Reinforce structure of prefabricated beam-column compression joint and construction method thereof

A technology for strengthening structures and prefabricated columns, applied in building structures, buildings, etc., can solve the problems of high concrete repair cost and easy slurry leakage, and achieve the effects of reducing construction support modulus, improving seismic performance and fast construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

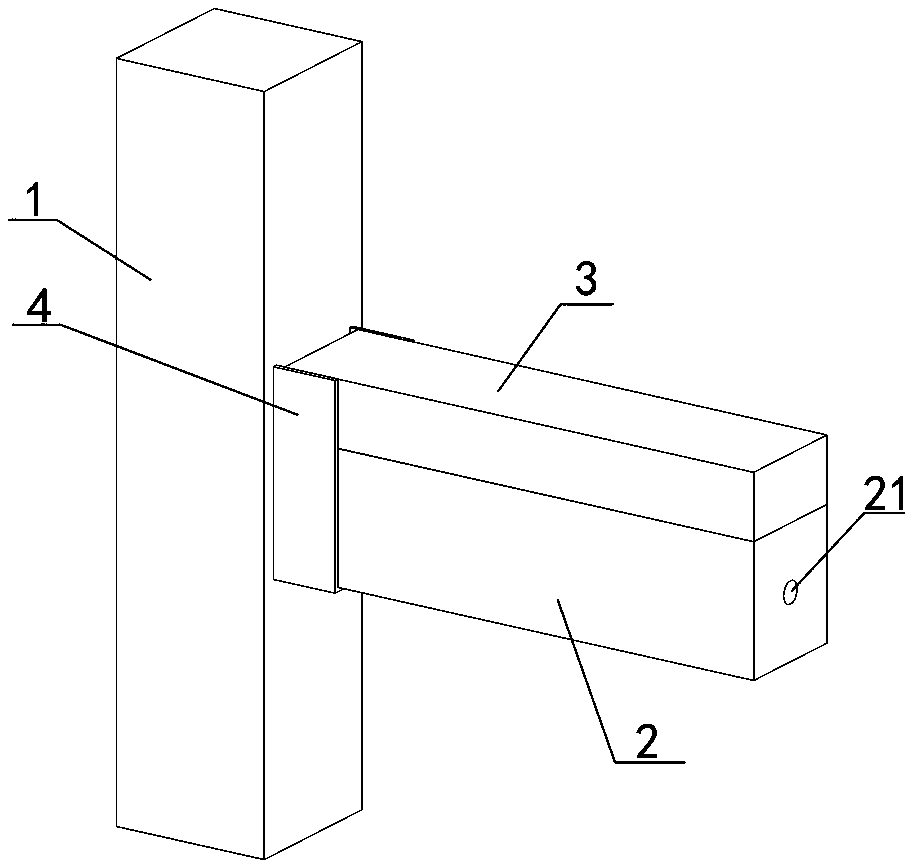

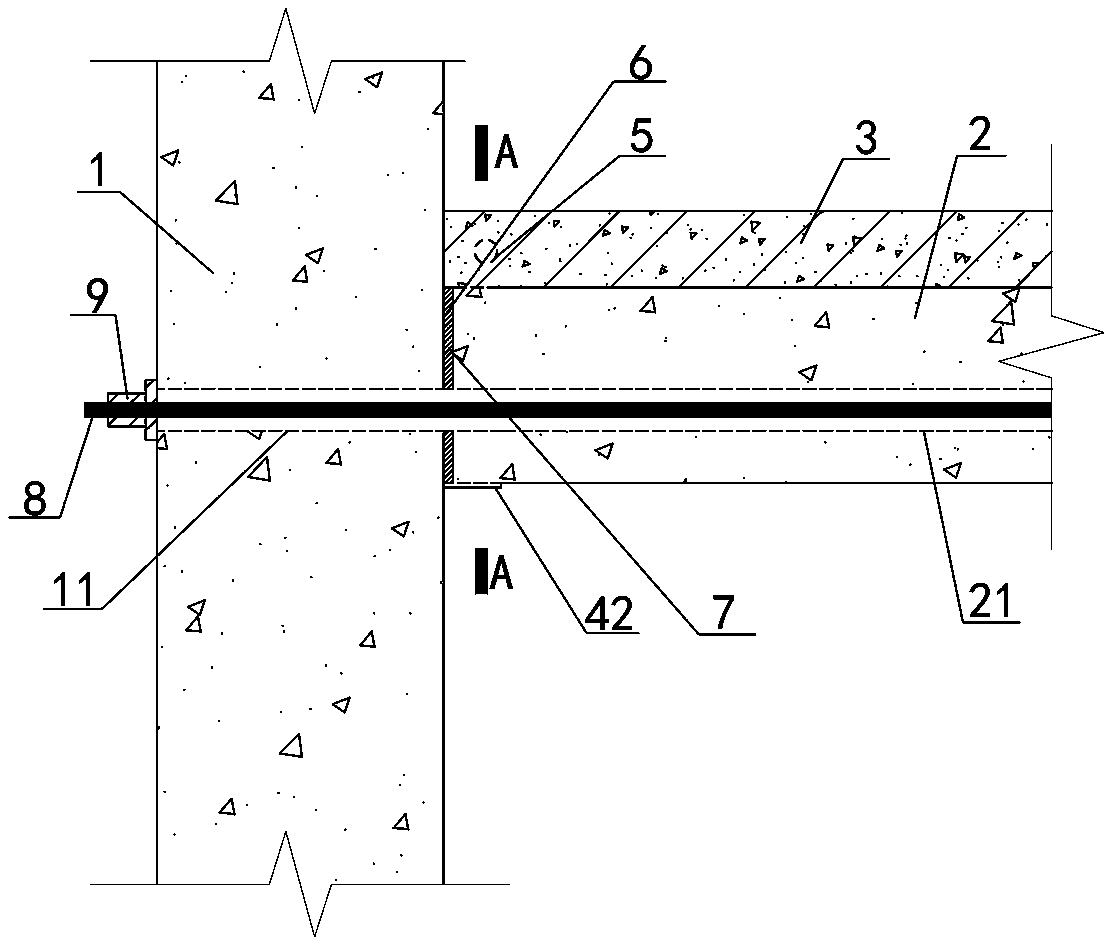

[0048] Embodiment one sees Figure 1-4 As shown, a prefabricated beam-column crimping joint reinforcement structure includes a connected concrete prefabricated column 1 and a concrete composite beam, and the composite beam includes a prefabricated lower part 2 and a cast-in-place upper part 3, and the The end of the composite beam is covered with a node strengthening device, and the node strengthening device includes a U-shaped bracket 4 and an anchor rod 5 .

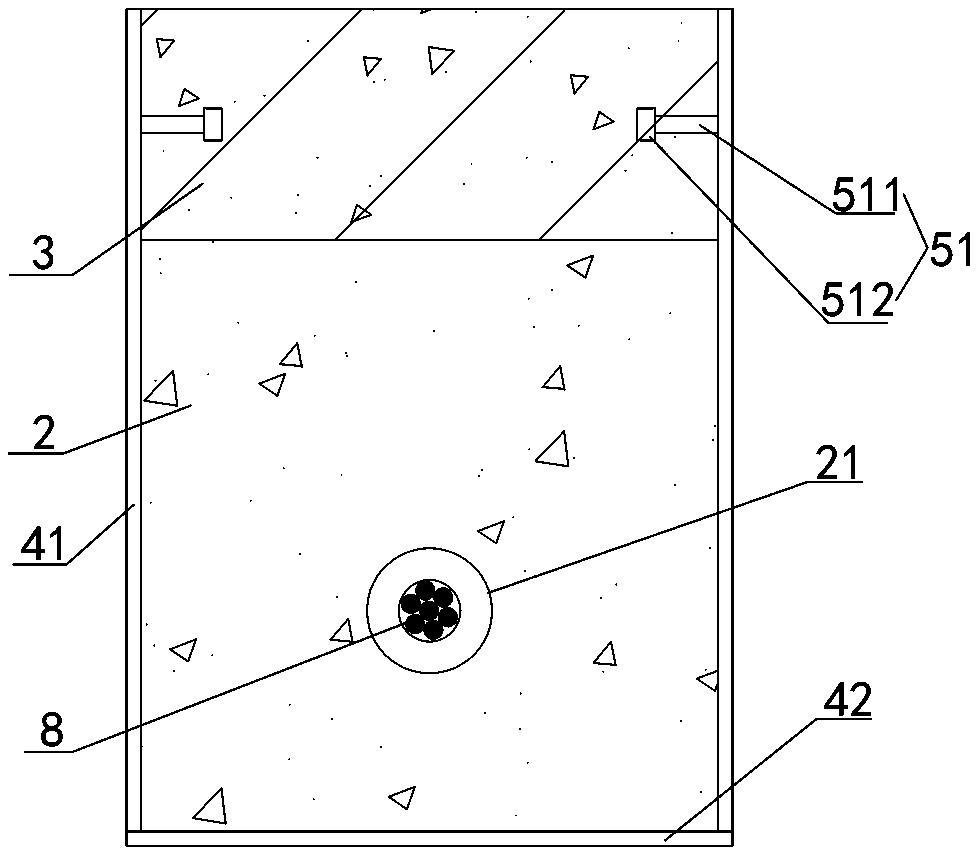

[0049] The U-shaped bracket includes two parallel vertical side plates 41 and a horizontal bottom plate 42 , and the two ends of the horizontal bottom plate 42 are respectively fixedly connected with the bottom of the vertical side plates 41 .

[0050]The upper side of the horizontal bottom plate 42 is close to the bottom side of the composite beam, the inner side of the vertical side plate 41 is close to the two outer sides of the width direction of the composite beam, and the front end surface of the vertical side pla...

Embodiment 2

[0065] Embodiment two see Figure 1-2 , 5-6, different from Embodiment 1, the anchor rod 5 is a screw rod 52, and the screw rod 52 is linear, and the length of the screw rod 52 is greater than the setting distance between the vertical side plates 41, and the screw rod 52 Both ends of the screw rod 52 are provided with external threads 521, and the corresponding positions of the two vertical side plates 41 are provided with opposite side plate screw holes 411, and the two ends of the screw rod 52 pass through the side plate screw holes 411 respectively, and the two external threads of the screw rod 52 521 are threadedly connected with two nuts 53 respectively, and the two ends of the screw rod 52 are also sleeved with two backing plates 10 with a backing plate screw hole in the center and close to the outer side of the vertical side plate 41, and the two nuts 53 are respectively tightened. Be fixed to the outer sides of the two backing plates 10.

[0066] The diameter of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com