Prestress assembly frame structure

A frame structure, prestressed technology, applied in the direction of building structure, construction, etc., can solve the problem of ineffective energy consumption of beam-column joints and column base joints, inability to protect concrete in the interface compression zone, and inconvenient realization of column-column joints To achieve the sustainable development of social economy, improve the level of industrialization of construction, and improve the effect of earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

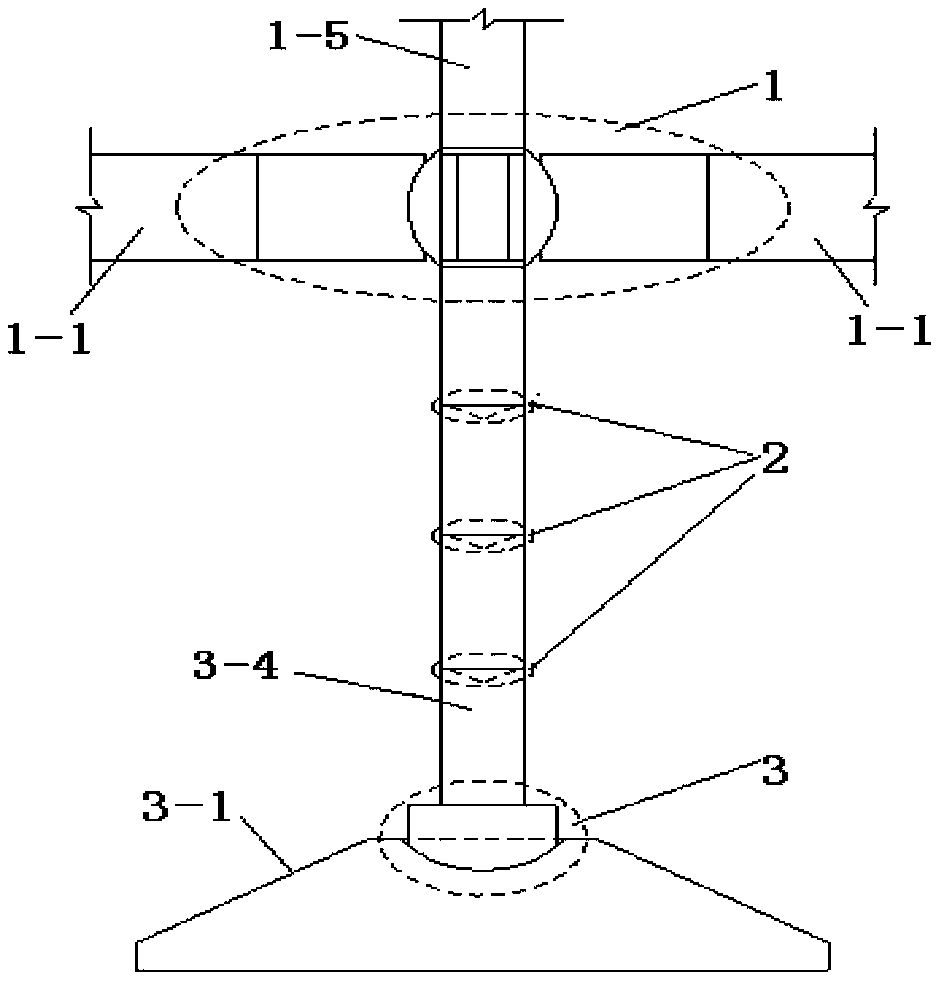

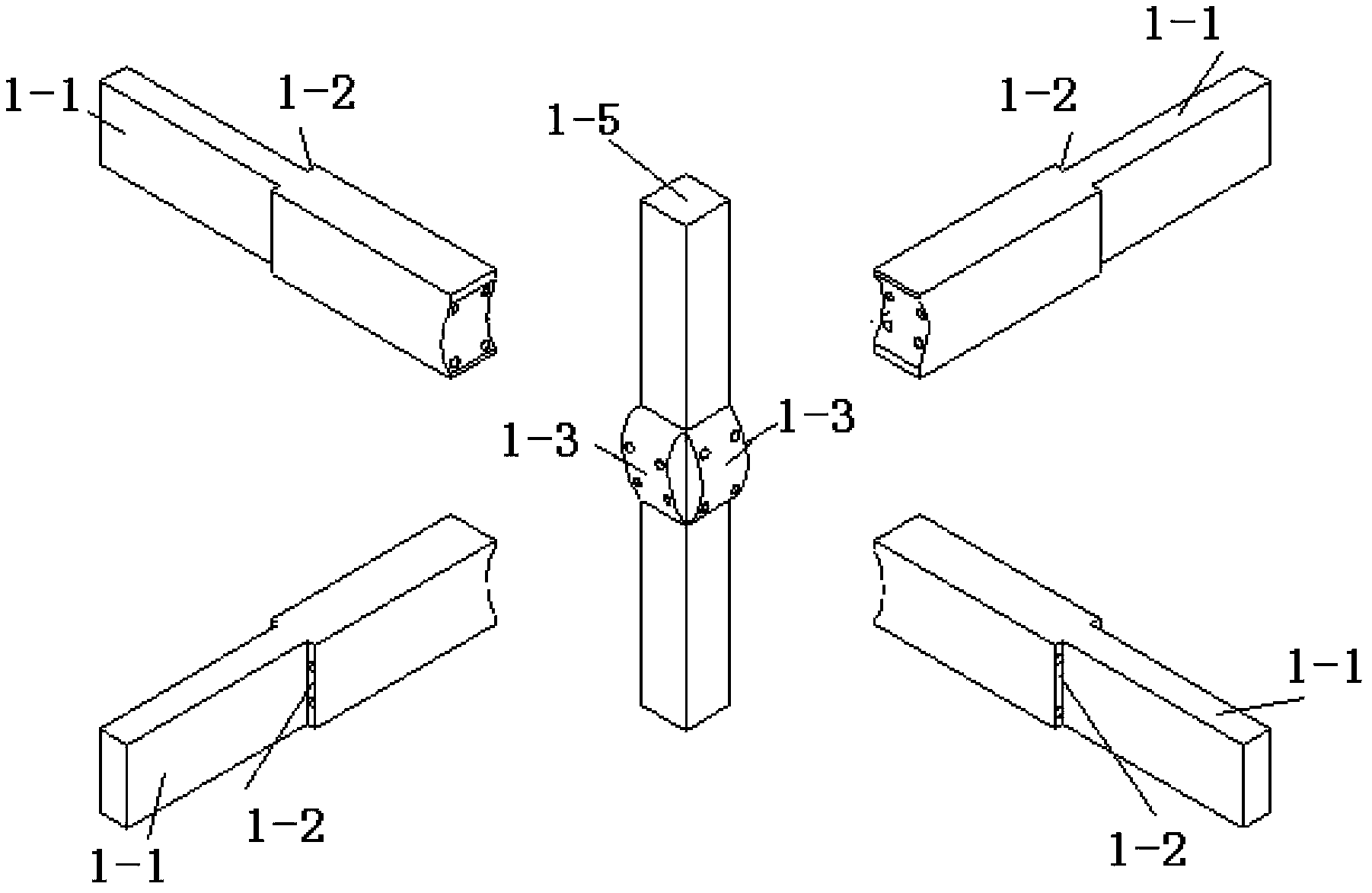

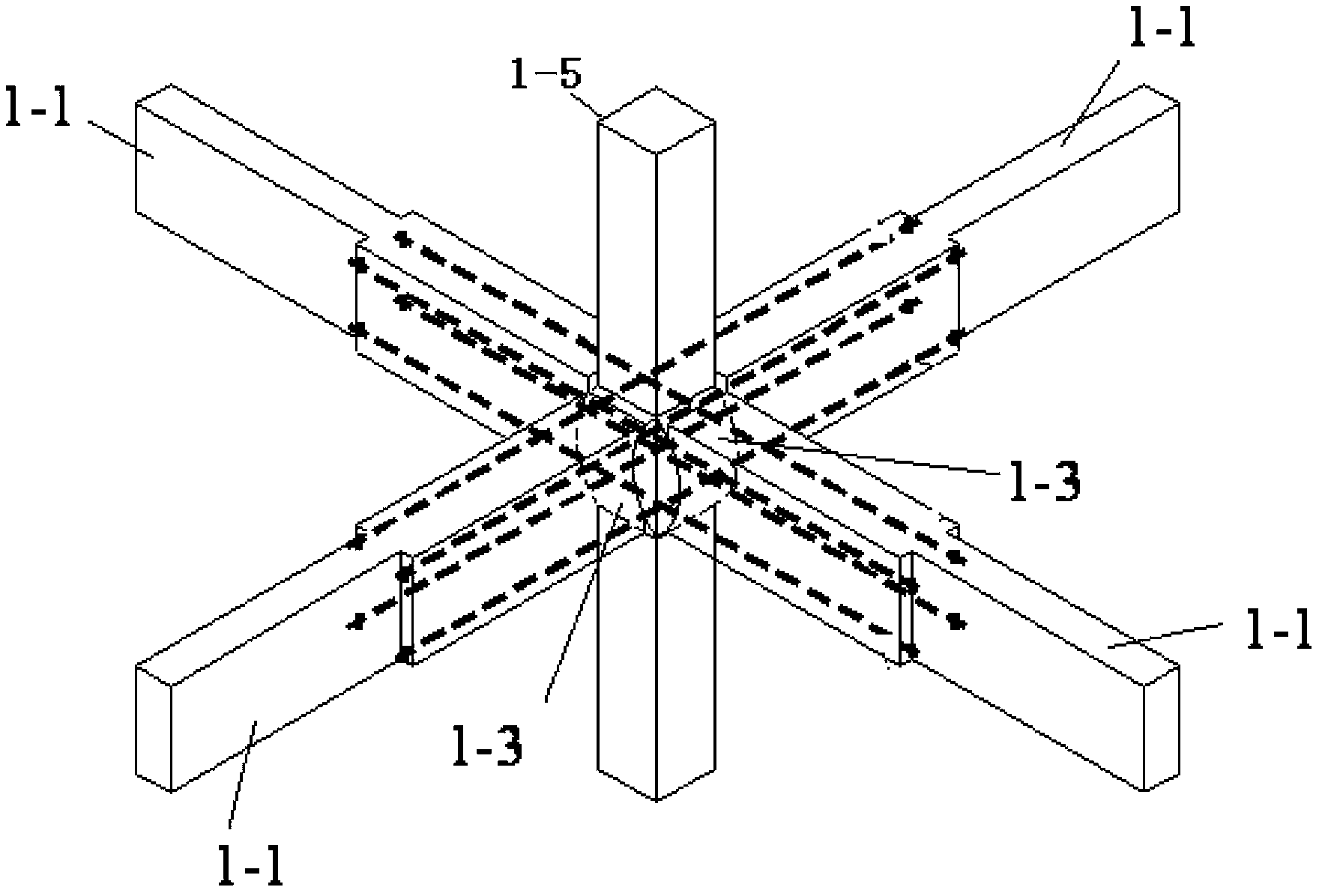

[0036] Embodiment one: if image 3 and 4Shown: When the end face of the side wall raised step 1-2 is wide enough to directly