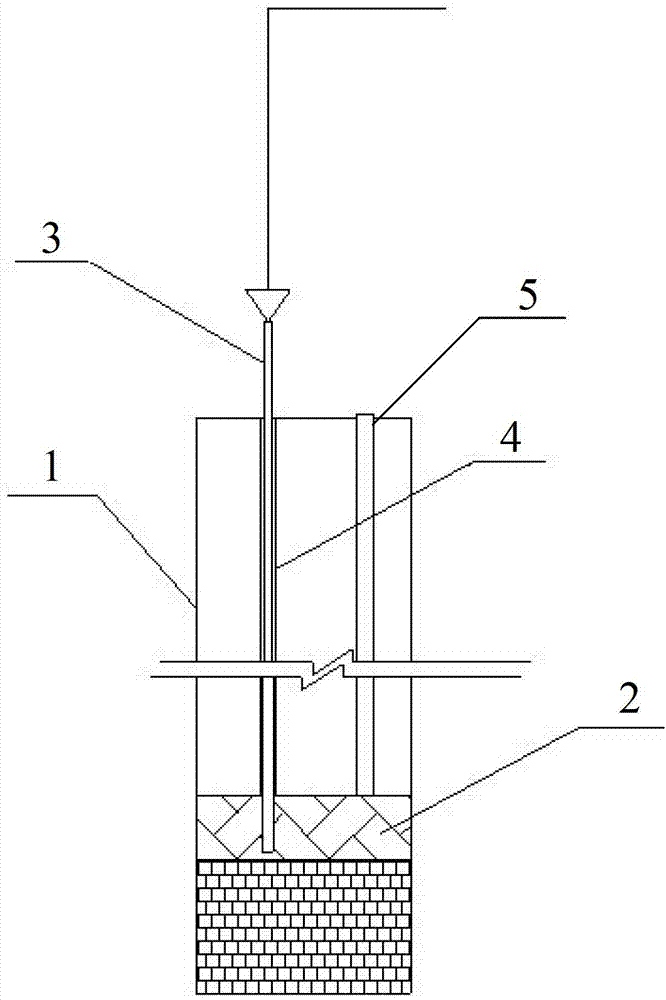

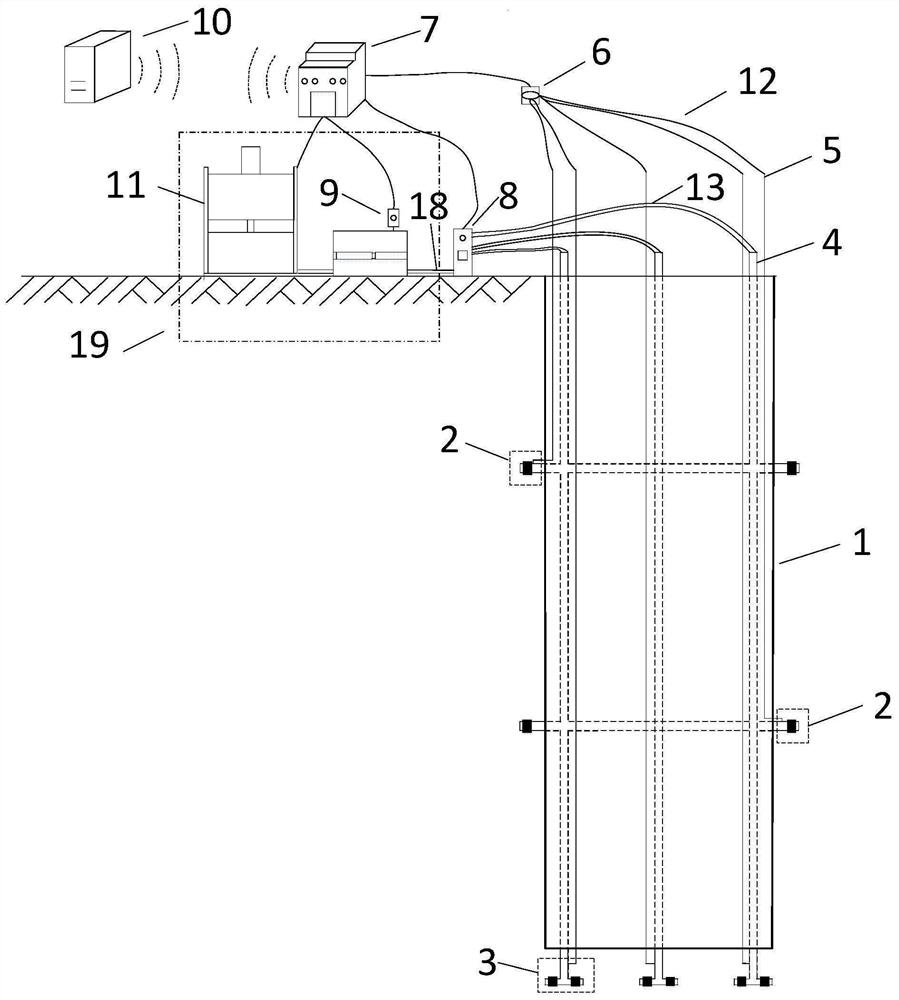

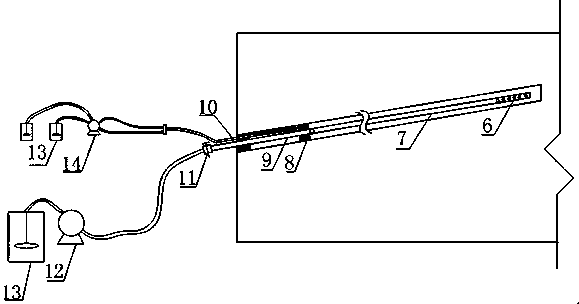

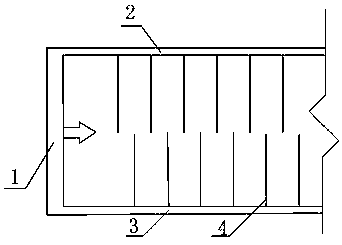

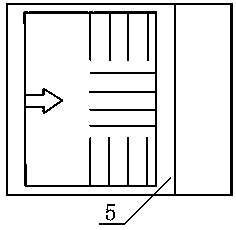

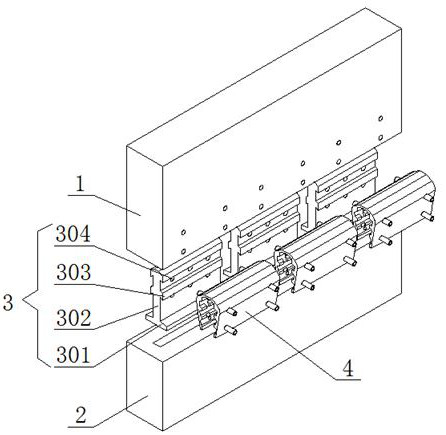

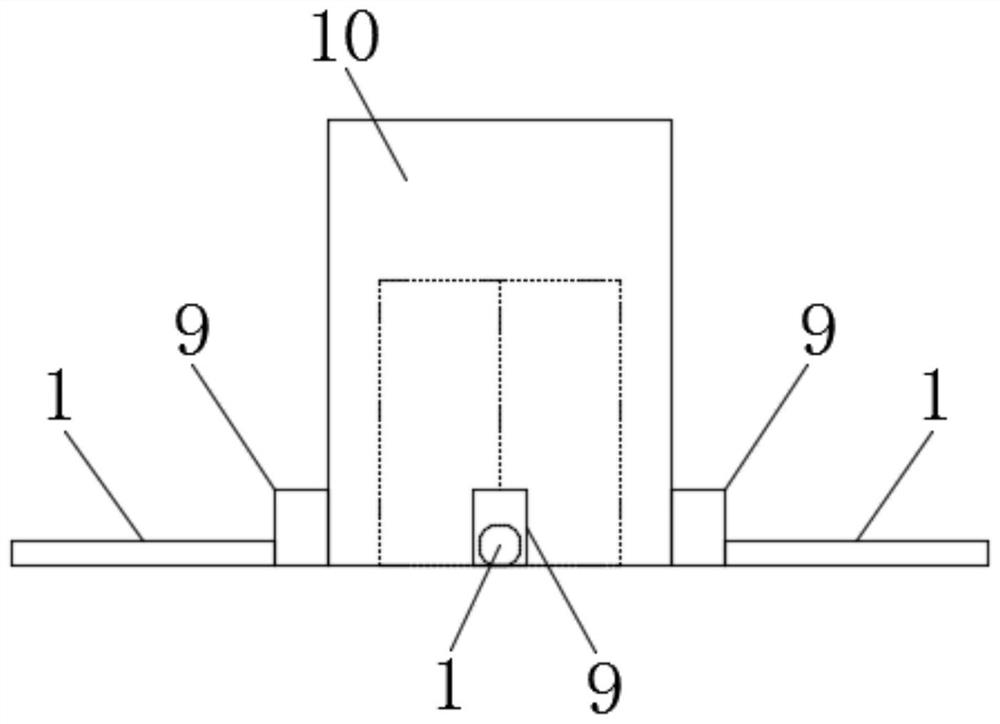

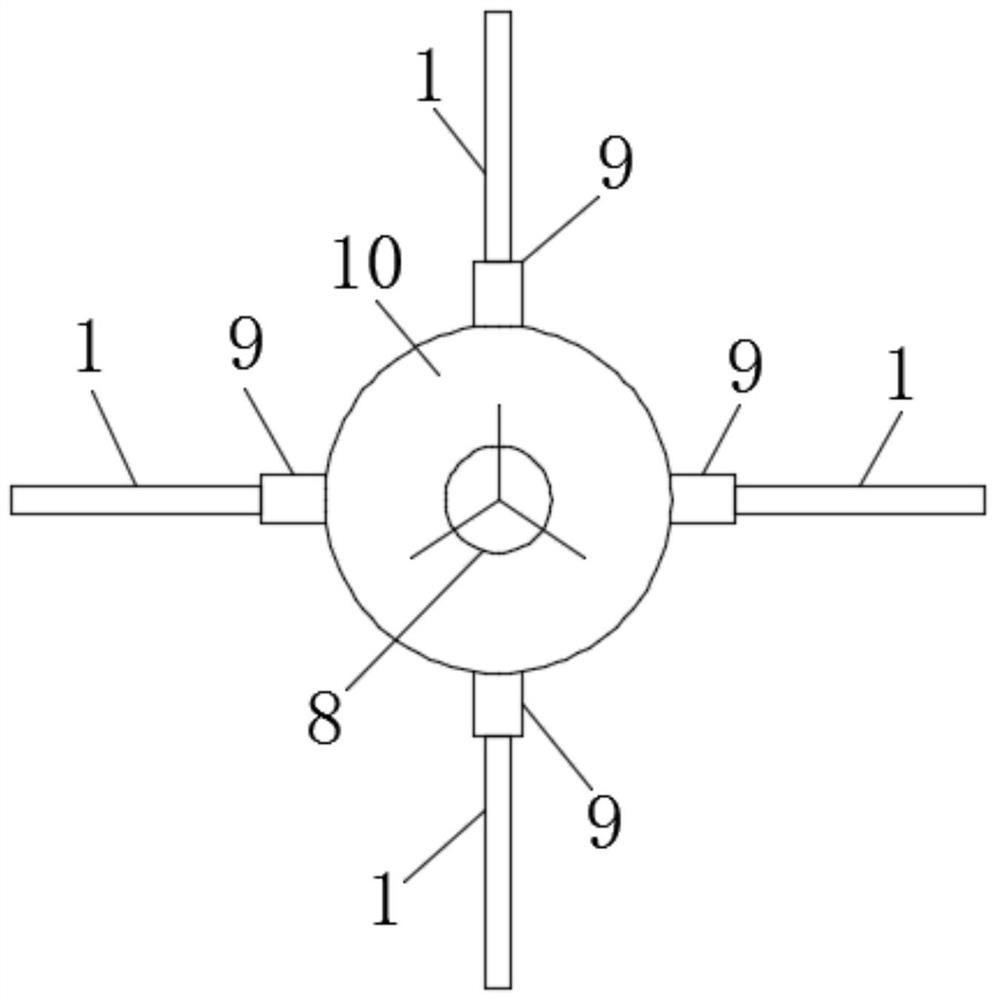

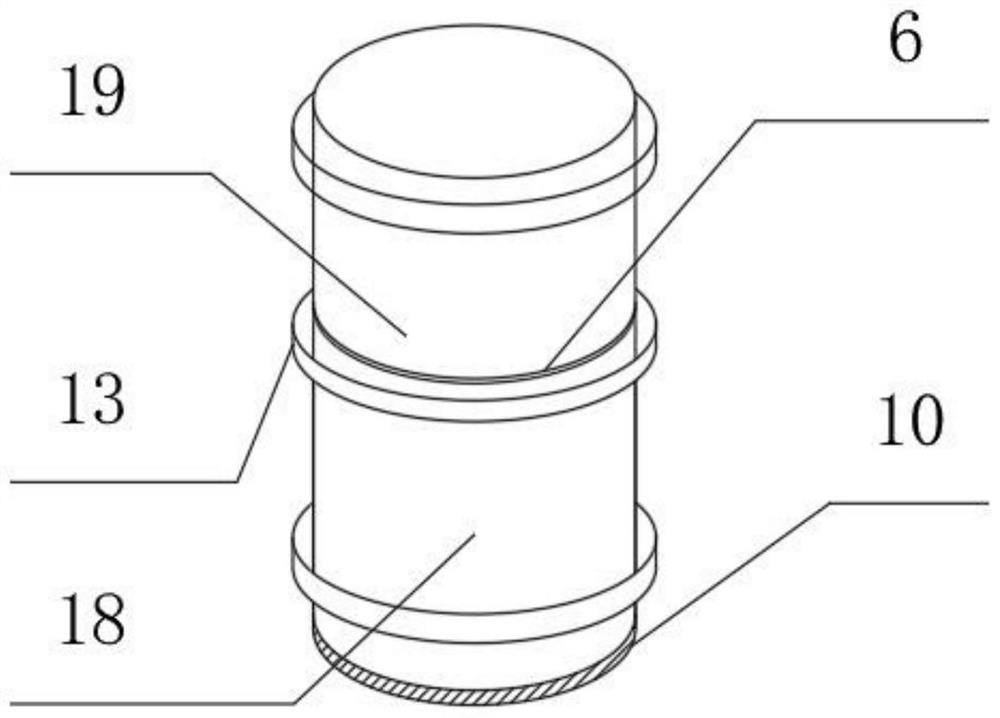

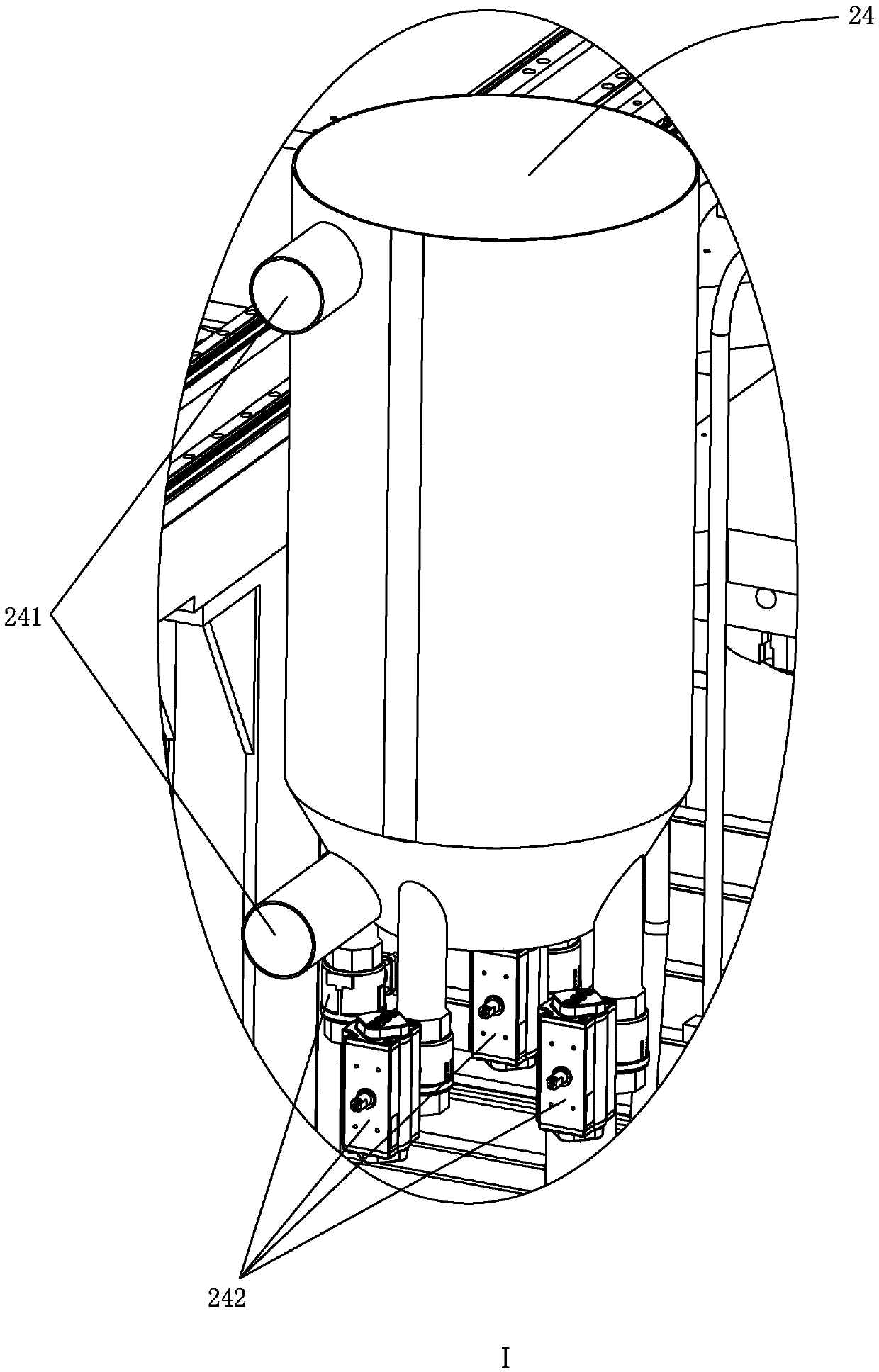

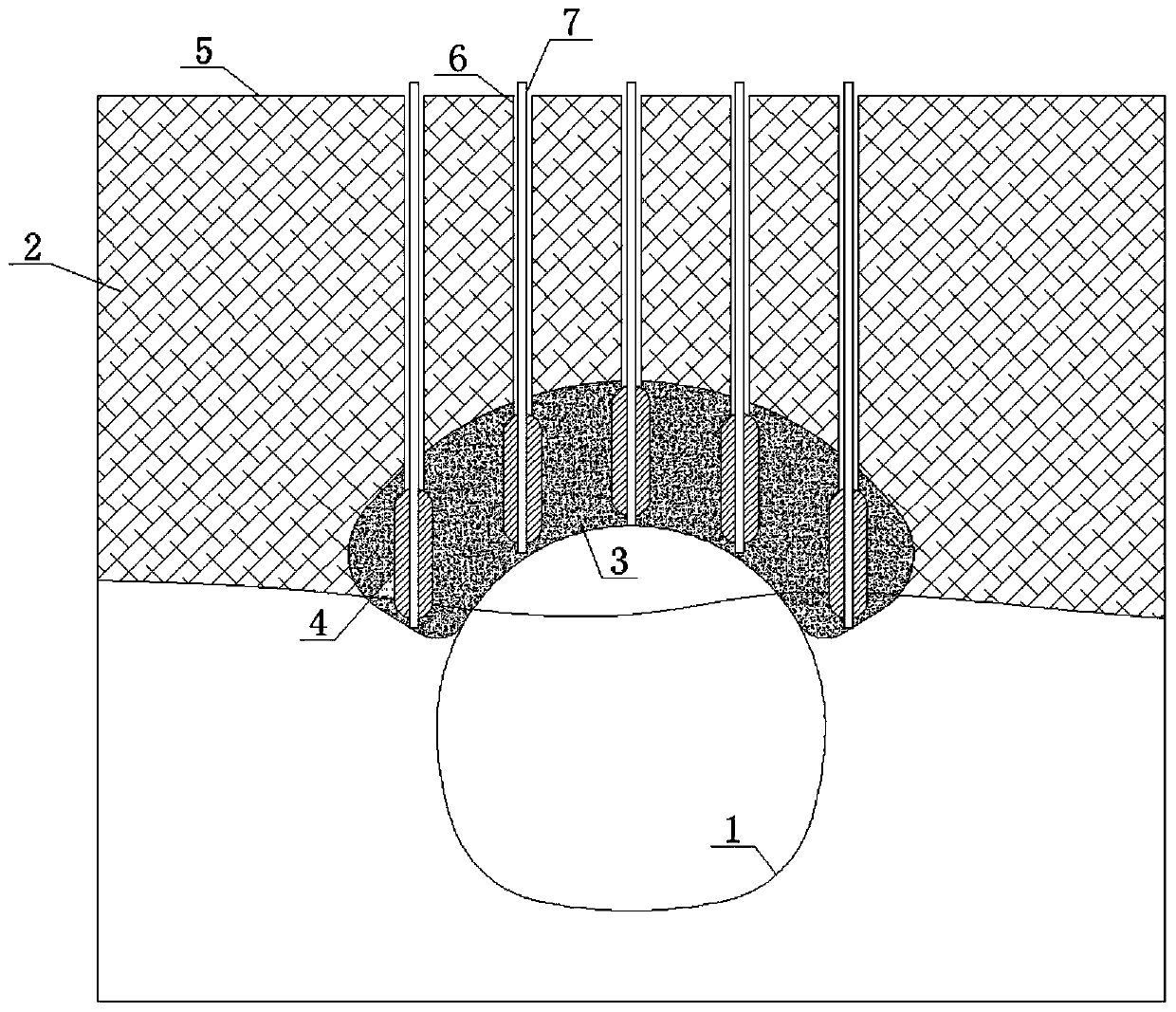

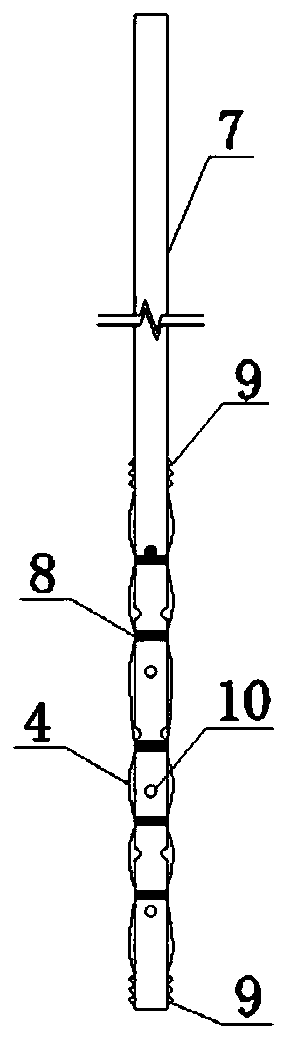

A microorganism low-temperature grouting and soil reinforcing method comprises the steps that a, a grouting shock tube 2 of a low-temperature grouting device is driven into a foundation 3; b, a microorganism with biological enzyme centrifugally separated out and removed is used for preparing low-temperature bacterium liquid at the temperature being 4 DEG C, the low-temperature bacterium liquid is mixed with mixed liquid of calcium chloride and urea at the temperature being 4 DEG C to prepare microorganism consolidating liquid, and the temperature is kept to be 4 DEG C, wherein the concentration OD600 of the bacterium liquid is about 1.2, the concentration of the calcium chloride of the mixed liquid ranges from 0.10 mol / L to 0.50 mol / L, and the concentration of the urea of the mixed liquid ranges from 0.10 mol / L-0.50 mol / L; c, the microorganism consolidating liquid 4 is poured into a to-be-cured soil body through a low-temperature grouting device composed of 1,2,5,6 and 7; d, after the temperature of the soil body obtained after grouting is increased to 15 DEG C and is subject to the constant temperature, standing is conducted for 1 h; and e, the step c and the step d are repeated, and grouting is stopped till the microorganism consolidating liquid cannot be injected into the soil body or the strength of the soil body meets the requirement.

Owner:NANJING FORESTRY UNIV

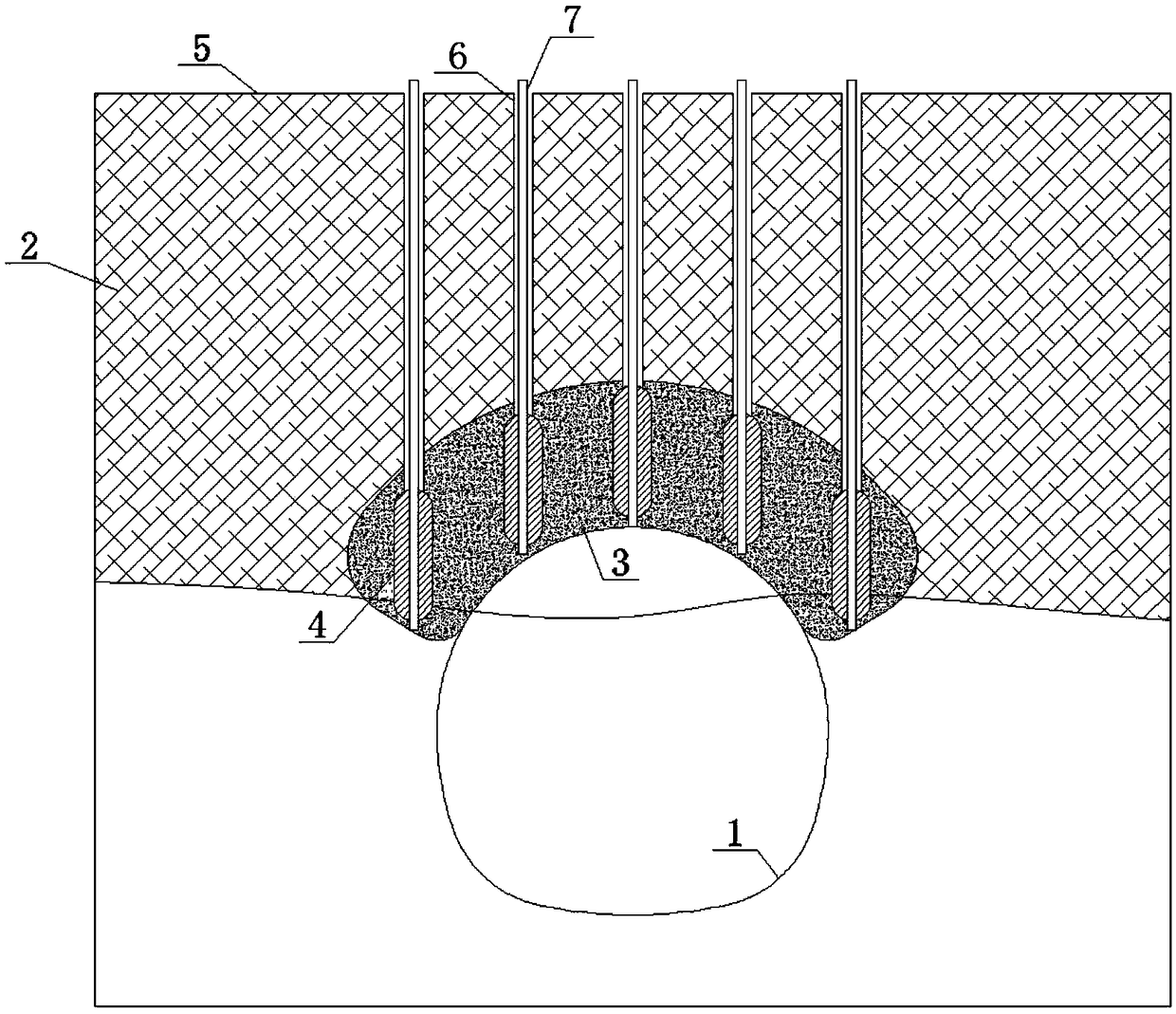

Method for advanced compaction grouting reinforcement of spongy stratum suitable for shallow-buried excavation tunnel

ActiveCN109162722AEffective reinforcementStrong mechanical propertiesUnderground chambersTunnel liningEarth surfaceGeotextile

The invention discloses a method for advanced compaction grouting reinforcement of a spongy stratum suitable for a shallow-buried excavation tunnel. The method comprises the following steps that: a stratum compaction performance of penetration of a tunnel into a spongy stratum is tested by the experiment and thus compaction degrees of the stratum under different grouting pressures as well as mechanical and anti-penetrability performances corresponding to different compaction degrees are determined; influences on tunnel excavation stability by the different stratum compaction degrees and grouting reinforcement ring thicknesses are analyzed, so that a target grouting pressure and a grouting reinforcement ring thickness are determined; a maximum expansion radius of an expansive soil geotextile bag and an earth surface grouting hole arrangement interval are determined; a grouting pipe with the expansive soil geotextile bag is made; grouting hole drilling work is carried out on the earth surface and the grouting pipe with the expansive soil geotextile bag is inserted after the grouting holes reache a predetermined depth; grouting is carried out by using a quick-setting grouting materialand grouting is stopped when the grouting pressure reaches the target grouting pressure; the gaps between the grouting pipe and the grouting holes are filled and sealed; and grouting work of all grouting holes is completed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Cup-type pre-grouting reinforcing method for full-section curtain grouting

InactiveCN109441482AObvious duration benefitSatisfy securityUnderground chambersTunnel liningDeep holeContour line

