Construction method of grouting for corrugated pipe channel with negative bending distance

A technology of tunnel grouting and construction method, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problem that the construction method of tunnel grouting for bellows with negative bending distance is not disclosed, and the construction of negative bending distance is dangerous and difficult to solve. problems, etc., to achieve the effect of convenient quality inspection and control, convenient grouting operation, and easy quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

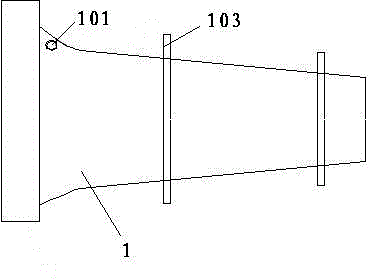

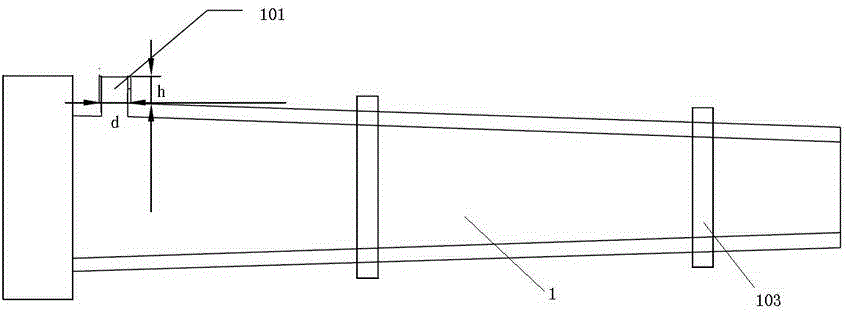

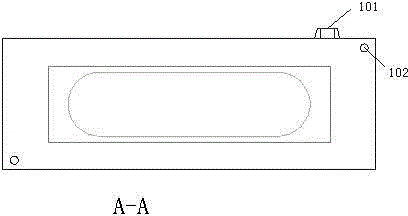

[0056] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the anchor backing plate 1 used for grouting of the bellows channel with negative bending distance, the anchor backing plate 1 is a hollow tower-like structure, the anchor backing plate 1 is provided with an improved grouting hole 101, and the center of the grouting hole 101 The angle between the axis and the side of the anchor plate is 60-90°. The grouting hole 101 extends upward from the side of the anchor backing plate and protrudes. The vertical distance between the top surface of the grouting hole 101 and the side of the anchor backing plate, that is, the height h of the protrusion, is 2-3 cm, and the outer diameter d of the grouting hole 101 is 1.5-2.5 cm. cm. The grouting hole 101 is provided with a threaded hole or a threaded thread for matching with the grouting pipe. The bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com