Self-propelled tunnel grouting trolley

A self-propelled and trolley technology, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of increased engineering investment and labor intensity, short construction distance of grouting equipment, and increased invalid construction time, so as to avoid repeated installation and The effects of handling process, saving invalid construction time, reducing engineering investment and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

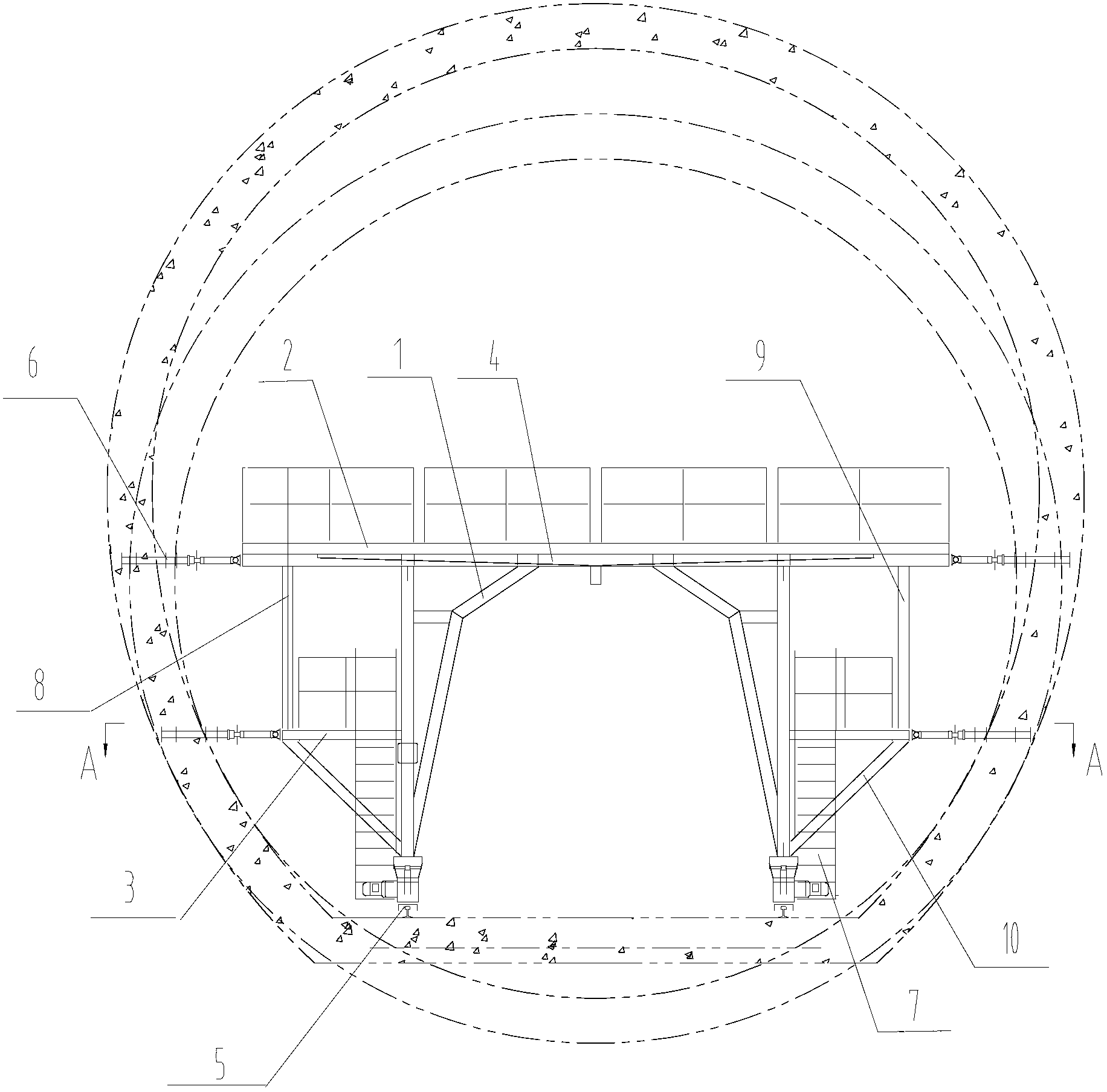

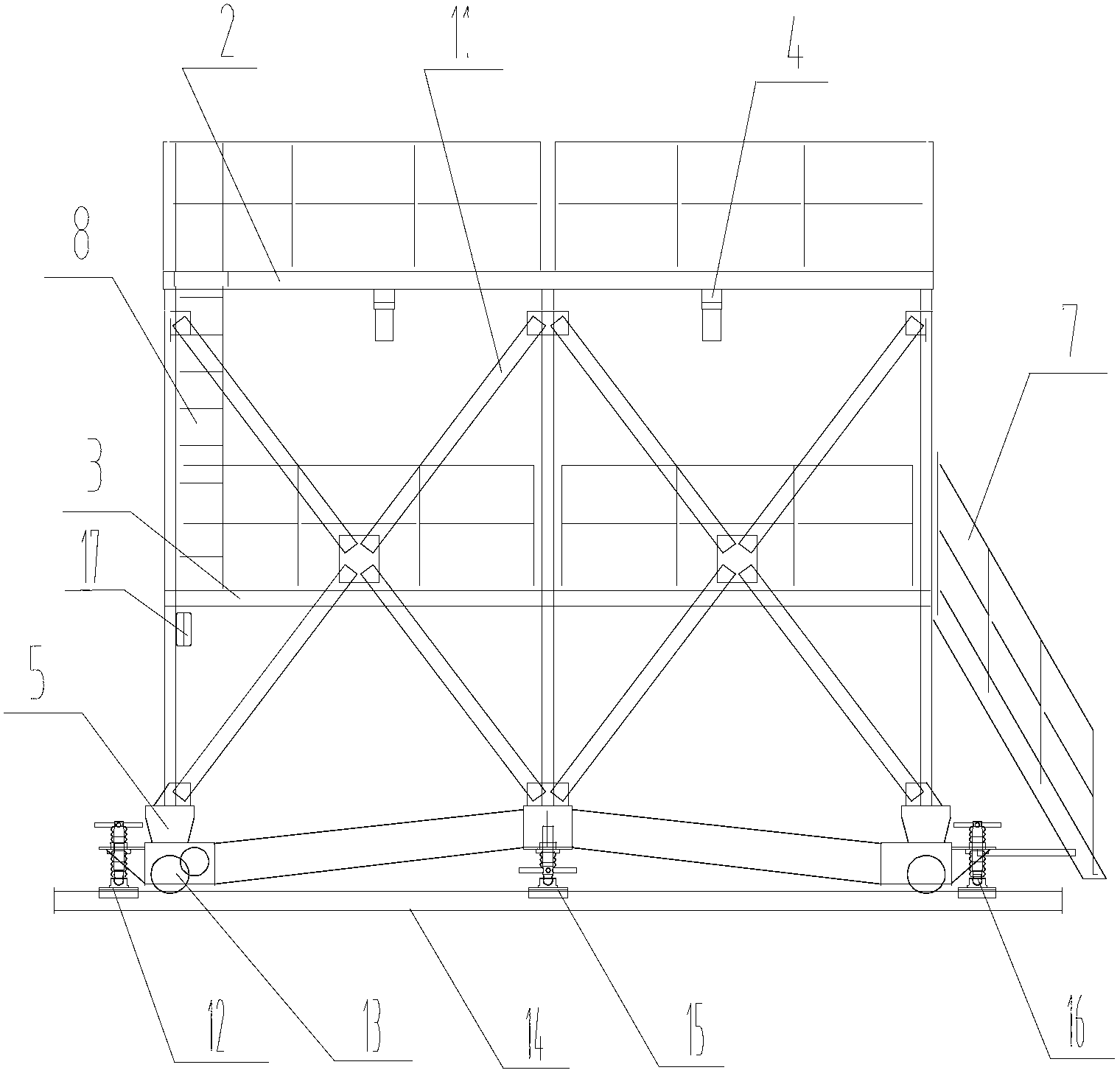

