Grouting device and grouting method for sleeve grouting

A sleeve grouting and sleeve technology, which is applied in the processing of building materials, structural elements, building components, etc., can solve problems such as holes in sleeve grouting, difficulty in ensuring grouting density, and inability to effectively remove air, so as to achieve construction efficiency High, shorten the construction time, avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

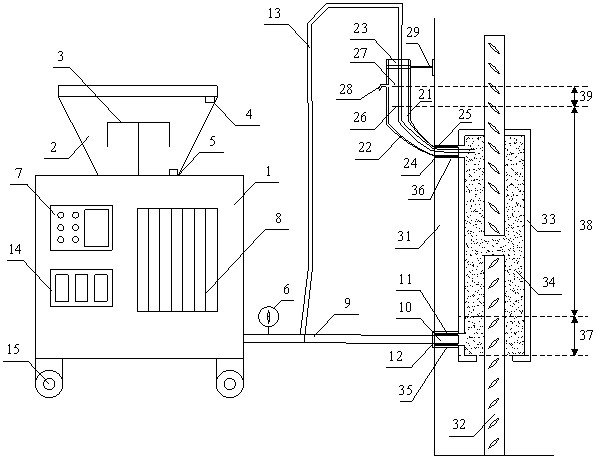

[0057] A grouting method for steel sleeve grouting is used for realizing high-efficiency grouting of the steel sleeve and ensuring the grouting quality.

[0058] (1) Pre-preparation: 1) Use an air compressor to remove dust, slag and other sundries inside steel bars and steel sleeves 33. If necessary, use clean water to wash away surface impurities, and use an air compressor to blow off excess water droplets; 2) Mix the grout mixture 34, the quality of the grout mixture 34 should meet the requirements of "Steel Sleeve Grout Mixture for Rebar Connection" (JG / T 408-2013), and it should be used within 30 minutes Finished; 3) Before connecting the grouting hole 35, carry out the test pumping to remove the air, water and other impurities in the grouting pipe 9, and remove the grouting material mixture 34 which is unevenly mixed, and wait for the mixing to be uniform and the color consistent The grouting material mixture 34 flows out for 2~3 s, and the grouting test is over; 4) Conne...

Embodiment 2

[0062] A grouting device and a grouting method for sleeve grouting, which are used to realize high-efficiency grouting of steel sleeves and ensure the quality of grouting.

[0063] In this embodiment, except for the grout filling pipe 13, the others are the same as in Embodiment 1.

[0064] If the grouting material mixture 34 on the booster pipe 21 drops below the suitable slurry line 26, the grout replenishment operation is performed, and the grout replenishment operation steps are as follows:

[0065] 1) Insert the grout filling pipe 13 from the booster pipe 21, and insert it into the steel sleeve 33 as deeply as possible;

[0066] 2) Keep the position of the grout feeding pipe 13 unchanged, feed grout at the first pressure until the mouth of the grout feeding pipe 13 is submerged by 5-20 mm, and the grout feeding speed is 3-5 mm / s;

[0067] 3) Keep the position of the grouting pipe unchanged, and use the pressure wave characterized by the second amplitude and the second fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com