Intelligent temperature control algorithm suitable for livestock and poultry breeding waste treatment

An intelligent temperature control, livestock and poultry breeding technology, applied in the field of livestock and poultry breeding waste treatment, can solve the problems of affecting aerobic fermentation, incomplete harmless treatment, waste of auxiliary heating of fermentation tanks, etc., to improve the control accuracy and effect. , Guarantee harmless treatment effect, control effect and high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

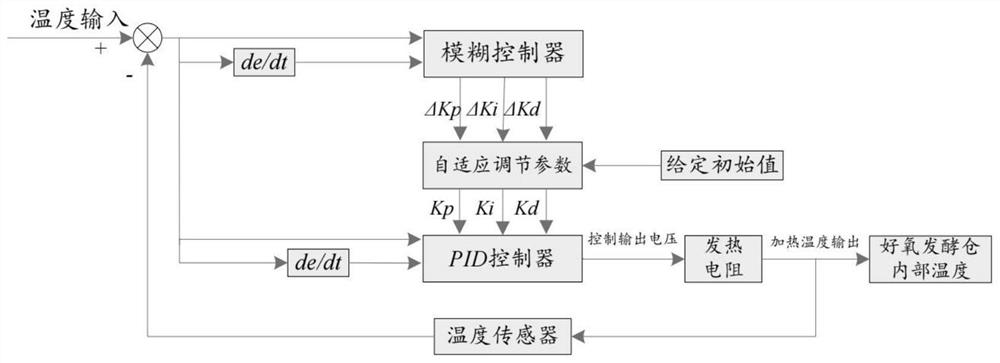

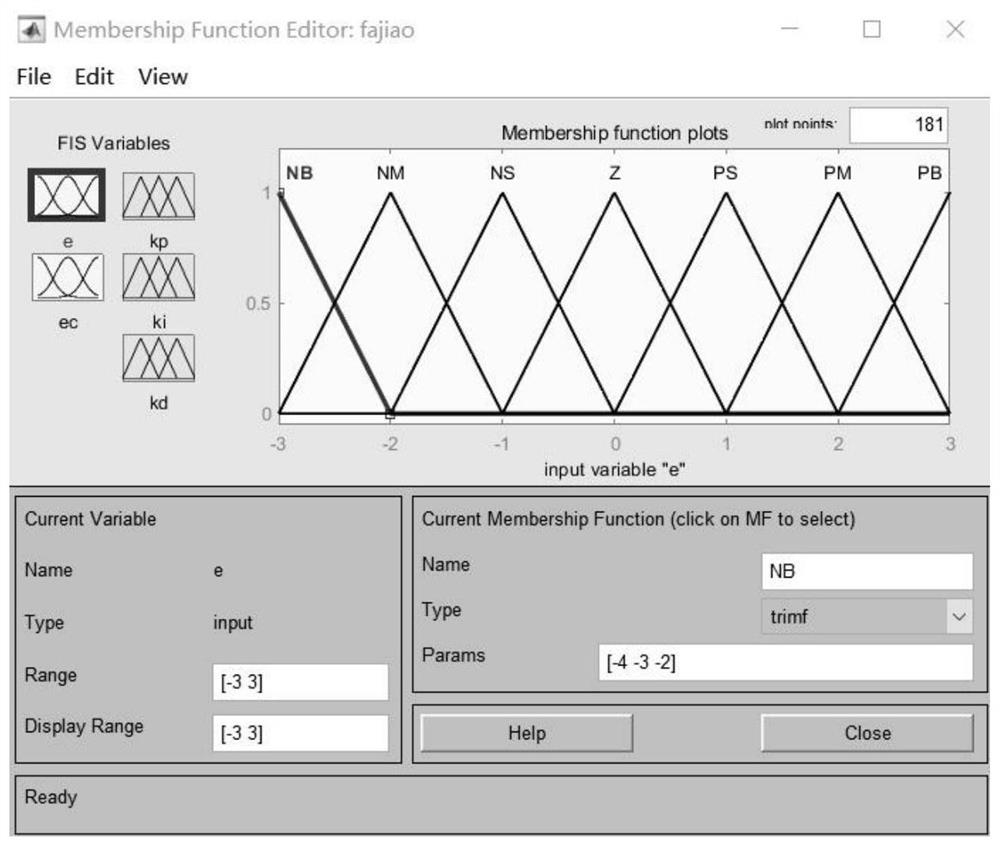

[0158] In step S2-1, a fuzzy PID controller is designed, and according to the control law of the fuzzy PID controller and the control method of the classical PID, the relevant fuzzy rules are determined and a fuzzy control rule table is established.

[0159] Fuzzy PID controller uses two-dimensional fuzzy controller. That is, take the deviation e of the target temperature value and the deviation change ec as the input, and take ΔK as the input. P , ΔK I , ΔK D is an adaptive fuzzy PID controller for the output.

[0160] figure 2 It is a block diagram of the fuzzy PID temperature control algorithm of livestock and poultry manure treatment-aerobic fermentation in the embodiment of the present invention.

[0161] like figure 2 As shown in the figure, the PID parameters are modified online using the fuzzy control rules summarized after many experiments at runtime.

[0162] Therefore, the fuzzy adaptive tuning of PID parameters is to find out the three PID parameters K p ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com