Pile foundation grouting pressure testing device and method based on optical fiber sensing

A technology of grouting pressure and optical fiber sensing, which is applied in the test of foundation structure, foundation structure engineering, construction, etc., can solve the problem of outdated pile foundation grouting pressure test device, limitation of grouting technology popularization, and interference of empirical value, etc. problems, to achieve the effect of ensuring reliability, increasing the bonding range, and reducing the grouting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

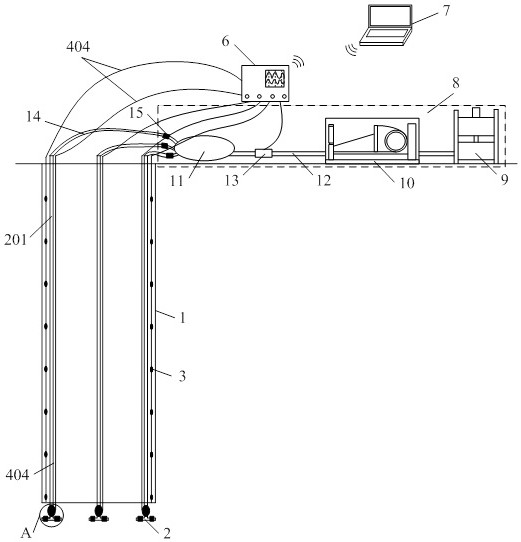

[0038] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

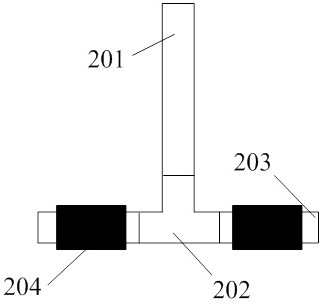

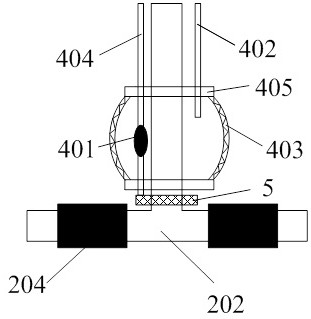

[0039] like figure 1As shown, a pile foundation grouting pressure test device and method based on optical fiber sensing in the present invention includes a steel cage 1, a pile end inverted T-shaped grouting device 2, an optical fiber strain sensor 3, a high-pressure elastic capsule, and a pressure test element 5 , data acquisition instrument 6, background processor 7 and grouting device 8. The inverted T-shaped grouting device 2 at the pile end is composed of a vertical grouting conduit 201, a tee joint 202 and a horizontal grouting device 203. The vertical grouting conduit 201 is connected to the grouting device by a distributor 11 through a grouting pipe 14. 8. The grouting device 8 includes a stirring slurry storage device 9, a grouting pump 10, a distributor 11, and a slurry delivery pipe 12. The slurry delivery pipe 12 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com