Pile bottom grouting method

A pile bottom and grouting technology, which is applied in construction and foundation structure engineering, can solve the problems of high cost and low efficiency of grouting operations, and achieve the effects of saving grouting time, high strength, and large vertical expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

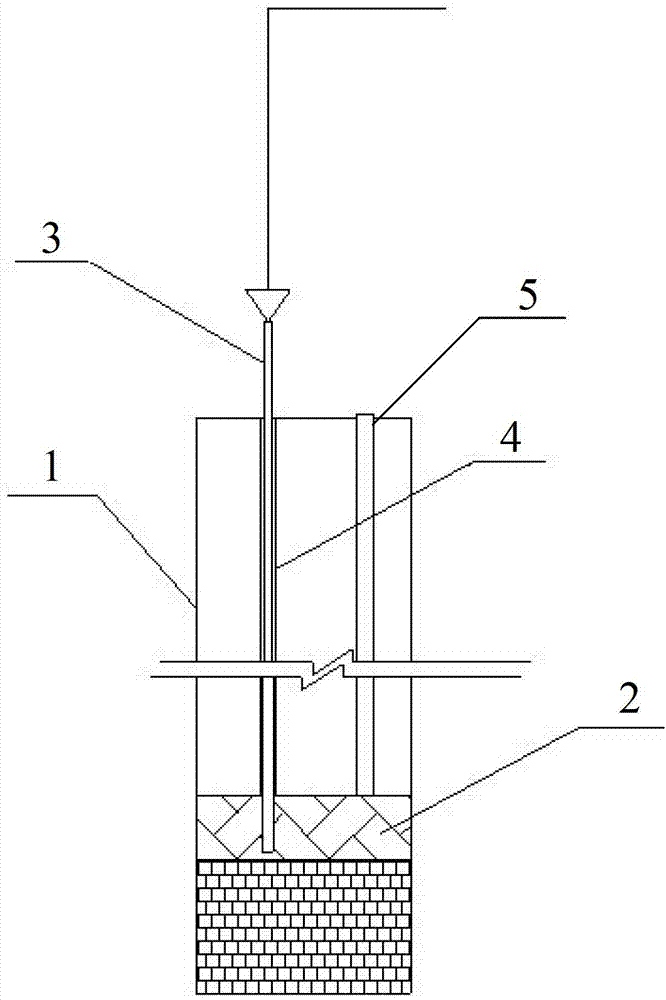

[0024] The method for pile bottom grouting proposed by the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

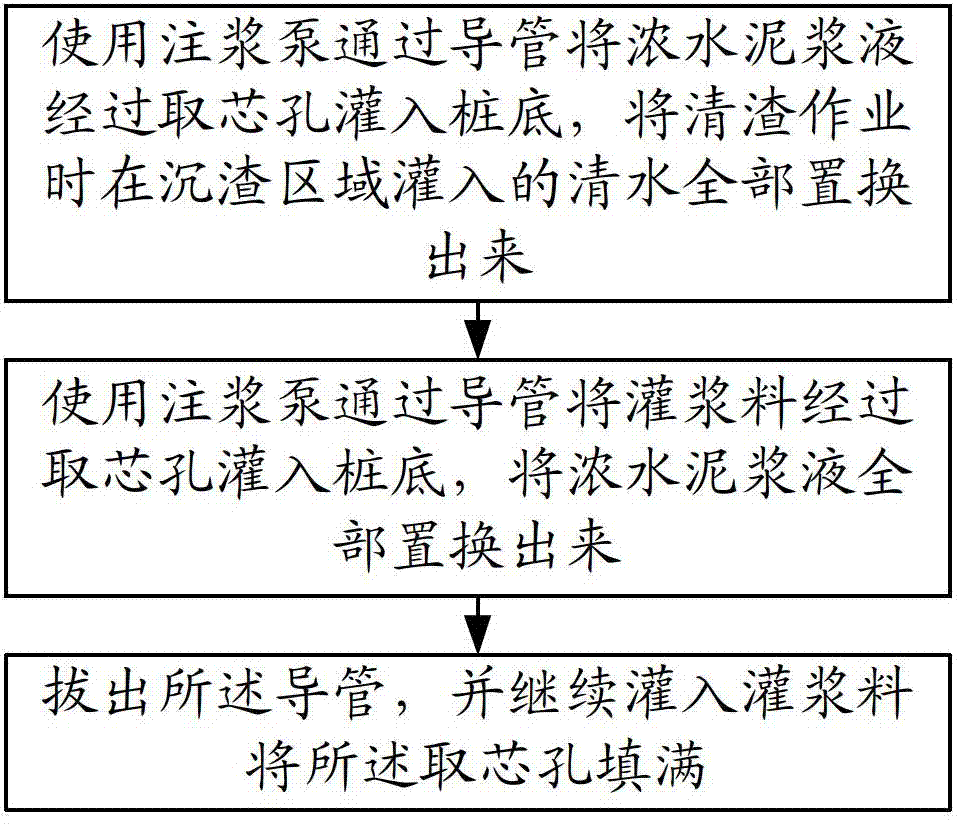

[0025] The core idea of the present invention is to provide a method for pile bottom grouting, which is used to fill the space left by the pile bottom sediment area of the pile foundation after removing the sediment. The pile bottom grouting method includes step 1: using The grouting pump pours the thick cement slurry into the bottom of the pile through the core hole through the conduit, and replaces all the clear water poured into the sediment area during the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com