Microorganism low-temperature grouting and soil reinforcing method

A technology of microorganisms and microbial glue, applied in chemical instruments and methods, soil protection, building structure, etc., can solve the problems of uneven grouting of microorganisms at room temperature, etc. blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

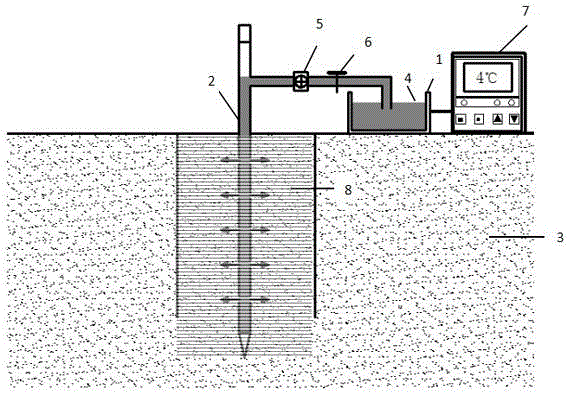

[0041] In this example, a microbial low-temperature grouting soil consolidation method is used to consolidate sandy soil foundations, and the method includes the following steps:

[0042] a. According to the actual engineering foundation soil conditions, choose summer for construction, and drive the grouting flower tube 2 of the low-temperature grouting equipment into the sandy soil foundation 3 according to the design requirements;

[0043] b. Use centrifugation to remove the existing biological enzymes and mix the 4°C low-temperature bacterial liquid with the mixture of 4°C calcium chloride and urea to make a microbial cementing liquid, and keep the temperature at 4°C, in which the concentration of the bacterial liquid is OD 600 =1.2, calcium chloride concentration is 0.50mol / L, urea concentration is 0.50mol / L;

[0044] c. Load the insulated container 1 with a well-proportioned 4°C low-temperature microbial cementing liquid 4, and the temperature control system 7 controls th...

Embodiment 2

[0049] In this example, a microbial low-temperature grouting soil consolidation method is used to solidify the silt foundation (the natural void ratio of the silt in the site is 0.87), and the method includes the following steps:

[0050]a. According to the actual project foundation soil conditions, choose summer for construction, and drive the grouting flower tube of the low-temperature grouting equipment into the powder soil foundation according to the design requirements;

[0051] b. Use centrifugation to remove the existing biological enzymes and prepare 4°C low-temperature bacterial liquid (bacterial liquid concentration OD 600 =1.2), mixed with a mixed solution of 4°C calcium chloride and urea (the concentration of calcium chloride is 0.25mol / L, and the concentration of urea is 0.25mol / L) to make a microbial cementing liquid, and keep the temperature at 4°C;

[0052] c. Load the insulated container 1 with a well-proportioned 4°C low-temperature microbial cementing liquid...

Embodiment 3

[0057] In this example, a microbial low-temperature grouting soil consolidation method is used to solidify the silt foundation (the natural void ratio of the silt in the site is 0.42), and the method includes the following steps:

[0058] a. According to the actual project foundation soil conditions, choose summer for construction, and drive the grouting flower tube of the low-temperature grouting equipment into the powder soil foundation according to the design requirements;

[0059] b. Use centrifugation to remove the existing biological enzymes and prepare 4°C low-temperature bacterial liquid (bacterial liquid concentration OD 600 =1.2), mixed with a mixed solution of 4°C calcium chloride and urea (the concentration of calcium chloride is 0.10mol / L, and the concentration of urea is 0.10mol / L) to make a microbial cementing liquid, and keep the temperature at 4°C;

[0060] c. Load the insulated container 1 with a well-proportioned 4°C low-temperature microbial cementing liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com