Patents

Literature

46results about How to "Fast grouting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

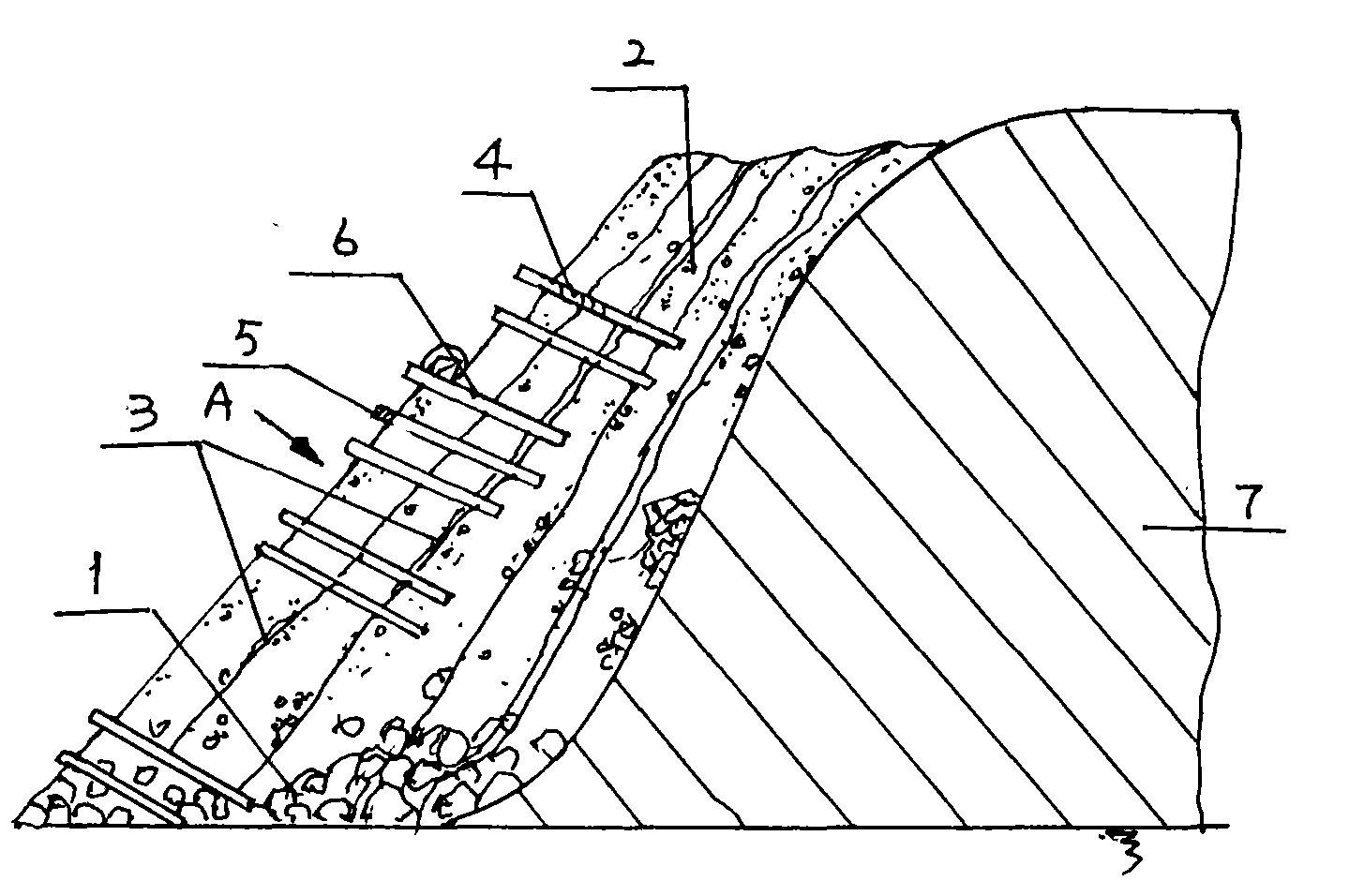

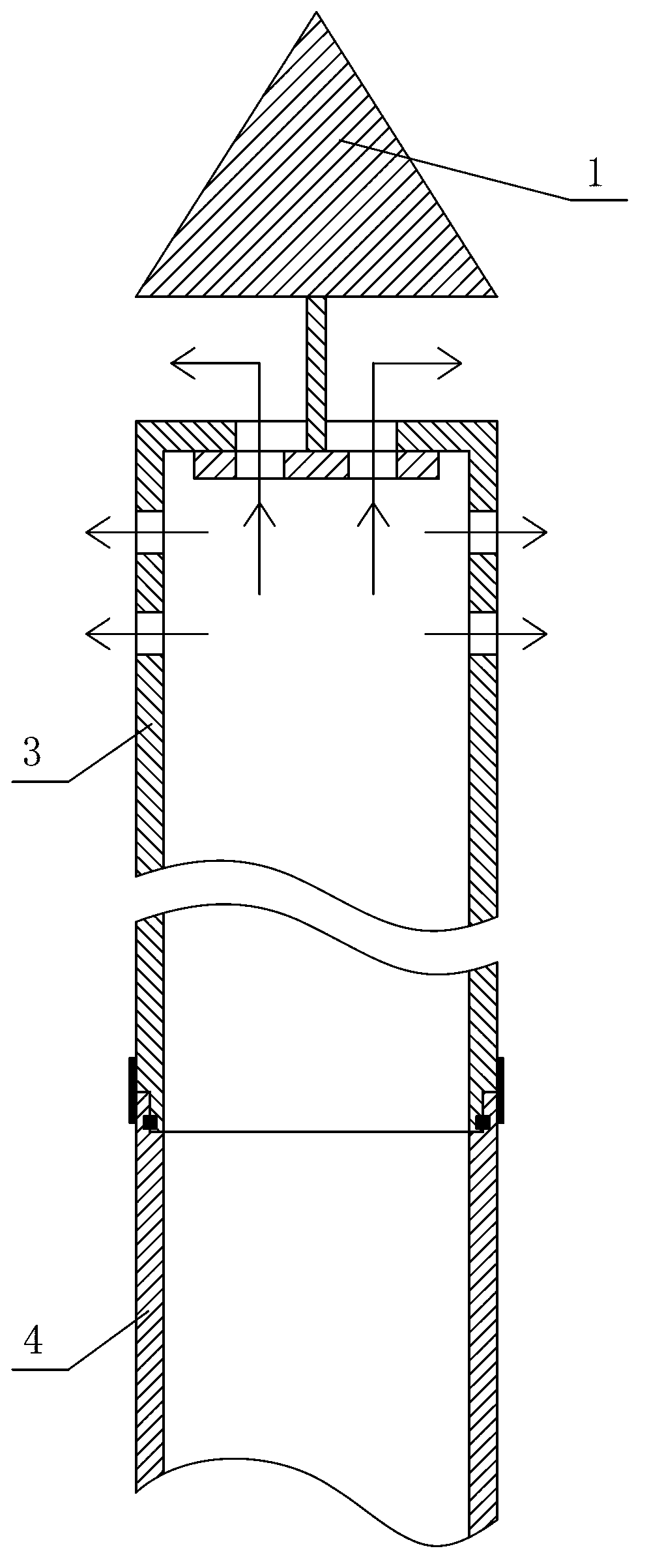

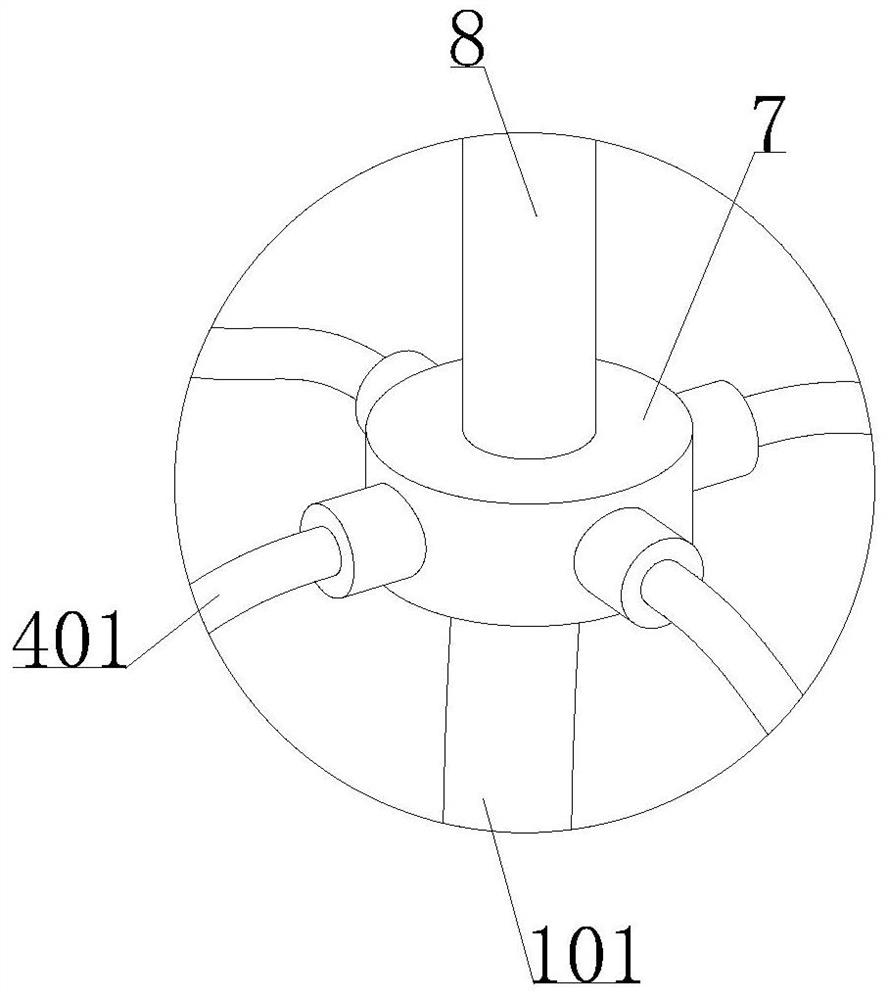

Autoignition coal gangue flow slope extinguishment and steadiness comprehensive treatment technology

InactiveCN103410140AChange structural propertiesBlock flowFire rescueExcavationsSurface layerEcological environment

The invention discloses an autoignition coal gangue flow slope extinguishment and steadiness comprehensive treatment technology, and belongs to the field of treatment of mineral product waste and ecological environment recovery. The autoignition coal gangue flow slope extinguishment and steadiness comprehensive treatment technology comprises the steps that shallow-hole curtain filling is adopted, and after dedicated grouting pipes (4) which are preset are regularly planted into a slope body of a coal gangue flow slope and grouting is carried out, and steel wire ropes (9) are used for carrying out net-shaped connection on ground surface nodes (5) of the grouting pipes (4). The effect of steel rib piling and the effect of grid connecting piling can be achieved, the effect of solidification grouting or the effect of curtain grouting can be achieved, flow of air and water in the slope body of the coal gangue flow slope can be effectively stopped, the chimney effect is eliminated, when evaporation of water is received, cooling extinguishment is preferentially carried out, a curtain is solidified to block the air and prevent fire, and can achieve the effect of preventing a forward landslide, the foundation is laid for later-stage surface layer ejection grouting blocking and soil dressing vegetation recovery, and the autoignition coal gangue flow slope extinguishment and steadiness comprehensive treatment technology is good in enablement and easy to operate, can ensure that ecological environment comprehensive treatment of the coal gangue flow slope can be achieved fundamentally and rapidly, and is beneficial to human and the society.

Owner:赵平

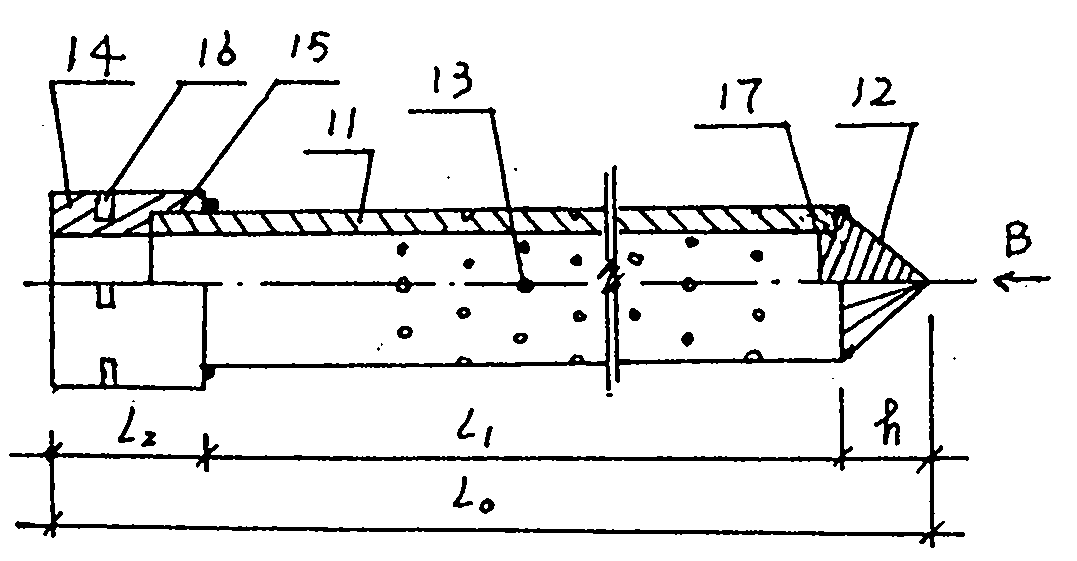

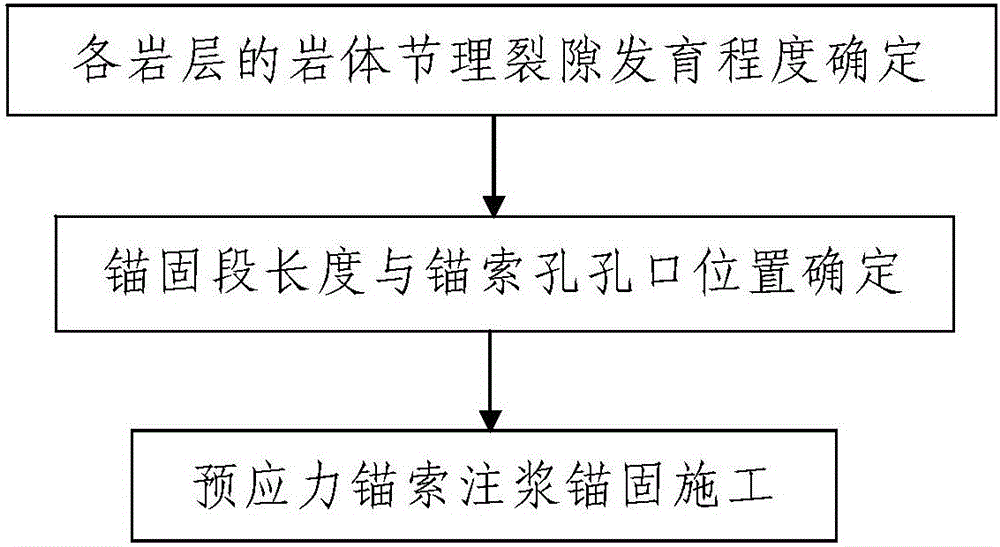

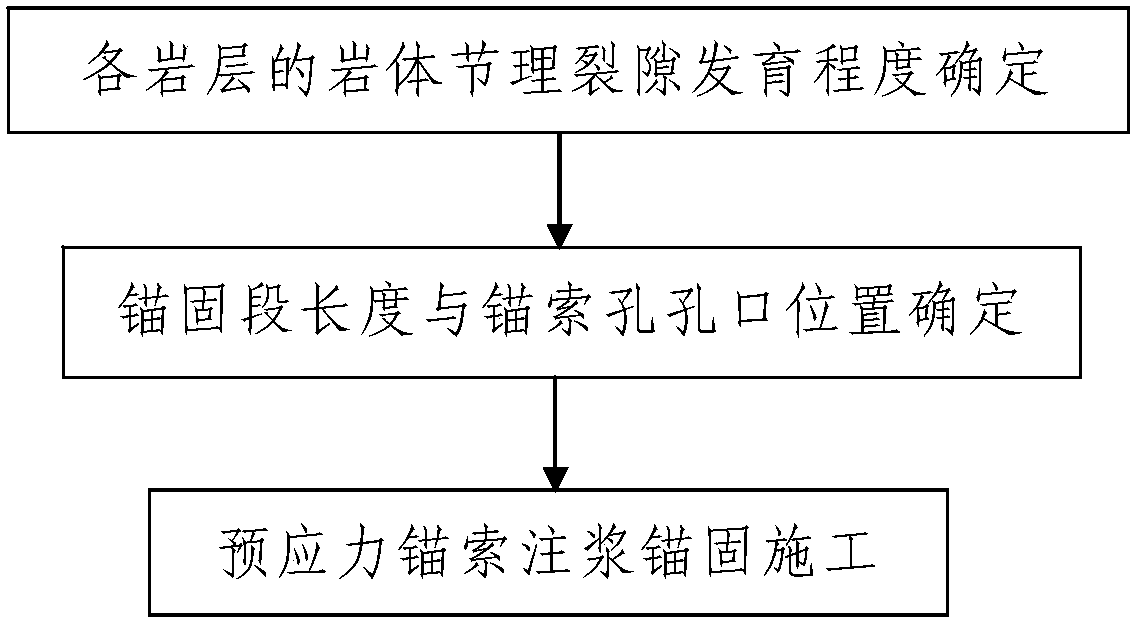

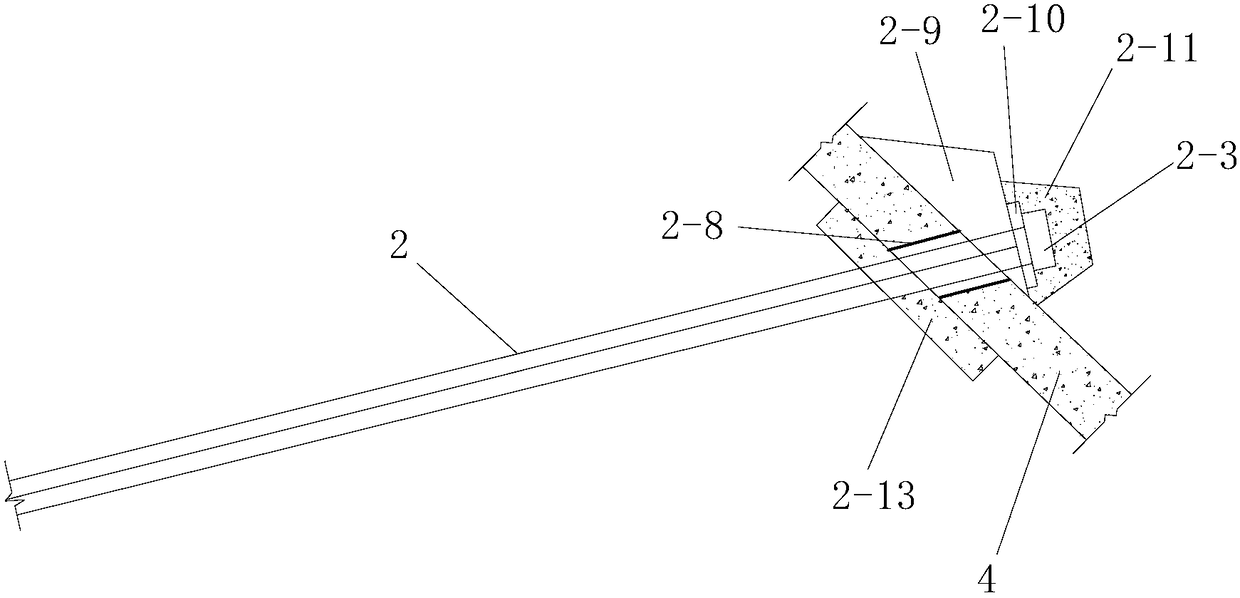

Fissure-contained rock soil stratum prestressed anchor cable grouting and anchoring construction method

ActiveCN106522243AThe method steps are simpleReasonable designExcavationsBulkheads/pilesPre stressHigh pressure

The invention discloses a fissure-contained rock soil stratum prestressed anchor cable grouting and anchoring construction method. Multiple prestressed anchor cables uniformly distributed on the same one plane are adopted to reinforce a slope to be reinforced; the method comprises the following steps: (1) the rock mass joint fissure development degree of each rock stratum is determined; (2) the lengths of anchoring sections and the hole port positions of anchor cable holes are determined; the prestressed anchor cables include anchor cable bodies, primary grouting pipes and secondary grouting pipes; anchoring tools are mounted at the back ends of the anchor cable bodies; and the anchor cable bodies include multiple steel strands; and (3) the prestressed anchor cables are grouted and anchored: when any one prestressed anchor cable is grouted and anchored, the construction includes the steps of drilling, placement of the anchor cables, normal-pressure grouting, high-pressure grouting, tensioning of the anchor cables and anchor sealing. The method is simple in steps, reasonable in design, convenient to construct, high in construction efficiency and excellent in use effect, and can conveniently and quickly finish the reinforcing process of the slope to be reinforced; and the adopted prestressed anchor cables are low in cost and higher in anchoring force, and can effectively reinforce the slope to be reinforced.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

