Intelligent automatic production line applied to paper mold formation

An automatic production line and forming paper technology, applied in the direction of cardboard articles, etc., can solve the problems of inability to improve production efficiency, low degree of integration automation, and restricting the development of the paper mold industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

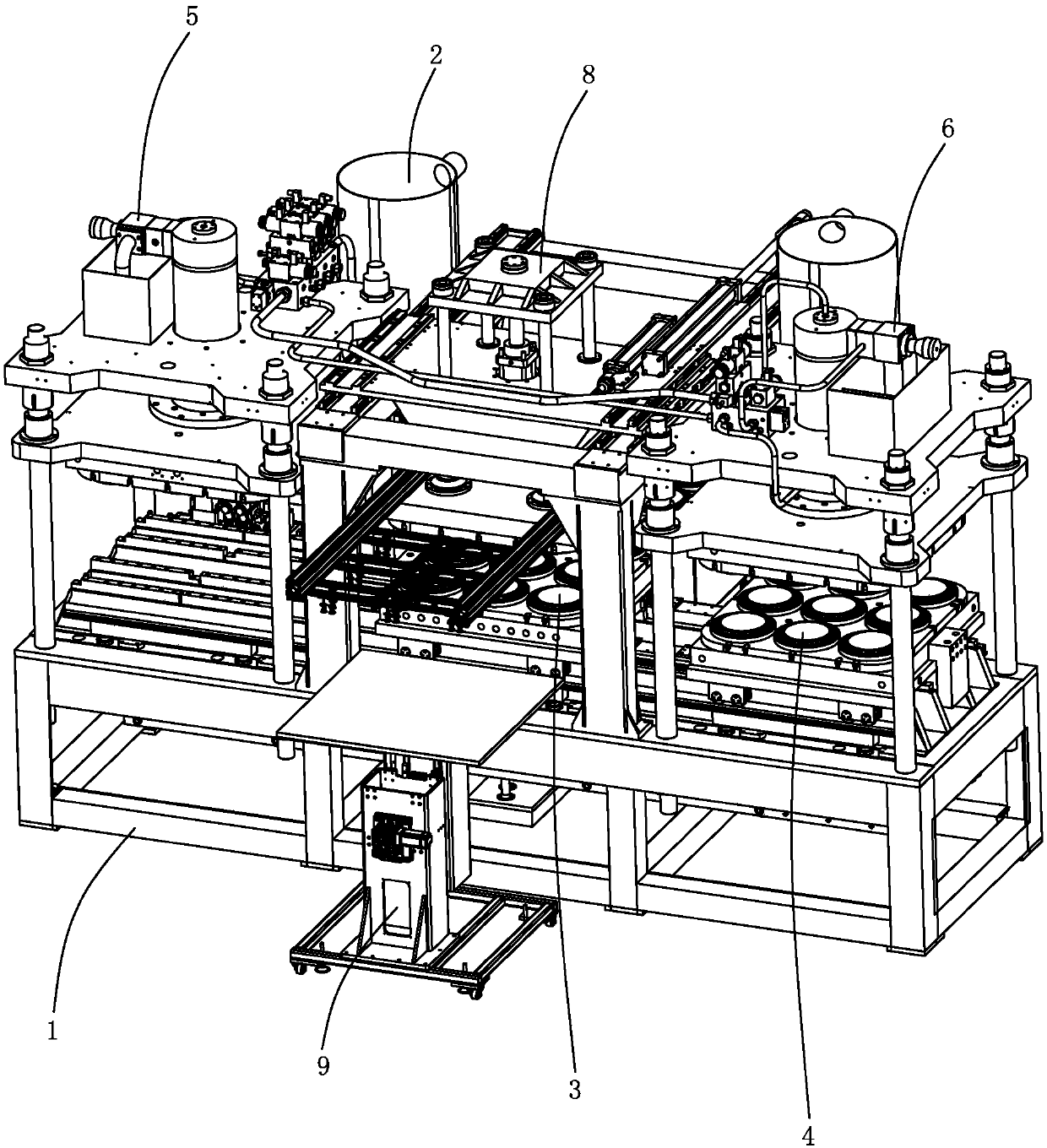

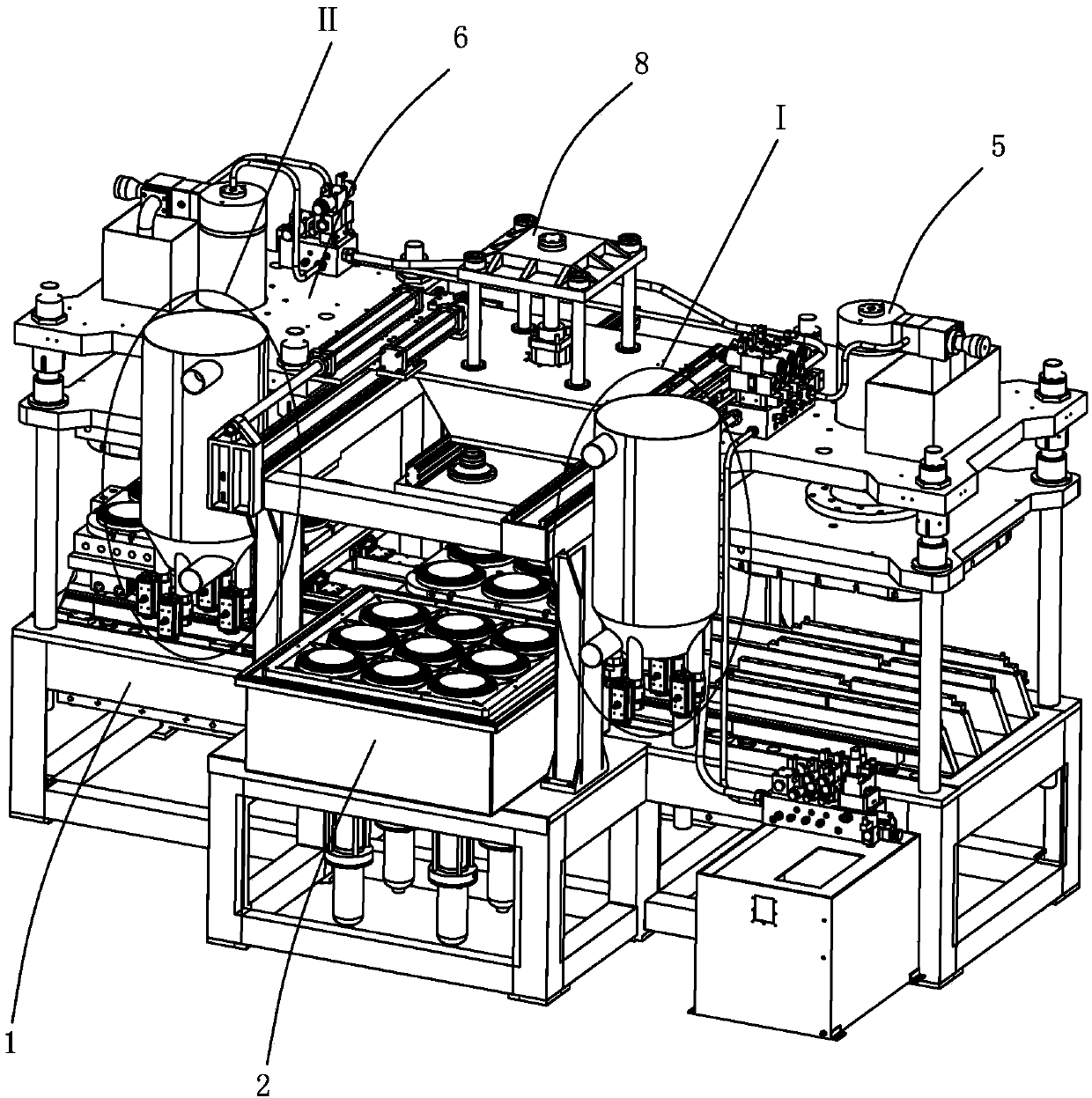