The invention discloses a cup-type pre-grouting reinforcing method for full-section curtain grouting. Through water-stop laccolith, namely the cup bottom formed by a surrounding curtain and the centerhole bottom which are grouted, the surrounding curtain comprises an arch part pipe curtain, a cup-type three-dimensional water-stop reinforcing ring is constituted, 10 m of grout-stop laccolith is reserved before entering a fault, an arch part is subjected to advanced pipe shed grouting within the range of 120 degrees to form the pipe curtain, and remaining surrounding holes are subjected to sectional retreating-type deep hole grouting to form a water-stop reinforcing curtain with the periphery of the contour line being excavated by 360 degrees. Cup-type pre-grouting construction of the method has three cycles; the consumed time of cup-type grouting of each cycle is reduced compared with the full-section curtain grouting time, and the construction period benefits are obvious; cup-type grouting and curtain grouting schemes both meet the requirements of safety and feasibility, but the cost and the construction period of curtain grouting are both not accepted, and cup-type grouting has the obvious advantages; and thus, the cup-type pre-grouting reinforcing method for full-section curtain grouting has the more obvious construction period benefits.

Owner:CHINA FIRST HIGHWAY ENG

Method for directed induction fracturing grouting in shallow tunnel

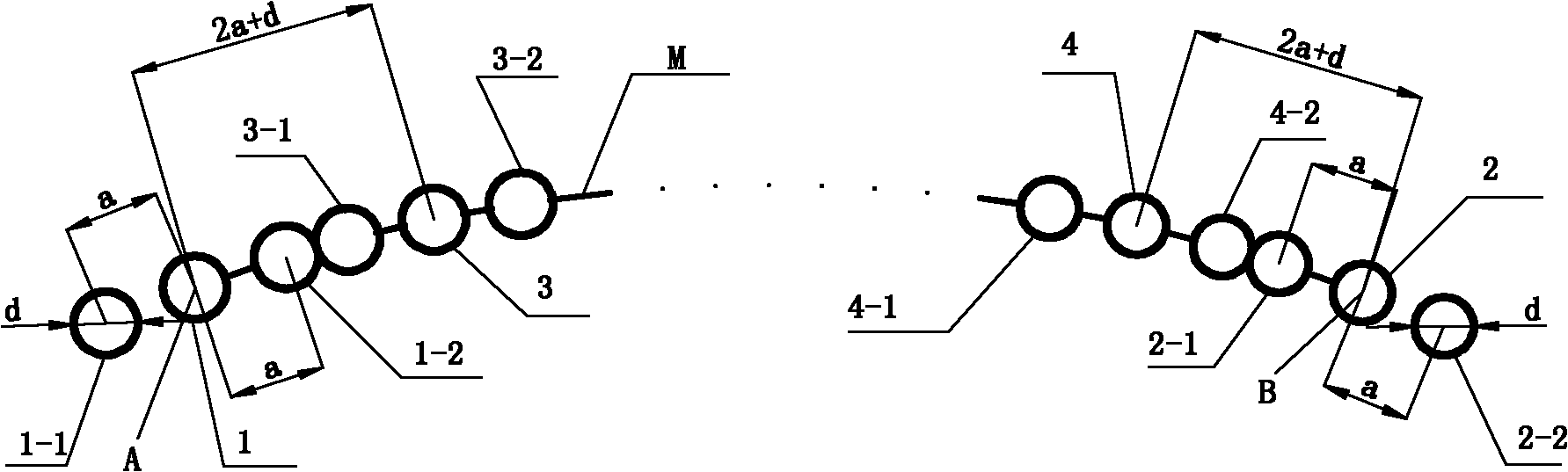

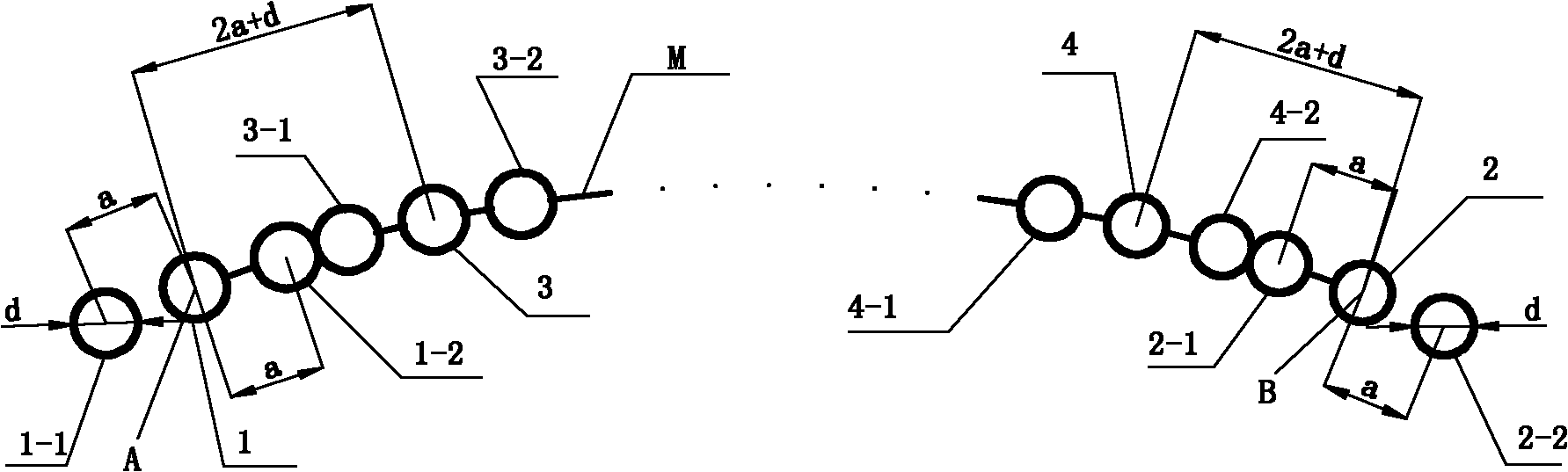

The invention discloses a method for directed induction fracturing grouting in a shallow tunnel, which belongs to the field of tunnel and underground engineering. The directed induction fracturing grouting is performed by the method, so that the grouting aim of economic, safe and effective water-blocked reinforcement is fulfilled. The method comprises the following steps of: drilling a first grouting hole at one end point (A) of a grouting profile line, drilling a first inducing hole and a second inducing hole respectively at positions which are 1.5d to 2d away from the two sides of the grouting hole, sealing, grouting to the grouting hole, and fracturing on the connecting lines of the grouting hole and the circle centers of the two inducing holes; and drilling a hole by the same method at the other end point (B) of the grouting profile line, and grouting so as to realize directed grouting. A third grouting hole is drilled at a position which is 4d to 5d away from the first grouting hole, and the process which is performed on the first grouting hole is repeated in the same way, so that the slurry of the inducing holes can be connected; the overall grouting profile line is accomplished according to the processes, so that the overall grouting curtain can be formed; and a fracturing direction in the fracturing grouting is started from a designed direction, so that the limited slurry can be injected into the position at which the slurry is most needed by only fracturing for one time.

Owner:BEIJING JIAOTONG UNIV

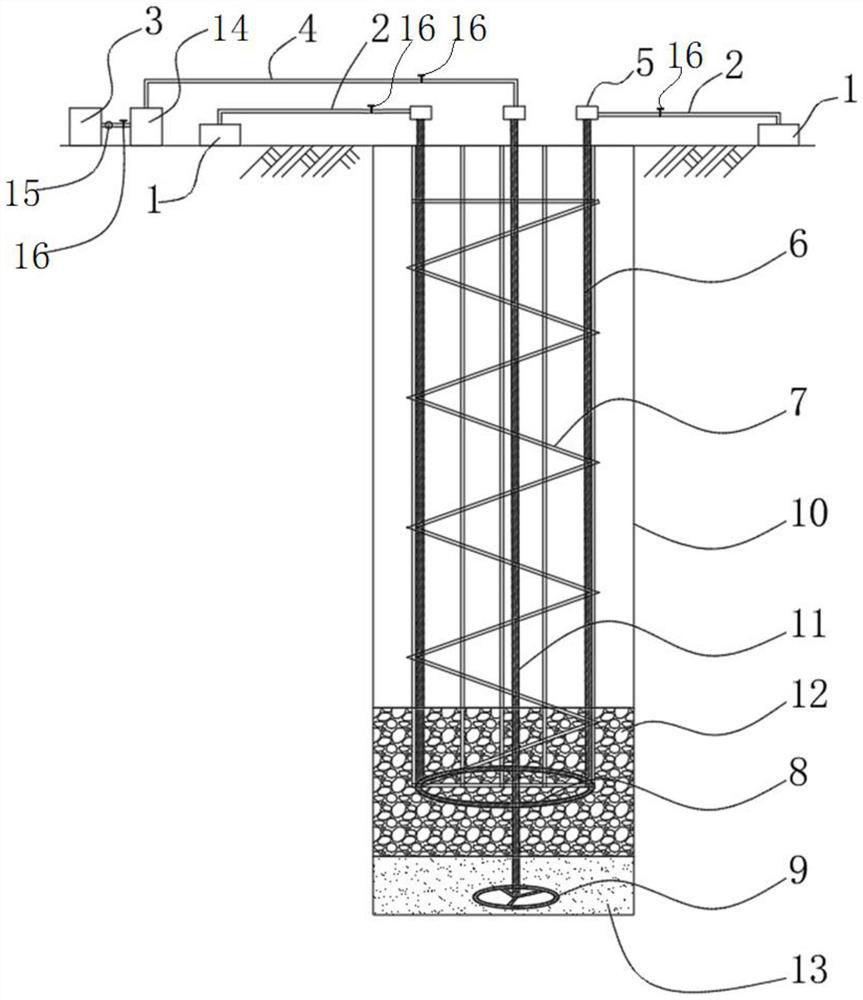

Pile foundation grouting pressure testing device and method based on optical fiber sensing

ActiveCN113513054APrecise and effective groutingGuaranteed reliabilityFoundation testingClassical mechanicsData acquisition

The invention discloses a pile foundation grouting pressure testing device and method based on optical fiber sensing. The device comprises a reinforcement cage, a pile end inverted-T-shaped grouting device and a high-pressure elastic capsule with an optical fiber type pressure sensor, wherein the high-pressure elastic capsule is externally connected with an oil pump through a high-pressure oil pipe to be filled with high-pressure oil, the elastic capsule is completely expanded to be in effective contact with grout in the grouting process, the optical fiber type pressure sensor and a data acquisition instrument in the high-pressure elastic capsule are used for monitoring and storing the dynamic change of the oil pressure in the high-pressure elastic capsule in real time, and the dynamic change is transmitted to a background processor. The problems that the pile foundation grouting pressure is accurately determined and is interfered by human factors can be effectively solved, grouting pressure parameters can be adjusted through the obtained accurate grouting pressure, and the grouting reliability is guaranteed; and secondly, unified standard accumulation test data can be formed for accurate calculation of the grouting pressure of a pile end grout outlet, and a reference basis is provided for analyzing the upward-returning height of the pile end pressure grout.