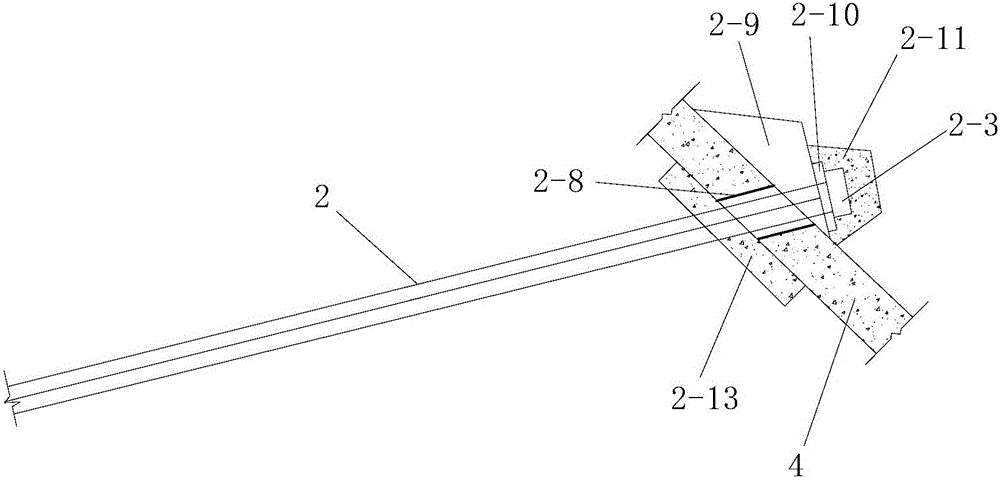

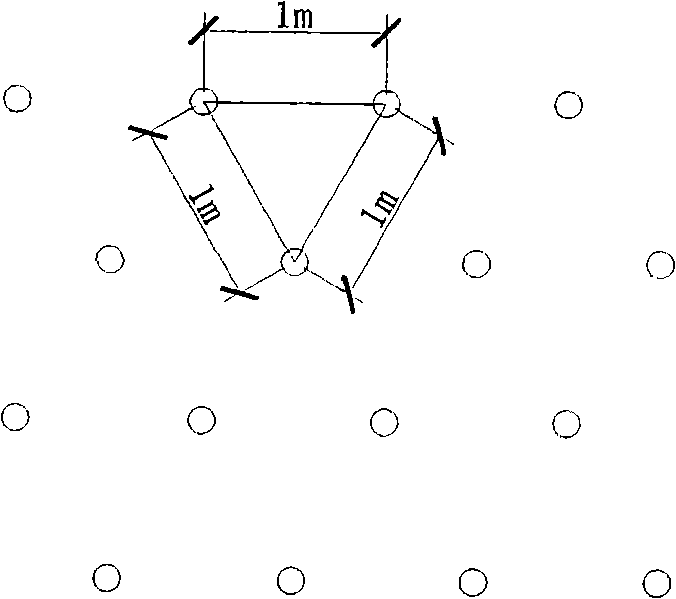

Advance support fast construction method in shallow tunnelling loose pebble bed

ActiveCN101818647ASolving Mobility IssuesSolve alignment problemsAnchoring boltsUnderground tunnelSlurry

The invention discloses an advance support fast construction method in shallow tunnelling loose pebble bed. A guide rail type independent rotary rock drill and a triangle drilling rig are adopted, and a self-advancing hollow grouting anchor bar is adopted to drive the advance support rod body; multi-hole spacing grouting is adopted, and appropriate double grout matching is selected. The invention has the beneficial effects that: part of pebble can be impacted to be crushed or be extruded into a hole, the problems of shifting and aligning of heavy duty drill in a narrow underground tunnel are effectively solved; not only grouting speed is increased, but also grout diffusion can be better controlled; the method can adapt loose pebble stratum well, not only perfect diffusion effect of grouting can be achieved, but also single-hole long-distance diffusion can be controlled, and reinforcing in unpermitted range can be achieved.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

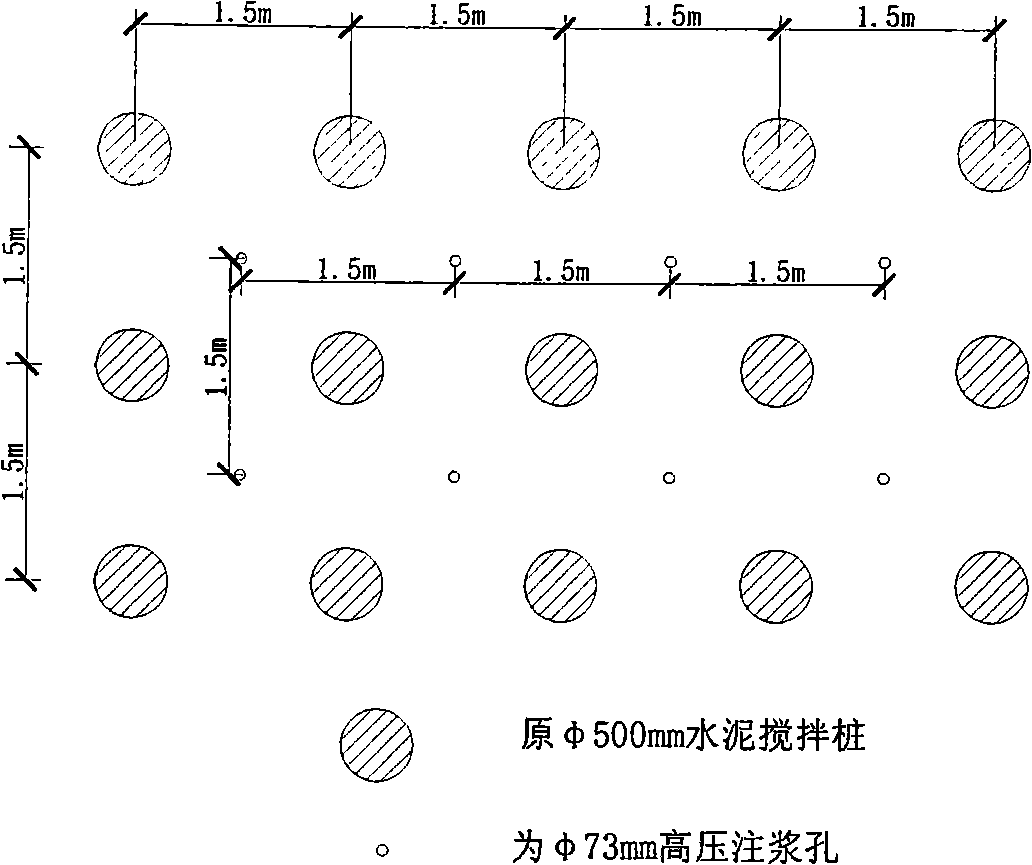

Given force splitting mud jacking enhancement type composite foundation construction method

The invention relates to a given force splitting and grouting reinforced type composite foundation construction method which is used for reinforcing the foundation of hydraulic fill sand soil and mixed fill soil; the given force effect is continuously exerted on the soil body by a borer and sleeve type high-pressure grouting equipment; a grouting pipe is inserted to a straight hole position or a slant hole position; a prepared granular mixed grout is poured to the grouting pipe for a veined splitting continuous grouting in order that the grout can form a vein-dissevering shaped and beaded shaped grout-coated concretion body and a pilaster-shaped grout-coated concretion body in a proper part of the soil body and form an uneven composite foundation with the soil body; for the reinforcement of the hydraulic fill sand soil, the standard of the given force is controlled in a scope of 0.78 to 0.92; for the reinforcement of the mixed fill soil; the standard of the given force is controlled in a scope of 0.82 to 0.94; the given force control standard is utilized to achieve the need of the compactness of the reinforced type grouting composite foundation.

Owner:NANJING UNIV OF TECH +1

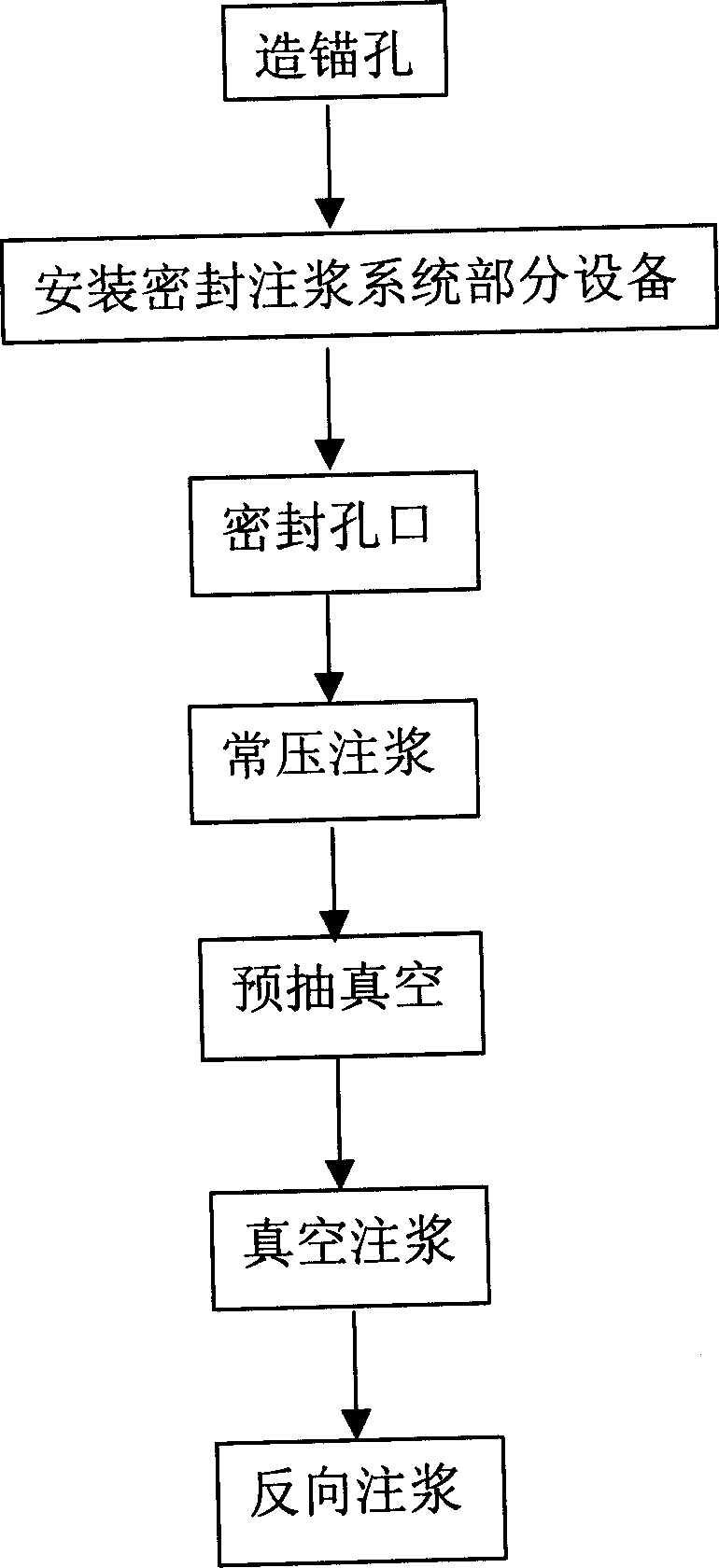

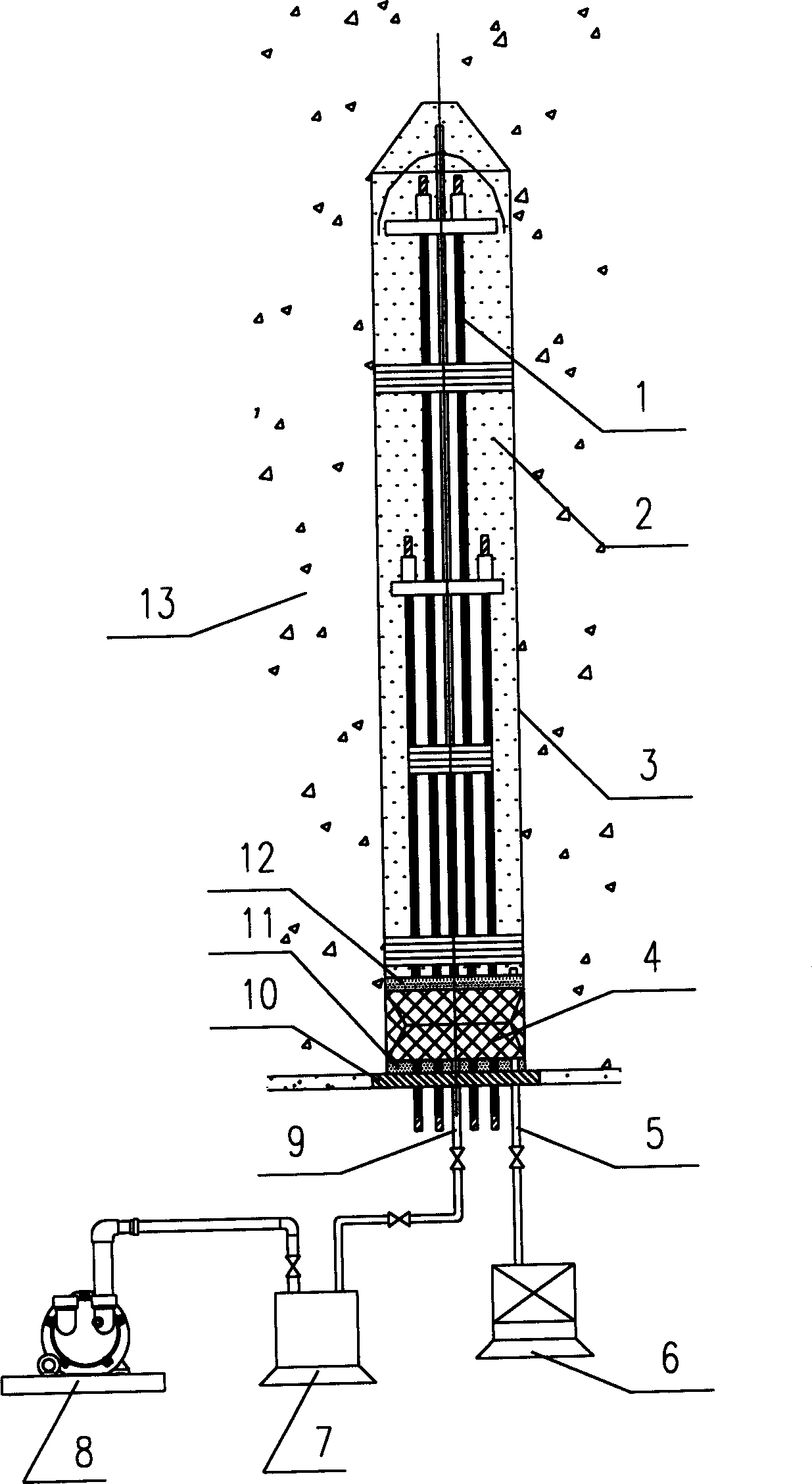

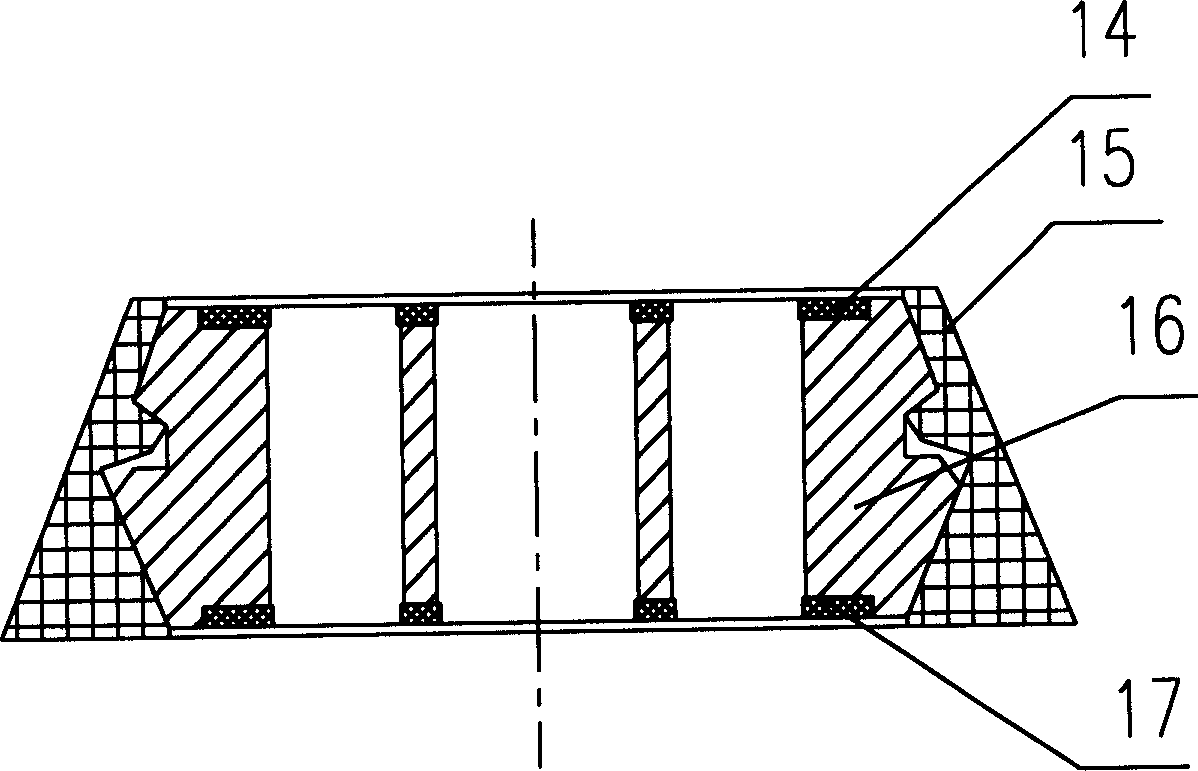

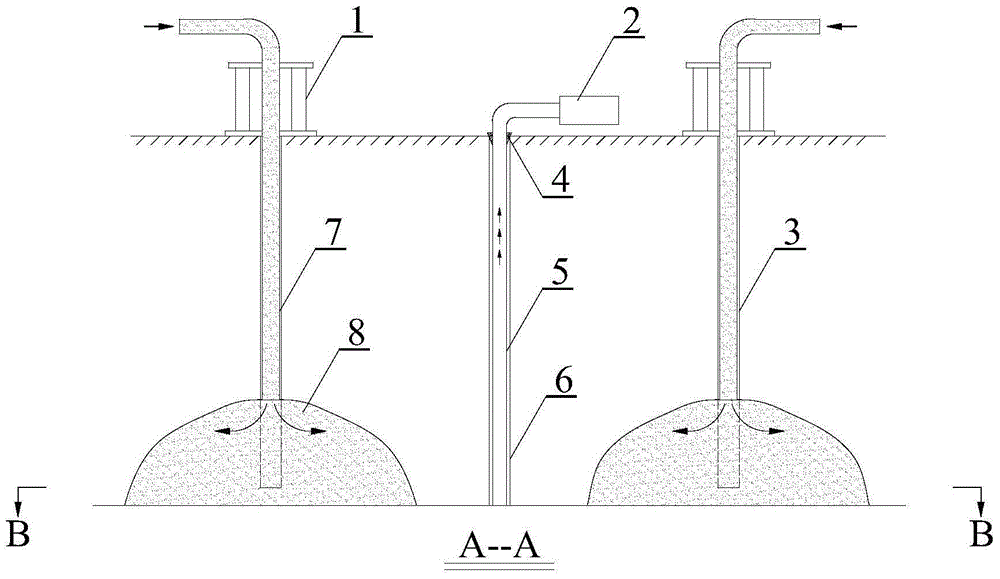

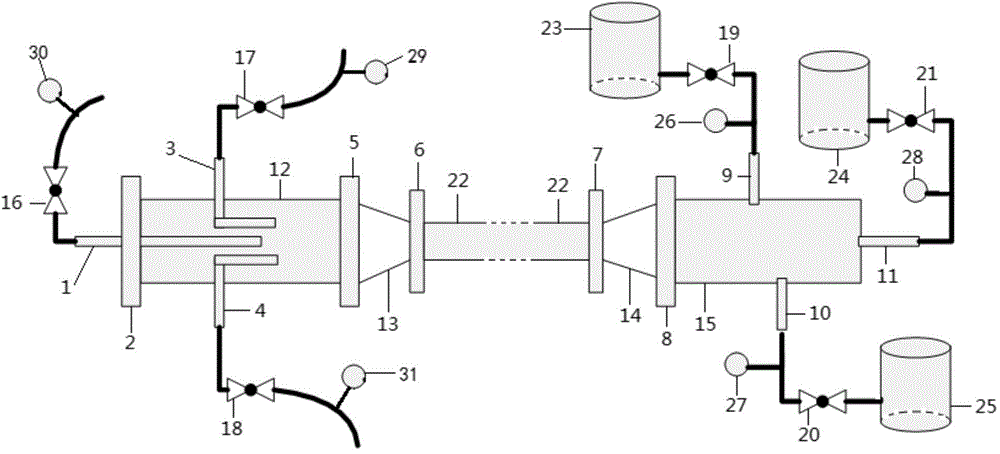

Vertical pipe vacuum pre pressing bidirectional slip casting method and sealed slip casting system thereof

The invention is a vertical-tube vacuum-precompression bidirectional slip casting method, comprising the steps of making hole, installing seal slip casting system, sealing orifice, normal-pressure slip casting, prevacuumizing, vacuum slip casting, reverse slip casting, and so on; the seal slip casting system includes anchor hole, anchorage cable, orifice grout sealer, vacuum pump, slip casting pump, sealing plate, slip casting tube and vacuum tube, the orifice grout sealer situated at the orifice of the anchor hole, the sealing plate situated on the end surface of the orifice, epoxy resin poured between the sealing plate and the orifice grout sealer, the orifice grout sealer being bowl-structured, and one or more orifice grout sealers linked in series in the same or counter direction and closely fitting anchor hole wall, the vacuum tube passing through the sealing plate and the orifice grout sealer to reach the top of the anchor hole, and the slip casting tube passing through the orifice grout sealer and 30-40cm higher than the internal end surface of the orifice grout sealer.

Owner:LIUZHOU OVM MASCH CO LTD

Method for widening grouting reinforcement and seepage and blockage prevention range of rock and soil

The invention discloses a method for widening the grouting reinforcement and seepage and blockage prevention range of rock and soil. Grouting holes and water drainage holes are distributed in the place where reinforcement and seepage prevention need to be conducted at intervals according to a certain form through combination of static pressure grouting and vacuum negative pressure water drainage. By means of vacuum negative pressure water drainage, the underground water level is lowered, underground water and air in holes of rock and soil are discharged, and dilution of underground water on grouting fluid is reduced. Negative pressure is formed at the water drainage positions, under the same grouting pressure condition, a forward pressure field is formed, the grouting speed is increased, and the grout expansion radius is increased. When a vacuum negative pressure pump works, underground water in holes of rock and soil surrounding the water drainage holes is collected towards the water drainage holes, dynamic water pressure is formed, and the grouting expansion radius is further increased. The grouting reinforcement and seepage and blockage prevention range of rock and soil is widened, the grouting effect is improved, the grouting quality is improved, and the grouting speed is increased. The method has the remarkable beneficial effects of being small in work amount, high in safety, good in grouting effect, wide in reinforcement and seepage prevention range, and the like.

