Complex geological region intelligent grouting system and method

A complex geological and grouting technology, which is applied in underground chambers, earthwork drilling, wellbore lining, etc., to achieve the effects of increasing grouting speed, high construction efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

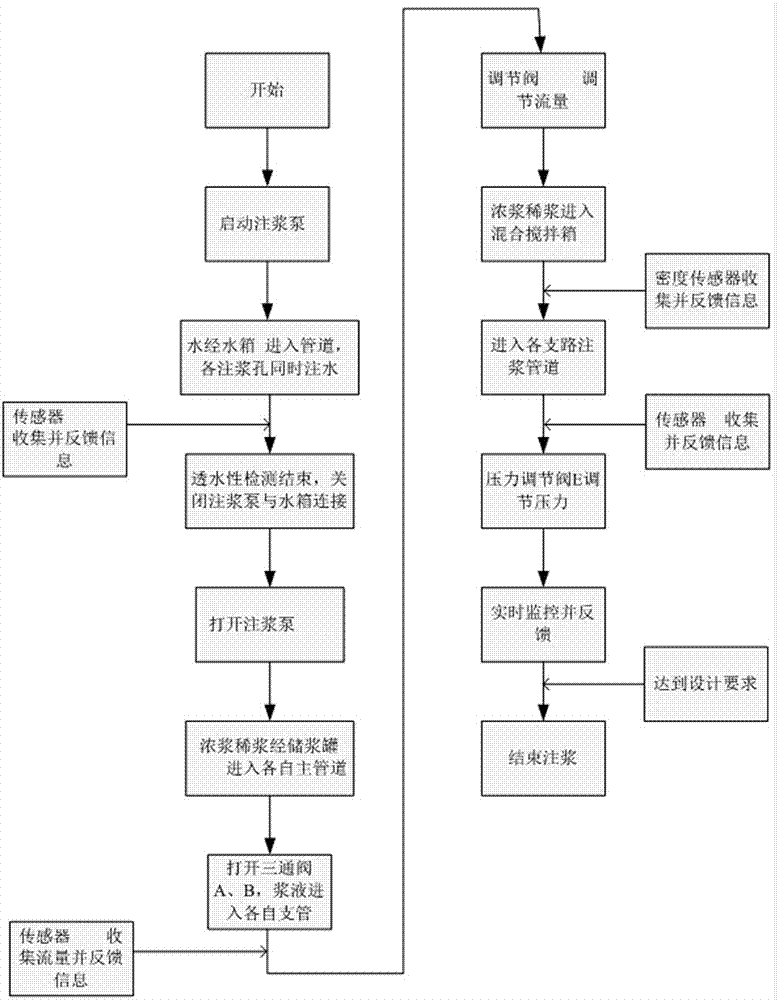

[0052] as attached figure 2 As shown, the present invention proposes the intelligent grouting method of the above system at the same time, and the specific steps are as follows:

[0053] Step 1. Select a section of the target grouting roadway for support, determine the location and size of the grouting holes according to the design requirements, and ensure that the distance between the grouting holes is not less than the diffusion radius of the grout.