Owner:江苏中云筑智慧运维研究院有限公司 +1

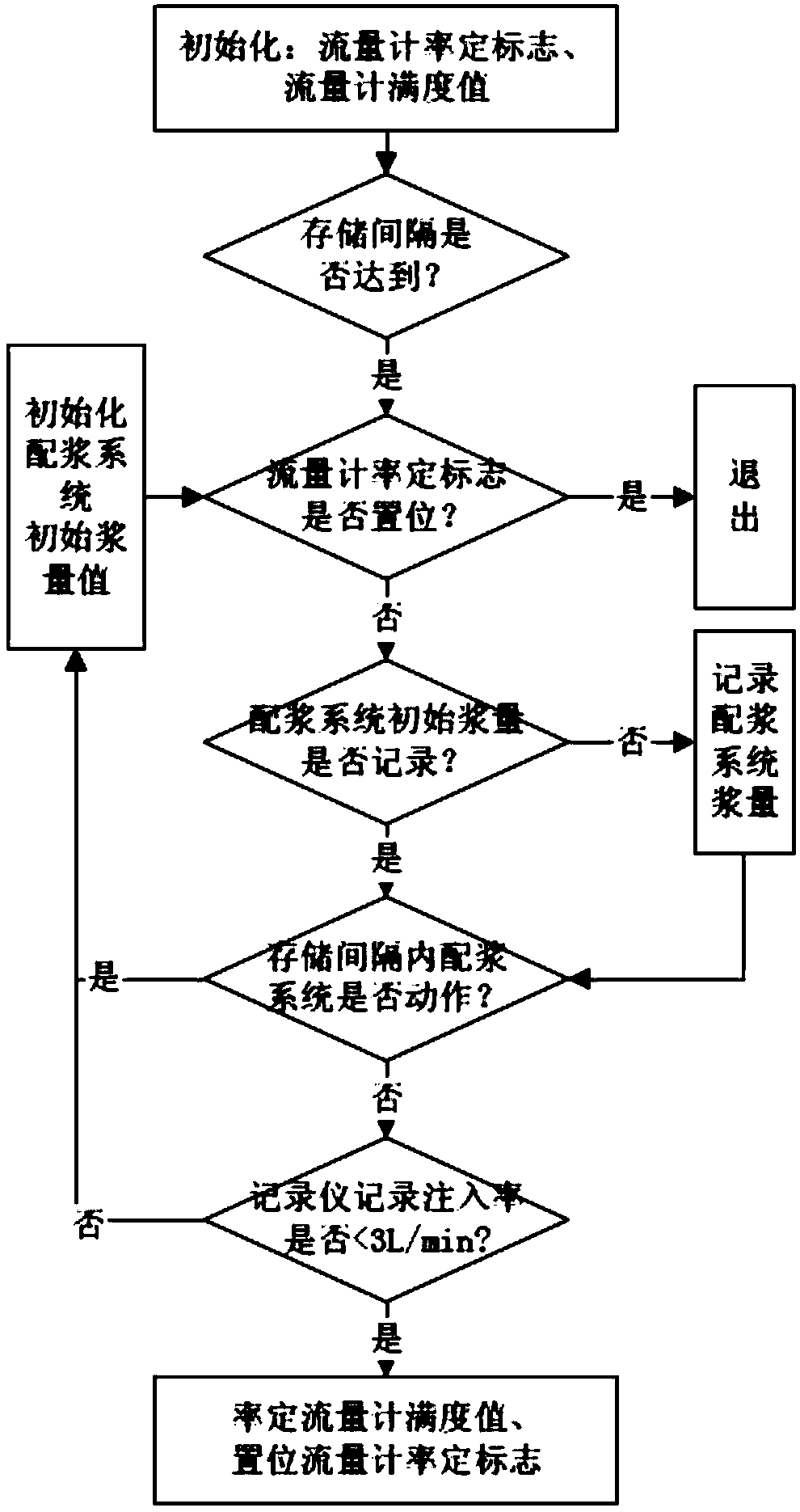

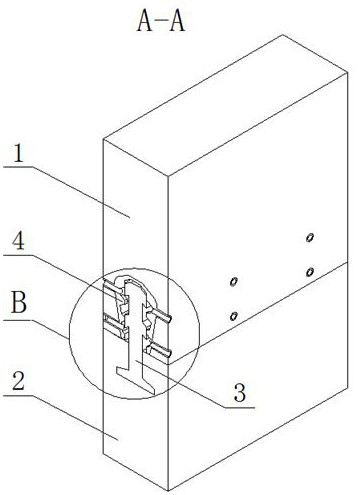

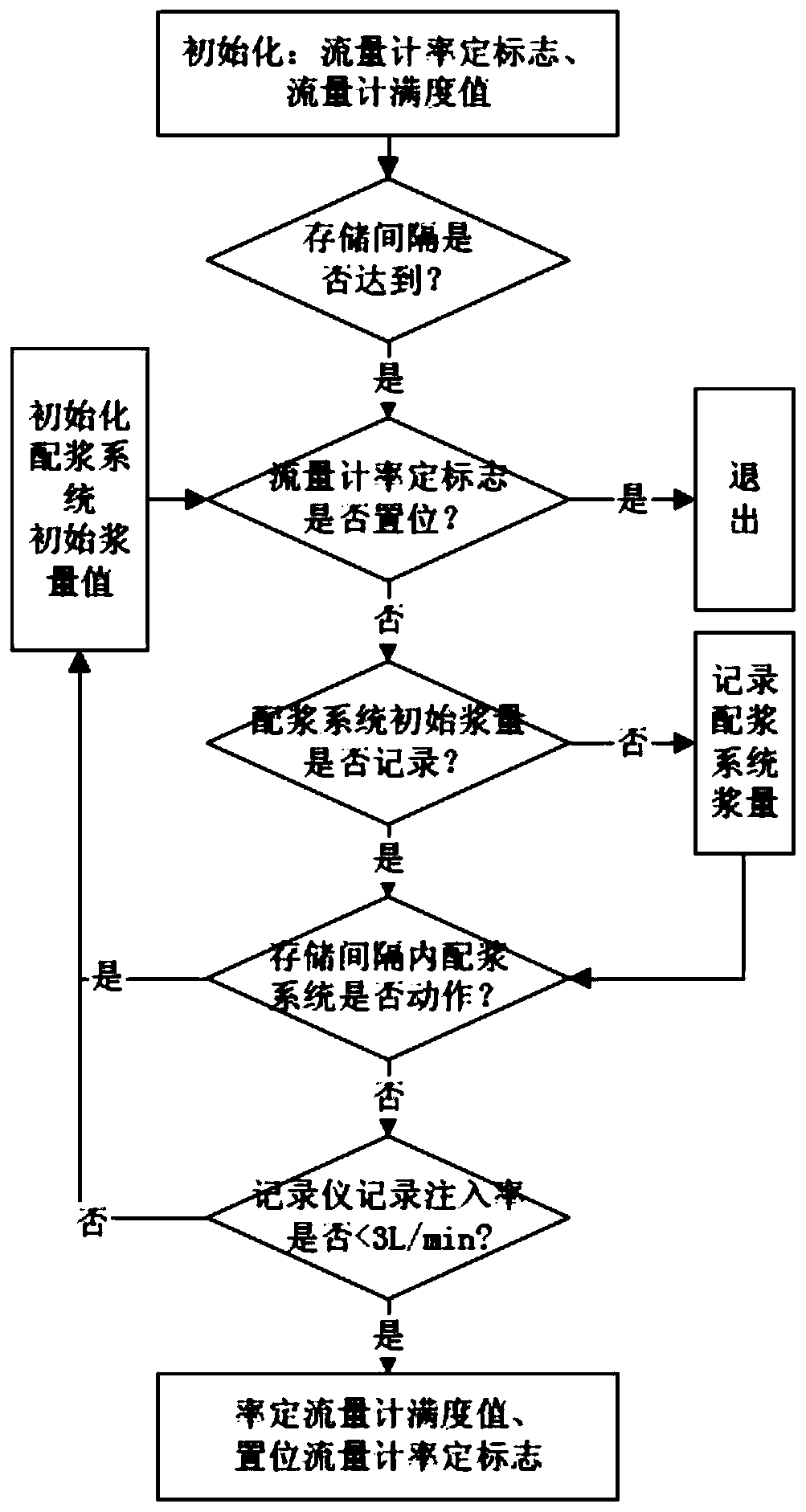

Grouting unit flowmeter calibration device and method

ActiveCN108801404AIncrease the level of automationReduce supervisory interventionTesting/calibration for volume flowFull scaleUltimate tensile strength

The invention discloses a grouting unit flowmeter calibration device and method. The method includes the following steps that a flowmeter calibration mark and a flowmeter full-scale value are initialized; when the storage interval of a recorder is reached, the grouting amount during the storage interval is recorded; whether a pulp preparation system runs during the storage interval is judged, if the pulp preparation system runs, the initial pulp amount of the pulp preparation system is initialized, and returning to the step 2 is executed; whether the pulp injection rate of the system is a small injection rate or not is judged, if the pulp injection rate of the system is not the small injection rate, returning to the step 2 is executed, if the pulp injection rate of the system is the smallinjection rate, the flowmeter full-scale value is calibrated and the flowmeter calibration mark is set. According to the device and the method, machines can be used for automatically measuring the grouting amount of a grouting barrel, the flowmeter is automatically calibrated, the automation level of a site can be improved, supervision interference and work intensity are reduced, key quality points of grouting are controlled, the grouting quality is improved, the unnecessary grouting time is reduced and the grouting progress is improved.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +1