Owner:CENT SOUTH UNIV

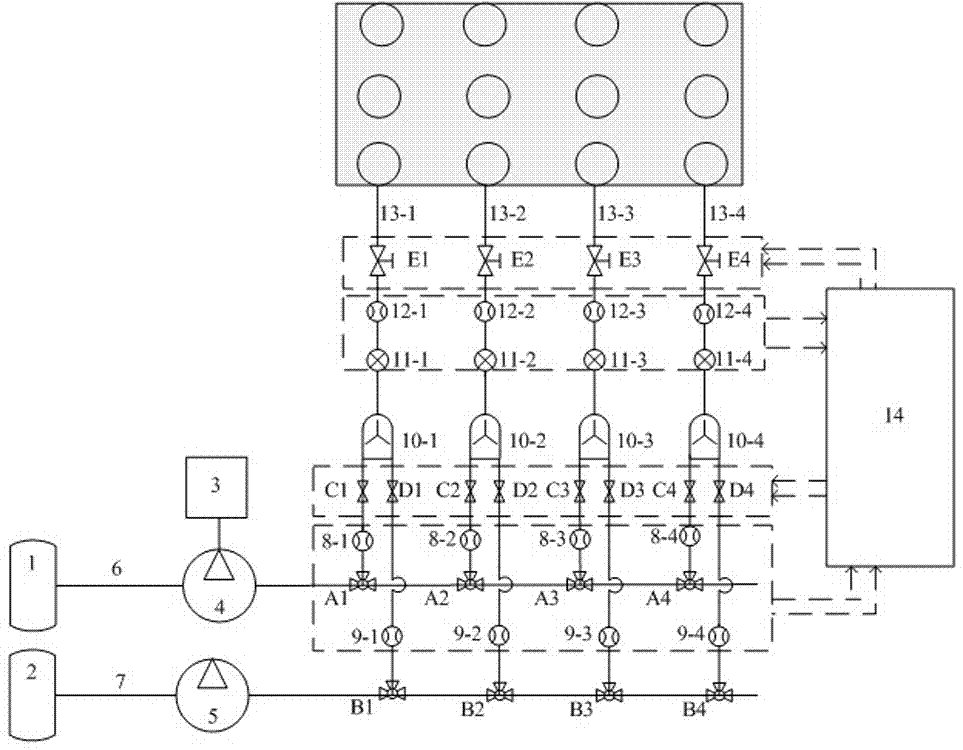

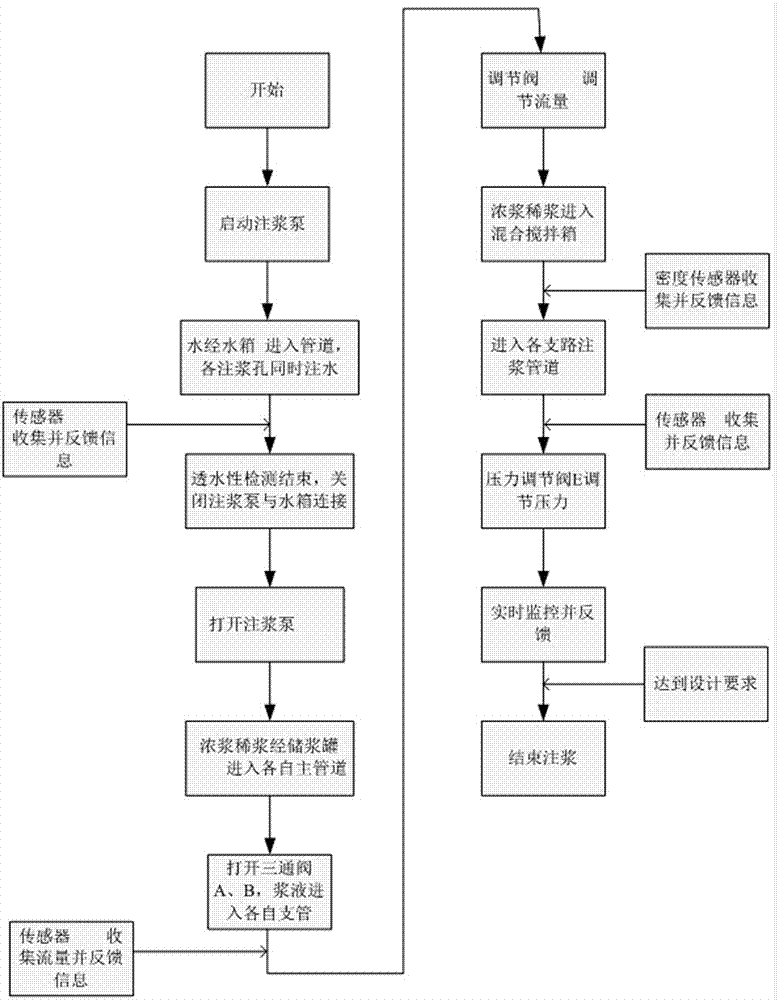

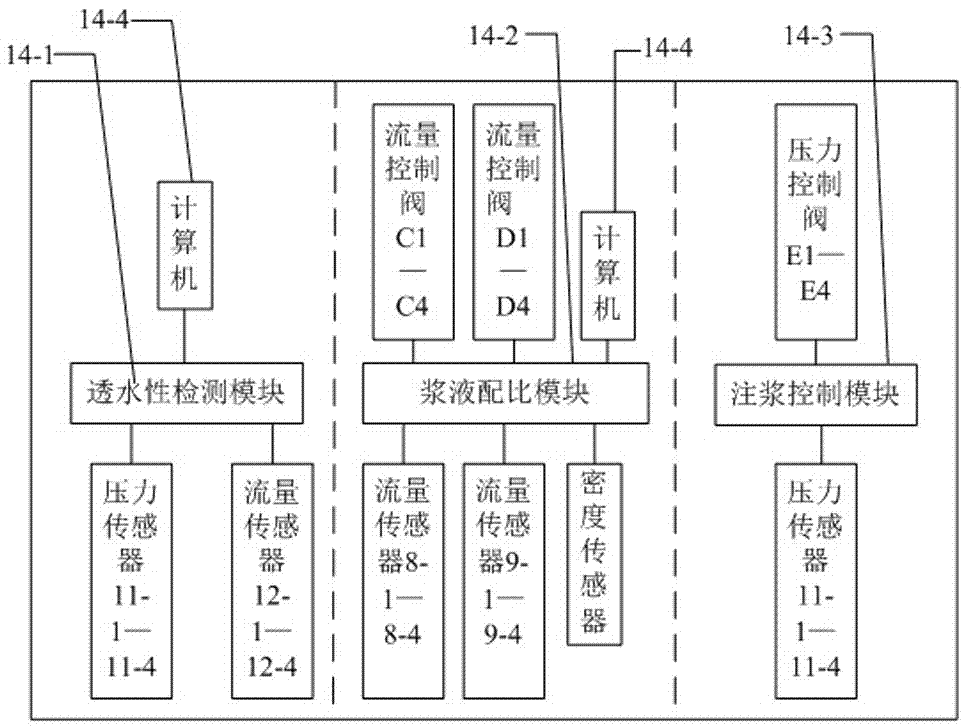

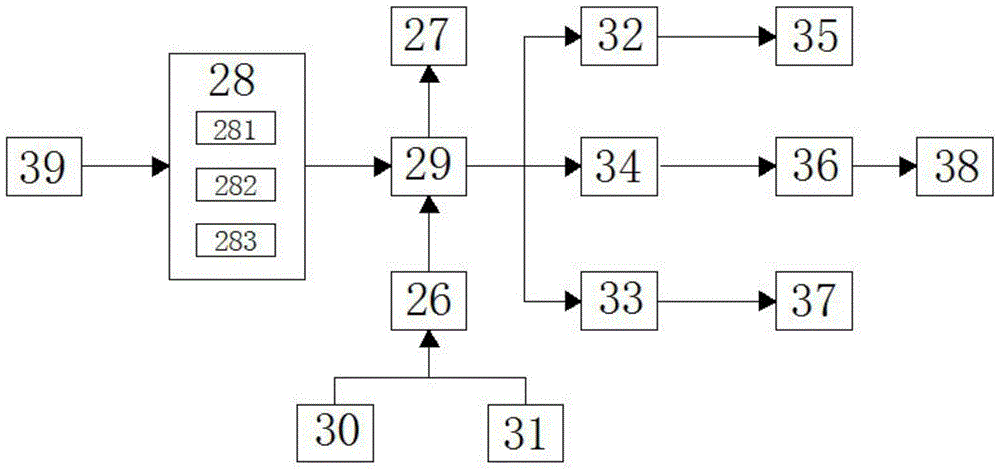

Complex geological region intelligent grouting system and method

ActiveCN107956483AFast groutingAchieve smart grouting effectUnderground chambersTunnel liningGeomorphologySlurry

The invention relates to a complex geological region intelligent grouting system and method. The method comprises the steps that the permeability coefficient of each grouting hole inside a region is obtained through water permeability detection, the best grout density suitable for each grouting hole is determined, and a sensor and a control valve are installed on each pipeline for performing real-time control to achieve the intelligent grouting effect; by controlling thick grout and thin grout of different flow ratios to be mixed, the best grout density suitable for each grouting hole is prepared to achieve the best grouting effect; a corresponding grouting end final pressure is provided, when the grouting pressure of a certain grouting hole in the middle of the region is increased suddenly, it is considered that the grouting hole design region is filled with grout, grouting of the hole is ended, and when all the grouting holes inside the target region reach the grout end final pressure, grouting of the region is finished. According to the method, intelligent grouting under complex geological conditions is achieved, the automatic degree is high, the roadway grouting speed can be greatly increased, the construction efficiency is high, and the construction efficiency and quality can be ensured.