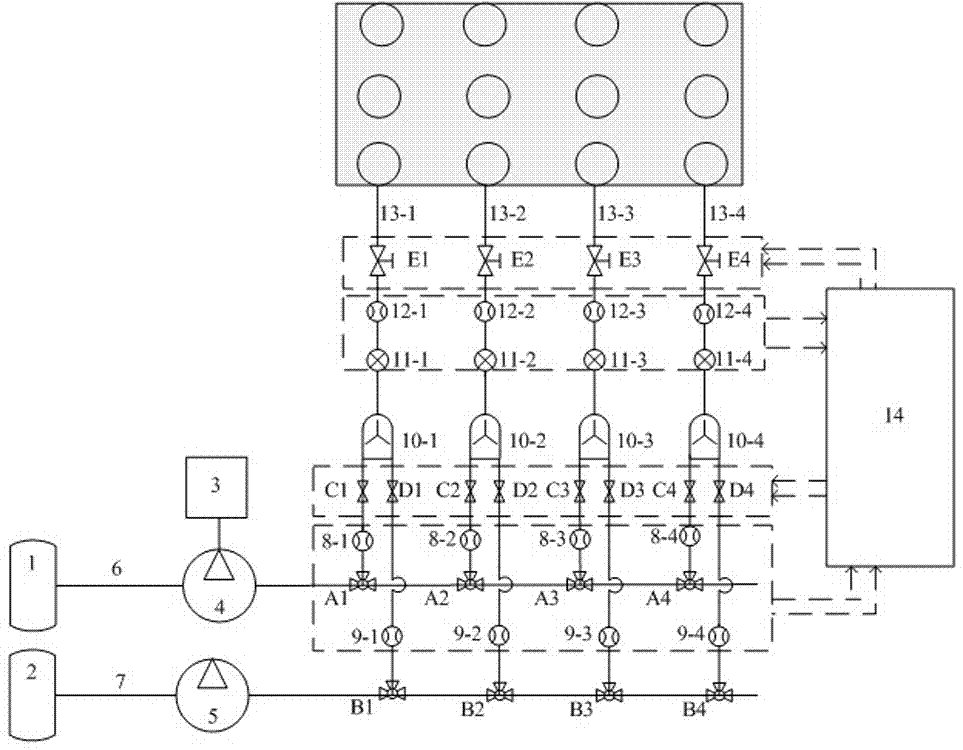

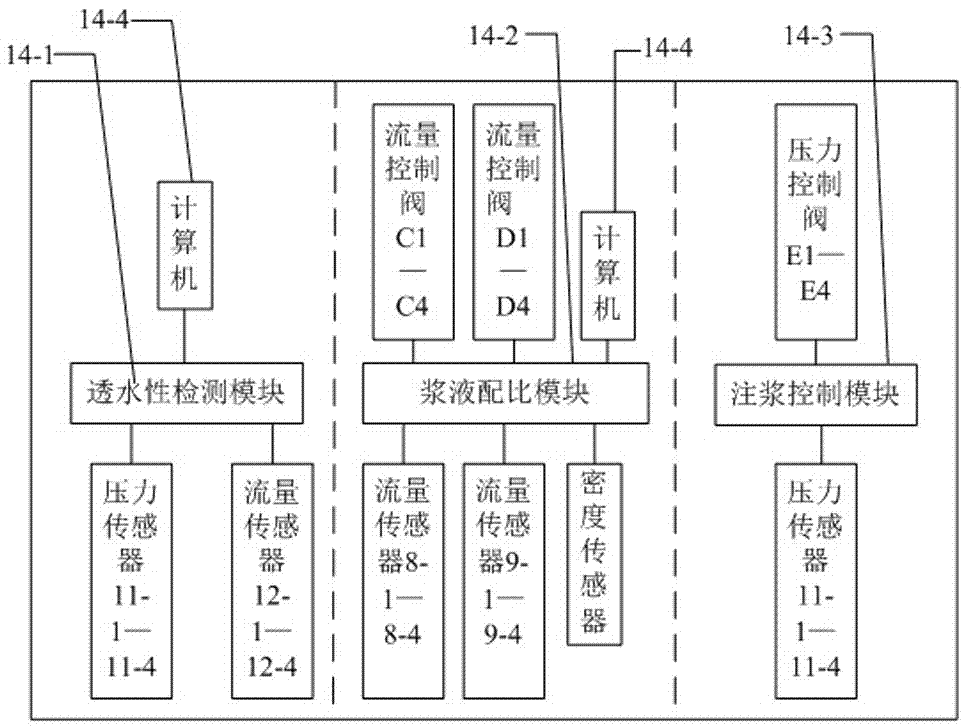

[0054] Step 2. Open the electronic three-way valves A1-A4 on the main grouting pipeline 6 of the thick slurry, and turn on the grouting pump 4. The water flows through the pipelines connected to the water tank 3 and diverted to each branch pipeline 13 through the electronic three-way valves A1-A4. -1-13-4, each grouting hole injects water at the same time, and obtains real-time water injection through the pressure sensor 11-1-11-4 and the flow sensor 12-1-12-4 on the branch pipeline 13-1-13-4 Pressure and flow, the collected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com