Slurry wiping machine

A technology of grouting machine and pulp plate, which is applied in building maintenance, construction, building construction, etc. It can solve the problems of affecting the quality of terrazzo ground, the consistency of cement ballast slurry, and the low efficiency of construction process, so as to eliminate sand holes and air bubbles , The grouting speed is fast, and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

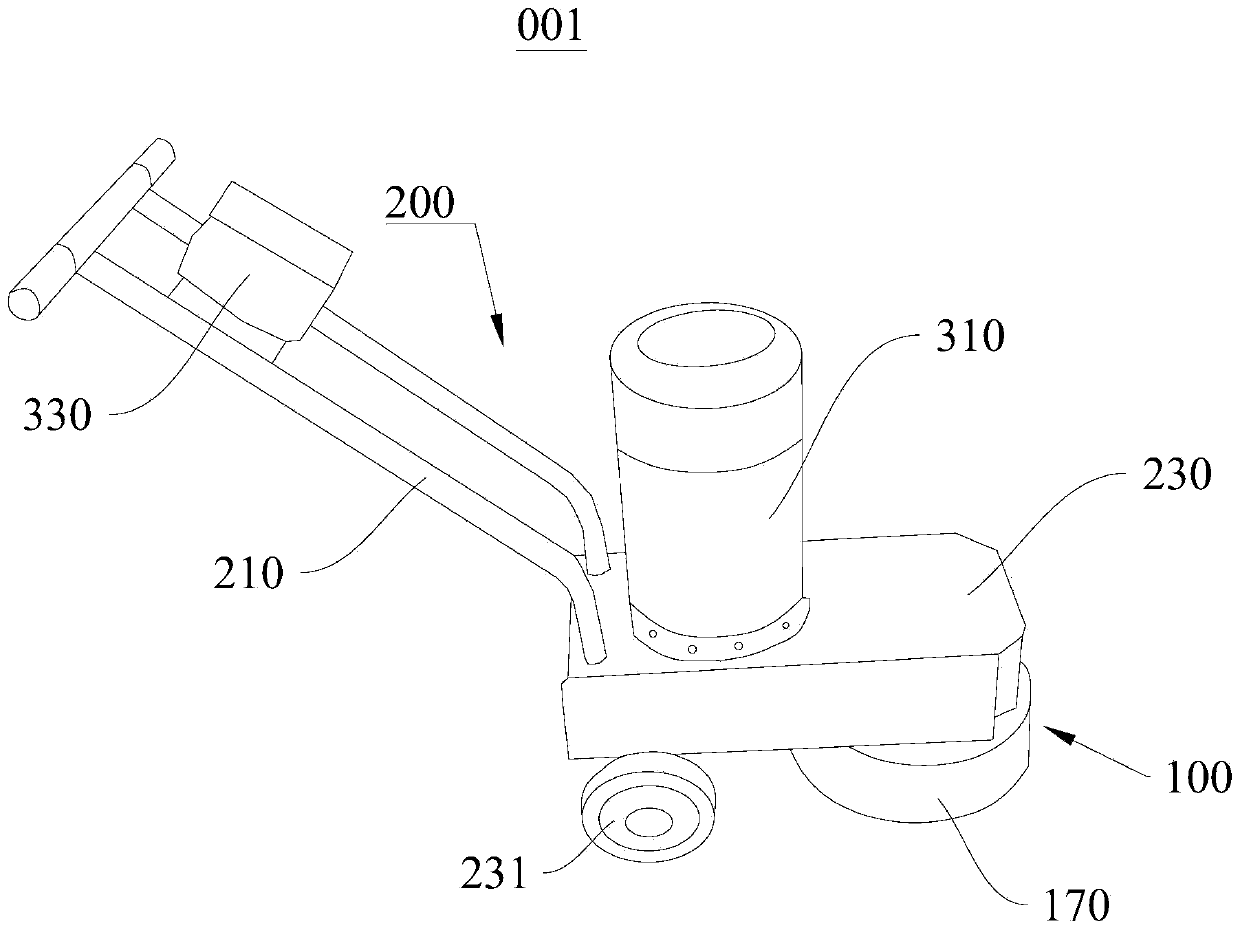

[0031] This embodiment provides a pulper 001, please refer to figure 1 , this grouting machine 001 includes a grouting disc 100 and a trolley 200;

[0032] The cart 200 includes a handle 210 and a car body 230 fixedly connected; push forward.