Owner:CHINA UNIV OF MINING & TECH

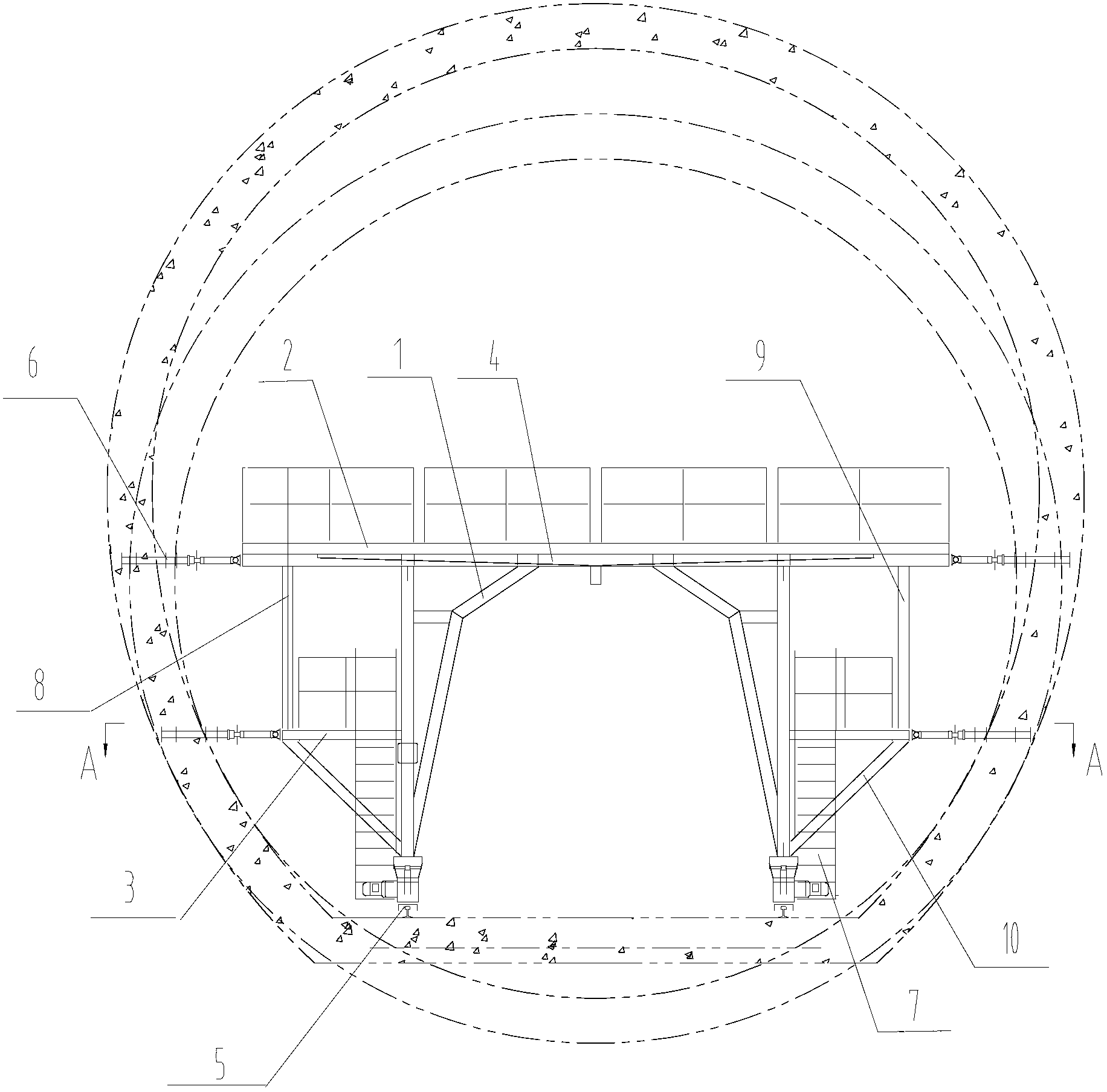

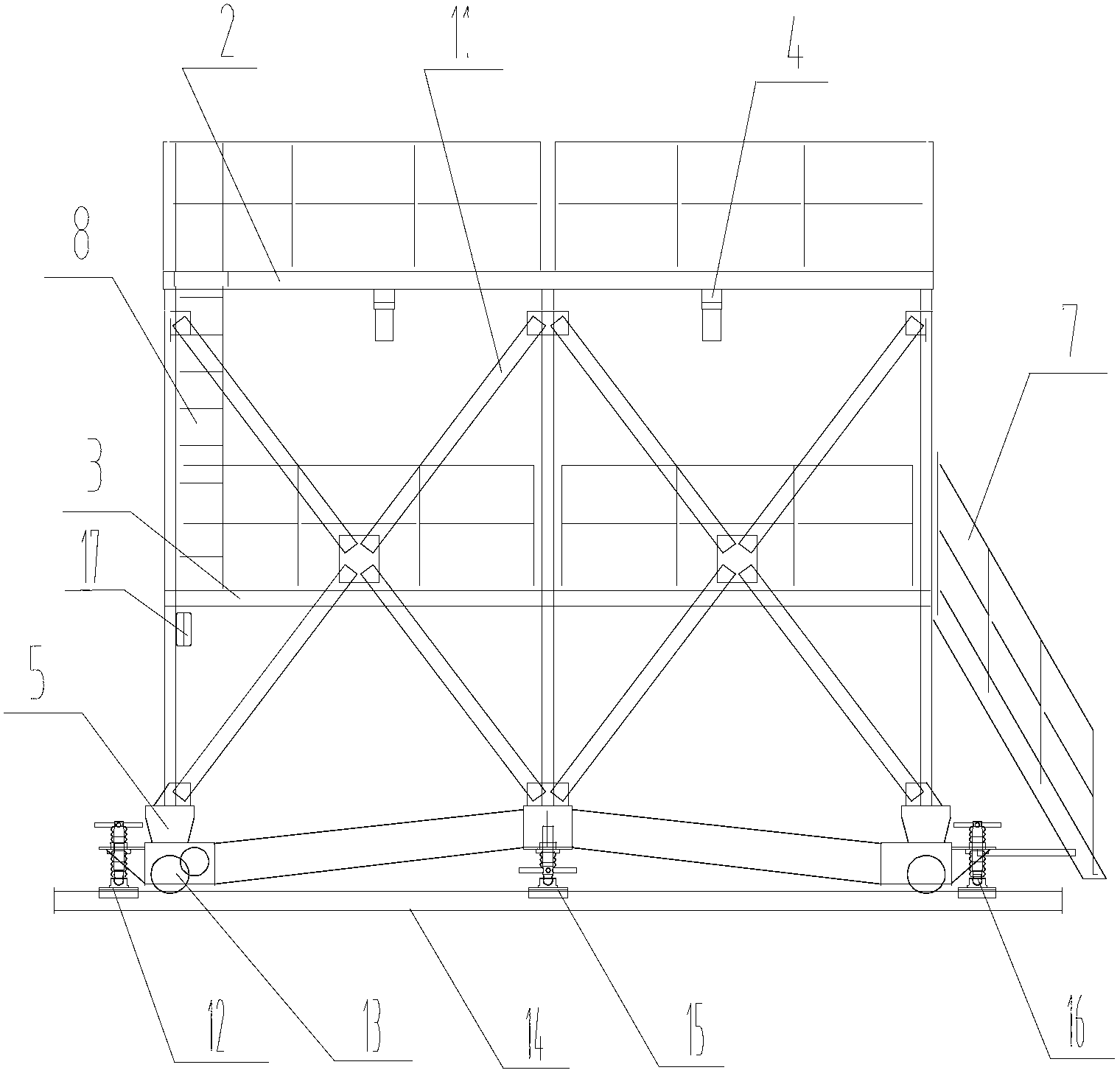

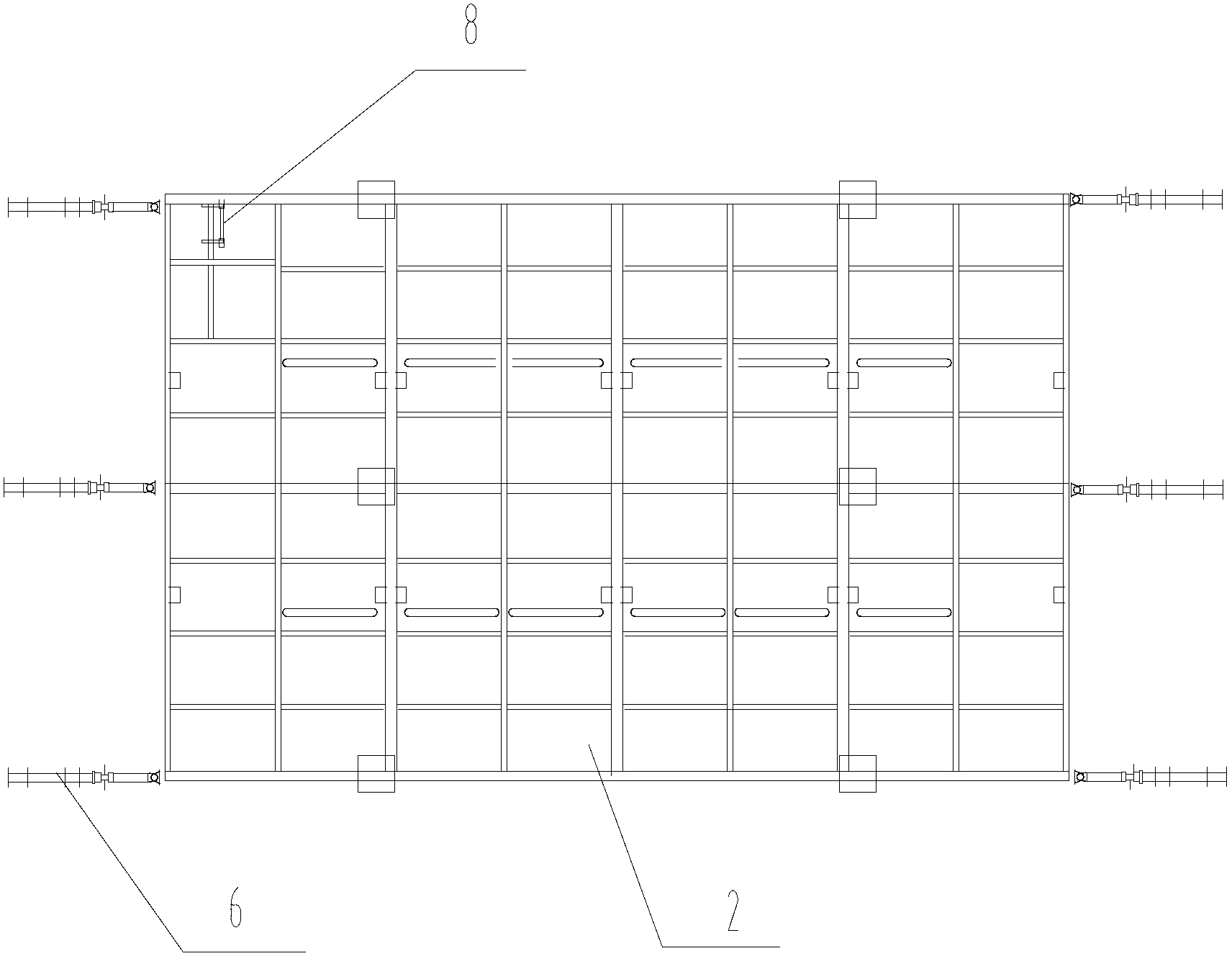

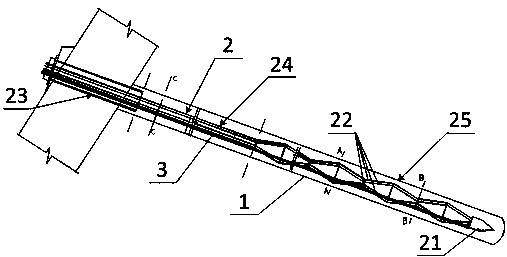

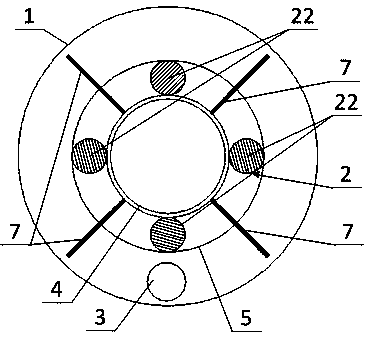

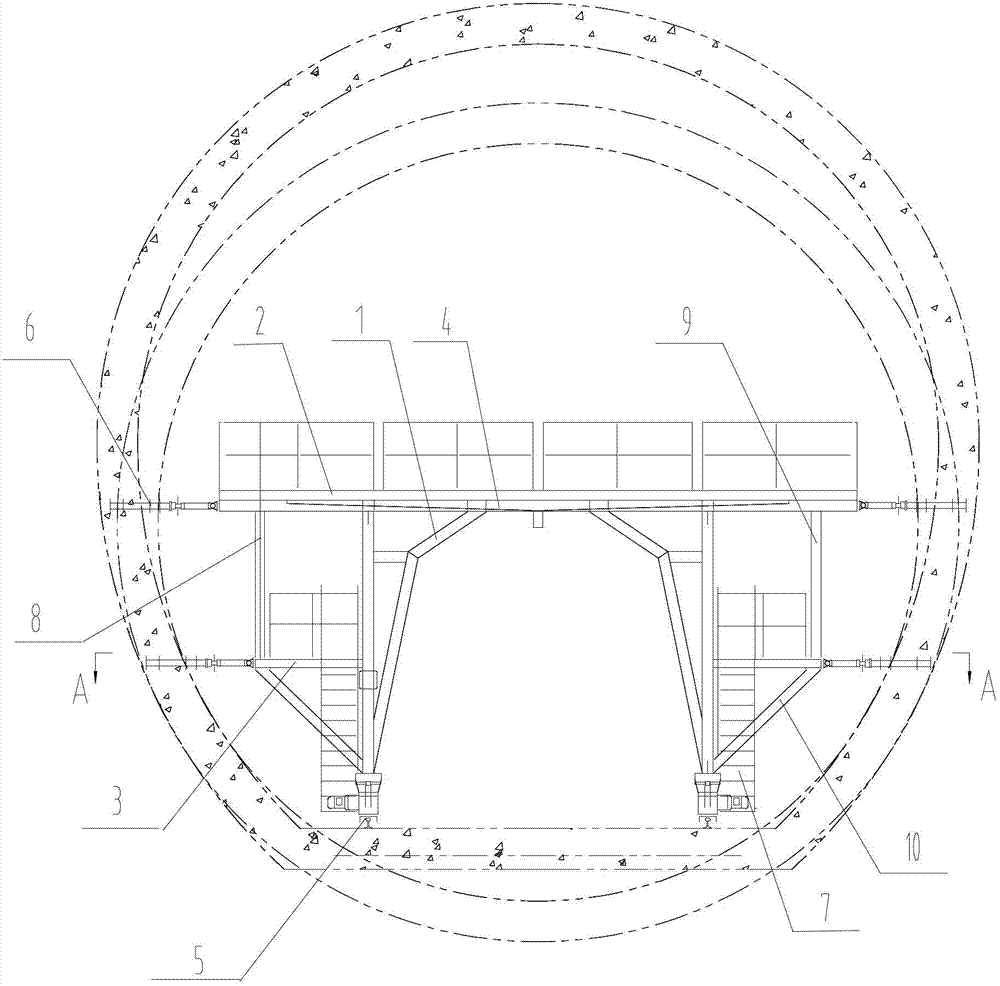

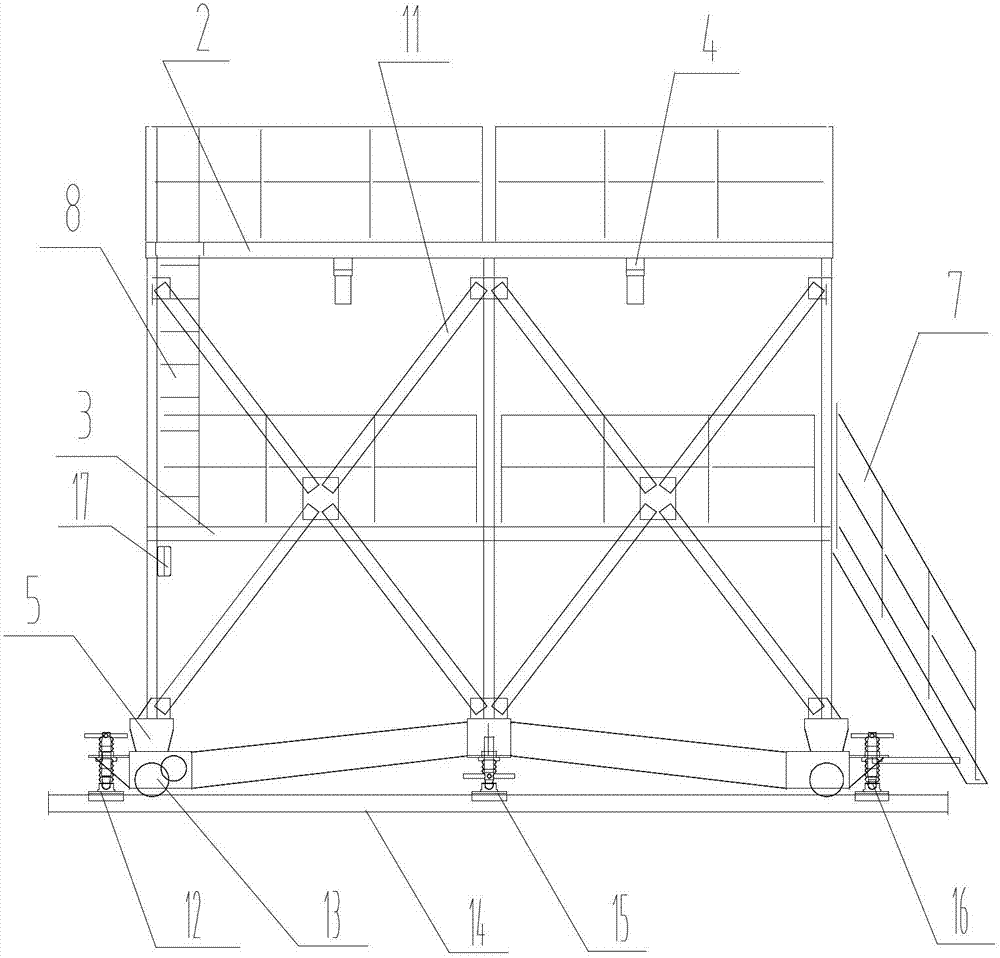

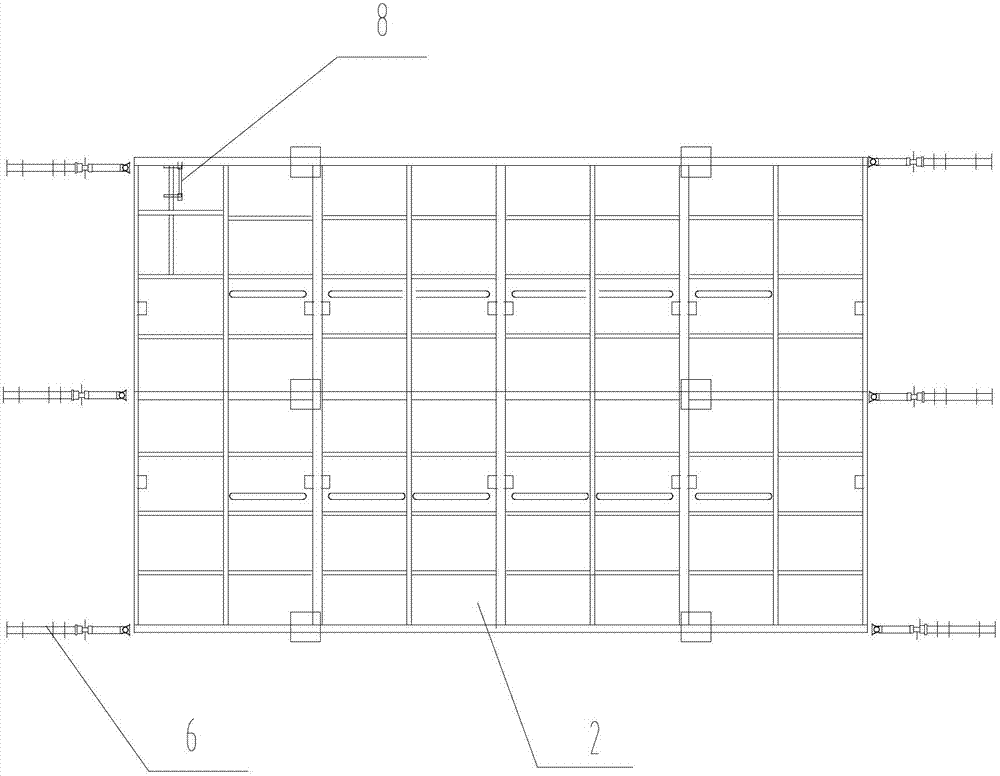

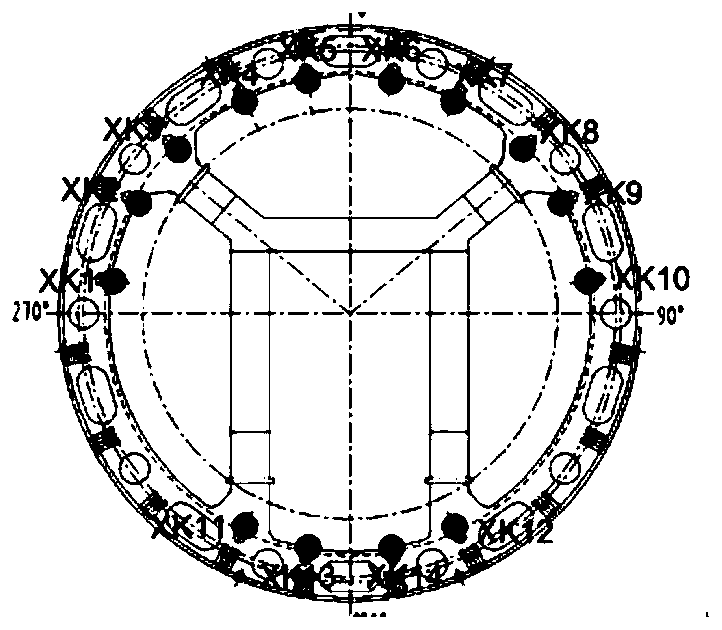

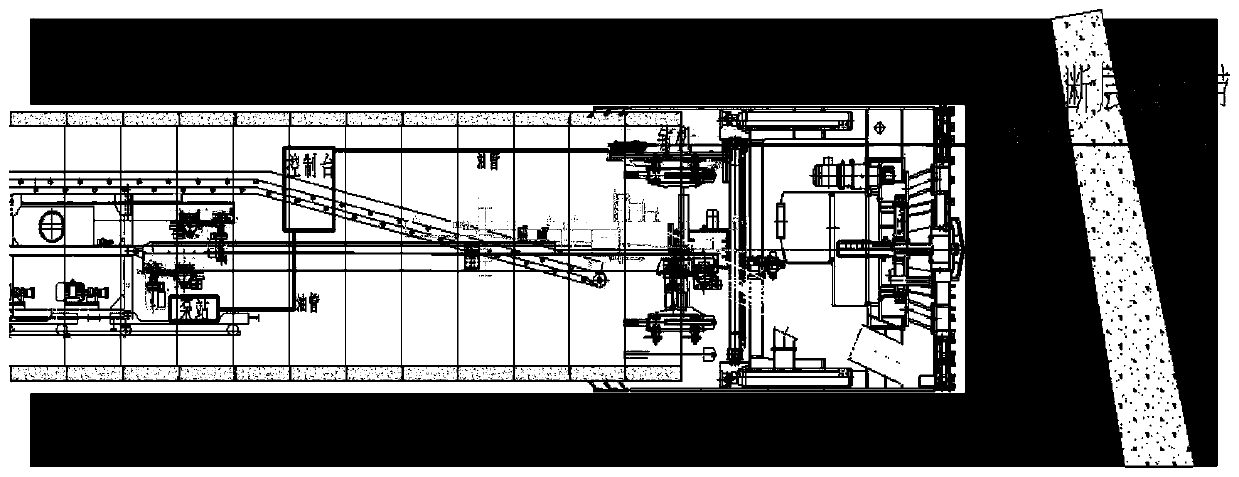

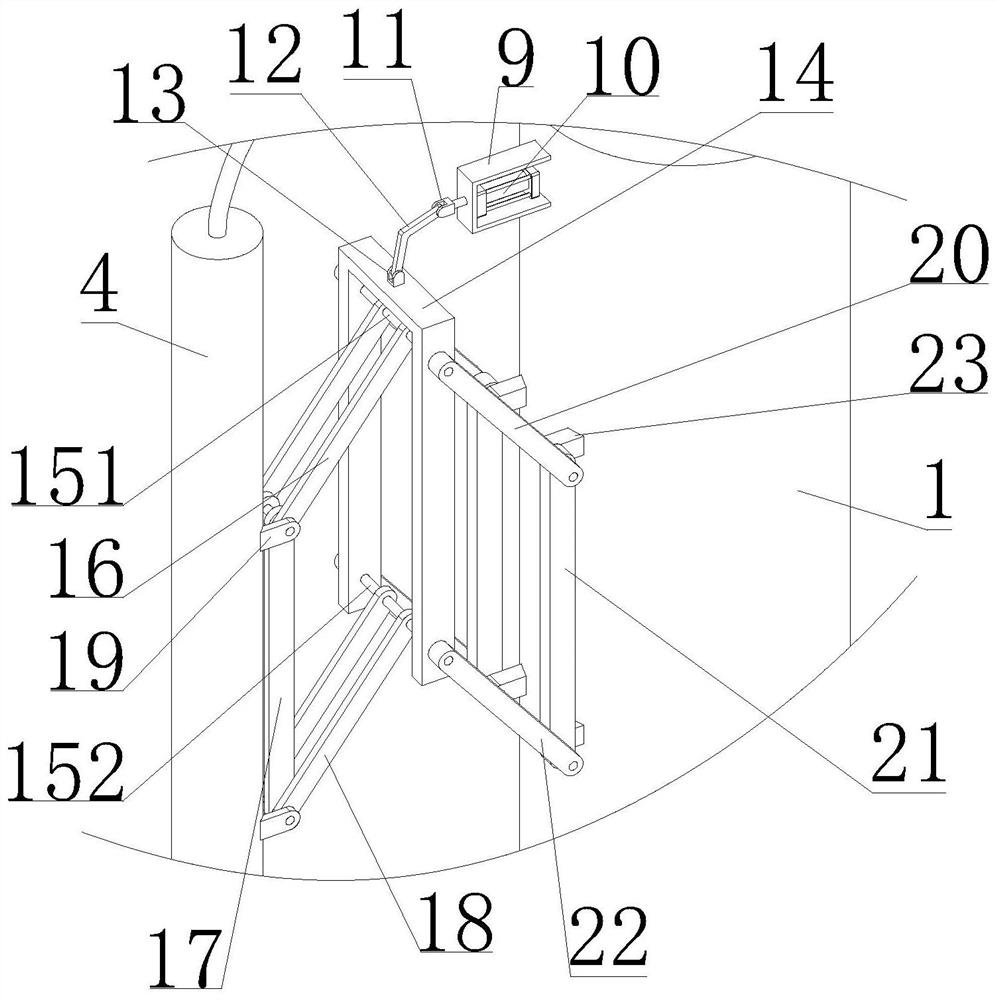

Self-propelled tunnel grouting trolley

ActiveCN102704952AExpand the scope ofMeet coverageUnderground chambersTunnel liningStructural engineeringEngineering

The invention provides a self-propelled tunnel grouting trolley. The self-propelled tunnel grouting trolley comprises a rack, a platform, a main girder, a traveling mechanism and lead screw lifting jacks; the rack is an open-spandrel framework and is arranged on the traveling mechanism; the main girder is arranged on the rack; the platform comprises a working platform and lower platforms; the working platform is arranged on the main girder; the lower platforms are respectively arranged under the working platform at the two sides of the rack along the direction of a tunnel; one ends of the lower platforms are vertically fixed on the rack, the upper sides of the end parts of the other ends of the lower platforms are connected with the main girder through first supports, and the lower sides of the end parts of the other ends of the lower platform are connected with the rack through second supports; the two side end parts of the working platform and the two side end parts of the lower platforms are connected on the rack through inclined struts; the lead screw lifting jacks are symmetrically arranged at the two sides of the working platform and the lower platforms; and the self-propelled tunnel grouting trolley has the advantages of being reasonable in structure, low in cost, capable of solving the traffic problem in the tunnel, realizing the synchronization of grouting, transportation and other operations, meeting the requirements of the engineering construction of diversion tunnels with large-sized cross sections and being rapid and efficient in grouting operation and capable of ensuring the construction period.