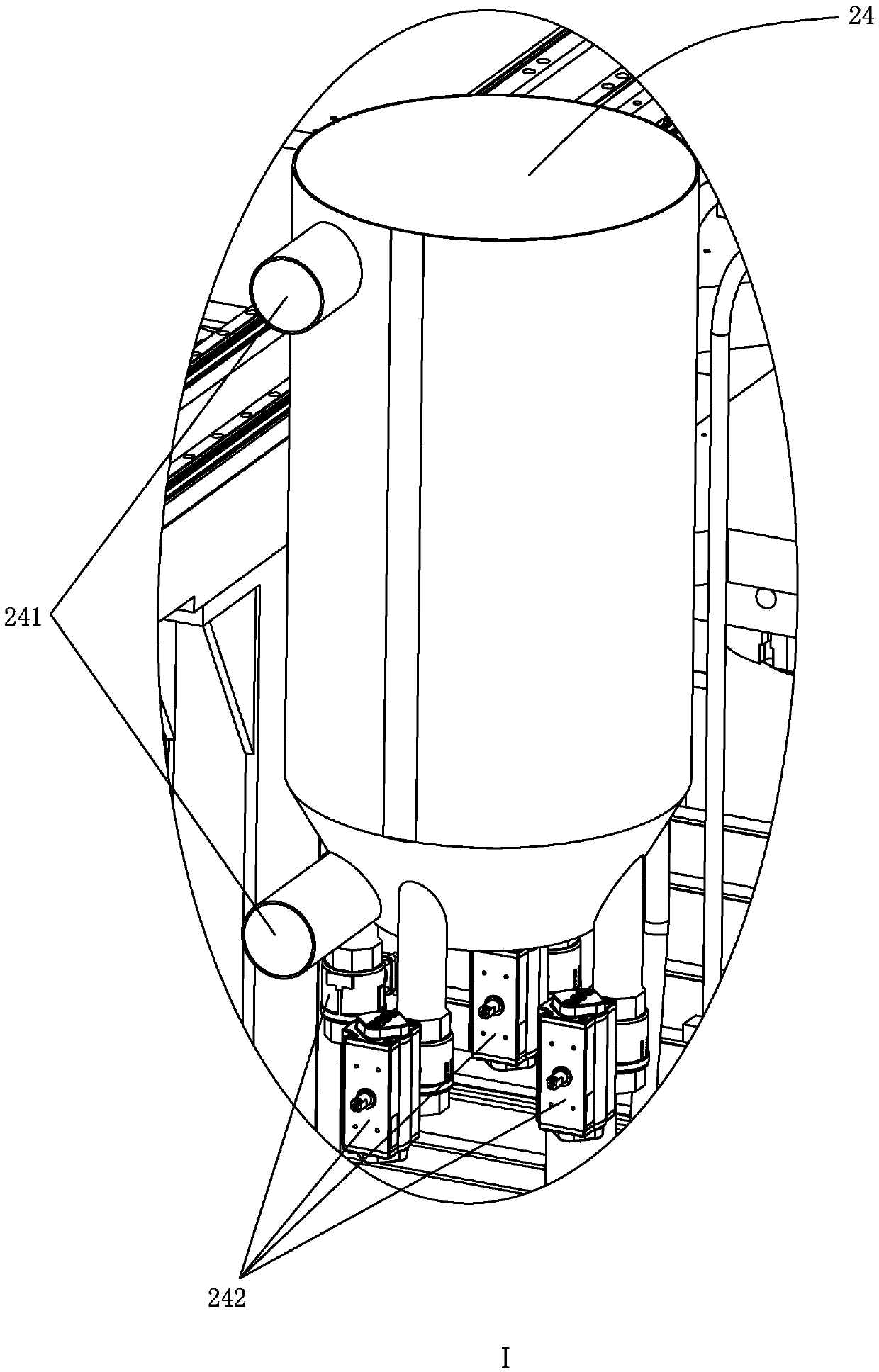

[0097] Such as Figure 1-14 As shown, the intelligent automatic production line applied to forming paper moulds, including frame 1, wet molding device 2, left workbench 3, right workbench 4, left hot press sizing device 5, right hot press sizing device 6, synchronous drive Mechanism 7, dry and wet mold handling device 8.

[0098] Specifically, the wet mold forming device 2 is arranged at the rear side of the frame 1 and is used for forming a wet paper mold. The left workbench 3 is arranged on the front side of the wet mold forming device 2, and is used for carrying a wet paper mold. The right workbench 4 is arranged on the right side of the left workbench 3 and is used for carrying wet paper molds. The left hot-press setting device 5 is arranged on the left side of the frame 1, and is used to cooperate with the left workbench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com