Guiding device for once grouting of equipment and manufacturing method thereof

The technology of a guide device and manufacturing method is applied in the processing of building materials, infrastructure engineering, construction, etc., which can solve the problems of easy waste of grouting materials, slow grouting speed, inconvenience, etc., and achieve fast grouting speed, correct grouting in place, and grouting good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The guide device for primary grouting of equipment of the present invention comprises a guide pipe, a funnel and a support frame.

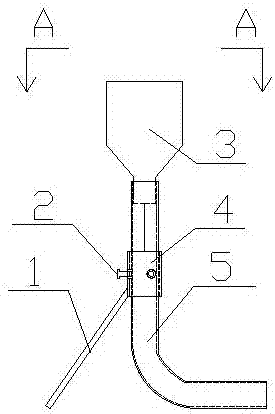

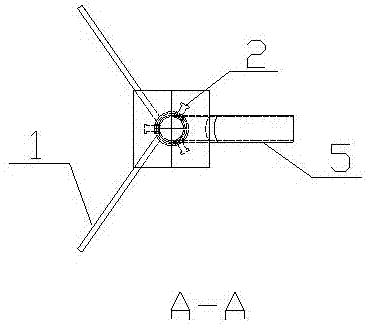

[0032] see now figure 1 with figure 2 , figure 1 It is a structural schematic diagram of the guiding device of the embodiment of the present invention, figure 2 for figure 1 Middle A-A sectional view. As shown in the figure, the guide pipe 5 is a 5Ф60x3.5mm steel pipe with a length of 0.8m, which is bent at 90 degrees at a distance of 0.5m from one end port, so that the guide pipe is bent at a right angle;

[0033] The funnel 3 is a plastic funnel 3 funnel, and the mouth of the funnel can be inserted into the guide tube;

[0034] The support frame includes a casing 4 and a support rod 1, the casing is Ф75.5x3.75mm, and the length is 0.1m. The nut is welded, the nut is equipped with a matching M12 locking screw 2, and two Ф12mm, 5m long round steel support rods arranged in a figure-eight shape are welded on the casing wall;

[0035]...

Embodiment 2

[0037] A method for manufacturing a guide device for primary grouting of equipment, comprising the following steps:

[0038] a. Guide pipe production: Take a Ф60x3.5mm steel pipe with a length of 0.8m, and bend it to 90 degrees from the center at 0.5m from one end;

[0039] b. Funnel production: Take a household cooking oil waste oil barrel, use a knife or scissors to cut off the bottom plate to make a plastic funnel;

[0040] c. Fabrication of the support frame: Take the pipe Ф75.5x3.75mm and the length 0.1m as the casing, cut holes Ф20mm in the same section in the same section in the middle of the casing, take three sets of bolts M12, and weld the nuts to the holes respectively; Take two round steel Ф12 with a length of 10m and weld them to the slope of the pipeline as support rods. The support rods of the support frame are arranged opposite to the direction of the bend of the right-angle bend. The inner diameter of the guide pipe is larger than the outer diameter of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com