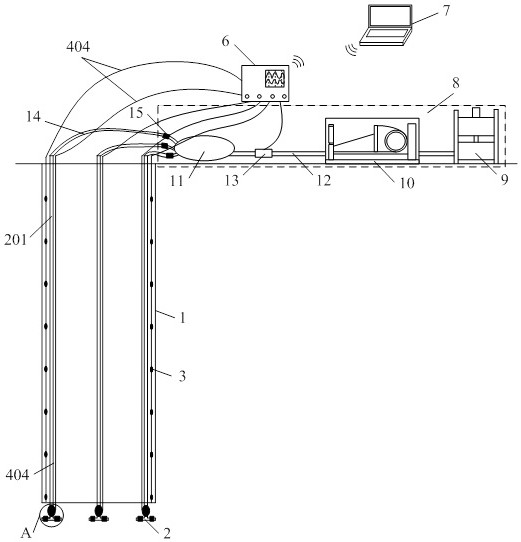

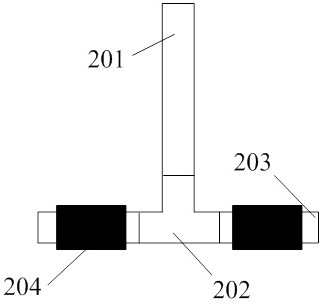

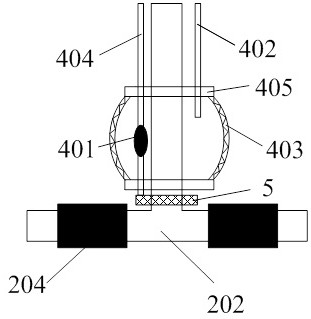

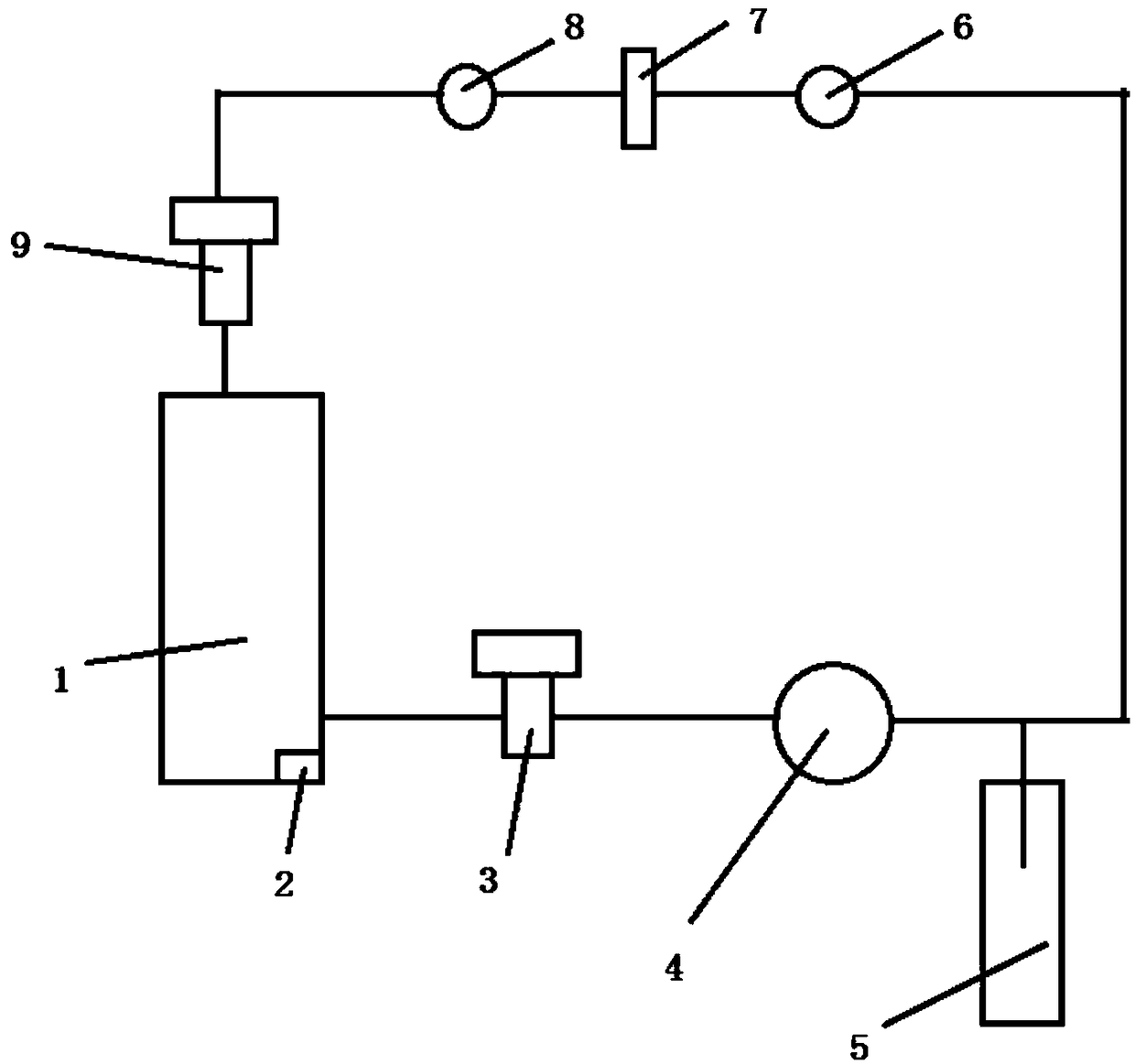

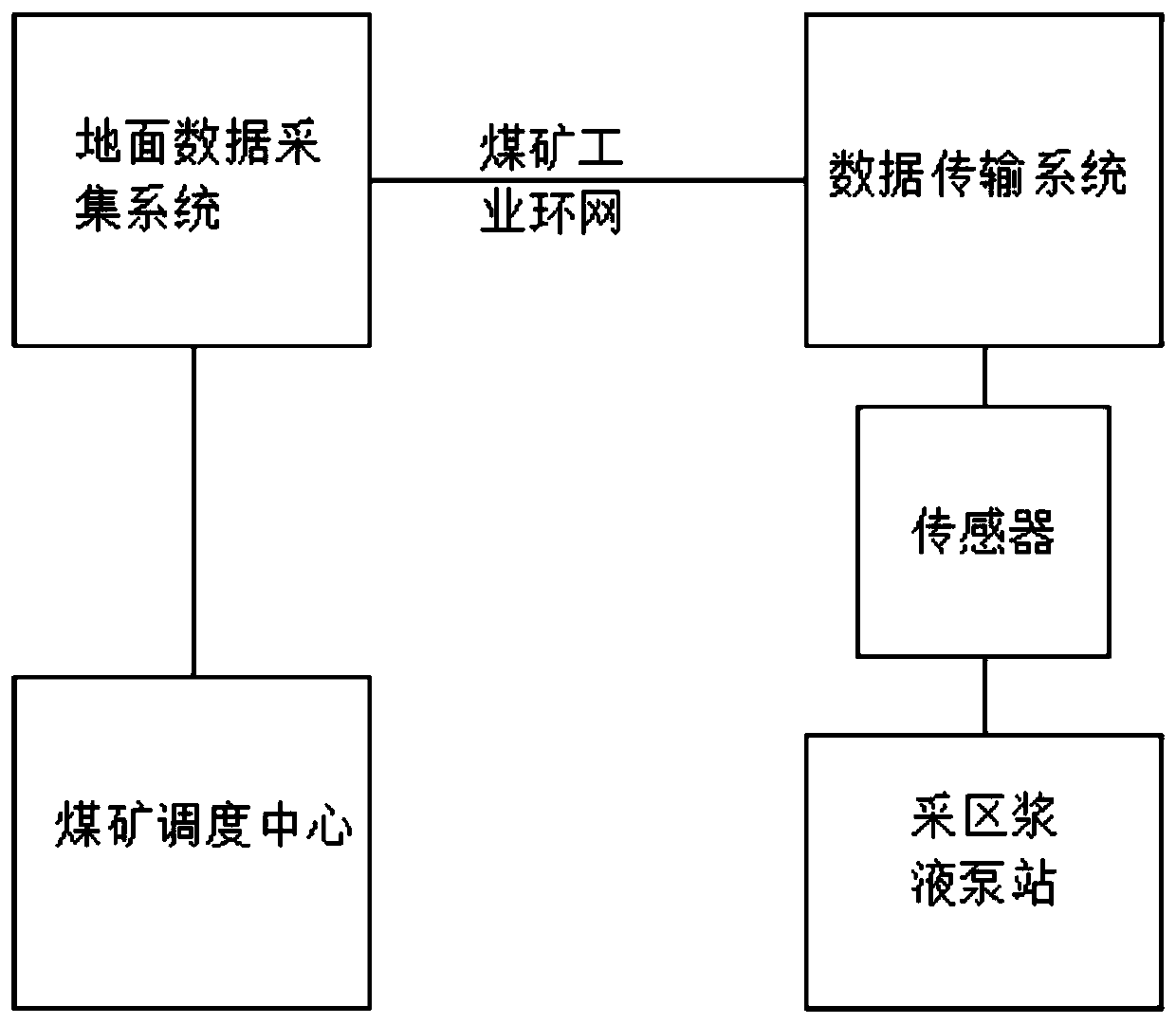

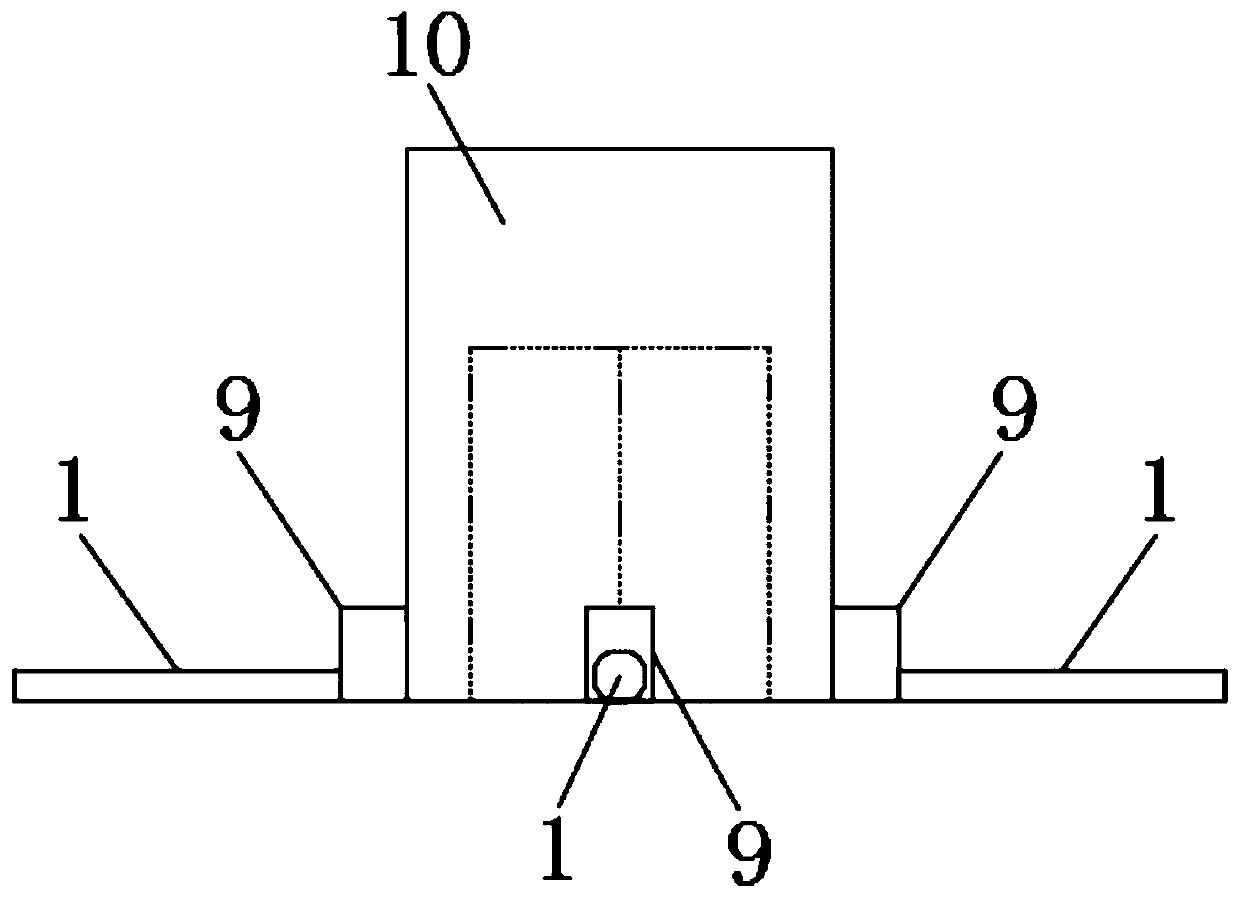

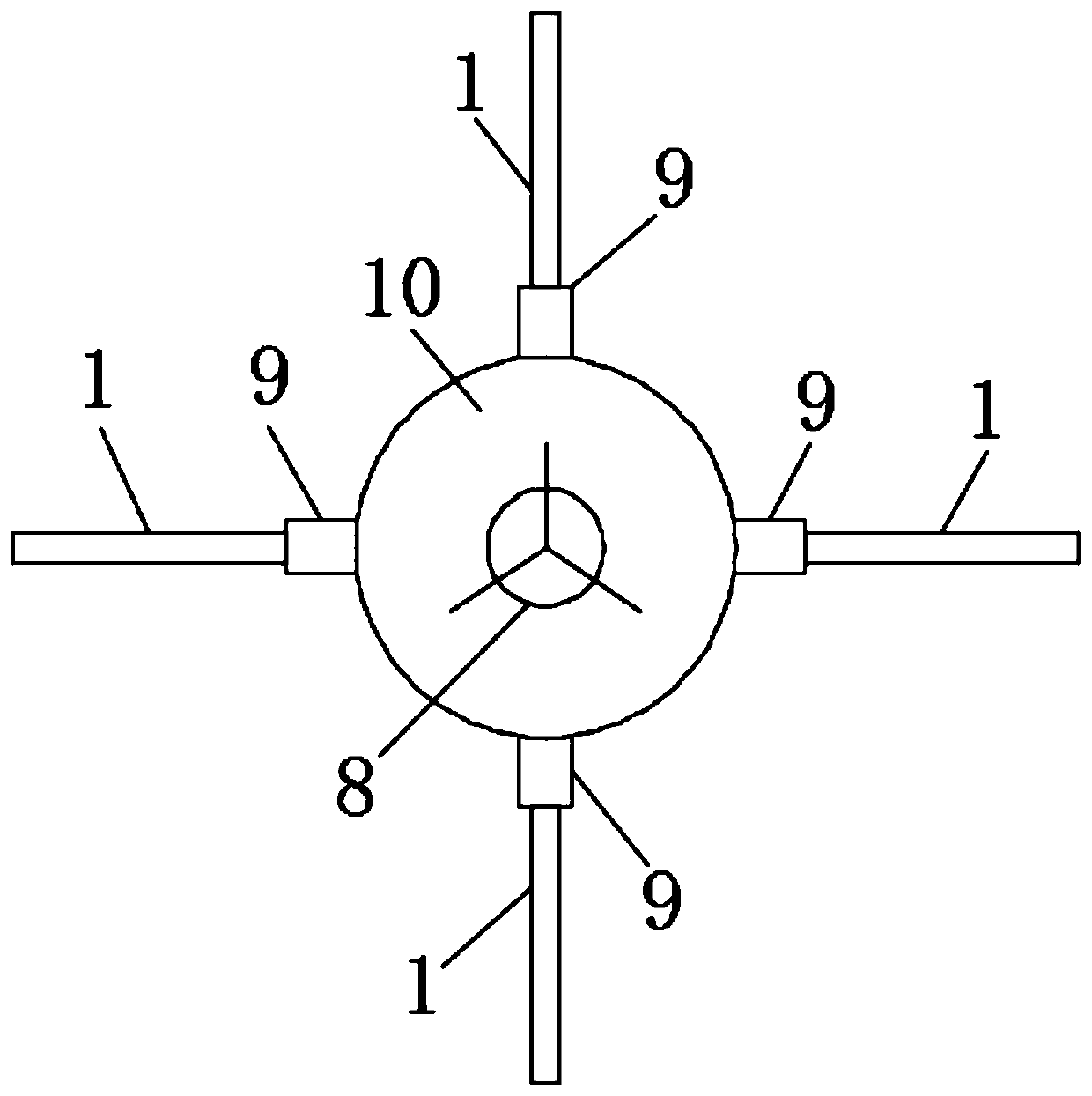

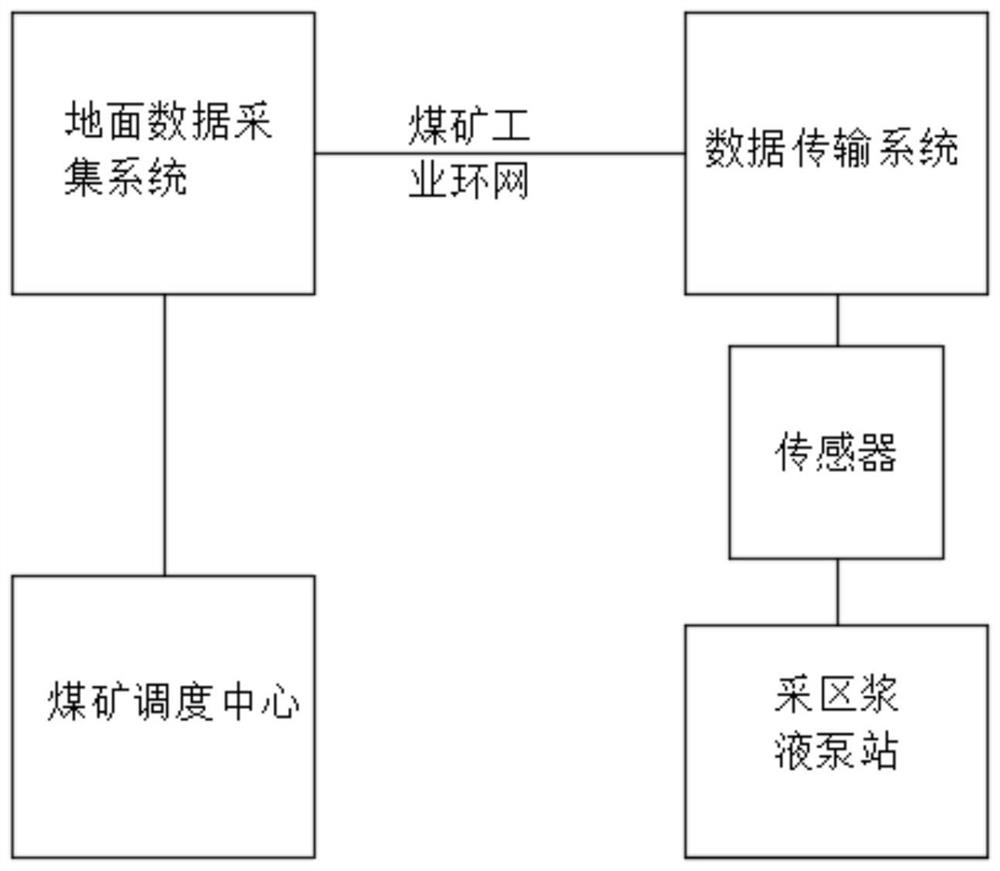

Intelligent and dynamic monitoring system for mine grouting and working method thereof

ActiveCN110118096AAvoid wastingSave resourcesMining devicesMeasurement devicesData acquisitionDynamic monitoring

The invention discloses an intelligent and dynamic monitoring system for mine grouting and a working method thereof. The system comprises grouting pipes, a ball valve, a grout recovery pump, a high-precision intrinsic safety type pressure sensor, a high-precision intrinsic safety type flow sensor, a grouting anchor rod positioning system, a grouting anchor rod, a stirring device, a mining area grout pump station, a data transmission system, a ground data acquisition system and a coal mine dispatching center, wherein a plurality of grouting connectors are arranged on the periphery of the miningarea grout pump station, and the grouting pipes are arranged on the sides, deviating from the mining area grout pump station, of the grouting connectors separately. Through interaction of the ball valve, the high-precision intrinsic safety type pressure sensor, the high-precision intrinsic safety type flow sensor, the grouting anchor rod positioning system, the grouting anchor rod and a ground data acquisition system, grouting parameters are accurately collected in the grouting process, the grouting effect is detected in real time, and the grouting anchor rod which does not reach the standardcan be timely repaired.

Owner:新汶矿业集团有限责任公司孙村煤矿 +2

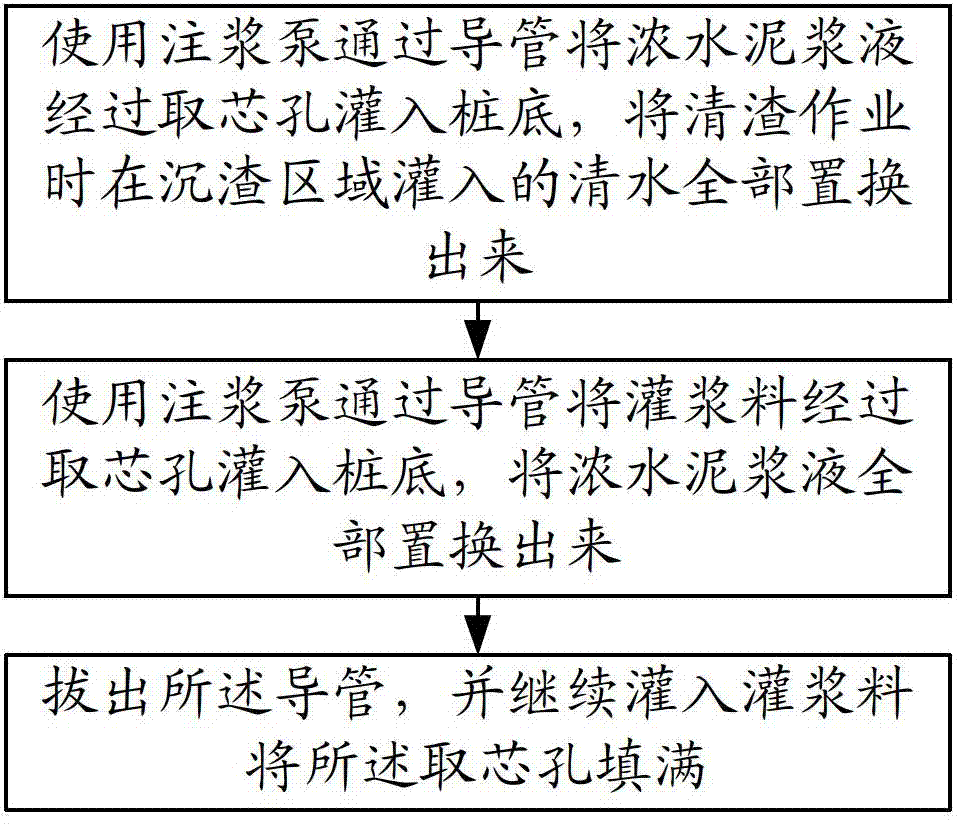

Pile bottom grouting method

ActiveCN103195062AImprove grouting efficiencyHigh vertical expansionFoundation engineeringCement slurryCement mortar

The invention provides a pile bottom grouting method. Grouting materials are utilized as pile bottom filling replacement materials to replace cement slurries, cement mortars or fine aggregate concretes. Compared with the cement slurries and the cement mortars, the grouting materials are large in vertical expansion ratio and high in strength; compared with the fine aggregate concretes, the grouting materials have pourable construction feasibility inside narrow and small holes; accordingly the grouting materials are capable of saving the grouting amount and grouting time when grouting operation is performed; and the pile bottom grouting efficiency is greatly improved.

Owner:SHANGHAI MECHANIZED CONSTR GRP

A kind of microbiological low-temperature grouting soil consolidation method

ActiveCN105714765BImprove uniformityOvercome the problem of easy cloggingBuilding constructionsOrganic fertilisersMicroorganismSoil science

Owner:NANJING FORESTRY UNIV

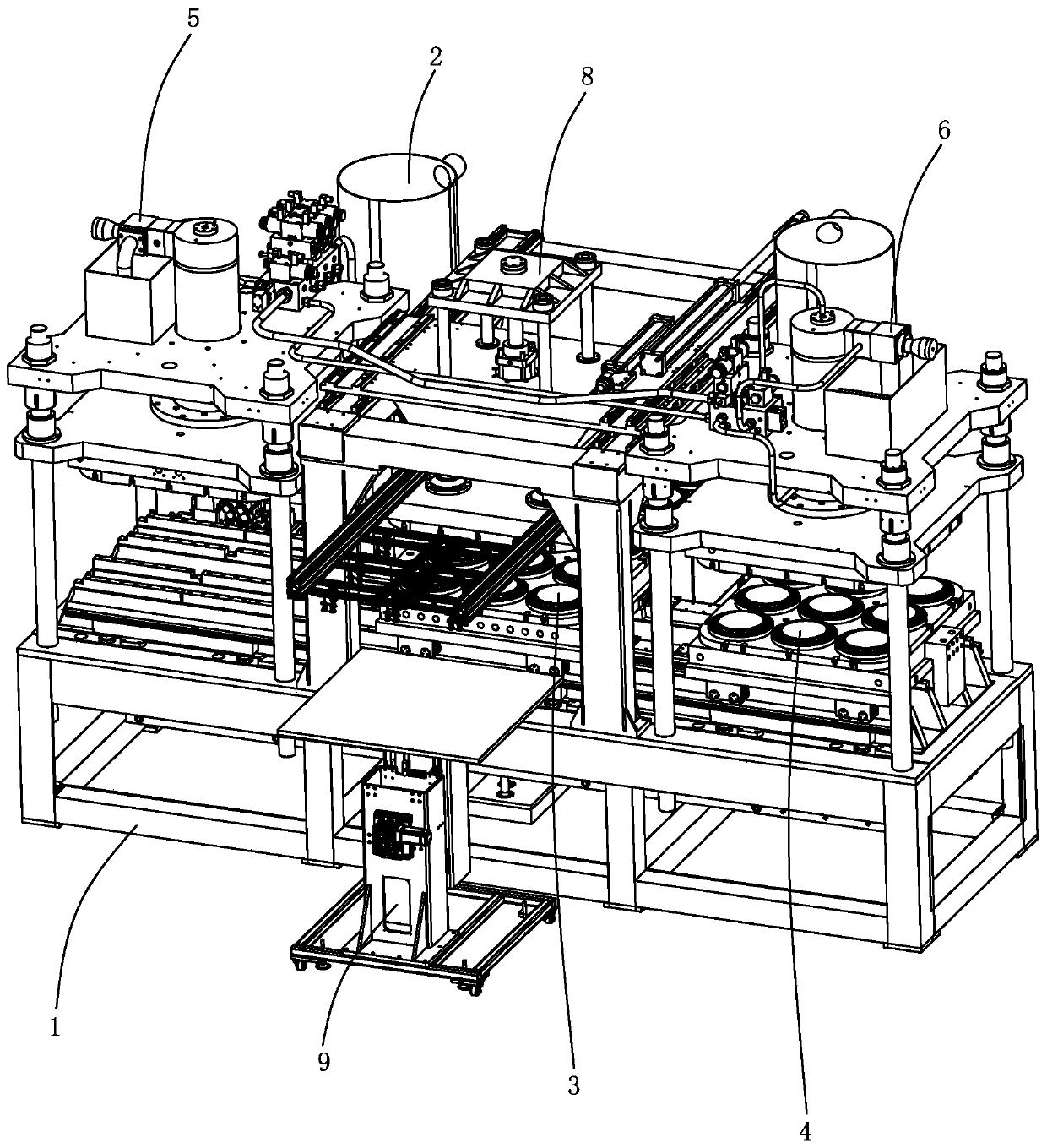

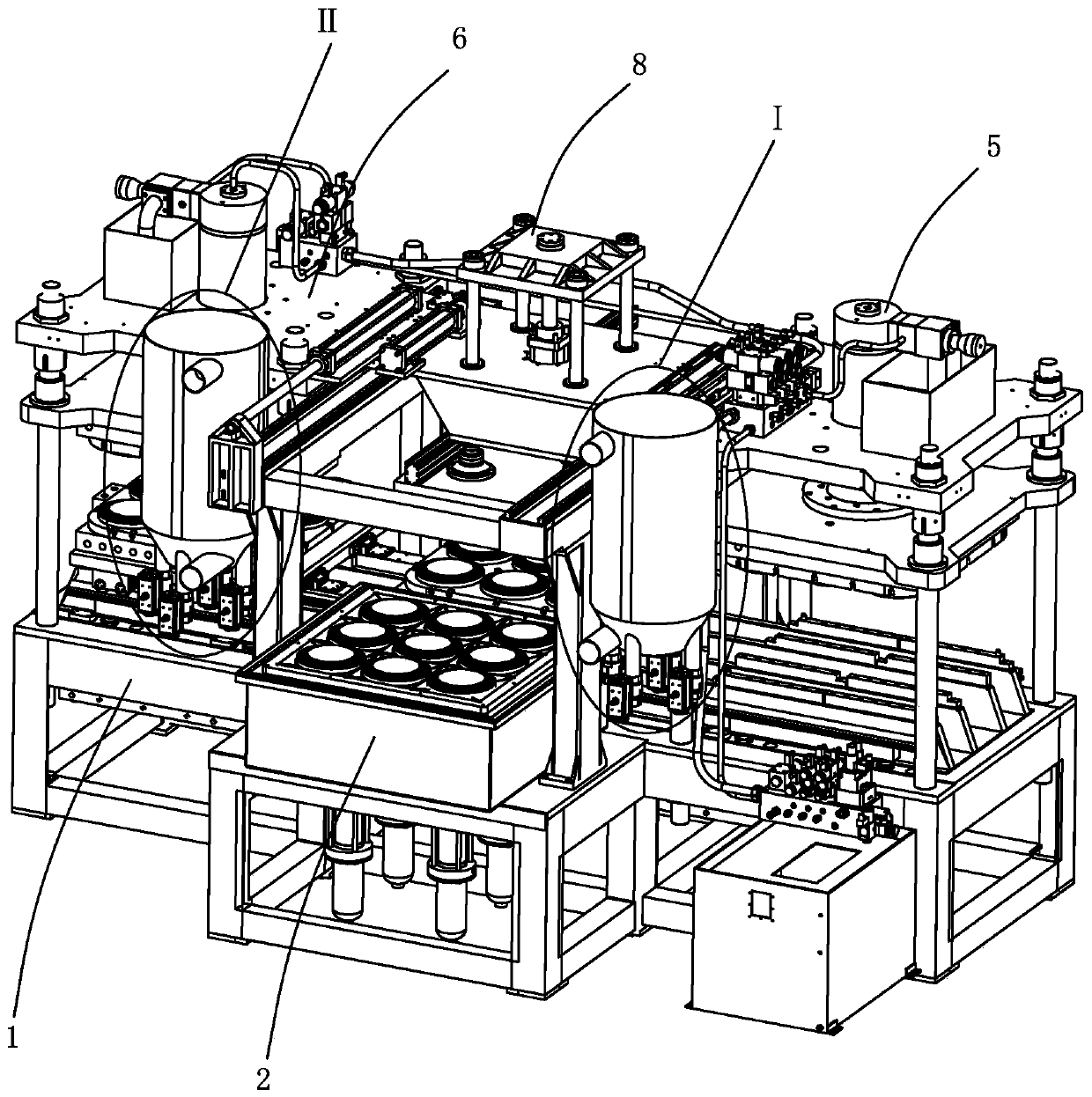

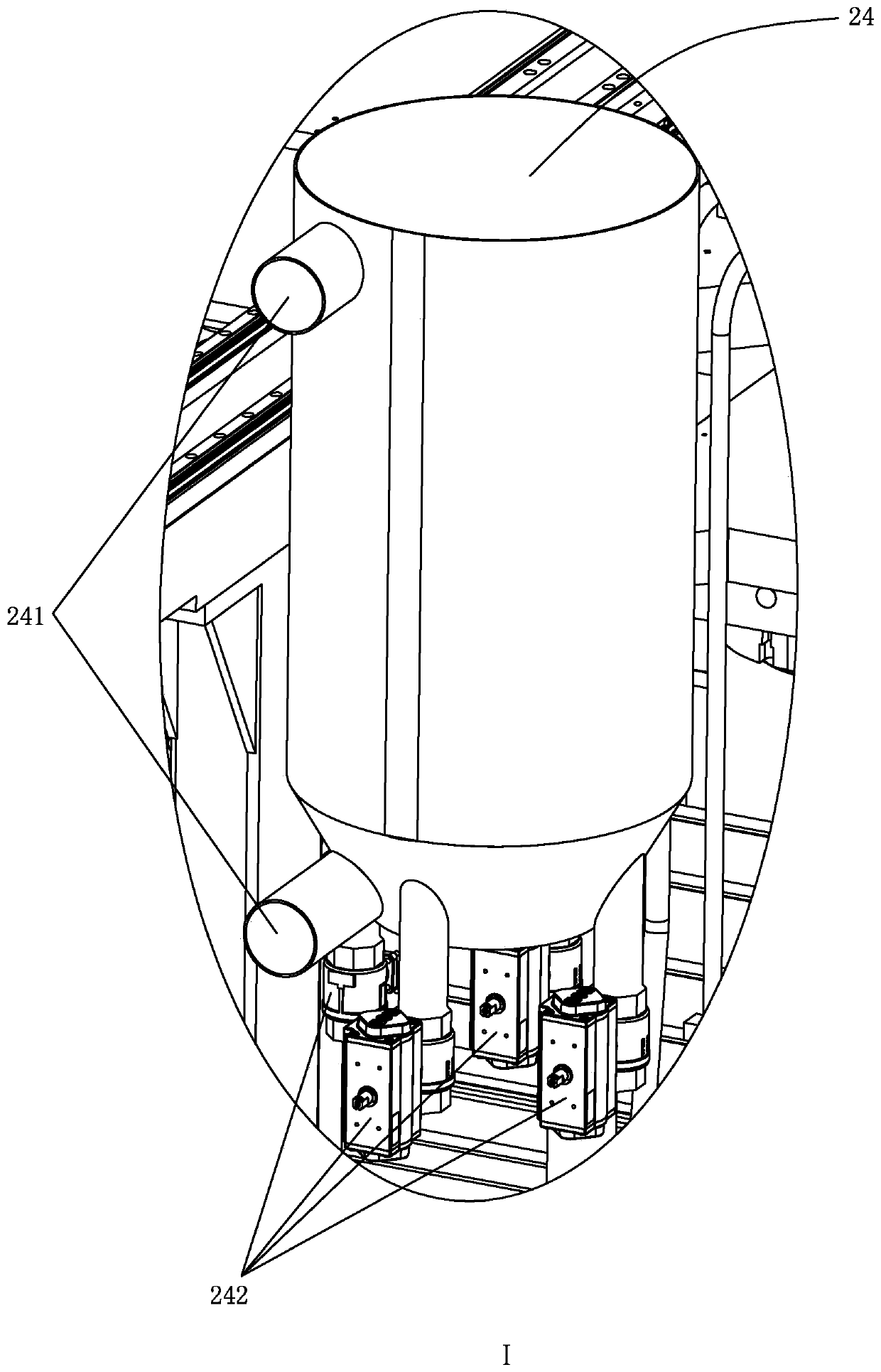

High-pressure integrated closestool forming machine

PendingCN108407055ASimple production processIncrease productivityMouldsCeramic extrusion diesSlurryHigh pressure

The invention discloses a high-pressure integrated closestool forming machine. The high-pressure integrated closestool forming machine comprises a fixed upper mold, a movable upper mold, a movable upper mold push device, a movable lower mold, a movable lower mold push device and a machine base, wherein the fixed upper mold is fixed to the machine base, the fixed upper mold and the movable upper mold are arranged side by side, the movable upper mold push device is connected with the movable upper mold and can push the movable upper mold to move horizontally, the movable lower mold can be matched with the fixed upper mold and the movable upper mold, and the movable lower mold push device is connected with the movable lower mold and can push the movable lower mold to move horizontally and vertically. A cavity in a whole closestool shape can be defined by the fixed upper mold, the movable upper mold and the movable lower mold, slurry is injected into the cavity, the integral closestool shape can be formed after extrusion is carried out, and a whole closestool blank can be formed at a time. The production process is greatly simplified, and the production efficiency is improved.

