A pre-construction formwork with concrete reinforcement as the main raw material

A technology of concrete reinforcement and formwork, which is applied in the direction of formwork/formwork/work frame, construction, building structure, etc., can solve the problems of insufficient mold bearing capacity, mold detachment, low adhesion of fiber cloth, etc., and achieves excellent results. Excellent, excellent anti-falling, improve bearing capacity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

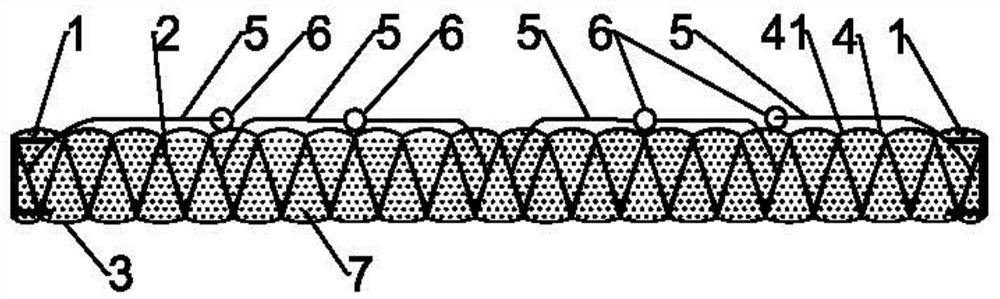

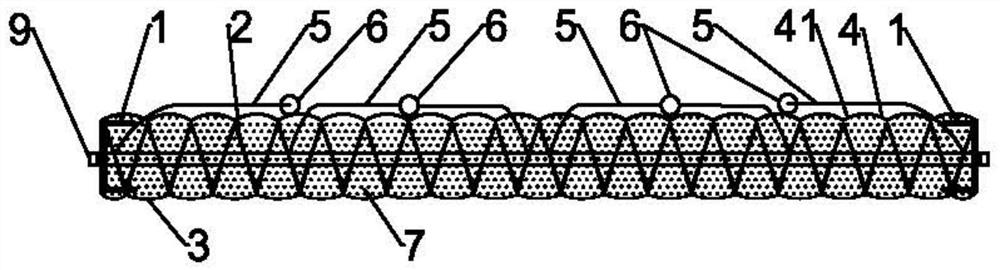

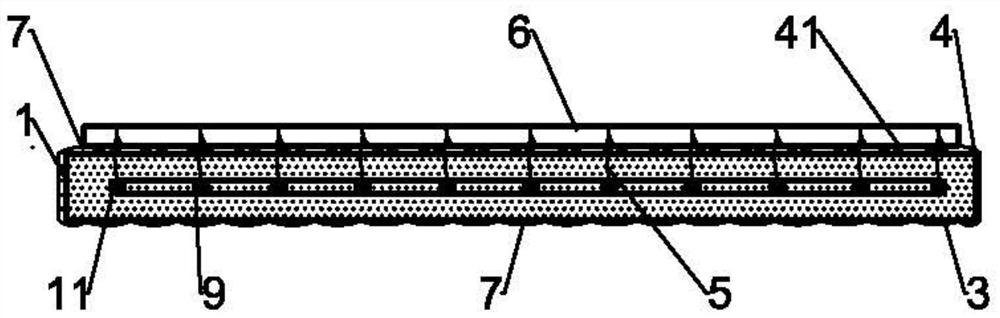

[0042] Such as Figure 1 to Figure 6 As shown in the present invention, a pre-stone slab formwork with concrete reinforcement as the main raw material, two square channel steels are placed parallel to each other longitudinally at both ends of the formwork as a shaped frame 1, and the openings are opposite, and the bottom of the groove is provided with parallel Equidistant openings 11, a number of triangle angle irons 2 uniform openings are arranged between the two shaped frame 1 square channel steels facing upwards, and are parallel to the square channel steels on the same horizontal plane, on the two walls of the triangle angle irons 2 There are several groups of perforations 21 corresponding in size and position to the openings 11 on the bottom surface of the shaping frame 1, and a bendable PVC pipe 9 is arranged in each row of horizontally corresponding perforations 21, and the PVC pipe 9 two ends pass through the opening 11 of the stereotyped frame 1, the two ends of all t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com