arrange the anchorage and tensioning equipment, in the direction of each main axis of the beam-column connection, the channels and floors in the curved corbel 1-3 The holes in the columns 1-5 and the holes in the floor beam 1-1 are in the shape of two straight lines, the cross-sectional area of the holes at the connection interface is larger than the cross-sectional area of the end of the holes, and the four straight-line holes are connected with the floor beams. The central axis of 1-1 is parallel, and the central axis is the symmetrical central line of the four channels.

Embodiment 2

[0037] Embodiment two: if Figure 5 and 6 Shown: When the end face of the side wall raised step 1-2 is narrow enough to directly arrange the anchorage and tensioning equipment, in the direction of each main axis of the beam-column connection, the holes in the curved corbel 1-3, The tunnels in the floor columns 1-5 and the tunnels in the floor beams 1-1 are in the shape of two curves, the cross-sectional area of the tunnels at the connection interface is larger than the cross-sectional area of the tunnel ends, and the four curved tunnels are along the floor. The central axis of the beam 1-1 is symmetrical to the center, and the tunnel in the floor beam 1-1 enters obliquely from the end surface of the raised step 1-2 on the side wall.

[0038] In the above-mentioned beam-column joints, when the floor column 1-5 is a central column, the side walls of the floor column 1-5 are provided with floor beams 1-1; when it is a side column, the three floor columns 1-5 The side walls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com