Method for reinforcing fault fracture zone through single-shield double-mode TBM advanced grouting

A technology of advanced grouting and grouting reinforcement, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve problems such as uneven grouting effect, small reinforcement range, and long operation time, and reduce the cost of cyclic installation and commissioning Time, high construction efficiency, and the effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

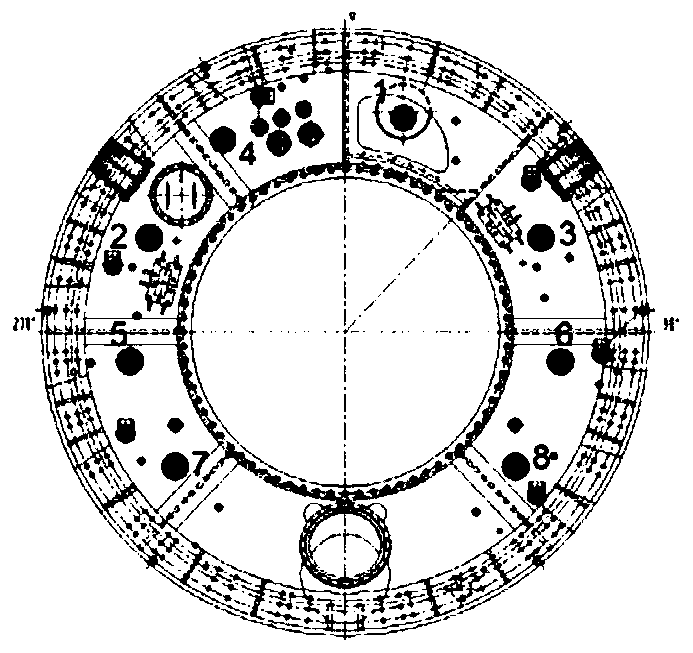

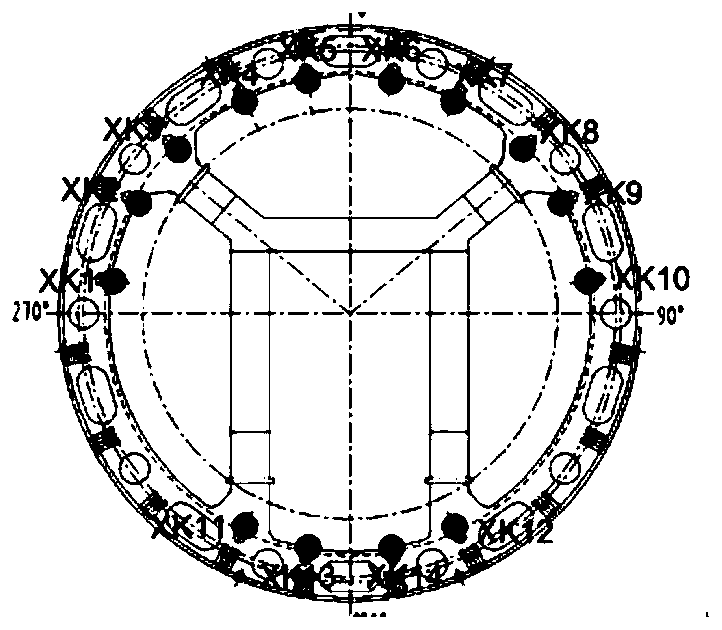

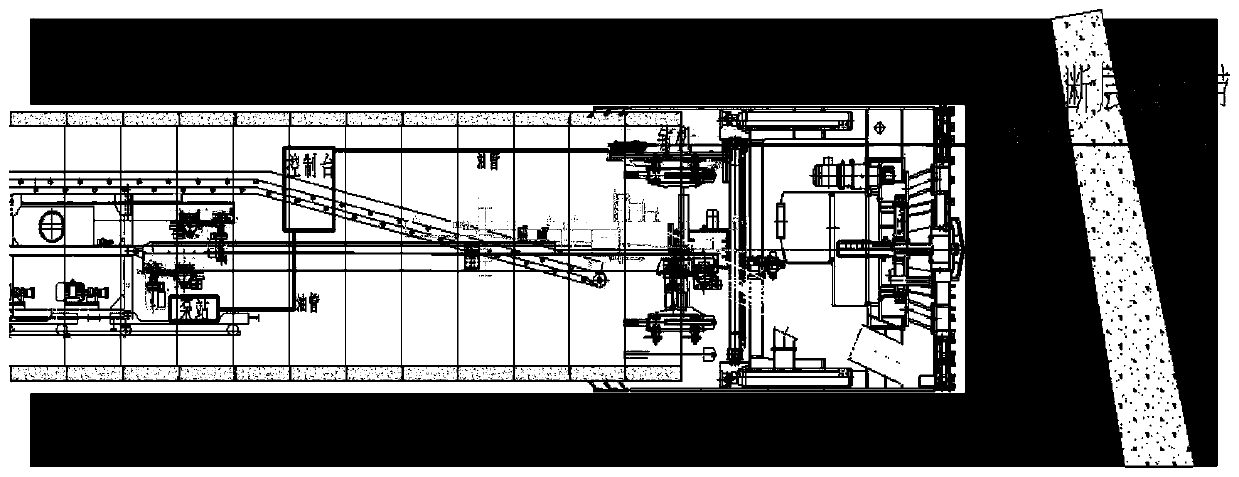

[0034] like Figure 1-5 As shown, a method for advance grouting of a single-shield dual-mode TBM of the present invention to strengthen the fault fracture zone includes the following steps:

[0035] A. Remove the TBM segment assembly platform, and use electric locomotives to transport the geological drilling rig and related equipment to the tunnel;

[0036] B. Install the drilling rig on the rotating disk of the TBM assembly machine, fix it firmly, and use the rotation angle of the assembly machine to realize the 360° rotation of the drilling rig, that is, to determine the angle of the drilling rig;

[0037] C. After the drilling rig is installed, the drilling rig is connected to the console through the power oil pipeline, and the console is connected to the pump station through the power oil pipeline to check the working performance of the equipment, and determine the number of drill pipes required for drilling and other tools required for construction. and materials, such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com