Autoignition coal gangue flow slope extinguishment and steadiness comprehensive treatment technology

A technology for comprehensive treatment and spontaneous combustion of coal, applied in fire rescue, soil protection, excavation, etc., can solve problems such as difficult implementation, few slurry discharge holes, and drilling depths ranging from ten meters to dozens of meters. Achieve the effect of improving governance efficiency, reducing governance costs, and being easy to operate and implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

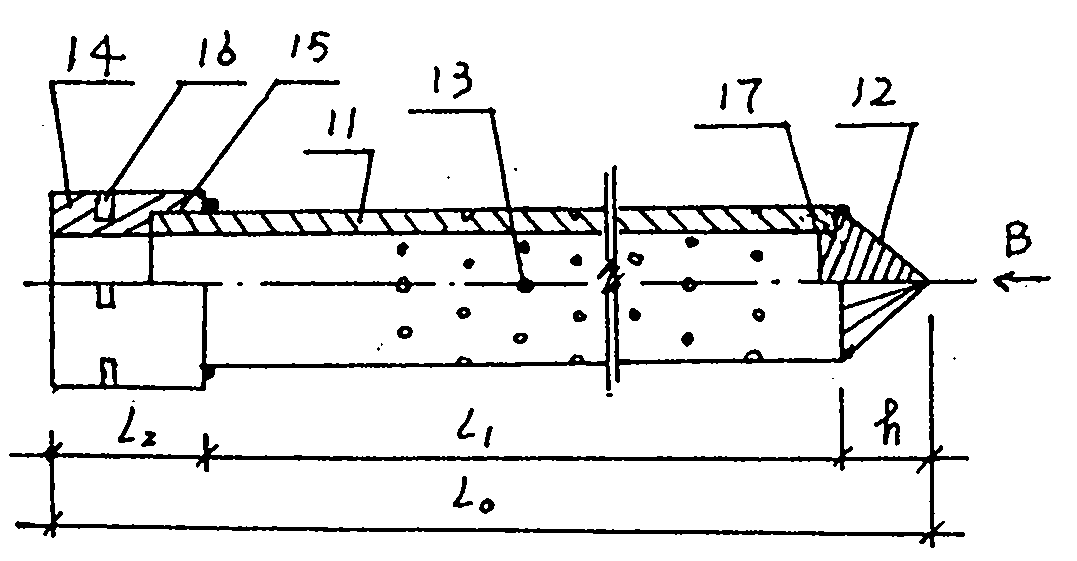

[0037] like image 3 , 4 Shown:

[0038] Grouting pipe 4 total length L 0 2500-3500mm, where the length L of the main body 11 1 is 2100-3000mm, the height h of the cone head 12 is 80-120mm, and the length L of the riveting tube 14 2 It is 300-400mm; in the main body 11 according to its axial direction, and extending upward from its lower port to the peripheral wall of its total length of 1400-2500mm, there are regularly distributed slurry holes 13; the outer diameter of the main body Φ 1 75 ~ 100mm, wall thickness δ 1 3 ~ 5mm, the outer diameter of riveting tube 14 Φ 2 85 ~ 108mm, wall thickness δ 2 6-12mm; the diameter of the bottom surface of the cone head 12 and the outer diameter Φ of the main body 11 1 Matching; diameter Φ of slurry discharge hole 13 3 8-12mm, arranged in rows and layers in the radial direction according to the axial direction of the main body 11, the distance between two adjacent rows is 60-80mm, and the distance between two adjacent layers is 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com