Owner:中国水利水电第七工程局成都水电建设工程有限公司

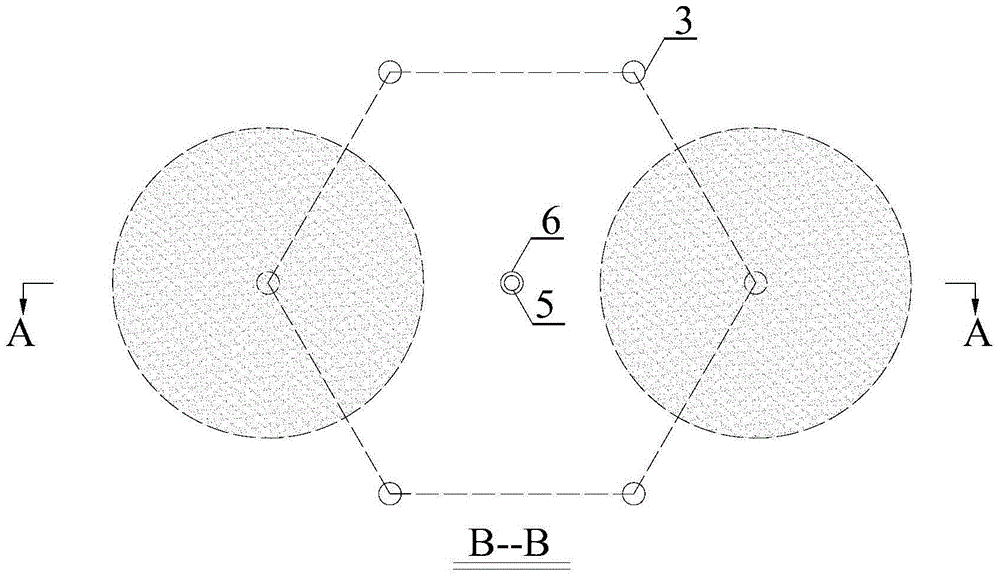

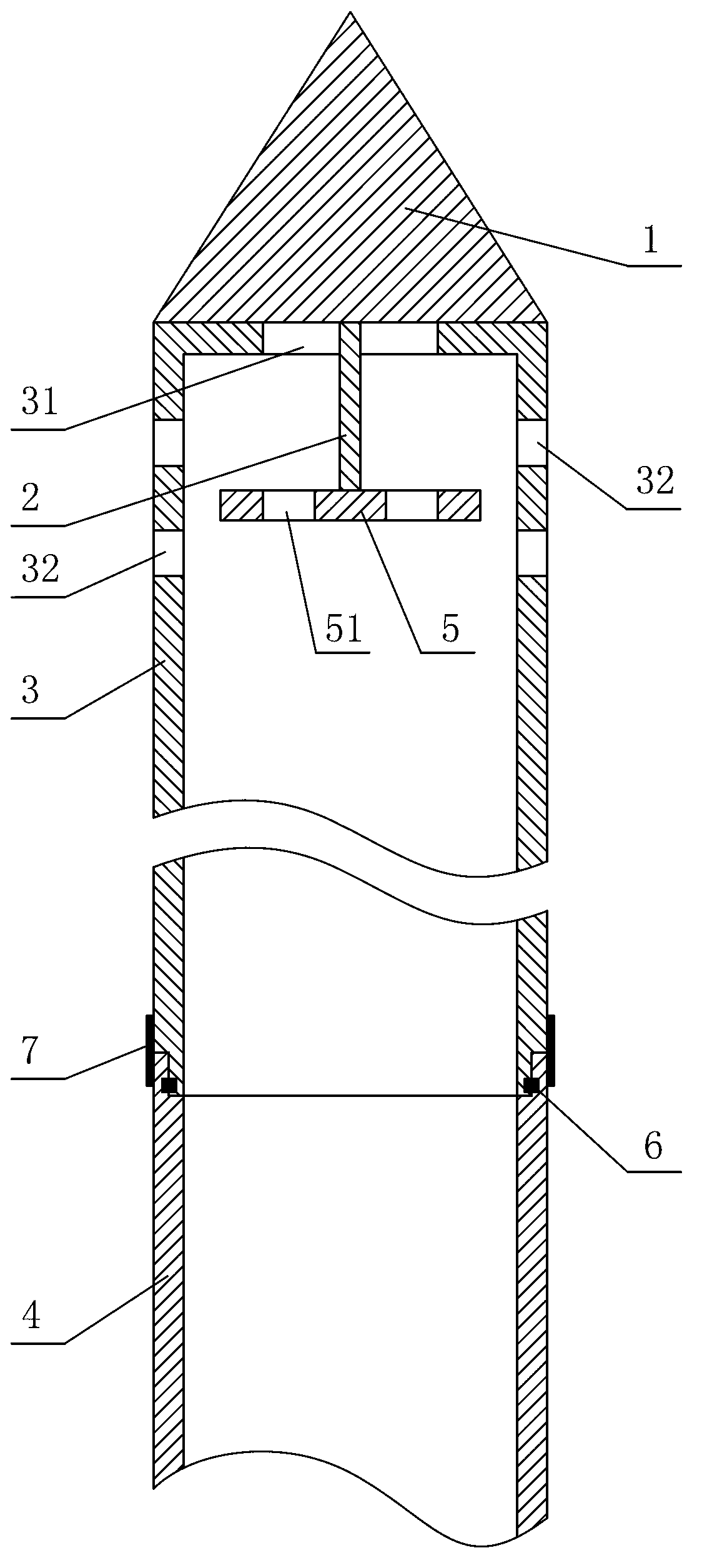

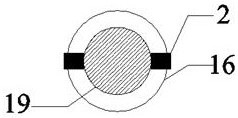

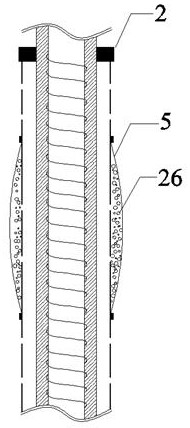

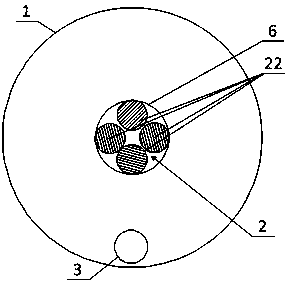

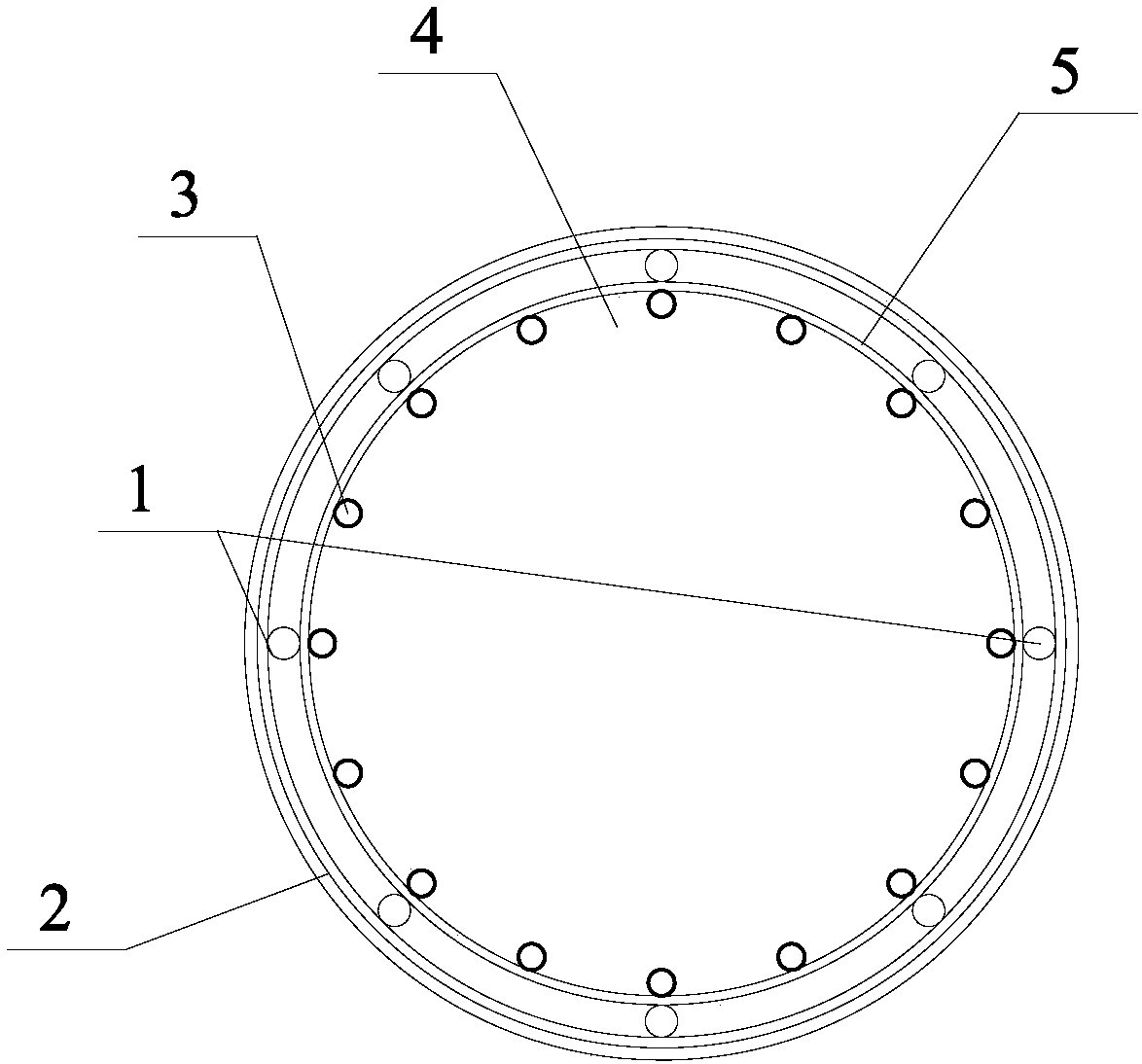

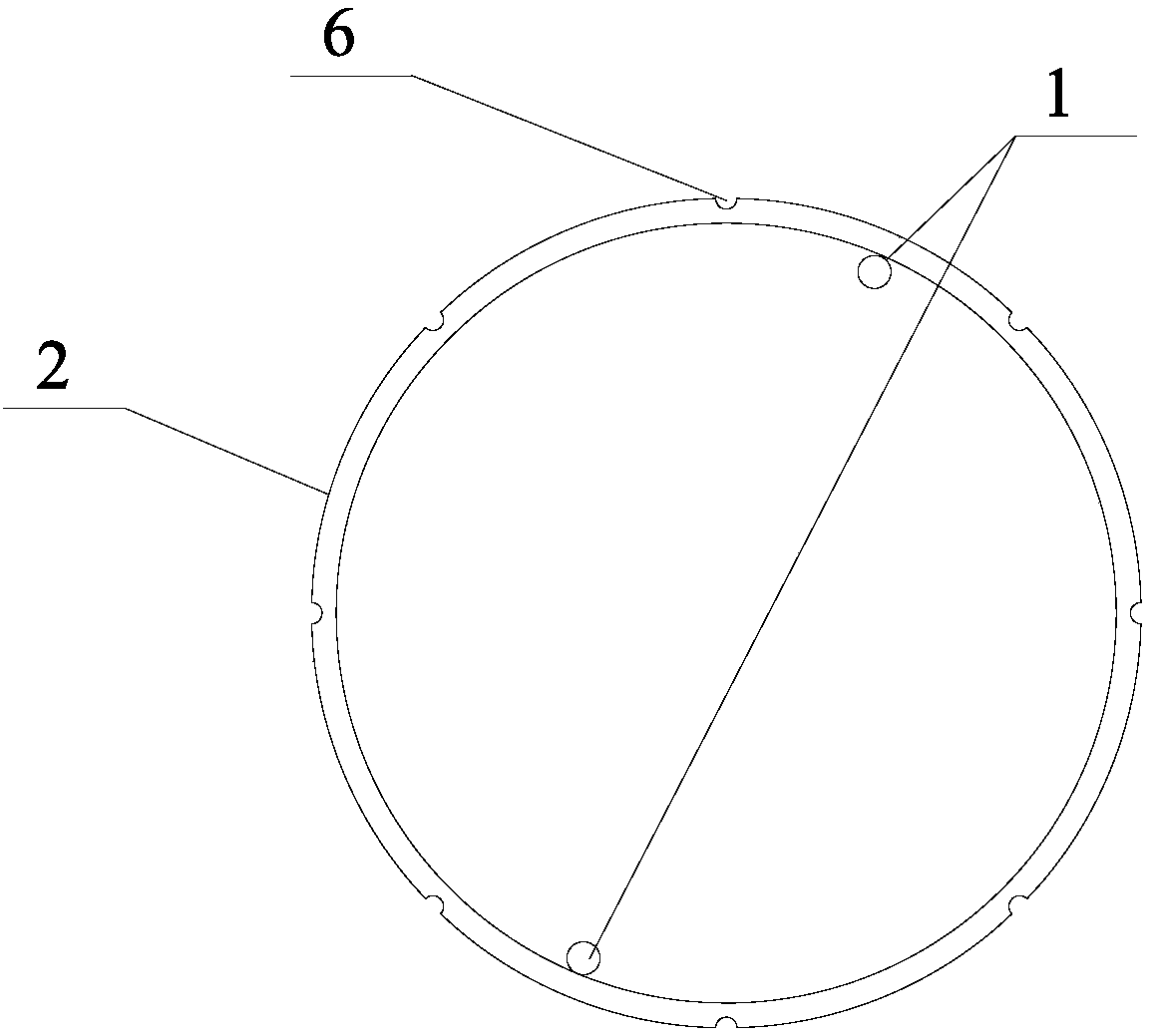

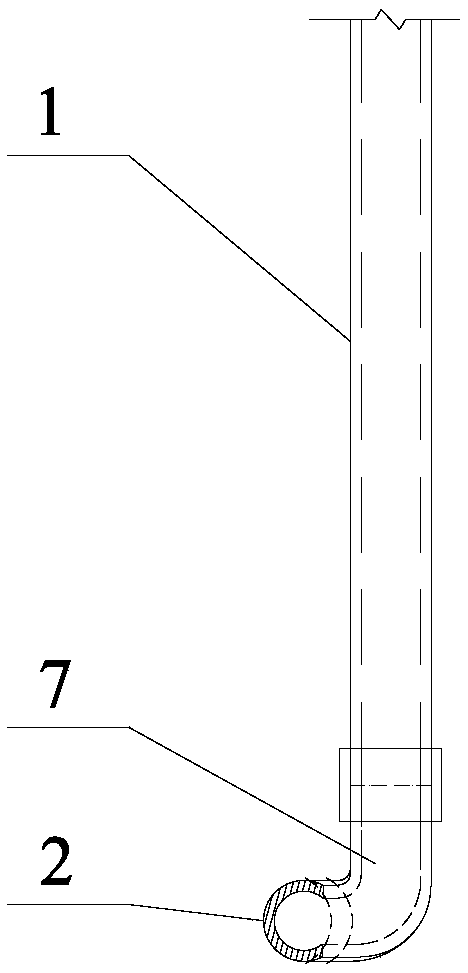

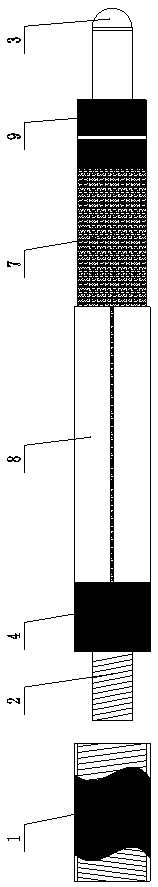

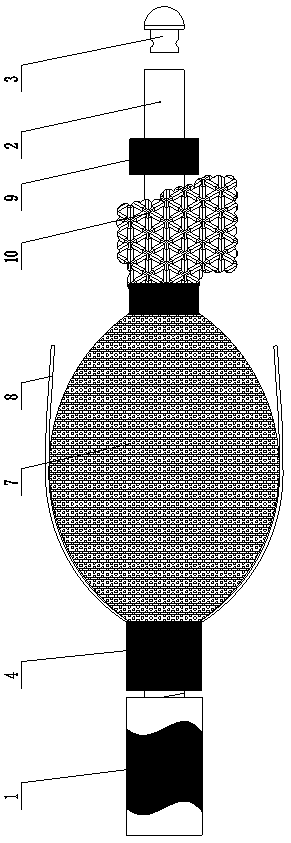

Grouting pipe

The invention discloses a grouting pipe and belongs to the technical field of building construction. The grouting pipe comprises a tapered plug, a connecting rod and a grouting pipe body which are sequentially connected, one end of the connecting rod is fixedly connected with the tapered plug, the other end of the connecting pipe extends into the grouting pipe body from a pipe orifice of the grouting pipe body, a chuck is fixedly arranged at the tail end of the connecting rod located in the grouting pipe body and movably clamped in the pipe orifice, a plurality of first through holes are reserved on the chuck and are all communicated with the pipe orifice, and a plurality of second through holes are reserved on the pipe wall of the grouting pipe body. The grouting pipe is capable of solving the problems of low grouting speed and slurry diffusion nonuniformity, and is simple in structure and convenient to manufacture.

Owner:浙江环宇建设集团有限公司

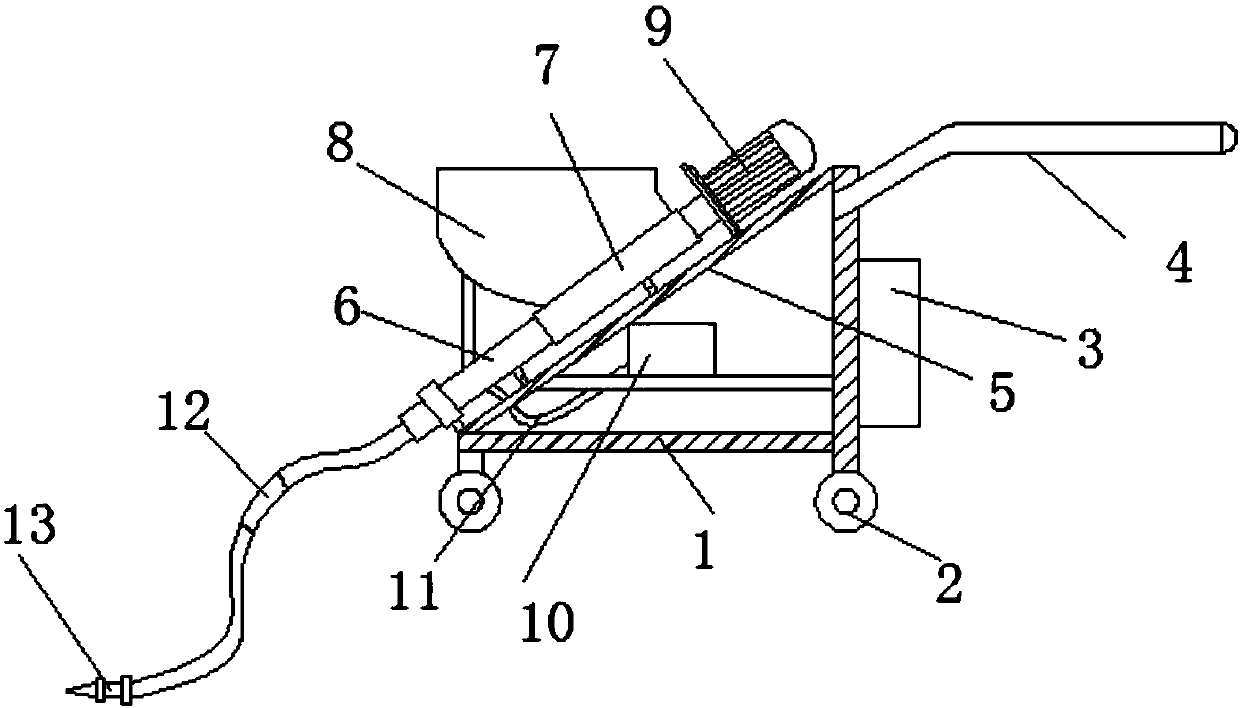

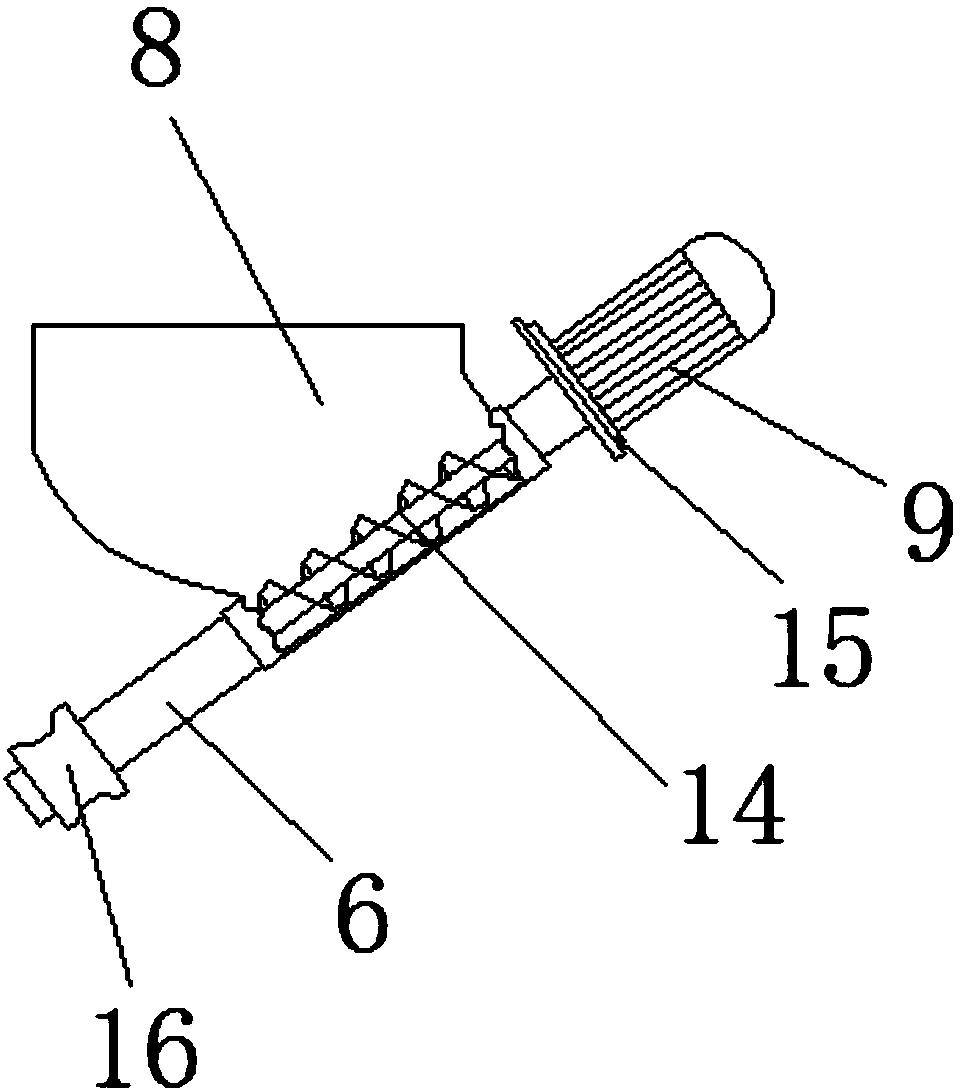

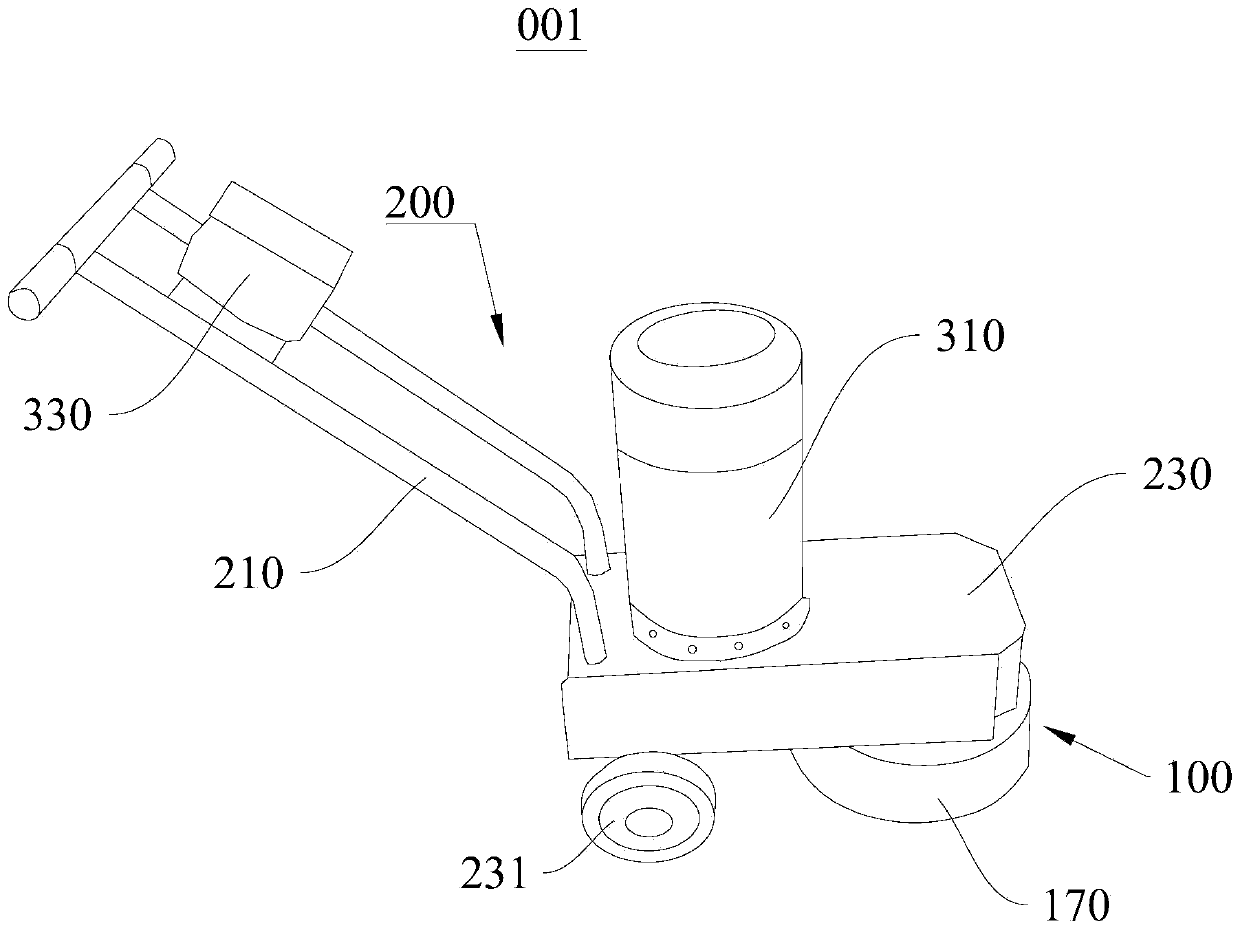

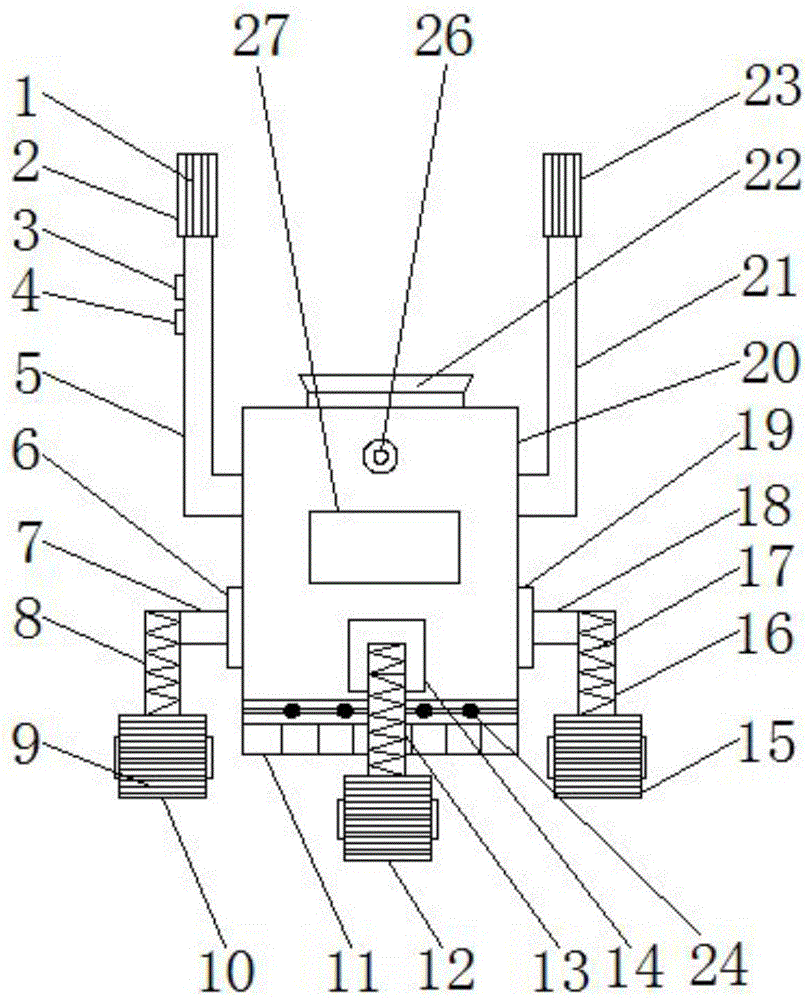

Cement grouting machine for maintenance

InactiveCN107762173AImprove stabilityIncrease the feeding speedBuilding repairsReduction driveSlurry

The invention discloses a cement grouting machine for maintenance. The cement grouting machine comprises a fixing frame, rolling wheels are arranged at the four corners at the bottom of the fixing frame, and an electric control box is fixed to the surface wall of one side of the fixing frame; a pushing hand is welded to the position, located above the electric control box, of the fixing frame, aninstalling inclined plate is welded to the fixing frame, and a discharging pipe is fixed to the installing inclined plate; a material drum is fixed to the discharging pipe through a sleeve, a discharging motor is fixed to the position, located at the top end of the discharging pipe, of the installing inclined plate, and the discharging motor is in transmission connection with a spiral conveying rod in the discharging pipe through a speed reducer; and the discharging pipe is connected with a grouting nozzle through a high-pressure pipe. According to the cement grouting machine for maintenance,through the arrangement of a flow control valve, the quantity of flow of grouted cement paste through the grouting nozzle can be controlled according to the size of a grouting crack, and overflow waste of the cement paste caused by the too-high quantity of flow is prevented; and the cement grouting machine is reasonable in design and convenient to control and use.