Owner:戴思施

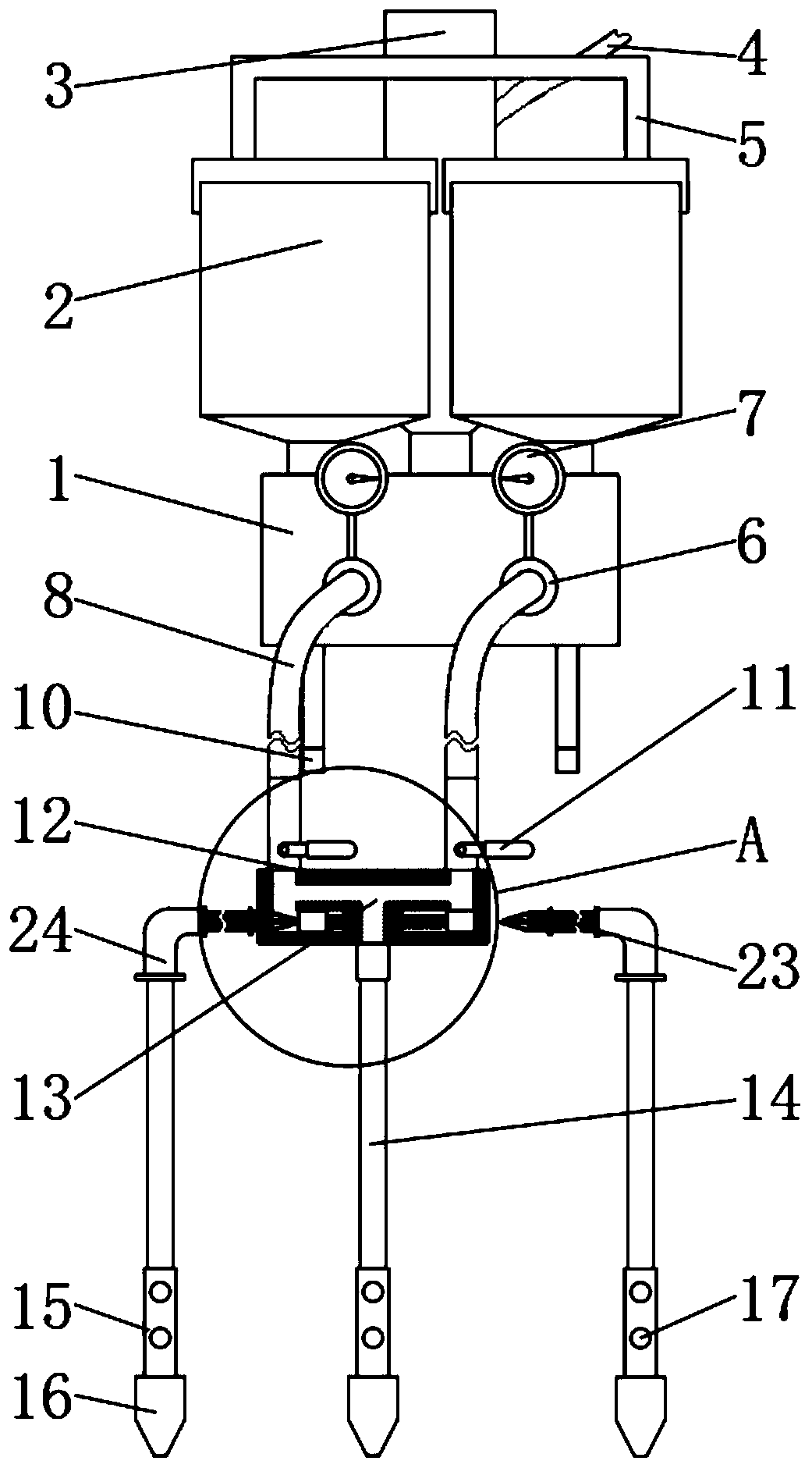

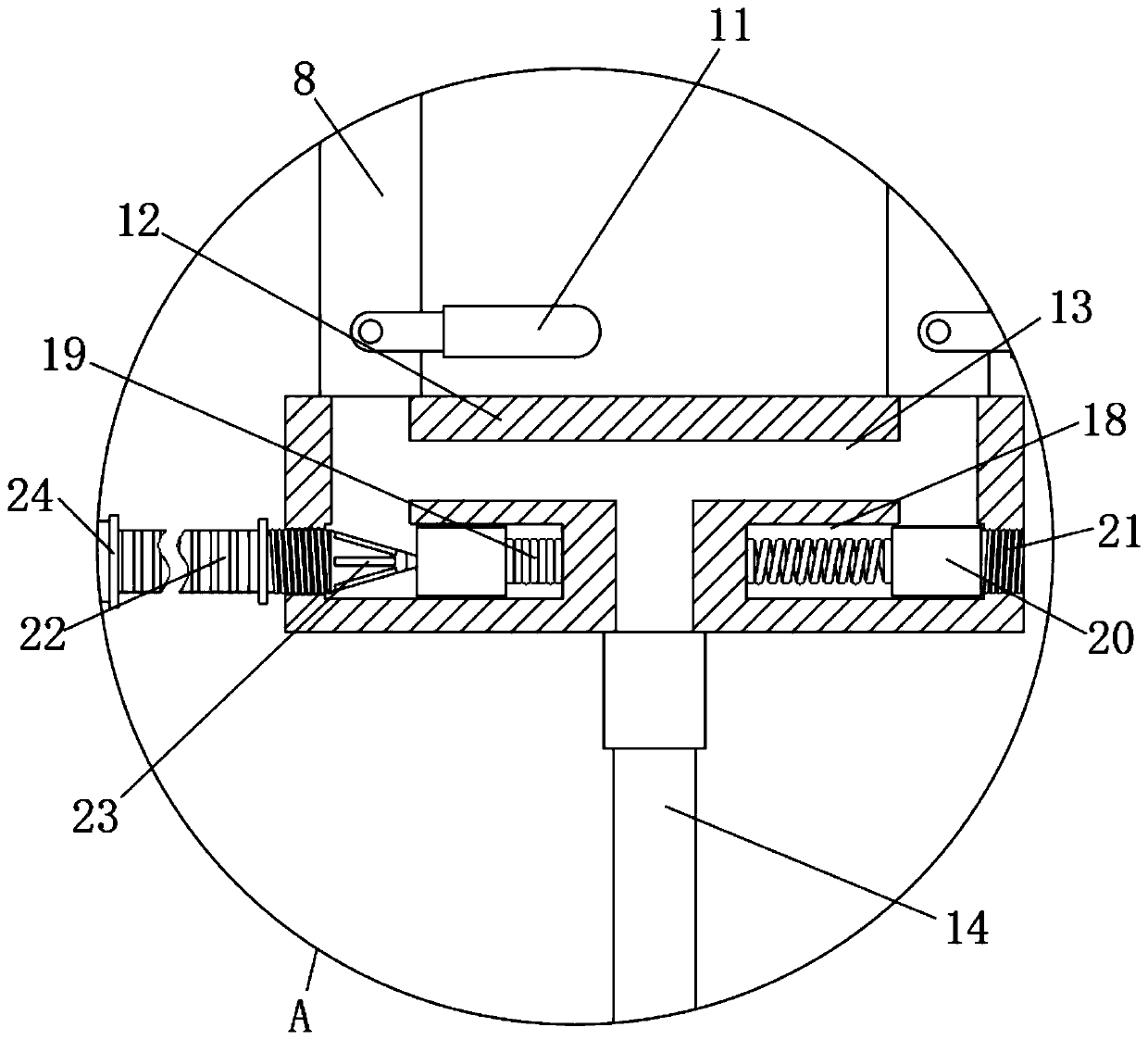

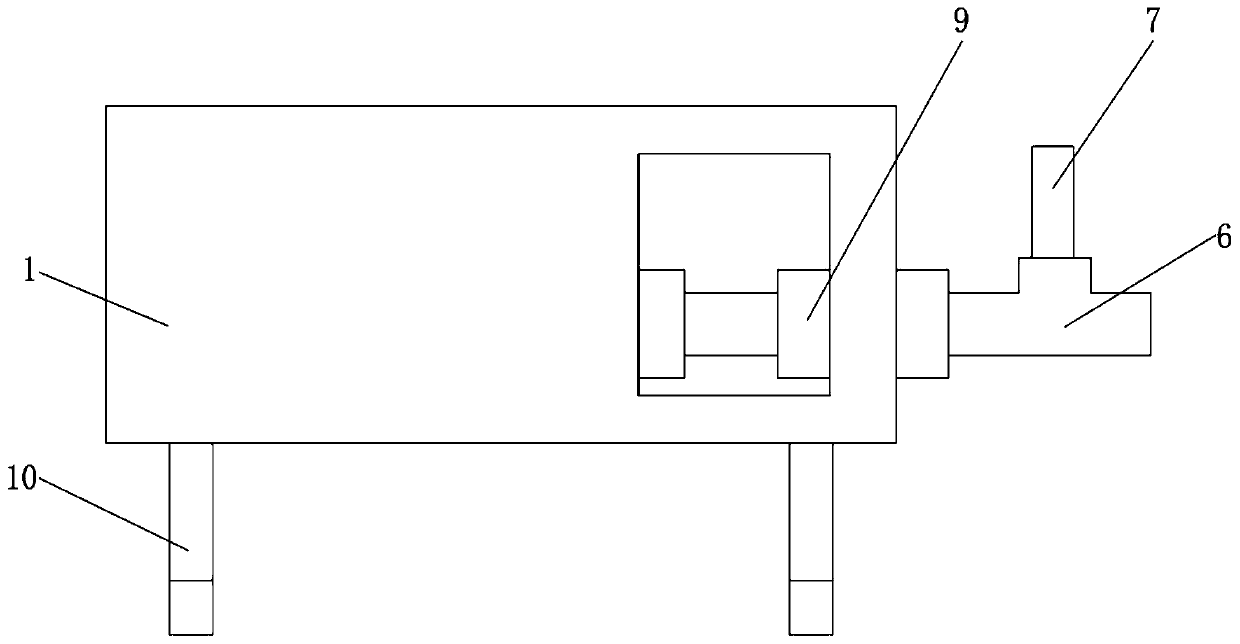

Double-pump double-pipe grouting machine for toilet plugging

InactiveCN110778143AImprove work efficiencyImprove grouting effectBuilding repairsStructural engineeringMachine

The invention relates to the technical field of plugging equipment, and discloses a double-pump double-pipe grouting machine for toilet plugging. The double-pump double-pipe grouting machine comprisesa machine body gearbox; a material cup is fixedly mounted on the upper surface of the machine body gearbox; a driving electric drill is fixedly mounted on the upper surface of the machine body gearbox and positioned on the back surface of the material cup; an extension wire is fixedly mounted on the back surface of the driving electric drill; and a handle is fixedly mounted on the upper surface of the machine body gearbox and positioned at the middle part of the material cup and the driving electric drill. Compared with the prior art, detachable extension pipes are adopted, so that in the process of grouting a long gap, extension pipes can be screwed on the two sides of a communicating valve to additionally arrange injection pipes; the double-pump double-pipe grouting machine has a plurality of grouting points on the gap, so that the grouting time of the double-pump double-pipe grouting machine for leaking cracks is shortened, the problem of low grouting efficiency due to only one injection pipe for grouting the cracks in the existing double-pump double-pipe grouting machine is solved, and the grouting efficiency of the double-pump double-pipe grouting machine for the leaking cracks is improved.

