Double-block type ballastless track interlayer mortar overflow treatment material and process

A ballastless track and double-block technology, which is applied in the field of rail transit, can solve the problems of low toughness, harsh conditions for repairing gaps between layers at the slurry point, and high quality requirements, and achieve good fatigue resistance and low temperature resistance. Good long-term effect and good volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

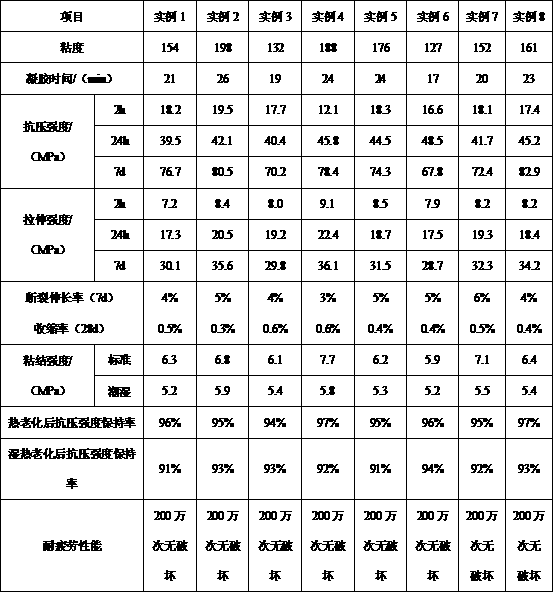

Examples

Embodiment 1

[0037]Slurry treatment materials between layers of double-block ballastless track:

[0038] Component A is composed of the following raw materials in parts by weight: 10 parts of silicone modified epoxy resin, 50 parts of polyurethane modified epoxy resin, 10 parts of polybutadiene modified epoxy resin, nitrile rubber modified epoxy resin 30 parts of resin, 10 parts of micro-expanded prepolymer, 10 parts of monoepoxy glycidyl ether, 10 parts of bisepoxy glycidyl ether, 5 parts of epoxy silane coupling agent;

[0039] Part B is composed of the following raw materials in parts by weight: 30 parts of modified alicyclic amine curing agent, 10 parts of modified fatty amine curing agent, 10 parts of polyetheramine, 10 parts of amino oligomer silicone, and 30 parts of plasticizer , 4 parts of aminosilane coupling agent, 1 part of defoamer;

[0040] The volume ratio of the two parts A and B is 1:1.

Embodiment 2

[0042] Slurry treatment materials between layers of double-block ballastless track:

[0043] Component A is composed of the following raw materials in parts by weight: 20 parts of silicone modified epoxy resin, 60 parts of polyurethane modified epoxy resin, 10 parts of polybutadiene modified epoxy resin, nitrile rubber modified epoxy resin 10 parts of resin, 20 parts of micro-expanded prepolymer, 10 parts of monoepoxy glycidyl ether, 30 parts of bisepoxy glycidyl ether, 10 parts of epoxy silane coupling agent;

[0044] Part B is composed of the following raw materials in parts by weight: 40 parts of modified alicyclic amine curing agent, 10 parts of modified fatty amine curing agent, 10 parts of polyether amine, 20 parts of amino oligomer silicone, and 60 parts of plasticizer , 8 parts of aminosilane coupling agent, 3 parts of defoamer;

[0045] The volume ratio of the two parts A and B is 1:1.

Embodiment 3

[0047] Slurry treatment materials between layers of double-block ballastless track:

[0048] Component A is composed of the following raw materials in parts by weight: 100 parts of polyurethane modified epoxy resin, 15 parts of micro-expanded prepolymer, 30 parts of diepoxy glycidyl ether, and 7.5 parts of epoxy silane coupling agent;

[0049] Part B is composed of the following raw materials in parts by weight: 70 parts of modified alicyclic amine curing agent, 45 parts of plasticizer, 6 parts of aminosilane coupling agent, and 2 parts of defoamer;

[0050] The volume ratio of the two parts A and B is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com