Owner:CHENGDU BAIFULONG PRECISION MACHINERY CO LTD

Full-anchor grouting anchor rod and anchoring method thereof

PendingCN112360534AStrong shear resistanceImprove grouting efficiencyAnchoring boltsRock boltThreaded rod

The invention relates to a full-anchor grouting anchor rod and an anchoring method thereof, and belongs to the technical field of anchor rod supporting. The full-anchor grouting anchor rod specifically comprises an anchoring section, a grouting section and a rod body. Two limiting blocks are arranged on the rod body, and the anchoring section and the grouting section are bounded by the limiting blocks. The anchoring section is used for solidifying the rod body in a drill hole, and the grouting section is used for grouting the drill hole. An inverted nail is arranged on the rod body, an inner threaded rod is arranged in the rod body, and a steel pipe is arranged outside the rod body. When the full-anchor grouting anchor rod is used, the anchoring of an anchoring agent is completed firstly,then anchorage device pre-tightening is completed, and finally grouting is conducted. According to the full-anchor grouting anchor rod and the anchoring method thereof, a common solid anchor rod and the grouting function are combined together, and full-anchor grouting is achieved through the connection of the anchoring section and the grouting section; and roadway surrounding rock can be activelysupported in time, the stress state of the roadway surrounding rock is improved, the bearing capacity of the surrounding rock is fully exerted, and the stability of the roadway surrounding rock in a high-stress environment is ensured.

Owner:KUNMING UNIV OF SCI & TECH

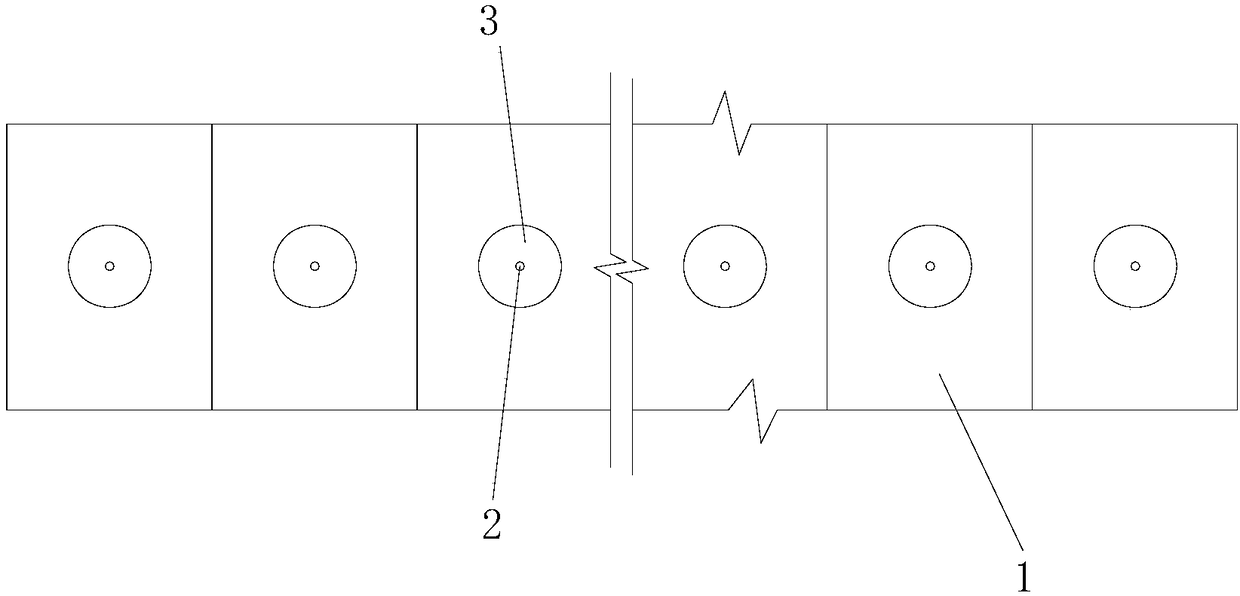

Prestressed anchor cable structure and one-time grouting construction method of prestressed anchor cable

The invention provides a prestressed anchor cable structure and a one-time grouting construction method of a prestressed anchor cable. The prestressed anchor cable structure comprises an anchor cablehole formed in a soil layer; the anchor cable hole is internally provided with an anchor cable and a grouting pipe, wherein the grouting pipe and the anchor cable are arranged at an interval, and thetail part of the anchor cable protrudes from the anchor cable hole; the anchor cable is a wire harness composed of a plurality of steel strands; a plurality of steel pipes arranged at intervals and side by side are arranged in a section of an anchoring section, the steel pipes are coaxially arranged, the steel strands are arranged along the outer wall of the steel pipes so that the steel strands can be isolated one another, and first fastening ring for fastening the steel strands to the steel pipes are arranged on the peripheries of the steel strands; and the steel strands between every two steel pipes are subjected to bundling independently and the peripheries are fastened by second fastening rings. The grouting pipe and the anchor cable exist independently of each other, so that the anchor cable is buried in slurry conveniently during the subsequent grouting, and the problem that grout needs to be supplemented due to shrinkage of the slurry due to the fact that the grouting pipe is damaged and the grouting pipe is buried in the slurry is solved.

Owner:CHINA MCC20 GRP CORP

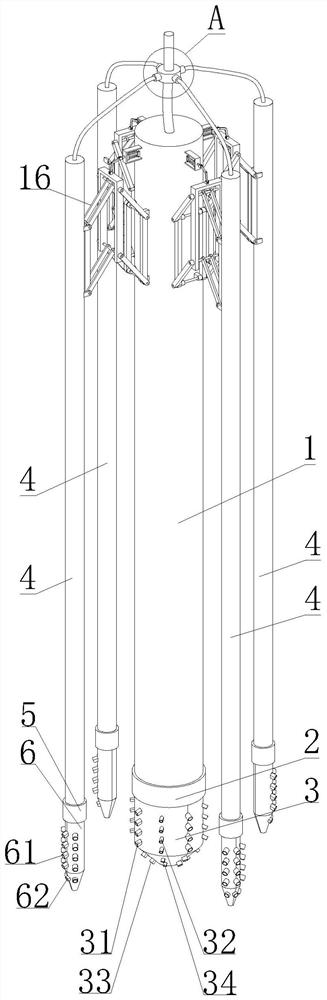

Uplift pile side post grouting device and construction method

The invention discloses an uplift pile side post grouting device. The uplift pile side post grouting device comprises a plurality of grouting vertical tubes and a plurality of grouting ring tubes withdifferent elevations, wherein the grouting vertical tubes are fixed on the periphery of an uplift pile reinforcement cage; the grouting ring tubes are connected with the grouting vertical tubes and are fixed on the outer sides of the grouting vertical tubes; the bottom ends of each two grouting vertical tubes communicate with one corresponding grouting ring tube; a plurality of slurry outlet nozzles are arranged on each grouting ring tube along the periphery; and each slurry outlet nozzle can be temporarily closed by a closing device which can be flushed away by water pumped in by a water pump. A construction method of the uplift pile side post grouting device comprises the following steps: fixing the prefabricated grouting vertical tubes and the prefabricated grouting ring tubes on a pile body reinforcement cage; temporarily closing the slurry outlet nozzles on the grouting ring tubes by wrapping adhesive tapes or one-way valves, wherein each one-way valve is connected with water-permeable and slurry-tight slurry bags at intervals in a sealed manner; and unplugging the grouting vertical tubes and the grouting ring tubes by high-pressure water and completing pile side post grouting in twice or at a time. By the device and method, post grouting on the side surfaces of the peripheries of uplift piles can be uniformly distributed along the peripheries, grouting is smooth, and theconstruction efficiency is high.

Owner:NINGBO HONGCHEN CONSTR

Self-propelled tunnel grouting trolley

ActiveCN102704952BGuarantee unimpededGuaranteed normal transportationUnderground chambersTunnel liningStructural engineeringEngineering

The invention provides a self-propelled tunnel grouting trolley. The self-propelled tunnel grouting trolley comprises a rack, a platform, a main girder, a traveling mechanism and lead screw lifting jacks; the rack is an open-spandrel framework and is arranged on the traveling mechanism; the main girder is arranged on the rack; the platform comprises a working platform and lower platforms; the working platform is arranged on the main girder; the lower platforms are respectively arranged under the working platform at the two sides of the rack along the direction of a tunnel; one ends of the lower platforms are vertically fixed on the rack, the upper sides of the end parts of the other ends of the lower platforms are connected with the main girder through first supports, and the lower sides of the end parts of the other ends of the lower platform are connected with the rack through second supports; the two side end parts of the working platform and the two side end parts of the lower platforms are connected on the rack through inclined struts; the lead screw lifting jacks are symmetrically arranged at the two sides of the working platform and the lower platforms; and the self-propelled tunnel grouting trolley has the advantages of being reasonable in structure, low in cost, capable of solving the traffic problem in the tunnel, realizing the synchronization of grouting, transportation and other operations, meeting the requirements of the engineering construction of diversion tunnels with large-sized cross sections and being rapid and efficient in grouting operation and capable of ensuring the construction period.

Owner:中国水利水电第七工程局成都水电建设工程有限公司

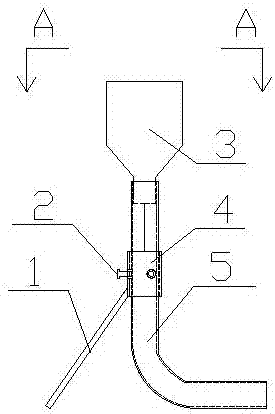

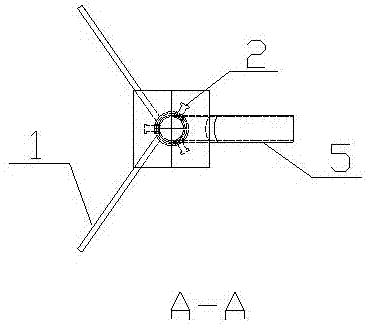

Guiding device for once grouting of equipment and manufacturing method thereof

PendingCN107304629ASimple structureEasy to manufactureFoundation engineeringBuilding material handlingPetroleum engineering

The invention relates to a guiding device for once grouting of equipment. The guiding device comprises a guiding pipe, a funnel and a support frame; the guiding device is characterized in that the guiding pipe is a steel pipe with the diameter more than or equal to 60mm; the part 0.5m away from a port at one end is bent into 90 degrees; the funnel is a plastic funnel or an iron funnel; the support frame comprises a sleeve and support rods; two circular steel support rods with diameter of phi 12mm and length of 5m which are arranged in a splayed form are welded on the sleeve wall; the sleeve is sleeved into the guiding pipe and is clamped by a locking screw rod and the guiding pipe; and the support rods are used for supporting the stability of the funnel and the guiding pipe. The guiding device for once grouting of equipment and the manufacturing method thereof provided by the invention have the advantages of simple structure of the guiding device for grouting, convenience in manufacturing, high grouting speed, correct grouting, high grouting quality and capabilities of saving grouting materials and lowering engineering cost.

Owner:MCC5 GROUP CORP SHANGHAI

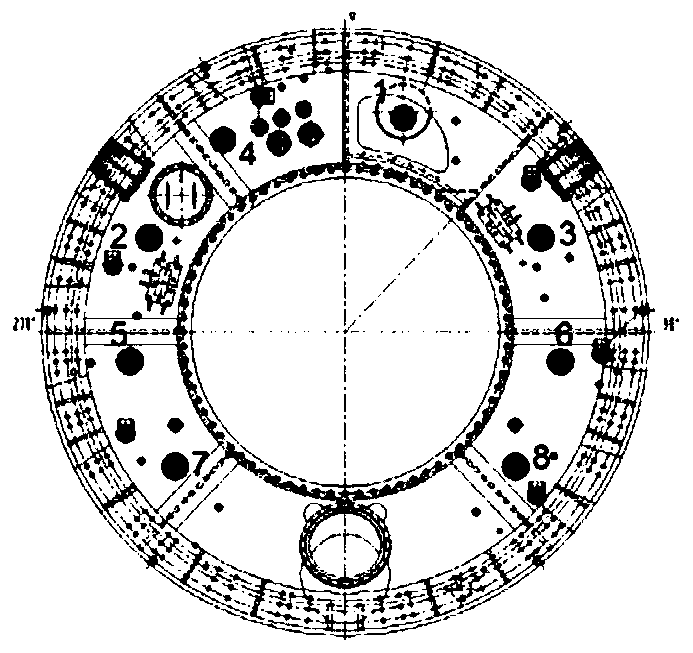

Method for reinforcing fault fracture zone through single-shield double-mode TBM advanced grouting

InactiveCN110259465AFast groutingFast reinforcementUnderground chambersTunnel liningGeomorphologyFracture zone

The invention discloses a method for reinforcing a fault fracture zone through single-shield double-mode TBM advanced grouting. The method comprises the steps: advanced drilling equipment is mounted on a rotating disc of a TBM assembly machine; advanced drilling is conducted through one or more hole positions in eight horizontal holes and fourteen oblique holes of a TBM; advanced grouting is conducted according to the drilling situation; and grouting reinforcing and hole sealing are conducted. The tunnel face fracture zone can be quickly subjected to grouting reinforcing, during operation, the former holes can be subjected to grouting reinforcing when the hole positions are drilled, thus the construction time is shortened greatly, manpower is saved, and the construction efficiency is high; and during construction through a mechanical method, matched grouting reinforcing equipment is used, the equipment cycle mounting and debugging time can be reduced greatly, the construction efficiency is improved, under an equipment reserved hole, a soil body of the fault fracture zone can be reinforced at the maximum range, and thus the method is worthy of being popularized in the EPB and TBM tunneling fault fracture zone.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

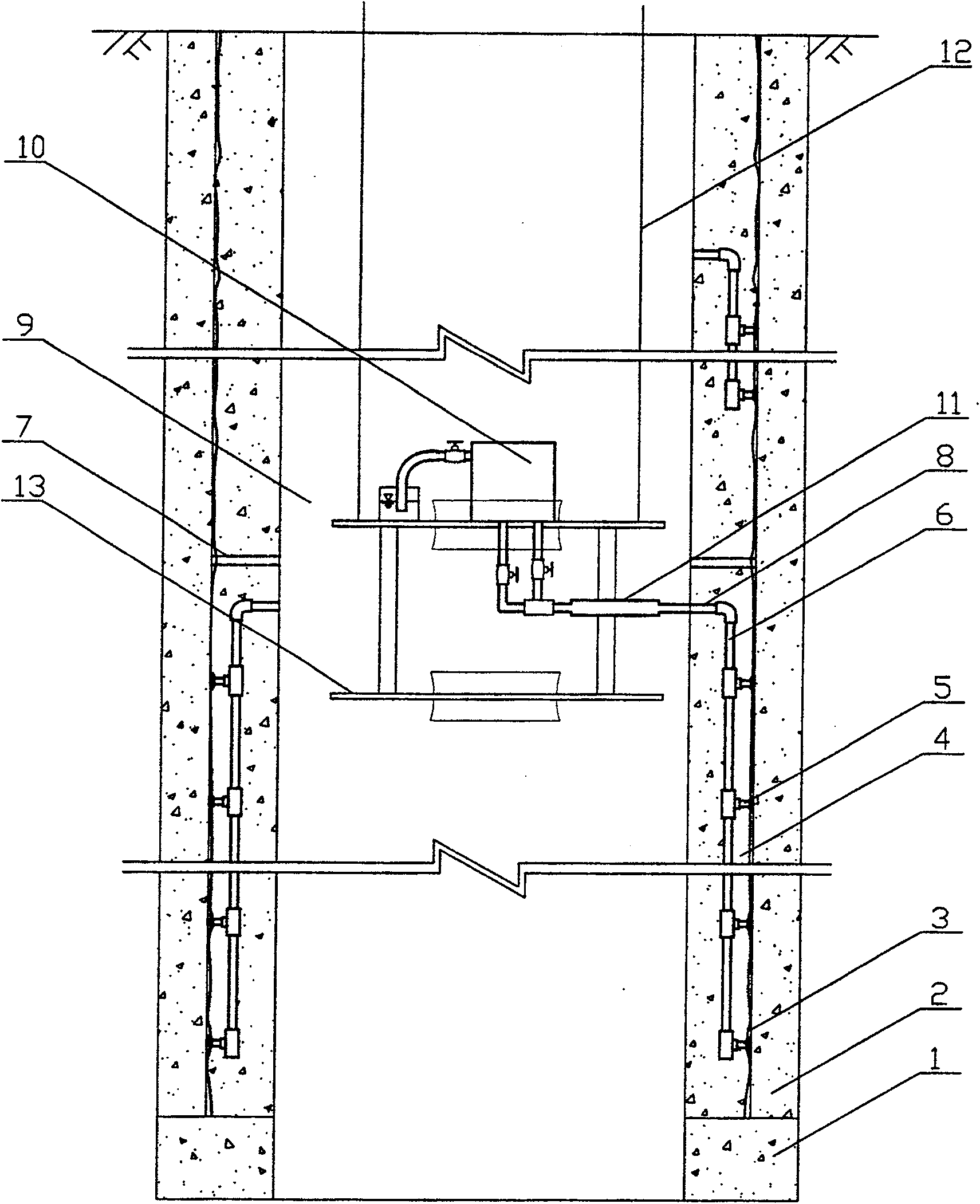

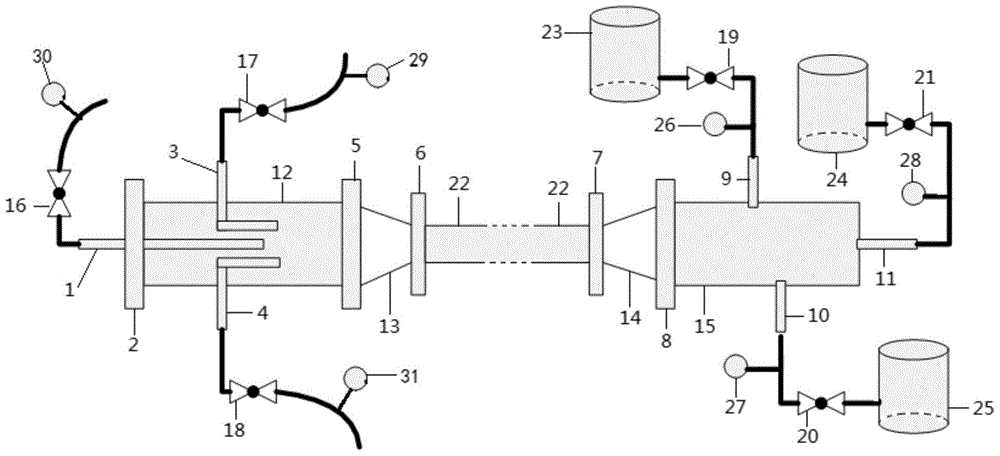

Multi-inlet vacuum-assisted grouting system for discarded pipes

ActiveCN104947673AEliminate stratification of water phenomenonEliminate the risk of vandalismFoundation engineeringVacuum assistedEngineering

The invention discloses a multi-inlet vacuum-assisted grouting system for discarded pipes, comprising a grouting tube, M grout inlets, a grout pump, an evacuating tube, N evacuating holes, and an evacuating pump. The front end of the grouting tube is connected with one end of a discarded pipe. The grout inlets are arranged in the rear end and / or sidewall of the grouting tube. The grout pump is connected with the grout inlets and is used for injecting grout into the grouting tube through the grout inlets and injecting the grout into the discarded pipe through the grouting tube. The front end of the evacuating tube is connected with the other end of the discarded pipe. The evacuating holes are provided in the rear end and / or sidewall of the evacuating tube. The evacuating tube is connected with the evacuating holes and is used for helping pump the grout from the grouting tube into the discarded pipe. The system has the advantages that grouting speed is higher, grouting power is higher, hierarchical bleeding of cement mortar is eliminated, grouting range is widened, grouting compactness and strength is improved, the potential hazard of later environmental disruption is eliminated.