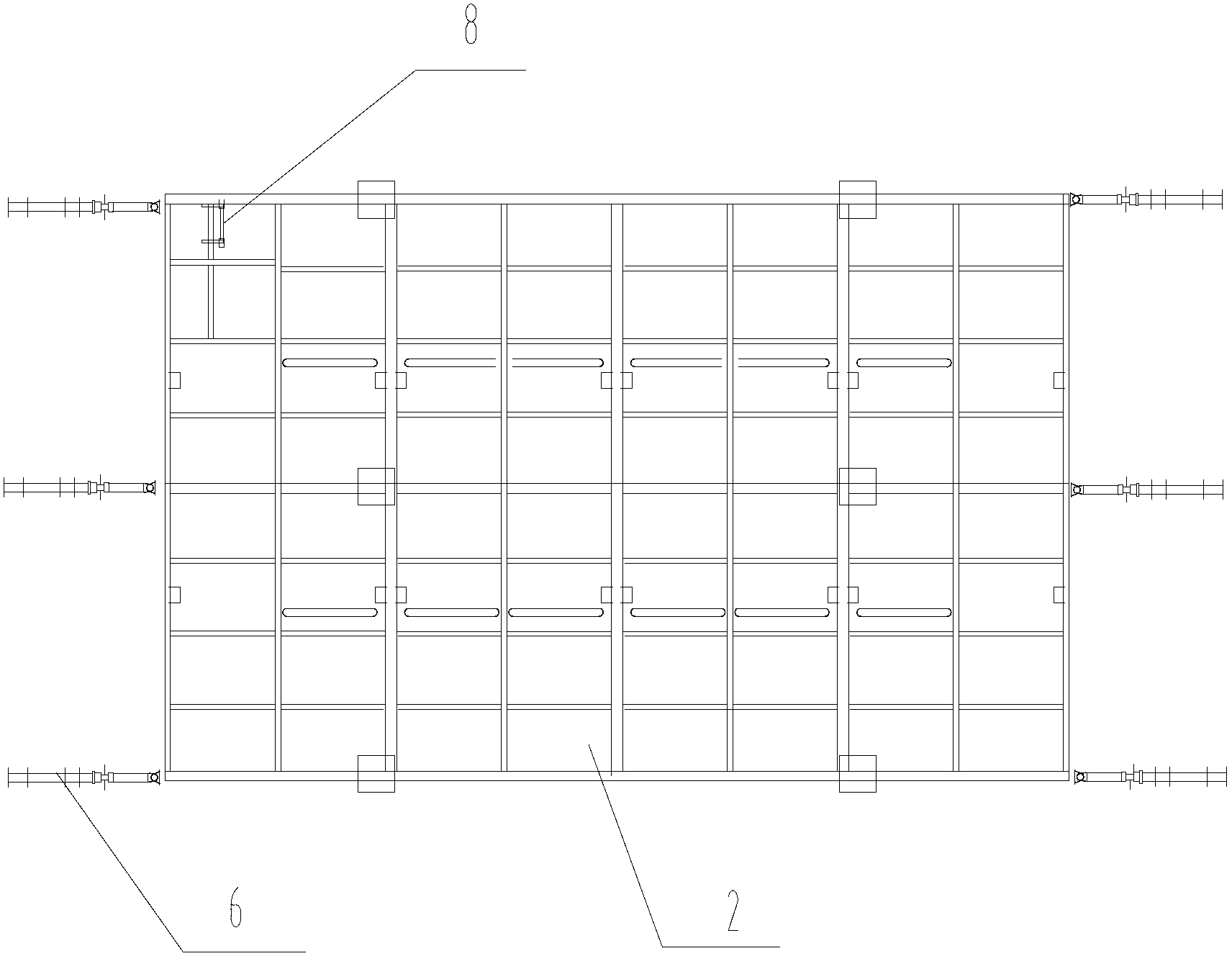

[0021] control Figure 1-Figure 4 , the present invention provides a self-propelled tunnel grouting trolley, which is composed of a frame 1, a platform, a main beam 4, a running mechanism 5, and a screw jack 6. The frame 1 is an empty stomach frame and is installed on the running mechanism 5 On the frame 1, a main beam 4 is arranged, and the platform includes a working platform 2 and a lower platform 3. The working platform 2 is arranged on the main beam 4. The working platform 2 is 6 meters long along the length of the tunnel, 9 meters wide, and 9 meters high. It is 5 meters, and the working platform 2 is rectangular, with a hole in the middle, and a cover plate at the opening, and a hole in the middle of the working platform so as to facilitate hoisting. A lower platform 3 is arranged under the working platform 2 and on both sides of the frame 1 along the direction of the tunnel. One end of the lower platform 3 is vertically fixed on the frame 1, and the other end is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com