Owner:湖南古圣砖瓦科技有限公司

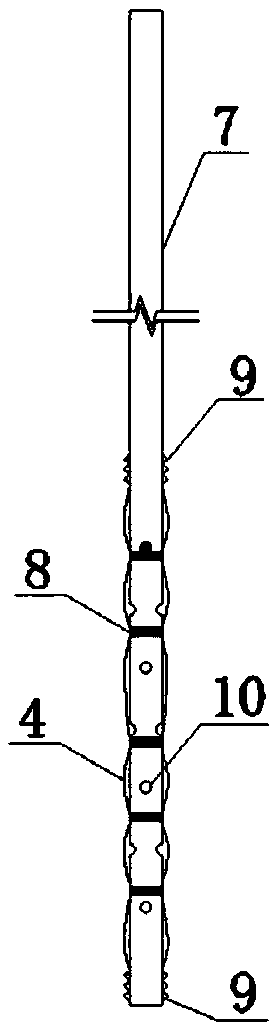

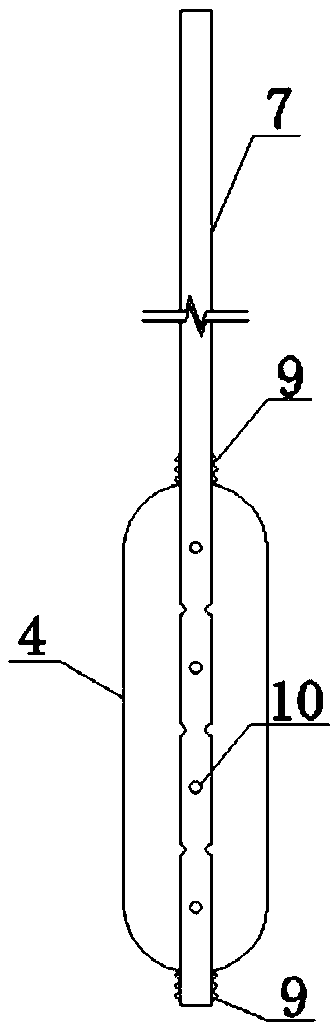

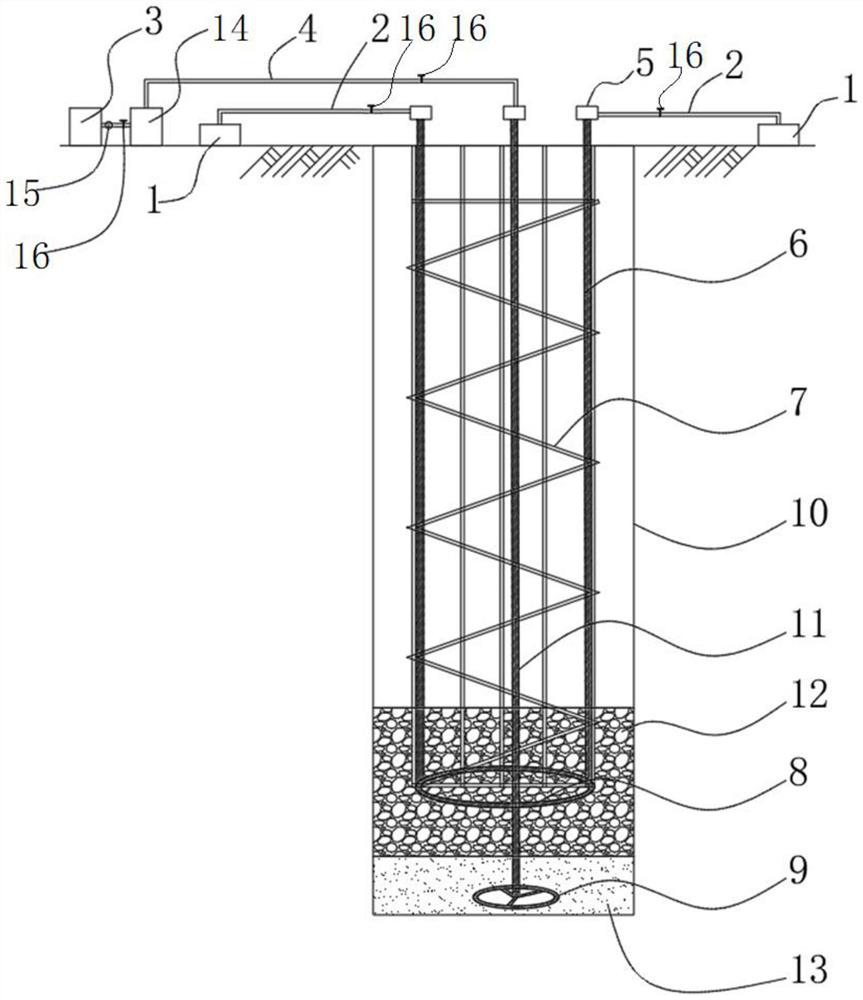

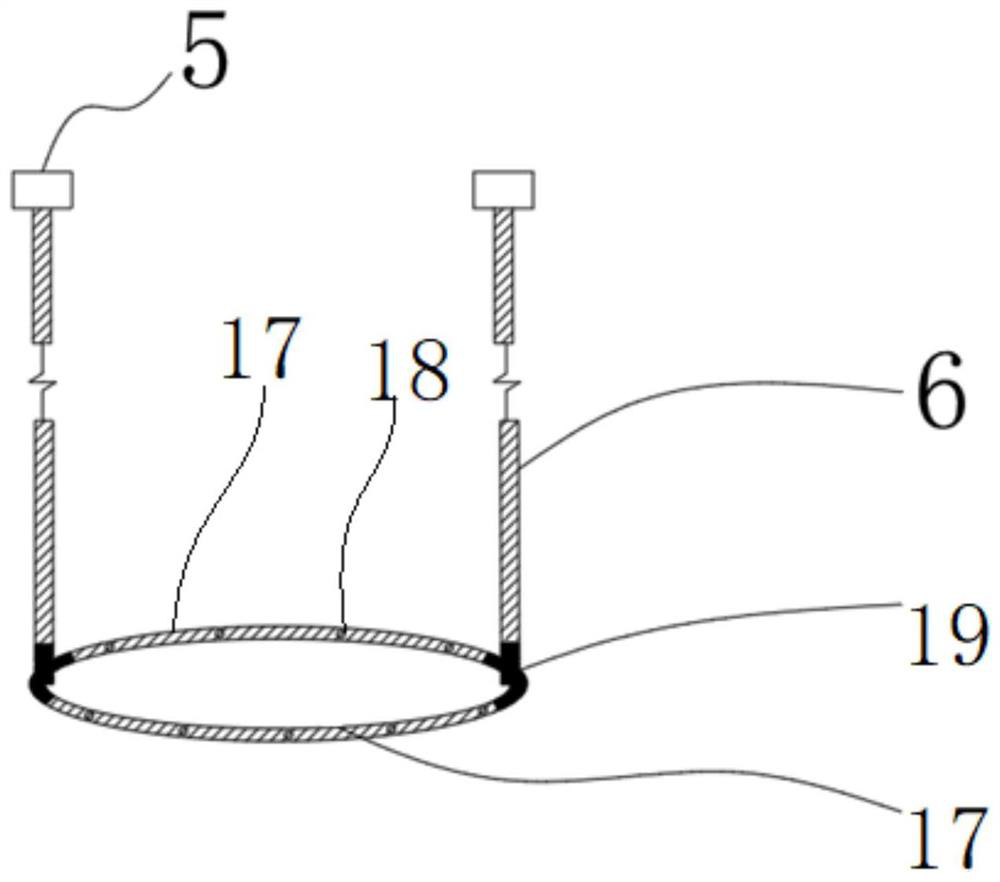

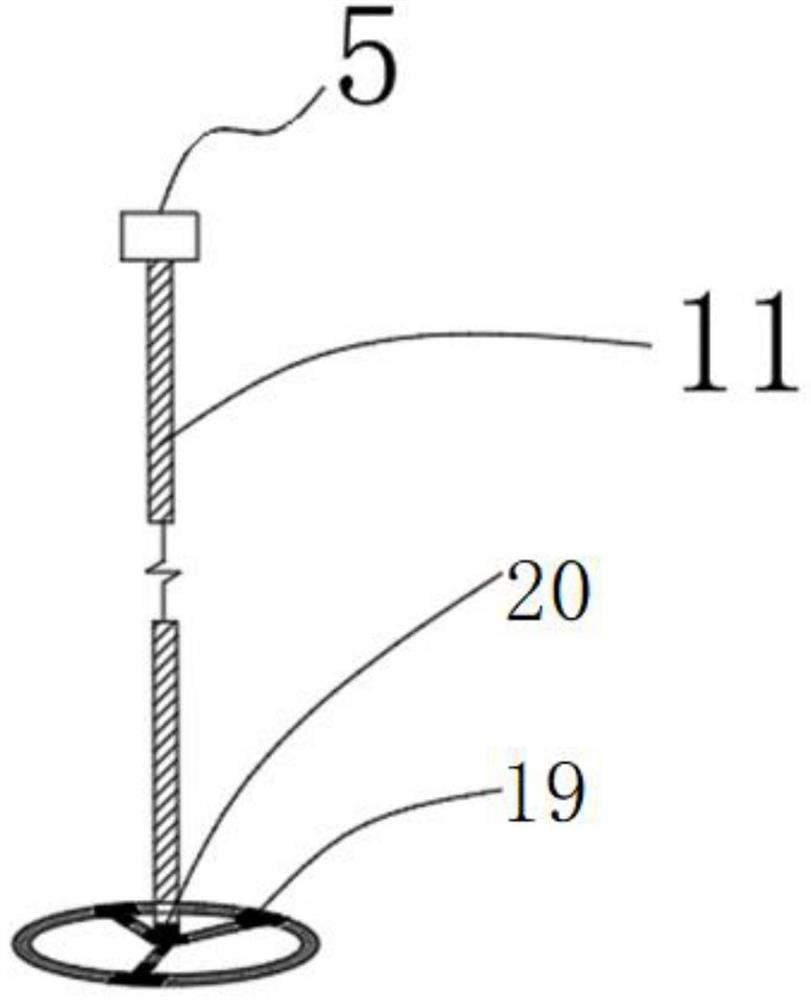

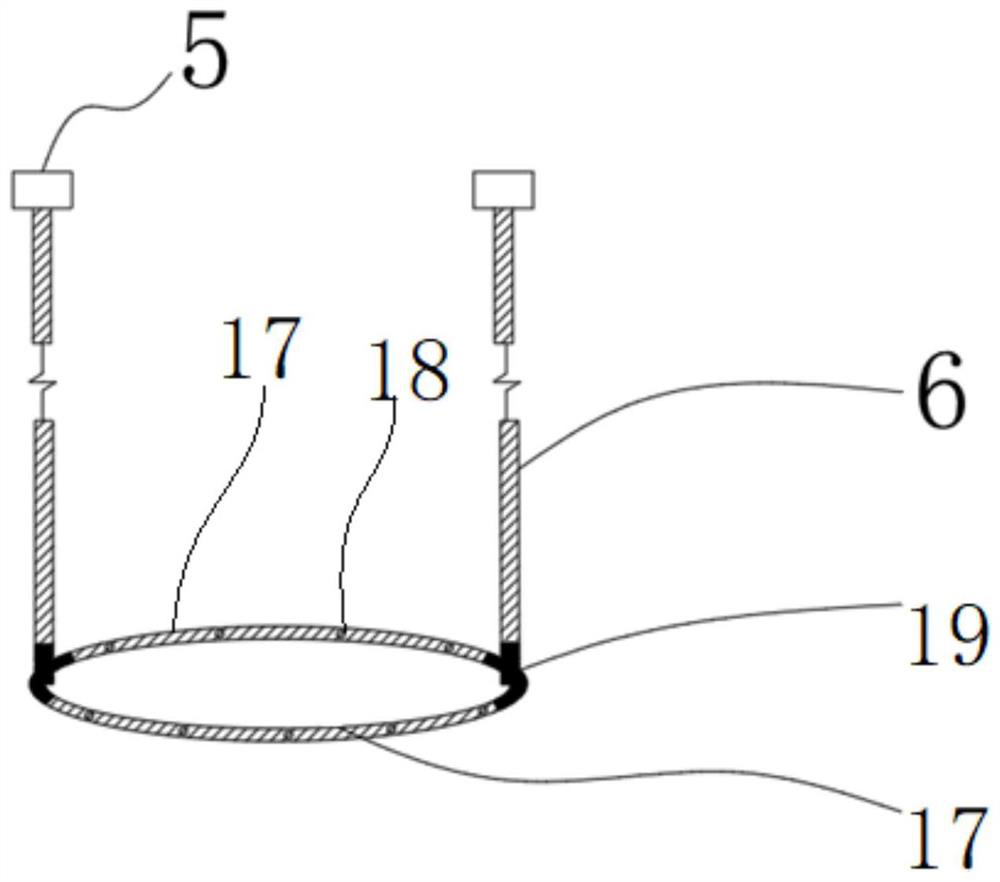

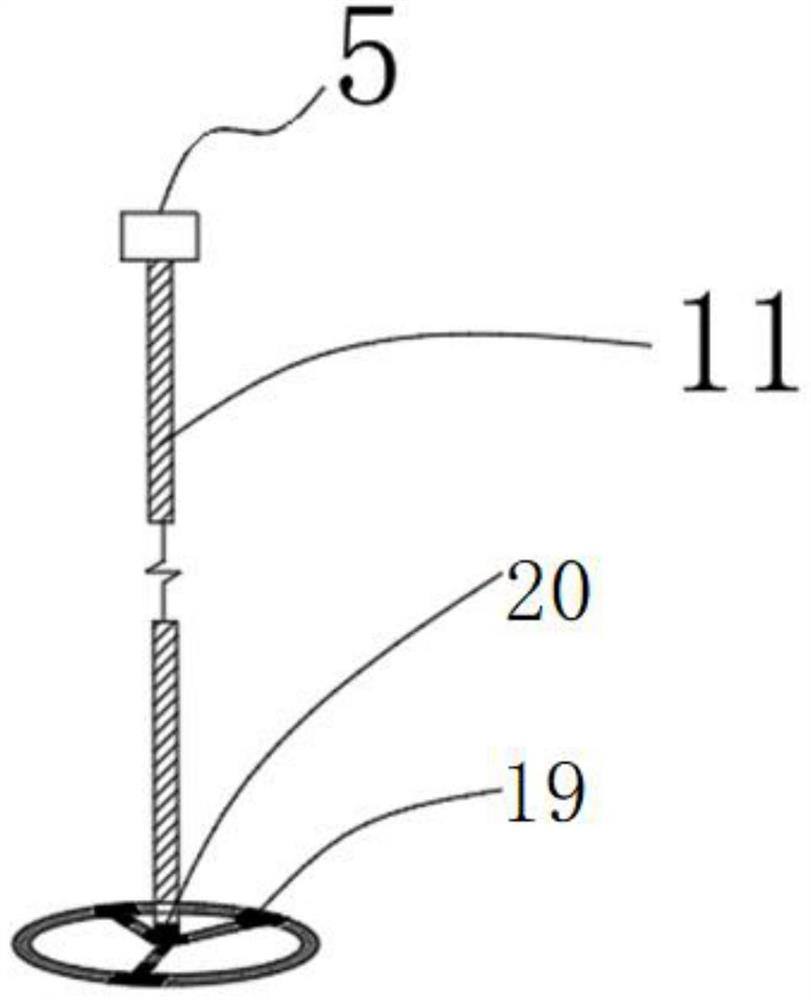

Vacuum-assisted post-grouting device and method for cast-in-situ bored pile

The invention discloses a vacuum-assisted post-grouting device and method for a cast-in-situ bored pile. The vacuum-assisted post-grouting device comprises grouting pumps, outer grouting pipes, innergrouting pipes, a grouting device, a vacuum pump, a vacuum bin, an outer vacuum pipe, an inner vacuum pipe, and a negative pressure device. Grouting holes are distributed in the grouting device and located in a gravel layer; negative pressure holes are distributed in the negative pressure device and located in a sand cushion layer; sand prevention cloth covers the negative pressure holes in the negative pressure device; the sand cushion layer is laid at the pile bottom, and the gravel layer is laid on the sand cushion layer; the lower ends of the inner grouting pipes are communicates with thegrouting device; the upper ends of the inner grouting pipes extend out of a pile hole and are detachably connected with the outer grouting pipes; the lower end of the inner vacuum pipe is communicatedwith the negative pressure device, and the upper end of the inner vacuum pipe extends out of the pile hole and then is detachably connected with the outer vacuum pipe; the upper ends of the inner grouting pipes and the upper ends of the inner vacuum pipes can be sealed through pipe caps; the inner grouting pipes, the grouting device, and the inner vacuum pipe are connected to a reinforcement cage, and the bottom end of the reinforcement cage is located inside the gravel layer; valves are arranged on the outer grouting pipes and the outer vacuum pipe; and a valve and a vacuum degree detectionpart are arranged between the vacuum pump and the vacuum bin. According to the vacuum-assisted post-grouting device and method for the cast-in-situ bored pile, the post-grouting quality is high.

Owner:CHINA FIRST METALLURGICAL GROUP

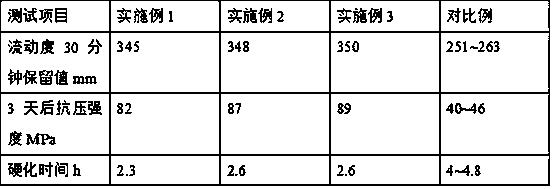

Method for preparing grouting material

The invention discloses a method for preparing a grouting material, and belongs to the field of building materials. Calcium carbide slag is used as an additive to improve the performances of fly ash,the calcium carbide slag and the fly ash are melted at a high temperature to achieve full melting in order to improve the grouting rate of the grouting material and shorten the grouting time; the obtained melt is mixed with vermiculite and boehmite, the water absorption expansion performance of the vermiculite improves the grouting effect, an ion channel formed between the vermiculite and boehmitemakes calcium ions in the obtained molten mixture exchange and flow in order to promote the activity and shorten the curing time, and the properties of boehmite are used to increase the flowability and the permeability of the grouting material; and the obtained mixture is then mixed with an assistant, sepiolite and the like, the water absorption expansion performance of the sepiolite makes the sepiolite become soft, and the added assistant excites the solidifying performance of the grouting material, so the problems of long setting period and poor fluidity off existing cement-based grouting materials are solved.

Owner:郭舒洋

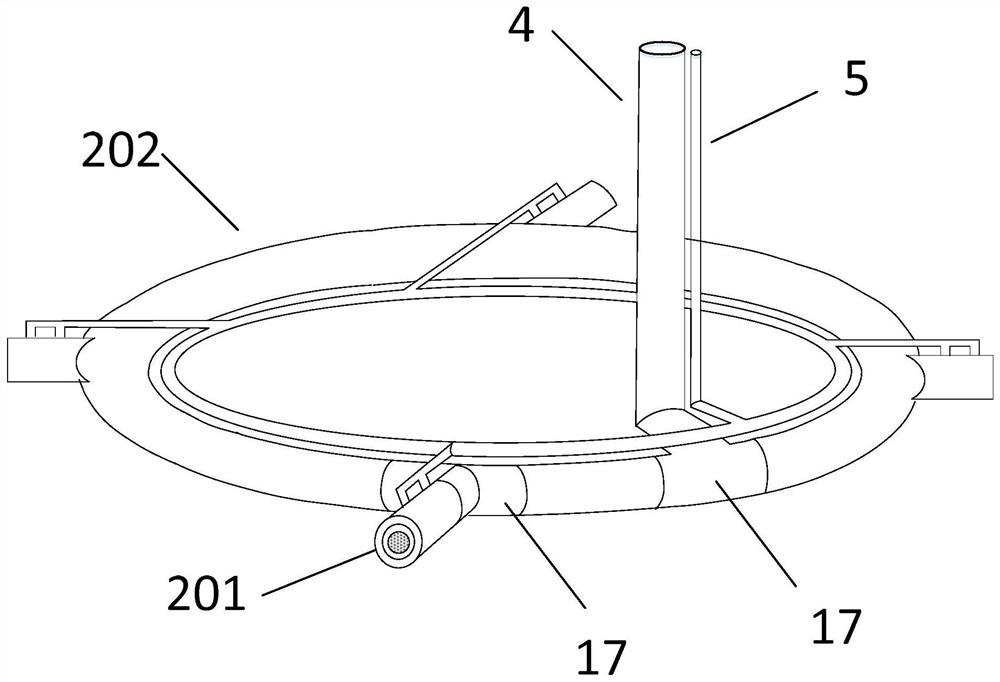

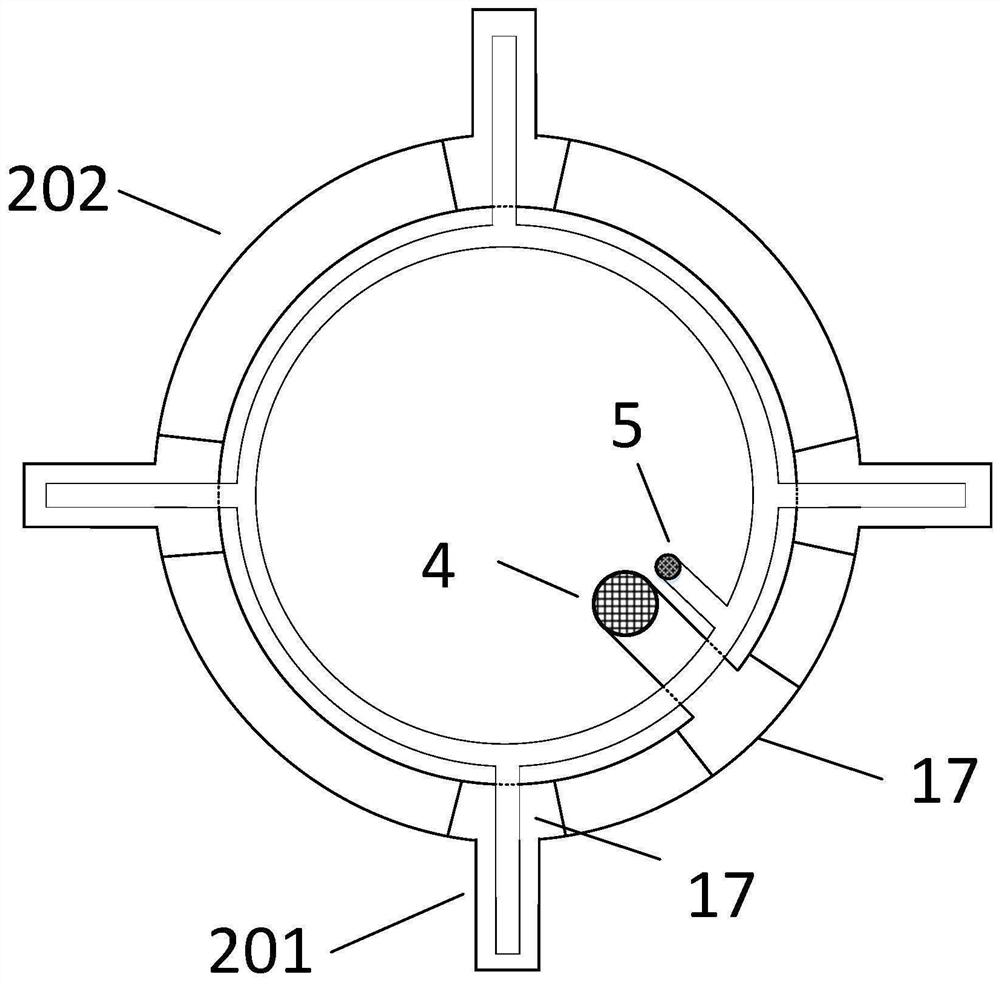

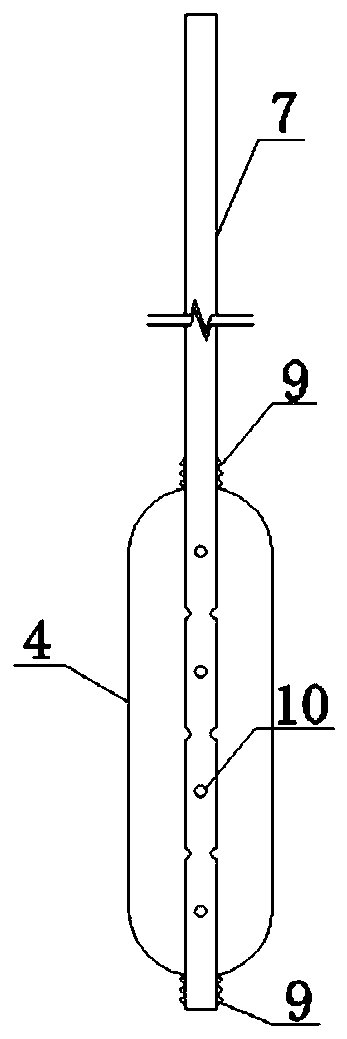

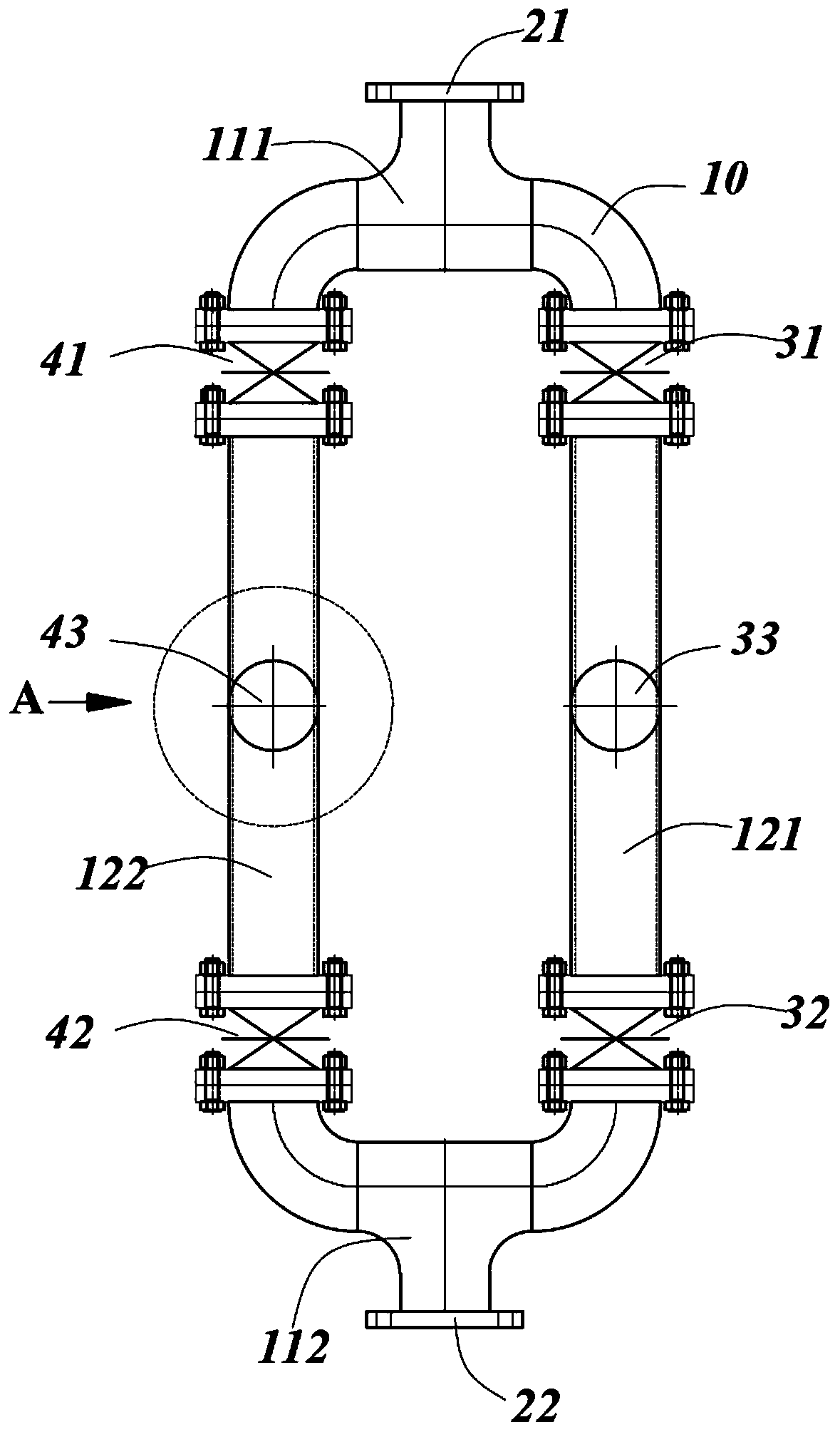

Real-time monitoring system and method for key grouting parameters after large-diameter cast-in-place pile combination

PendingCN114108710APrecise and effective groutingGuaranteed reliabilityFoundation testingInformatizationReal-time data

The invention discloses a real-time monitoring system and method for key grouting parameters after large-diameter cast-in-place pile combination. The system comprises a reinforcement cage, a pile side ring pipe grouting device, a pile end inverted-T-shaped grouting device, an electromagnetic flowmeter, a pressure sensor and a check valve. Controllable grouting under the low-pressure working condition is achieved through the check valve, and key grouting parameters at the grout outlet are monitored in real time through the electromagnetic flowmeter and the pressure sensor so that dynamic grouting parameter adjustment can be conducted according to the actual working condition. According to the method, the problems that the grouting parameters of the large-diameter cast-in-place pile are difficult to accurately determine in real time and are interfered by human factors can be effectively solved; grouting parameters at a grout outlet are accurately monitored and dynamically adjusted, so that the grouting reliability is guaranteed; real-time data are recorded and uploaded, standard test data are accumulated by means of informatization, and large data analysis can be conveniently conducted on grouting parameters in the grouting project in the follow-up process.