Owner:PIPECHINA SOUTH CHINA CO

Construction Method of Prestressed Anchor Cable Grouting and Anchor in Cracked Rock and Soil Strata

ActiveCN106522243BThe method steps are simpleReasonable designExcavationsBulkheads/pilesPre stressHigh pressure

The invention discloses a grouting and anchoring construction method for prestressed anchor cables in cracked rock soil strata. A plurality of prestressed anchor cables all arranged on the same plane are used to reinforce the slope to be reinforced. The steps include: 1. The degree of development of rock mass joints and fissures is determined; 2. The length of the anchorage section and the position of the anchor cable hole are determined; the prestressed anchor cable includes the anchor cable body, the primary grouting pipe and the secondary grouting pipe. The anchor cable body includes multiple steel strands; 3. Prestressed anchor cable grouting and anchoring construction: when performing grouting and anchoring construction on any prestressed anchor cable, it includes steps: drilling, laying anchor cables, normal pressure injection Grouting, high-pressure grouting and cable tensioning and anchor sealing. The method of the invention has simple steps, reasonable design, convenient construction, high construction efficiency and good application effect, and can simply and quickly complete the reinforcement process of the slope to be reinforced. The prestressed anchor cable used has low cost and high anchoring force, and can Reinforce the slope for effective reinforcement.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

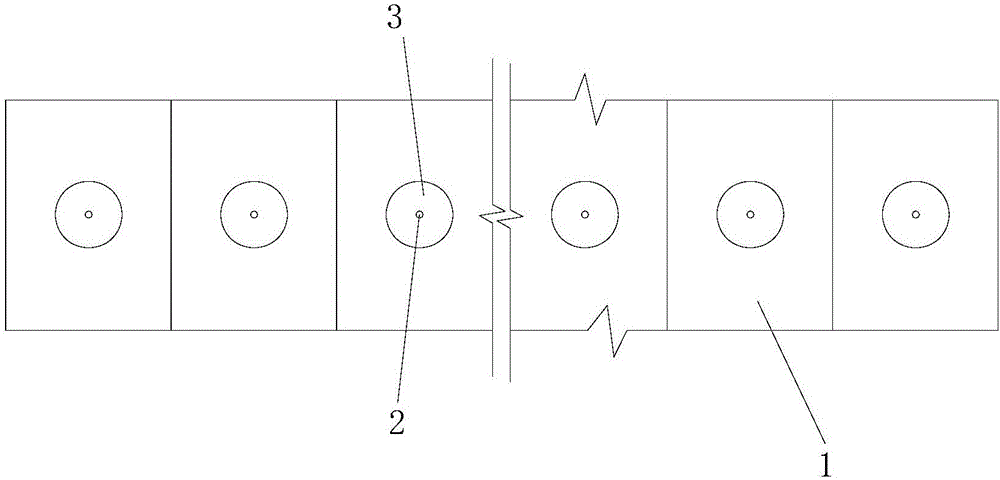

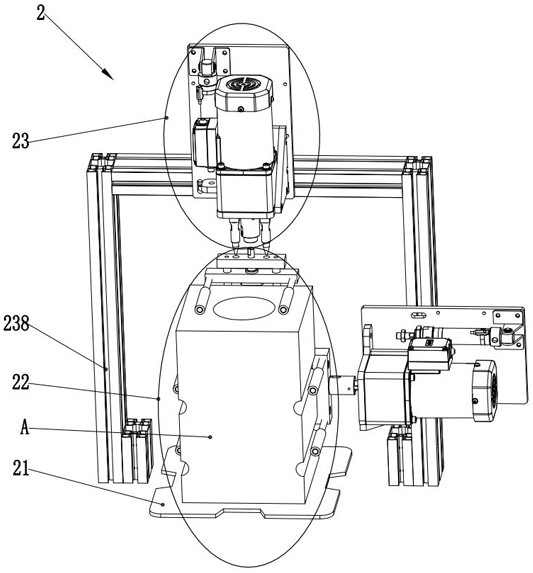

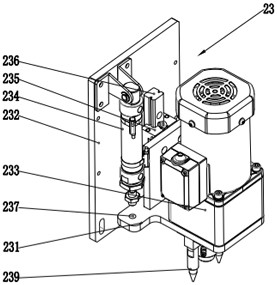

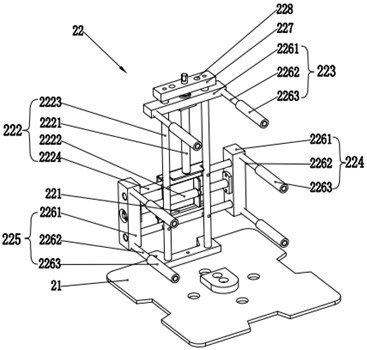

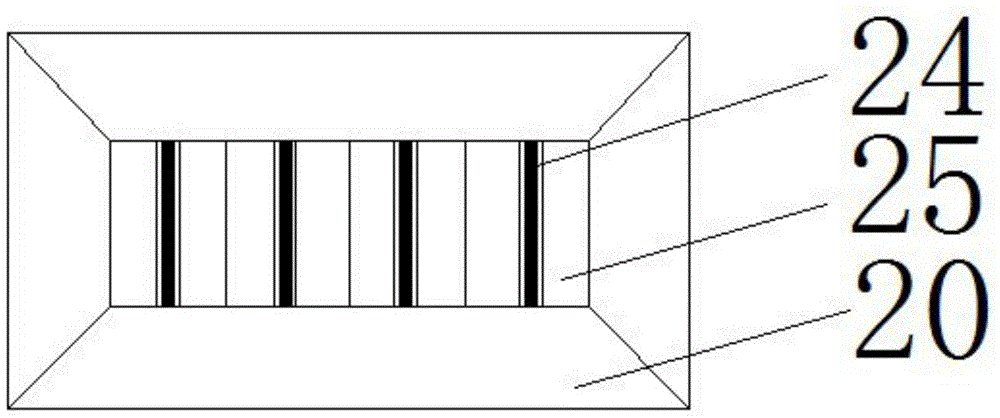

Grouting production line

ActiveCN113246287AInhibit sheddingFast groutingDischarging arrangementCeramic shaping plantsPlaster CastsProcess engineering

The invention discloses a grouting production line. The grouting production line comprises a drying device, a grouting device, a slurry suction device, a slurry pouring device, a slurry draining device and a demolding device. The drying device is used for drying an empty plaster mold before grouting and drying a plaster mold full of slurry during slurry draining; the grouting device is used for grouting the empty plaster mold; the slurry suction device is used for transporting the plaster mold full of the slurry to the slurry pouring device, and the plaster mold full of the slurry completes slurry suction in the transportation process; the slurry pouring device comprises a slurry pouring conveying belt and an overturning assembly which are laid on a slurry pouring rack, and the slurry pouring device is used for overturning the plaster mold full of the slurry after slurry suction; the slurry draining device comprises a conveying mechanism, the conveying mechanism is used for conveying the turned plaster mold full of the slurry to the demolding device, and slurry draining is completed in the transportation process of the plaster mold full of the slurry; and the demolding device is used for executing demolding operation on the plaster mold. Automatic production of all links in the grouting production process is achieved, the production cost is reduced, and the efficiency is improved; and meanwhile, the production line is suitable for automatic production of different manufacturers, different varieties (complex dies) and different processes.

Owner:ZHIXINLONG TECH (GUANGDONG) CO LTD

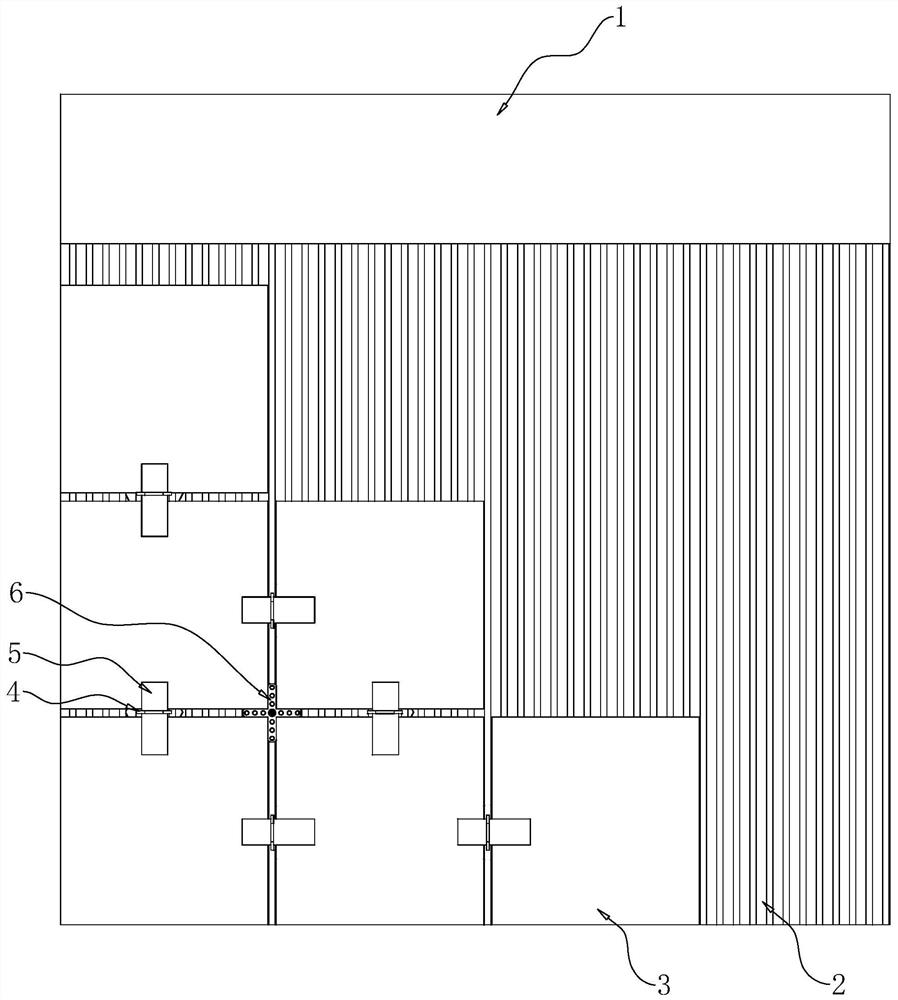

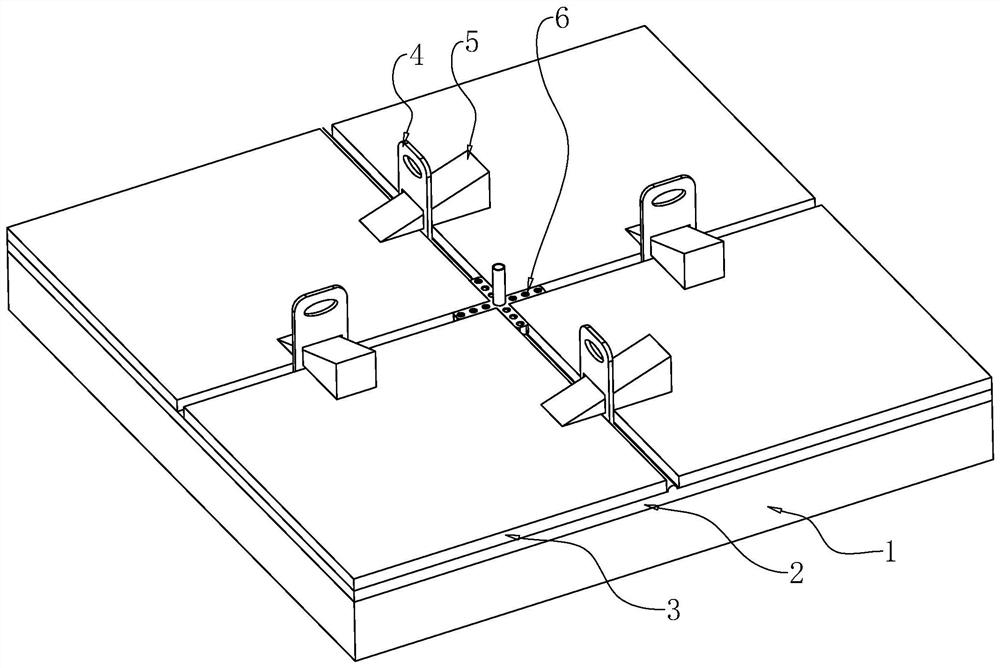

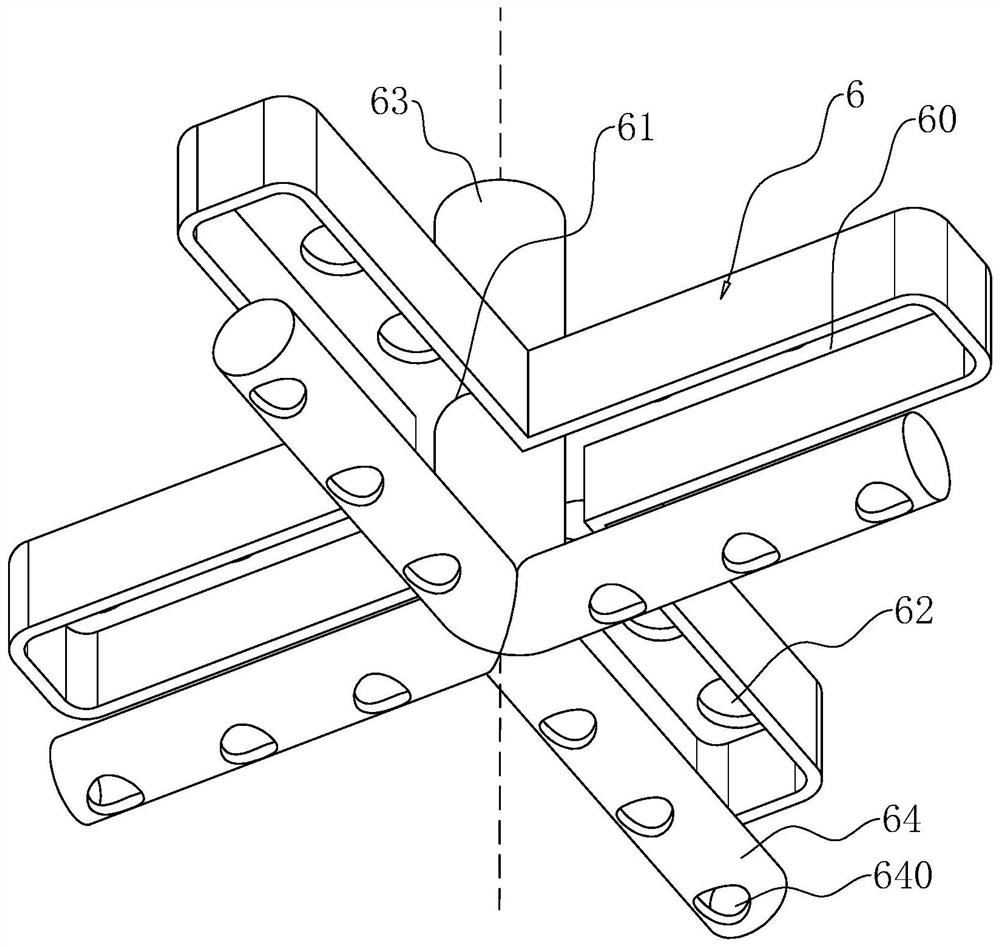

Ceramic tile thin pasting method layer structure and construction process thereof

ActiveCN112065000AEmpty position fillingExpand the scope of groutingBuilding constructionsComposite materialCeramic tiles

The invention relates to the field of decoration engineering, in particular to a ceramic tile thin pasting method layer structure and a construction process thereof. The ceramic tile thin pasting method layer structure comprises a base layer, a ceramic tile adhesive layer and ceramic tiles, all of which are sequentially arranged, a disposable base is placed between every two adjacent ceramic tiles, wedges are inserted onto the disposable bases, a cross-shaped positioning frame is mounted at a cross-shaped gap among the four adjacent ceramic tiles, and an avoiding hole is formed in the center position of the cross-shaped positioning frame. The ceramic tile thin pasting method layer structure has the effect of effectively solving the problem of hollowing below the end corners of the ceramictiles.