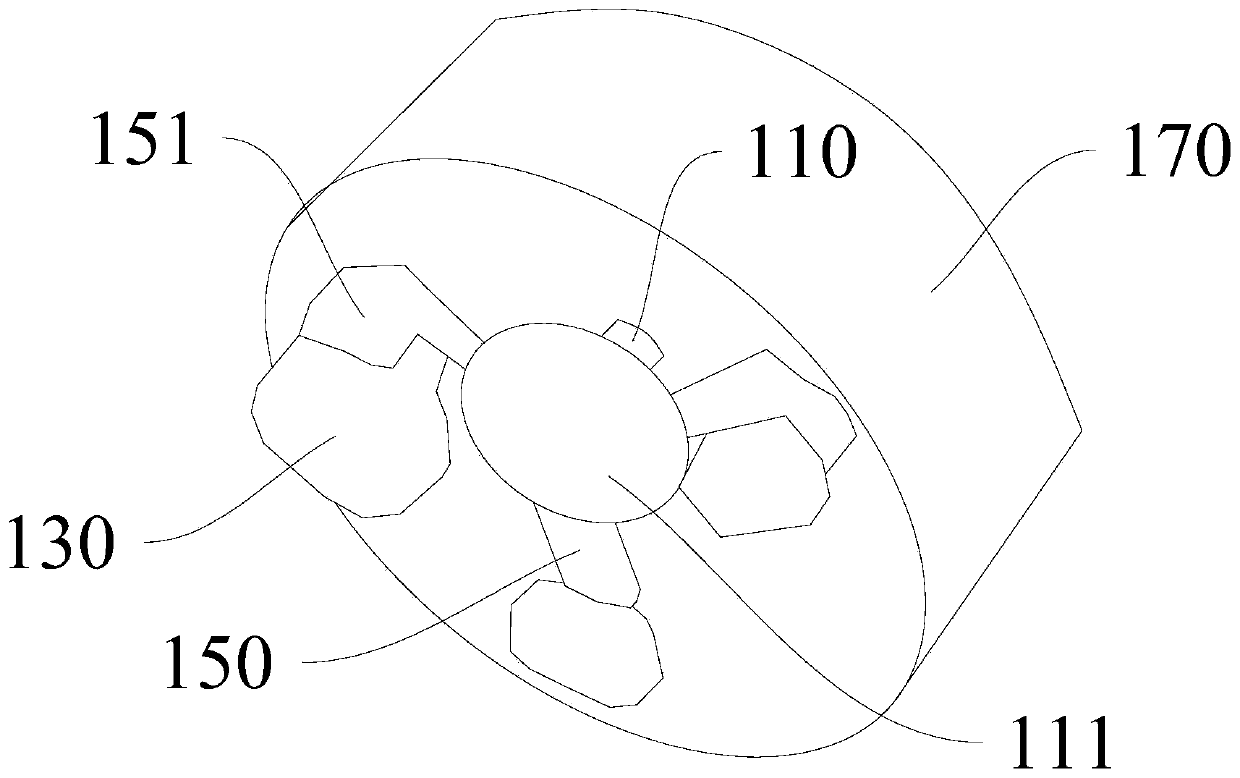

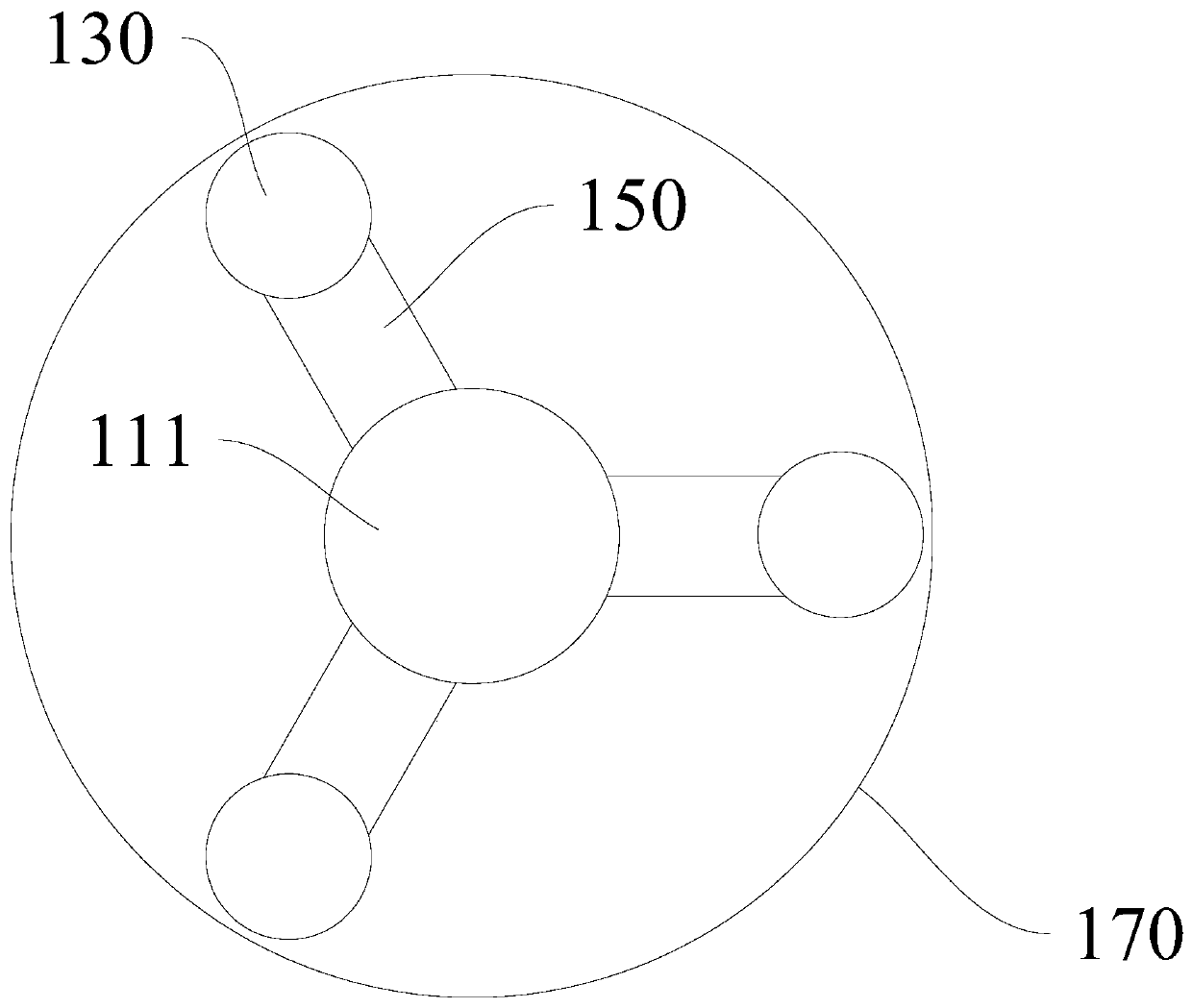

[0033] see figure 1 , figure 2 and image 3 , the grouting disc 100 includes a rotating shaft 110 and a grouting ball 130, the outer periphery of the rotating shaft 110 is provided with at least one radially outwardly extending support 150, and the grouting ball 130 is arranged on one end of the support 150 away from the rotating shaft 110; the grouting ball 130 is used It is used to wipe the surface of terrazzo after rough grinding.

[0034] In this embodiment, the grout ball 130 is a wear-resistant nylon cloth compressed into a spherical shape, that is, a wear-resistant nylon layer is formed on the surface. Nylon cloth has a delicate surface, and after rubbing the coarsely ground surface of the terrazzo, it can evenly disperse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com