Owner:深圳市人才安居集团有限公司 +1

A technology and method of deep hole grouting in the advanced bearing pressure zone of fully mechanized coal mining face

ActiveCN105909287BImprove mechanical propertiesReshape IntegrityAnchoring boltsEngineeringHigh pressure

The invention provides a deep hole grouting technology and method at an advanced abutment pressure region for a comprehensive mining work surface of a coal mine. According to the method disclosed by the invention, early strength deep hole grouting materials are matched with a high-pressure mass-flow grouting pump, and an advanced hole forming technology, a pipe inserting technology, a hole sealing technology and a grouting technology for the advanced abutment pressure region are adopted, so that the problem that high-yield high-efficiency coal mining work surfaces with large mining height, top coal caving and the like can are often subjected to rib spalling can be solved; the method does not influence the production of the work surface, the mechanical properties of coal bodies are essentially improved, the completeness of the coal bodies is re-molded, and the method has a favorable popularization property.

Owner:HENAN POLYTECHNIC UNIV +1

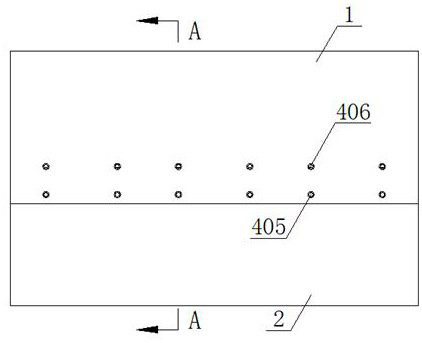

A grouting connection structure and grouting method based on combined box-type substation foundation

ActiveCN109778901BReduce difficultyImprove docking installation efficiencyFoundation engineeringTransformerArchitectural engineering

Owner:内蒙古利元管涵工程有限责任公司

Calibration device and method for flowmeter of grouting unit

ActiveCN108801404BIncrease the level of automationReduce work intensityTesting/calibration for volume flowSlurryMechanical engineering

The invention discloses a device and a method for calibrating a flowmeter of a grouting unit, comprising the following steps: initializing the calibrating sign of the flowmeter and the full scale value of the flowmeter; Check whether the slurry mixing system operates within the interval. If the slurry mixing system operates, initialize the initial slurry volume of the slurry mixing system and return to step 2; judge whether the system slurry injection rate is a small injection rate. If it is not a small injection rate, return to step 2. If it is small Injection rate, calibration flowmeter full scale value and set flowmeter calibration flag. The invention can use the machine to automatically measure the slurry volume of the slurry tank, and automatically calibrate the flowmeter, which can improve the automation level of the site, reduce supervision intervention and work intensity; control the key quality points of grouting, improve the quality of grouting, and reduce unnecessary grouting Time, improve the grouting progress.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +1

Vacuum-assisted post-grouting device and method for bored piles

Owner:CHINA FIRST METALLURGICAL GROUP

Grouting method for large-scale equipment base in high-temperature drying environment

The invention discloses a grouting method for a large-scale equipment base in a high-temperature drying environment. The grouting method includes preparation before grouting, flowing grouting and grouting material maintenance. The grouting method for the large-scale equipment base in the high-temperature drying environment has the technical effect that through the cyclic operation method includinggrouting, vibrator vibrating and re-grouting, bubbles in the equipment base can be effectively removed; and meanwhile, a method of injecting a grouting material into the equipment base from a grouting opening in the center of the upper surface of the equipment base is adopted, the problem of poor fluidity of the grouting material under the high-temperature drying condition can be solved, groutingis compact, and the construction quality is better.

Owner:MCC5 GROUP CORP SHANGHAI

A kind of plant growth regulator for promoting corn grain filling and its application

ActiveCN113383796BReduce pollutionEasy breathingBiocidePlant growth regulatorsBiotechnologyGrowth plant

The present invention provides a plant growth regulator for promoting corn grain filling and its application, including the following effective active ingredients and auxiliary synergistic ingredients, wherein the effective active ingredients include: 1-30 parts of ethephon; 1.5 parts; the auxiliary and synergistic ingredients include: 1-5 parts of fatty glucosinolates; 1-5 parts of calcium salts; and 1-5 parts of magnesium salts. The plant growth regulator of the invention can significantly improve the grain filling speed of corn grains, can significantly shorten the grain filling time, and reduce the production cost; achieve the effect of increasing production.

Owner:天津天隆在田农业科技有限公司

An intelligent and dynamic monitoring system for mine grouting and its working method

ActiveCN110118096BAvoid wastingSave resourcesMining devicesMeasurement devicesFlow transducerIntrinsic safety

The invention discloses an intelligent and dynamic monitoring system for mine grouting and a working method thereof. The system comprises grouting pipes, a ball valve, a grout recovery pump, a high-precision intrinsic safety type pressure sensor, a high-precision intrinsic safety type flow sensor, a grouting anchor rod positioning system, a grouting anchor rod, a stirring device, a mining area grout pump station, a data transmission system, a ground data acquisition system and a coal mine dispatching center, wherein a plurality of grouting connectors are arranged on the periphery of the miningarea grout pump station, and the grouting pipes are arranged on the sides, deviating from the mining area grout pump station, of the grouting connectors separately. Through interaction of the ball valve, the high-precision intrinsic safety type pressure sensor, the high-precision intrinsic safety type flow sensor, the grouting anchor rod positioning system, the grouting anchor rod and a ground data acquisition system, grouting parameters are accurately collected in the grouting process, the grouting effect is detected in real time, and the grouting anchor rod which does not reach the standardcan be timely repaired.

Owner:新汶矿业集团有限责任公司孙村煤矿 +2

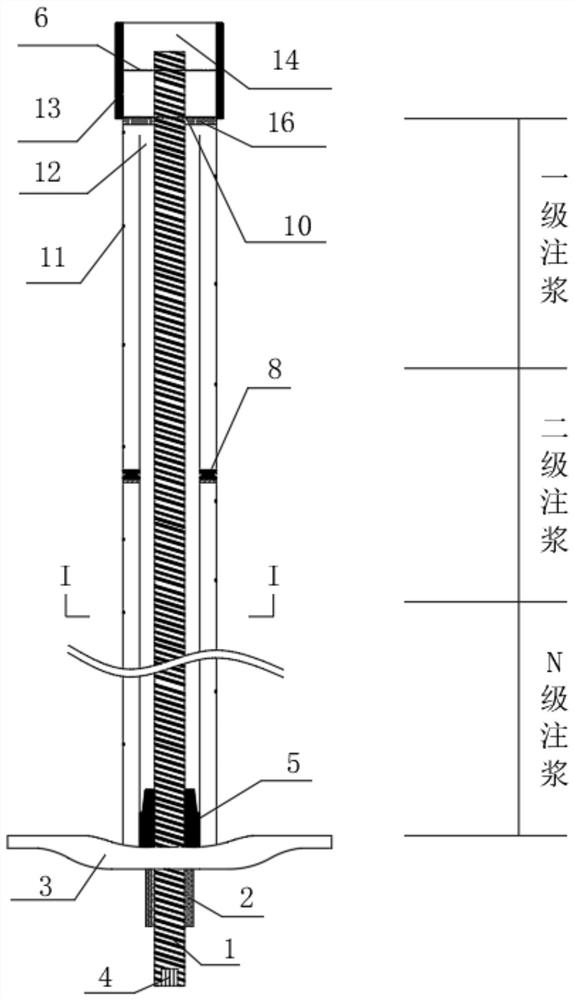

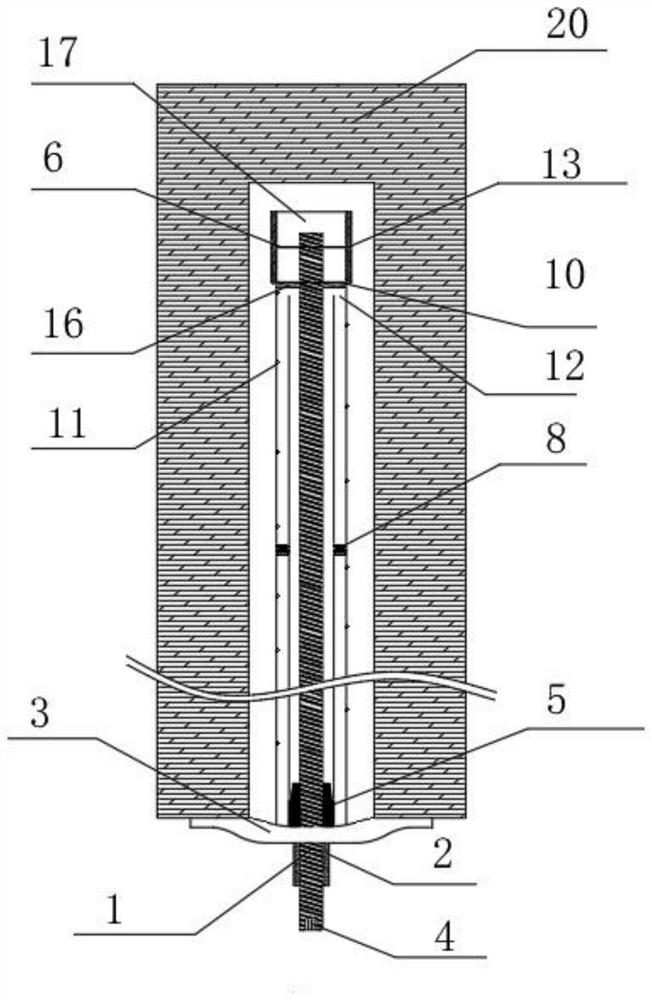

Piston type graded grouting anchor cable and grouting method

InactiveCN112682080AConsistent grouting pressureEven and smooth groutingAnchoring boltsCable trayPiston ring

The invention relates to a piston type graded grouting anchor cable and a grouting method in the technical field of safe and efficient mining of coal mine resources. The piston type graded grouting anchor cable comprises an anchor cable body, a lock, an anchor cable tray, a screwed plug, a grout stop plug, a piston pushing device, a grout stop film, a grouting hole, a water stop strip and an end self-anchoring device, wherein the piston pushing device comprises an inner piston ring, an outer piston ring and the grout stop film; a pressure sensor is mounted on the piston pushing device; and the grout stop film is attached to the rear portion of the piston pushing device. The piston type graded grouting anchor cable is convenient and fast to machine, the grouting pressure of the anchor cable can be automatically and dynamically adjusted through the piston pushing device, and graded and partitioned stable-pressure grouting is conducted in sequence from inside to outside and from deep to shallow under the rated grouting pressure; and through the end self-anchoring device, end anchoring is conducted without a resin cartridge, mounting is fast during grouting, operation is convenient, economic benefits are good, the supporting effect is greatly improved, and the engineering problems that in the prior art, preferential permeation is likely to happen during roadway shallow grouting, and consequently shallow grout leakage and low deep grouting efficiency are caused are effectively solved.

Owner:ANHUI UNIV OF SCI & TECH

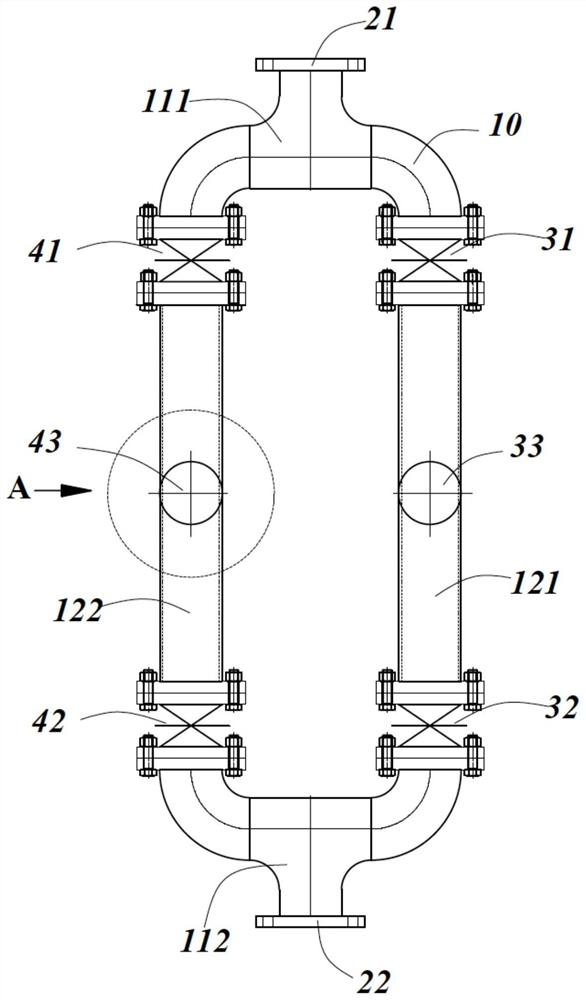

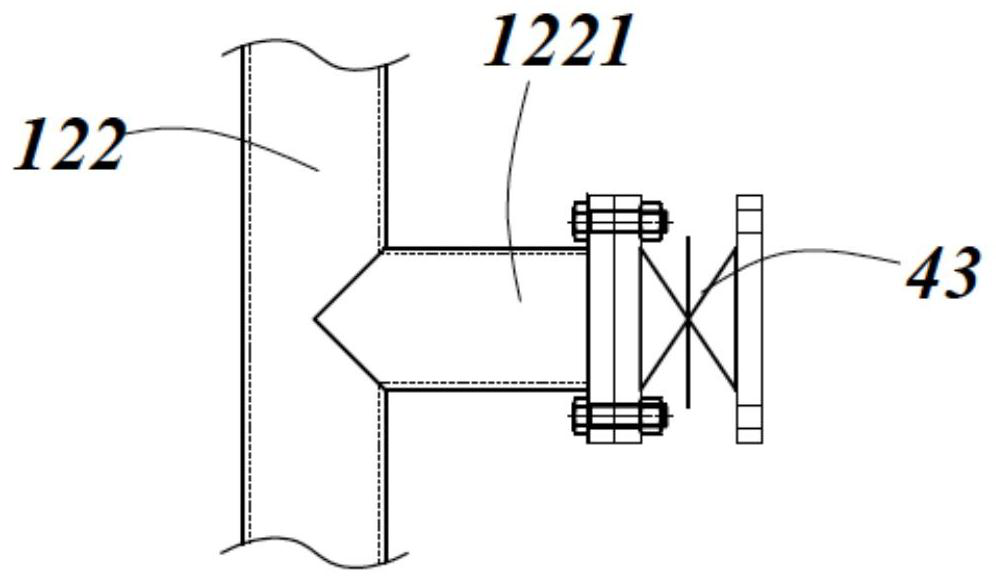

Wet film forming device and automatic paper matrix production line

PendingCN109706794AAchieve standardizationRealize large-scale productionTextiles and paperProduction linePulp and paper industry

The invention discloses a wet film forming device. The device comprises a paper pulp tank, a left pulp injection barrel arranged at the left side of the paper pulp tank and communicated with the paperpulp tank, a right pulp injection barrel arranged at the right side of the paper pulp tank and communicated with the paper pulp tank, a wet film forming module arranged in the paper pulp tank, and anup-and-down driving group sleeving the paper pulp tank. The automatic injection of a paper pulp into the paper pulp tank is realized through the left pulp injection barrel and the right pulp injection barrel, and the left pulp injection barrel and the right pulp injection barrel are respectively connected with multiple ends of the paper pulp tank to make the paper pulp tank instantaneously injected with the paper pulp, so the pulp injection time is saved; and the up-and-down driving group drives the wet film forming module to move up and down in order to fast form a wet paper matrix, so the paper matrix production efficiency is improved, thereby the purpose of fully automatically forming the wet paper matrix is achieved, more and more practical use needs are further met, and the further development of the paper matrix industry is benefited. The present invention also discloses an automatic paper matrix production line.

Owner:广东卡雷尔环保科技有限公司

Grain injecting device and grain injecting method

ActiveCN110374639BSimple structureRealize continuous operationUnderground chambersSealing/packingCereal grainGate valve

The invention discloses a grain injection device and a grain injection method. The grain injection device includes a grouting pipeline, and the grouting pipeline includes a first interface connected with a grouting hole and a first interface connected with a grouting pump. Two ports, the grouting pipeline is provided with a first gate valve on the side of the first port, a second gate valve on the side of the second port, and a third gate valve between the first gate valve and the second gate valve, the third gate valve Used to load grain into grain lines. The structure of the grain injection device of the present invention is simple, and the grain injection and grouting can be realized through the grouting pipeline and multiple gate valves; multiple branch pipelines alternately carry out grain injection and grouting, which can realize continuous operation, and the loaded grain can be continuously It is continuously fed into the borehole, which greatly improves the grouting efficiency and shortens the grouting time.