Owner:YENOVA NOVARTIS HOME DECORATION GRP CO LTD

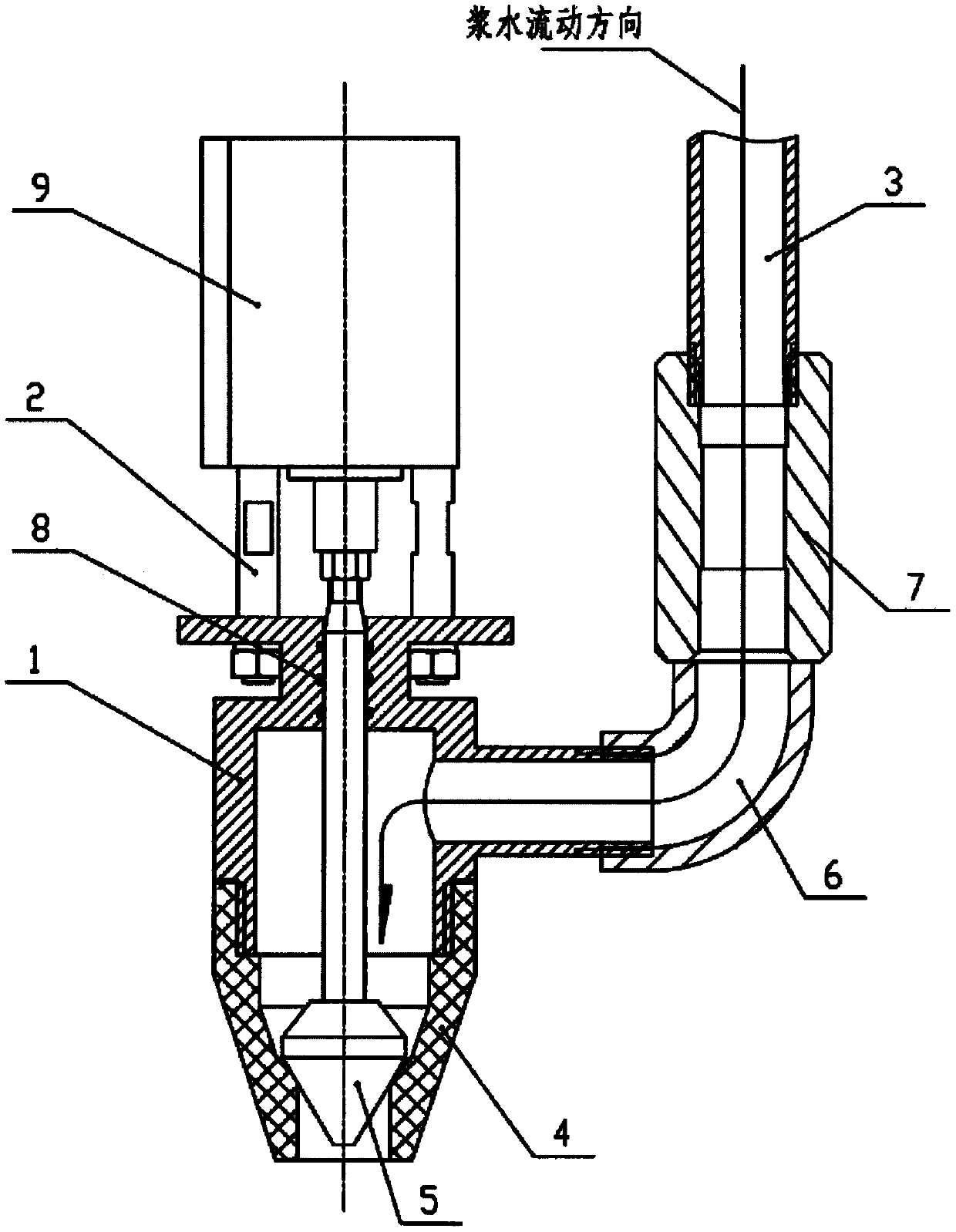

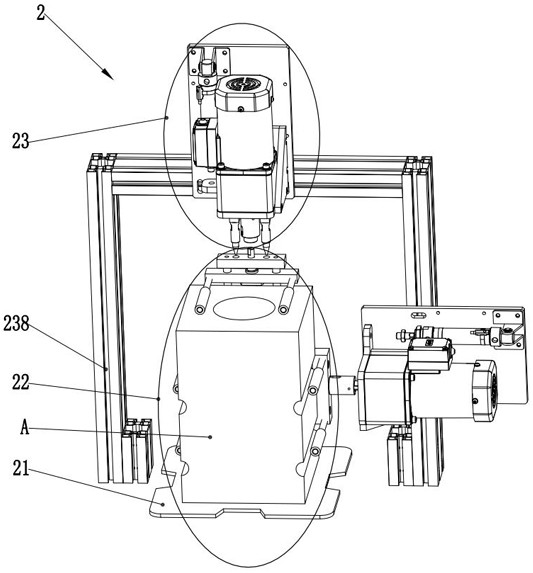

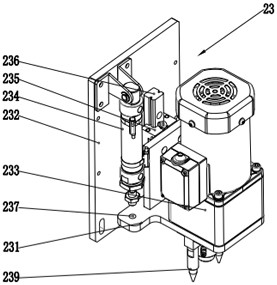

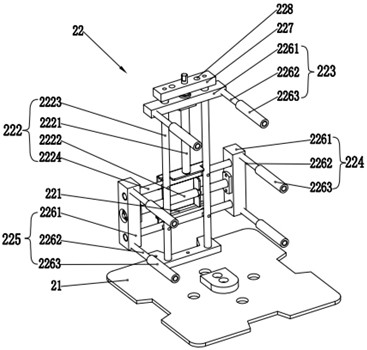

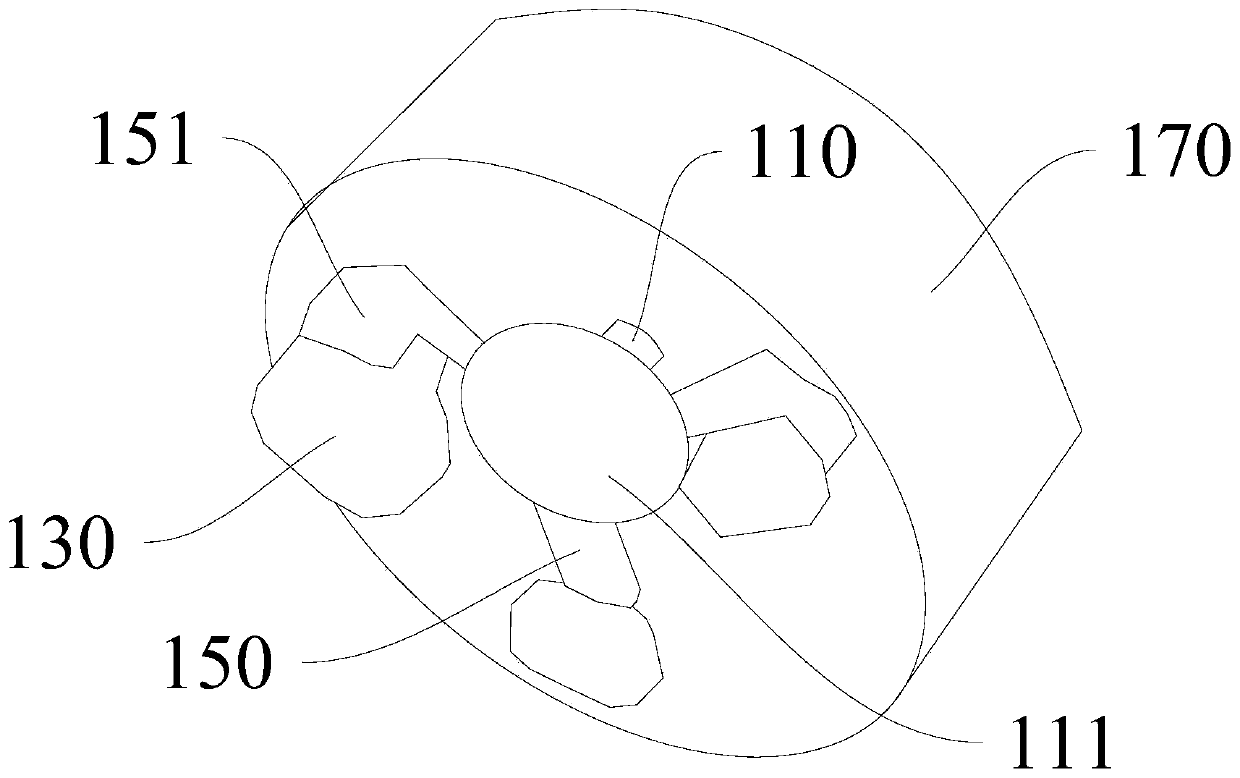

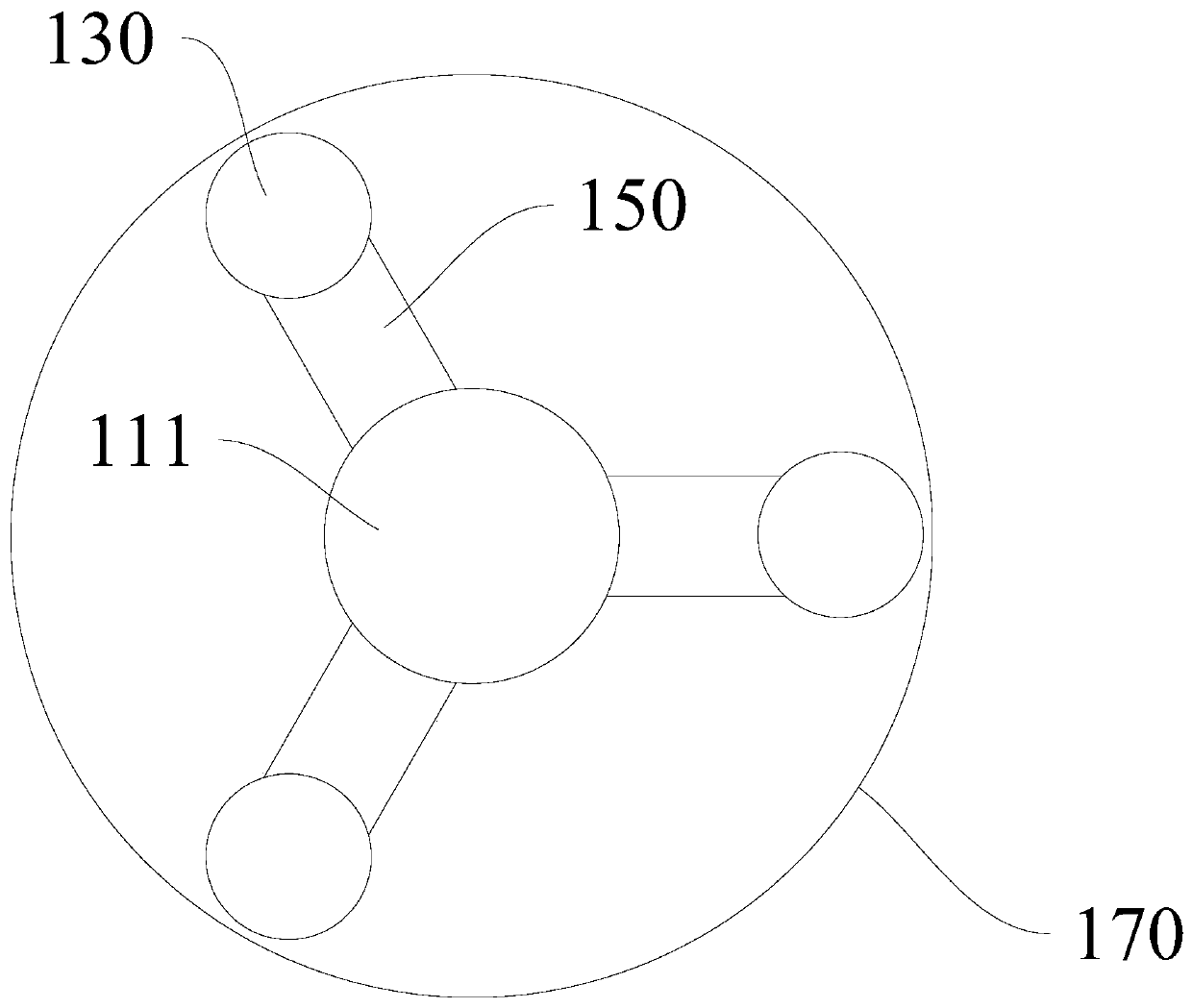

Domestic ceramic large/small flow intelligent switching grouting mechanism

PendingCN111015900AMeet the requirements of small flow rate and low flow rate for groutingHigh trafficAuxillary shaping apparatusControl systemSteel ball

The invention discloses a domestic ceramic large / small flow intelligent switching grouting mechanism, which comprises a reducing sleeve, a slurry outlet and a double-stroke air cylinder, wherein the upper end of the reducing sleeve is connected with a shaft; the right end of the reducing sleeve is connected with a stainless steel elbow; the right end of the stainless steel elbow is connected witha stainless steel ball valve; the upper end of the stainless steel ball valve is connected with a slurry flowing pipe; the slurry outlet is formed in the bottom of the reducing sleeve; a silica gel plug is clamped in the slurry outlet; and the double-stroke air cylinder is arranged on the upper portion of the reducing sleeve. According to the domestic ceramic large / small flow intelligent switchinggrouting mechanism, in the grouting process, the electromagnetic valve can be controlled through the control system, the extending length of the piston rod of the multi-stroke air cylinder is adjusted and controlled at any time according to the grouting process, then the flow and flow speed of slurry flowing out of the slurry outlet are controlled, and the special process requirements of specificceramic grouting products are well met.

Owner:湖南中航里程科技有限公司

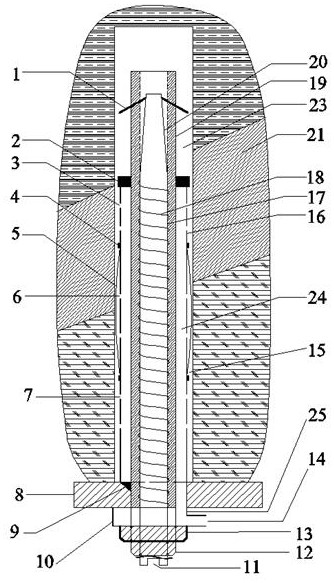

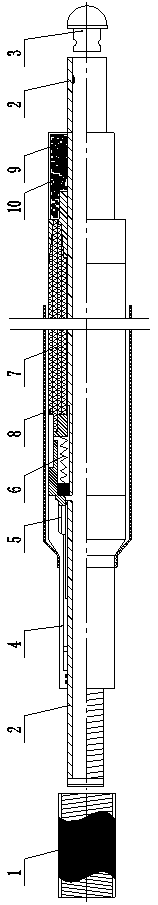

Coal mine underground deep hole quick sealing and grouting device

The invention discloses a coal mine underground deep hole quick sealing and grouting device and belongs to the technical field of coal mine underground grouting and hole sealing. The grouting device is high in engineering timeliness and grouting speed and large in diffusion radius and can achieve the objective of single-hole sectional continuous grouting. A one-way valve joint is of an internal thread structure with a forward thread at one end and a reverse thread at the other end, the reverse thread of the one-way valve joint is connected with the front end of a grouting central pipe, a sealing cover is hermetically mounted at the rear end of the grouting central pipe in a sleeved manner, a top cap, a turnbuckle, a one-way valve and a rubber sleeve are sequentially and fixedly mounted onthe outer wall of the grouting central pipe in a sleeved manner, the front end of the one-way valve is abutted against the top cap and the turnbuckle, each of two ends of the rubber sleeve is clampedand shaped through an iron core and an iron loop, an upper iron core on the rubber sleeve is fixed on the grouting central pipe, a lower iron core movably sleeves the grouting central pipe, and an inlet of the one-way valve is communicated with the inside of the grouting central pipe while an outlet of the same is communicated with the rubber sleeve.

Owner:刘彦俊

Breeding method of continuously and directly seeding carly and late rice breed

InactiveCN100350829CStable vegetative periodLow Thousand Kernel WeightPlant genotype modificationRice cultivationHigh resistanceInterspecific hybridization

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

A grouting production line

ActiveCN113246287BInhibit sheddingFast groutingDischarging arrangementCeramic shaping plantsPlaster CastsSlurry

A grouting production line, including a drying device, a grouting device, a grouting device, a grouting device, a draining device and a demoulding device; the drying device is used for emptying plaster molds before grouting and for filling The grouting plaster mold is dried; the grouting device is used to grout the empty plaster mold; the grout suction device is used to transport the full grout plaster mold to the pouring device, and the full grout plaster mold is sucked during the transportation process; the grouting device Including the pouring conveyor belt and the turning assembly laid on the pouring frame, the pouring device is used to turn over the filled plaster mold after the slurry is sucked; the draining device includes a conveying mechanism, and the conveying mechanism is used to convey the turned full plaster mold From the mold to the demoulding device, the full slurry plaster mold is drained during transportation; the demoulding device is used to perform the demoulding operation on the plaster mold. The invention realizes the automatic production of each link in the grouting production process, reduces the production cost and improves the efficiency; at the same time, it is suitable for automatic production of different manufacturers, different varieties (complex molds) and different processes.

Owner:ZHIXINLONG TECH (GUANGDONG) CO LTD

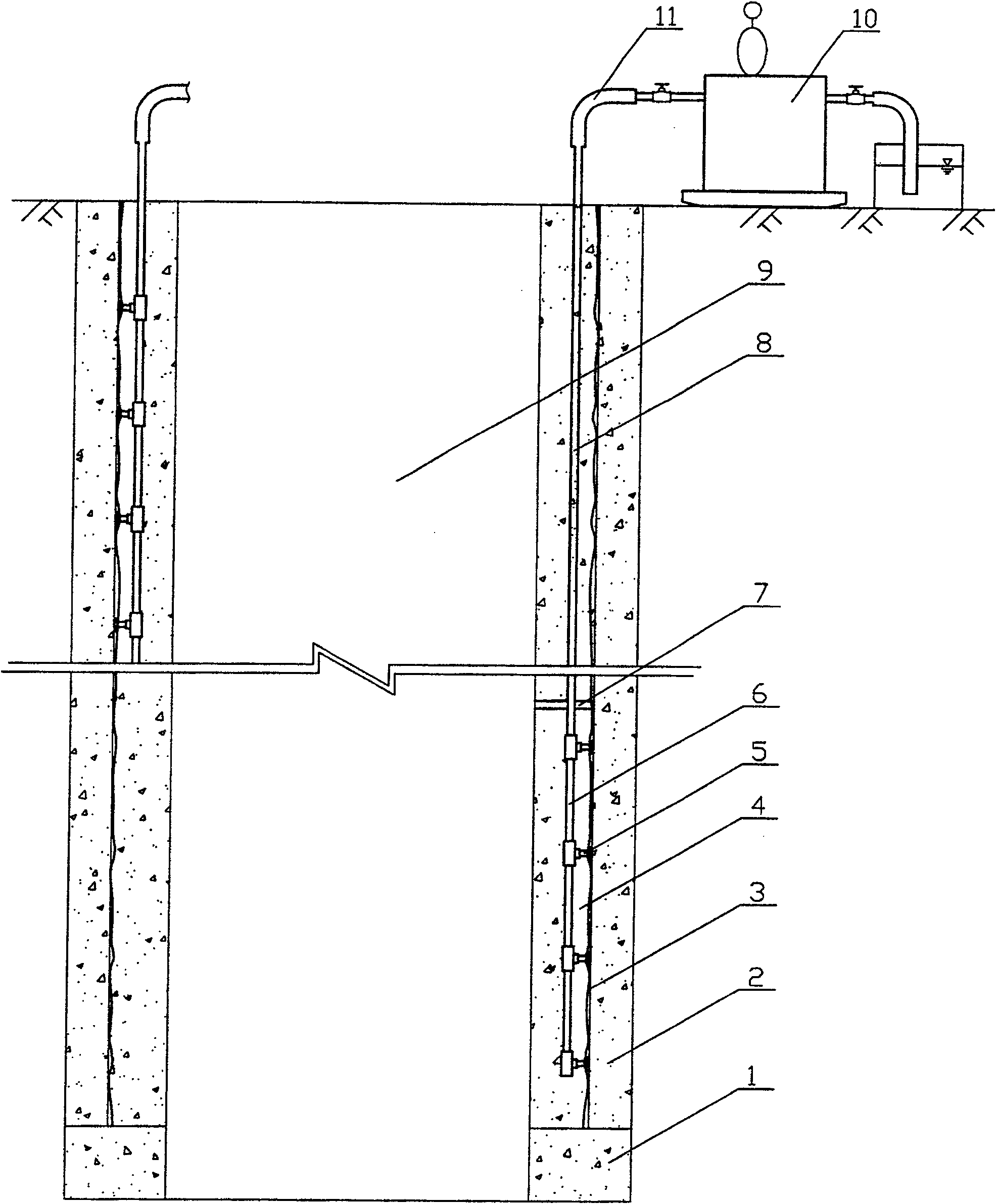

Fast slip casting technique between composite well wall

The invention discloses a rapid injection technique to cavity among walls of compound shaft. The shaft is sectioned by injection in accordance with the frozen shaft depth, shaft wall thickness and strength and stratigraphic position of water-bearing bed, and the section has height of 100-200 m. When constructing inner layer shaft wall, pre-installing and pre-embedding a vertical sectioned injection pipe adaptable to the height of the injected section, a plurality of injection heads are equipped on the sectioned injection head and communicated with the cavity among walls of plastic interlayer, a plurality of injection points are formed at the same time at one section, the upper end of the sectioned injection pipe is connected with a delivery pipe, and the other end of the delivery pipe is connected with an injection pump via a connecting rubber pipe. The invention has the advantages of simple process, safe and reliable performance, high injection speed, high efficiency, and low cost. And, the occupied time of injection process to cavity among walls to the shaft construction is reduced by 60-90 percent, so as to shorten the shaft construction period.

Owner:盛天宝 +1

Slurry wiping machine

InactiveCN111270871AQuality improvementAvoid repeated contaminationBuilding repairsProcess engineeringSlurry

The invention provides a slurry wiping machine, and belongs to the field of building construction machines. The slurry wiping machine comprises a slurry wiping disc and a cart, the cart comprises a handle and a cart body which are fixedly connected, the slurry wiping disc is arranged on the side, away from the handle, of the cart body, the slurry wiping disc comprises a rotating shaft and a slurrywiping ball, at least one support extending outwards in the radial direction is arranged on the periphery of the rotating shaft, and the slurry wiping ball is arranged at the end, away from the rotating shaft, of the support; and the slurry wiping ball is used for wiping the surface of a terrazzo subjected to rough grinding. By means of the slurry wiping machine, sand holes and bubbles on the surface of the terrazzo after rough grinding can be effectively eliminated, the slurry wiping speed is high, the whole process is relatively dry, an extra drying process is not needed, the efficiency canbe greatly improved, and the construction period can be greatly shortened. Due to the arrangement of an outer disc body of the slurry wiping machine, repeated pollution to a slurry wiping area in theslurry wiping process can be avoided, the slurry wiping effect is improved, and the quality of a finished product is improved.

Owner:CHINA MCC5 GROUP CORP

Vacuum-assisted grouting system with multiple grouting ports for abandoned pipelines

ActiveCN104947673BEliminate stratification of water phenomenonEliminate the risk of vandalismFoundation engineeringVacuum assistedEngineering

The invention discloses a multi-inlet vacuum-assisted grouting system for discarded pipes, comprising a grouting tube, M grout inlets, a grout pump, an evacuating tube, N evacuating holes, and an evacuating pump. The front end of the grouting tube is connected with one end of a discarded pipe. The grout inlets are arranged in the rear end and / or sidewall of the grouting tube. The grout pump is connected with the grout inlets and is used for injecting grout into the grouting tube through the grout inlets and injecting the grout into the discarded pipe through the grouting tube. The front end of the evacuating tube is connected with the other end of the discarded pipe. The evacuating holes are provided in the rear end and / or sidewall of the evacuating tube. The evacuating tube is connected with the evacuating holes and is used for helping pump the grout from the grouting tube into the discarded pipe. The system has the advantages that grouting speed is higher, grouting power is higher, hierarchical bleeding of cement mortar is eliminated, grouting range is widened, grouting compactness and strength is improved, the potential hazard of later environmental disruption is eliminated.

Owner:PIPECHINA SOUTH CHINA CO

A grouting valve at the bottom of a cast-in-place pile for geotechnical engineering construction

ActiveCN111535312BFully filledStable structureBulkheads/pilesMechanical engineeringCylinder (engine)

Owner:KUNMING PROSPECTING DESIGN INST OF CHINA NONFERROUS METALS IND

A mobile grouting device for building construction

InactiveCN105275216BGuaranteed stabilityImprove securityBuilding material handlingAdditive ingredientHigh definition

The invention discloses a mobile mortar laying device for building construction, which belongs to the technical field of building equipment. The mobile mortar laying device for building construction comprises a mortar laying box; the bottom part of the mortar laying box is provided with mortar leaking holes; the mortar laying box is internally provided with a rotation bearing; two sides of the rotation bearing are provided with page doors; the front surface of the mortar laying box is provided with a first fixing block; the upper side of the first fixing block is provided with a display screen; the upper side of the display screen is provided with a high-definition camera; the high-definition camera is electrically connected with an infrared sensor, an orientation sensor and a central processor respectively; the central processor is electrically connected with the display screen and an ingredient detection unit respectively. According to the mobile mortar laying device for building construction, intelligent and full automatic mortar laying can be carried out, the quality of the mortar ingredient inside the mortar laying device can be detected, the mortar laying process is quick and accurate, material is divided uniformly, mortar laying is quick, the labor intensity is small, mortar laying is uniform, the mortar laying efficiency is high, and safety and stability are high.

Owner:鄄城县舜德董氏食品有限公司

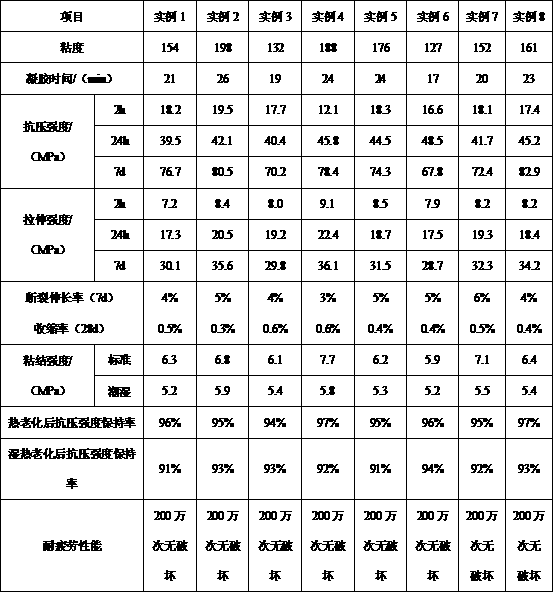

Double-block type ballastless track interlayer mortar overflow treatment material and process

The invention relates to a double-block type ballastless track interlayer mortar overflow treatment material and process. The material is characterized in that the material is composed of a part A anda part B. The part A is composed of the following raw materials in parts by mass: 100 parts of modified epoxy resin, 10-20 parts of a micro-expansion prepolymer, 20-40 parts of an active dilution toughening agent and 5-10 parts of a silane coupling agent; the part B is prepared from the following raw materials in parts by mass: 60-80 parts of an amine curing agent, 30-60 parts of a plasticizer, 4-8 parts of a silane coupling agent and 1-3 parts of an organic silicon defoaming agent; and the volume ratio of the part A to the part B is 1: 1. The interlayer mortar overflow treatment process comprises the steps of grouting hole forming, edge sealing, grouting and surface modification. According to the interlayer mortar overflow treatment material and process, the skylight time can be utilized, the interlayer mortar overflow disease of the double-block type ballastless track is rapidly and effectively solved, normal operation of a train is not affected, and the structural stability and durability of the double-block type ballastless track are recovered.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com