Owner:CHINA COAL NO 3 CONSTR GRP

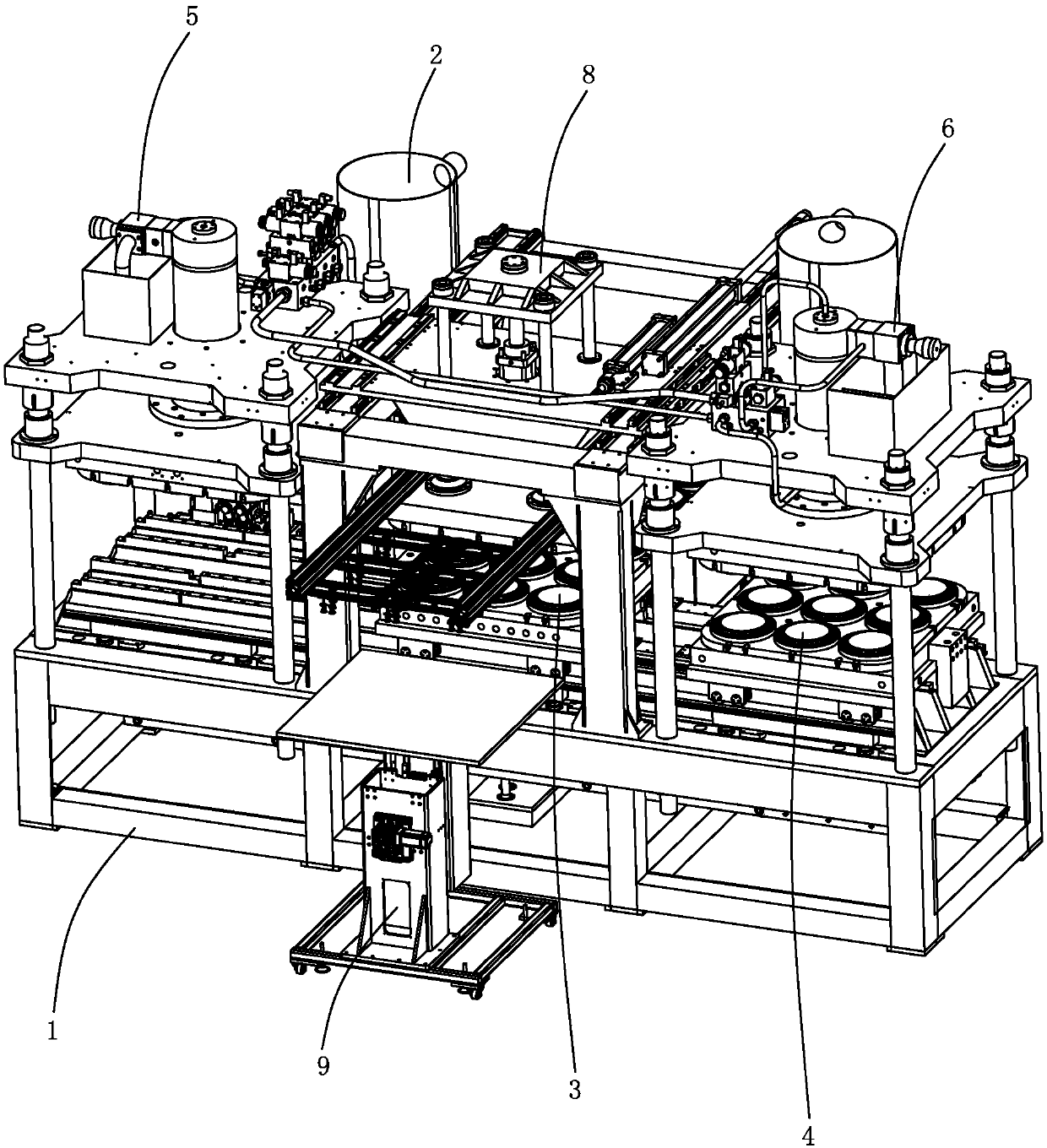

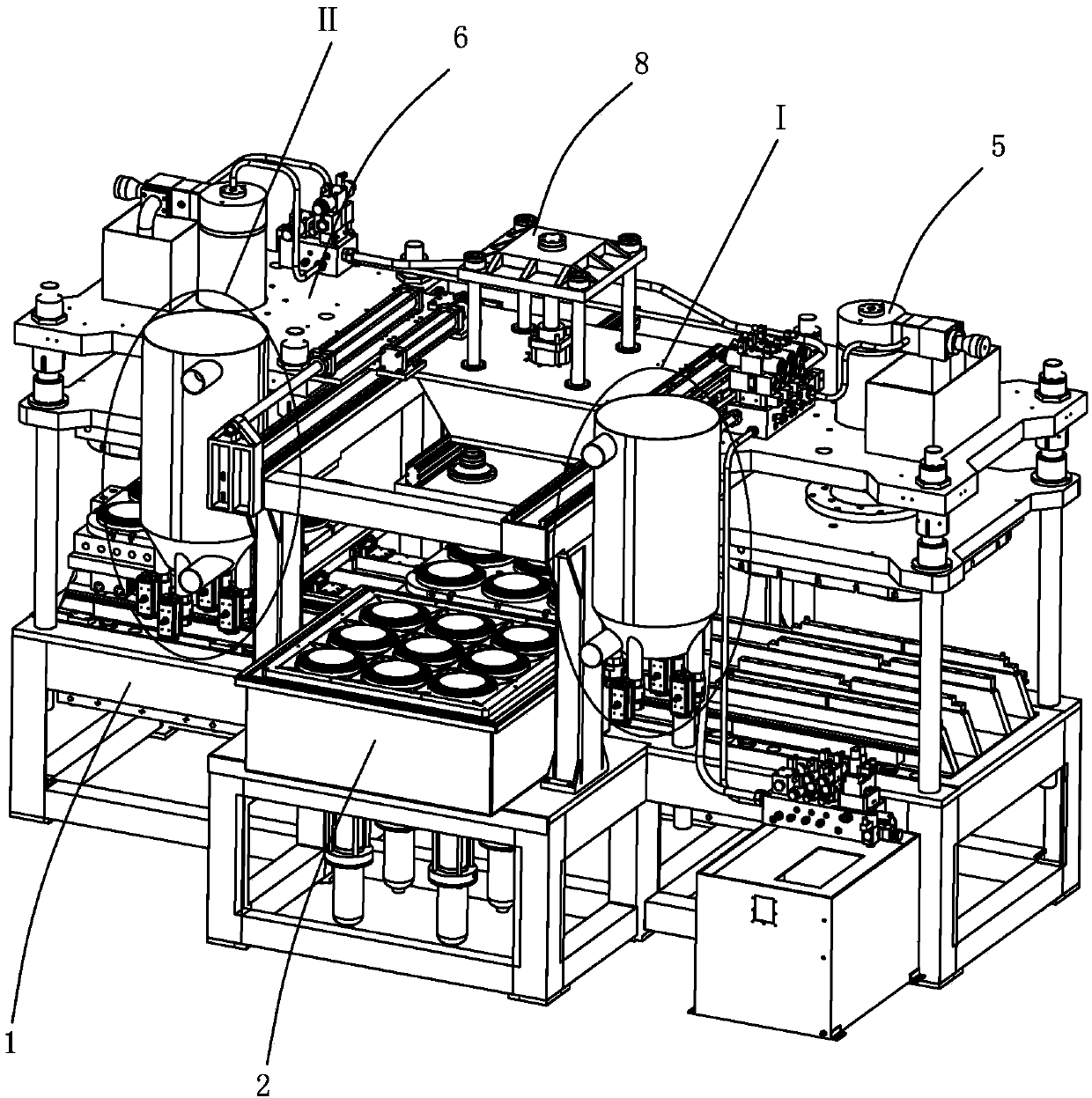

Intelligent automatic production line applied to paper mold formation

PendingCN109677015AIncrease productivityAchieve standardizationPaper/cardboard articlesProduction linePulp and paper industry

The invention discloses an intelligent automatic production line applied to paper mold formation. The production line comprises a frame, a wet mold forming device, a left worktable, a right worktable,a left hot-press shaping device, a right hot-press shaping device, a synchronous driving mechanism and a dry and wet mold carrying device. Through cooperation of the wet mold forming device with theleft worktable, the right worktable, the left hot-press shaping device, the right hot-press shaping device, the synchronous driving mechanism and the dry and wet mold carrying device, the purpose of full-automatic intelligent production of paper molds is achieved, so that the paper mold production efficiency can be greatly improved, more and more actual use demands can be further met, enterprisesfacilitate realization of large-scale standard production, and the further development of the paper mold industry is facilitated.

Owner:广东卡雷尔环保科技有限公司

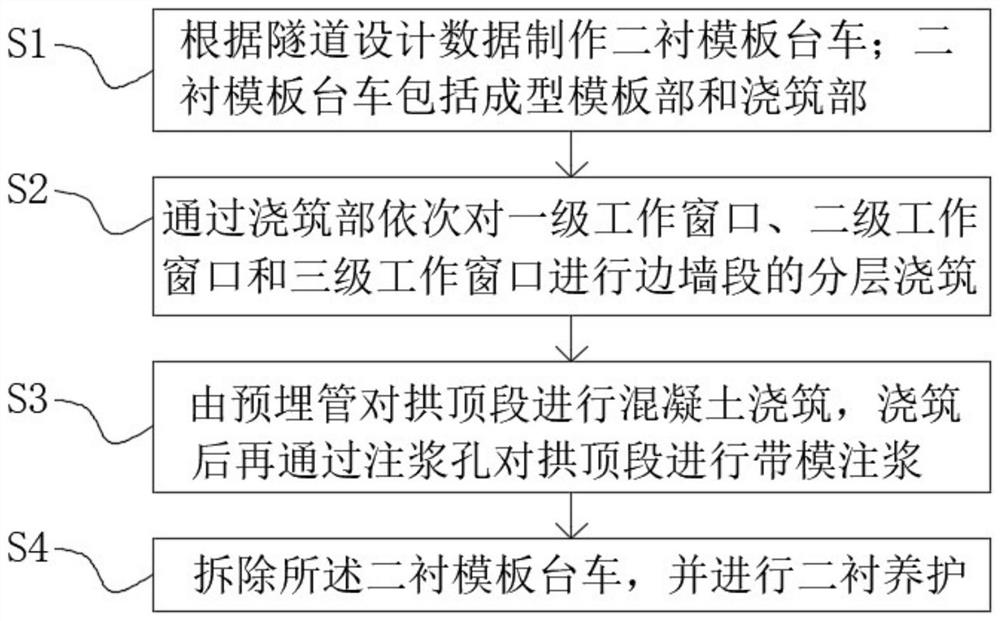

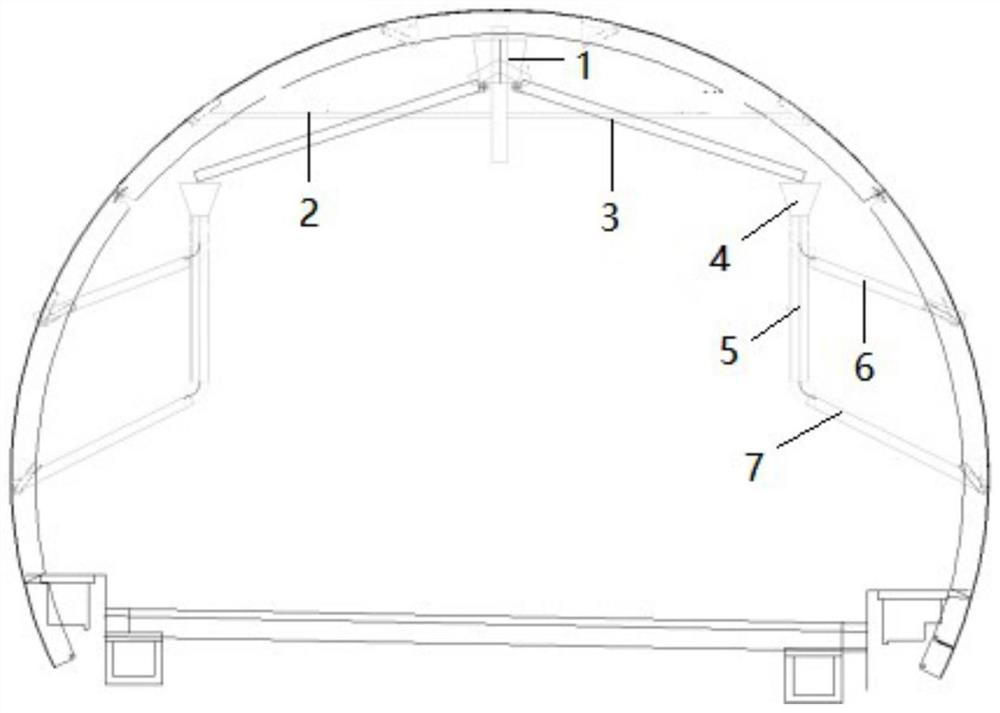

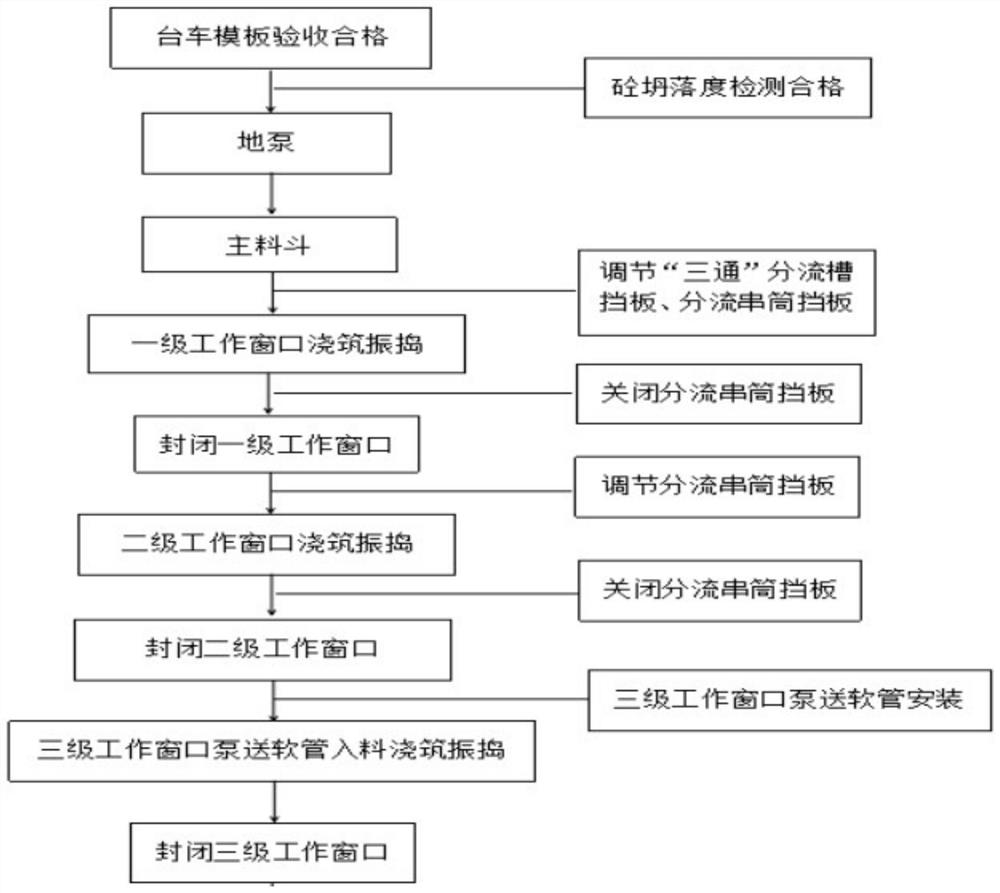

Tunnel secondary lining construction process

PendingCN114876520ASmooth drainageAvoid concentrationUnderground chambersHydro energy generationArchitectural engineeringStructural engineering

The invention discloses a tunnel secondary lining construction technology. The tunnel secondary lining construction technology comprises the following steps that S1, a secondary lining formwork trolley is manufactured according to tunnel design data; the secondary lining formwork trolley comprises a forming formwork part and a pouring part. And S2, side wall section layered pouring is conducted on the first-stage working window, the second-stage working window and the third-stage working window in sequence through a pouring part. And S3, concrete pouring is carried out on the arch crown section through the embedded pipe, and formwork grouting is carried out on the arch crown section through the grouting holes after pouring. And S4, the secondary lining formwork trolley is dismantled, and secondary lining maintenance is conducted. By means of window-by-window layered pouring of the secondary lining formwork trolley, the sand surface formed by vibrating and material driving and cold joints caused by pipe connecting delay can be effectively reduced, multiple same-level working windows are all utilized, and skip layer pouring and concentrated material distribution are avoided.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

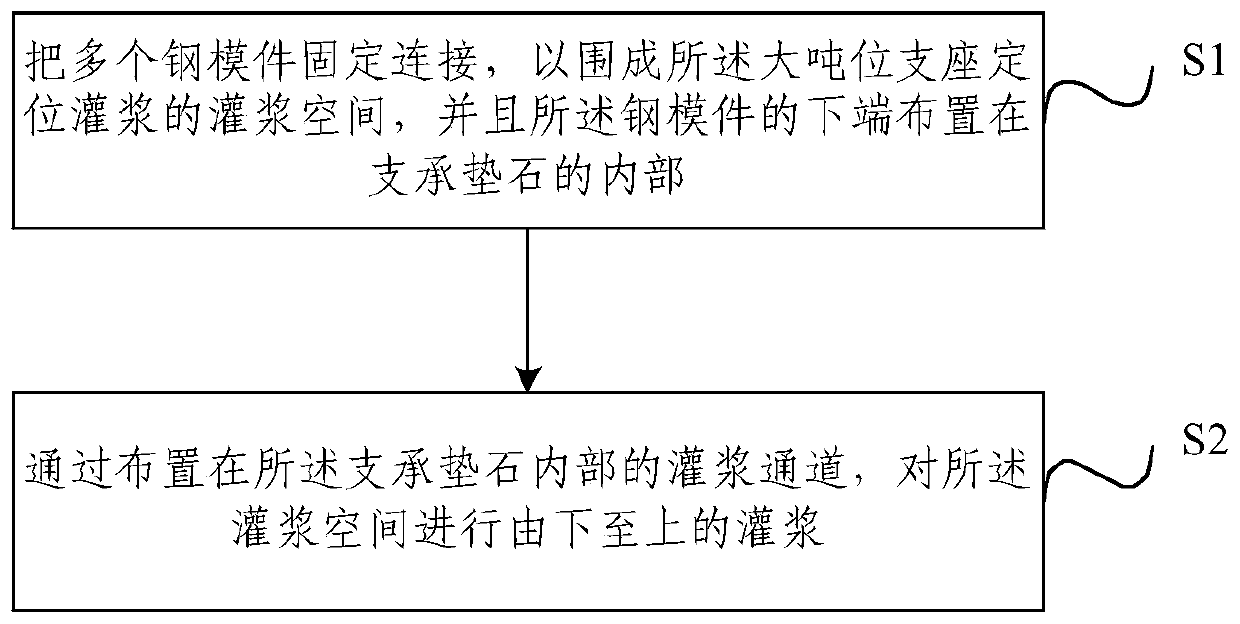

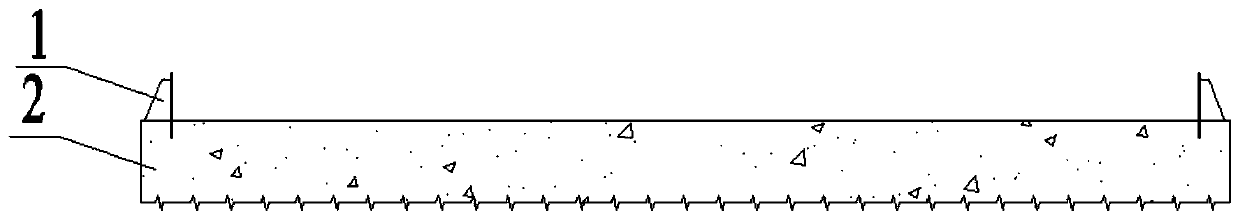

A Positioning Grouting Method for Large Tonnage Bearings

ActiveCN107858926BPrevent diseaseImprove appearance qualityBridge structural detailsBridge erection/assemblyGroutCivil engineering

The invention provides a large-tonnage support locating grouting method. The large-tonnage support locating grouting method comprises the following steps of S1, fixedly connecting a plurality of steelmold pieces to enclose a grouting space of the large-tonnage support locating grouting, wherein the lower ends of the steel mold pieces are placed within a bearing pad stone; and S2, grouting the grouting space from bottom to top through a grouting passage formed in the bearing pad stone. According to the large-tonnage support locating grouting method, as the grouting space of the large-tonnage support locating grouting is grouted by using the mode from bottom to the top, the grouting time is reduced, the bubble eliminating efficiency is enhanced, bubbles, sinking, pitted surface, edge cornerslump and mortar leakage ratio on the surface of a mortar bed of a large-tonnage support can be reduced in a maximized manner, a problem of uncompacted grouting in the middle of the mortar bed of thelarge-tonnage support is reduced or avoided to prevent damages of the large-tonnage support, and meanwhile, the appearance quality of the mortar bed of the large-tonnage support is improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

Advanced compaction grouting reinforcement method for loose and weak strata suitable for shallow buried tunnels

ActiveCN109162722BAddressing Difficult Diffusion Control ProblemsImprove effective utilizationUnderground chambersTunnel liningEarth surfaceGeotextile

The invention discloses a pre-compacting and grouting reinforcement method for loose and weak strata suitable for shallow-buried tunnels, which includes testing the compaction performance of the stratum when the tunnel passes through the loose and weak stratum through experiments, and determining the ability of the stratum under different grouting pressures. The degree of compaction achieved, and the mechanical properties and impermeability properties corresponding to different compaction degrees; analyze the influence of different compaction degrees of formations and the thickness of the grouting reinforcement ring on the stability of tunnel excavation, so as to determine the target grouting pressure, grouting The thickness of the grout reinforcement ring; determine the maximum expansion radius of the expansive geotextile bag and the arrangement spacing of the grouting holes on the surface; make the grouting pipe with the expansive geotextile bag; implement the grouting hole drilling operation on the surface, and drill the grouting hole after reaching the predetermined depth. Insert the grouting pipe with expansive geotextile bag; use quick-setting grouting material for grouting, and stop grouting when the grouting pressure reaches the target grouting pressure; fill the gap between the grouting pipe and the grouting hole Closed; complete grouting of all grouting holes.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Cereal injection device and cereal injection method

ActiveCN110374639AImplement injectionRealize groutingUnderground chambersSealing/packingContinuous operationInjection device

The invention discloses a cereal injection device and a cereal injection method. The cereal injection device comprises a grouting pipeline, wherein the grouting pipeline comprises a first interface and a second interface, the first interface communicates with a grouting drill hole, the second interface communicates with a grouting pump, a first gate valve, a second gate valve and a third gate valve are arranged on the grouting pipeline, the first gate valve is arranged at one side of the first interface, the second gate valve is arranged at one side of the second interface, the third gate valve is arranged between the first gate valve and the second gate valve, and the first gate valve is used for loading cereal in a cereal pipeline. The cereal injection device is simple in structure, andcereal injection and grouting can be achieved by the grouting pipeline and a plurality of gate valves; a plurality of branch pipelines are alternatively used for performing cereal injection and grouting, continuous operation can be achieved, the loaded cereal is continuously and constantly sent into the drill hole, the grouting efficiency is greatly improved, and the grouting time is shortened.

Owner:CHINA COAL NO 3 CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com